MITSUBISHI LANCER 2005 Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 361 of 788

WINDSHIELD WIPER AND WASHER

EXTERIOR51-23

WINDSHIELD WIPER AND WASHER

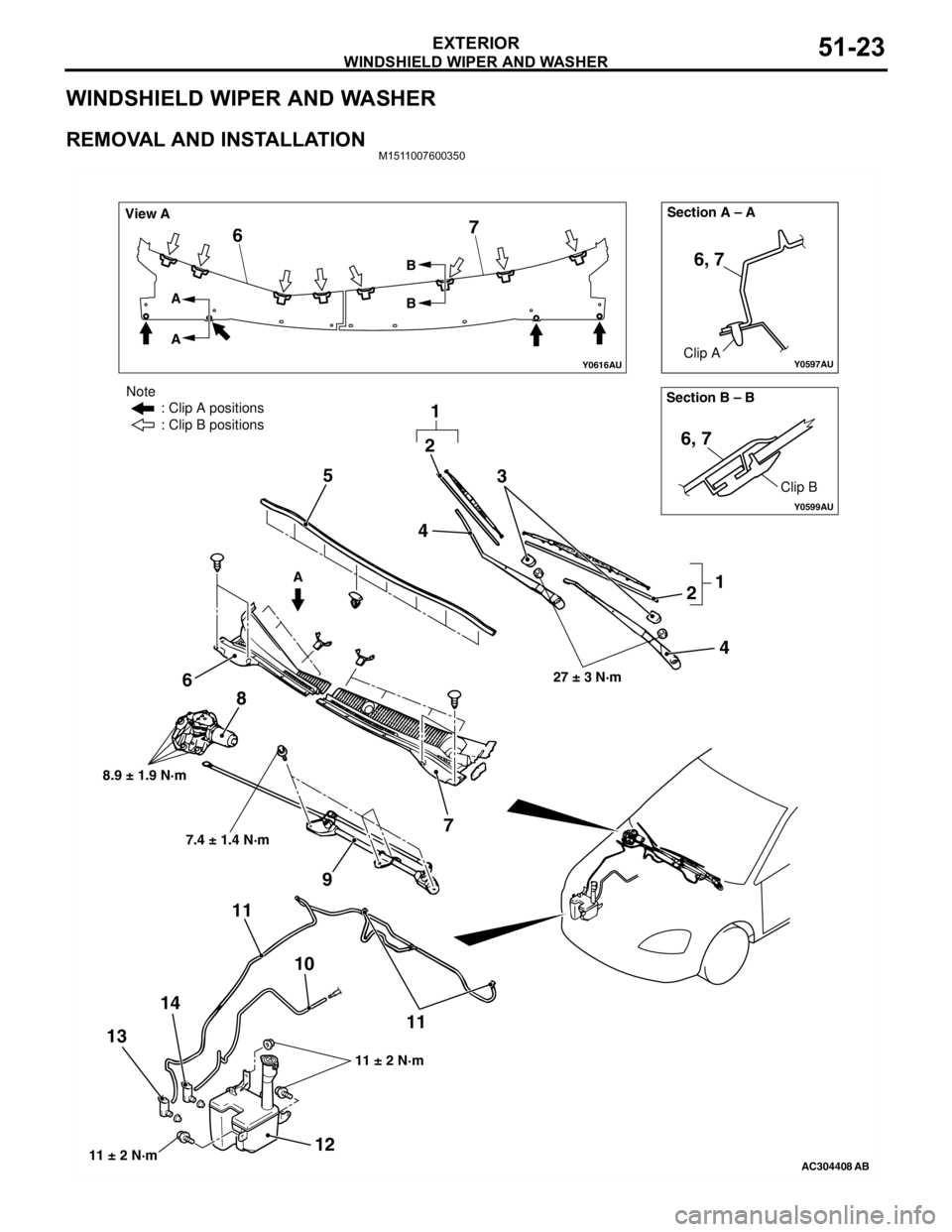

REMOVAL AND INSTALLATIONM1511007600350

Y0597AU

Y0616AU

Y0599AU

AC304408AB

Section B – B Section A – A

View A

A A

AB

B

Clip A

Clip B

6, 7

6, 7

67

3

2 5

6

7 8

9

10 11

11

12 1314

27 ± 3 N·m

8.9 ± 1.9 N·m

11 ± 2 N·m

Note

: Clip A positions

: Clip B positions

11 ± 2 N·m

7.4 ± 1.4 N·m

2

1

1 4

4

Page 362 of 788

WINDSHIELD WIPER AND WASHER

EXTERIOR51-24

NOTE: For removal and installation of the wiper and

washer switch, refer to GROUP 54A, Column switch

P.54A-87.

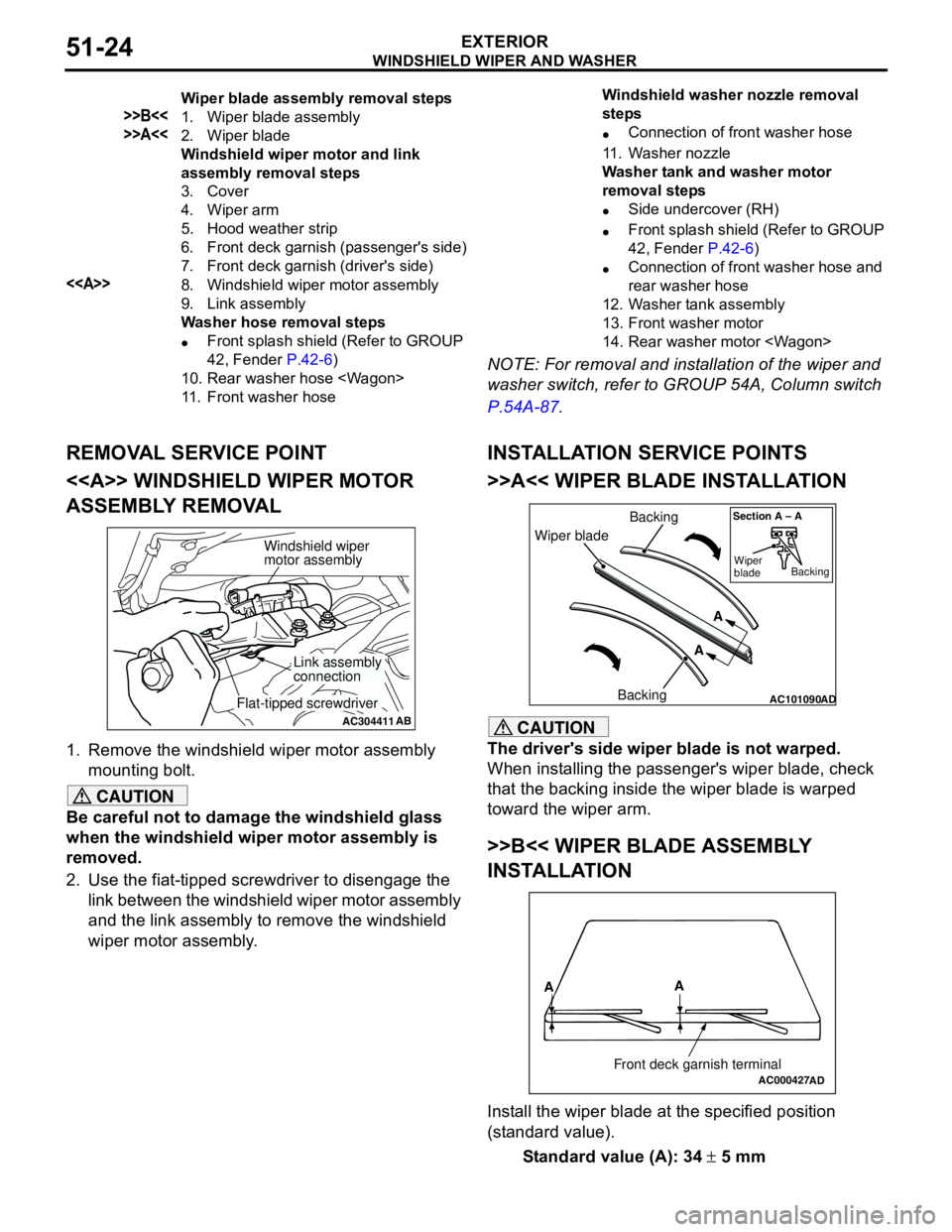

REMOVAL SERVICE POINT

<> WINDSHIELD WIPER MOTOR

ASSEMBLY REMOVAL

1. Remove the windshield wiper motor assembly

mounting bolt.

CAUTION

Be careful not to damage the windshield glass

when the windshield wiper motor assembly is

removed.

2. Use the fiat-tipped screwdriver to disengage the

link between the windshield wiper motor assembly

and the link assembly to remove the windshield

wiper motor assembly.

INSTALLATION SERVICE POINTS

>>A<< WIPER BLADE INSTALLATION

CAUTION

The driver's side wiper blade is not warped.

When installing the passenger's wiper blade, check

that the backing inside the wiper blade is warped

toward the wiper arm.

>>B<< WIPER BLADE ASSEMBLY

INSTALLATION

Install the wiper blade at the specified position

(standard value).

Standard value (A): 34 ± 5 mm

Wiper blade assembly removal steps

>>B<<1. Wiper blade assembly

>>A<<2. Wiper blade

Windshield wiper motor and link

assembly removal steps

3. Cover

4. Wiper arm

5. Hood weather strip

6. Front deck garnish (passenger's side)

7. Front deck garnish (driver's side)

<>8. Windshield wiper motor assembly

9. Link assembly

Washer hose removal steps

•Front splash shield (Refer to GROUP

42, Fender P.42-6)

10. Rear washer hose

11. Front washer hoseWindshield washer nozzle removal

steps

•Connection of front washer hose

11. Washer nozzle

Washer tank and washer motor

removal steps

•Side undercover (RH)

•Front splash shield (Refer to GROUP

42, Fender P.42-6)

•Connection of front washer hose and

rear washer hose

12. Washer tank assembly

13. Front washer motor

14. Rear washer motor

AC304411AB

Windshield wiper

motor assembly

Link assembly

connection

Flat-tipped screwdriverAC101090AD

Wiper bladeBacking

BackingA

A

Section A – A

Wiper

bladeBacking

AC000427

A

A

Front deck garnish terminalAD

Page 363 of 788

WINDSHIELD WIPER AND WASHER

EXTERIOR51-25

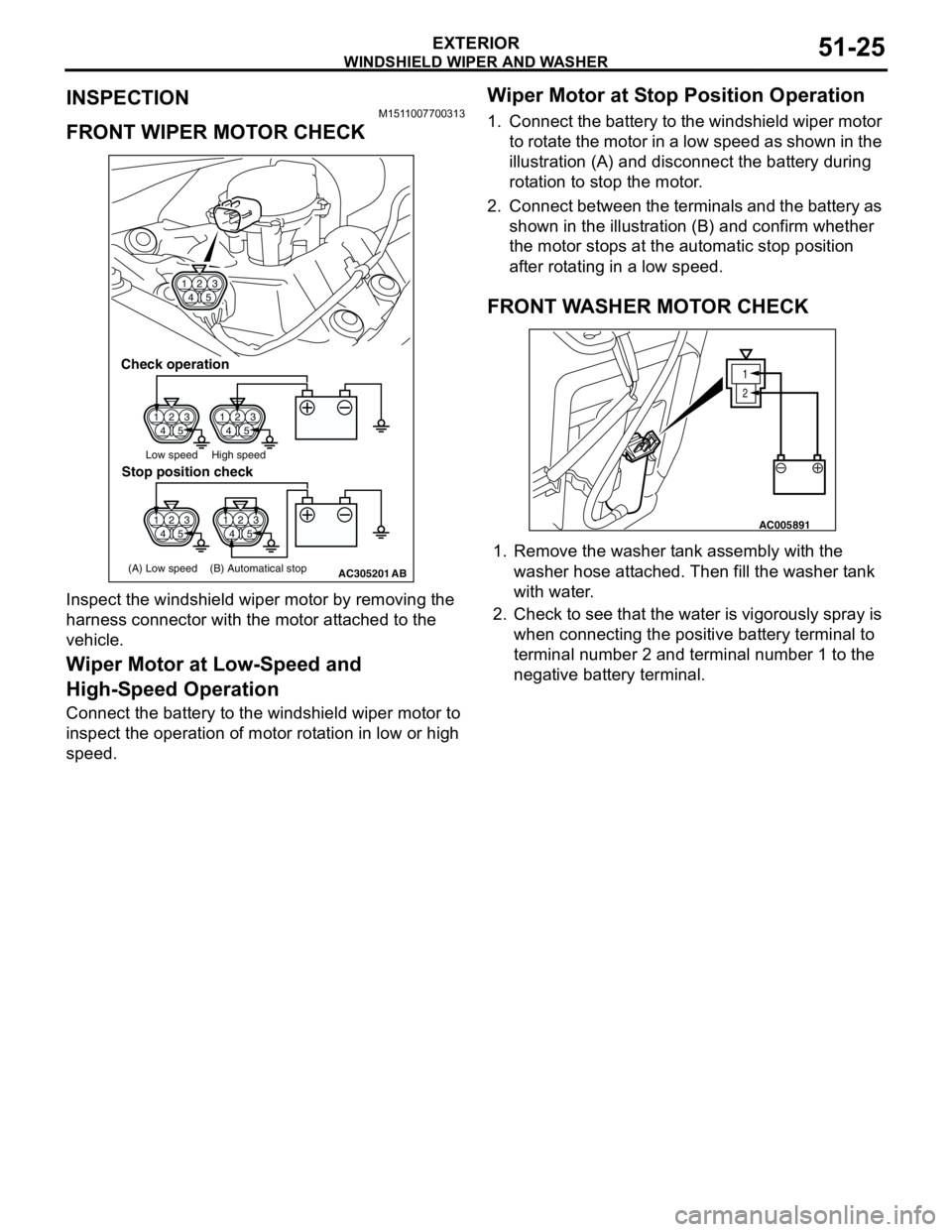

INSPECTIONM1511007700313

FRONT WIPER MOTOR CHECK

Inspect the windshield wiper motor by removing the

harness connector with the motor attached to the

vehicle.

Wiper Motor at Low-Speed and

High-Speed Operation

Connect the battery to the windshield wiper motor to

inspect the operation of motor rotation in low or high

speed.

Wiper Motor at Stop Position Operation

1. Connect the battery to the windshield wiper motor

to rotate the motor in a low speed as shown in the

illustration (A) and disconnect the battery during

rotation to stop the motor.

2. Connect between the terminals and the battery as

shown in the illustration (B) and confirm whether

the motor stops at the automatic stop position

after rotating in a low speed.

FRONT WASHER MOTOR CHECK

1. Remove the washer tank assembly with the

washer hose attached. Then fill the washer tank

with water.

2. Check to see that the water is vigorously spray is

when connecting the positive battery terminal to

terminal number 2 and terminal number 1 to the

negative battery terminal.

1

423

5

1

423

51

423

5

1

423

5

AC305201

1

423

5

Check operation

Low speed High speed

(A) Low speed (B) Automatical stop

Stop position check

AB

1

2

AC005891

Page 364 of 788

WINDSHIELD WIPER AND WASHER

EXTERIOR51-26

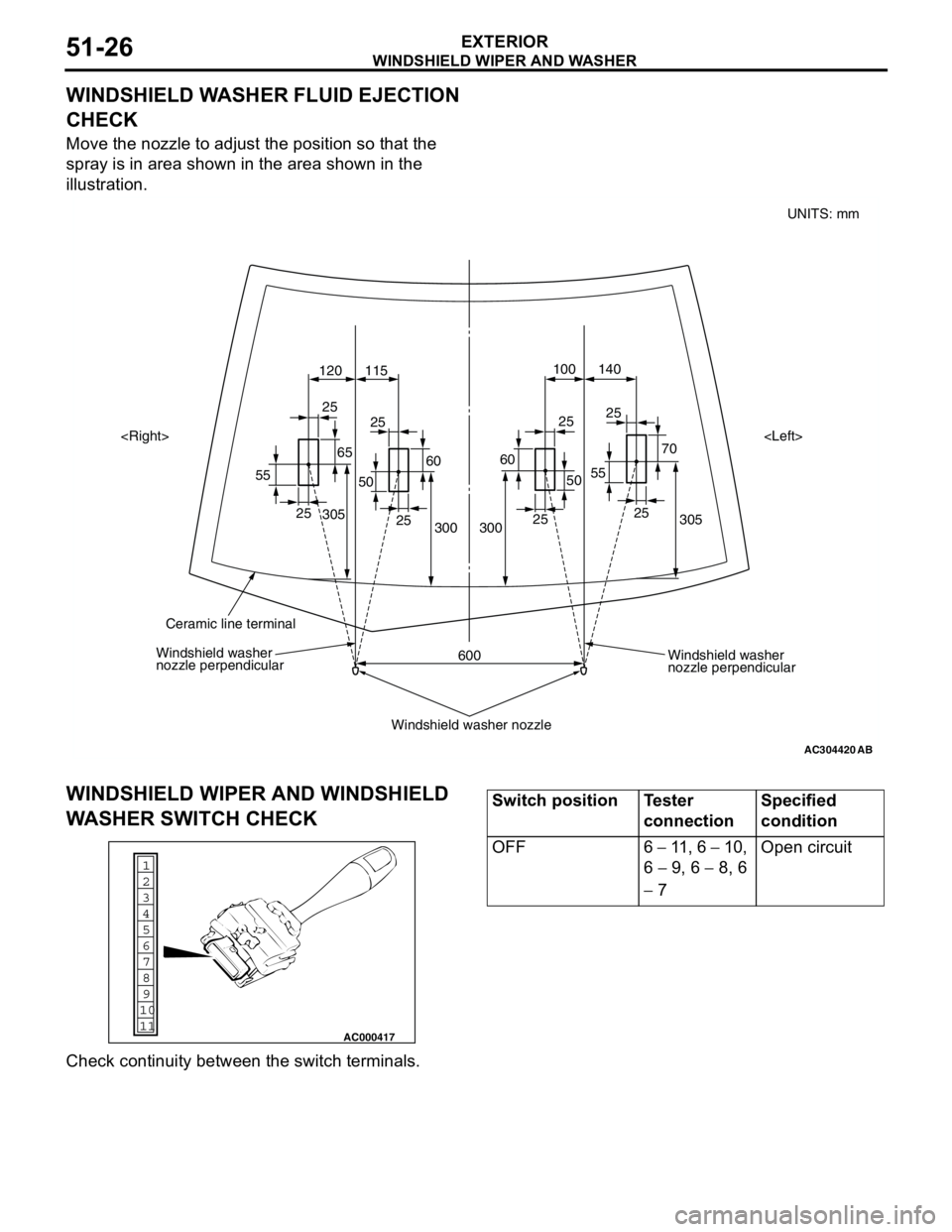

WINDSHIELD WASHER FLUID EJECTION

CHECK

Move the nozzle to adjust the position so that the

spray is in area shown in the area shown in the

illustration.

WINDSHIELD WIPER AND WINDSHIELD

WASHER SWITCH CHECK

Check continuity between the switch terminals.

AC304420

305 70 25

55140 100

120 115

305

300

600 300252525

25

25

25 25

55

6560

50

60

50

AB

Windshield washer

nozzle perpendicular Windshield washer

nozzle perpendicular

Windshield washer nozzle

Ceramic line terminal

UNITS: mm

1

6

8

11 109 7

5 4

3

2

AC000417

Switch position Tester

connectionSpecified

condition

OFF 6 − 11 , 6 − 10,

6 − 9, 6 − 8, 6

− 7Open circuit

Page 365 of 788

WINDSHIELD WIPER AND WASHER

EXTERIOR51-27

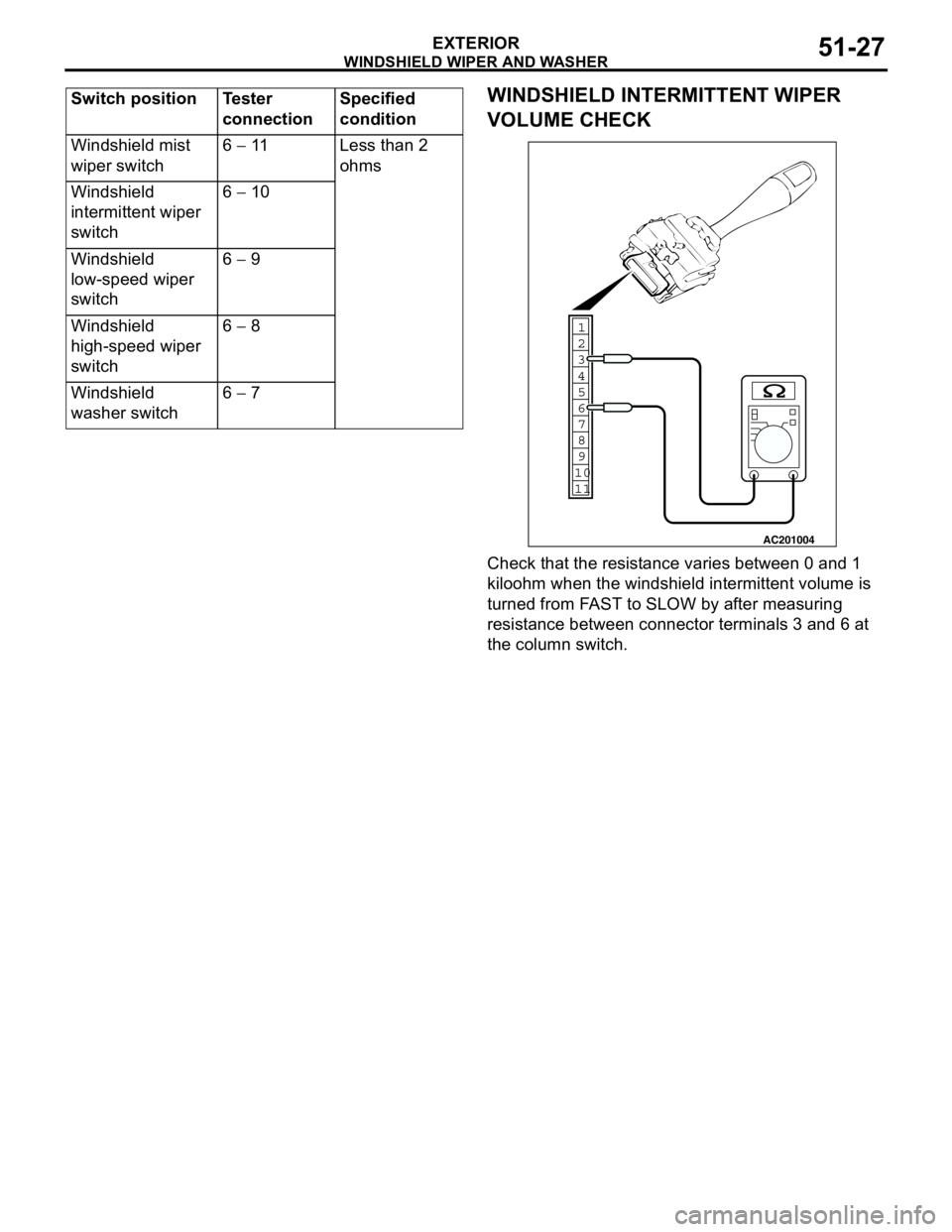

WINDSHIELD INTERMITTENT WIPER

VOLUME CHECK

Check that the resistance varies between 0 and 1

kiloohm when the windshield intermittent volume is

turned from FAST to SLOW by after measuring

resistance between connector terminals 3 and 6 at

the column switch. Windshield mist

wiper switch6 − 11 Less than 2

ohms

Windshield

intermittent wiper

switch6 − 10

Windshield

low-speed wiper

switch6 − 9

Windshield

high-speed wiper

switch6 − 8

Windshield

washer switch6 − 7 Switch position Tester

connectionSpecified

condition

1

6

8

11 109 7

5 4 3

2

AC201004

Page 366 of 788

REAR WIPER AND WASHER

EXTERIOR51-28

REAR WIPER AND WASHER

GENERAL INFORMATIONM1511000100525

REAR WIPER AND WASHER OPERATION

Rear Wiper Operation

•If the rear wiper and washer switch is turned to

"INT" position with the ignition switch at "ACC" or

"ON" position, the ETACS-ECU turns ON the rear

wiper drive signal for three seconds

(approximately two cycles), then 7.4 seconds

later the intermittent motion operates every eight

seconds. If the selector lever is moved to the "R"

position when the rear wiper and washer switch is

turned to the "INT" position and the ignition

switch is at the "ACC" or "ON" position, the inhibitor switch "R" turns ON. One second later,

the ETACS-ECU turns ON the rear wiper drive

signal for three seconds (approximately two

cycles). Then, 7.4 seconds later, the intermittent

motion of eight seconds' cycle is restored.

Rear Washer Operation

•If the rear wiper and washer switch is turned to

the ON (washer) position with the ignition switch

at the "ACC" or "ON" position, the rear washer

ON signal is sent to the ETACS-ECU, causing the

rear wiper signal to turn on after 0.3 second. After

the rear washer switch signal turns off, the rear

wiper signal turns off in three seconds. If the rear

washer switch is turned to the ON position while

the rear wiper is in intermittent mode, the rear

washer works for that period when the washer

switch remains on. Then the rear wipers return to

the intermittent mode.

SERVICE SPECIFICATIONM1511000300336

TROUBLESHOOTINGM1511000700334

The rear wiper and washer are controlled by the

Smart Wiring System (SWS). For troubleshooting,

refer to GROUP 54B, Troubleshooting P.54B-17 or

GROUP 54C, Troubleshooting P.54C-4.

ON-VEHICLE SERVICEM1511000800472

CHECK OF REAR WIPER OPERATION

WHEN SELECTOR LEVER IS AT THE "R"

POSITION

1. When the selector lever is moved to the "R"

position with the rear wiper switch at the "INT"

position, the wiper should operate twice or three

times at low speed after approximately one

second.

2. If not, carry out the troubleshooting (Refer to

GROUP 54B, Troubleshooting P.54B-17 or

GROUP 54C, Troubleshooting P.54C-4). ItemStandard value

Rear wiper blade park position mm 42 ± 5

Page 367 of 788

REAR WIPER AND WASHER

EXTERIOR51-29

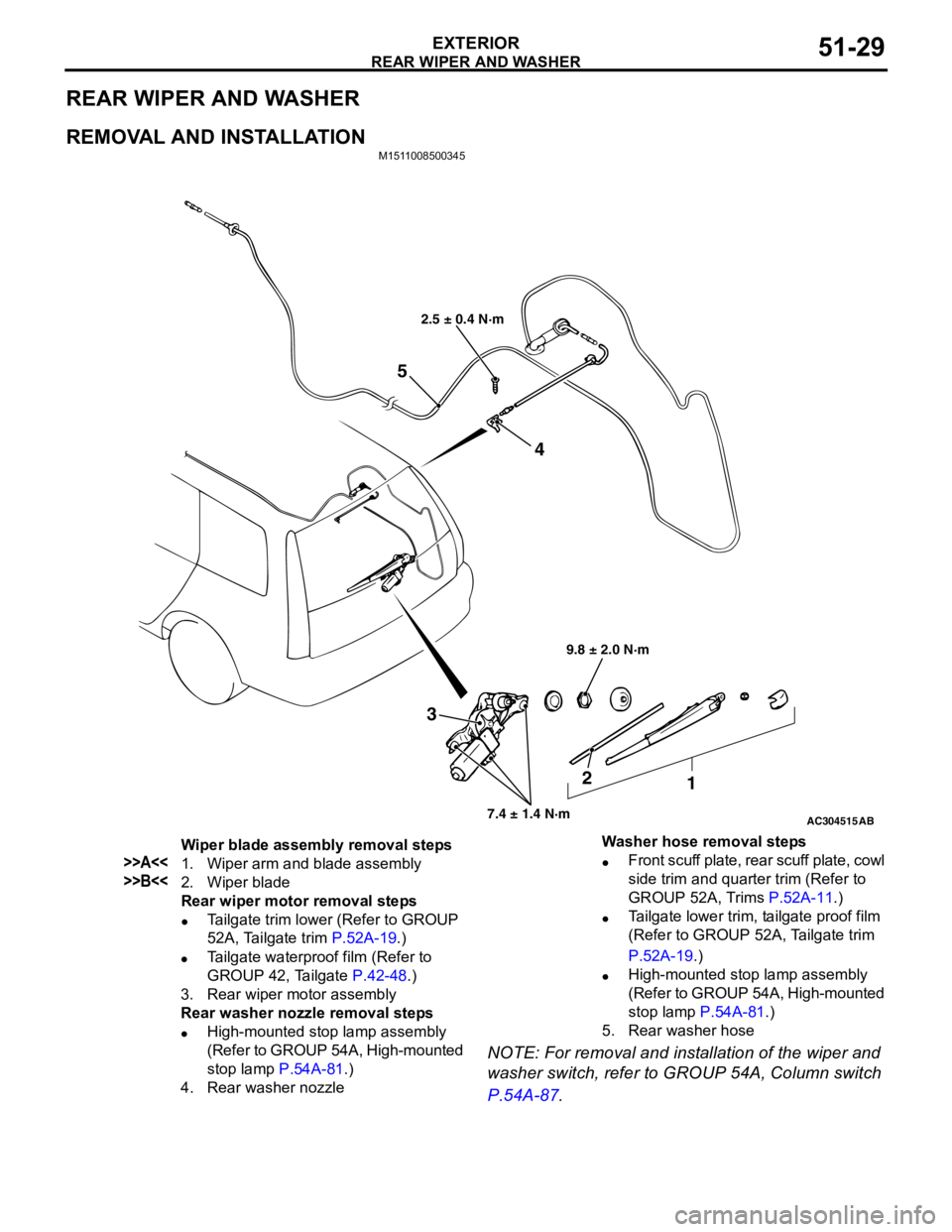

REAR WIPER AND WASHER

REMOVAL AND INSTALLATION

M1511008500345

NOTE: For removal and installation of the wiper and

washer switch, refer to GROUP 54A, Column switch

P.54A-87.

AC304515

2.5 ± 0.4 N·m

9.8 ± 2.0 N·m

7.4 ± 1.4 N·m

3

2

1 4

5

AB

Wiper blade assembly removal steps

>>A<<1. Wiper arm and blade assembly

>>B<<2. Wiper blade

Rear wiper motor removal steps

•Tailgate trim lower (Refer to GROUP

52A, Tailgate trim P.52A-19.)

•Tailgate waterproof film (Refer to

GROUP 42, Tailgate P.42-48.)

3. Rear wiper motor assembly

Rear washer nozzle removal steps

•High-mounted stop lamp assembly

(Refer to GROUP 54A, High-mounted

stop lamp P.54A-81.)

4. Rear washer nozzleWasher hose removal steps

•Front scuff plate, rear scuff plate, cowl

side trim and quarter trim (Refer to

GROUP 52A, Trims P.52A-11.)

•Tailgate lower trim, tailgate proof film

(Refer to GROUP 52A, Tailgate trim

P.52A-19.)

•High-mounted stop lamp assembly

(Refer to GROUP 54A, High-mounted

stop lamp P.54A-81.)

5. Rear washer hose

Page 368 of 788

REAR WIPER AND WASHER

EXTERIOR51-30

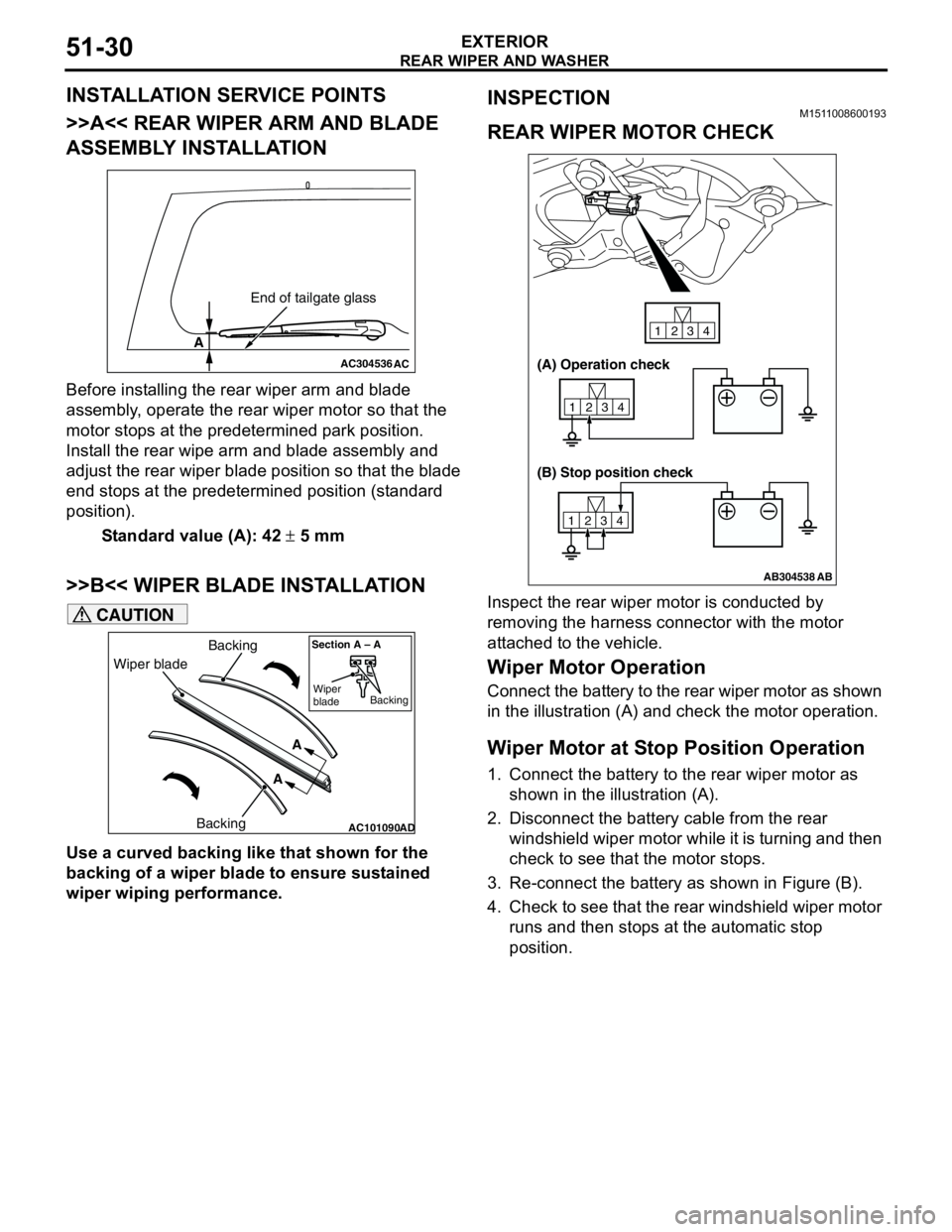

INSTALLATION SERVICE POINTS

>>A<< REAR WIPER ARM AND BLADE

ASSEMBLY INSTALLATION

Before installing the rear wiper arm and blade

assembly, operate the rear wiper motor so that the

motor stops at the predetermined park position.

Install the rear wipe arm and blade assembly and

adjust the rear wiper blade position so that the blade

end stops at the predetermined position (standard

position).

Standard value (A): 42 ± 5 mm

>>B<< WIPER BLADE INSTALLATION

CAUTION

Use a curved backing like that shown for the

backing of a wiper blade to ensure sustained

wiper wiping performance.

INSPECTIONM1511008600193

REAR WIPER MOTOR CHECK

Inspect the rear wiper motor is conducted by

removing the harness connector with the motor

attached to the vehicle.

Wiper Motor Operation

Connect the battery to the rear wiper motor as shown

in the illustration (A) and check the motor operation.

Wiper Motor at Stop Position Operation

1. Connect the battery to the rear wiper motor as

shown in the illustration (A).

2. Disconnect the battery cable from the rear

windshield wiper motor while it is turning and then

check to see that the motor stops.

3. Re-connect the battery as shown in Figure (B).

4. Check to see that the rear windshield wiper motor

runs and then stops at the automatic stop

position.

AC304536

A

AC

End of tailgate glass

AC101090AD

Wiper bladeBacking

BackingA

A

Section A – A

Wiper

bladeBacking

AB304538

1234

1234

1234

AB

(A) Operation check

(B) Stop position check

Page 369 of 788

REAR WIPER AND WASHER

EXTERIOR51-31

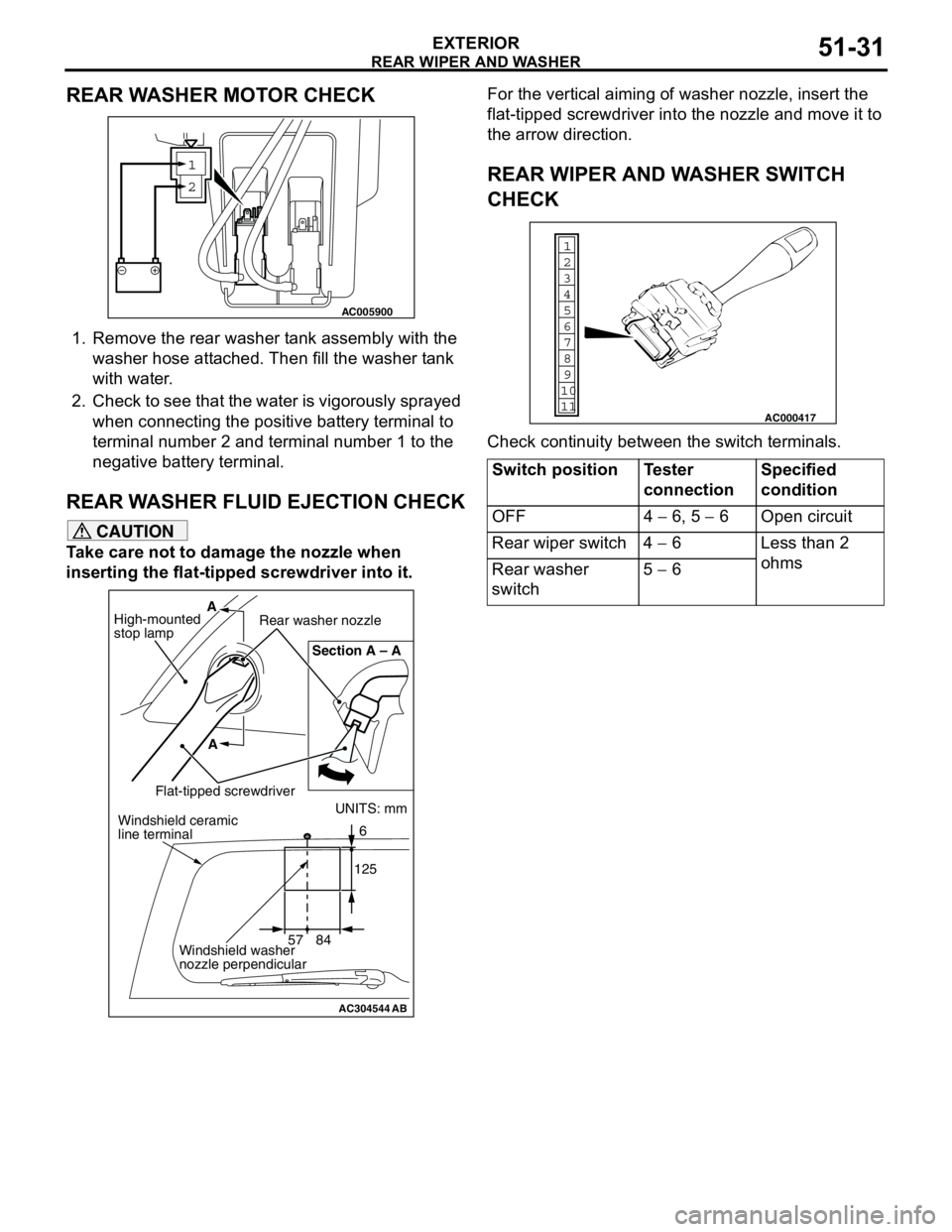

REAR WASHER MOTOR CHECK

1. Remove the rear washer tank assembly with the

washer hose attached. Then fill the washer tank

with water.

2. Check to see that the water is vigorously sprayed

when connecting the positive battery terminal to

terminal number 2 and terminal number 1 to the

negative battery terminal.

REAR WASHER FLUID EJECTION CHECK

CAUTION

Take care not to damage the nozzle when

inserting the flat-tipped screwdriver into it.For the vertical aiming of washer nozzle, insert the

flat-tipped screwdriver into the nozzle and move it to

the arrow direction.

REAR WIPER AND WASHER SWITCH

CHECK

Check continuity between the switch terminals.

1

2

AC005900

AC304544AB

UNITS: mm

57 841256 Section A – A

A A

High-mounted

stop lampRear washer nozzle

Flat-tipped screwdriverWindshield ceramic

line terminal

Windshield washer

nozzle perpendicular

Switch position Tester

connectionSpecified

condition

OFF 4 − 6, 5 − 6 Open circuit

Rear wiper switch 4 − 6 Less than 2

ohms

Rear washer

switch5 − 6

1

6

8

11 109 7

5 4

3

2

AC000417

Page 370 of 788

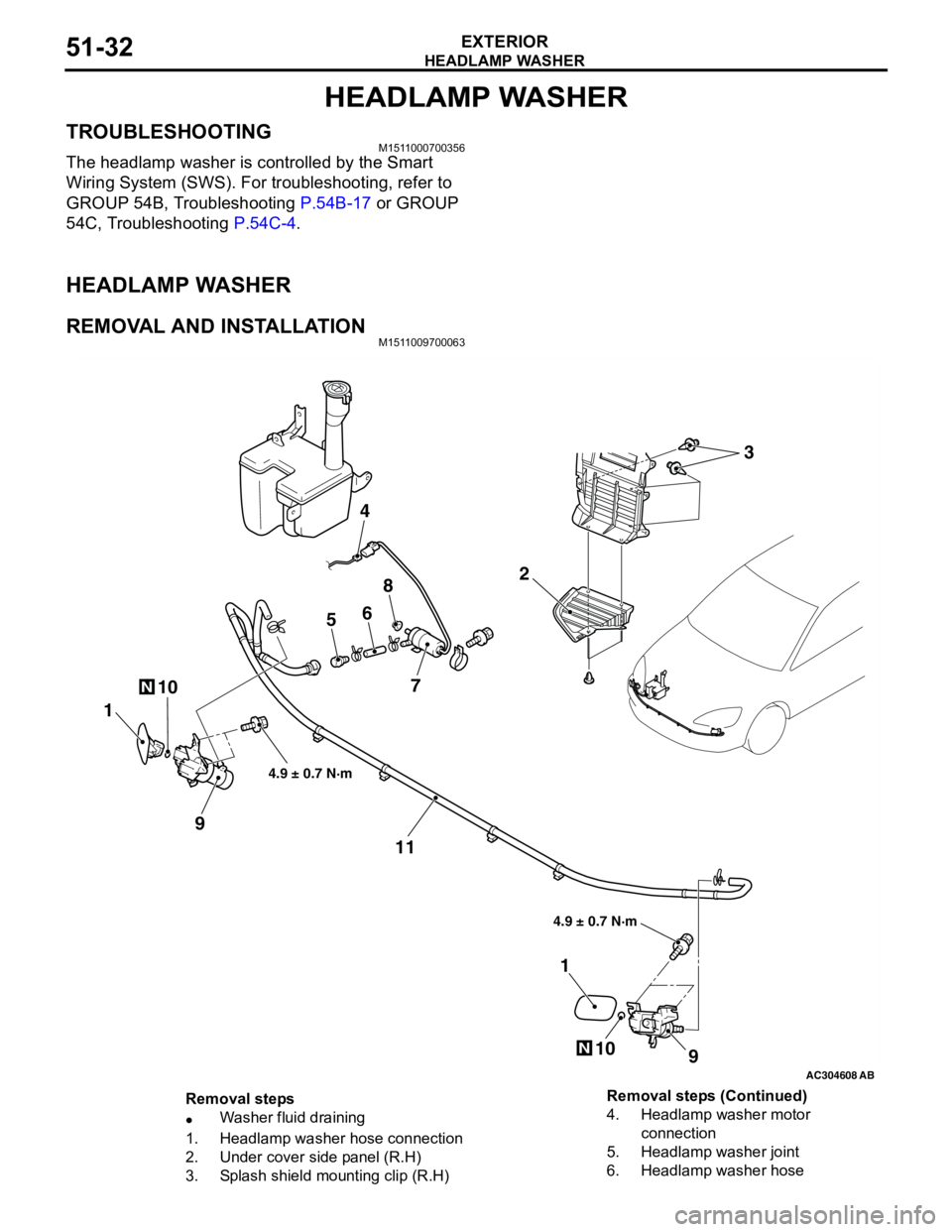

HEADLAMP WASHER

EXTERIOR51-32

HEADLAMP WASHER

TROUBLESHOOTINGM1511000700356

The headlamp washer is controlled by the Smart

Wiring System (SWS). For troubleshooting, refer to

GROUP 54B, Troubleshooting P.54B-17 or GROUP

54C, Troubleshooting P.54C-4.

HEADLAMP WASHER

REMOVAL AND INSTALLATIONM1511009700063

AC304608AB

10N

2

4

56

8

7

1

9

11

9

1

10N

4.9 ± 0.7 N·m 4.9 ± 0.7 N·m

3

Removal steps

•Washer fluid draining

1. Headlamp washer hose connection

2. Under cover side panel (R.H)

3. Splash shield mounting clip (R.H)4. Headlamp washer motor

connection

5. Headlamp washer joint

6. Headlamp washer hose Removal steps (Continued)