MITSUBISHI MONTERO 1987 1.G Workshop Manual

MONTERO 1987 1.G

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/7559/w960_7559-0.png

MITSUBISHI MONTERO 1987 1.G Workshop Manual

Trending: Vacuum, Fuse, oil reset, fuel tank capacity, Relay, torque, overdrive

Page 181 of 284

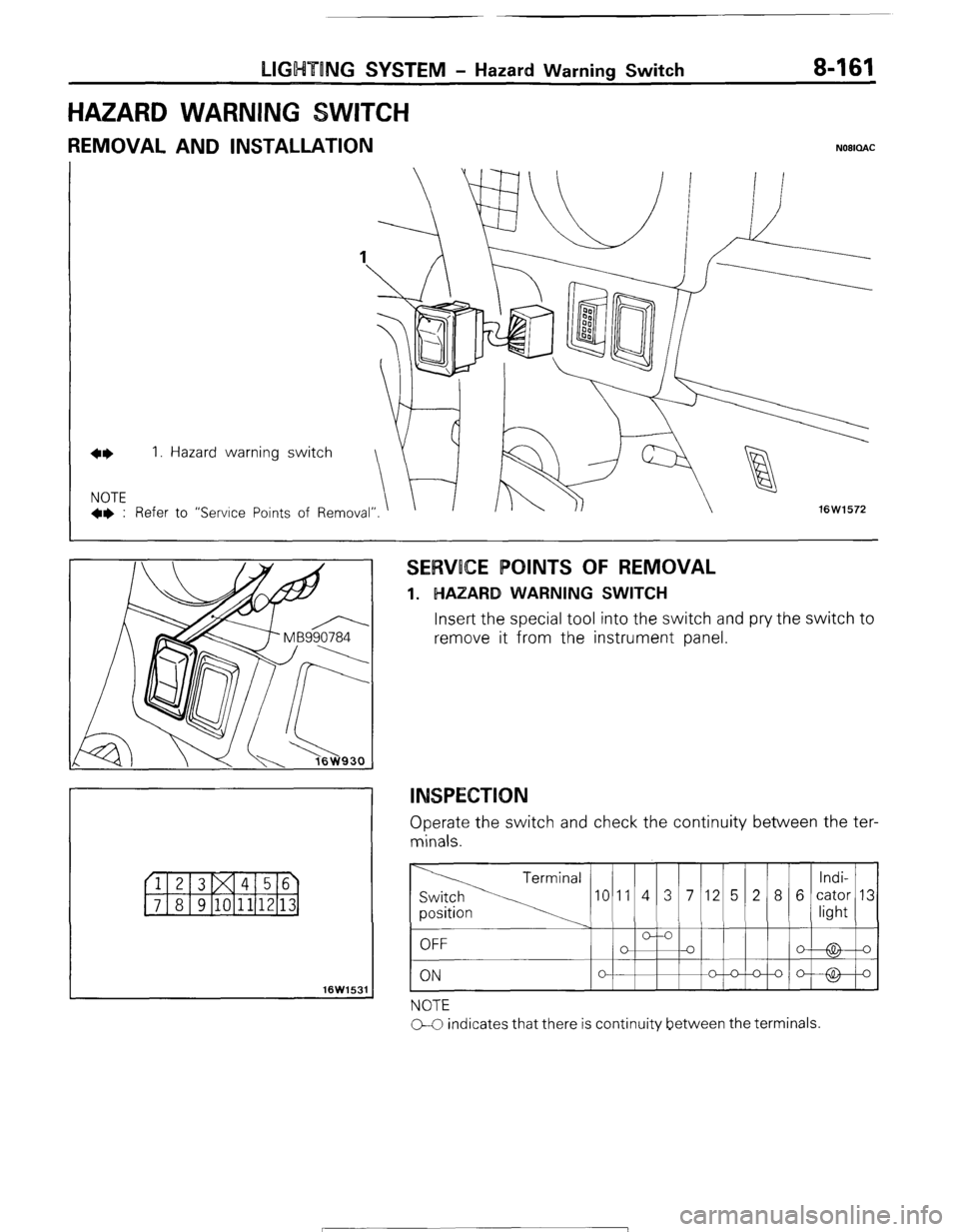

LIGHTING SYSTEM - Hazard Warning Switch 8-161

HAZARD WARNING

REMOVAL AND INSTALLATION NOBICLAC

16W1531

SERVOCE POINTS OF REMOVAL

1. HAZARD WARNING SWITCH

Insert the special tool into the switch and pry the switch to

remove it from the instrument panel.

INSPECTION

Operate the switch and check the continuity between the ter-

minals.

NOTE

CC indicates that there is continuity between the terminals.

STB Revision

Page 182 of 284

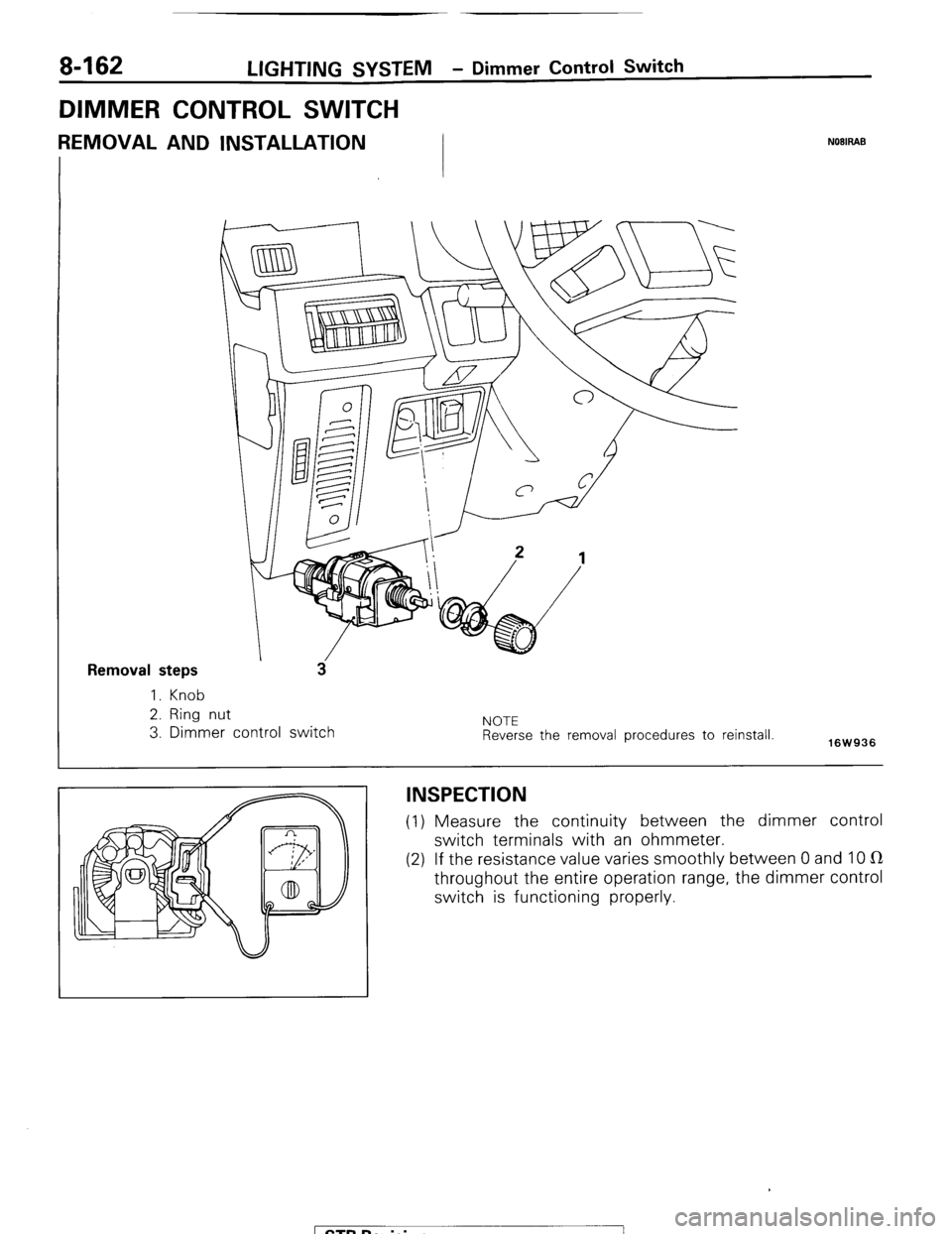

8-162 LIGHTING SYSTEM - Dimmer Control Switch

DIMMER CONTROL SWITCH

REMOVAL AND INSTALLATION NOBIRAB

Removal steps

1. Knob

2. Ring nut

3. Dimmer control switch NOTE

Reverse the removal procedures to reinstall.

16W936

INSPECTION

(1) Measure the continuity between the dimmer control

switch terminals with an ohmmeter.

(2) If the resistance value varies smoothly between 0 and 10 IR

throughout the entire operation range, the dimmer control

switch is functioning properly.

1 STB Revision

Page 183 of 284

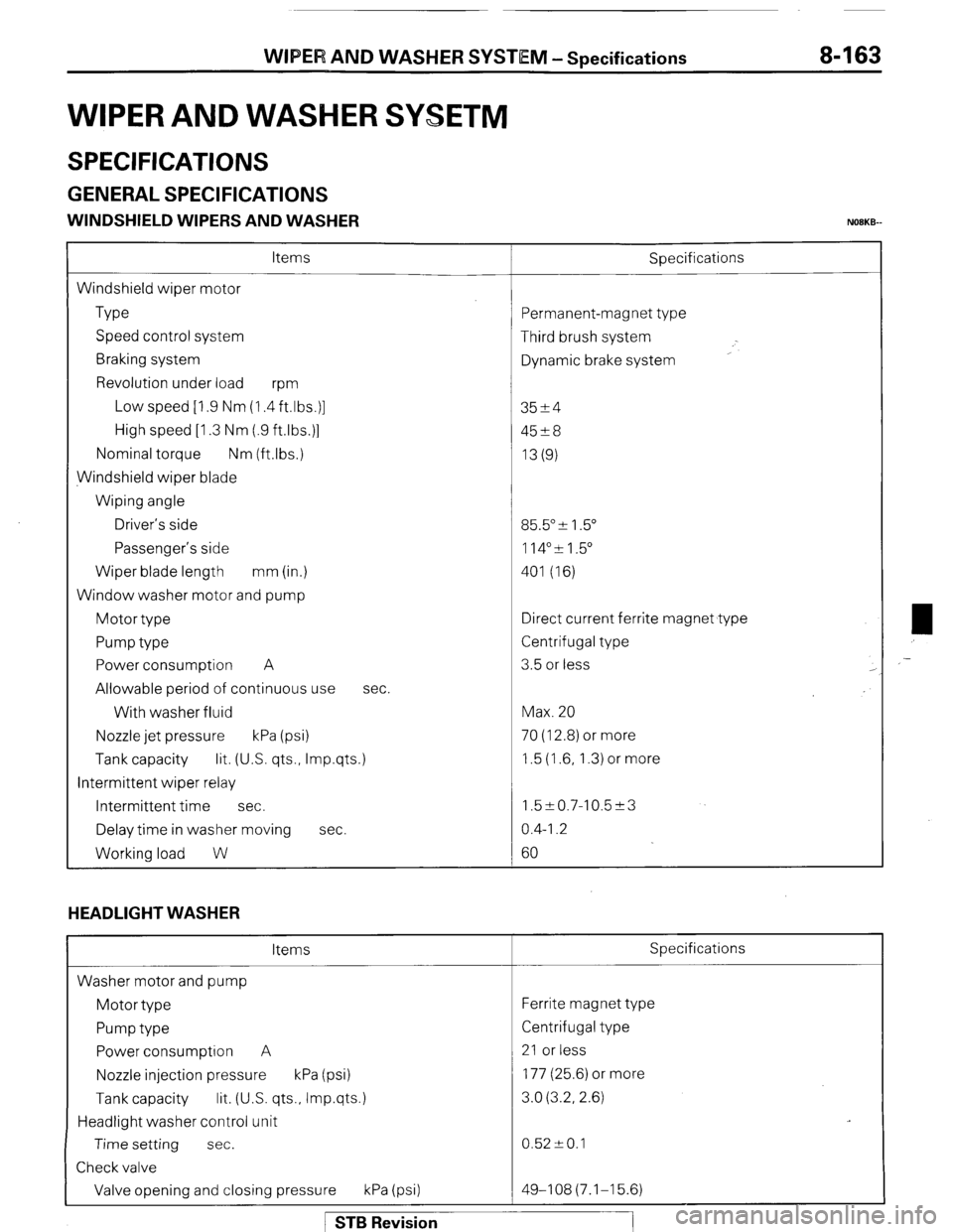

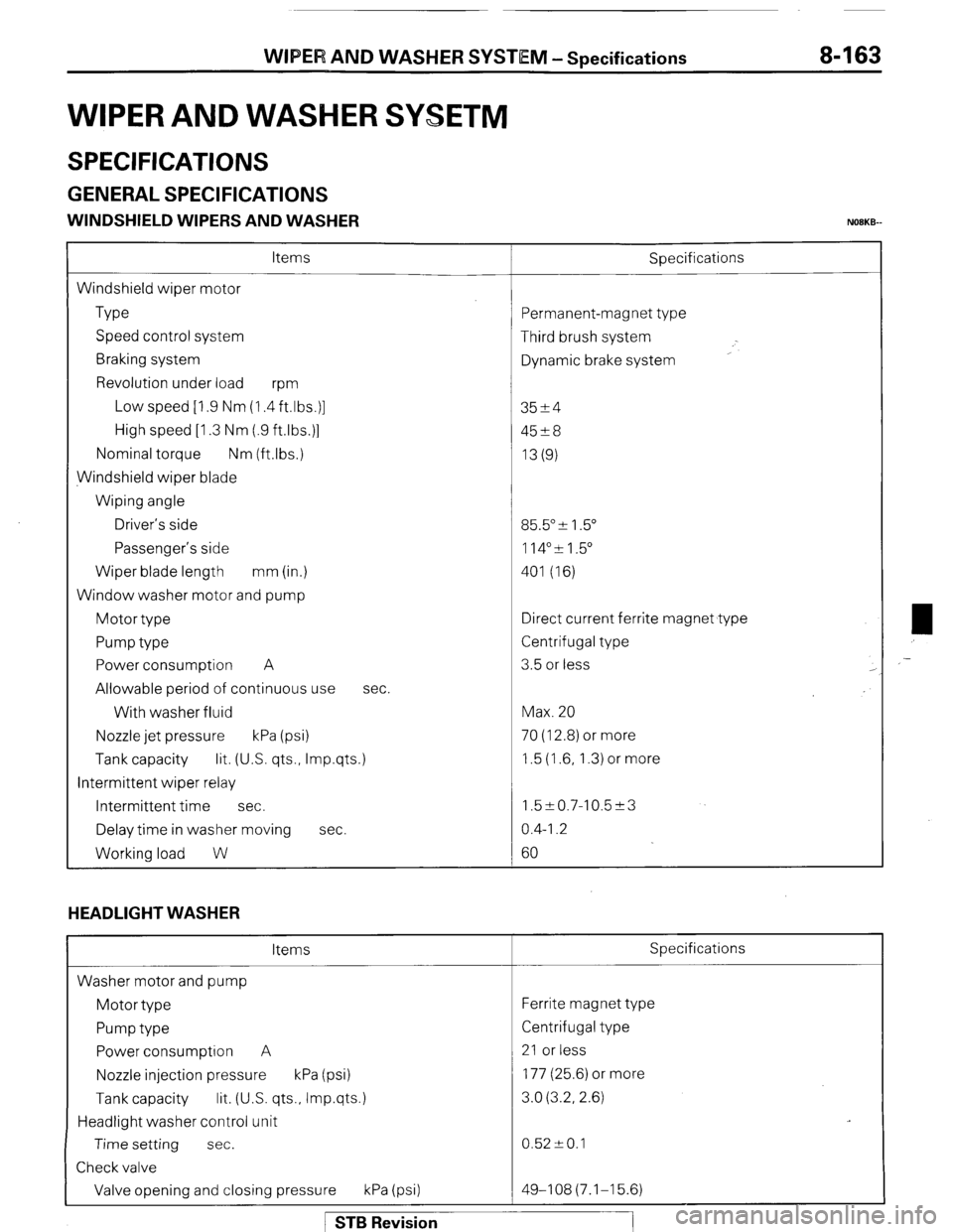

WIPER AND WASHER SYSTEM -Specifications 8-163

WIPER AND WASHER SYSETM

SPECIFICATIONS

GENERAL SPECIFICATIONS

WINDSHIELD WIPERS AND WASHER NOBKB-

Items

Windshield wiper motor

Type

Speed control system

Braking system

Revolution under load

wm

Low speed [I .9 Nm (1.4 ft.lbs.)]

High speed [I .3 Nm (.9 ftlbs.)]

Nominal torque Nm (ftlbs.)

Windshield wiper blade

Wiping angle

Driver’s side

Passenger’s side

Wiper blade length mm (in.)

Window washer motor and pump

Motor type

Pump type

Power consumption A

Allowable period of continuous use

With washer fluid

Nozzle jet pressure kPa (psi) Sbecifications

sec.

Tank capacity lit. (US. qts., Imp.qts.)

Intermittent wiper relay

Intermittent time sec.

Delay time in washer moving sec.

Working load W

HEADLIGHT WASHER

Items

Washer motor and pump

Motor type

Pump type

Power consumption A

Nozzle injection pressure kPa (psi)

Tank capacity lit. (U.S. qts., Imp.qts.)

Headlight washer control unit

Time setting sec.

Check valve

Valve opening and closing pressure kPa (psi) ‘ermanent-magnet type

Third brush system

Dynamic brake system

3524

45?8

13(g)

35.5” & 1.5”

114”51.5”

401 (16)

Iirect current ferrite magnet type

Zentrifugal type

3.5 or less

Max. 20

70 (12.8) or more

1.5 (1.6, 1.3) or more

1.5~0.7-10.5~3

0.4-I .2

60

Specifications

Ferrite magnet type

Centrifugal type

21 or less

177 (25.6) or more

3.0 (3.2, 2.6)

0.52 -+ 0.1

49-108(7.1-15.6) ,-

1 STB Revision

Page 184 of 284

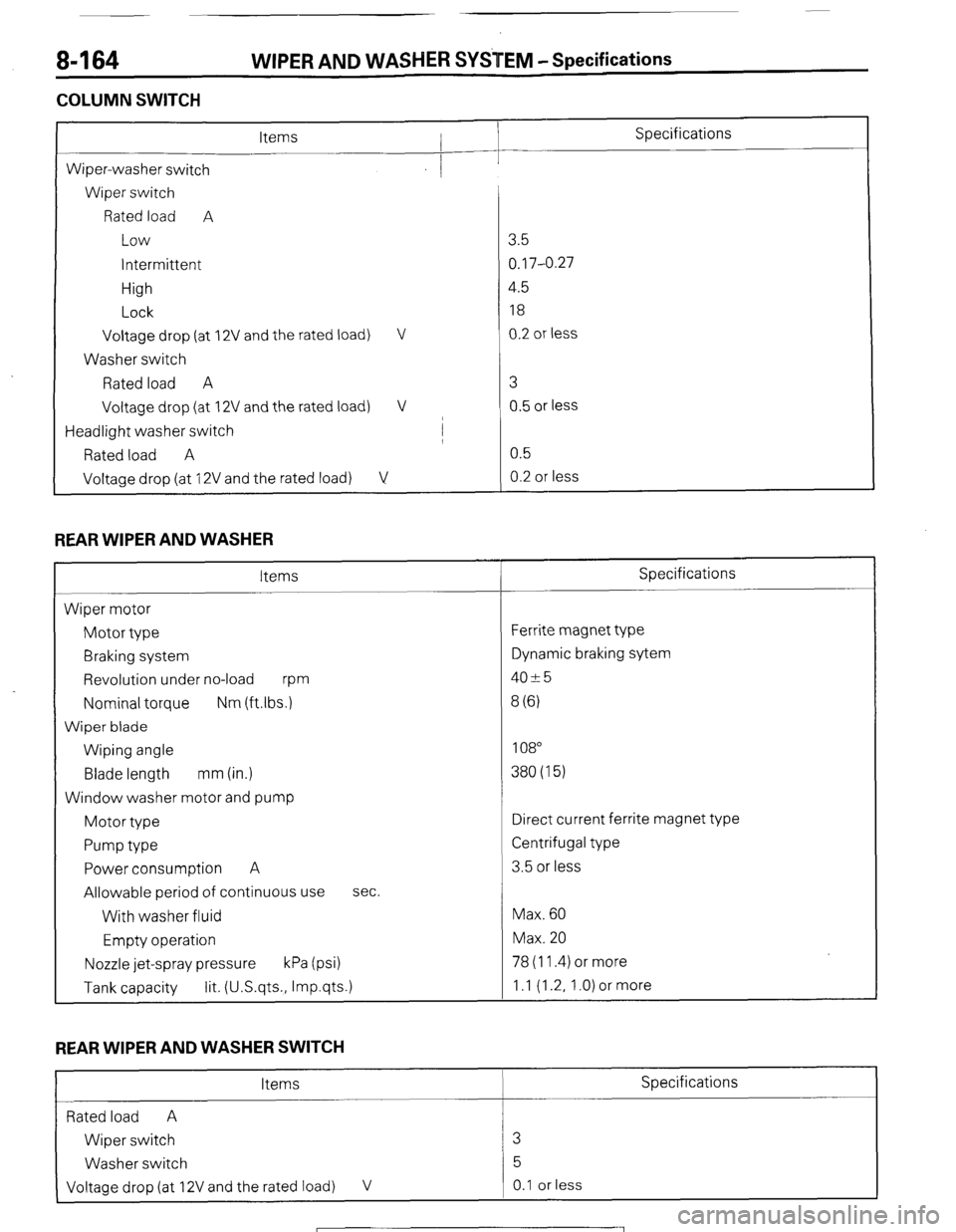

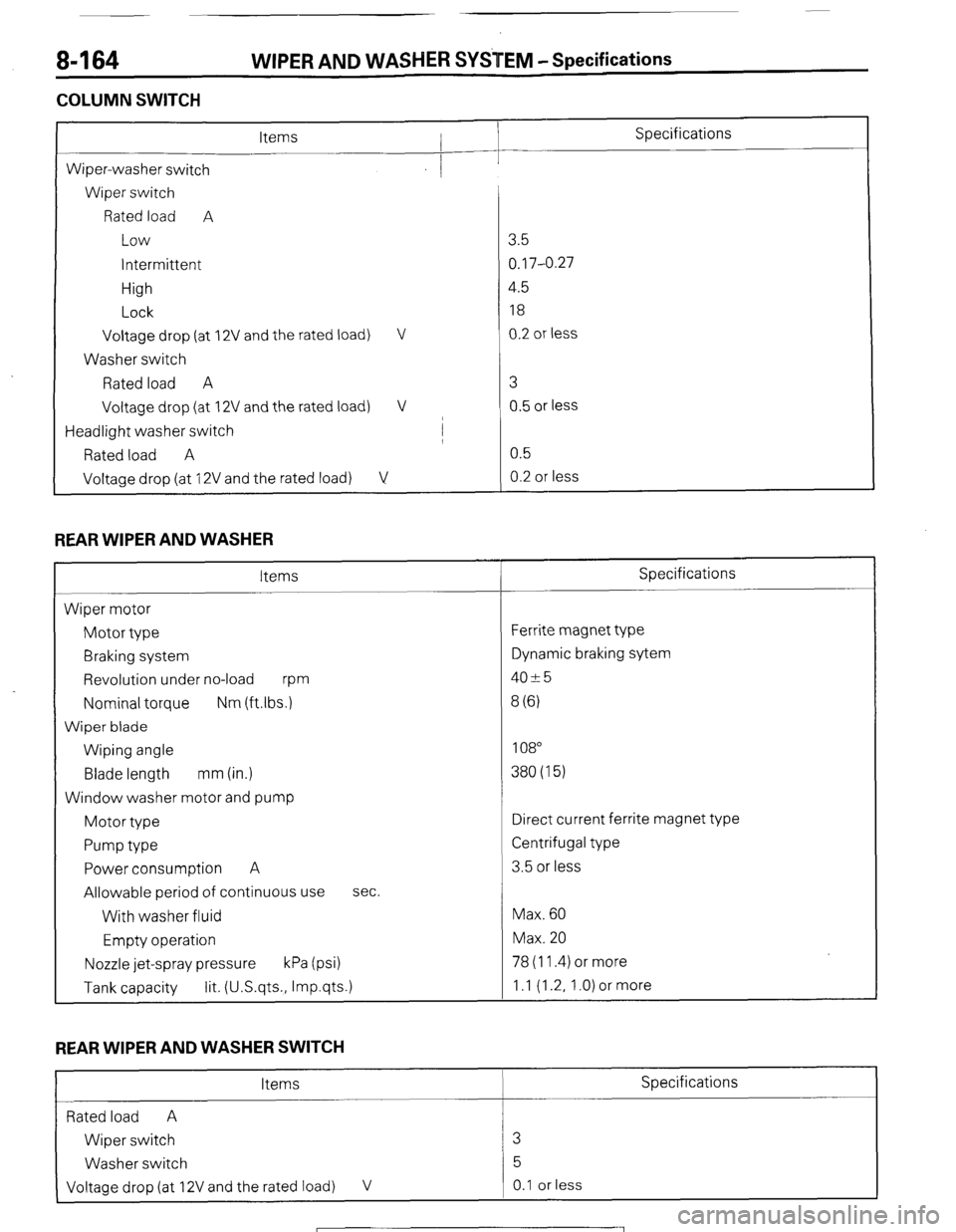

8-164 WIPER AND WASHER SYSTEM -Specifications

COLUMN SWITCH

L

Specifications

Wiper-washer switch

Wiper switch

Rated load A

Low

intermittent

High

Lock

Voltage drop (at

Washer switch

Rated load A

Voltage drop (at 2V and the rated load) V

2V and the rated load) V

/

Headlight washer switch I

Rated load A

Voltage drop (at 12V and the rated load) V

REAR WIPER AND WASHER

Items

Wiper motor

Motor type

Braking system

Revolution under no-load

m

Nominal torque Nm (ftlbs.)

Wiper blade

Wiping angle

Blade length mm (in.)

Window washer motor and pump

Motor type

Pump type

Power consumption A

Allowable period of continuous use

With washer fluid

Empty operation sec.

Nozzle jet-spray pressure kPa (psi) 78 (11.4) or more

Tank capacity lit. (U.S.qts., Imp.qts.) 1 .I (1.2, 1 .O) or more 3.5

0.17-0.27

4.5

18

0.2 or less

3

0.5 or less

0.5

0.2 or less

Specifications

Ferrite magnet type

Dynamic braking sytem

4025

8 (6)

108

380(15)

Direct current ferrite magnet type

Centrifugal type

3.5 or less

Max. 60

Max. 20

REAR WIPER AND WASHER SWITCH

Items Specifications

Rated load A

Wiper switch 3

Washer switch 5

Voltage drop (at 12V and the rated load) V 0.1 or less

1 STB Revision

Page 185 of 284

WIPER AND WASHER SYSETM - Specifications / Special TOOIS 8-165

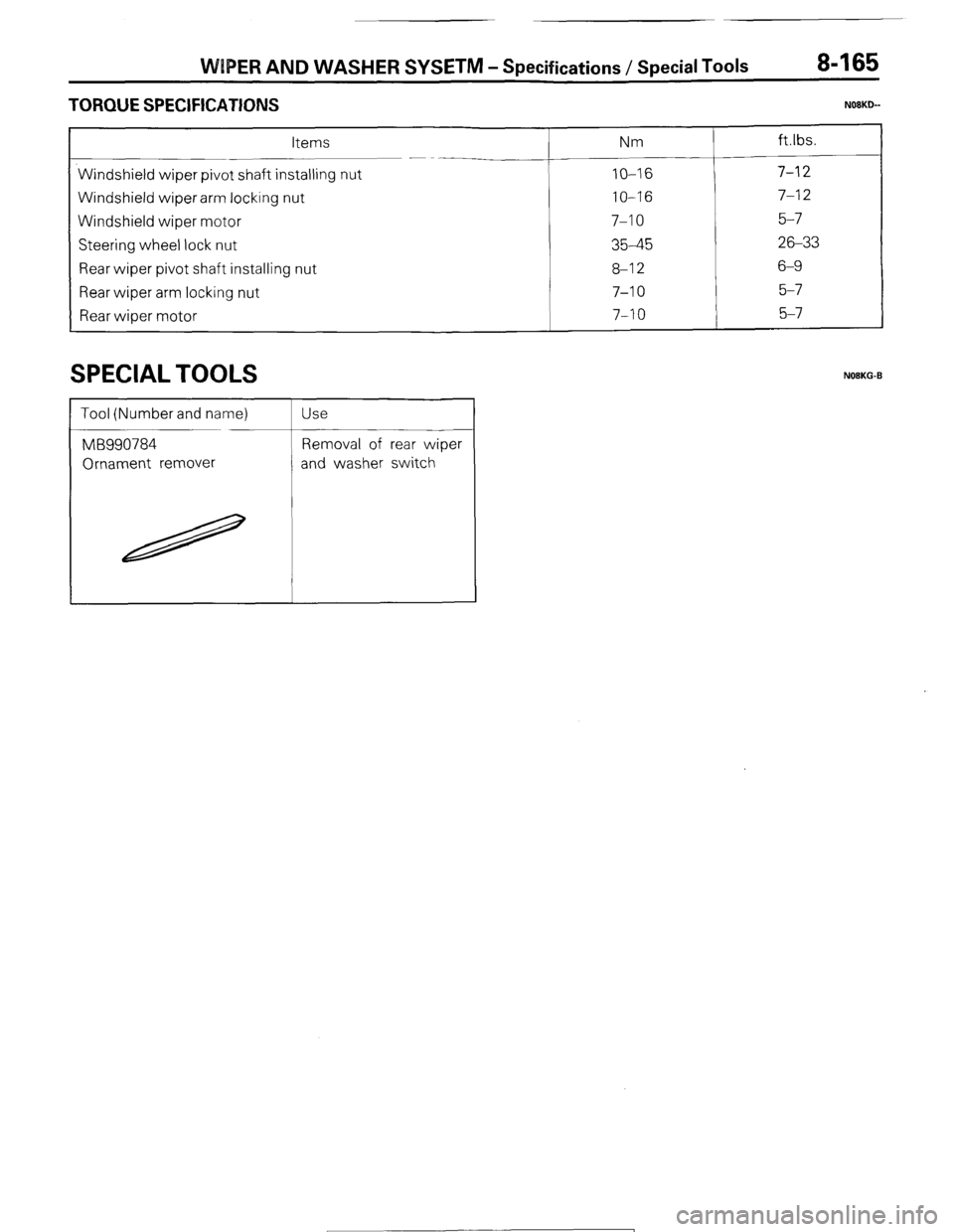

TORQUE SPECIFICATIONS N08KLb-

Items Nm

Windshield wiper pivot shaft installing nut

IO-16 Windshield wiper arm locking nut

IO-16 Windshield wiper motor

7-10 Steering wheel lock nut

35-45 Rear wiper pivot shaft installing nut

8-12 Rear wiper arm locking nut

7-10 Rear wioer motor

7-10

SPECIAL TOOLS NOEKG-B

1 STB Revision

Page 186 of 284

8-166 WIPER AND WASHER SYSTEM -Troubleshooting

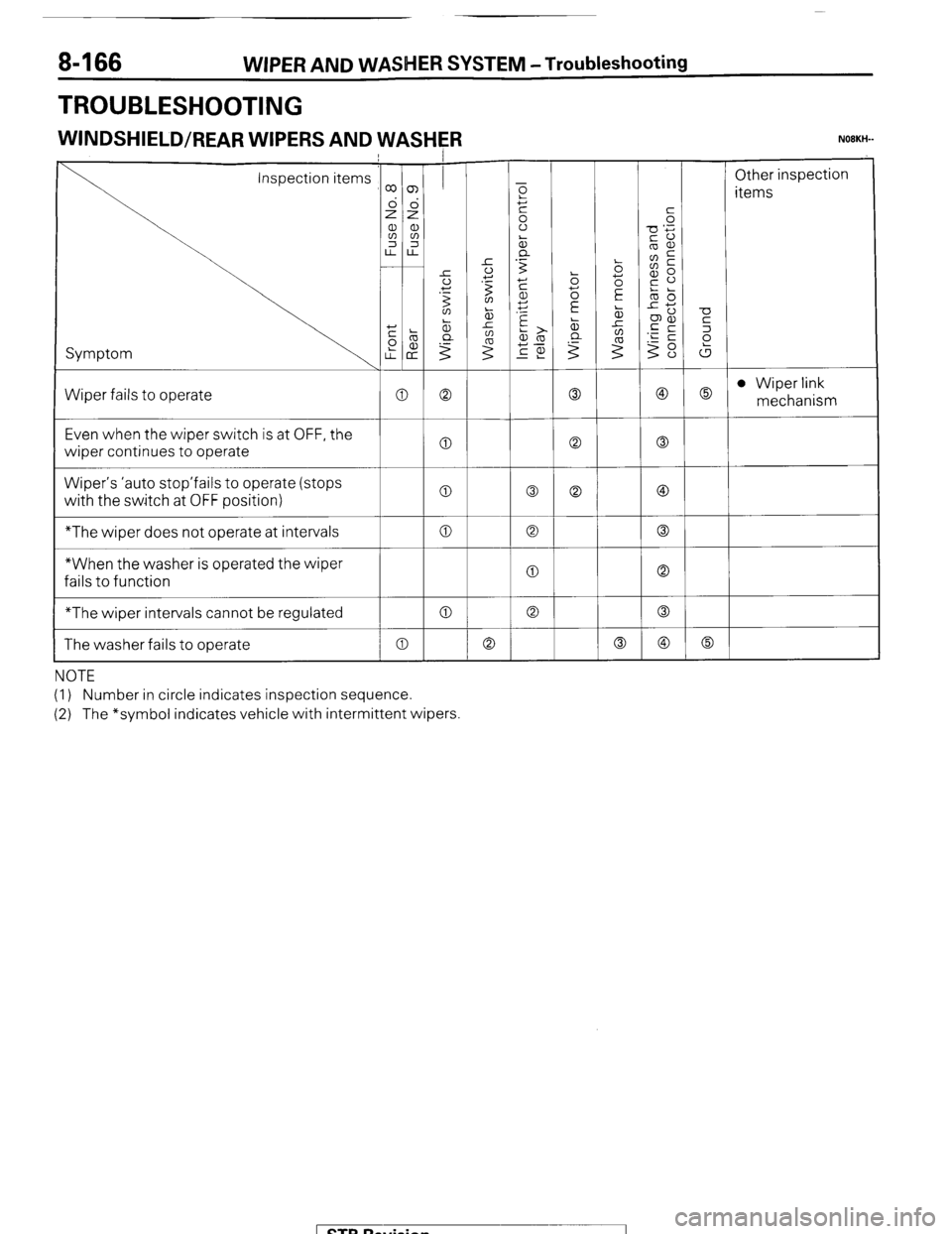

TROUBLESHOOTING

WINDSHIELD/REAR WIPERS AND WASHER N08KW

Symptom

Wiper fails to operate /

Inspection items co ~ Other inspectior

T items

2s +c

a, al E E

2 2 -0 ‘i;

&

Ll-LL

1 .-

1 0 ; 6%

Even when the wiper switch is at OFF, the

wiper continues to operate a 0 0

Wiper’s ‘auto stop’fails to operate (stops

vyith the switch at OFF position) 0 0 0 @

*The wiper does not operate at intervals 0 0 0

*When the washer is operated the wiper

fails to function 0 0

*The wiper intervals cannot be regulated 0 0 0

The washer fails to operate 0 0 0 @ 0

NOTE

(1) Number in circle indicates inspection sequence.

(2) The *symbol indicates vehicle with intermittent wipers

1 STB Revision

-7

Page 187 of 284

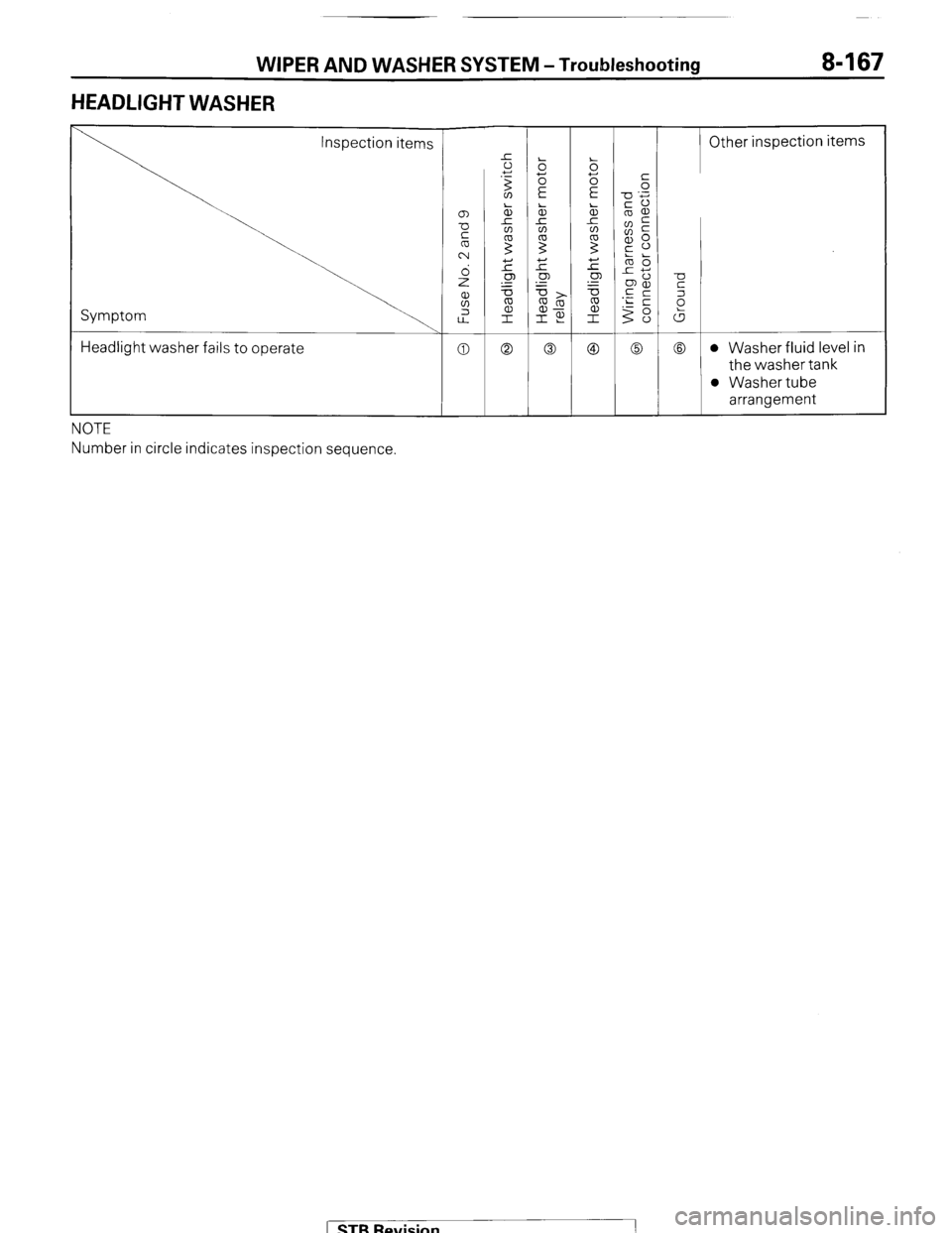

WIPER AND WASHER SYSTEM -Troubleshooting 8-167

HEADLIGHT WASHER

Inspection items

Symptom

Headlight washer fails to operate

NOTE

Number in circle indicates inspection sequence. -

Other inspection items

1 STB Revision

Page 188 of 284

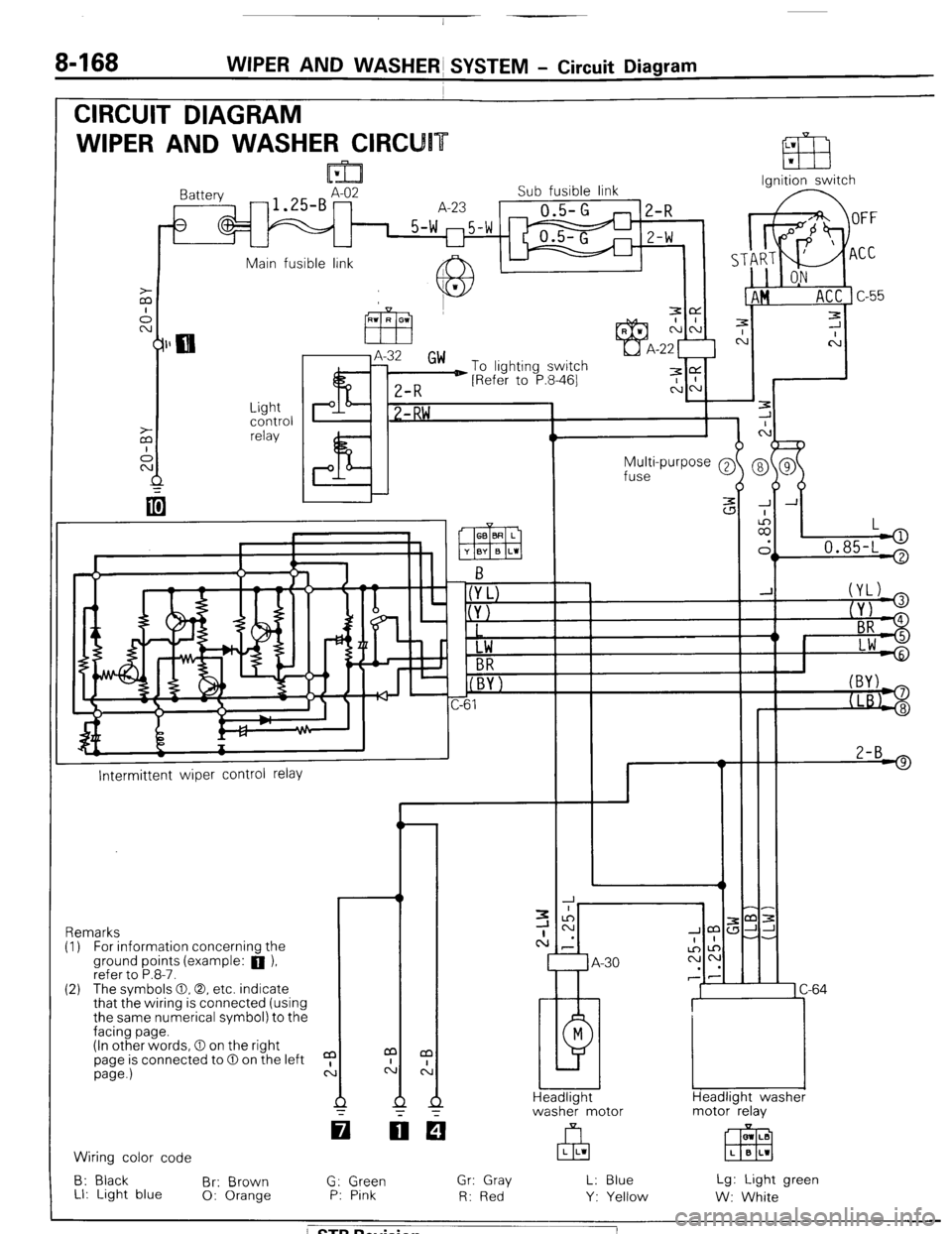

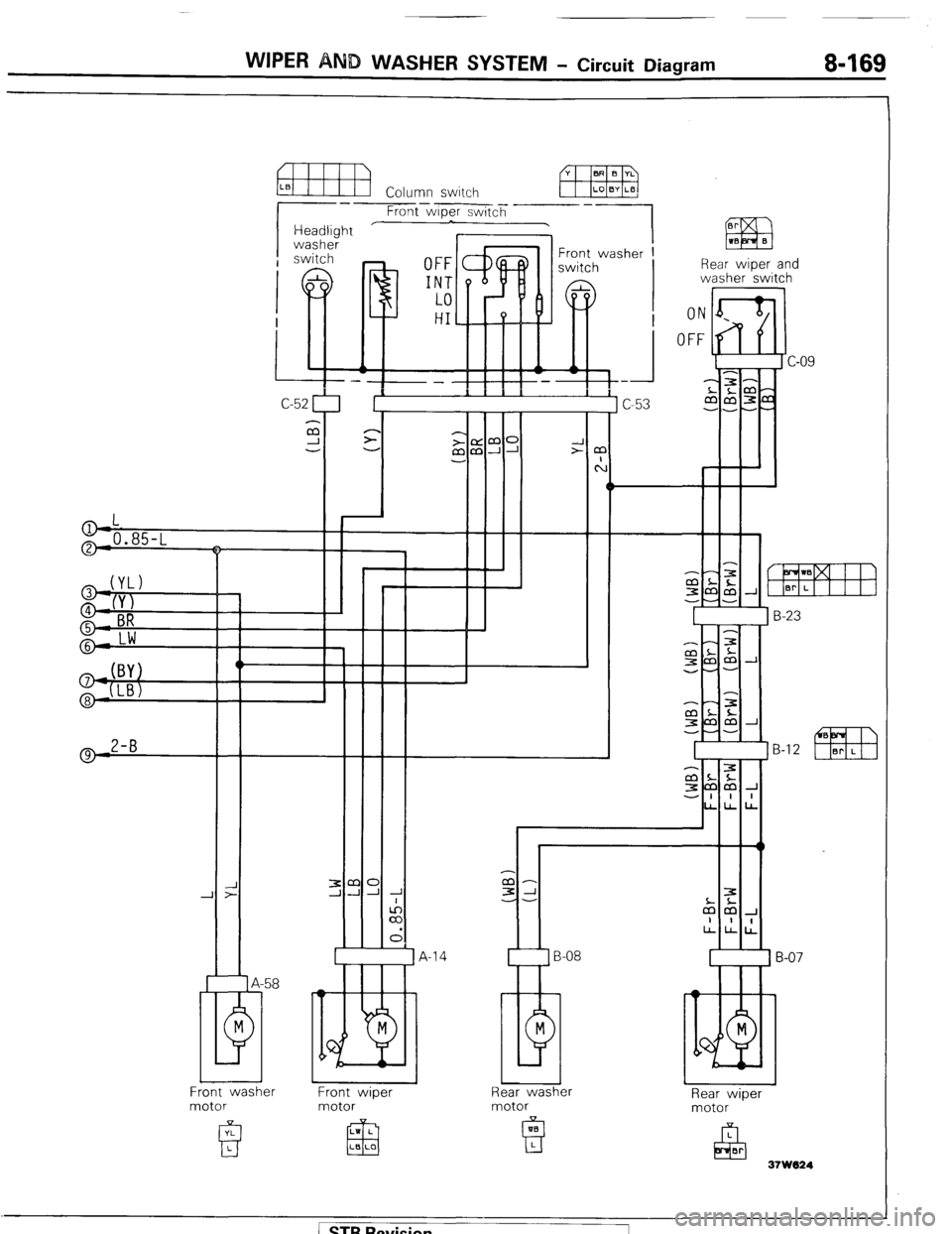

8468 WIPER AND WASHERS SYSTEM - Circuit Diagram

CIRCUIT DIAGRAM

WIPER AND WASHER CIRCU

Ignition switch

lattery

-1.SBAz2 Sub fusible link

A-23

0.5-G

1 5-w m5-w

U

2-R

Z-W

Main fusible link A IL

J.

c

7

C

-

-

-

-

-

-

J A

:

II,

L

.

> 0.85-L '

Light

control

relay P I? 1 -RW ,

Multi-purpose @

fuse

2-B 9

I--

Intermittent wiper control relay

-r ,m:

JJ-

-.

1 C-64

Headlight washer

motor relay Remarks

(I) For information concernina the

ground points (example: a ),

refer to P.8-7.

(2) The svmbols 0.0. etc. indicate

that the wiring is connected (using

the same numerical symbol) to the

facing page.

(In other words, 0 on the right

page is connected to 0 on the left

page.)

a

c: m LB

EEEI L B L1 Wiring color code

B: Black

Br: Brown

LI: Light blue 0: Orange G: Green

P: Pink Gr: Gray

R: Red L: Blue

Y: Yellow Lg: Light green

W: White

/ STB Revision

Page 189 of 284

WIPER AND WASHER SYSTEM - Circuit Diagram 8469

m Column switch -- Front-koer switch -1

Rear wiper and

washer switch

r I Headlight

washer

switch

o-(YL)

@JYJ

(+ BR

@- Lw

L B-l 2

w2-B

! )

1

L

(

7 A-14

1 B-07

81

M

A-58

>

1

GE&washer I

Rear wiper Front washer

motor Front wiper

motor motor

motor

37W124

/ STB Revision

Page 190 of 284

8-170 WIPER AND WASHER SYSTEM - Service Adjustment Procedures

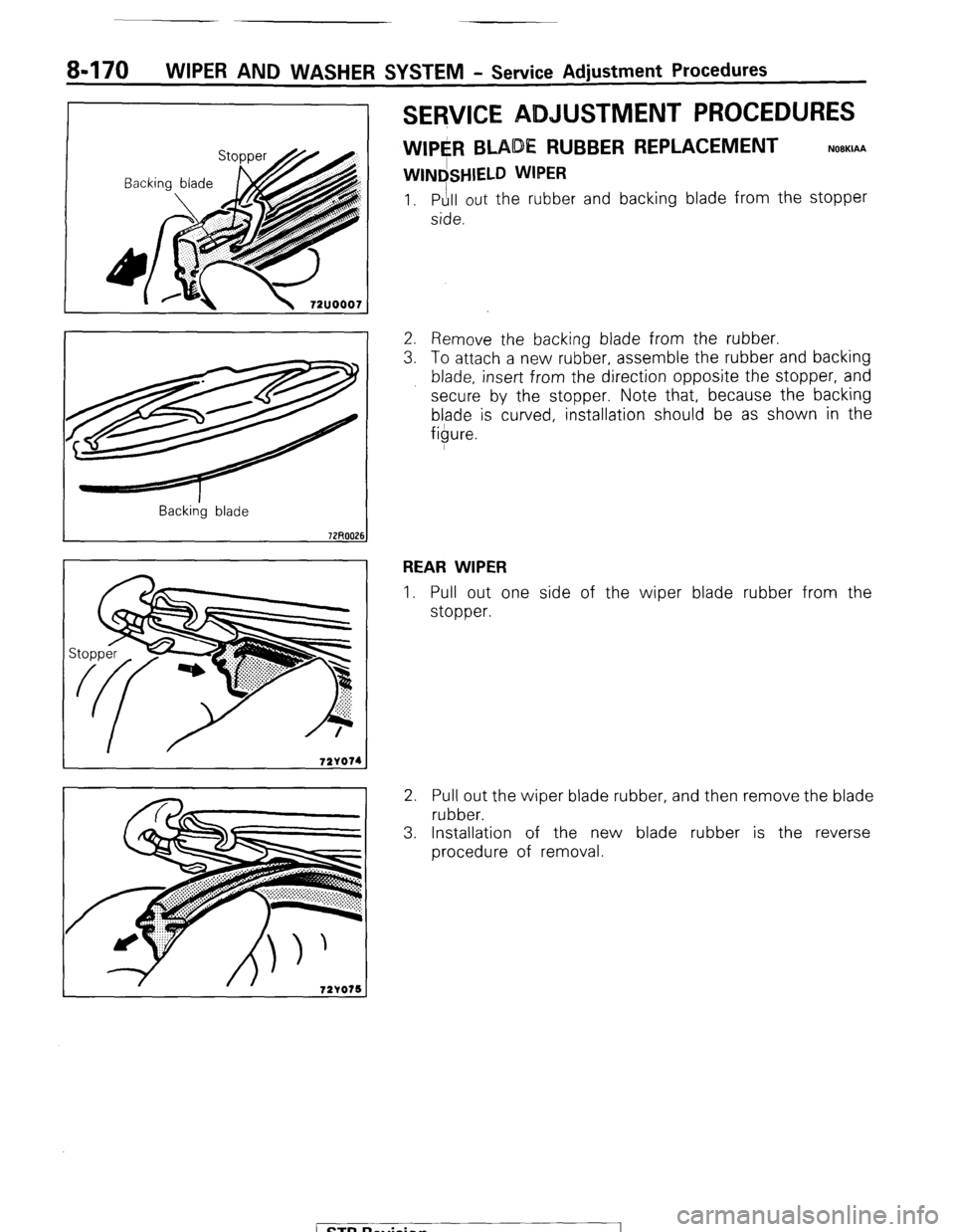

SERVICE ADJUSTMENT PROCEDURES

WIPE#l BLADE RUBBER REPLACEMENT

WINdSHIELD WIPER

NOBKIAA

1. Pull out the rubber and backing blade from the stopper

side.

Back&g blade

2. Remove the backing blade from the rubber.

3. To attach a new rubber, assemble the rubber and backing

blade, insert from the direction opposite the stopper, and

secure by the stopper. Note that, because the backing

blade is curved, installation should be as shown in the

figure.

REAR WIPER

1. Pull out one side of the wiper blade rubber from the

stopper.

2. Pull out the wiper blade rubber, and then remove the blade

rubber.

3. Installation of the new blade rubber is the reverse

procedure of removal.

( ST6 Revision

Trending: reset, wiring, hazard flasher unit, jump start, radiator cap, instrument panel, 4WD