MITSUBISHI 3000GT 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 951 of 1146

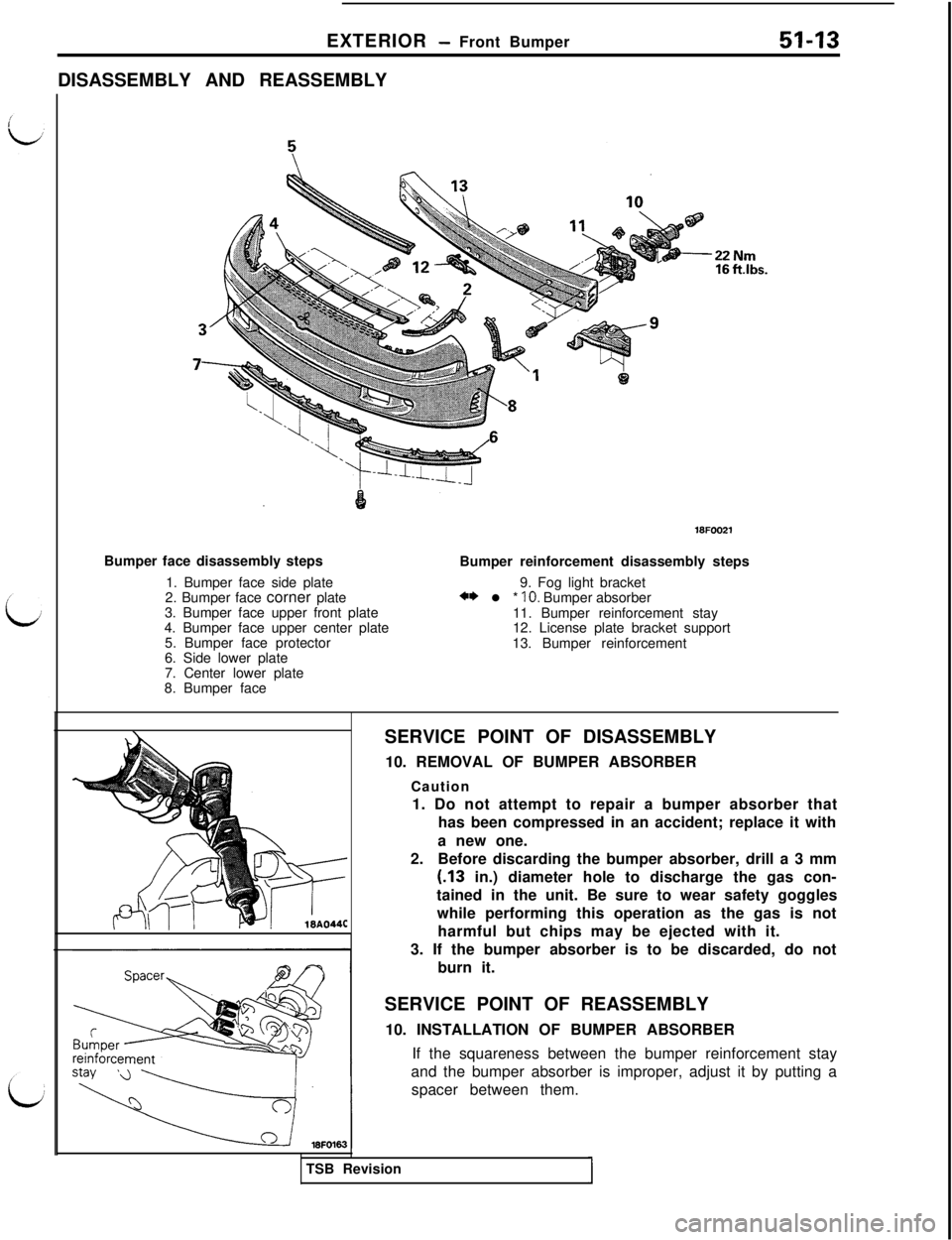

EXTERIOR - Front Bumper51-13DISASSEMBLY AND REASSEMBLY

22 Nm16 ftlbs.

Bumper face disassembly steps

1. Bumper face side plate

2. Bumper face corner plate

3. Bumper face upper front plate

4. Bumper face upper center plate

5. Bumper face protector

6. Side lower plate

7. Center lower plate

8. Bumper faceBumper reinforcement disassembly steps

9. Fog light bracket

** l * IO. Bumper absorber

11. Bumper reinforcement stay

12. License plate bracket support

13. Bumper reinforcement

SERVICE POINT OF DISASSEMBLY

10. REMOVAL OF BUMPER ABSORBER

Caution

1. Do not attempt to repair a bumper absorber that

has been compressed in an accident; replace it with

a new one.

2.Before discarding the bumper absorber, drill a 3 mm(.13 in.) diameter hole to discharge the gas con-

tained in the unit. Be sure to wear safety goggles

while performing this operation as the gas is not

harmful but chips may be ejected with it.

3. If the bumper absorber is to be discarded, do not

burn it.

SERVICE POINT OF REASSEMBLY

10. INSTALLATION OF BUMPER ABSORBER

If the squareness between the bumper reinforcement stay

and the bumper absorber is improper, adjust it by putting a

spacer between them.

TSB Revision

Page 952 of 1146

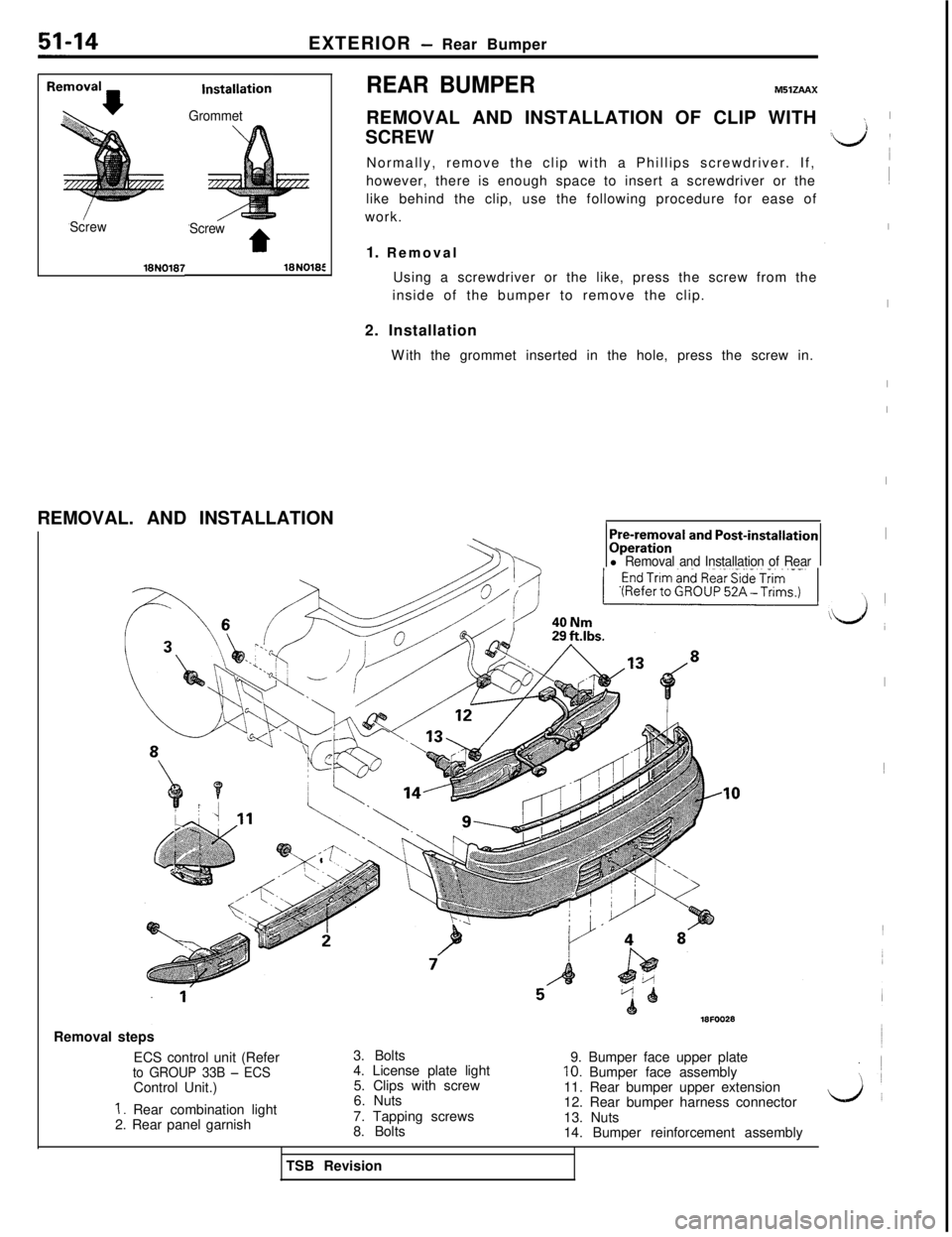

EXTERIOR - Rear Bumper

ScrewGrommet

Screw

t

REAR BUMPERMllZAAXREMOVAL AND INSTALLATION OF CLIP WITH

SCREW

Normally, remove the clip with a Phillips screwdriver. If,

however, there is enough space to insert a screwdriver or the

like behind the clip, use the following procedure for ease of

work.

1. Removal

Using a screwdriver or the like, press the screw from the

inside of the bumper to remove the clip.

2. Installation

With the grommet inserted in the hole, press the screw in.

REMOVAL. AND INSTALLATION

/Pre-removal and Post-installationOperationlRemoval and Installation of RearRemovalsteps

ECS control unit (Refer

to GROUP 33B - ECSControl Unit.)

1. Rear combination light

2. Rear panel garnish3. Bolts

4. License plate light

5. Clips with screw

6. Nuts

7. Tapping screws

8. Bolts9. Bumper face upper plate

10. Bumper face assembly

11. Rear bumper upper extension

12. Rear bumper harness connector

LA’13. Nuts

14. Bumper reinforcement assembly

I

d ’~

I

I

I

I

I

I

Ld;

I1

TSB Revision

Page 953 of 1146

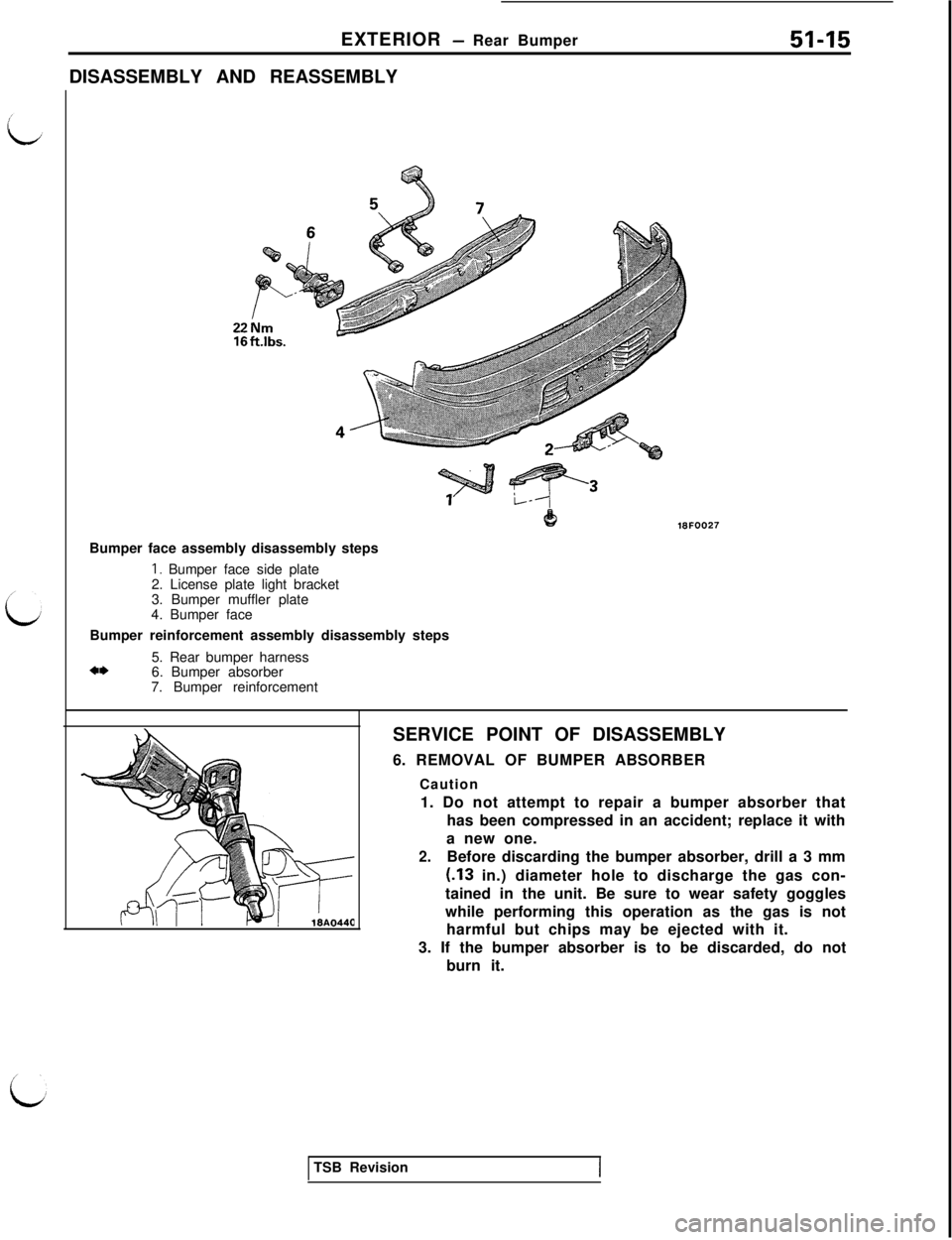

EXTERIOR - Rear Bumper

DISASSEMBLY AND REASSEMBLY51-15

221618FOO27

Bumper face assembly disassembly steps

I. Bumper face side plate

2. License plate light bracket

3. Bumper muffler plate

4. Bumper face

Bumper reinforcement assembly disassembly steps

5. Rear bumper harness

+I)6. Bumper absorber

7. Bumper reinforcement

SERVICE POINT OF DISASSEMBLY

6. REMOVAL OF BUMPER ABSORBER

Caution

1. Do not attempt to repair a bumper absorber that

has been compressed in an accident; replace it with

a new one.

2.Before discarding the bumper absorber, drill a 3 mm(.13 in.) diameter hole to discharge the gas con-

tained in the unit. Be sure to wear safety goggles

while performing this operation as the gas is not

harmful but chips may be ejected with it.

3. If the bumper absorber is to be discarded, do not

burn it.

TSB Revision

Page 954 of 1146

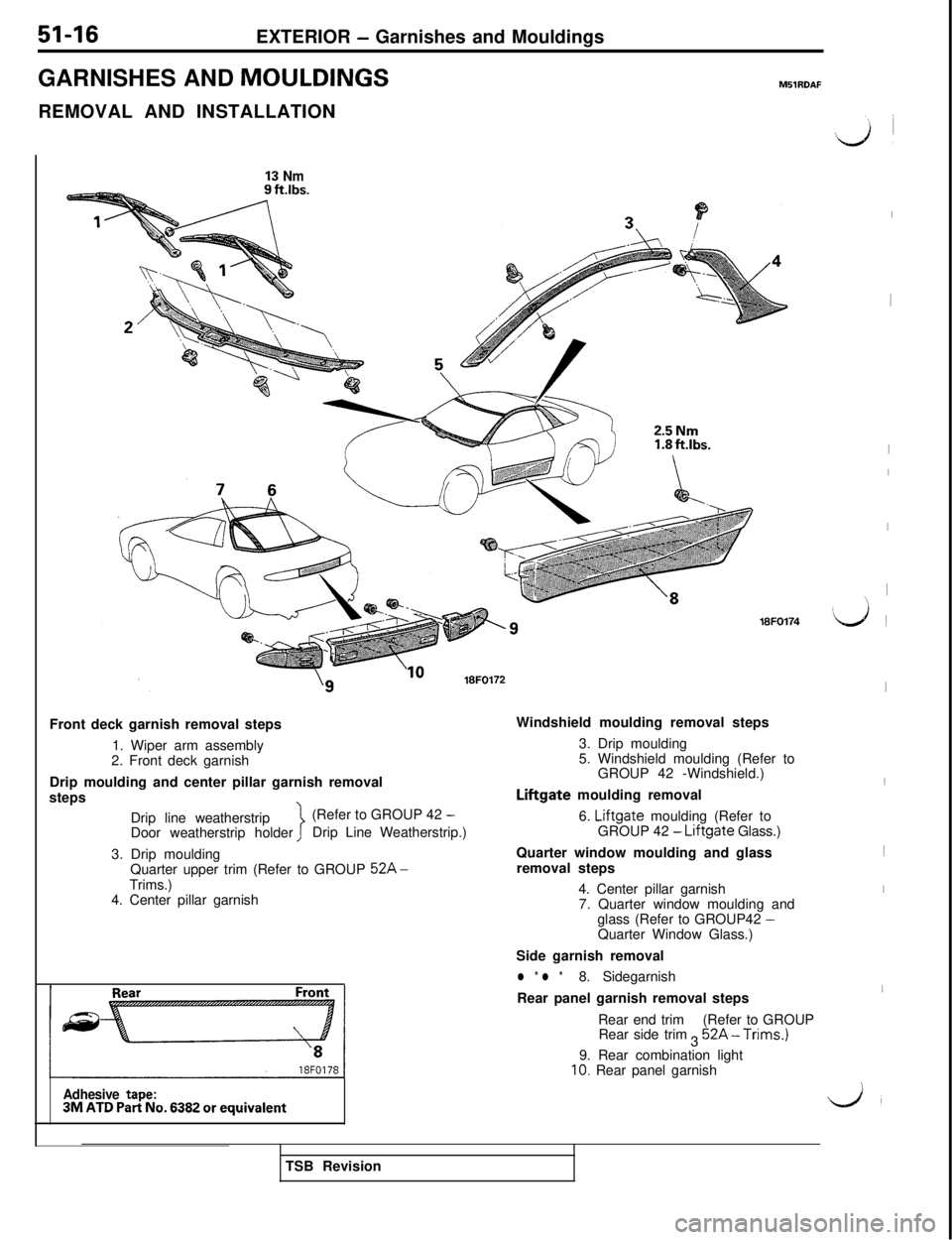

51-16

EXTERIOR - Garnishes and Mouldings

GARNISHES AND MOULDINGS

M51RDAFREMOVAL AND INSTALLATION

13 Nm2.5Nm18FO174

Front deck garnish removal steps

1. Wiper arm assembly

2. Front deck garnish

Drip moulding and center pillar garnish removal

steps

Drip line weatherstrip(Refer to GROUP 42

-Door weatherstrip holderDrip Line Weatherstrip.)

3. Drip moulding

Quarter upper trim (Refer to GROUP

52A-Trims.)

4. Center pillar garnish

Adhesive tape:3M ATD Part No. 6382 or equivalentWindshield moulding removal steps

3. Drip moulding

5. Windshield moulding (Refer to

GROUP 42 -Windshield.)

Liftgate moulding removal

6.

Liftgate moulding (Refer to

GROUP 42 - Liftgate Glass.)

Quarter window moulding and glass

removal steps

4. Center pillar garnish

7. Quarter window moulding and

glass (Refer to GROUP42

-Quarter Window Glass.)

Side garnish removal

l * l *8. Sidegarnish

Rear panel garnish removal steps

Rear end trim

Rear side trim

3(Refer to GROUP

52A-Trims.)9. Rear combination light

10. Rear panel garnish

I

I

I

I

I1

~

:Ij ~

I

I1

I

I

L.JTSB Revision

Page 955 of 1146

EXTERIOR - Garnishes and Mouldings51-17

Protective tape/

i

I18FO181

Pressure sensitive

double-sided tape

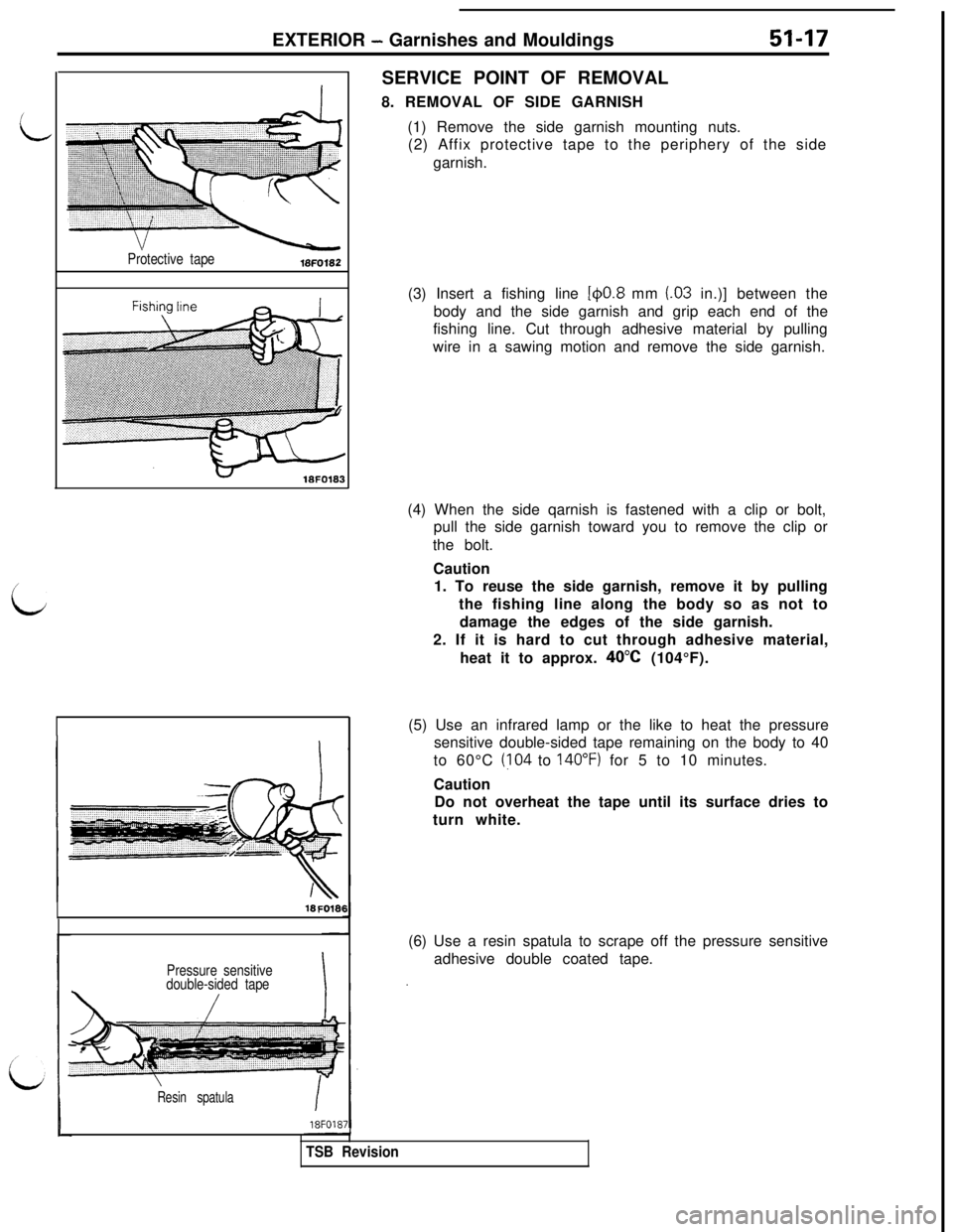

Resin spatulaSERVICE POINT OF REMOVAL

8. REMOVAL OF SIDE GARNISH

(1) Remove the side garnish mounting nuts.

(2) Affix protective tape to the periphery of the side

garnish.

(3) Insert a fishing line

[@0.8 mm (03 in.)] between the

body and the side garnish and grip each end of the

fishing line. Cut through adhesive material by pulling

wire in a sawing motion and remove the side garnish.

(4) When the side qarnish is fastened with a clip or bolt,

pull the side garnish toward you to remove the clip or

the bolt.

Caution

1. To reuse the side garnish, remove it by pulling

the fishing line along the body so as not to

damage the edges of the side garnish.

2. If it is hard to cut through adhesive material,

heat it to approx.

40°C (104°F).-I

TSB Revision(5) Use an infrared lamp or the like to heat the pressure

sensitive double-sided tape remaining on the body to 40

to 60°C

(?04 to 140°F) for 5 to 10 minutes.

Caution

Do not overheat the tape until its surface dries to

turn white.

(6) Use a resin spatula to scrape off the pressure sensitive

adhesive double coated tape.

Page 956 of 1146

51-18EXTERIOR - Garnishes and Mouldings

~~~,~,.

. . . .>cpe

~-~~~~~o

18FO19;,

RearFront

Pressure sensitive

double-sided tape

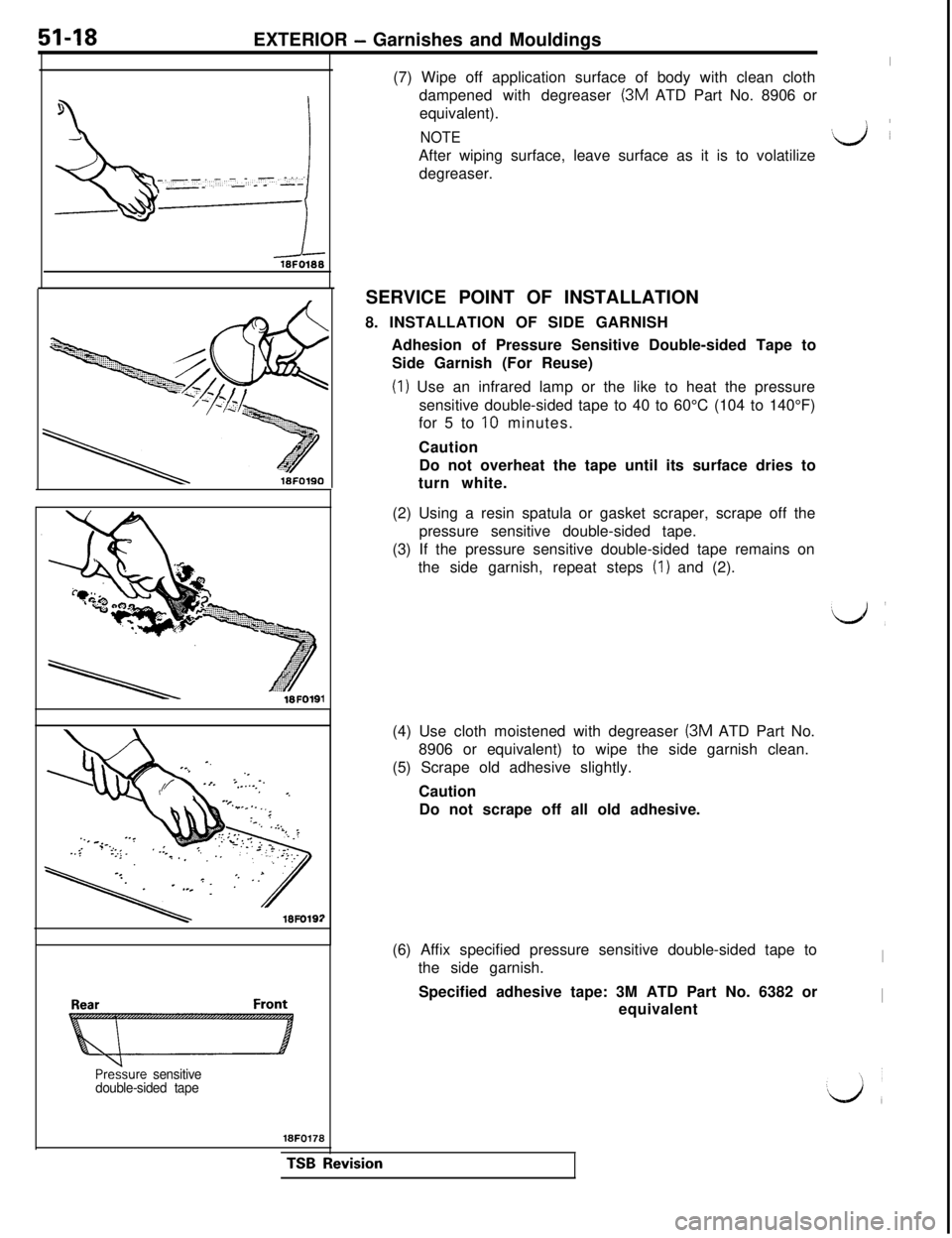

18FO178(7) Wipe off application surface of body with clean cloth

dampened with degreaser (3M ATD Part No. 8906 or

equivalent).

NOTEGJ ~

After wiping surface, leave surface as it is to volatilize

degreaser.

SERVICE POINT OF INSTALLATION

8. INSTALLATION OF SIDE GARNISH

Adhesion of Pressure Sensitive Double-sided Tape to

Side Garnish (For Reuse)

(1) Use an infrared lamp or the like to heat the pressure

sensitive double-sided tape to 40 to 60°C (104 to 140°F)

for 5 to

10 minutes.

Caution

Do not overheat the tape until its surface dries to

turn white.

(2) Using a resin spatula or gasket scraper, scrape off the

pressure sensitive double-sided tape.

(3) If the pressure sensitive double-sided tape remains on

the side garnish, repeat steps

(1) and (2).

(4) Use cloth moistened with degreaser

(3M ATD Part No.

8906 or equivalent) to wipe the side garnish clean.

(5) Scrape old adhesive slightly.

Caution

Do not scrape off all old adhesive.

(6) Affix specified pressure sensitive double-sided tape to

the side garnish.

ISpecified adhesive tape: 3M ATD Part No. 6382 or

equivalent

ITSB Revision

Page 957 of 1146

EXTERIOR - Garnishes and Mouldings51-19

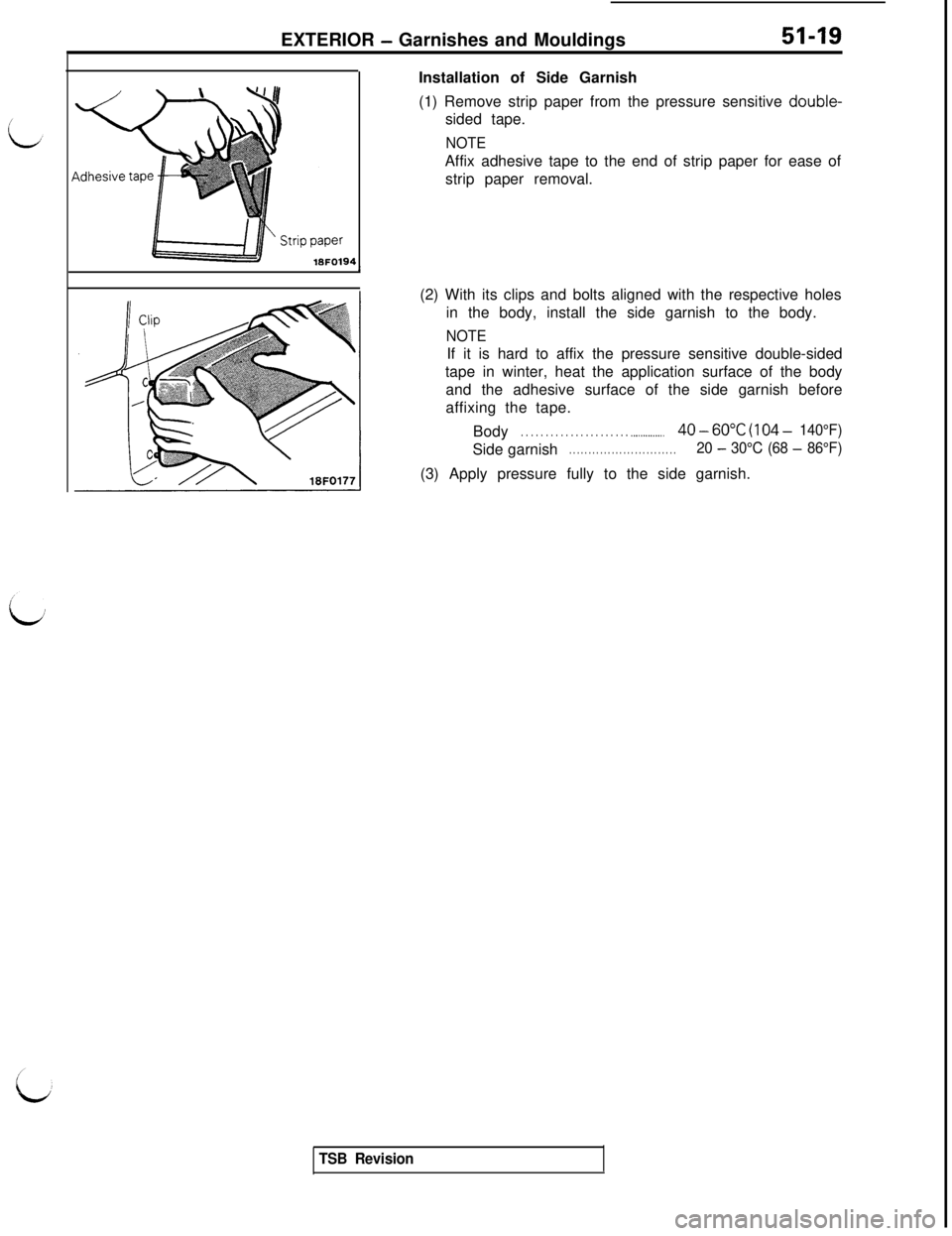

18FO194Installation of Side Garnish

(1) Remove strip paper from the pressure sensitive double-

sided tape.

NOTEAffix adhesive tape to the end of strip paper for ease of

strip paper removal.

(2) With its clips and bolts aligned with the respective holes

in the body, install the side garnish to the body.

NOTEIf it is hard to affix the pressure sensitive double-sided

tape in winter, heat the application surface of the body

and the adhesive surface of the side garnish before

affixing the tape.

Body

. . . . . . . . . . . . . . . . . . . . . . .._...........40-60°C (104- 140°F)Side garnish

. . . . . . . . . . . . . . . . . . . . . . . . . . . .20 - 30°C (68 - 86°F)(3) Apply pressure fully to the side garnish.

TSB Revision

Page 958 of 1146

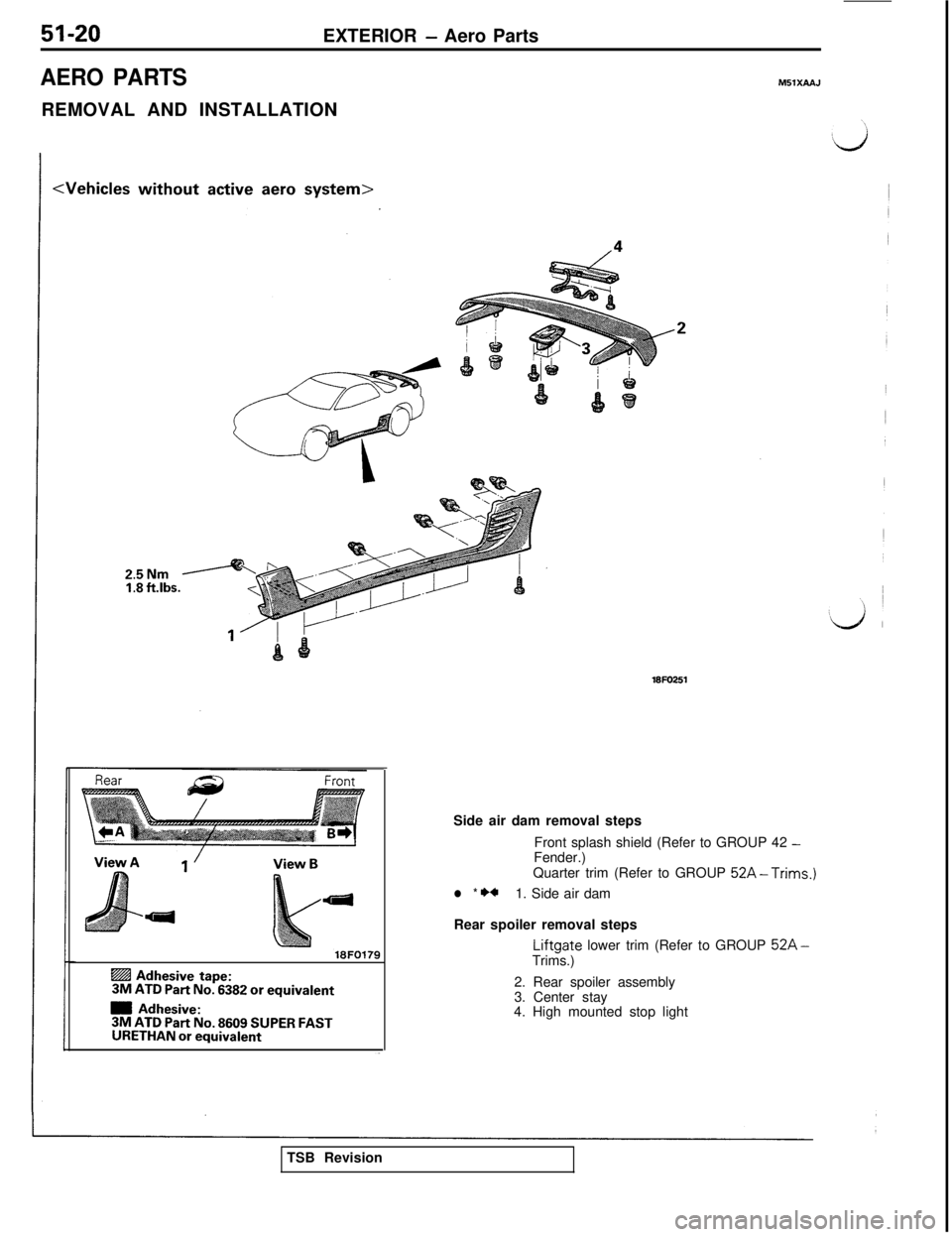

51-20EXTERIOR - Aero Parts

AERO PARTSM5lXAA.J

REMOVAL AND INSTALLATION

25NmI:8 ft.lbs.

18FO179

@ Adhesive tape:3M ATD Part No. 6382 or equivalent

m Adhesive:3M ATD Part No. 8609 SUPER FASTURETHAN or equivalent

18FO251Side air dam removal steps

Front splash shield (Refer to GROUP 42

-Fender.)

Quarter trim (Refer to GROUP

52A-Trims.)

l * **1. Side air dam

Rear spoiler removal steps

Liftgate lower trim (Refer to GROUP 52A-Trims.)

2. Rear spoiler assembly

3. Center stay

4. High mounted stop light

TSB Revision

Page 959 of 1146

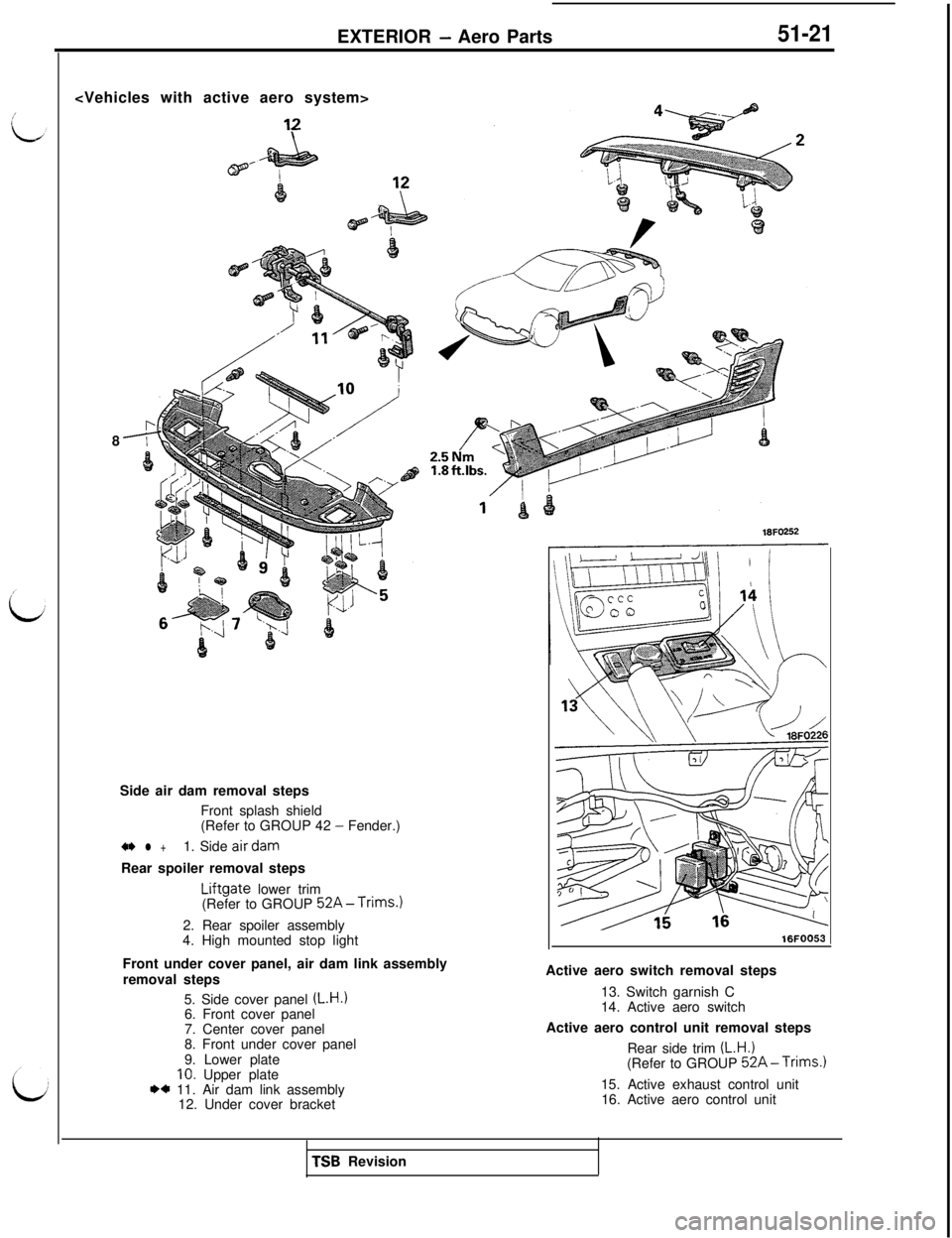

EXTERIOR - Aero Parts51-21

8

Side air dam removal steps

Front splash shield

(Refer to GROUP 42

- Fender.)

+I) l +1. Side airdamRear spoiler removal steps

Liftgate lower trim

(Refer to GROUP 52A-Trims.)2. Rear spoiler assembly

4. High mounted stop light

Front under cover panel, air dam link assembly

removal steps

5. Side cover panel

(L.H.)6. Front cover panel

7. Center cover panel

8. Front under cover panel

9. Lower plate

10. Upper plateI)* 11. Air dam link assembly

12. Under cover bracket

16FO252

16FOO53Active aero switch removal steps

13. Switch garnish C

14. Active aero switch

Active aero control unit removal steps

Rear side trim

(L.H.)(Refer to GROUP 52A-Trims.)15. Active exhaust control unit

16. Active aero control unitTSB Revision

Page 960 of 1146

51-22

EXTERIOR - Aero Parts

1 MotorLimit switch )

iLimit switch--Motor /_I

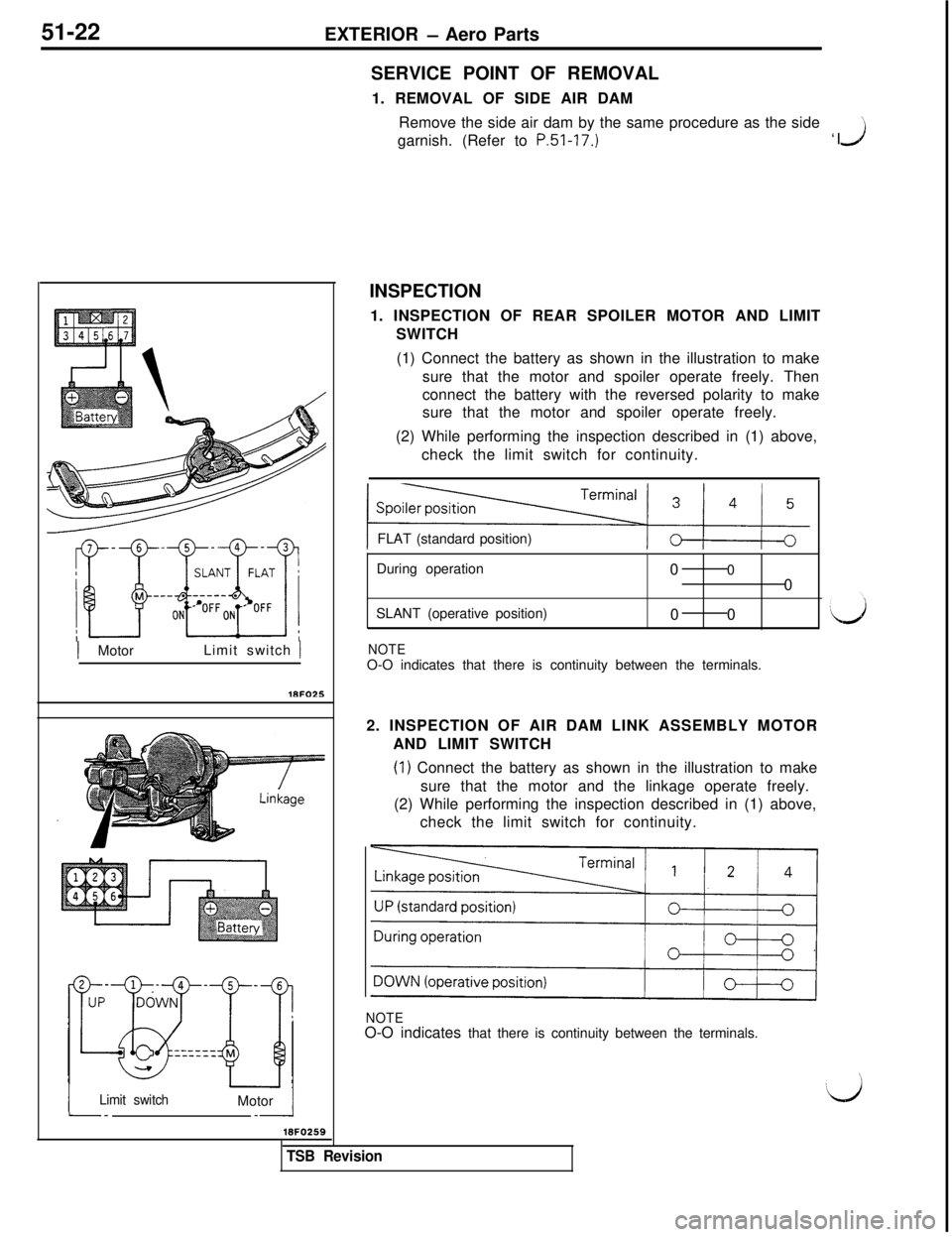

18FO259SERVICE POINT OF REMOVAL

1. REMOVAL OF SIDE AIR DAM

Remove the side air dam by the same procedure as the side

’garnish. (Refer to P.51-17.)‘IJINSPECTION

1. INSPECTION OF REAR SPOILER MOTOR AND LIMIT

SWITCH

(1) Connect the battery as shown in the illustration to make

sure that the motor and spoiler operate freely. Then

connect the battery with the reversed polarity to make

sure that the motor and spoiler operate freely.

(2) While performing the inspection described in (1) above,

check the limit switch for continuity.

FLAT (standard position)

During operation

00

0

SLANT (operative position)

00

NOTEO-O indicates that there is continuity between the terminals.

2. INSPECTION OF AIR DAM LINK ASSEMBLY MOTOR

AND LIMIT SWITCH

(1) Connect the battery as shown in the illustration to make

sure that the motor and the linkage operate freely.

(2) While performing the inspection described in (1) above,

check the limit switch for continuity.

NOTEO-O indicates that there is continuity between the terminals.

TSB Revision