ESP MITSUBISHI ECLIPSE 1990 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 280 of 391

-

!-I

I!I

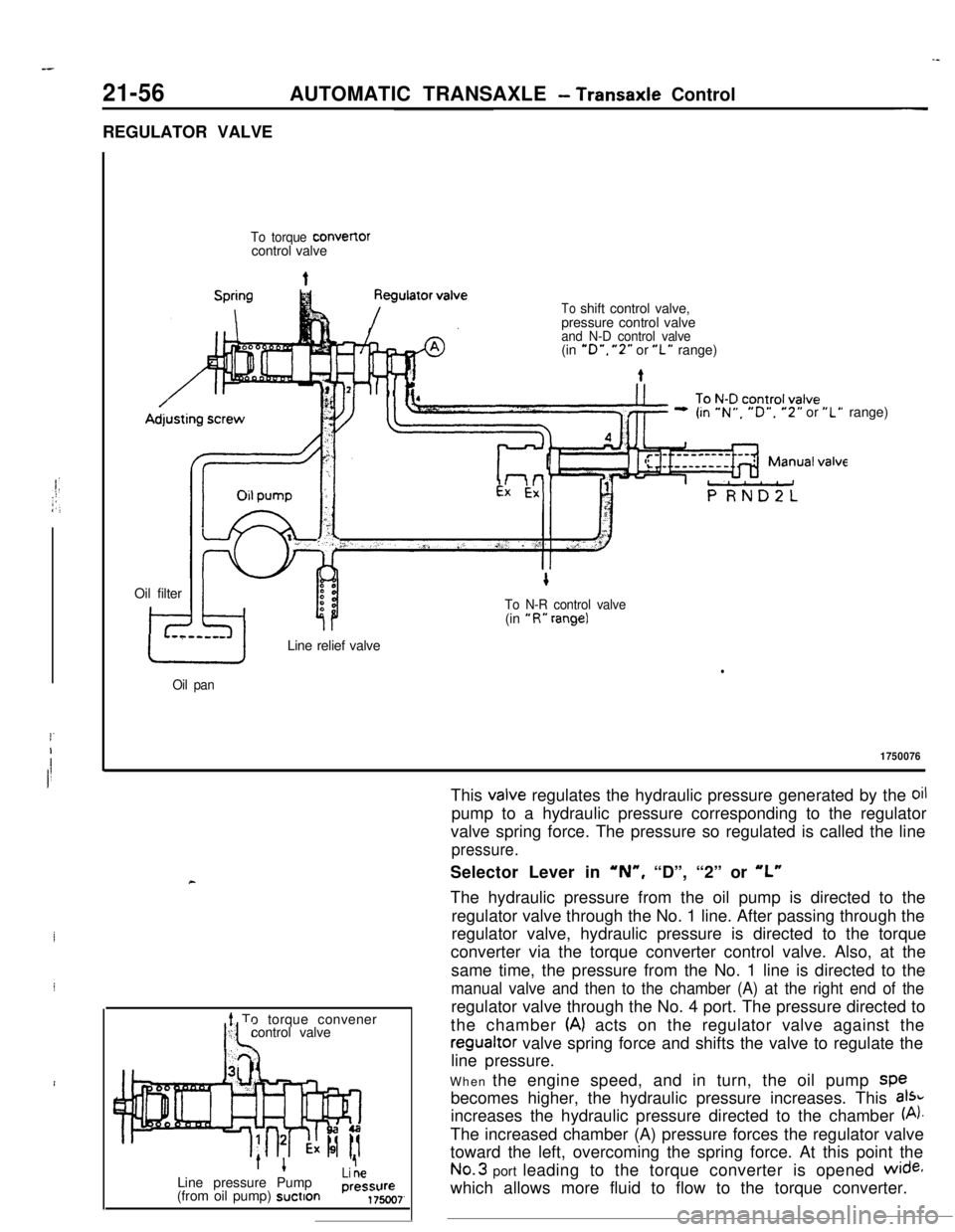

21-56AUTOMATIC TRANSAXLE - Transaxle Control~-REGULATOR VALVE

To torque convener

control valve

t

Toshift control valve,

pressure control valve

and N-D control valve(in “D”. ”2” or “L” range)

“D”.“2” or “L” range)

Oil filter

I1

To N-R control valve(in “R” range)Line relief valve

Oil pan

l

1750076

! To torque convener

IL‘I:control valve

Line pressure Pump

Li Ae(from oil pump) suctionprest$$)7,This

valve regulates the hydraulic pressure generated by the oilpump to a hydraulic pressure corresponding to the regulator

valve spring force. The pressure so regulated is called the line

pressure.Selector Lever in

‘N”, “D”, “2” or “L”The hydraulic pressure from the oil pump is directed to the

regulator valve through the No. 1 line. After passing through the

regulator valve, hydraulic pressure is directed to the torque

converter via the torque converter control valve. Also, at the

same time, the pressure from the No. 1 line is directed to the

manual valve and then to the chamber (A) at the right end of theregulator valve through the No. 4 port. The pressure directed to

the chamber

(A) acts on the regulator valve against theregualtor valve spring force and shifts the valve to regulate the

line pressure.

When the engine speed, and in turn, the oil pump spe

becomes higher, the hydraulic pressure increases. This

aI%increases the hydraulic pressure directed to the chamber

(A).The increased chamber (A) pressure forces the regulator valve

toward the left, overcoming the spring force. At this point theNo.3 port leading to the torque converter is opened

wide+which allows more fluid to flow to the torque converter.

Page 284 of 391

21-60AUTOMATIC TRANSAXLE - Transaxle Control

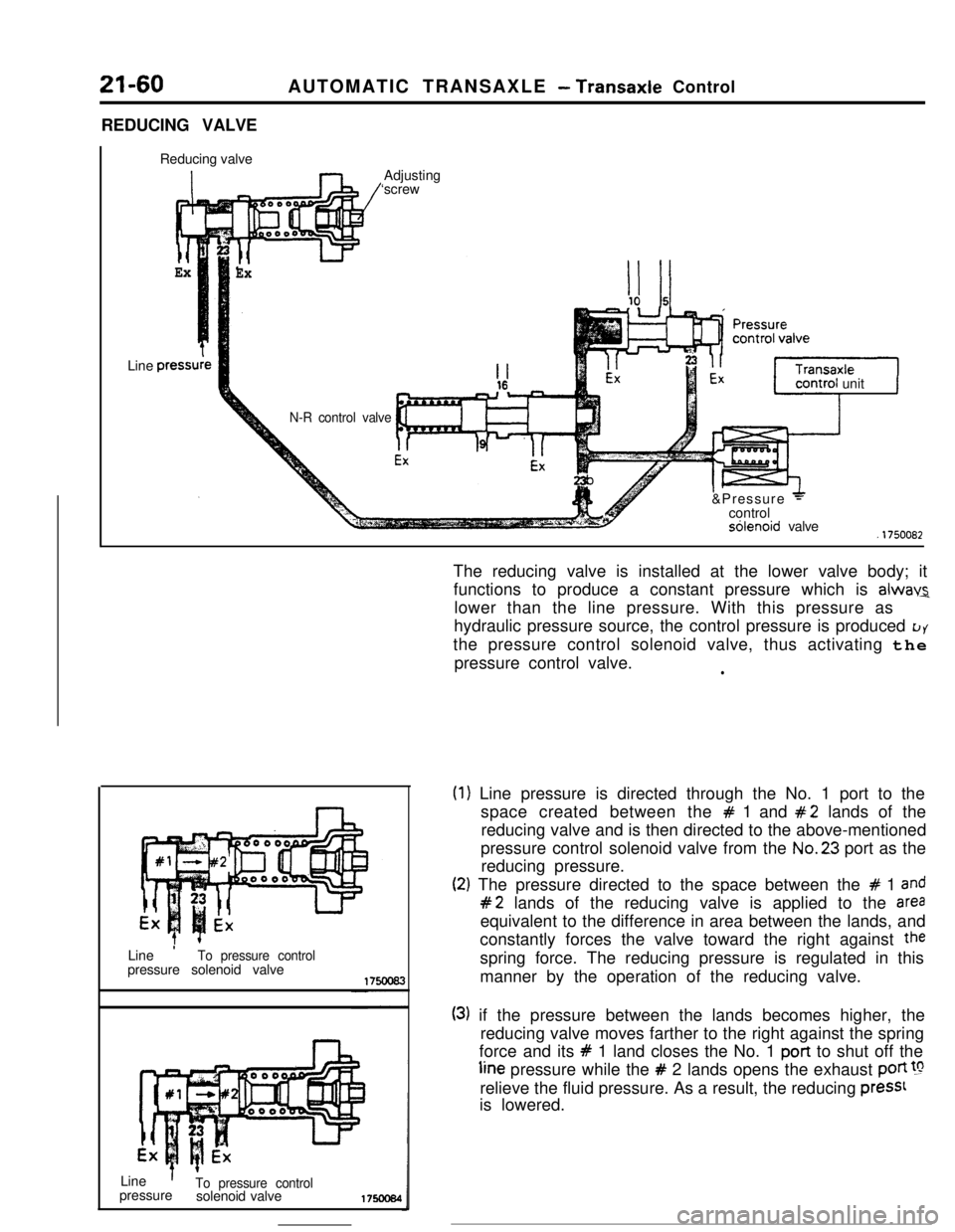

REDUCING VALVE

Reducing valve

ExLine

press1

ExAdjusting

‘screw

N-R control valveunit

J&Pressure

+controlsblenoid valve.1750082

Line

’To pressure controlpressure solenoid valve

Line

’To pressure controlpressure

solenoid valve175ocs4The reducing valve is installed at the lower valve body; it

functions to produce a constant pressure which is

alwav2lower than the line pressure. With this pressure as

hydraulic pressure source, the control pressure is produced

LJYthe pressure control solenoid valve, thus activating the

pressure control valve.

l

(1

(2

) Line pressure is directed through the No. 1 port to the

space created between the

# 1 and #2 lands of the

reducing valve and is then directed to the above-mentioned

pressure control solenoid valve from the No.23 port as the

reducing pressure.

:) The pressure directed to the space between the # 1 and

#2 lands of the reducing valve is applied to the areaequivalent to the difference in area between the lands, and

constantly forces the valve toward the right against

thespring force. The reducing pressure is regulated in this

manner by the operation of the reducing valve.

(3) if the pressure between the lands becomes higher, the

reducing valve moves farther to the right against the spring

force and its

# 1 land closes the No. 1 port to shut off theline pressure while the

# 2 lands opens the exhaust poti !grelieve the fluid pressure. As a result, the reducing

press1is lowered.

Page 291 of 391

/gi--__ .--.-9

Reducingvalve

To kickdown

servo via 1 - 2

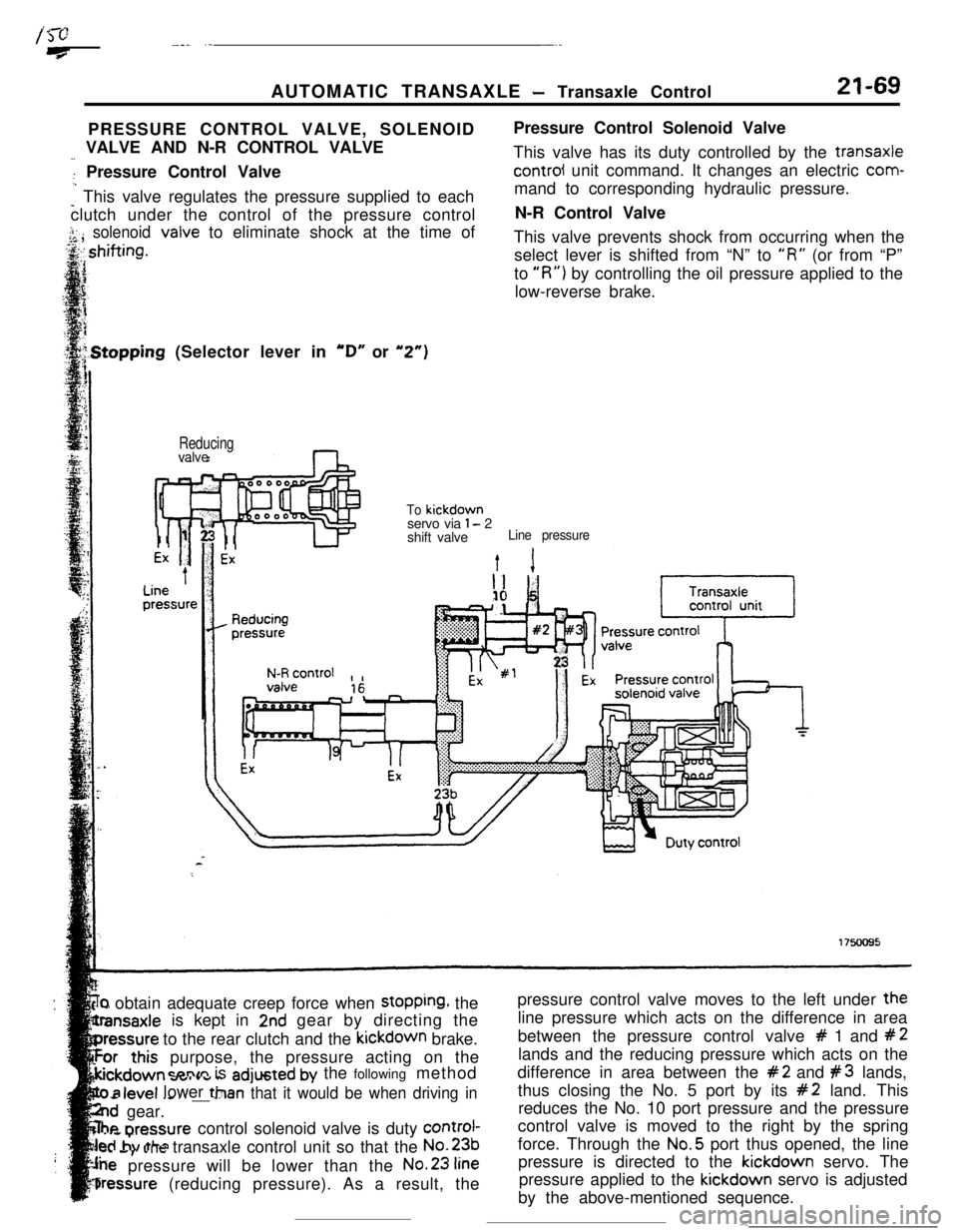

shift valveLine pressureAUTOMATIC TRANSAXLE

- Transaxle Control21-69

PRESSURE CONTROL VALVE, SOLENOID

-_ VALVE AND N-R CONTROL VALVE

: Pressure Control Valve

: This valve regulates the pressure supplied to each

clutch under the control of the pressure control

j.. solenoid<,A ,valve to eliminate shock at the time ofPressure Control Solenoid Valve

This valve has its duty controlled by the transaxlecontrol unit command. It changes an electric com-

mand to corresponding hydraulic pressure.

N-R Control Valve

This valve prevents shock from occurring when the

select lever is shifted from “N” to

“R” (or from “P”

to

“R”) by controlling the oil pressure applied to the

low-reverse brake..Stopping (Selector lever in

“D” or “2”)

‘r) obtain adequate creep force when stopping, the

is kept in

2nd gear by directing the

to the rear clutch and the kickdown brake.

purpose, the pressure acting on the

=nnm is adjusted by the following method

- .--v.._ _ _ __ --Tan that it would be when driving in

..d gear.

he nrennurecontrol solenoid valve is duty control-

..s,. ..Jtransaxle control unit so that the No.231..a

pressure will be lower than the No.23

fine

bressure (reducing pressure). As a result, the

level lower ttlpressure control valve moves to the left under the

line pressure which acts on the difference in area

between the pressure control valve

# 1 and #2lands and the reducing pressure which acts on the

difference in area between the

#2 and #3 lands,

thus closing the No. 5 port by its

#2 land. This

reduces the No. 10 port pressure and the pressure

control valve is moved to the right by the spring

force. Through the No.5 port thus opened, the line

pressure is directed to the kickdown servo. The

pressure applied to the kickdown servo is adjusted

by the above-mentioned sequence.

-

Page 295 of 391

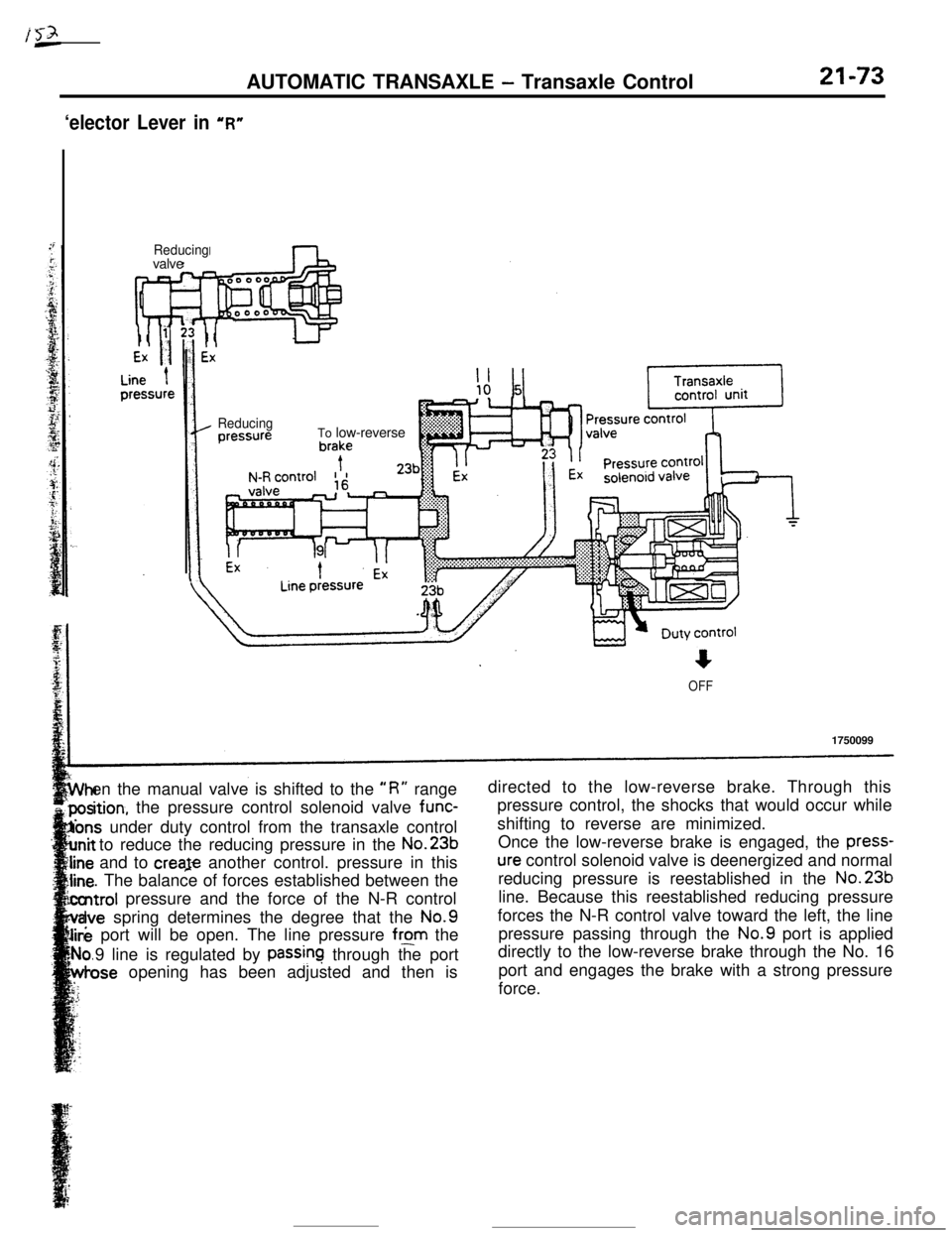

AUTOMATIC TRANSAXLE - Transaxle Control21-73

‘elector Lever in “R”

Reducingvalve

ReducingTo low-reverse

OFF1750099

en the manual valve is shifted to the

“R” rangedirected to the low-reverse brake. Through this

ition, the pressure control solenoid valve func-pressure control, the shocks that would occur while

Ions under duty control from the transaxle controlshifting to reverse are minimized.

to reduce the reducing pressure in the No.23bOnce the low-reverse brake is engaged, the press-and to creaje another control. pressure in this

ure control solenoid valve is deenergized and normal

. The balance of forces established between thereducing pressure is reestablished in the No.23bntrol pressure and the force of the N-R controlline. Because this reestablished reducing pressure

Ivespring determines the degree that the No.9forces the N-R control valve toward the left, the line

e port will be open. The line pressure from thepressure passing through the No.9 port is applied

9 line is regulated by

passinq through the portdirectly to the low-reverse brake through the No. 16

ose opening has been adjusted and then isport and engages the brake with a strong pressure

force.

Page 298 of 391

?

I

21-76AUTOMATIC TRANSAXLE - Transaxle Control

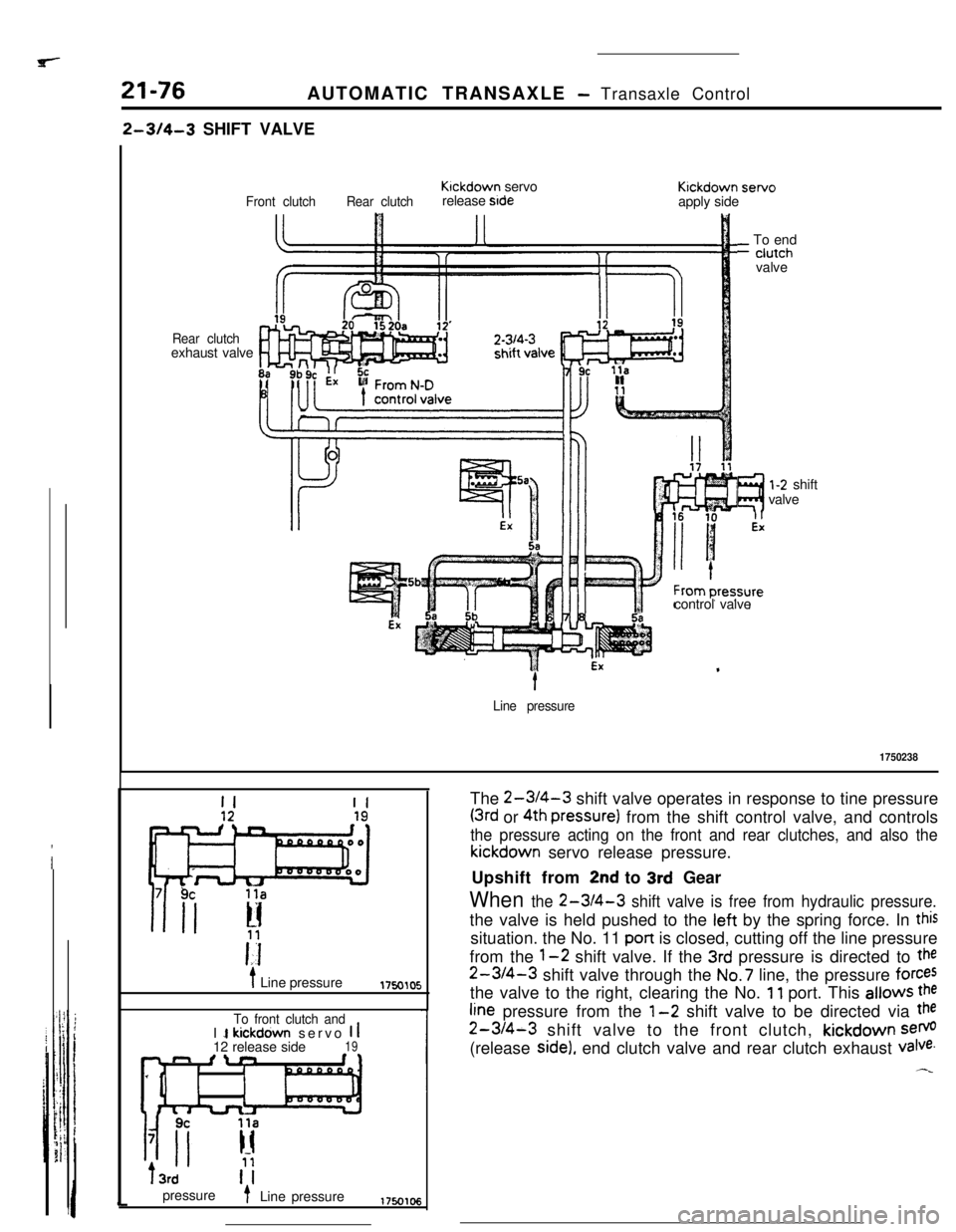

2-314-3 SHIFT VALVE

Rear clutchexhaust valve

Front clutchRear clutchKlckdown servo

release stdeKickdown servo

apply side

?I

l-2 shift

valve

control valve

_ To end- ciutch

valvet

Line pressure

1750238

II

i Line pressure1750105

To front clutch andI 1 kickdown servo 1 112 release side19n fln

IIT3rd

pressure

t- Line pressureThe

2-WI-3 shift valve operates in response to tine pressure

(3rd or 4th pressure) from the shift control valve, and controls

the pressure acting on the front and rear clutches, and also thekickdown servo release pressure.

Upshift from

2nd to 3rd Gear

When the 2-3/4-3 shift valve is free from hydraulic pressure.the valve is held pushed to the left by the spring force. In

thissituation. the No. 11 pan is closed, cutting off the line pressure

from the

1-2 shift valve. If the 3rd pressure is directed to the

2-3/4-3 shift valve through the No.7 line, the pressure forcesthe valve to the right, clearing the No.

11 port. This allows the

fine pressure from the l-2 shift valve to be directed via the

2-3/4-3 shift valve to the front clutch, kickdown sem(release

side), end clutch valve and rear clutch exhaust valve.

Page 381 of 391

EMISSION CONTROL SYSTEMS - Exhaust Car Recirculation (EGR) System25-7Duty ratio

I .,

ON e-_-m-L--l

T2L1.TlOFF---

m

1c1-i1e2100260 msec. 60 msec.

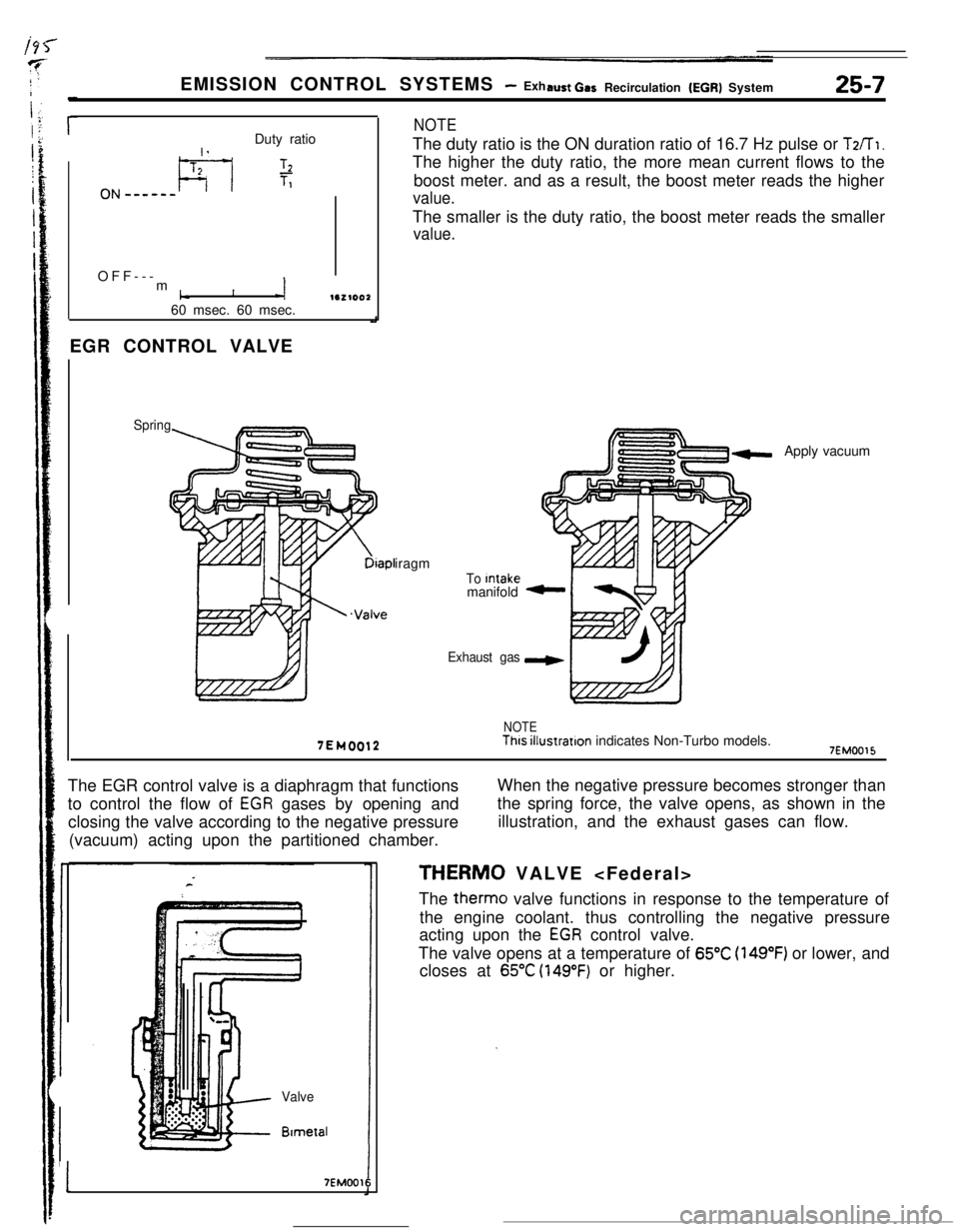

EGR CONTROL VALVE

Spring

NOTEThe duty ratio is the ON duration ratio of 16.7 Hz pulse or

T2/T1.The higher the duty ratio, the more mean current flows to the

boost meter. and as a result, the boost meter reads the higher

value.The smaller is the duty ratio, the boost meter reads the smaller

value.

Diapl

.Valveiragm

To Intakemanifold

Exhaust gasApply vacuum

7EM0012

NOTEThis illustration indicates Non-Turbo models.7EMOO15The EGR control valve is a diaphragm that functions

to control the flow of

EGR gases by opening and

closing the valve according to the negative pressure

(vacuum) acting upon the partitioned chamber.When the negative pressure becomes stronger than

the spring force, the valve opens, as shown in the

illustration, and the exhaust gases can flow.

Valve

BlmetzII

17EMOO16

THERM0 VALVE

The therm0 valve functions in response to the temperature of

the engine coolant. thus controlling the negative pressure

acting upon the

EGR control valve.

The valve opens at a temperature of

65°C (149°F) or lower, and

closes at

65°C (149°F) or higher.

Page 384 of 391

25-10EMISSION CONTROL SYSTEMS - Crankcase Ventilation Svstem-

CRANKCASE VENTILATION SYS-fUSFAAA,r

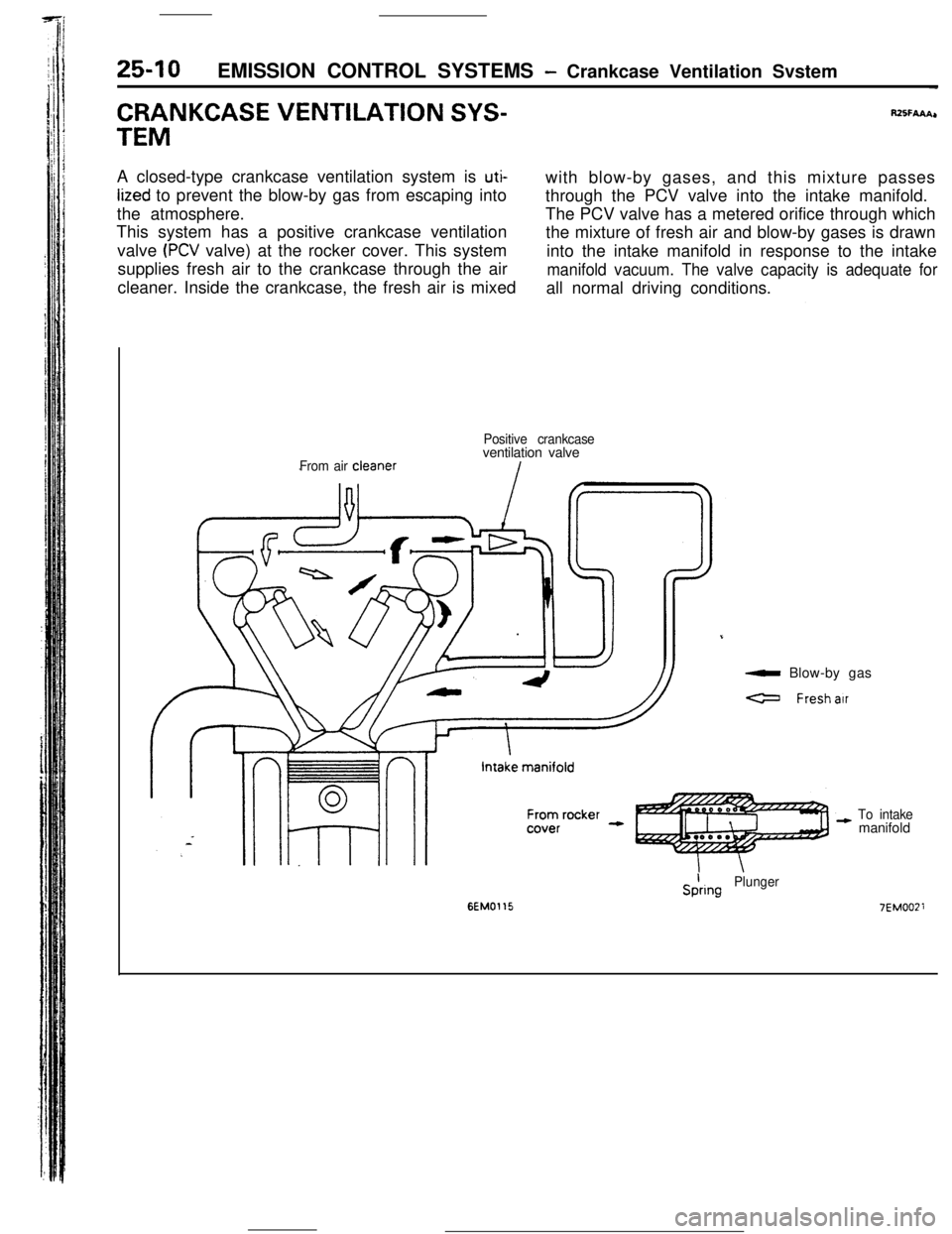

TEMA closed-type crankcase ventilation system is

uti-with blow-by gases, and this mixture passes

lized to prevent the blow-by gas from escaping into

through the PCV valve into the intake manifold.

the atmosphere.The PCV valve has a metered orifice through which

This system has a positive crankcase ventilation

the mixture of fresh air and blow-by gases is drawn

valve

(PCV valve) at the rocker cover. This system

into the intake manifold in response to the intake

supplies fresh air to the crankcase through the air

manifold vacuum. The valve capacity is adequate forcleaner. Inside the crankcase, the fresh air is mixed

all normal driving conditions.

From air cleanerPositive crankcaseventilation valve

a Blow-by gas

a Freshair

To intakemanifold

6EM0115

SiringPlunger

7EMOOZi