MITSUBISHI 3000GT 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 971 of 1146

EXTERIOR - Windshield Wiper and Washer51-33

L

lj

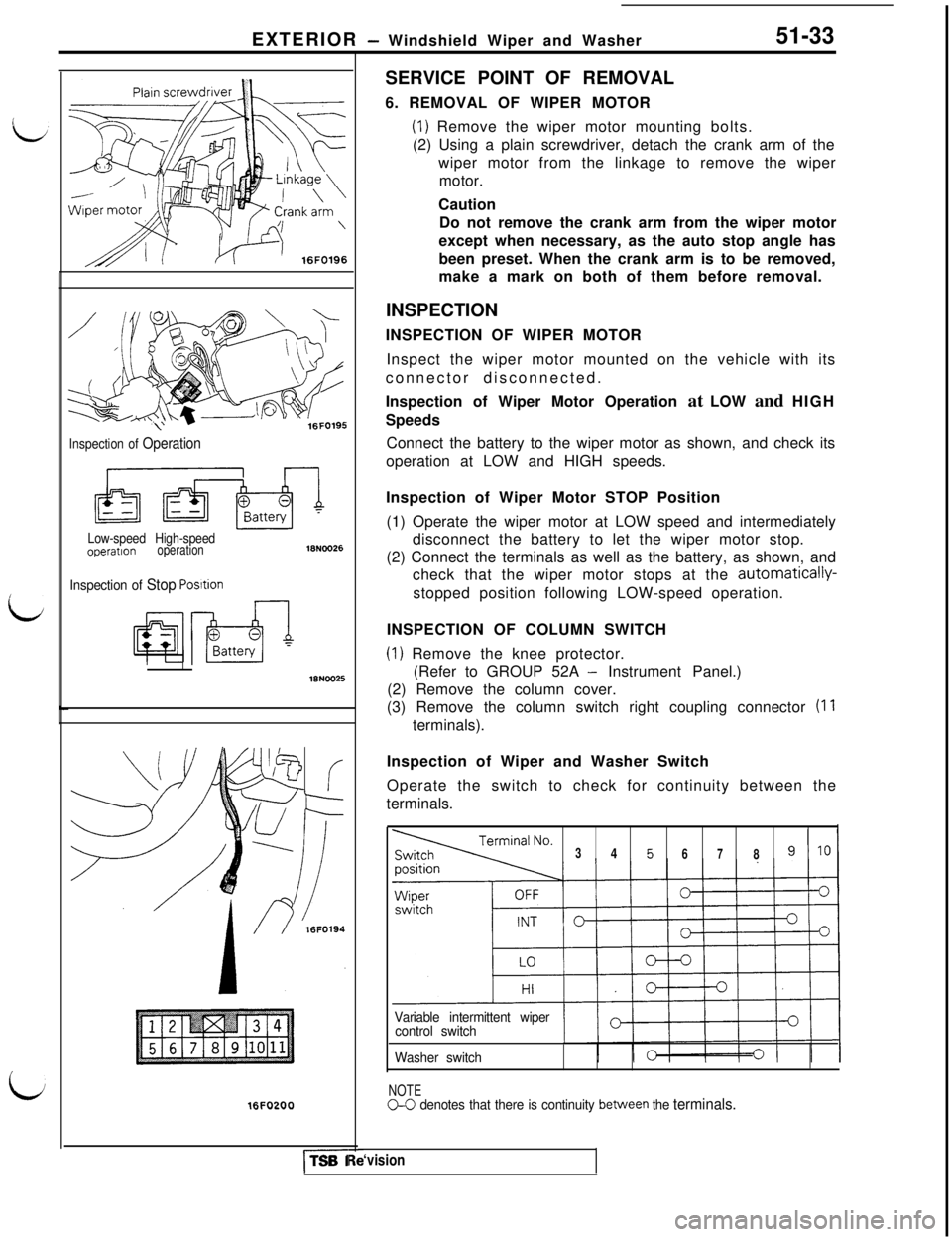

Inspection of Operation

Low-speed High-speedoperationoperation1610026

Inspection of Stop Posltion

n

16NOO25

16FO200

ITSB ISERVICE POINT OF REMOVAL

6. REMOVAL OF WIPER MOTOR

(1) Remove the wiper motor mounting bolts.

(2) Using a plain screwdriver, detach the crank arm of the

wiper motor from the linkage to remove the wiper

motor.

Caution

Do not remove the crank arm from the wiper motor

except when necessary, as the auto stop angle has

been preset. When the crank arm is to be removed,

make a mark on both of them before removal.

INSPECTION

INSPECTION OF WIPER MOTOR

Inspect the wiper motor mounted on the vehicle with its

connector disconnected.

Inspection of Wiper Motor Operation at LOW and HIGH

Speeds

Connect the battery to the wiper motor as shown, and check its

operation at LOW and HIGH speeds.

Inspection of Wiper Motor STOP Position

(1) Operate the wiper motor at LOW speed and intermediately

disconnect the battery to let the wiper motor stop.

(2) Connect the terminals as well as the battery, as shown, and

check that the wiper motor stops at the automatically-

stopped position following LOW-speed operation.

INSPECTION OF COLUMN SWITCH

(1) Remove the knee protector.

(Refer to GROUP 52A

- Instrument Panel.)

(2) Remove the column cover.

(3) Remove the column switch right coupling connector

(11terminals).

Inspection of Wiper and Washer Switch

Operate the switch to check for continuity between the

terminals.

345678

Variable intermittent wiper

control switch

Washer switch

NOTEC-0 denotes that there is continuity between the terminals.

‘vision

Page 972 of 1146

51-34

EXTERIOR - Windshield Wiper and Washer

Connector B

-____1.310027lXN007t

1

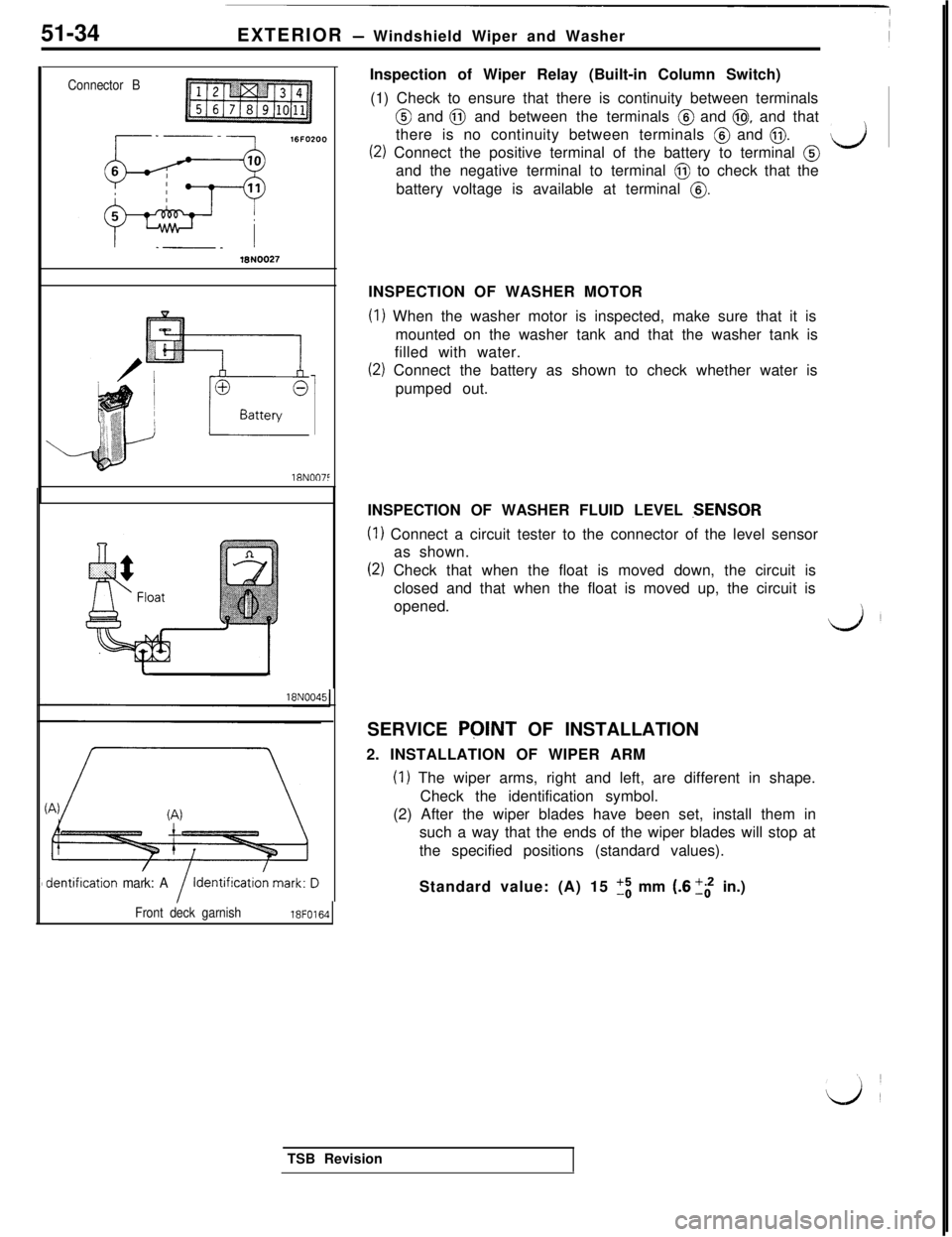

dentification mark: AInspection of Wiper Relay (Built-in Column Switch)

(1) Check to ensure that there is continuity between terminals@ and @ and between the terminals @ and

@, and that

there is no continuity between terminals @ and

@.

(2) Connect the positive terminal of the battery to terminal @dand the negative terminal to terminal @ to check that the

battery voltage is available at terminal

@.INSPECTION OF WASHER MOTOR

(I) When the washer motor is inspected, make sure that it is

mounted on the washer tank and that the washer tank is

filled with water.

(2) Connect the battery as shown to check whether water is

pumped out.

INSPECTION OF WASHER FLUID LEVEL

,SENSOR

(1) Connect a circuit tester to the connector of the level sensor

as shown.

(2) Check that when the float is moved down, the circuit is

closed and that when the float is moved up, the circuit is

opened.

Front deck garnish18FO164SERVICE POINT OF INSTALLATION

2. INSTALLATION OF WIPER ARM

(1) The wiper arms, right and left, are different in shape.

Check the identification symbol.

(2) After the wiper blades have been set, install them in

such a way that the ends of the wiper blades will stop at

the specified positions (standard values).

Standard value: (A) 15

tz mm (.6 tf in.)

dTSB Revision

Page 973 of 1146

EXTERIOR - Rear Wber and Washer51-35

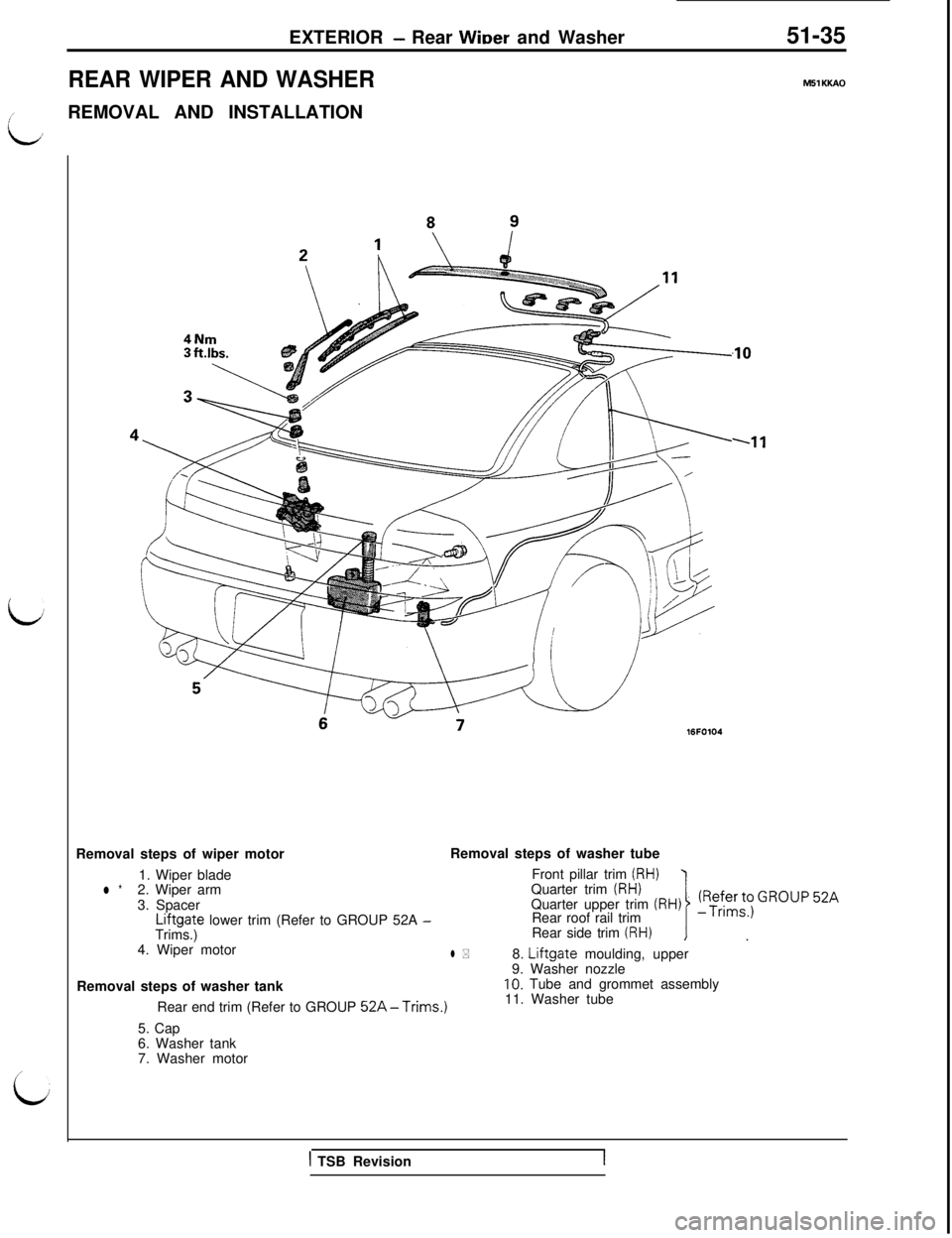

REAR WIPER AND WASHERM51 KKAO

,/REMOVAL AND INSTALLATION

16FO104.lO

.llRemoval steps of wiper motor

1. Wiper blade

l *2. Wiper arm

3. SpacerRemoval steps of washer tube

Front pillar trim

(RH)Quarter trim (RH)

Liftgate lower trim (Refer to GROUP 52A -Quarter upper trim

(RH)Rear roof rail trim!R$$f$$ GRoUP 52A

Trims.)Rear side trim

(RH)i .

4. Wiper motor

l *8. Liftgate moulding, upper

9. Washer nozzle

Removal steps of washer tank

Rear end trim (Refer to GROUP

52A-Trims.)5. Cap

6. Washer tank

7. Washer motor

10. Tube and grommet assembly

11. Washer tube

1 TSB Revision

Page 974 of 1146

51-36EXTERIOR - Rear Wiper and Washer

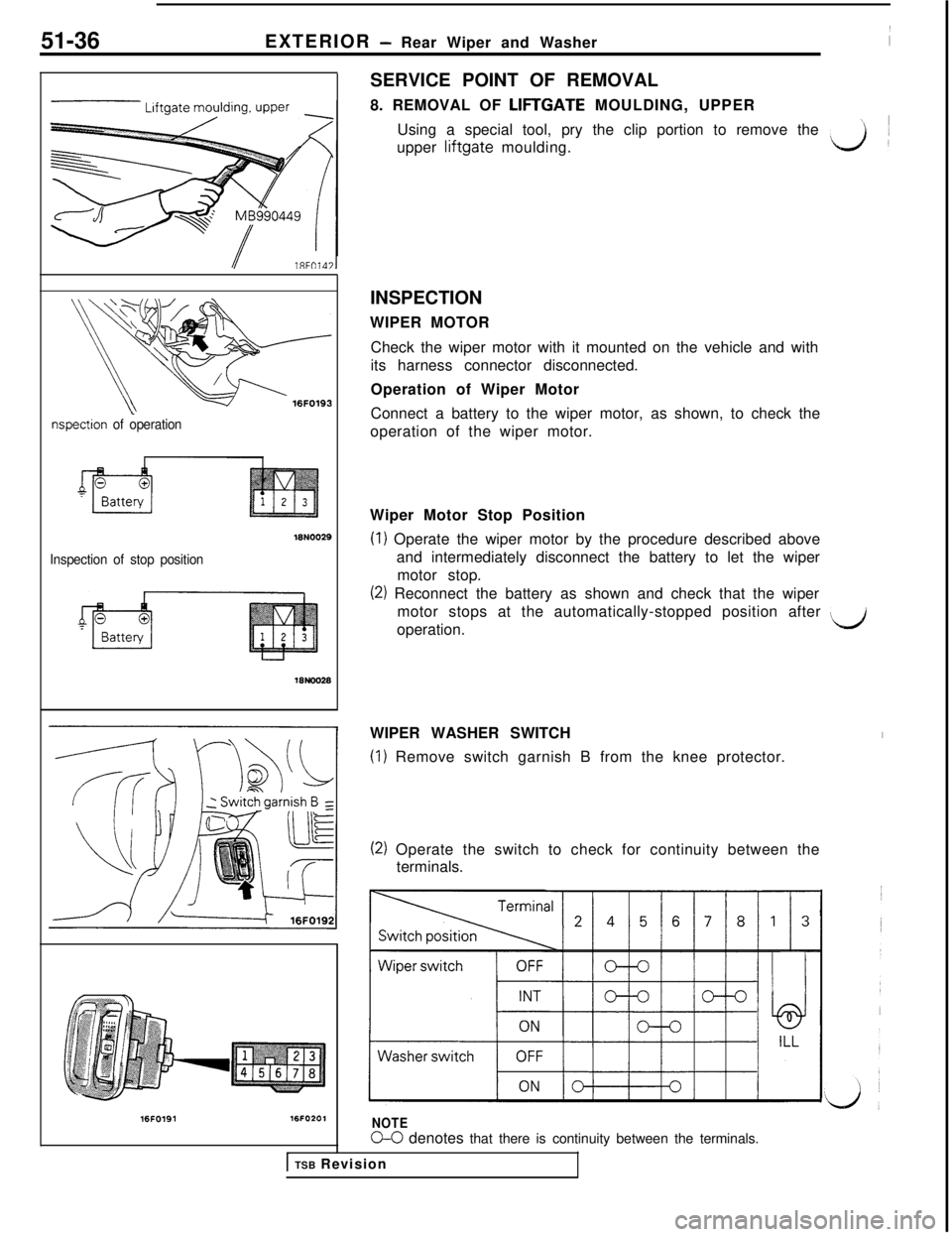

nspection of operation16N0029

Inspection of stop position

16FO19116FO201SERVICE POINT OF REMOVAL

8. REMOVAL OF LIFTGATE MOULDING, UPPER

Using a special tool, pry the clip portion to remove the

’~

upper liftgate moulding.

INSPECTION

WIPER MOTOR

Check the wiper motor with it mounted on the vehicle and with

its harness connector disconnected.

Operation of Wiper Motor

Connect a battery to the wiper motor, as shown, to check the

operation of the wiper motor.

Wiper Motor Stop Position

(1) Operate the wiper motor by the procedure described above

and intermediately disconnect the battery to let the wiper

motor stop.

(2) Reconnect the battery as shown and check that the wiper

motor stops at the automatically-stopped position after

operation.

‘dWIPER WASHER SWITCH

(I) Remove switch garnish B from the knee protector.

(2) Operate the switch to check for continuity between the

terminals.

NOTEO-0 denotes that there is continuity between the terminals.

1 TSB Revision

Page 975 of 1146

EXTERIOR - Rear Wiper and Washer

51-3718N007F

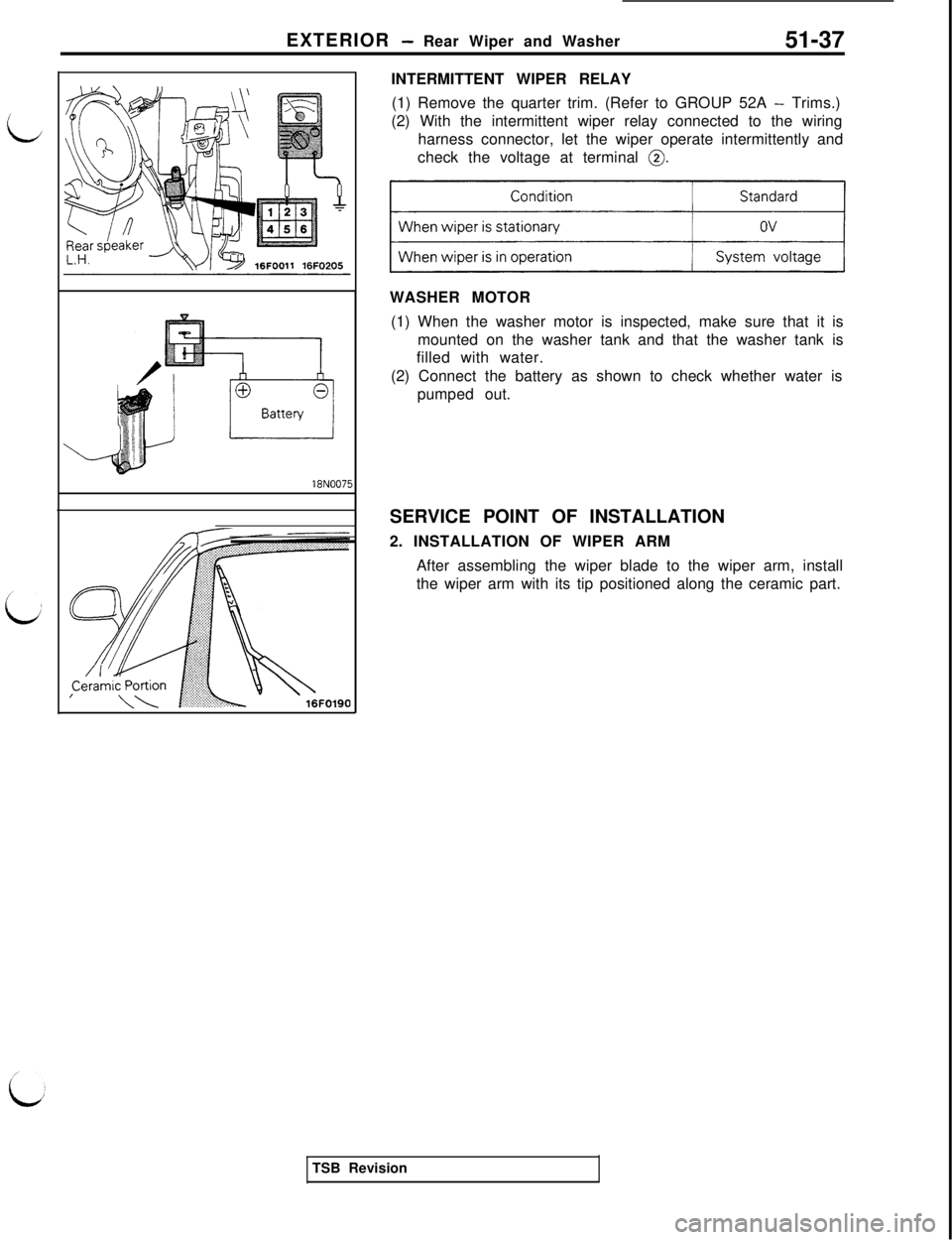

jINTERMITTENT WIPER RELAY

(1) Remove the quarter trim. (Refer to GROUP 52A

- Trims.)

(2) With the intermittent wiper relay connected to the wiring

harness connector, let the wiper operate intermittently and

check the voltage at terminal

0.WASHER MOTOR

(1) When the washer motor is inspected, make sure that it is

mounted on the washer tank and that the washer tank is

filled with water.

(2) Connect the battery as shown to check whether water is

pumped out.

SERVICE POINT OF INSTALLATION

2. INSTALLATION OF WIPER ARM

After assembling the wiper blade to the wiper arm, install

the wiper arm with its tip positioned along the ceramic part.

TSB Revision

Page 976 of 1146

51-38EXTERIOR - Door Mirror

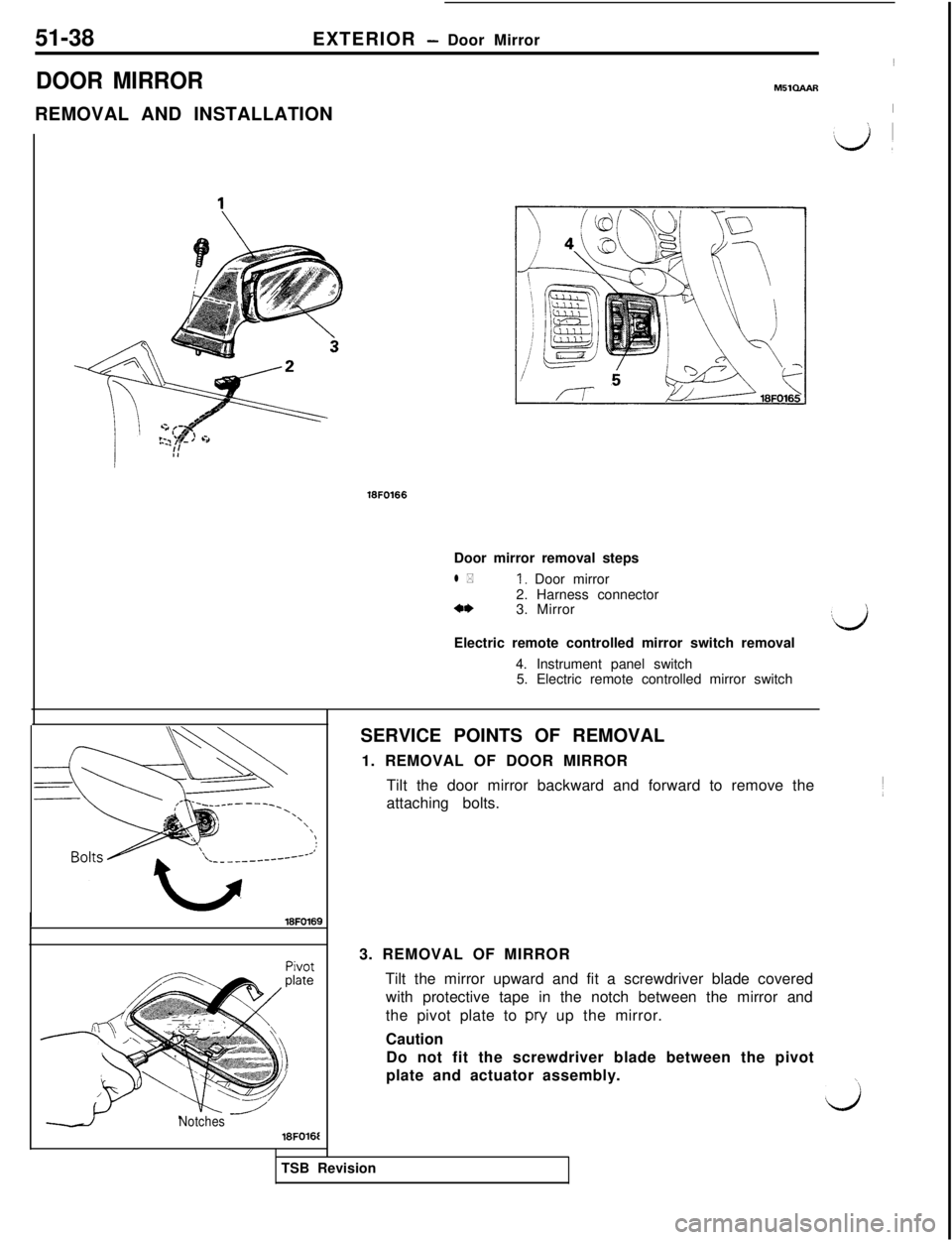

DOOR MIRRORREMOVAL AND INSTALLATION~MSlGAAR

I18FO166

Door mirror removal steps

l *I. Door mirror

2. Harness connector

a*3. Mirror

Electric remote controlled mirror switch removal

4. Instrument panel switch

5. Electric remote controlled mirror switch

Pivnt

NotchesSERVICE POINTS OF REMOVAL

1. REMOVAL OF DOOR MIRROR

Tilt the door mirror backward and forward to remove the

attaching bolts.

3. REMOVAL OF MIRROR

Tilt the mirror upward and fit a screwdriver blade covered

with protective tape in the notch between the mirror and

the pivot plate to pry up the mirror.

Caution

Do not fit the screwdriver blade between the pivot

plate and actuator assembly.

\

LjTSB Revision

Page 977 of 1146

cEXTERIOR

- Door Mirror

51-39

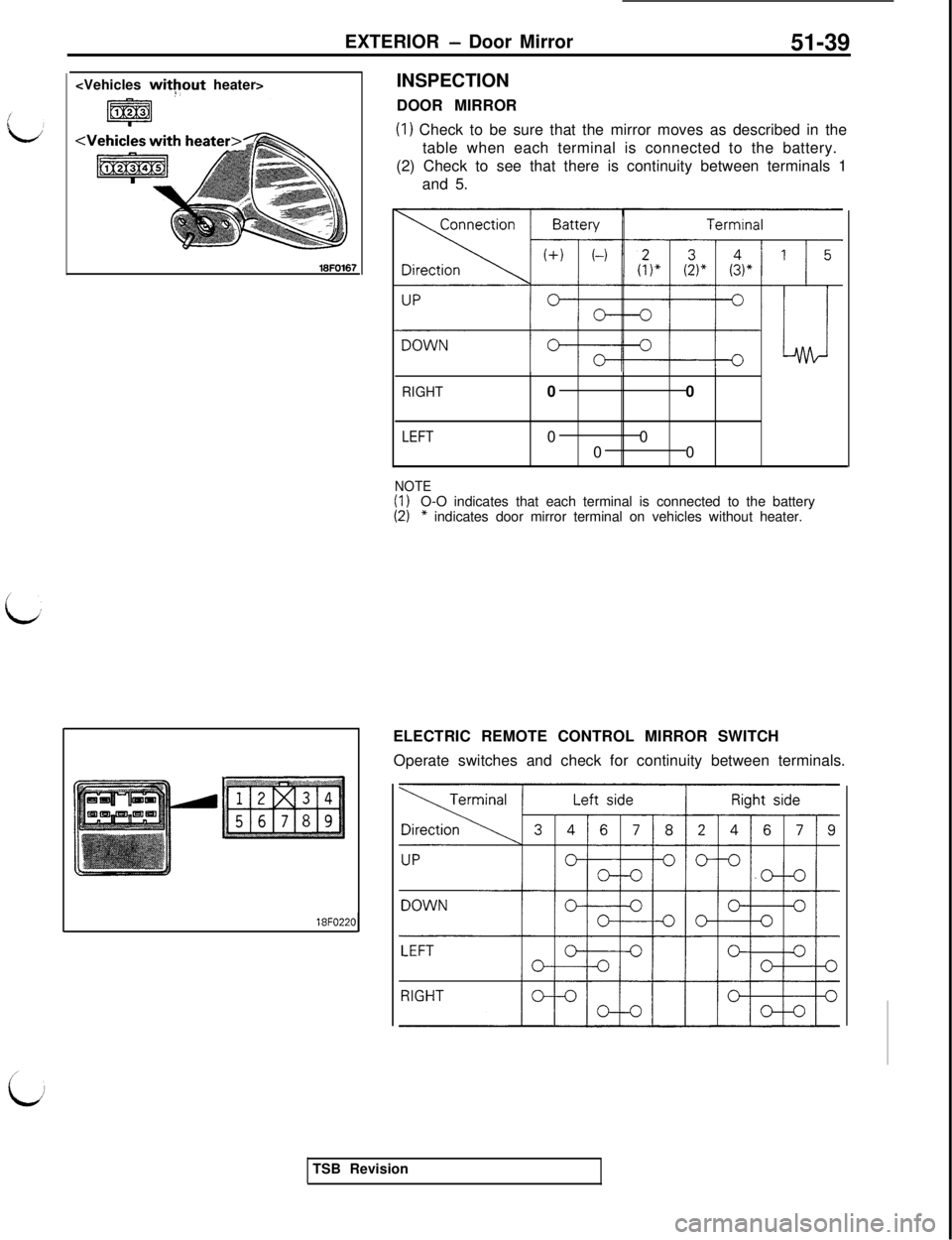

18FO22(!IINSPECTION

DOOR MIRROR

(1) Check to be sure that the mirror moves as described in the

table when each terminal is connected to the battery.

(2) Check to see that there is continuity between terminals 1

and 5.

RIGHT00

LEFT00

00

NOTE(I)

(2)O-O indicates that each terminal is connected to the battery* indicates door mirror terminal on vehicles without heater.

ELECTRIC REMOTE CONTROL MIRROR SWITCH

Operate switches and check for continuity between terminals.

TSB Revision

Page 978 of 1146

Page 979 of 1146

INTERIORCONTENTSNWAA-A~

FLOOR CONSOLE*

____....._.........__._..._......_..._...... 11

REAR SEAT . .._._____..______....____.._.._._..___.._._____.....___....24

FRONT SEAT*

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18SEAT BELT*. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25IHEADLINING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17TRIMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12INSTRUMENT PANEL*

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . .

i

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

(1)A Supplemental Restraint System (SRS), which uses a driver-side air bag, has been installed in the 3000GT.(2)The SRS includes the following components: impact sensors, SRS diagnosis unit: SRS warning light, air bagmodule, clock spring, interconnecting wiring. Other SRS-related components, (that may have to beremoved/installed in connection with SRS service or maintenance) are indicated in the table of contents byan asterisk (*).

WARNING!(I)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead topersonal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (fromrendering the SRS inoperative).(2) Service or maintenance of any SRS component or SRS-related component must be performed only at anauthorized MITSUBISHI dealer.(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B -Supplemental Restraint System (SRS), before beginning any service or maintenance of any component of theSRS or any SRS-related component.

2I

Page 980 of 1146

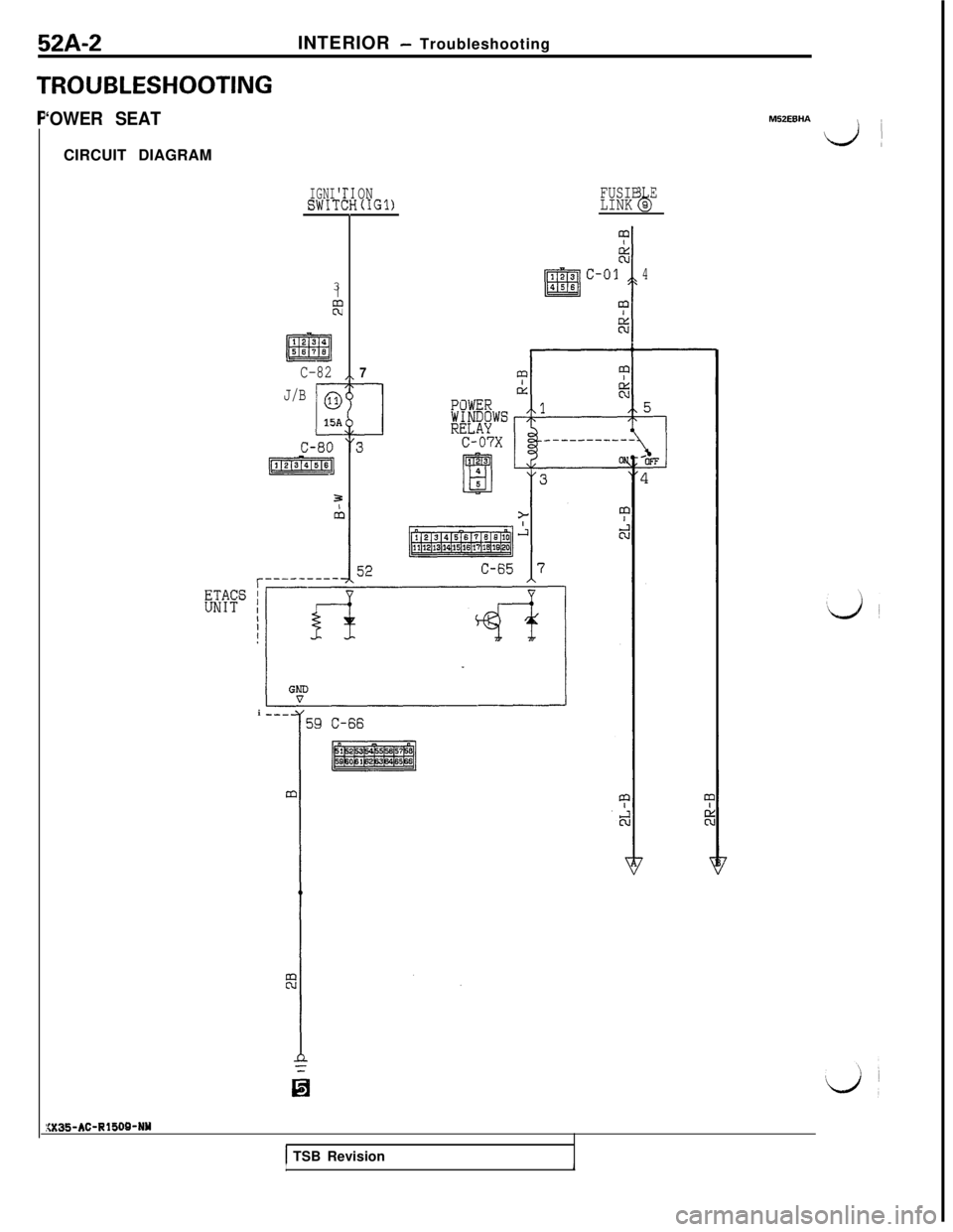

52A-2INTERIOR - Troubleshooting

TROUBLESHOOTING

‘OWER SEATCIRCUIT DIAGRAMMSZEBHA

dl

IGNI'SWITl3

I

kt

C-82

J/B

i

0

15A

C-80

p77ziFq

ON(IGl)TII-I

/

,\777

"3

FUSIB ELINK Qb

m

3

123 c-01

lm456

'1

4

m

%

__---_----_i

1 TSB RevisionII