MITSUBISHI ECLIPSE 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 751 of 1216

MANUAL TRANSAXLE

Spline201065

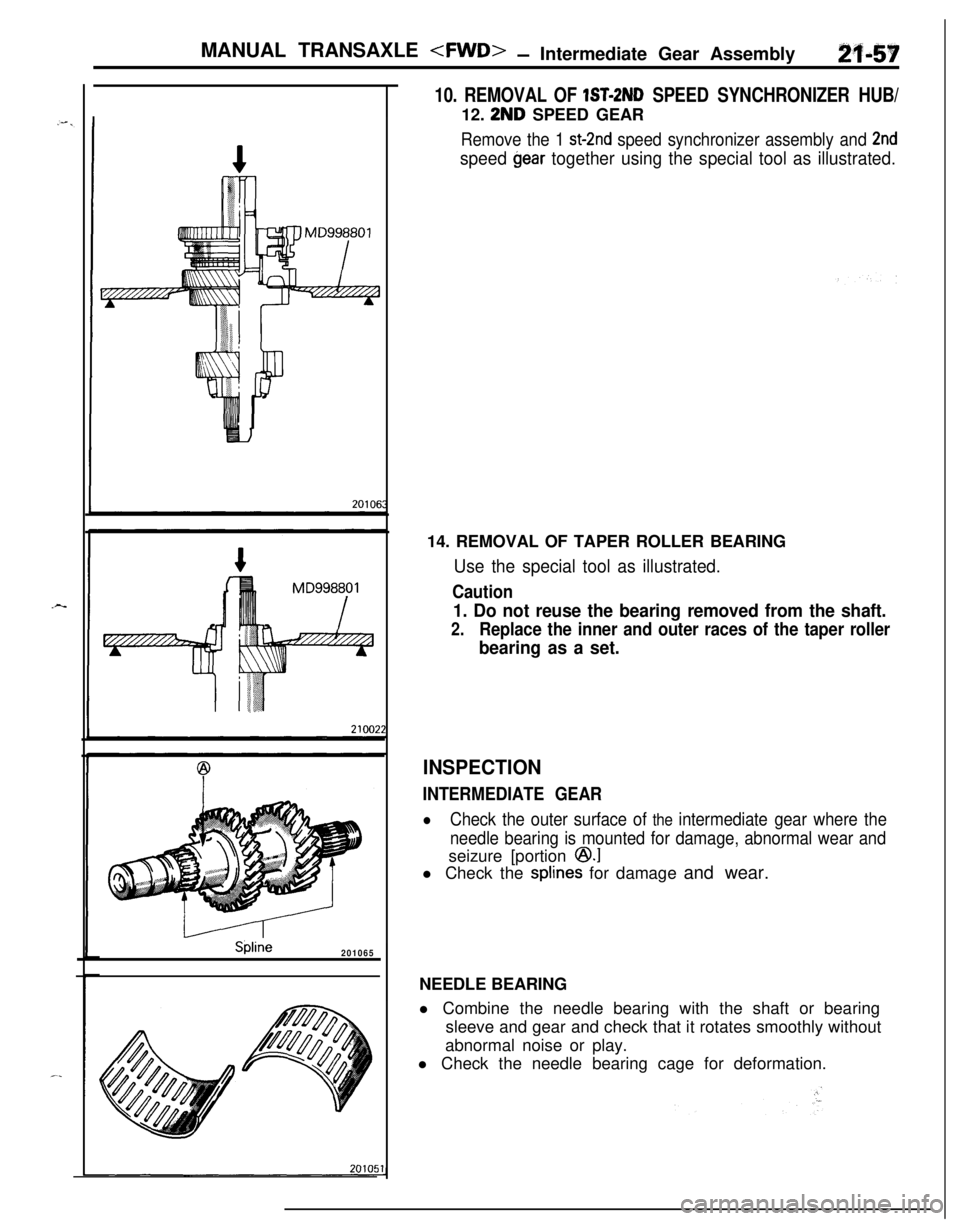

10. REMOVAL OF lST-2ND SPEED SYNCHRONIZER HUB/12. 2ND SPEED GEAR

Remove the 1 st-2nd speed synchronizer assembly and 2nd

speed gear together using the special tool as illustrated.14. REMOVAL OF TAPER ROLLER BEARING

Use the special tool as illustrated.

Caution

1. Do not reuse the bearing removed from the shaft.

2.Replace the inner and outer races of the taper roller

bearing as a set.

INSPECTION

INTERMEDIATE GEAR

lCheck the outer surface of the intermediate gear where the

needle bearing is mounted for damage, abnormal wear andseizure [portion

@.Il Check the

splines for damage and wear.

NEEDLE BEARING

l Combine the needle bearing with the shaft or bearing

sleeve and gear and check that it rotates smoothly without

abnormal noise or play.

l Check the needle bearing cage for deformation.

Page 752 of 1216

21-58MANUAL TRANSAXLE

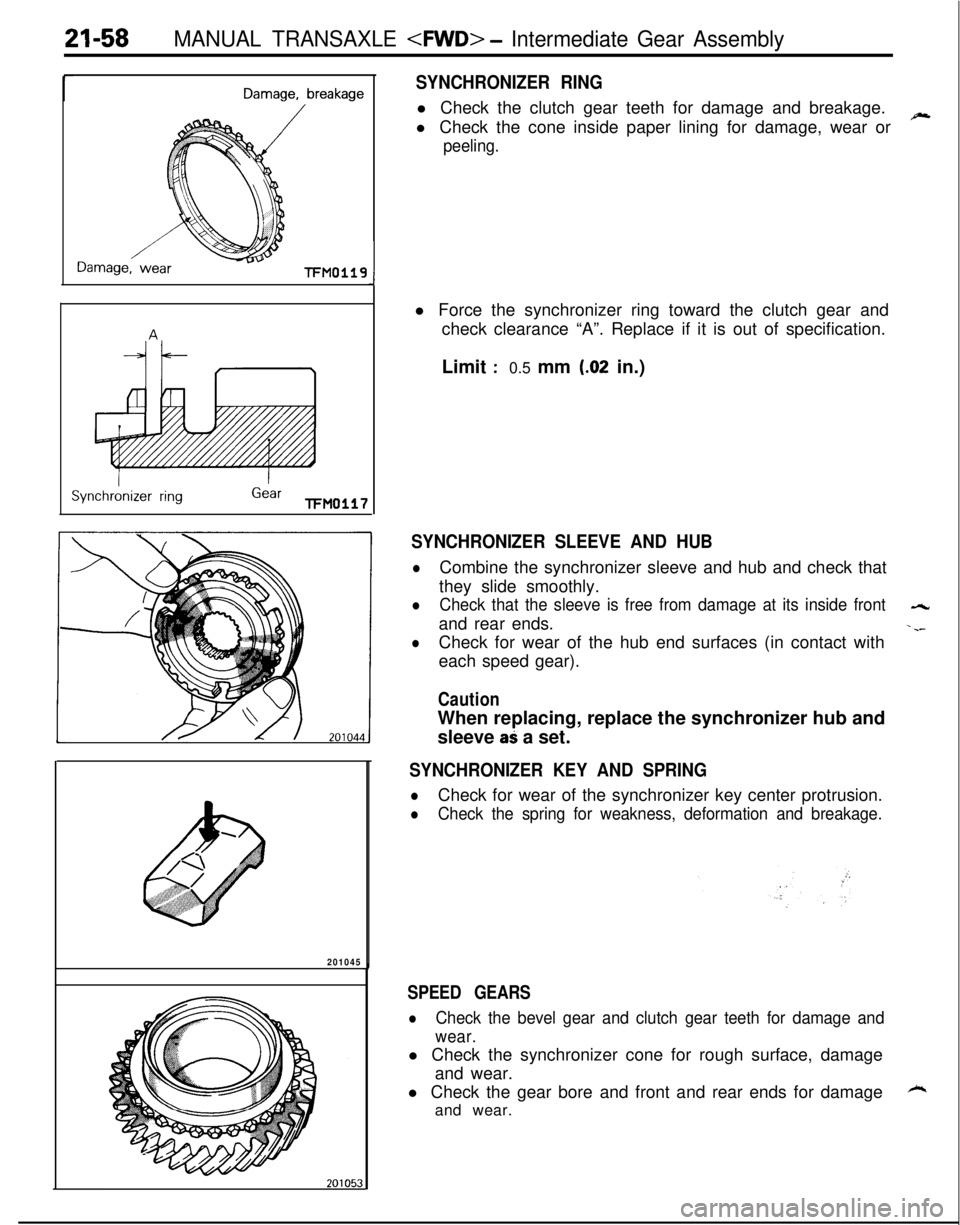

rDamage, breakage

Damage, wearl-FM0119

ISynchronizer ring

IGearTFM0117

SYNCHRONIZER RINGl Check the clutch gear teeth for damage and breakage.

l Check the cone inside paper lining for damage, wear or

~

peeling.

J

201045l Force the synchronizer ring toward the clutch gear and

check clearance “A”. Replace if it is out of specification.

Limit

:0.5 mm (.02 in.)

SYNCHRONIZER SLEEVE AND HUB

lCombine the synchronizer sleeve and hub and check that

they slide smoothly.

lCheck that the sleeve is free from damage at its inside front-4rand rear ends.

-.--

lCheck for wear of the hub end surfaces (in contact with

each speed gear).

CautionWhen replacing, replace the synchronizer hub and

sleeve

aS a set.

SYNCHRONIZER KEY AND SPRING

lCheck for wear of the synchronizer key center protrusion.

lCheck the spring for weakness, deformation and breakage.

SPEED GEARS

lCheck the bevel gear and clutch gear teeth for damage and

wear.l Check the synchronizer cone for rough surface, damage

and wear.

l Check the gear bore and front and rear ends for damage

kand wear.

Page 753 of 1216

MANUAL TRANSAXLE

.-_

Front +Identi-fication

mark

210031

Springprotrusion

Key2010018

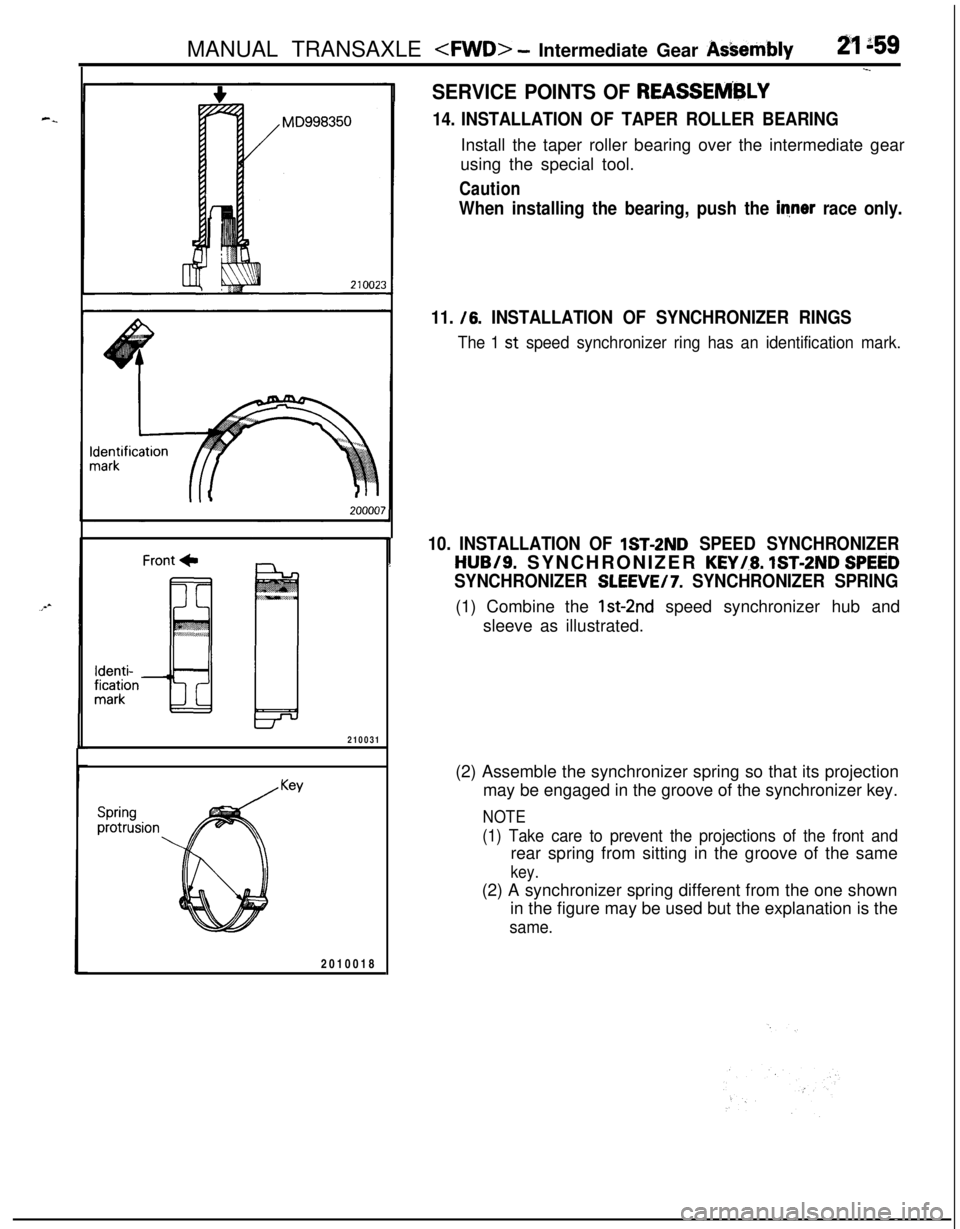

SERVICE POINTS OF REASSElViBLY

14. INSTALLATION OF TAPER ROLLER BEARINGInstall the taper roller bearing over the intermediate gear

using the special tool.

Caution

When installing the bearing, push the inner race only.

11. /6.

INSTALLATION OF SYNCHRONIZER RINGS

The 1 st speed synchronizer ring has an identification mark.

10. INSTALLATION OF lST-2ND SPEED SYNCHRONIZER

HUB/S. SYNCHRONIZER KEYi.8. IST-2ND SPEED

SYNCHRONIZER SLEEVE/7. SYNCHRONIZER SPRING(1) Combine the

lst-2nd speed synchronizer hub and

sleeve as illustrated.

(2) Assemble the synchronizer spring so that its projection

may be engaged in the groove of the synchronizer key.

NOTE

(1) Take care to prevent the projections of the front andrear spring from sitting in the groove of the same

key.(2) A synchronizer spring different from the one shown

in the figure may be used but the explanation is the

same.

Page 754 of 1216

21-60MANUAL TRANSAXLE

MD998350

/

1 st-2ndspeedsynchronizerassembly

201069

. MD998350

I

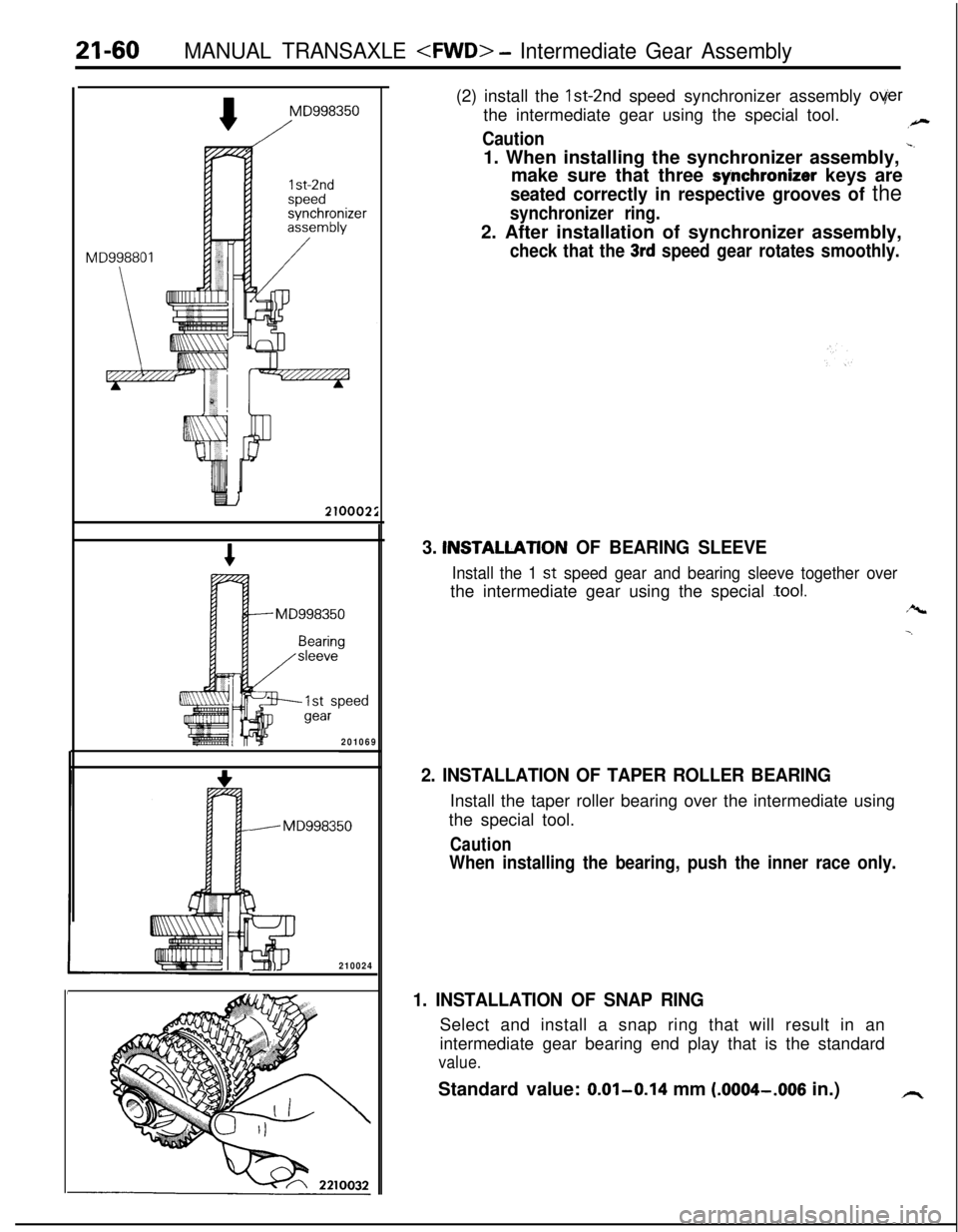

3210024(2) install the Ist-2nd speed synchronizer assembly

overthe intermediate gear using the special tool.

,-

Caution1. When installing the synchronizer assembly,

-‘make sure that three

synchronizer keys are

seated correctly in respective grooves of the

synchronizer ring.2. After installation of synchronizer assembly,

check that the 3rd speed gear rotates smoothly.

3. INSTALLATlON OF BEARING SLEEVE

Install the 1 st speed gear and bearing sleeve together overthe intermediate gear using the special

-tool.

r%

-.

2. INSTALLATION OF TAPER ROLLER BEARINGInstall the taper roller bearing over the intermediate using

the special tool.

Caution

When installing the bearing, push the inner race only.

1. INSTALLATION OF SNAP RINGSelect and install a snap ring that will result in an

intermediate gear bearing end play that is the standard

value.Standard value: 0.01-0.14 mm

(.0004-.OOS in.)h

Page 755 of 1216

MANUAL TRANSAXLE

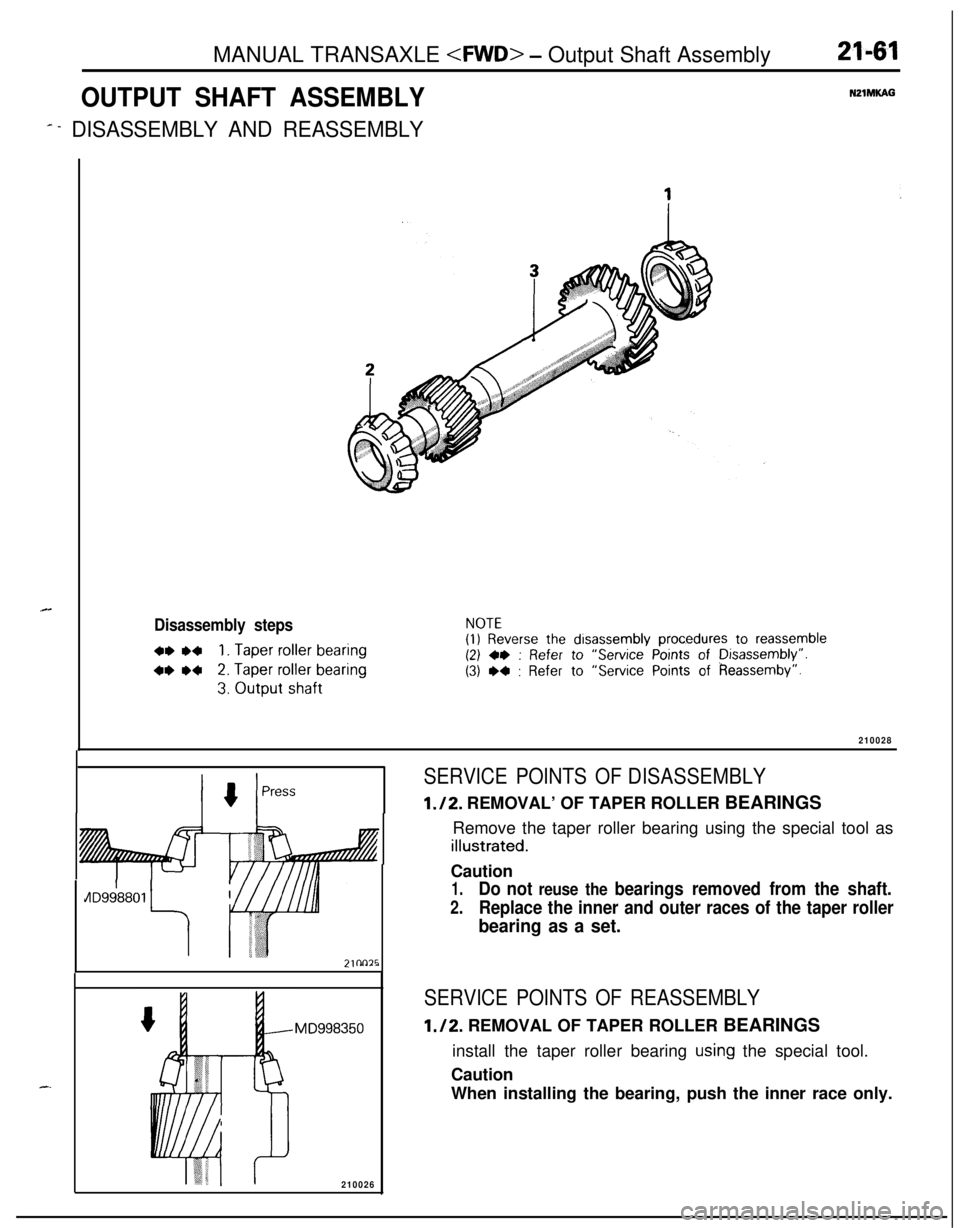

OUTPUT SHAFT ASSEMBLYNZlMKAG

# - DISASSEMBLY AND REASSEMBLY

.C

Disassembly steps

+* .+1. Taper roller bearing

4* w2. Taper roller bearing

3. Output shaft

NOTE

(I) Reverse the disassembly procedures to reassemble(2) +e : Refer to “Service Points of Disassembly”.

(3) W : Refer to “Service Points of Reassemby”.

210028

PressSERVICE POINTS OF DISASSEMBLY

1./2. REMOVAL’ OF TAPER ROLLER BEARINGS

Remove the taper roller bearing using the special tool as

illustrated.

AD9d880.l

il7inn75

I-. ----

MD998350

210026Caution

1.Do not reuse the bearings removed from the shaft.

2.Replace the inner and outer races of the taper roller

bearing as a set.

SERVICE POINTS OF REASSEMBLY

1./2. REMOVAL OF TAPER ROLLER BEARINGS

install the taper roller bearing

using the special tool.

Caution

When installing the bearing, push the inner race only.

Page 756 of 1216

21-62MANUAL TRANSAXLE

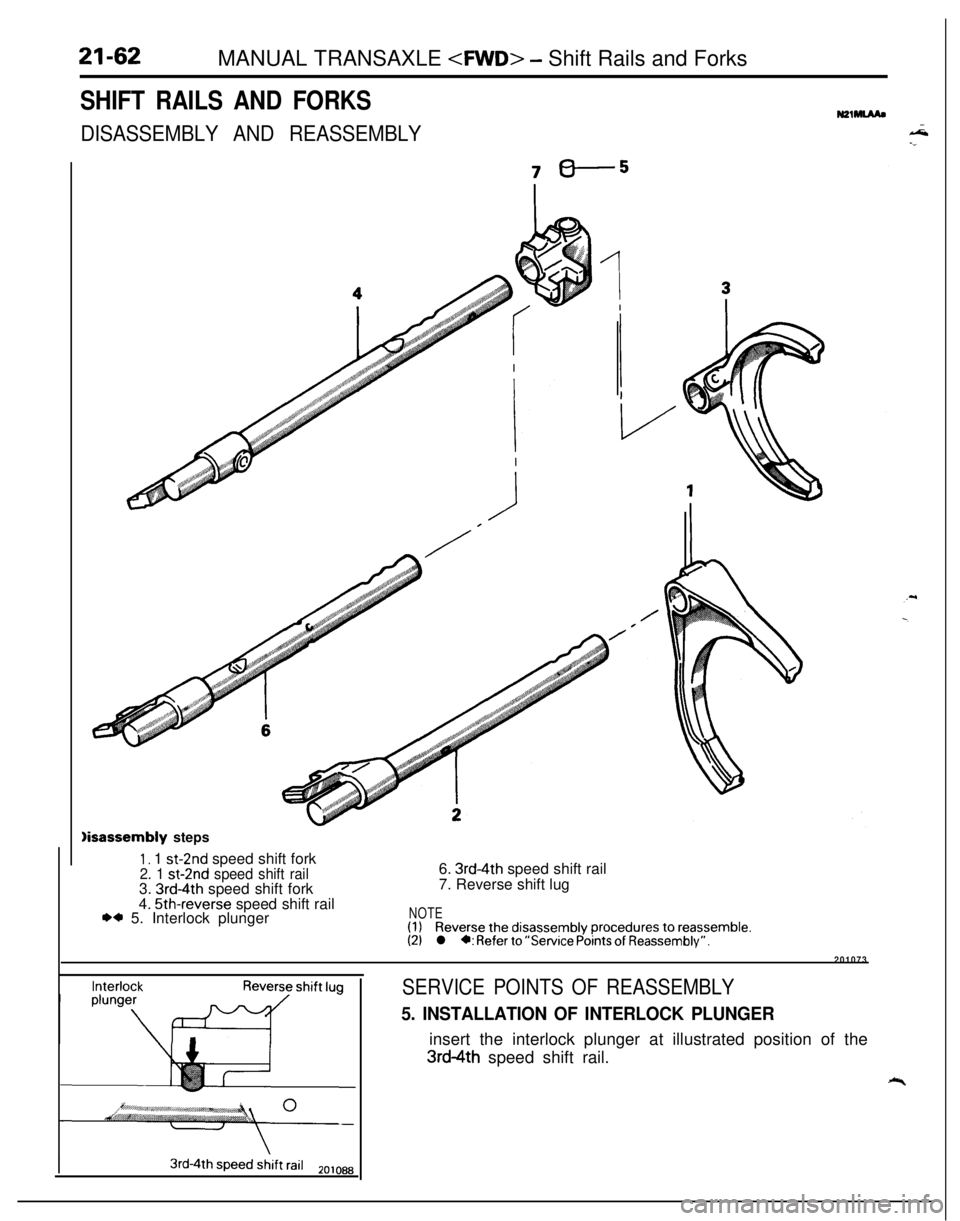

SHIFT RAILS AND FORKS

DISASSEMBLY AND REASSEMBLY

N21-

sbdisassembly steps

1, 1 st-2nd speed shift fork2. 1 st-2nd speed shift rail3. 3rd-4th speed shift fork

4. 5th-reverse speed shift rail** 5. Interlock plunger6.

3rd-4th speed shift rail

7. Reverse shift lug

NOTE(1)Reverse the disassembly procedures to reassemble.(2)l *: Refer to “Service Points of Reassembly”.

201073

InterlockReverse shift lugSERVICE POINTS OF REASSEMBLY

5. INSTALLATION OF INTERLOCK PLUNGERinsert the interlock plunger at illustrated position of the

3rd4th speed shift rail.

“r

3rd-4th speed shift rail2ojoaa

Page 757 of 1216

MANUAL TRANSAXLE 4WD> - Differential Assembly21-63

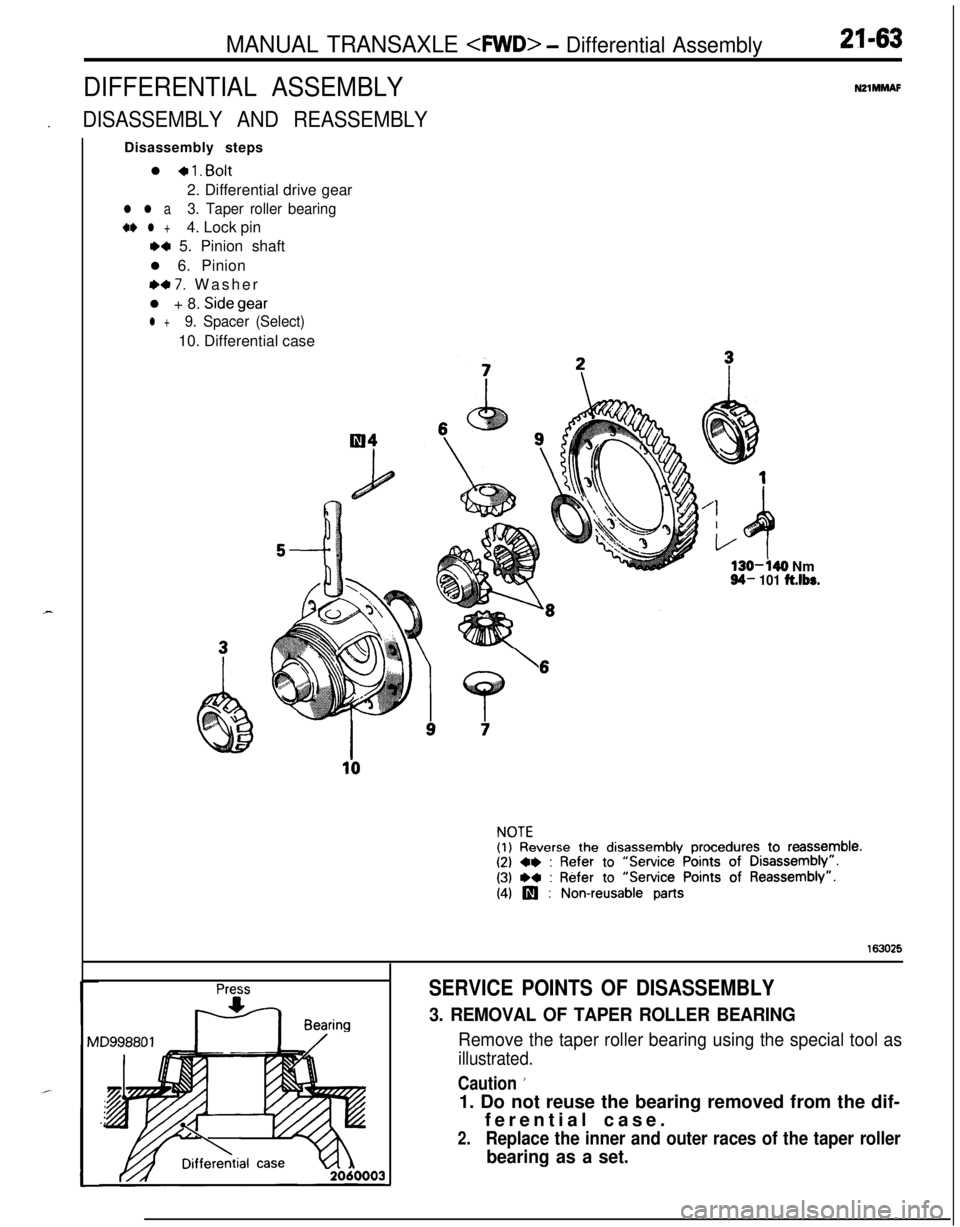

DIFFERENTIAL ASSEMBLYNZlMMAF.

DISASSEMBLY AND REASSEMBLYDisassembly steps

l

+ 1. Bolt2. Differential drive gear

l l a3. Taper roller bearing

+e l +4. Lock pin

M 5. Pinion shaft

l 6. Pinion

e+ 7. Washer

l + 8. Sidegear

l +9. Spacer (Select)10. Differential case

130-440 Nm94- 101 ft.lbs.

\6

NOTE(1) Reverse the disassembly procedures to reassemble.(2) ~~ : Refer to “Service Points of Disassembly”.

(3) ,+ : Refer to “Service Points of Reassembly”.

(4) p : Non-reusable parts

163025

Press

F+ Bearing

SERVICE POINTS OF DISASSEMBLY

3. REMOVAL OF TAPER ROLLER BEARING

Remove the taper roller bearing using the special tool as

illustrated.

Caution ’1. Do not reuse the bearing removed from the dif-

ferential case.

2.Replace the inner and outer races of the taper roller

bearing as a set.

Page 758 of 1216

21-64MANUAL TRANSAXLE

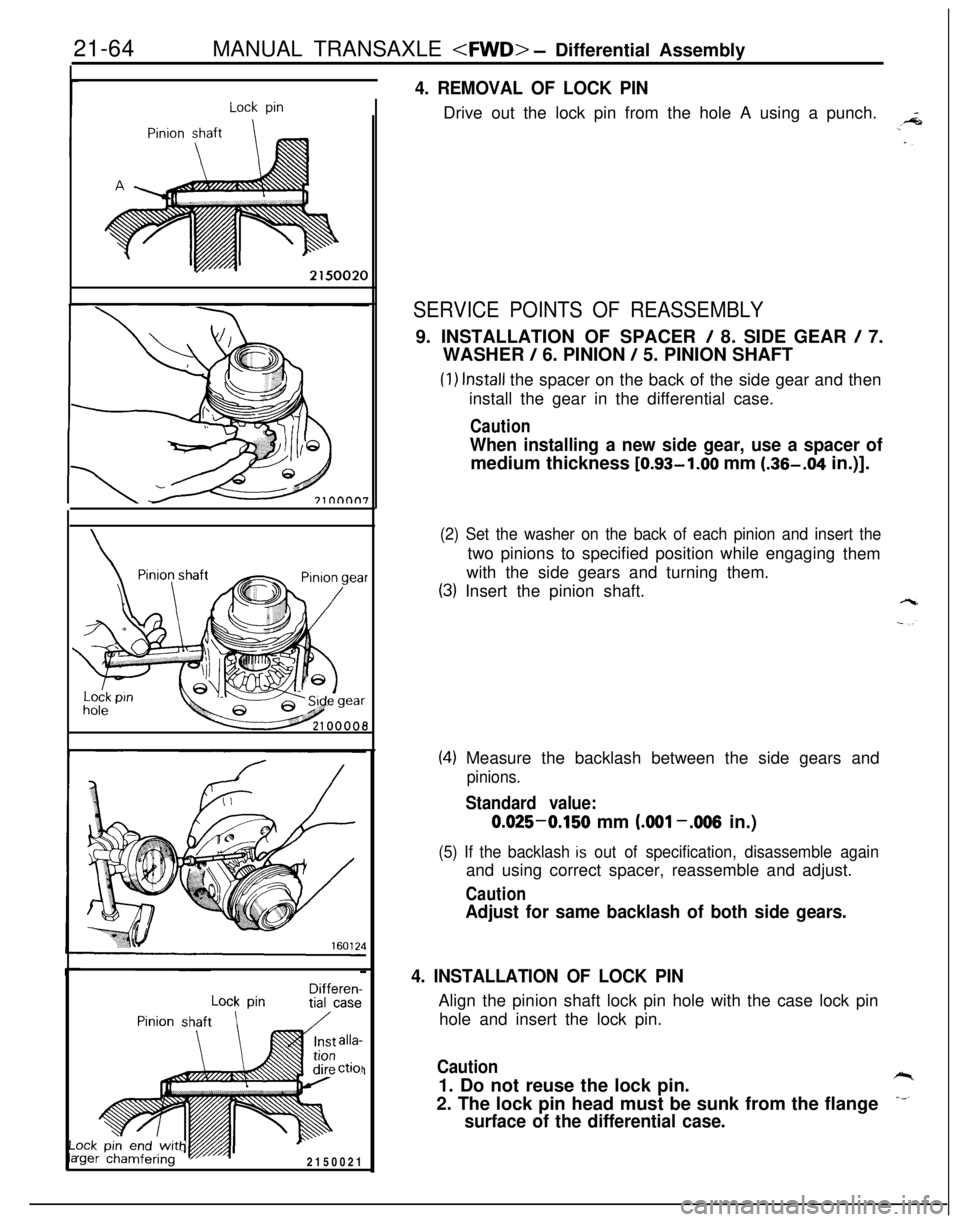

Lock pin

Llla

Lock pinDifferen-tial case

alla-ctiol

ock pinendwith2150021

4. REMOVAL OF LOCK PINDrive out the lock pin from the hole A using a punch.

SERVICE POINTS OF REASSEMBLY9. INSTALLATION OF SPACER

/ 8. SIDE GEAR / 7.

WASHER

/ 6. PINION / 5. PINION SHAFT

(1) Install the spacer on the back of the side gear and then

install the gear in the differential case.

Caution

When installing a new side gear, use a spacer ofmedium thickness [0.93-1.00 mm (.36-.04 in.)].

(2) Set the washer on the back of each pinion and insert thetwo pinions to specified position while engaging

them

with the side gears and turning them.

(3) Insert the pinion shaft.

(4) Measure the backlash between the side gears and

pinions.

Standard value:0.025-0.150 mm

LOO1 -.006 in.)

(5) If the backlash is out of specification, disassemble againand using correct spacer, reassemble and adjust.

Caution

Adjust for same backlash of both side gears.

4. INSTALLATION OF LOCK PINAlign the pinion shaft lock pin hole with the case lock pin

hole and insert the lock pin.

Caution1. Do not reuse the lock pin.

2. The lock pin head must be sunk from the flange

surface of the differential case.

Page 759 of 1216

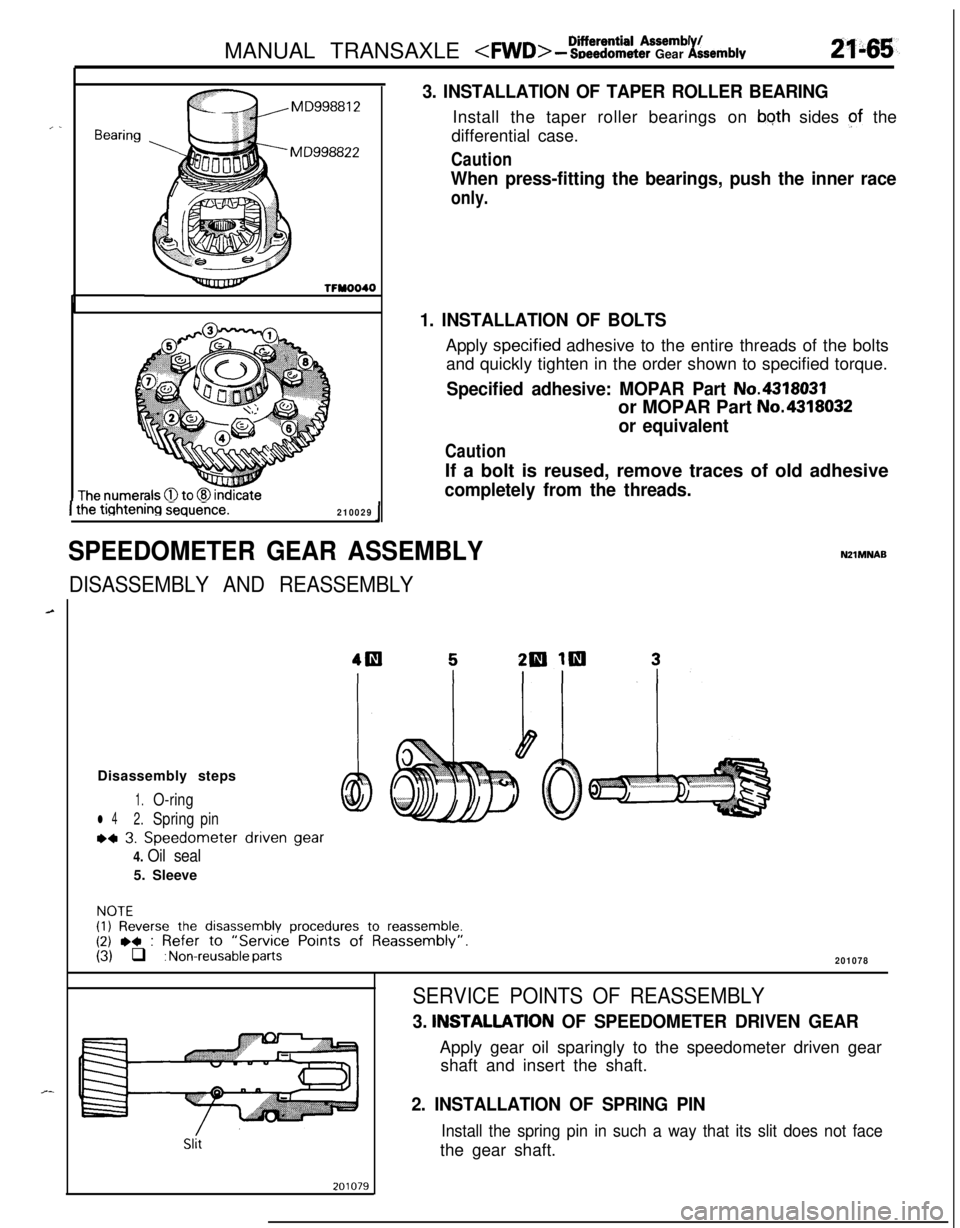

bierential Assembl /MANUAL TRANSAXLE

, .Bearing

TFYOOIO

The numerals 0 to (8 indicate1 the tiqhtening Gequeice.210029I

SPEEDOMETER GEAR ASSEMBLY

3. INSTALLATION OF TAPER ROLLER BEARINGInstall the taper roller bearings on

bqth sides of the

differential case.

Caution

When press-fitting the bearings, push the inner race

only.

1. INSTALLATION OF BOLTSApply

spec.ified adhesive to the entire threads of the bolts

and quickly tighten in the order shown to specified torque.

Specified adhesive: MOPAR Part No.4318031or MOPAR Part

No.4318032

or equivalent

CautionIf a bolt is reused, remove traces of old adhesive

completely from the threads.

DISASSEMBLY AND REASSEMBLY

NZlMNABDisassembly steps

1.O-ring

l 42.Springpin

~4 3. Speedometer driven gear

4. Oil seal5. Sleeve

NOTE(1) Reverse the disassembly procedures to reassemble.(2) ,+ : Refer to “Service Points of Reassembly”.(3) q : Non-reusable parts201078

Slit

SERVICE POINTS OF REASSEMBLY

3. INSTALLATlON OF SPEEDOMETER DRIVEN GEARApply gear oil sparingly to the speedometer driven gear

shaft and insert the shaft.

2. INSTALLATION OF SPRING PIN

Install the spring pin in such a way that its slit does not facethe gear shaft.

Page 760 of 1216

21-66MANUAL TRANSAXLE

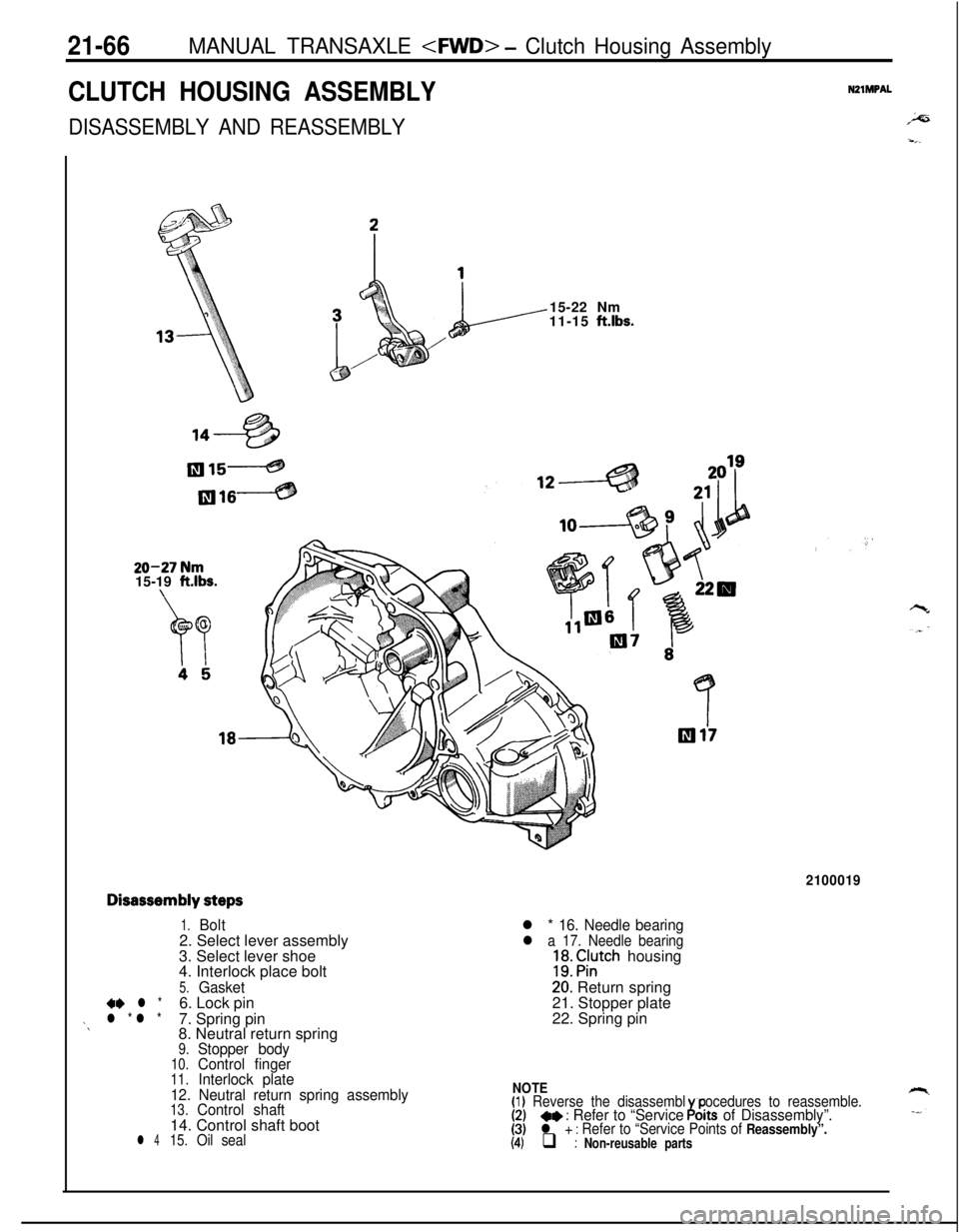

CLUTCH HOUSING ASSEMBLYNZlMPAL

DISASSEMBLY AND REASSEMBLY

2=

-,_

1

L--15-22 Nm

11-15 ftlbs.

20-27 Nm15-19 ft.lbs.

Disassembly steps

1.Bolt2. Select lever assembly

3. Select lever shoe

4. Interlock place bolt

5.Gasket+e l *6. Lock pinj\l * l *7. Spring pin

8. Neutral return spring

9.Stopper body10.Control finger11.Interlock plate

12. Neutral return spring assembly

13.Control shaft14. Control shaft boot

l 415.Oil seal

2100019

l * 16. Needle bearing

l a 17. Needle bearing;EJ. Fil;tch housing

20: Return spring

21. Stopper plate

22. Spring pin

NOTE(1) Reverse the disassembl procedures to reassemble.(2)~~ : Refer to “Service ornts of Disassembly”.6.(3)l + : Refer to “Service Points of Reassembly”.(4) q : Non-reusable parts