MITSUBISHI LANCER 2005 Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 391 of 788

54A-3

REAR COMBINATION

LAMP . . . . . . . . . . . . . . . . . . . . .

54A-79

TROUBLESHOOTING . . . . . . . . . .

54A-79

SPECIAL TOOL . . . . . . . . . . . . . . .54A-79

REAR COMBINATION LAMP . . . .54A-79

REMOVAL AND INSTALLATION . . . . . 54A-79

HIGH-MOUNTED

STOP LAMP. . . . . . . . . . . . . . . .

54A-80

ON-VEHICLE SERVICE. . . . . . . . .

54A-80

HIGH-MOUNTED STOP LAMP BULB

REPLACEMENT

HIGH-MOUNTED STOP LAMP . . .54A-81

REMOVAL AND INSTALLATION . . . . . 54A-81

LICENCE PLATE LAMP . . . . . .54A-84

REMOVAL AND INSTALLATION .

54A-84

HAZARD WARNING LAMP

SWITCH . . . . . . . . . . . . . . . . . . .

54A-85

TROUBLESHOOTING . . . . . . . . . .

54A-85

SPECIAL TOOL . . . . . . . . . . . . . . .54A-85

HAZARD WARNING LAMP SWITCH54A-86

REMOVAL AND INSTALLATION . . . . . 54A-86

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-86

COLUMN SWITCH. . . . . . . . . . .54A-87

SPECIAL TOOL . . . . . . . . . . . . . . .

54A-87

COLUMN SWITCH. . . . . . . . . . . . .54A-87

REMOVAL AND INSTALLATION . . . . . 54A-87

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-88

HORN . . . . . . . . . . . . . . . . . . . . 54A-89

REMOVAL AND INSTALLATION . . . . . . 54A-89

HORN RELAY CONTINUITY CHECK . . 54A-89

CLOCK . . . . . . . . . . . . . . . . . . . 54A-90

SPECIAL TOOL . . . . . . . . . . . . . . .

54A-90

CLOCK . . . . . . . . . . . . . . . . . . . . . .54A-90

REMOVAL AND INSTALLATION . . . . . . 54A-90

CIGARETTE LIGHTER . . . . . . 54A-91

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-91

RHEOSTAT . . . . . . . . . . . . . . . 54A-91

REMOVAL AND INSTALLATION . . . . . . 54A-91

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-92

SPEAKER. . . . . . . . . . . . . . . . . 54A-93

REMOVAL AND INSTALLATION . . . . . . 54A-93

ANTENNA . . . . . . . . . . . . . . . . 54A-94

REMOVAL AND INSTALLATION . . . . . . 54A-94

REAR WINDOW

DEFOGGER . . . . . . . . . . . . . . .

54A-95

GENERAL INFORMATION . . . . . .

54A-95

TROUBLESHOOTING . . . . . . . . . .54A-95

ON-VEHICLE SERVICE . . . . . . . . .54A-96

PRINTED HEATER LINES CHECK . . . . 54A-96

REAR WINDOW DEFOGGER

SWITCH . . . . . . . . . . . . . . . . . . . . .

54A-96

REMOVAL AND INSTALLATION . . . . . . 54A-96

INSPECTION . . . . . . . . . . . . . . . . . . . . . 54A-96

Page 392 of 788

BATTERY

CHASSIS ELECTRICAL54A-4

BATTERY

SERVICE SPECIFICATIONSM1541000300209

ON-VEHICLE SERVICE

FLUID LEVEL AND SPECIFIC GRAVITY

CHECK

M1541001000438

CAUTION

•If the battery fluid is below the LOWER

LEVEL, the battery could explode in using.

•If the battery fluid is over the UPPER LEVEL,

leakage could result.

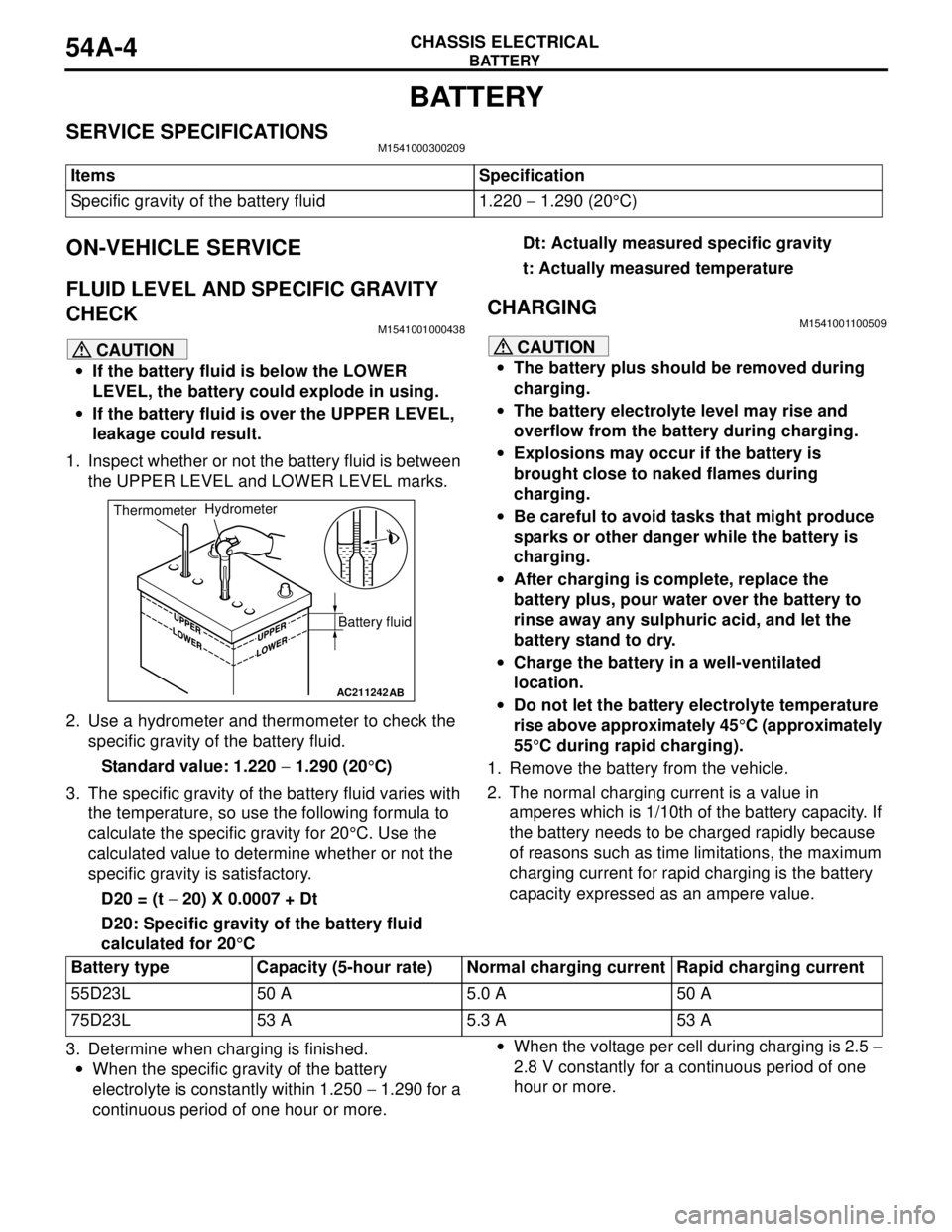

1. Inspect whether or not the battery fluid is between

the UPPER LEVEL and LOWER LEVEL marks.

2. Use a hydrometer and thermometer to check the

specific gravity of the battery fluid.

Standard value: 1.220 − 1.290 (20°C)

3. The specific gravity of the battery fluid varies with

the temperature, so use the following formula to

calculate the specific gravity for 20°C. Use the

calculated value to determine whether or not the

specific gravity is satisfactory.

D20 = (t − 20) X 0.0007 + Dt

D20: Specific gravity of the battery fluid

calculated for 20°CDt: Actually measured specific gravity

t: Actually measured temperature

CHARGINGM1541001100509

CAUTION

•The battery plus should be removed during

charging.

•The battery electrolyte level may rise and

overflow from the battery during charging.

•Explosions may occur if the battery is

brought close to naked flames during

charging.

•Be careful to avoid tasks that might produce

sparks or other danger while the battery is

charging.

•After charging is complete, replace the

battery plus, pour water over the battery to

rinse away any sulphuric acid, and let the

battery stand to dry.

•Charge the battery in a well-ventilated

location.

•Do not let the battery electrolyte temperature

rise above approximately 45°C (approximately

55°C during rapid charging).

1. Remove the battery from the vehicle.

2. The normal charging current is a value in

amperes which is 1/10th of the battery capacity. If

the battery needs to be charged rapidly because

of reasons such as time limitations, the maximum

charging current for rapid charging is the battery

capacity expressed as an ampere value.

3. Determine when charging is finished.

•When the specific gravity of the battery

electrolyte is constantly within 1.250 − 1.290 for a

continuous period of one hour or more.•When the voltage per cell during charging is 2.5 −

2.8 V constantly for a continuous period of one

hour or more. Items Specification

Specific gravity of the battery fluid 1.220 − 1.290 (20°C)

AC211242AB

Battery fluid ThermometerHydrometer

Battery type Capacity (5-hour rate) Normal charging current Rapid charging current

55D23L 50 A 5.0 A 50 A

75D23L 53 A 5.3 A 53 A

Page 393 of 788

BATTERY

CHASSIS ELECTRICAL54A-5

BATTERY TESTM1541001200506

BATTERY TESTING PROCEDURE

STEP 1. Check the battery cables.

Remove the negative cable, then the positive cable.

Check for dirty or corroded connections.

Q: Are the battery cables dirty or have corroded

connections?

YES :

Clean the battery cables. Then go to Step 2.

NO : Go to Step 2.

STEP 2. Check the battery post.

Check for loose battery post.

Q: Are the battery post faulty?

YES :

Replace the battery. Then go to Step 4.

NO : Go to Step 3.

STEP 3. Check the battery case and cover.

(1) Remove the hold-downs and shields.

(2) Check for broken/cracked case or cover.

Q: Is the battery case or cover faulty?

YES :

Replace the battery. Then go to Step 4.

NO : Go to Step 4.

STEP 4. Check the open circuit voltage.

(1) Turn headlamps on for 15 seconds.

(2) Turn headlamps off for two minutes to allow

battery positive voltage to stabilize.

(3) Disconnect the battery cables.

(4) Read open circuit voltage.

Q: Is open circuit voltage 12.4 volts or more?

YES :

Go to Step 6.

NO : Go to Step 5.

STEP 5. Charge battery.

Q: Charging the battery?

YES :

Go to Step 6.

NO : Charge the battery at 5 amps for 15 hours.

Then re-test, go to Step 4.

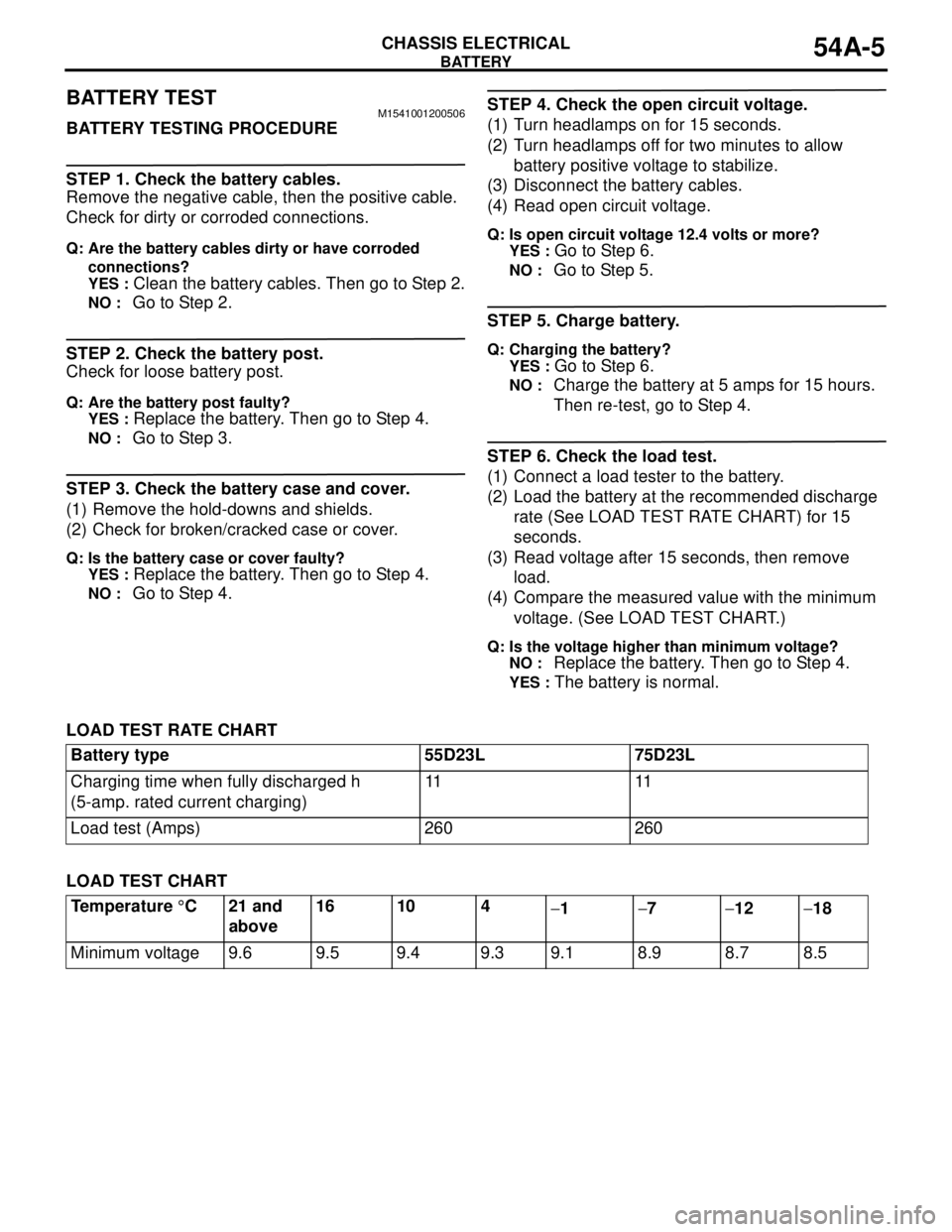

STEP 6. Check the load test.

(1) Connect a load tester to the battery.

(2) Load the battery at the recommended discharge

rate (See LOAD TEST RATE CHART) for 15

seconds.

(3) Read voltage after 15 seconds, then remove

load.

(4) Compare the measured value with the minimum

voltage. (See LOAD TEST CHART.)

Q: Is the voltage higher than minimum voltage?

NO :

Replace the battery. Then go to Step 4.

YES : The battery is normal.

LOAD TEST RATE CHART

LOAD TEST CHARTBattery type 55D23L 75D23L

Charging time when fully discharged h

(5-amp. rated current charging)11 11

Load test (Amps) 260 260

Temperature °C 21 and

above16 10 4

−1−7−12−18

Minimum voltage 9.6 9.5 9.4 9.3 9.1 8.9 8.7 8.5

Page 394 of 788

IGNITION SWITCH

CHASSIS ELECTRICAL54A-6

IGNITION SWITCH

GENERAL INFORMATIONM1543009901274

IGNITION KEY REMINDER BUZZER

The ignition key reminder buzzer will sound under

the following condition, and warn the driver to

remove the ignition key.

•The driver's door is opened when the ignition

switch is at "LOCK" (OFF) or "ACC" position

without removing the ignition key.

However, the lamp reminder buzzer will take

precedence over this function.

DOOR LOCK PREVENTION FUNCTION

If the key is left in the ignition switch while the driver’s

door opened or the assistant door opened, all door

are automatically unlock to prevent locking the

ignition key in the vehicle after door is locked.

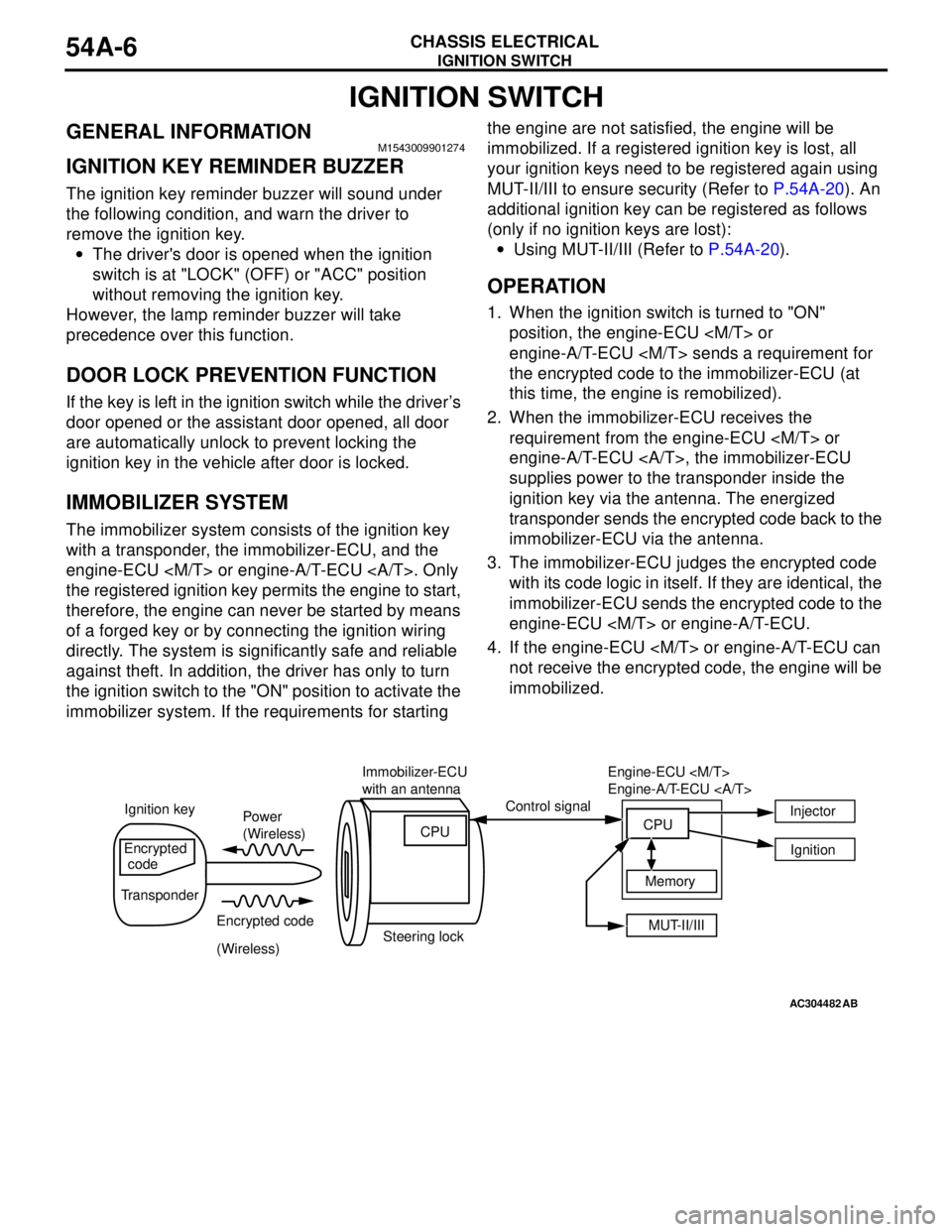

IMMOBILIZER SYSTEM

The immobilizer system consists of the ignition key

with a transponder, the immobilizer-ECU, and the

engine-ECU

the registered ignition key permits the engine to start,

therefore, the engine can never be started by means

of a forged key or by connecting the ignition wiring

directly. The system is significantly safe and reliable

against theft. In addition, the driver has only to turn

the ignition switch to the "ON" position to activate the

immobilizer system. If the requirements for starting the engine are not satisfied, the engine will be

immobilized. If a registered ignition key is lost, all

your ignition keys need to be registered again using

MUT-II/III to ensure security (Refer to P.54A-20). An

additional ignition key can be registered as follows

(only if no ignition keys are lost):

•Using MUT-II/III (Refer to P.54A-20).

OPERATION

1. When the ignition switch is turned to "ON"

position, the engine-ECU

engine-A/T-ECU

the encrypted code to the immobilizer-ECU (at

this time, the engine is remobilized).

2. When the immobilizer-ECU receives the

requirement from the engine-ECU

engine-A/T-ECU , the immobilizer-ECU

supplies power to the transponder inside the

ignition key via the antenna. The energized

transponder sends the encrypted code back to the

immobilizer-ECU via the antenna.

3. The immobilizer-ECU judges the encrypted code

with its code logic in itself. If they are identical, the

immobilizer-ECU sends the encrypted code to the

engine-ECU

4. If the engine-ECU

not receive the encrypted code, the engine will be

immobilized.

AC304482AB

Power

(Wireless)

Encrypted code

(Wireless) Ignition keyControl signal

Encrypted

code

TransponderImmobilizer-ECU

with an antenna

Steering lockCPU

MUT-II/III Memory Engine-ECU

Engine-A/T-ECU

CPUInjector

Ignition

Page 395 of 788

IGNITION SWITCH

CHASSIS ELECTRICAL54A-7

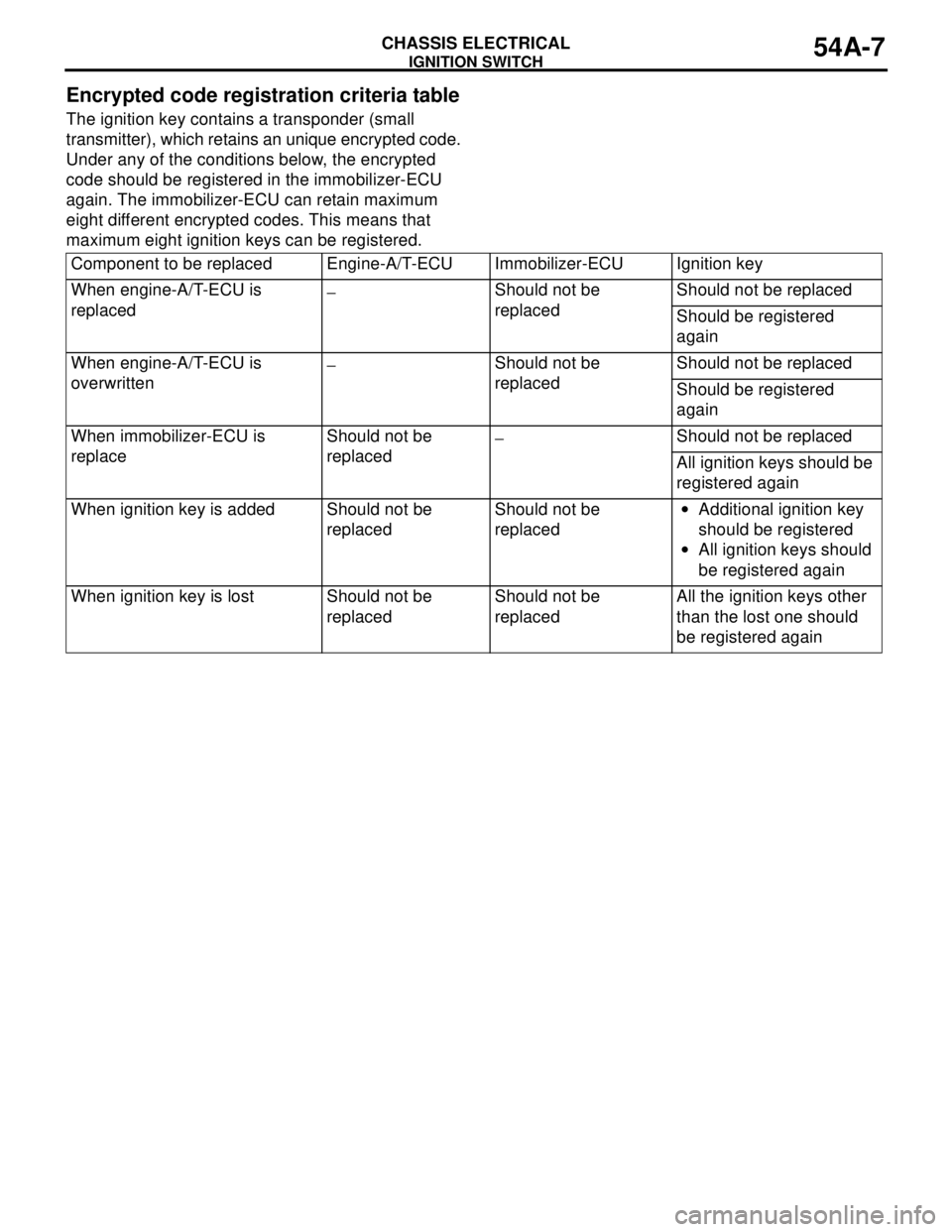

Encrypted code registration criteria table

The ignition key contains a transponder (small

transmitter), which retains an unique encrypted code.

Under any of the conditions below, the encrypted

code should be registered in the immobilizer-ECU

again. The immobilizer-ECU can retain maximum

eight different encrypted codes. This means that

maximum eight ignition keys can be registered.

Component to be replaced Engine-A/T-ECU Immobilizer-ECU Ignition key

When engine-A/T-ECU is

replaced−Should not be

replacedShould not be replaced

Should be registered

again

When engine-A/T-ECU is

overwritten−Should not be

replacedShould not be replaced

Should be registered

again

When immobilizer-ECU is

replaceShould not be

replaced−Should not be replaced

All ignition keys should be

registered again

When ignition key is added Should not be

replacedShould not be

replaced•Additional ignition key

should be registered

•All ignition keys should

be registered again

When ignition key is lost Should not be

replacedShould not be

replacedAll the ignition keys other

than the lost one should

be registered again

Page 396 of 788

IGNITION SWITCH

CHASSIS ELECTRICAL54A-8

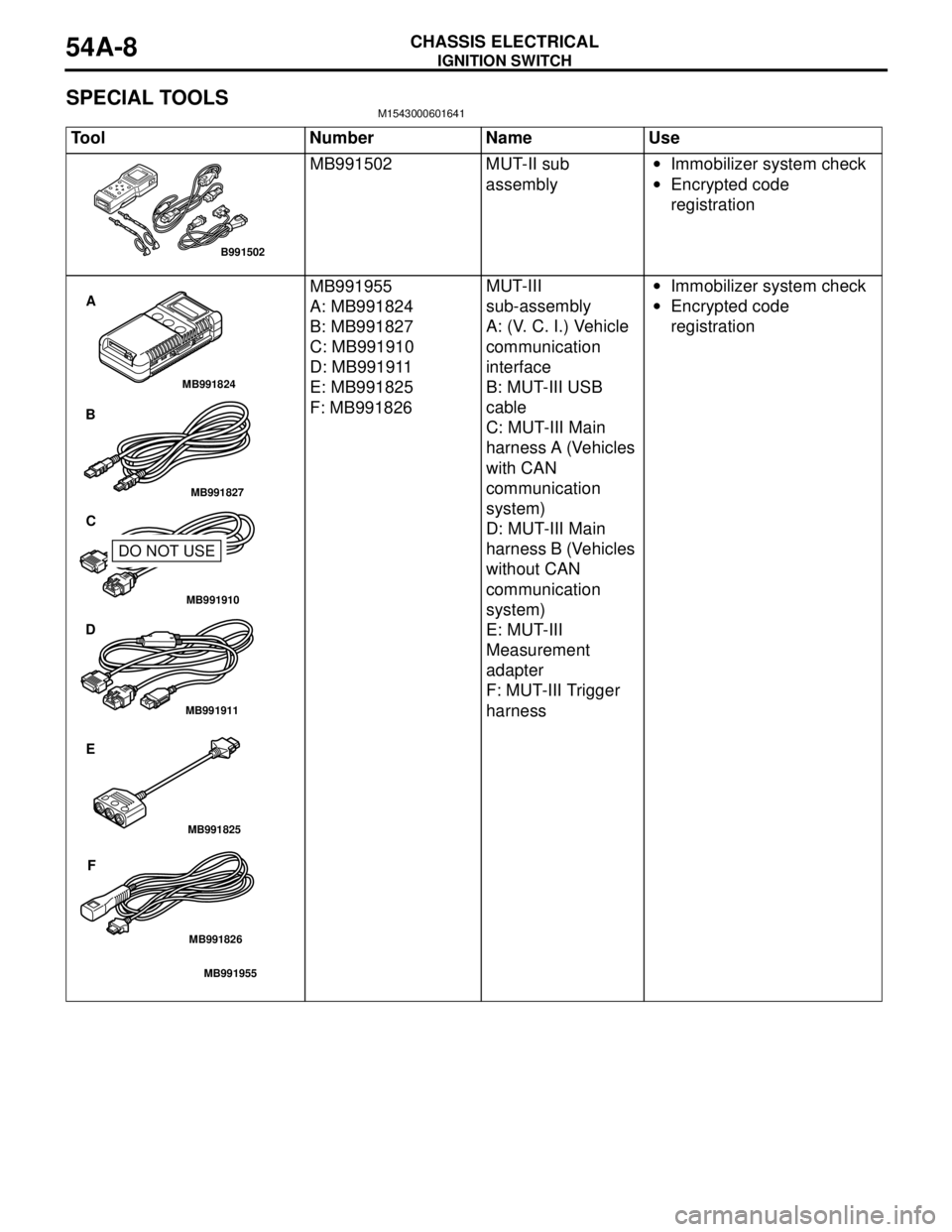

SPECIAL TOOLSM1543000601641

Tool Number Name Use

MB991502 MUT-II sub

assembly•Immobilizer system check

•Encrypted code

registration

MB991955

A: MB991824

B: MB991827

C: MB991910

D: MB991911

E: MB991825

F: MB991826MUT-III

sub-assembly

A: (V. C. I.) Vehicle

communication

interface

B: MUT-III USB

cable

C: MUT-III Main

harness A (Vehicles

with CAN

communication

system)

D: MUT-III Main

harness B (Vehicles

without CAN

communication

system)

E: MUT-III

Measurement

adapter

F: MUT-III Trigger

harness•Immobilizer system check

•Encrypted code

registration

B991502

MB991910

MB991826

MB991955

MB991911

MB991824

MB991827

MB991825

A

B

C

D

E

F

DO NOT USE

Page 397 of 788

IGNITION SWITCH

CHASSIS ELECTRICAL54A-9

TROUBLESHOOTING

IGNITION KEY REMINDER BUZZER AND

DOOR LOCK PREVENTION FUNCTION

TROUBLESHOOTING

M1543000701002

The ignition key reminder buzzers are controlled by

the Smart Wiring System (SWS). For

troubleshooting, refer to respective Groups below.

•Not using SWS monitor: GROUP 54B, SWS

Diagnosis P.54B-38.

•Using SWS monitor: GROUP 54C, SWS

Diagnosis P.54C-22.

IMMOBILIZER SYSTEM

TROUBLESHOOTING

DIAGNOSIS CODE CHARTM1543007100417

CAUTION

During diagnosis, a diagnosis code associated

with other system may be set when the ignition

switch is turned on with connector(s)

disconnected. On completion, confirm all

systems for diagnosis code code(s). If diagnosis

code code(s) are set, erase them all.

Use the following chart to develop proper diagnostic

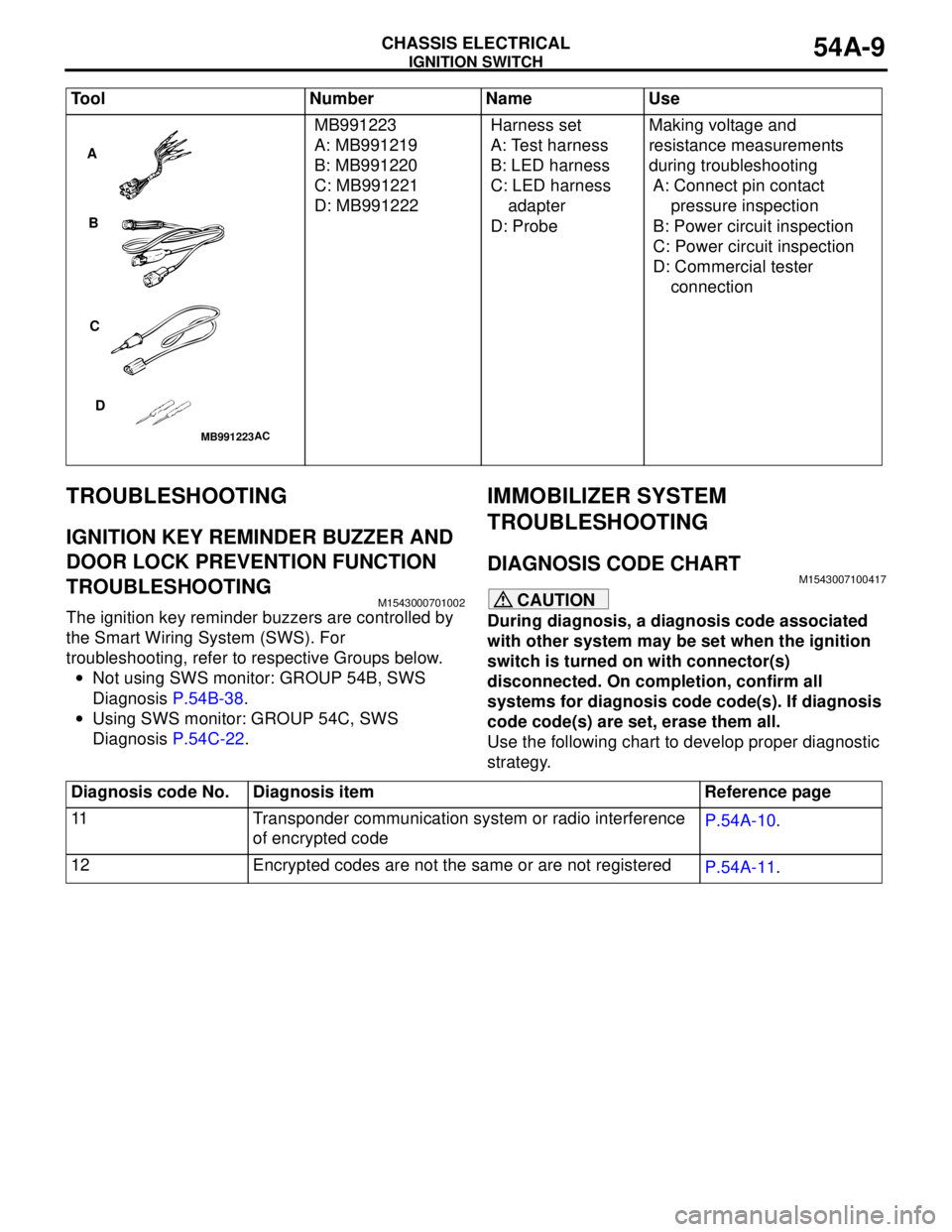

strategy. MB991223

A: MB991219

B: MB991220

C: MB991221

D: MB991222Harness set

A: Test harness

B: LED harness

C: LED harness

adapter

D: ProbeMaking voltage and

resistance measurements

during troubleshooting

A: Connect pin contact

pressure inspection

B: Power circuit inspection

C: Power circuit inspection

D: Commercial tester

connection Tool Number Name Use

MB991223

A

B

C

D

AC

Diagnosis code No. Diagnosis item Reference page

11 Transponder communication system or radio interference

of encrypted codeP.54A-10.

12 Encrypted codes are not the same or are not registered

P.54A-11.

Page 398 of 788

IGNITION SWITCH

CHASSIS ELECTRICAL54A-10

DIAGNOSTIC TROUBLE CODE

PROCEDURES

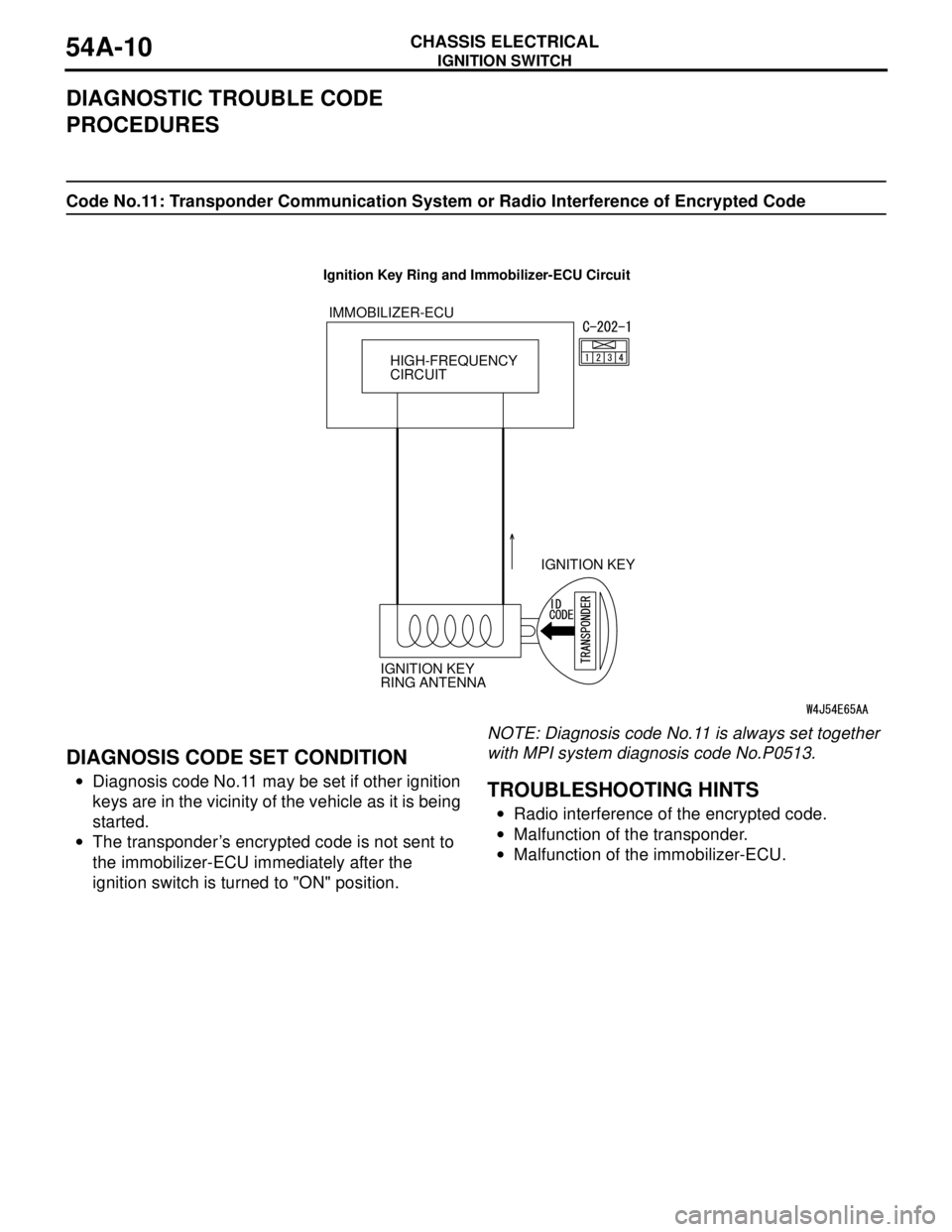

Code No.11: Transponder Communication System or Radio Interference of Encrypted Code

DIAGNOSIS CODE SET CONDITION

•Diagnosis code No.11 may be set if other ignition

keys are in the vicinity of the vehicle as it is being

started.

•The transponder’s encrypted code is not sent to

the immobilizer-ECU immediately after the

ignition switch is turned to "ON" position.NOTE: Diagnosis code No.11 is always set together

with MPI system diagnosis code No.P0513.TROUBLESHOOTING HINTS

•Radio interference of the encrypted code.

•Malfunction of the transponder.

•Malfunction of the immobilizer-ECU.

HIGH-FREQUENCY

CIRCUIT IMMOBILIZER-ECU

IGNITION KEY

IGNITION KEY

RING ANTENNA

Ignition Key Ring and Immobilizer-ECU Circuit

Page 399 of 788

IGNITION SWITCH

CHASSIS ELECTRICAL54A-11

DIAGNOSIS PROCEDURE

STEP 1. Check for presence of other key near the

key in the ignition.

Q: Is there any other key near the key in the ignition?

YES :

Move the other key well away from key

being used. Retest the system.

NO : Go to Step 2.

STEP 2. Check that the engine start using the

spare ignition key which encrypted code has

been registered.

Q: Does the engine start using the spare ignition key

for which the encrypted code has been registered?

YES :

Replace the ignition key that does not work.

Then register the password (secret code)

and encrypted code P.54A-20. Retest the

system.

NO : Go to Step 3.

STEP 3. Check whether the diagnosis code is

reset.

Q: Which diagnosis code is set, code No.11 or 12 the

encrypted code has been registered?

Code No.12 is set :

Refer toP.54A-11.

Code No.11 is set : Go to Step 4.

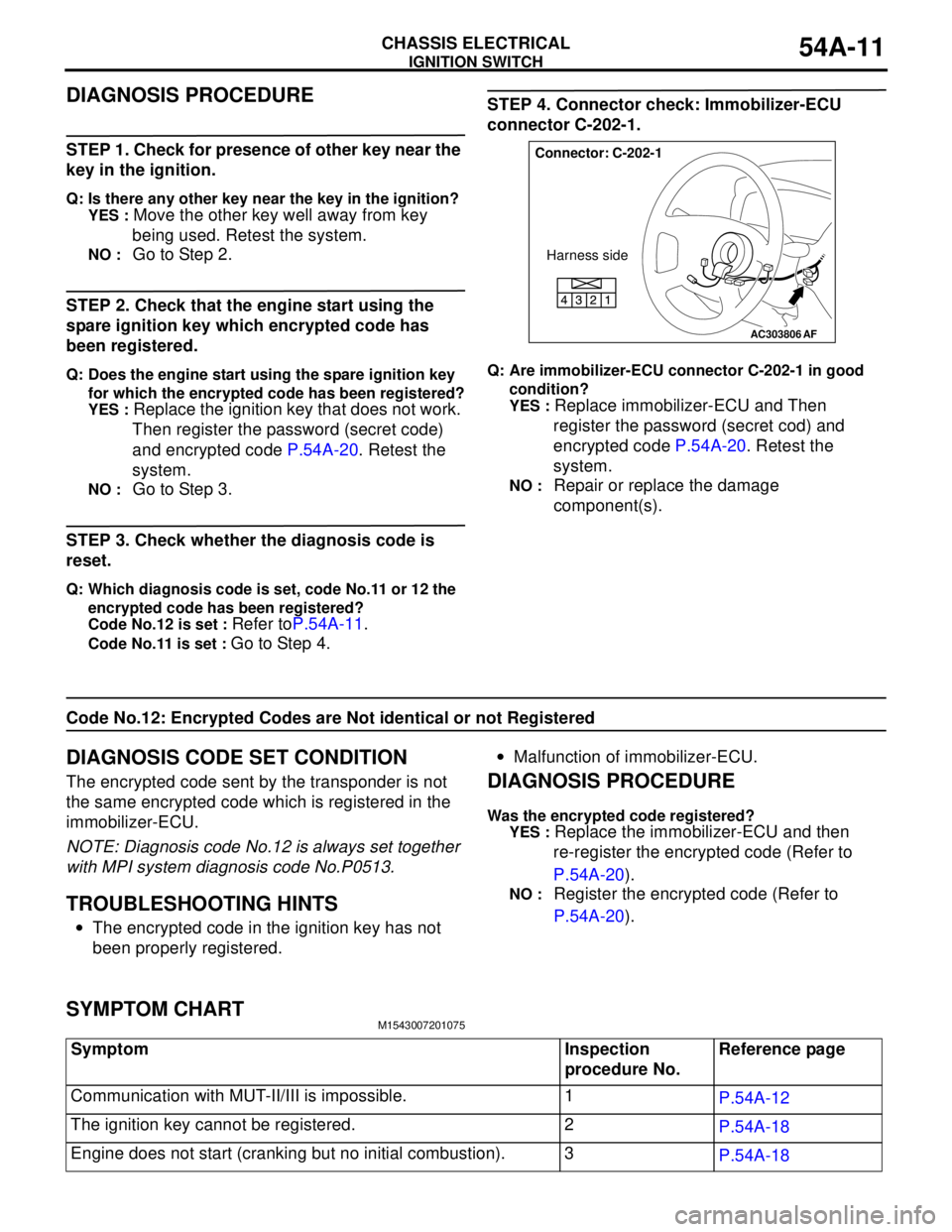

STEP 4. Connector check: Immobilizer-ECU

connector C-202-1.

Q: Are immobilizer-ECU connector C-202-1 in good

condition?

YES :

Replace immobilizer-ECU and Then

register the password (secret cod) and

encrypted code P.54A-20. Retest the

system.

NO : Repair or replace the damage

component(s).

Code No.12: Encrypted Codes are Not identical or not Registered

DIAGNOSIS CODE SET CONDITION

The encrypted code sent by the transponder is not

the same encrypted code which is registered in the

immobilizer-ECU.

NOTE: Diagnosis code No.12 is always set together

with MPI system diagnosis code No.P0513.

TROUBLESHOOTING HINTS

•The encrypted code in the ignition key has not

been properly registered.•Malfunction of immobilizer-ECU.

DIAGNOSIS PROCEDURE

Was the encrypted code registered?

YES :

Replace the immobilizer-ECU and then

re-register the encrypted code (Refer to

P.54A-20).

NO : Register the encrypted code (Refer to

P.54A-20).

SYMPTOM CHARTM1543007201075

AC303806

Connector: C-202-1

Harness side

AF

Symptom Inspection

procedure No.Reference page

Communication with MUT-II/III is impossible. 1

P.54A-12

The ignition key cannot be registered. 2

P.54A-18

Engine does not start (cranking but no initial combustion). 3

P.54A-18

Page 400 of 788

IGNITION SWITCH

CHASSIS ELECTRICAL54A-12

SYMPTOM PROCEDURES

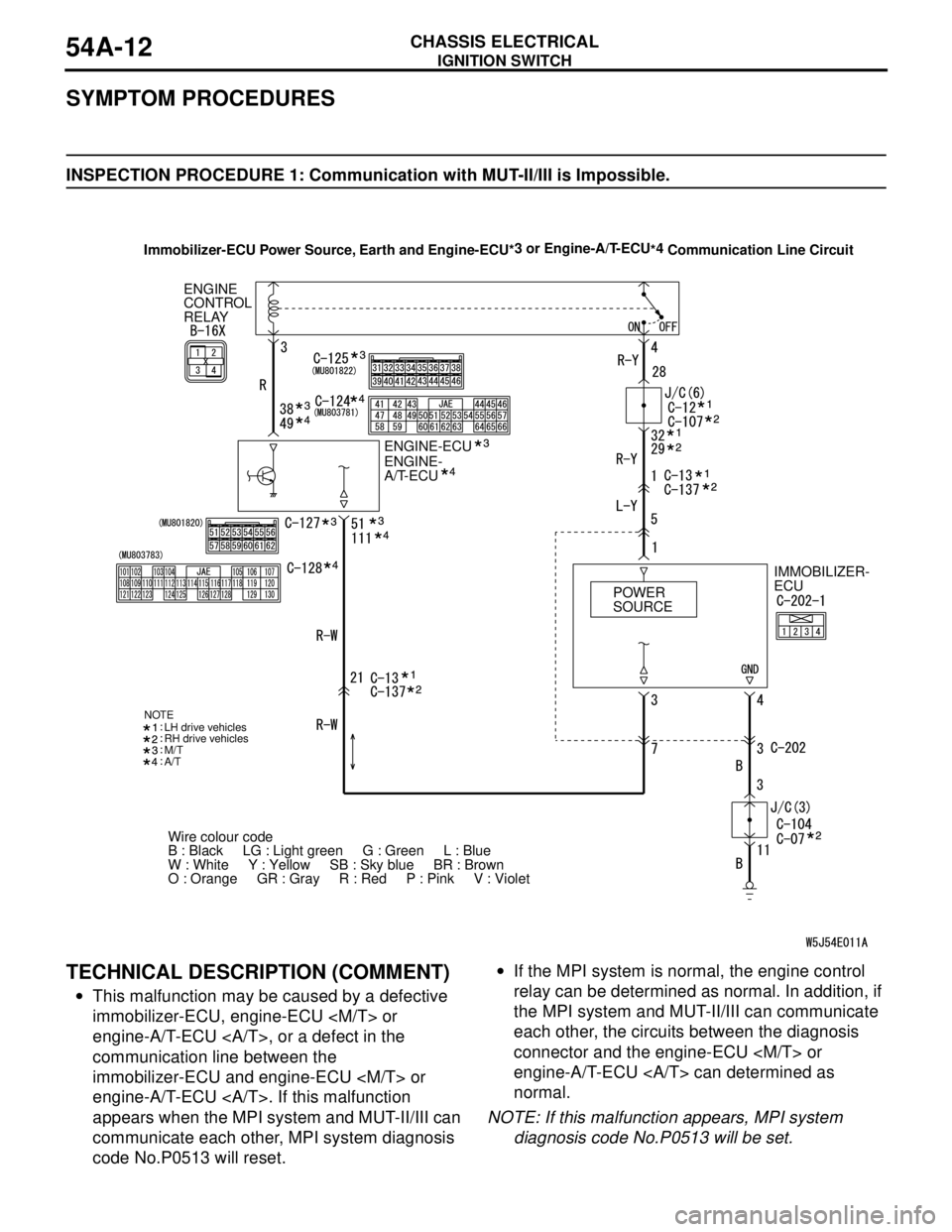

INSPECTION PROCEDURE 1: Communication with MUT-II/III is Impossible.

TECHNICAL DESCRIPTION (COMMENT)

•This malfunction may be caused by a defective

immobilizer-ECU, engine-ECU

engine-A/T-ECU , or a defect in the

communication line between the

immobilizer-ECU and engine-ECU

engine-A/T-ECU . If this malfunction

appears when the MPI system and MUT-II/III can

communicate each other, MPI system diagnosis

code No.P0513 will reset.•If the MPI system is normal, the engine control

relay can be determined as normal. In addition, if

the MPI system and MUT-II/III can communicate

each other, the circuits between the diagnosis

connector and the engine-ECU

engine-A/T-ECU can determined as

normal.

NOTE: If this malfunction appears, MPI system

diagnosis code No.P0513 will be set.

ENGINE-ECU ENGINE

CONTROL

RELAY

ENGINE-

A/T-ECU

IMMOBILIZER-

ECU

Wire colour code

B : Black LG : Light green G : Green L : Blue

W : White Y : Yellow SB : Sky blue BR : Brown

O : Orange GR : Gray R : Red P : Pink V : Violet POWER

SOURCE

M/T

A/T NOTE

LH drive vehicles

RH drive vehicles

Immobilizer-ECU Power Source, Earth and Engine-ECU*3 or Engine-A/T-ECU

*4

Communication Line Circuit