ESP MITSUBISHI ECLIPSE 1990 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 124 of 391

140’I2FUEL SYSTEM- Intake Air Control

INTAKE AIR CONTROL

GENERAL DESCRIPTION

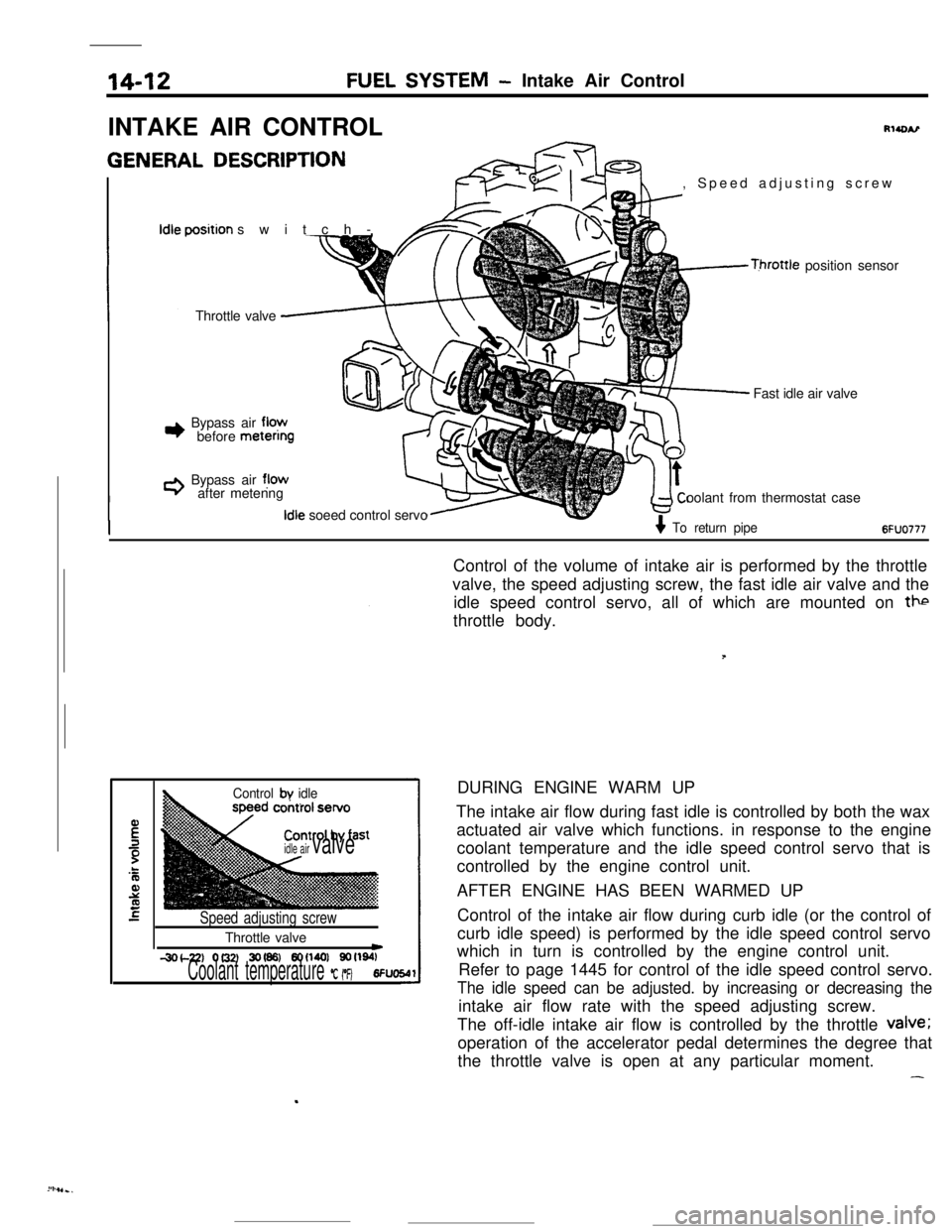

Rl4oA?, Speed adjusting screwIdle oositionswitch-

Throttle valve

0

+ Bypass air flow

before metenng

Q Bypass air fjow

Iafter metenng

Idle soeed control servo

-?hrottle position sensor

Fast idle air valve

oolant from thermostat case

ITo return pipe6FUO777Control of the volume of intake air is performed by the throttle

valve, the speed adjusting screw, the fast idle air valve and the

idle speed control servo, all of which are mounted on

ttithrottle body.

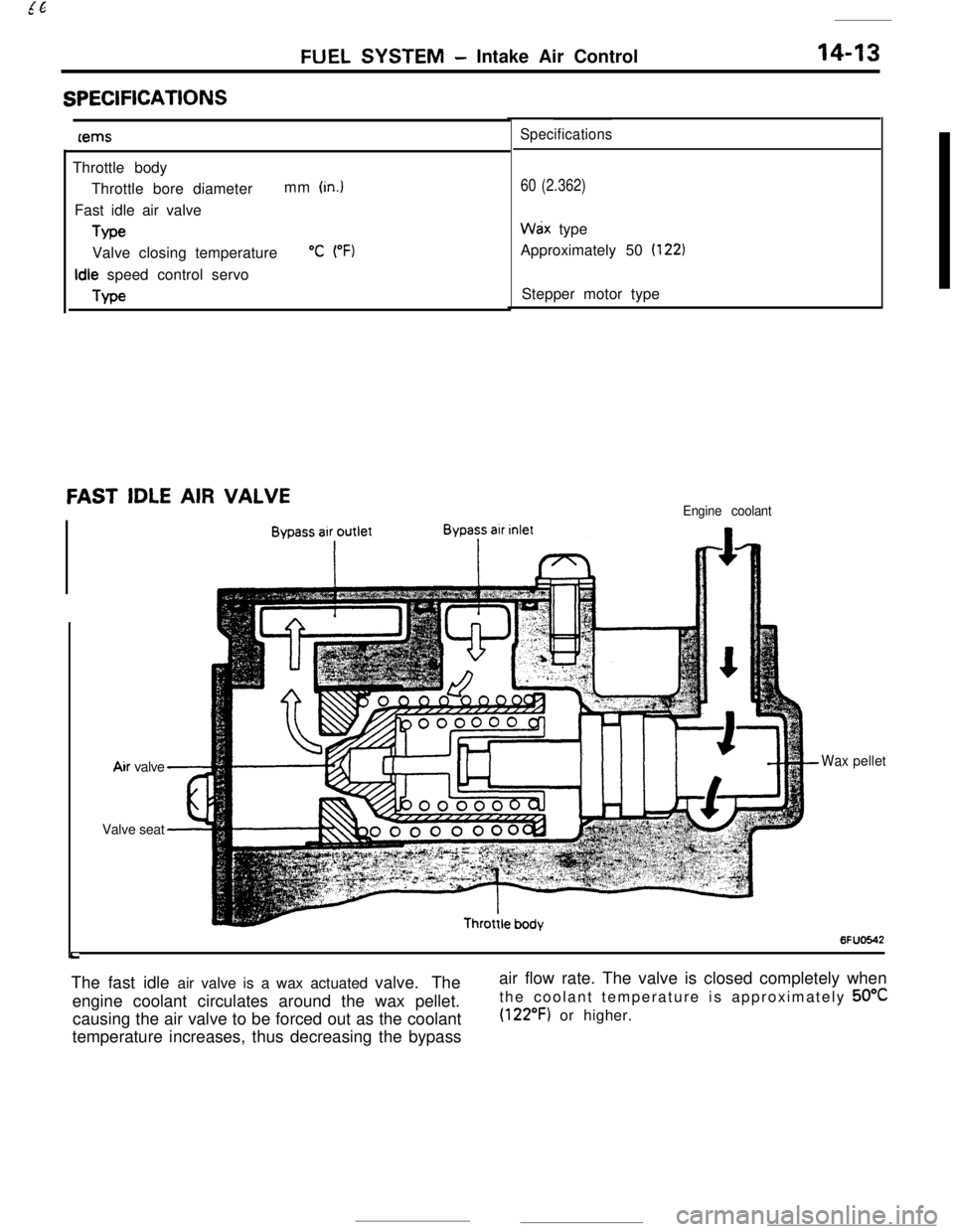

iControl by idle

w/d c;zk;;fast

hhidle air valve

Speed adjusting screwThrottle valve

m-30~22) of321 sofm 6of140~ 901164

Coolant temperature ‘C (OF)6Fuo!DURING ENGINE WARM UP

The intake air flow during fast idle is controlled by both the wax

actuated air valve which functions. in response to the engine

coolant temperature and the idle speed control servo that is

controlled by the engine control unit.

AFTER ENGINE HAS BEEN WARMED UP

Control of the intake air flow during curb idle (or the control of

curb idle speed) is performed by the idle speed control servo

which in turn is controlled by the engine control unit.

Refer to page 1445 for control of the idle speed control servo.The idle speed can be adjusted. by increasing or decreasing theintake air flow rate with the speed adjusting screw.

The off-idle intake air flow is controlled by the throttle

valve;operation of the accelerator pedal determines the degree that

the throttle valve is open at any particular moment.

-

.?‘h,

. .

Page 125 of 391

FUEL SYSTEM- Intake Air Control

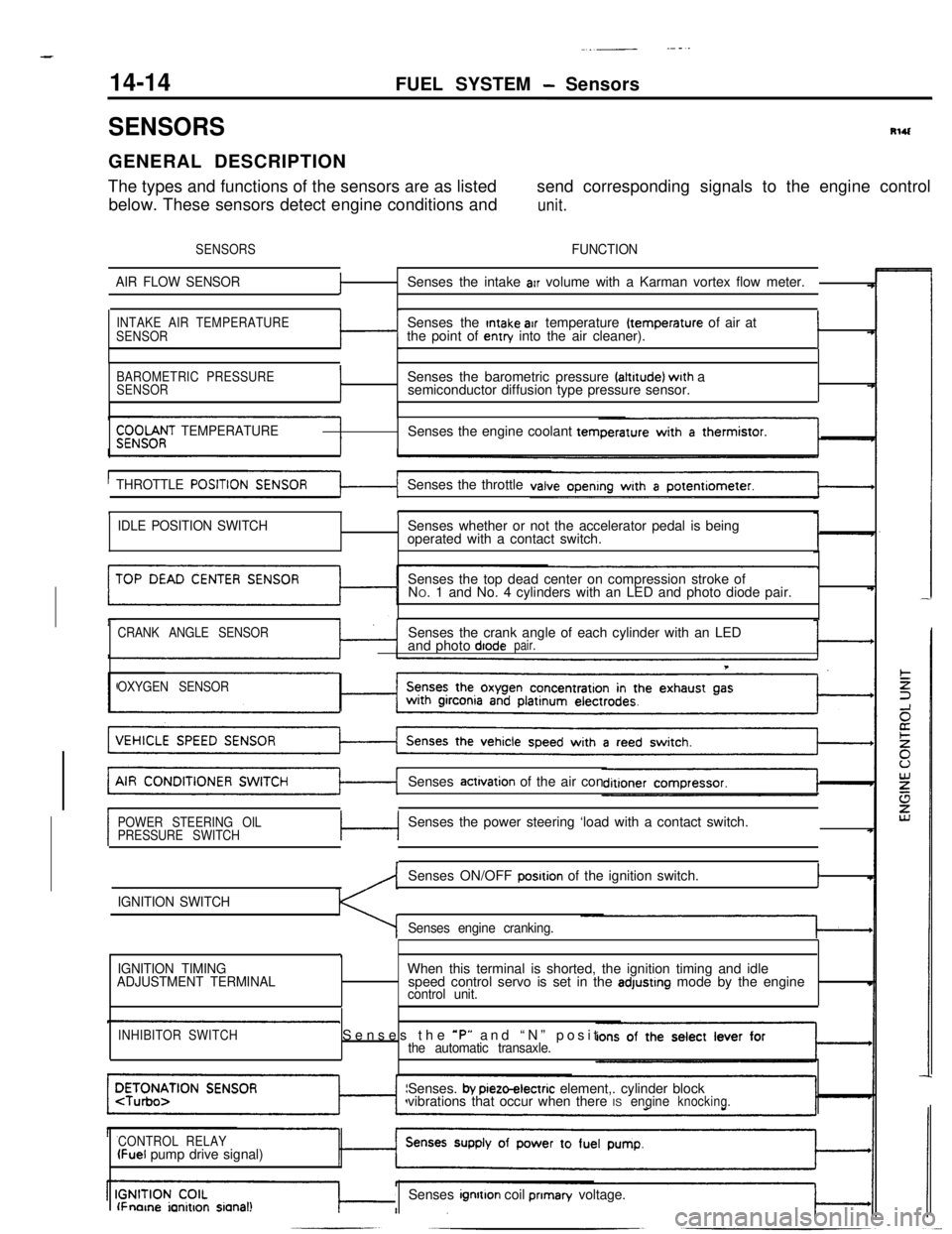

SPECIFICATIONS

ternsThrottle body

Throttle bore diametermm

(in.1Fast idle air valve

TwValve closing temperature

“C (“F)

Idle speed control servo

TypeSpecifications

60 (2.362)

WAX type

Approximately 50

(122)Stepper motor type

FAST IDLE AIR VALVEEngine coolant

LAir valve

Waxpellet

Valve seat

6FUO642The fast idle air valve is a wax actuated valve. The

engine coolant circulates around the wax pellet.

causing the air valve to be forced out as the coolant

temperature increases, thus decreasing the bypassair flow rate. The valve is closed completely when

the coolant temperature is approximately 50°C

(122°F) or higher.

Page 126 of 391

14-14

.._~- ---.FUEL SYSTEM

- Sensors

SENSORSRlUGENERAL DESCRIPTION

The types and functions of the sensors are as listedsend corresponding signals to the engine control

below. These sensors detect engine conditions and

unit.

SENSORSFUNCTION

AIR FLOW SENSOR

fSenses the intake arr volume with a Karman vortex flow meter.

INTAKE AIR TEMPERATURE

SENSORSenses the Intake air temperature (temperature of air at

the point of entry into the air cleaner).I

BAROMETRIC PRESSURE

SENSORISenses the barometric pressure faltrtude) wrth a

semiconductor diffusion type pressure sensor.

$;;OOf;T TEMPERATURESenses the engine coolant tern

THROTTLE

POSITISenses the throttle

tI

IDLE POSITION SWITCHSenses whether or not the accelerator pedal is being

operated with a contact switch.

Senses the top dead center on compression stroke of

NO. 1 and No. 4 cylinders with an LED and photo diode pair.

CRANK ANGLE SENSORSenses the crank angle of each cylinder with an LED

and photo diodepair.

T

OXYGEN SENSORSenses

actrvation of the air con

POWER STEERING OIL

PRESSURE SWITCHc-lSenses the power steering ‘load with a contact switch.

IGNITION SWITCHSenses ON/OFF

posrtion of the ignition switch.I

Senses engine cranking.

,

IGNITION TIMING

ADJUSTMENT TERMINALWhen this terminal is shorted, the ignition timing and idle

speed control servo is set in the adjustrng mode by the enginecontrol unit.

INHIBITOR SWITCHSenses the *P” and “N” positthe automatic transaxle.Senses.

by pieto-electric element,. cylinder block

vibrations that occur when there ISengineknocking.

CONTROL RELAY

(Fuel pump drive signal)

lFnorne ianitron sianal!Senses ignrtton coil prIman/ voltage.

Page 133 of 391

FUEL SYSTEM - Sensors14-21When exposed to light, the photo diode conducts

urrent in a direction opposite to an ordinary diode.

.s a result, current flows in the direction indicated

by the arrow and dotted line and a voltage (5 volts) isapplied to the comparator of the sensor unit so that

the terminal voltage of the engine control unit

becomes 5 volts. When the disc rotates further andthe slit moves beyond the space between the

LED/photo diode pair, the light can no longer reach

the photo diode, thus the current indicated by the

dotted line ceases to flow and the terminal voltage

of the engine control unit becomes 0 volt.

tn this

way, pulse signals are sent to the engine control

unit from the sensor unit.

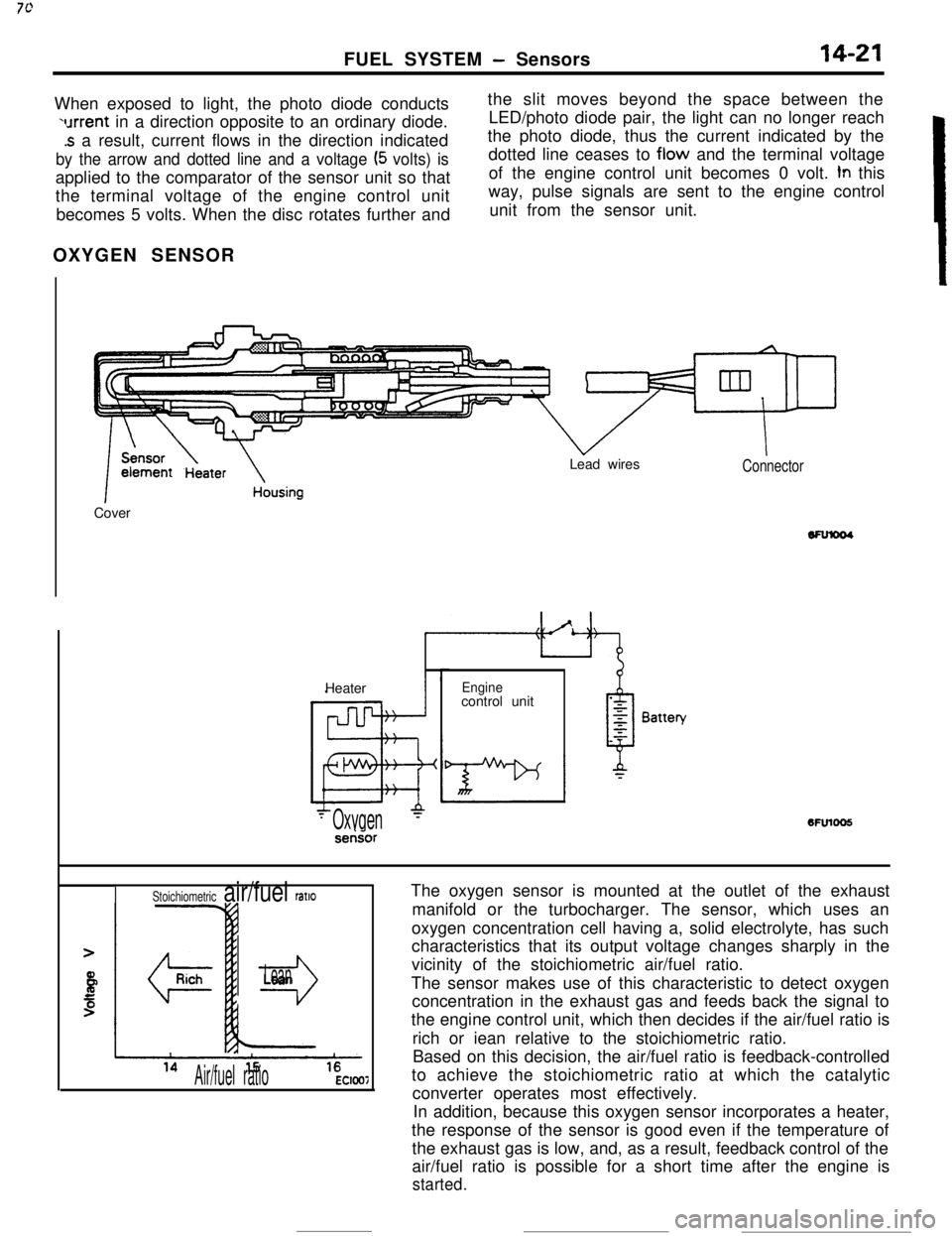

OXYGEN SENSOR

k

1 ~~~~t13ate~ousingCoverLead wiresConnectorHeater

Enginecontrol unit6FUlOO5

- Oxygen‘-serisor

The oxygen sensor is mounted at the outlet of the exhaust

manifold or the turbocharger. The sensor, which uses an

oxygen concentration cell having a, solid electrolyte, has such

characteristics that its output voltage changes sharply in the

vicinity of the stoichiometric air/fuel ratio.

The sensor makes use of this characteristic to detect oxygen

concentration in the exhaust gas and feeds back the signal to

the engine control unit, which then decides if the air/fuel ratio is

rich or iean relative to the stoichiometric ratio.

Based on this decision, the air/fuel ratio is feedback-controlled

to achieve the stoichiometric ratio at which the catalytic

converter operates most effectively.

In addition, because this oxygen sensor incorporates a heater,

the response of the sensor is good even if the temperature of

the exhaust gas is low, and, as a result, feedback control of the

air/fuel ratio is possible for a short time after the engine is

started.

Stoichiometric air/fuel ratlo

r3

Lean

Air/fuel ratioEC1007

Page 136 of 391

--

,

14-24FUEL SYSTEM - Sensors

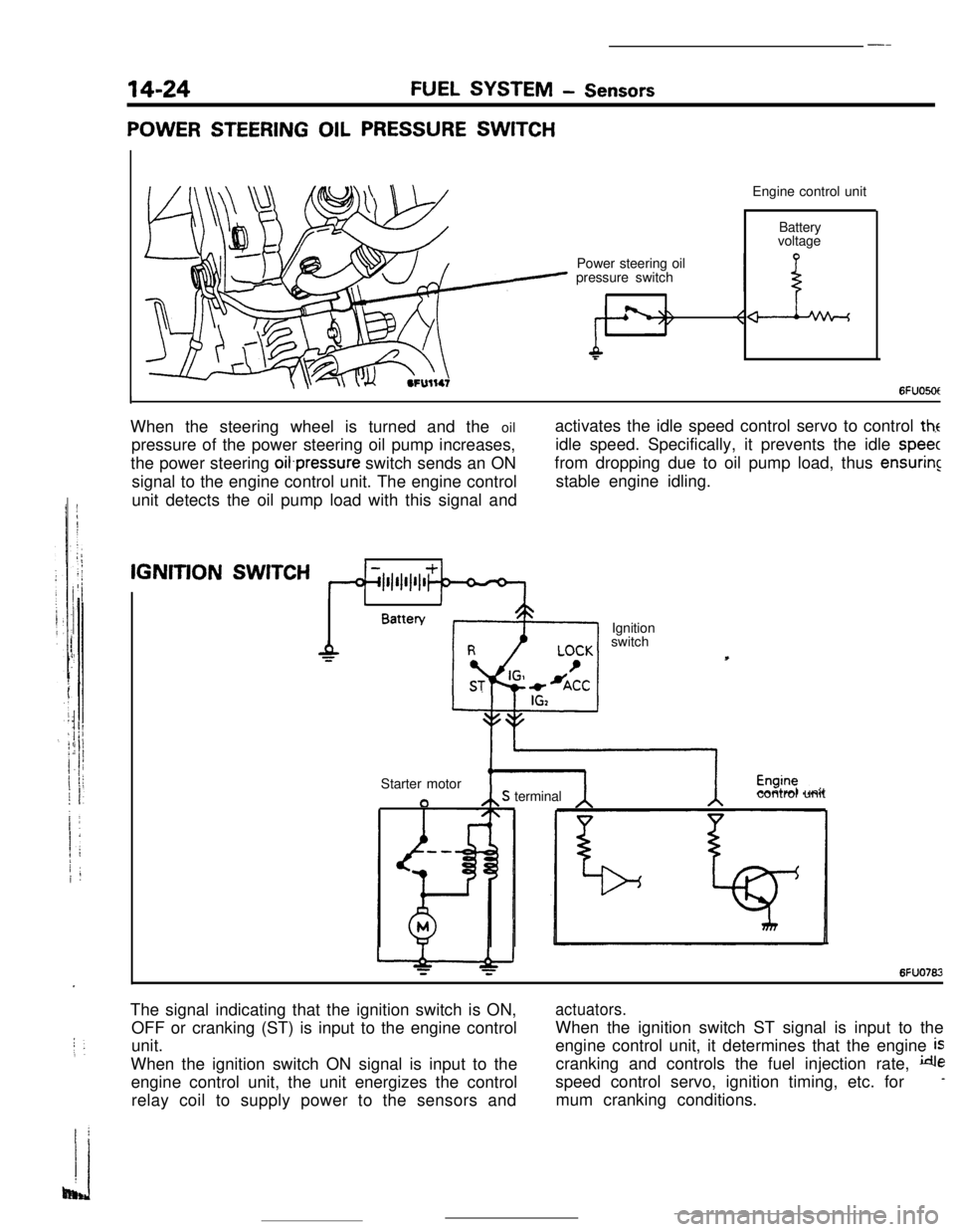

POWER STEERING OIL PRESSURE SWITCHEngine control unit

Power steering oil

pressure switchBattery

voltage

6FUO5OtIWhen the steering wheel is turned and the oil

pressure of the power steering oil pump increases,

the power steering oifpressure switch sends an ON

signal to the engine control unit. The engine control

unit detects the oil pump load with this signal andactivates the idle speed control servo to control

theidle speed. Specifically, it prevents the idle

speecfrom dropping due to oil pump load, thus

ensuringstable engine idling.IGNITION

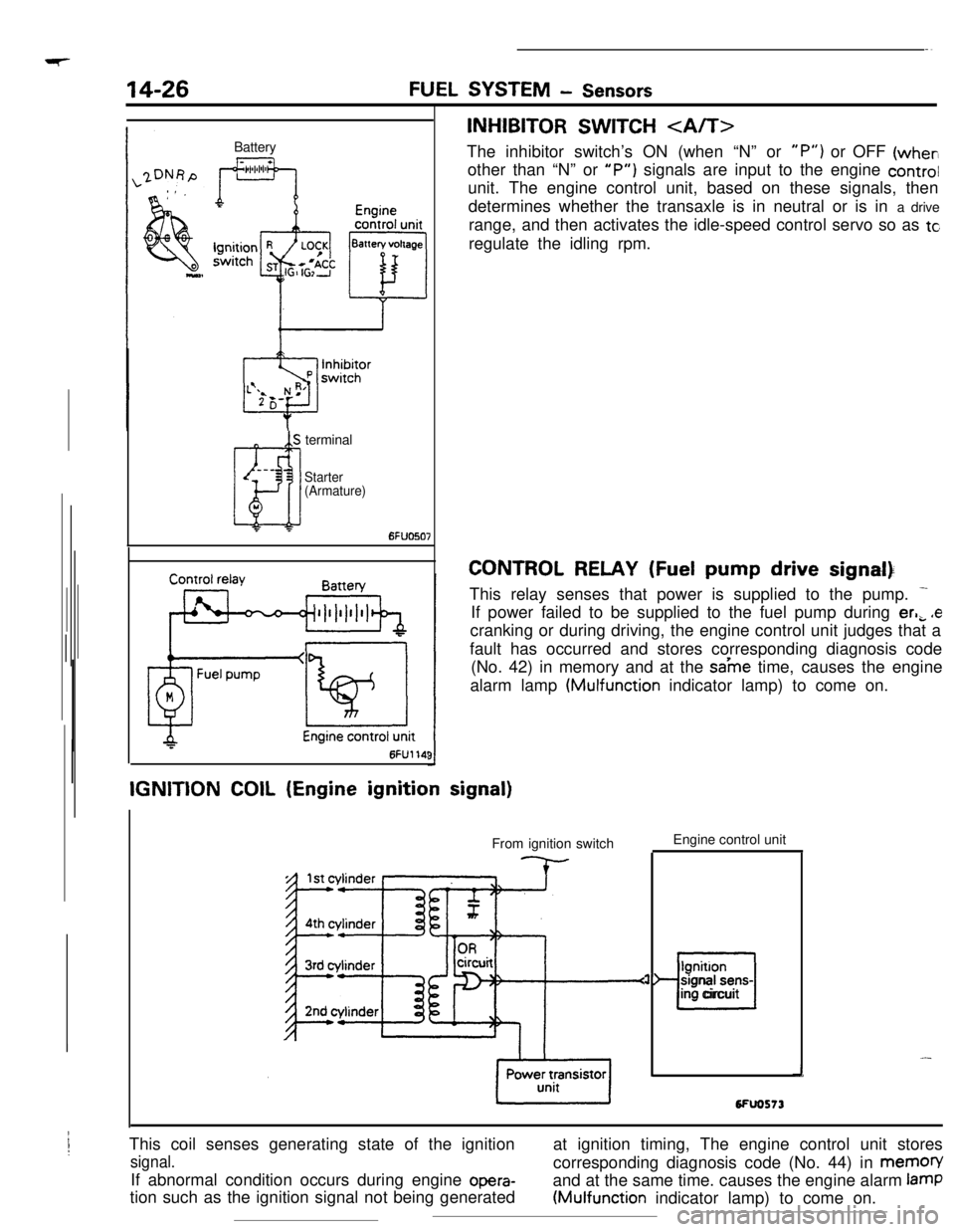

SWITCH

1IBattery

Ignition

switch

Starter motor

aS terminalcontrol unit

6FUO762The signal indicating that the ignition switch is ON,

OFF or cranking (ST) is input to the engine control

unit.

When the ignition switch ON signal is input to the

engine control unit, the unit energizes the control

relay coil to supply power to the sensors and

actuators.When the ignition switch ST signal is input to the

engine control unit, it determines that the engine

iscranking and controls the fuel injection rate,

despeed control servo, ignition timing, etc. for

-mum cranking conditions.

Page 137 of 391

FUEL SYSTEM - Sensors14-25Terminal for

ignition timing

adjustment

l-l6FUO51:7

W$ht(/.

Piezo-electncelements

I6FUOSlO

DetonationEngine control

unit

sensor

I-

I t i A-- >--t.--‘-3 -

wt4rlIGNITION TlMlNG ADJUSTMENT TERMINAL

This terminal

is used when adjusting the basic ignition timing or

basic idle speed.

When this terminal is shorted to ground, the engine control unit

cancels the

ignition timing control and idle speed control, and

sets the ignition

timing and idle speed control servos in their

adjusting mode.

For the basic idle speed adjustment, the diagnosis terminal is

also shorted to ground.

DETONATION SENSOR

The detonation sensor is installed at a position where it can

detect, with a high degree of precision, knocking generated at

each cylinder; it detects cylinder block vibrations caused by

knocking, and outputs voltage proportional to the magnitude of

those vibrations.

Because cylinder block vibrations caused by knocking vary

from engine to engine, the engine control unit passes this

through a frequncy filter, detecting only the knocking, thus

resulting in a spark retardation of the ignition timing that

corresponds to the strength of the knocking.

Page 138 of 391

Page 145 of 391

FUEL SYSTEM- Fuel Injection Control14-33

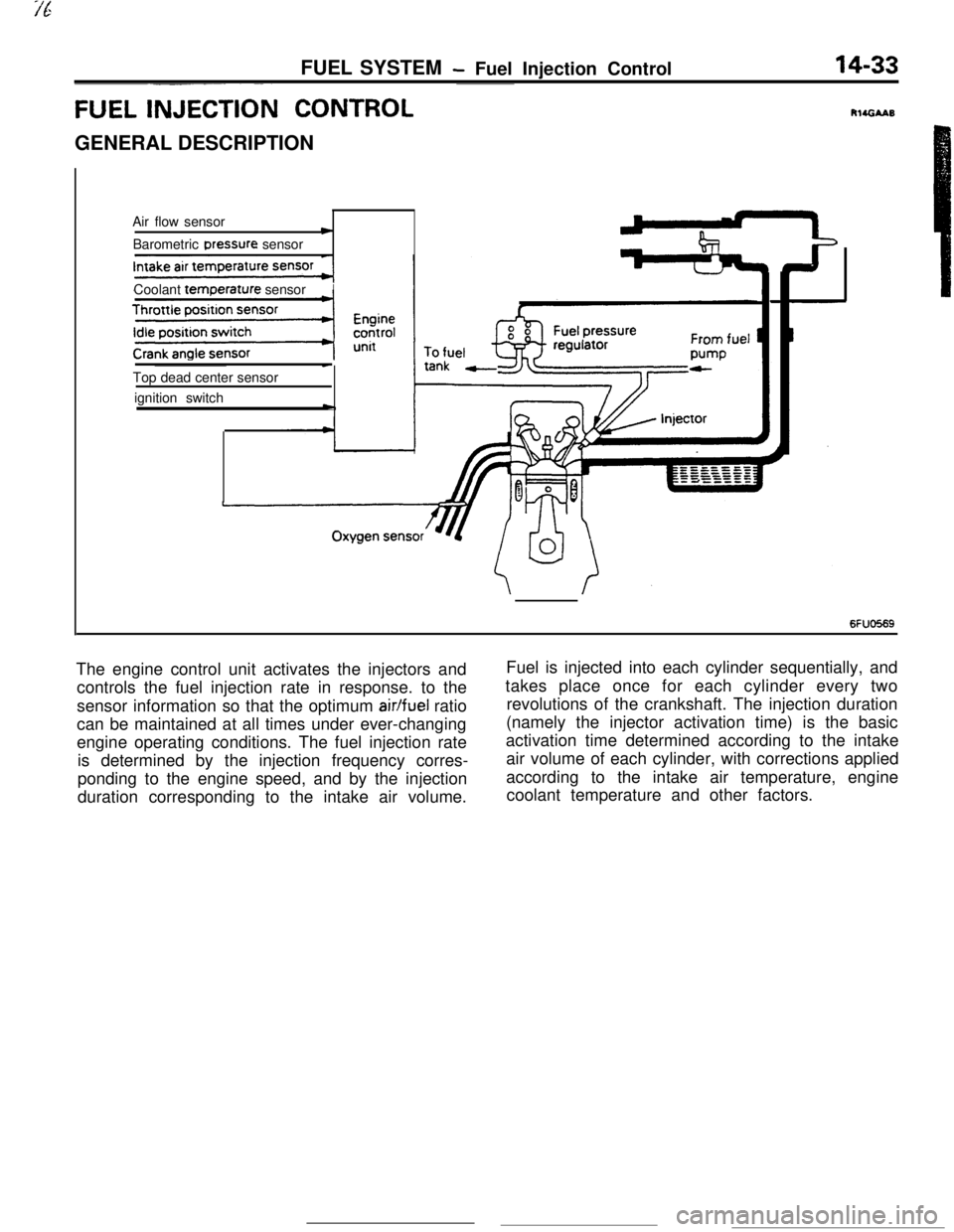

FUEL INJECTI& CONTROLGENERAL DESCRIPTION

Air flow sensor

cBarometric Dressure sensor

Coolant

temr3erature sensorITop dead center sensor

ignition switch

-

c

6FUO569The engine control unit activates the injectors andFuel is injected into each cylinder sequentially, and

controls the fuel injection rate in response. to thetakes place once for each cylinder every two

sensor information so that the optimum

air/fuel ratiorevolutions of the crankshaft. The injection duration

can be maintained at all times under ever-changing(namely the injector activation time) is the basic

engine operating conditions. The fuel injection rateactivation time determined according to the intake

is determined by the injection frequency corres-air volume of each cylinder, with corrections applied

ponding to the engine speed, and by the injectionaccording to the intake air temperature, engine

duration corresponding to the intake air volume.coolant temperature and other factors.

Page 148 of 391

14-36FUEL SYSTEM- Fuel lniection Control

SFUOSlS

RESISTOR

co,.of the injector.

Because the injector must respond instantly to fuel-injection

signals, the number of windings of the coil is reduced in order

to facilitate current rise when the current is flowing in the coil.

By doing so, the resistance of the injector coil becomes smaller

and a greater amount of current can flow, with the result that

the calorific value of the injector coil becomes greater, and

1overheating occurs.

For this reason, for turbocharger-equipped models (which have

low resistance of the injector coil), a resistor is provided

between the power supply (+) and the injector in order to

regulate the amount of current flowing in the coil.

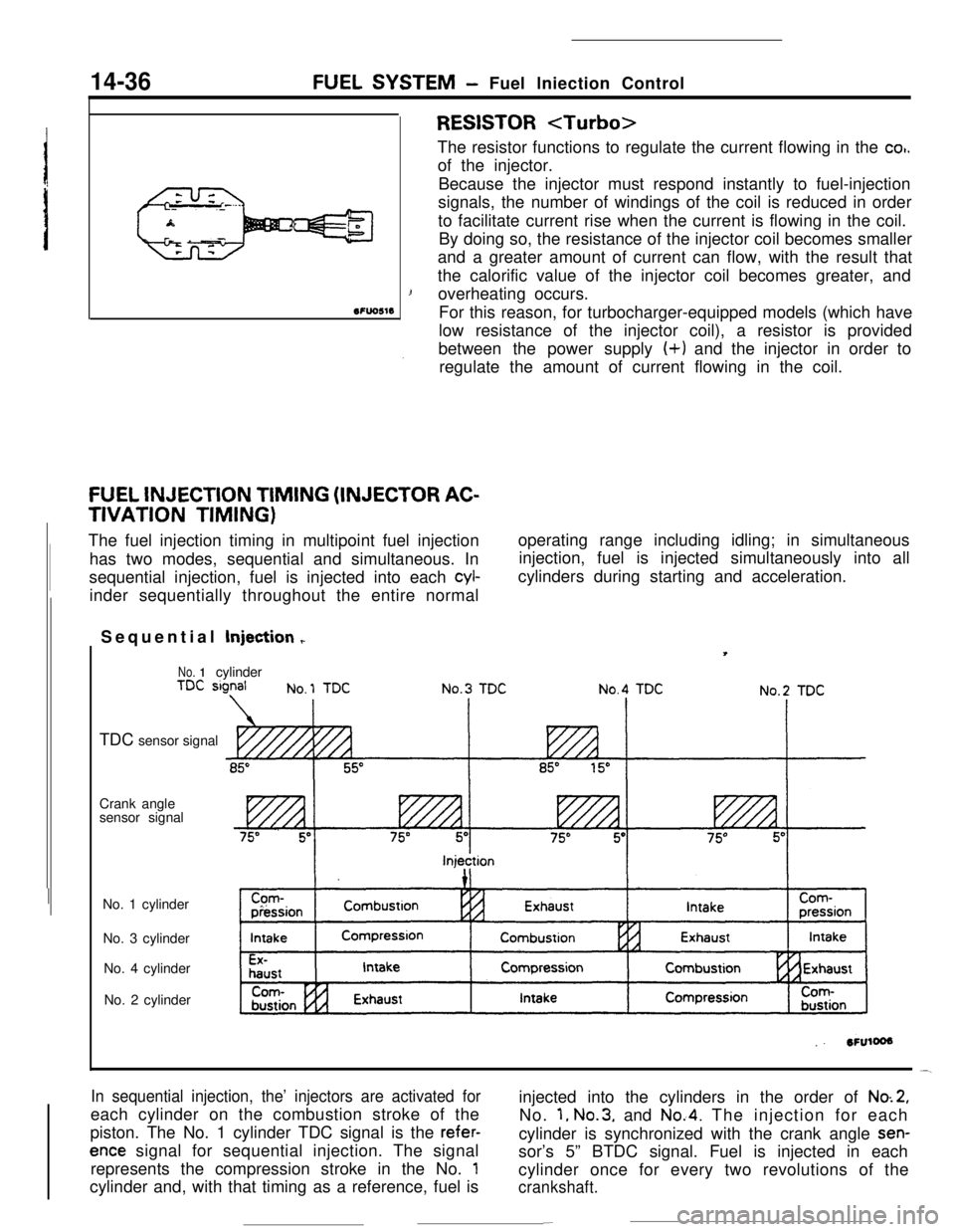

FUEL INJECTION TIMING (INJECTOR AC-

TIVATION TIMING)

The fuel injection timing in multipoint fuel injection

has two modes, sequential and simultaneous. In

sequential injection, fuel is injected into each

cyl-inder sequentially throughout the entire normaloperating range including idling; in simultaneous

injection, fuel is injected simultaneously into all

cylinders during starting and acceleration.

Sequential Injection

r

No. 1cylinder

TDC sensor signal

Crank angle

sensor signal

No. 1 cylinder

No. 3 cylinder

No. 4 cylinder

No. 2 cylinder

In sequential injection, the’ injectors are activated foreach cylinder on the combustion stroke of the

piston. The No. 1 cylinder TDC signal is the

refer-

ence signal for sequential injection. The signal

represents the compression stroke in the No.

1cylinder and, with that timing as a reference, fuel isinjected into the cylinders in the order of

No.2,No.

1, No.3, and No.4. The injection for each

cylinder is synchronized with the crank angle

sen-sor’s 5” BTDC signal. Fuel is injected in each

cylinder once for every two revolutions of the

crankshaft.

-

Page 158 of 391

.

14-46FUEL SYSTEM- Idle Speed Control

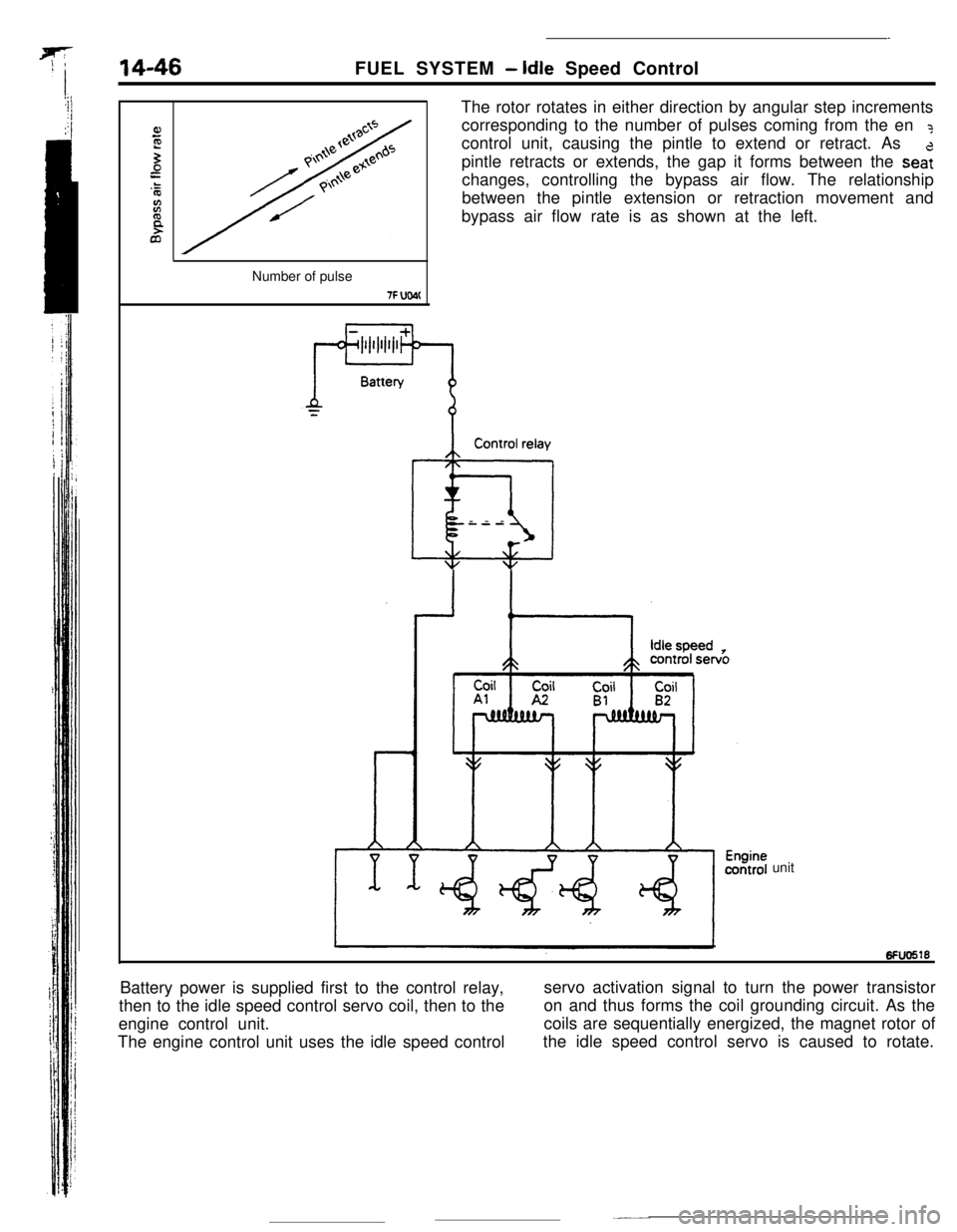

The rotor rotates in either direction by angular step increments

corresponding to the number of pulses coming from the en

?control unit, causing the pintle to extend or retract. As

pintle retracts or extends, the gap it forms between the

sea:changes, controlling the bypass air flow. The relationship

between the pintle extension or retraction movement and

bypass air flow rate is as shown at the left.

Number of pulse

7F UW(Control relay

@iI---

unit

Battery power is supplied first to the control relay,

then to the idle speed control servo coil, then to theservo activation signal to turn the power transistor

engine control unit.on and thus forms the coil grounding circuit. As the

The engine control unit uses the idle speed controlcoils are sequentially energized, the magnet rotor of

the idle speed control servo is caused to rotate.