MITSUBISHI MONTERO 1987 1.G Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 191 of 284

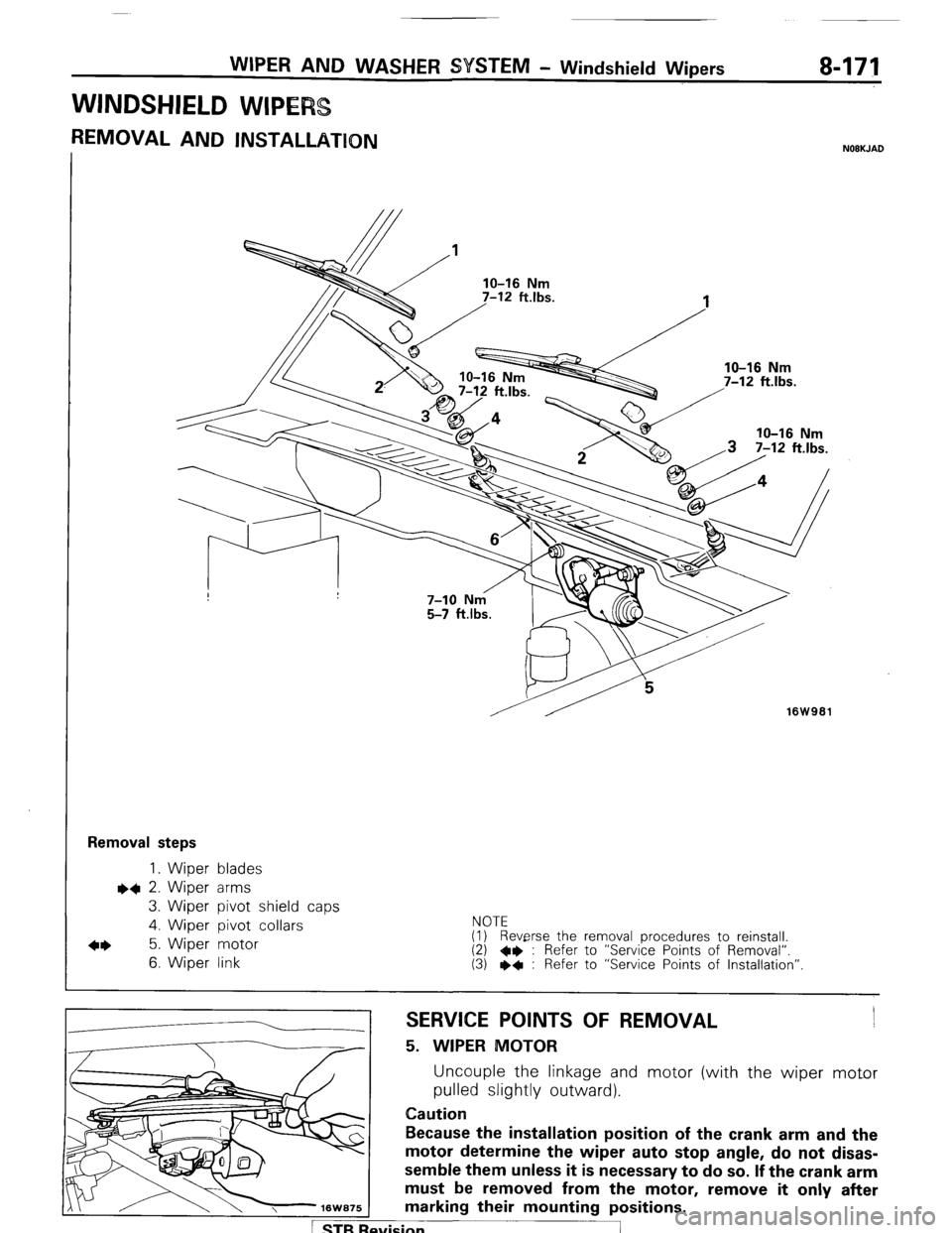

WIPER AND WASHER SYSTEM - Windshield Wipers 8-171

WINDSHIELD WIPE

REMOVAL AND INSTALLATION NOBKJAD

16W961

Removal steps

1. Wiper blades l

+ 2. Wiper arms

3. Wiper pivot shield caps

4. Wiber pivot collars NOTE

4* 5. Wiper motor (1) Reverse the removal procedures to reinstall.

6. Wiper link (2) 4* : Refer to “Service Points of Removal”.

(3) I)* : Refer to “Service Points of Installation”

SERVICE POINTS OF REMOVAL

5. WIPER MOTOR

Uncouple the linkage and motor (with the wiper motor

pulled slightly outward).

Caution

Because the installation position of the crank arm and the

motor determine the wiper auto stop angle, do not disas-

semble them unless it is necessary to do so. If the crank arm

must be removed from the motor, remove it only after

marking their mounting positions.

svision

I

Page 192 of 284

8-172 WIPER AND WAsHER SYSTEM - Windshield Wipers

nm (in.1 16Y1568 I

I

J (v L

I 2

Battery

II I , +

Battery @

16W1538

bv

J’ L

.jr 2.

Battery

3 4

I

16W1539

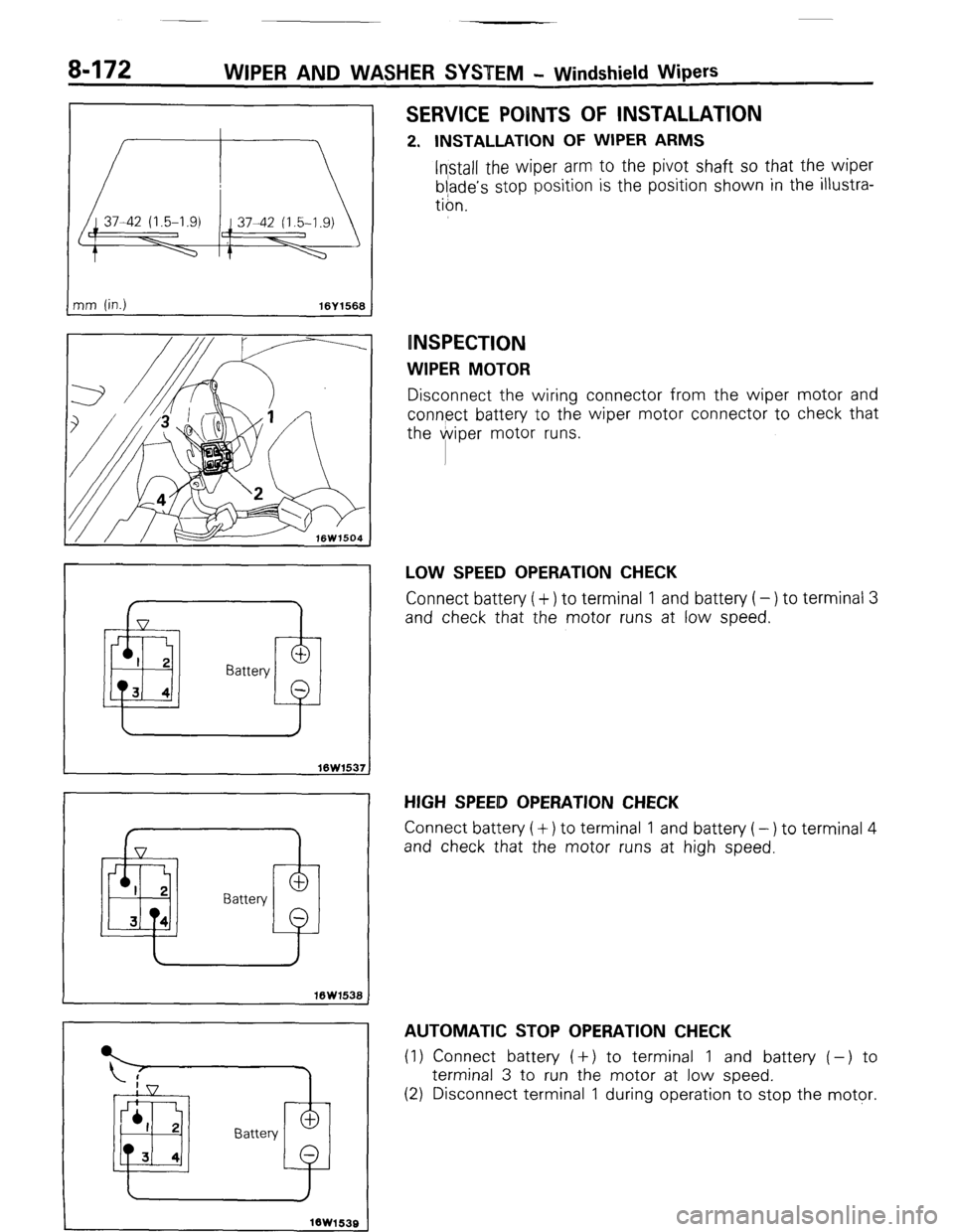

SERVICE POINTS OF INSTALLATION

2. INSTALLATION OF WIPER ARMS

Install the wiper arm to the pivot shaft so that the wiper

blade’s stop position is the position shown in the illustra-

tion.

INSPECTION

WIPER MOTOR

Disconnect the wiring connector from the wiper motor and

connect battery to the wiper motor connector to check that

the @viper motor runs.

LOW SPEED OPERATION CHECK

Connect battery ( + ) to terminal 1 and battery ( - ) to terminal 3

and check that the motor runs at low speed.

HIGH SPEEID OPERATION CHECK

Connect battery (+) to terminal 1 and battery (-) to terminal 4

and check that the motor runs at high speed.

AUTOMATIC STOP OPERATION CHECK

(1) Connect battery ( +) to terminal 1 and battery ( -) to

terminal 3 to run the motor at low speed.

(2) Disconnect terminal 1 during operation to stop the motor.

1 STB Revision

-7

Page 193 of 284

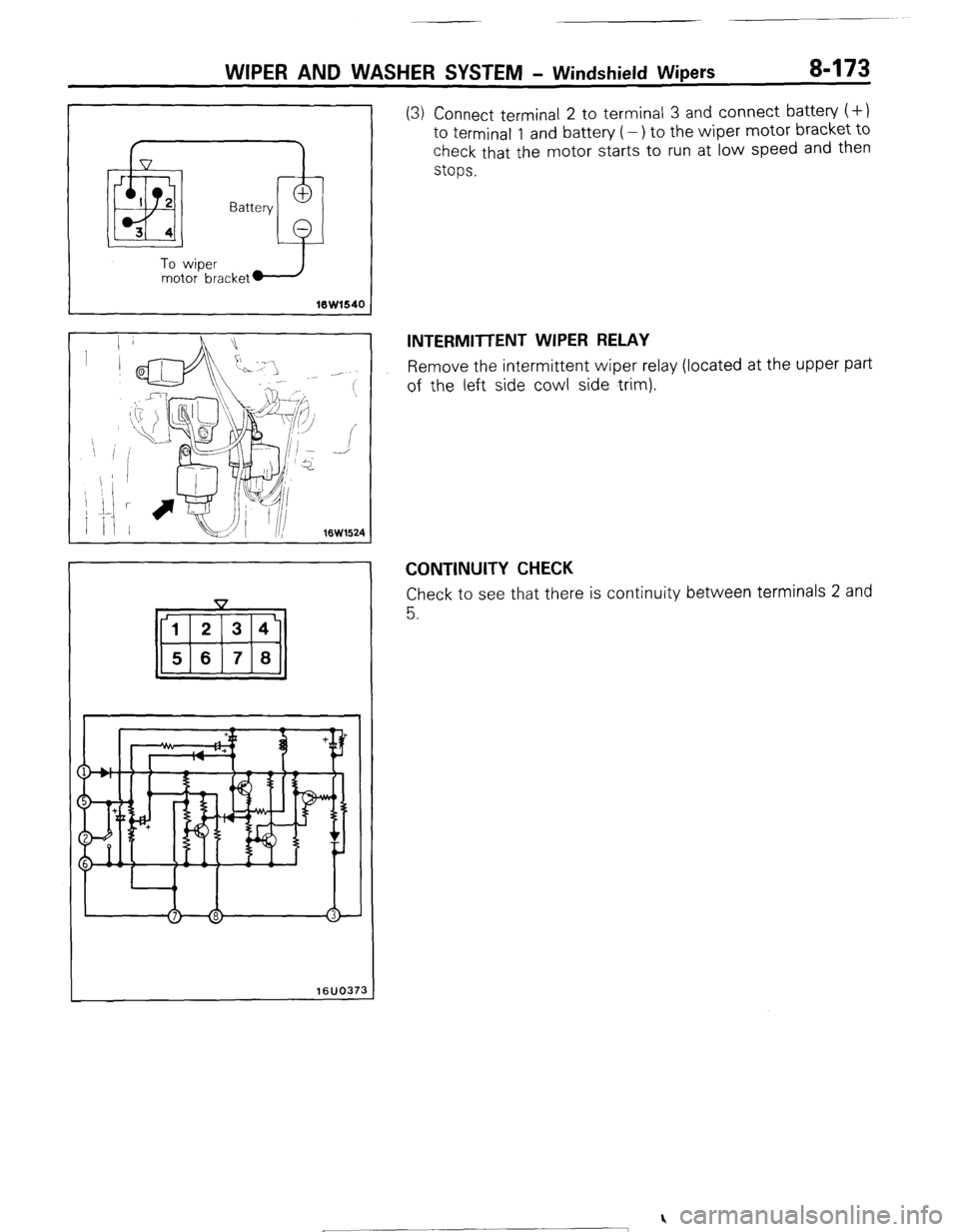

WIPER AND WASHER SYSTEM - Windshield Wipers 8-173

I Battery

To wiper

motor bracket

16W1540

16W1524

16UO373

(3) Connect terminal 2 to terminal 3 and connect battery (+)

to terminal 1 and battery (-) to the wiper motor bracket to

check that the motor starts to run at low speed and then

stops.

INTERMITTENT WIPER RELAY

Remove the intermittent wiper relay (located at the upper part

of the left side cowl side trim).

CONTINUITY CHECK

Check to see that there is continuity between terminals 2 and

5.

) STB Revision

Page 194 of 284

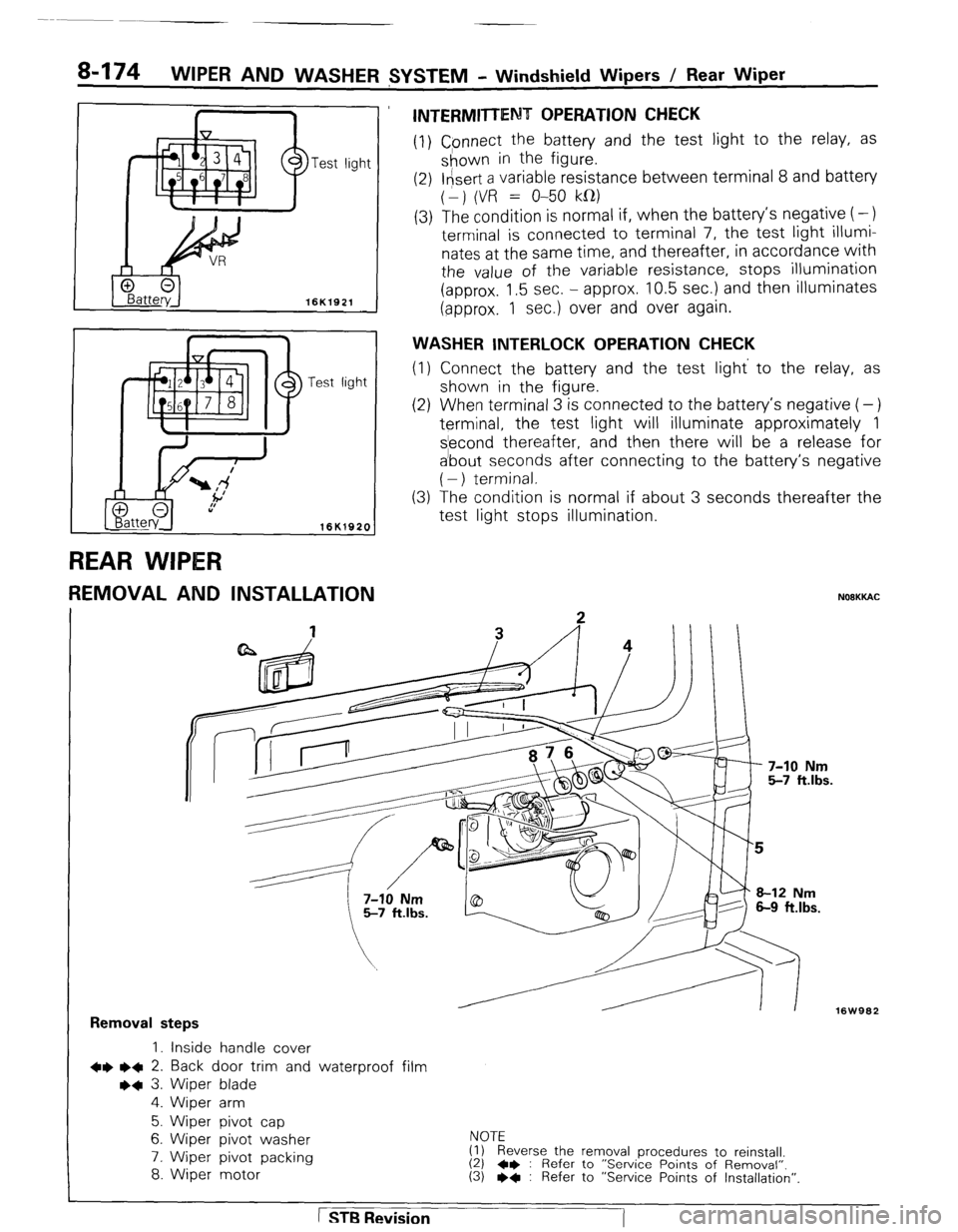

a-174 WIPER AND WASHER $YSTEM - Windshield Wipers / Rear Wiper

REAR WIPtER

7

-est light

16K1920

t

REMOVAL AND INSTALLATION

INTERMITTENT OPERATION CHECK

(1) Cpnnect the battery and the test light to the relay, as

shown in the figure.

(2) l&ert a variable resistance between terminal 8 and battery

(1) (VR = O-50 kfl)

(3) The condition is normal if, when the battery’s negative (-)

terminal is connected to terminal 7, the test light illumi-

nates at the same time, and thereafter, in accordance with

the value of the variable resistance, stops illumination

(approx. 1.5 sec. - approx. 10.5 sec.) and then illuminates

(approx. 1 sec.) over and over again.

WASHER INTERLOCK OPERATION CHECK

(1) Connect the battery and the test light’ to the relay, as

shown in the .figure.

(2) When terminal 3 is connected to the battery’s negative (-)

terminal, the test light will illuminate approximately 1

s’econd thereafter, and then there will be a release for

a’bout seconds after connecting to the battery’s negative

( - ) terminal.

The condition is normal if about 3 seconds thereafter the

test light stops illumination. (3

NOOKKAC

16W962

Removal steps

1. inside handle cover

+e l + 2. Back door trim and waterproof film

++ 3. Wiper blade

4. Wiper arm

5. Wiper pivot cap

6. Wiper pivot washer

7. Wiper pivot packing

8. Wiper motor NOTE

(1) Reverse the removal procedures to reinstall.

(2) 4* : Refer to “Service Points of Removal”. (3) l * : Refer to “Service Points of Installation”.

1 STB Revision

-7

Page 195 of 284

WIPER AND WASHER SYSTEM - Rear Wiper 8-175

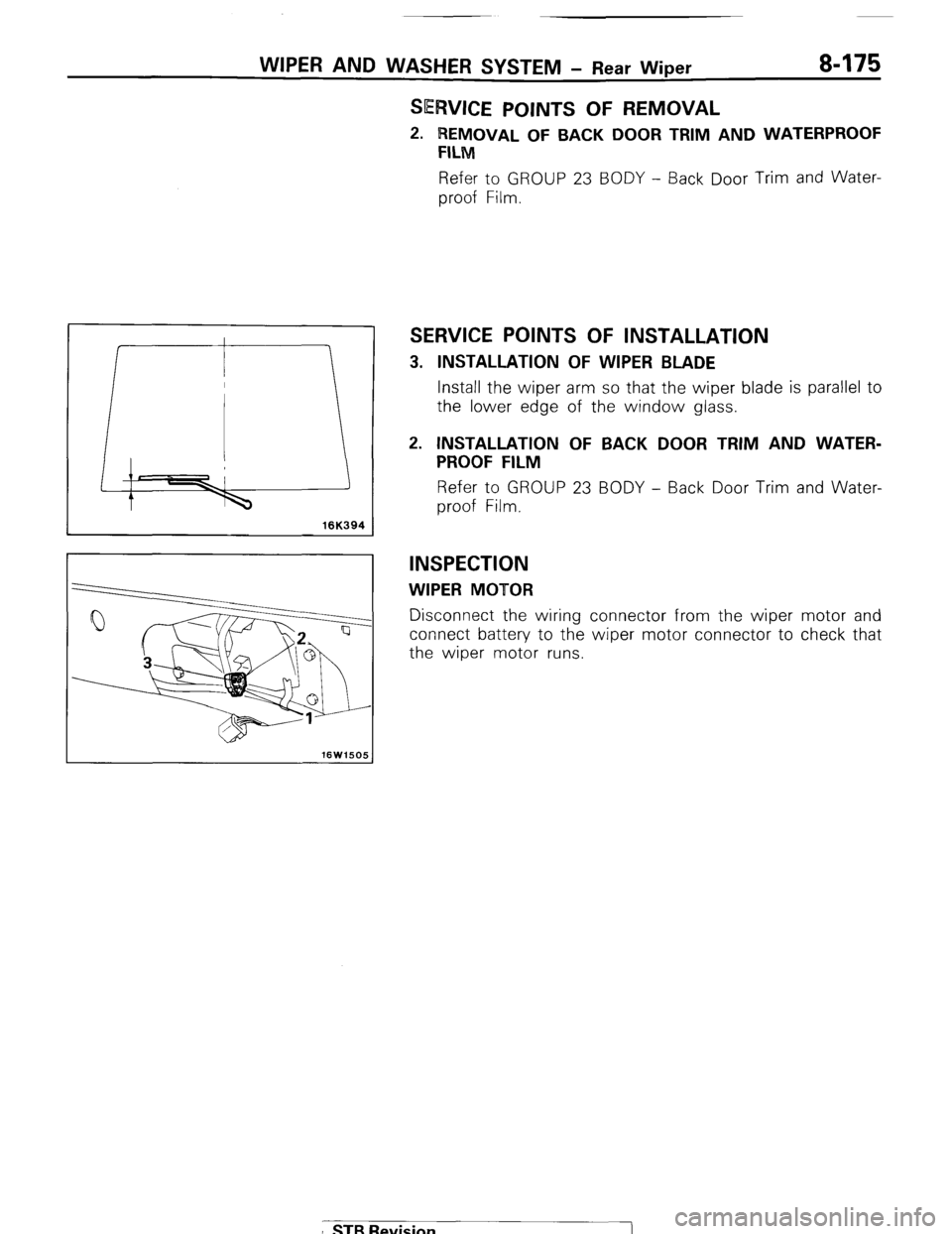

SERVICE POINTS OF REMOVAL

2. REMOVAL OF BACK DOOR TRIM AND WATERPROOF

FILM

Refer to GROUP 23 BODY - Back Door Trim and Water-

proof Film.

I 16K394 1

SERVICE POINTS OF INSTALLATION

3. INSTALLATION OF WIPER BLADE

Install the wiper arm so that the wiper blade is parallel to

the lower edge of the window glass.

2. INSTALLATION OF BACK DOOR TRIM AND WATER-

PROOF FILM

Refer to GROUP 23 BODY - Back Door Trim and Water-

proof Film.

INSPECTION

WIPER MOTOR

Disconnect the wiring connector from the wiper motor and

connect battery to the wiper motor connector to check that

the wiper motor runs.

I STB Revision

Page 196 of 284

8476 WIPER AND WASHER SYSTEM - Rear Wiper

16W1541

Battery

2.3

t

Battery

-

To wiper

motor bracket +

10w1543

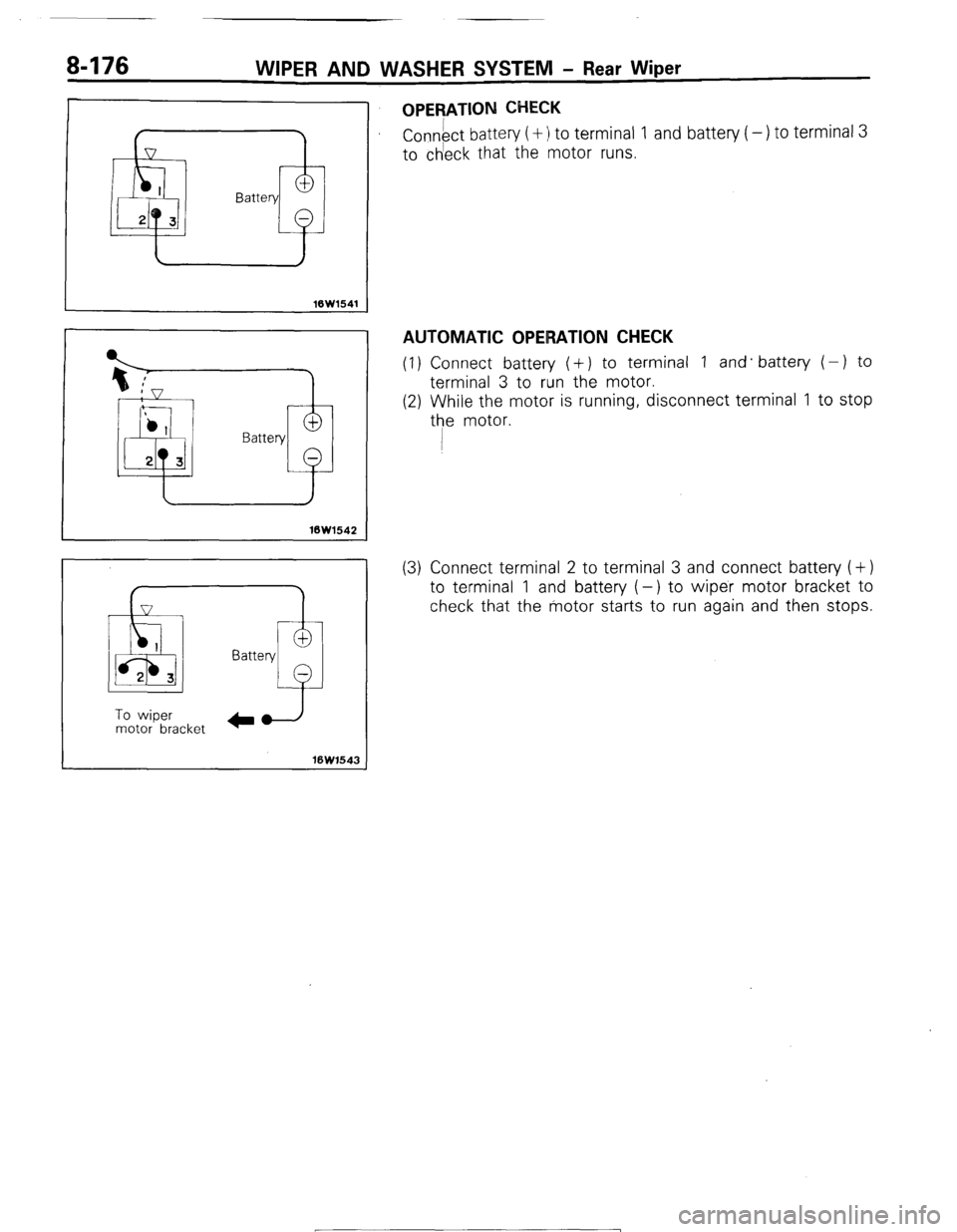

OPERATION CHECK

Connect battery (+ :I to terminal 1 and battery ( -) to terminal 3

to ch’eck that the motor runs.

AUTOMATIC OPERATION CHECK

(1) Connect battery (+) to terminal 1 and. battery ( - ) to

terminal 3 to run the motor.

(2) While the motor is running, disconnect terminal 1 to stop

the motor.

(3) Connect terminal 2 to terminal 3 and connect battery (+)

to terminal 1 and battery (-) to wiper motor bracket to

check that the motor starts to run again and then stops.

1 STB Revision

-7

Page 197 of 284

WIPER AND WASHER SYSTEM - Windshield Washer 8-177

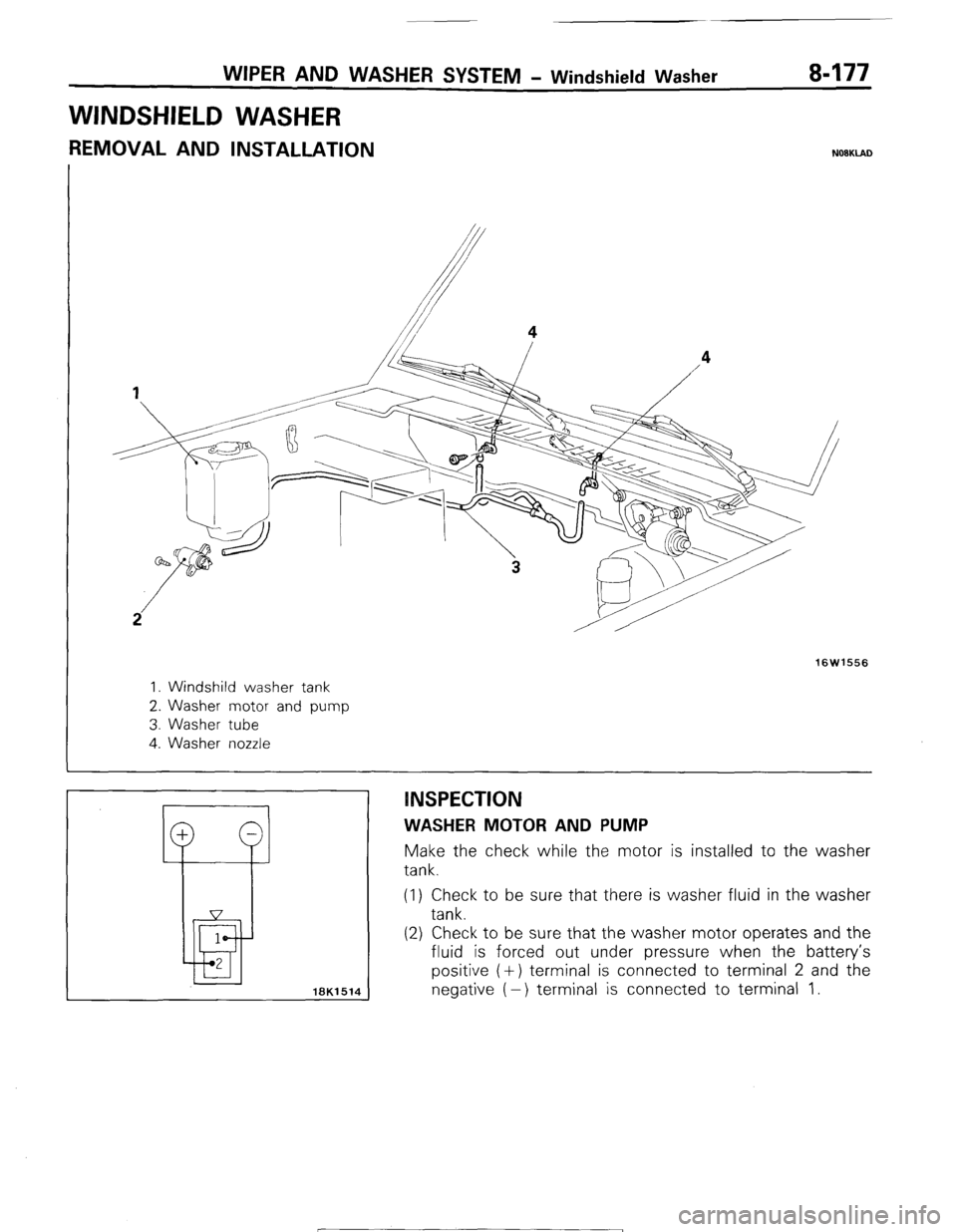

WINDSHIELD WASHER

REMOVAL AND INSTALLATION N08KlAD

16W1556

1. Windshild washer tank

2. Washer motor and pump

3. Washer tube

4. Washer nozzle

::I:;rl _

INSPECTION

+ -

WASHER MOTOR AND PUMP

Make the check while the motor is installed to the washer

tank.

1

2

18K1514

(1) Check to be sure that there is washer fluid in the washer

tank.

(2) Check to be sure that the washer motor operates and the

fluid is forced out under pressure when the battery’s

positive (+) terminal is connected to terminal 2 and the negative ( -) terminal is connected to terminal I.

[ STB Revision

Page 198 of 284

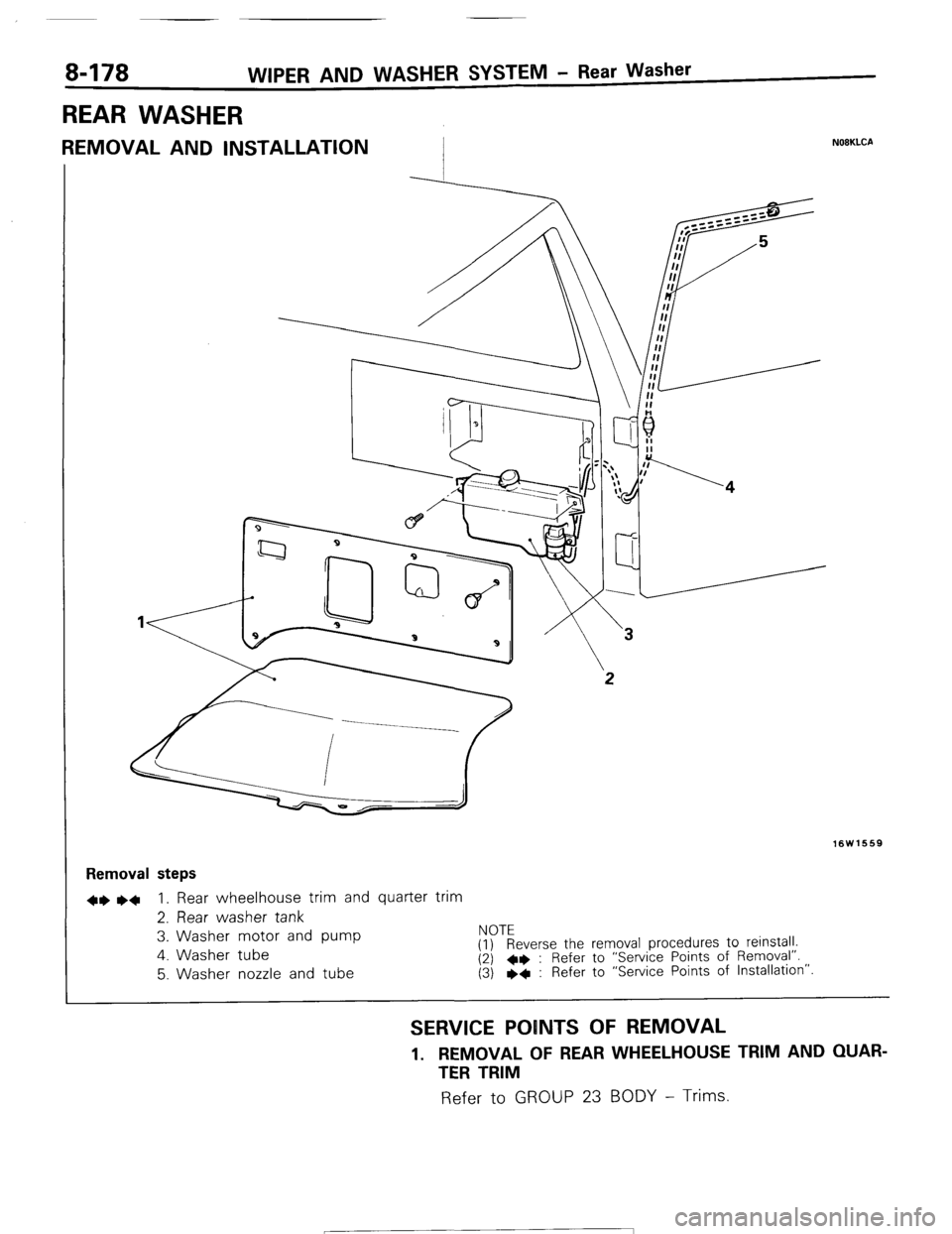

8-178 WIPER AND WASHER SYSTEM - Rear Washer

REAR WASHER

REMOVAL AND INSTALLATION I N08KLCA

16W1669

Removal steps

+e ~~ 1. Rear wheelhouse trim and quarter trim

2. Rear washer tank

3. Washer motor and pump NOTE

4. Washer tube

(1) Reverse the removal procedures to reinstall.

(2) l * : Refer to “Service Points of Removal”. 5. Washer nozzle and tube (3) l + : Refer to “Service Points of Installation”.

SERVICE POINTS OF REMOVAL

1. REMOVAL OF REAR WHEELHOUSE TRIM AND QUAR-

TER TRIM Refer to

GROUP 23 BODY - Trims.

1 STR Ravisinn -7

Page 199 of 284

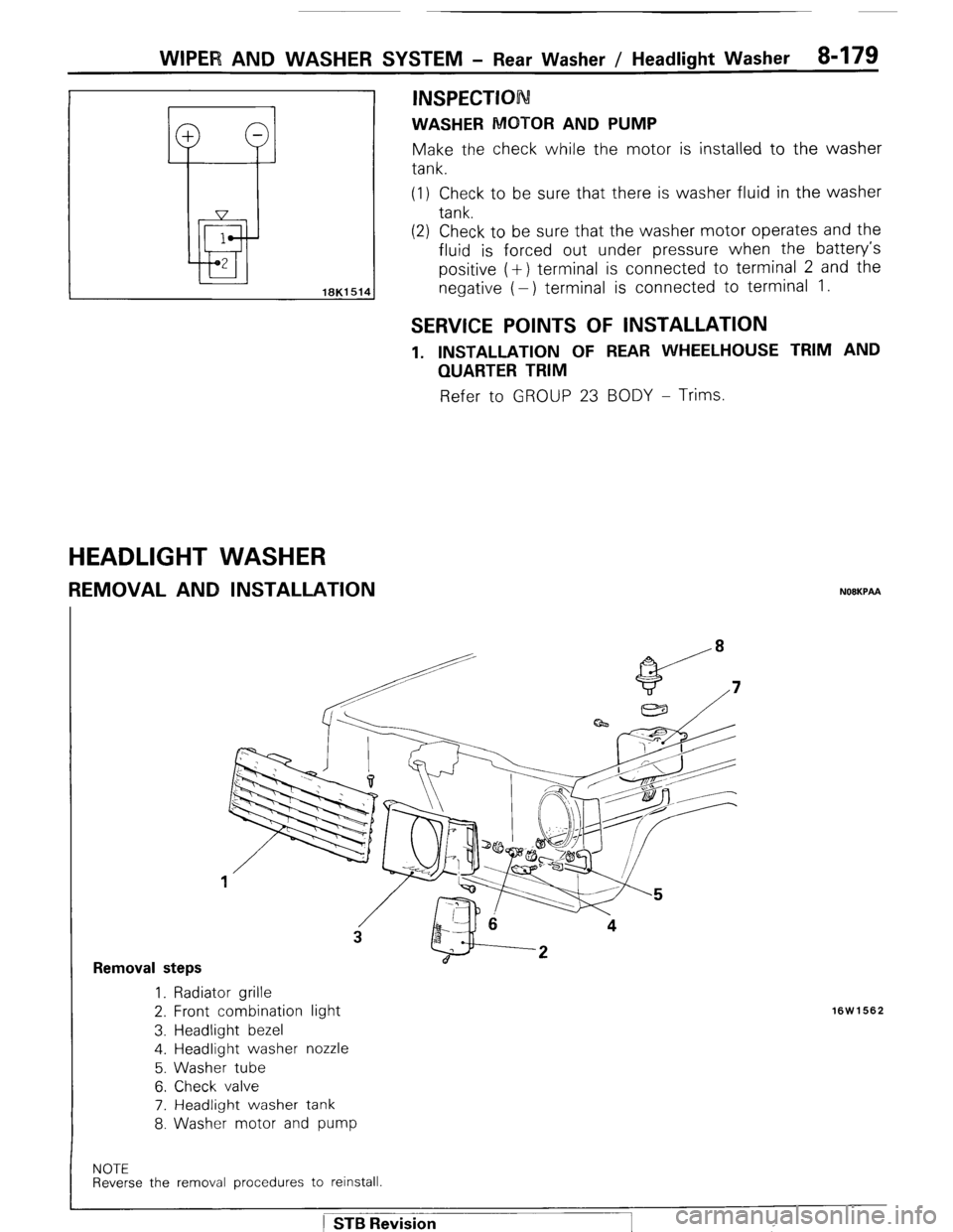

I 1

+ -

li.if 1

2

WIPER AND WASHER SYSTEM - Rear Washer / Headlight Washer 8-179 (1) Check to be sure that there is washer fluid in the washer

tank.

(2) Check to be sure that the washer motor operates and the

fluid is forced out under pressure when the battery’s

positive (+) terminal is connected to terminal 2 and the

negative (-) terminal is connected to terminal 1.

INSPECTION

WASHER MOTOR AND PUMP Make the check while the motor is installed to the washer

tank.

SERVICE POINTS OF INSTALLATION

1. INSTALLATION OF REAR WHEELHOUSE TRIM AND

QUARTER TRIM Refer to GROUP 23 BODY - Trims.

HEADLIGHT WASHER

REMOVAL AND INSTALLATION NOEKPAA

Removal steps 1. Radiator grille

2. Front combination light

3. Headlight bezel

4. Headlight washer nozzle

5. Washer tube

6. Check valve

7. Headlight washer tank

8. Washer motor and pump

16W1562

NOTE Reverse the removal procedures to reinstall.

) STB Revision

Page 200 of 284

WIPER AND WASHER SYSTEM - Headlight Washer

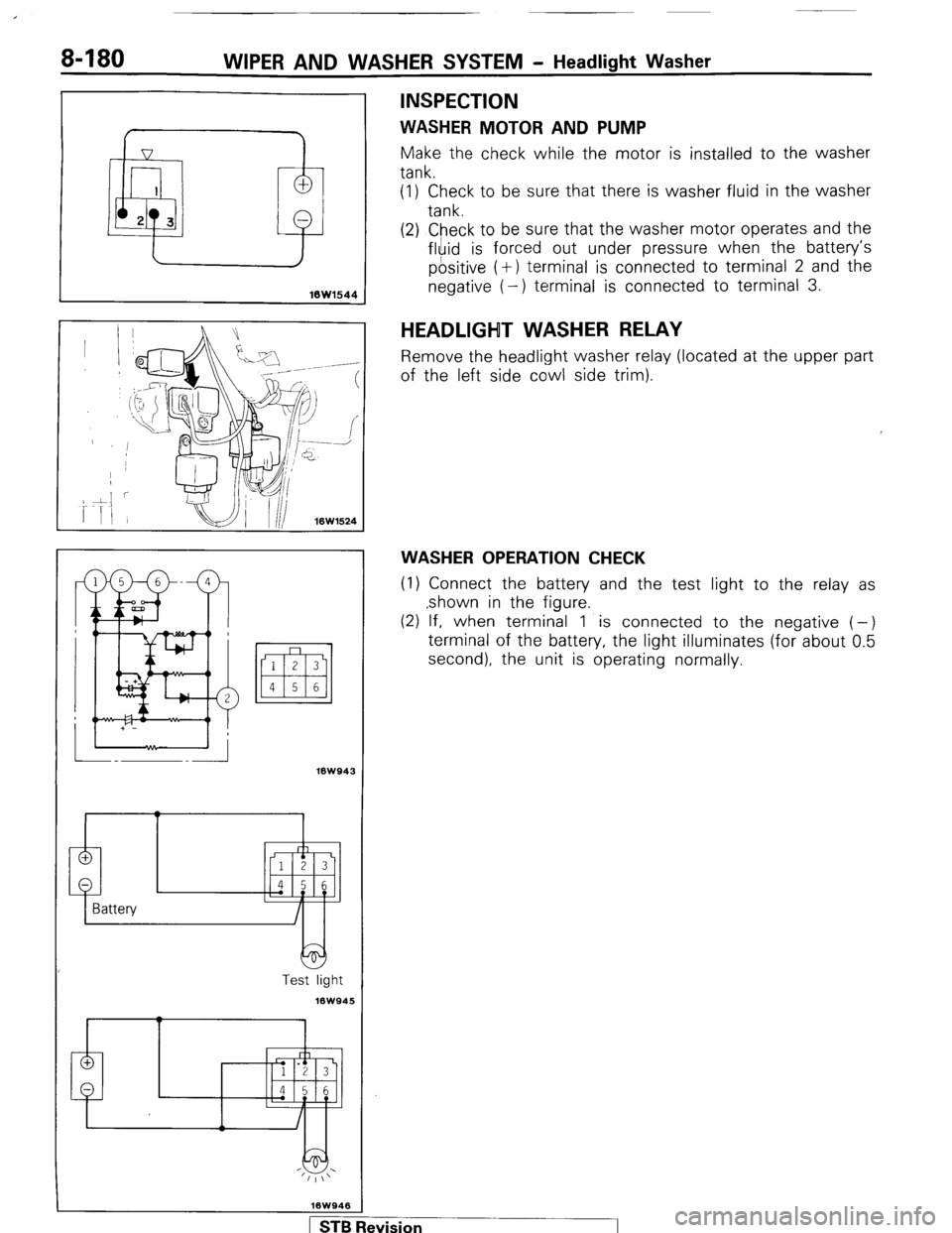

INSPECTION

WASHER MOTOR AND PUMP

Make the check while the motor is installed to the washer

tank.

(1) Check to be sure that there is washer fluid in the washer

tank.

16Wl544

(2) Check to be sure that the washer motor operates and the

fluid is forced out under pressure when the battery’s

positive (+) terminal is connected to terminal 2 and the

negative (-) terminal is connected to terminal 3.

18W943

Test light

16W945

HEADLIGHT WASHER RELAY

Remove the headlight washer relay (located a

of the left side cowl side trim). It the upper part

WASHER OPERATION CHECK

(1) Connect the battery and the test light to the relay as

,shown in the figure.

(2) If, when terminal 1 is connected to the negative (-)

terminal of the battery, the light illuminates (for about 0.5

second), the unit is operating normally.

1 STB Revision -1