MITSUBISHI SPYDER 1990 Service Repair Manual

SPYDER 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57345/w960_57345-0.png

MITSUBISHI SPYDER 1990 Service Repair Manual

Trending: lights, air suspension, hood open, spark plugs, seat adjustment, MPG, service schedule

Page 1431 of 2103

AUTOMATIC TRANSAXLE OVERHAUL

Guide bracketI

Split sleeve

.

bracket anchor

ide

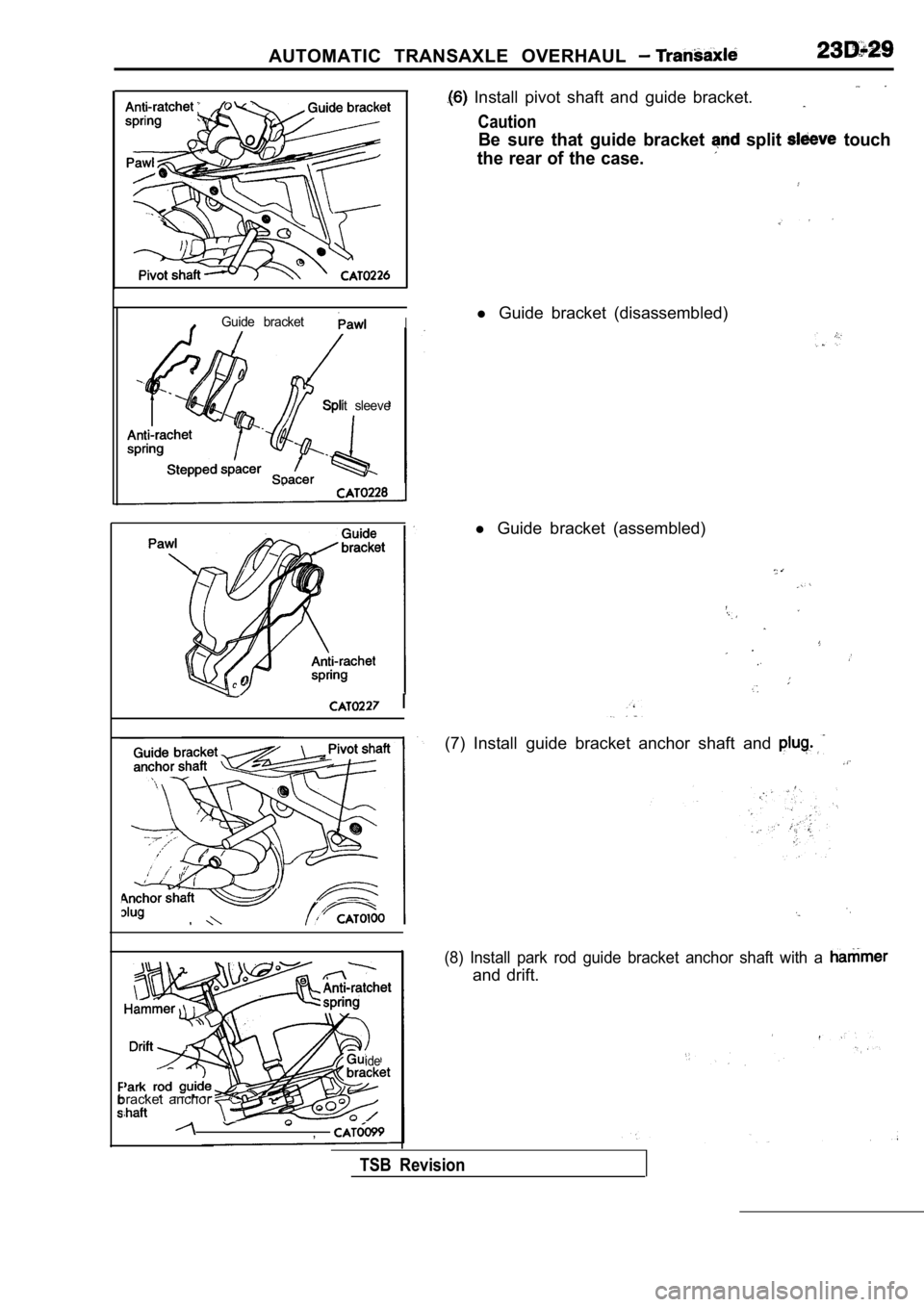

Install pivot shaft and guide bracket.

Caution

Be sure that guide bracket split touch

the rear of the case.

l Guide bracket (disassembled)

l Guide bracket (assembled)

(7) Install guide bracket anchor shaft and

(8) Install park rod guide bracket anchor shaft wit h a

and drift.

,

TSB Revision

Page 1432 of 2103

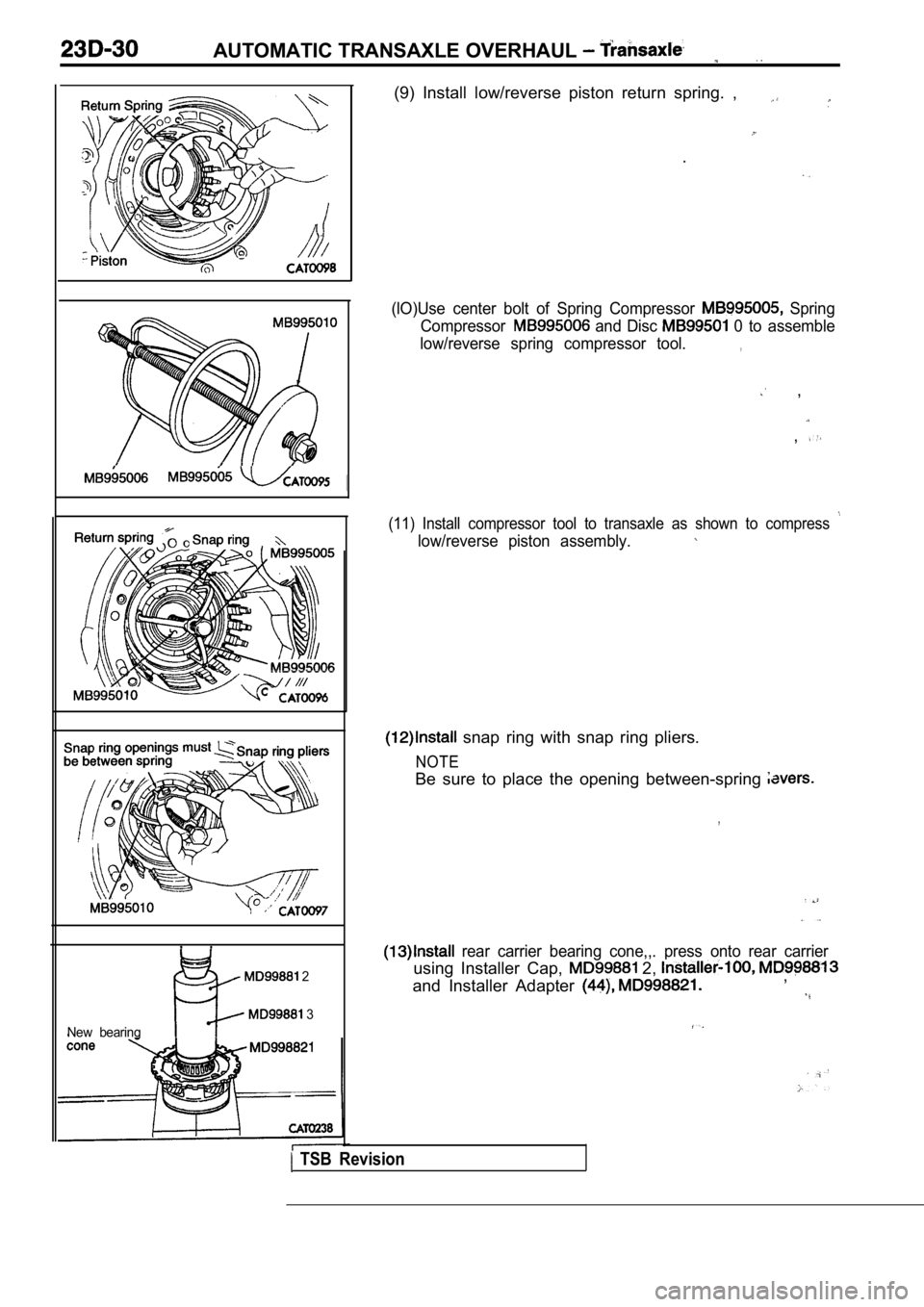

(lO)Use center bolt of Spring Compressor Spring

Compressor

and Disc 0 to assemble

low/reverse spring compressor tool.

,

,

,

(11) Install compressor tool to transaxle as shown to compress

low/reverse piston assembly.

AUTOMATIC TRANSAXLE OVERHAUL

(9) Install low/reverse piston return spring. ,

.

snap ring with snap ring pliers.

NOTE

Be sure to place the opening between-spring

,

rear carrier bearing cone,,. press onto rear carrier

2using Installer Cap, 2,

and Installer Adapter ,

3

New bearing

TSB Revision

Page 1433 of 2103

AUTOMATIC TRANSAXLE OVERHAUL .

I

4

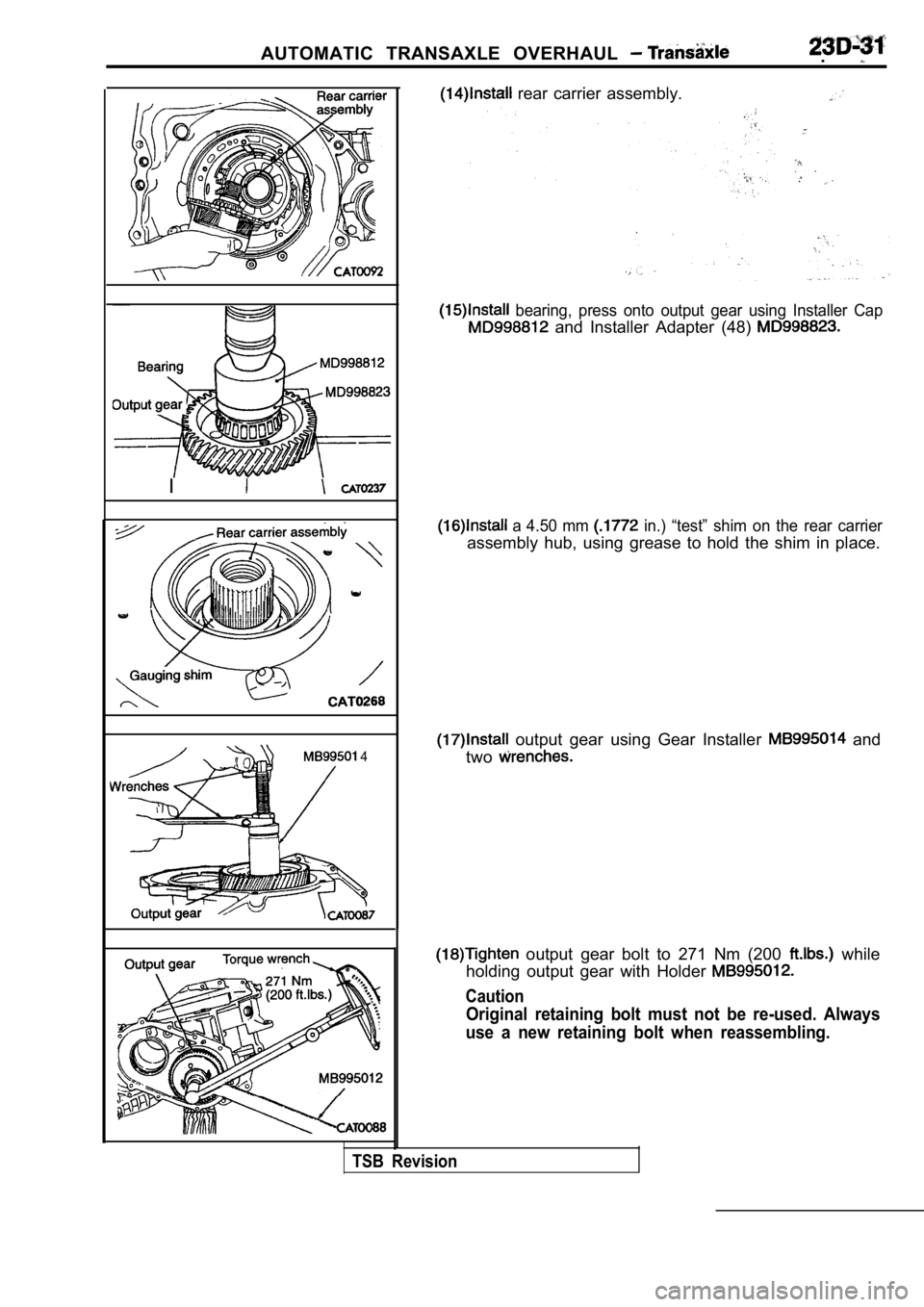

rear carrier assembly.

bearing, press onto output gear using Installer Cap

and Installer Adapter (48)

a 4.50 mm in.) “test” shim on the rear carrier

assembly hub, using grease to hold the shim in plac e.

output gear using Gear Installer and

two

output gear bolt to 271 Nm (200 while

holding output gear with Holder

Caution

Original retaining bolt must not be re-used. Always

use a new retaining bolt when reassembling.

TSB Revision

Page 1434 of 2103

AUTOMATIC TRANSAXLE OVERHAUL

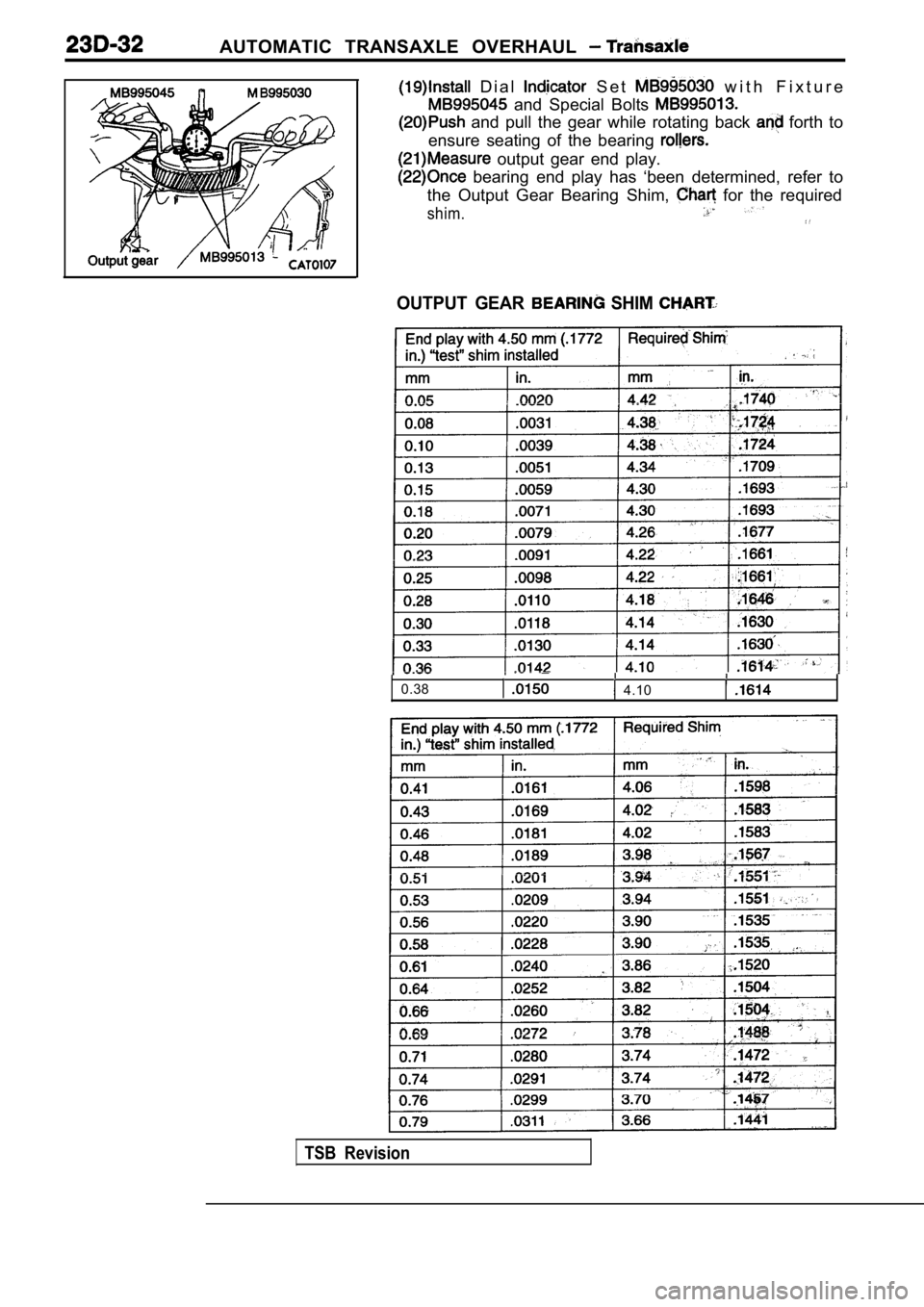

D i a l S e t w i t h F i x t u r e

and Special Bolts

and pull the gear while rotating back forth to

ensure seating of the bearing

output gear end play.

bearing end play has ‘been determined, refer to

the Output Gear Bearing Shim,

for the required

shim.

OUTPUT GEAR SHIM

0.384.10

TSB Revision

Page 1435 of 2103

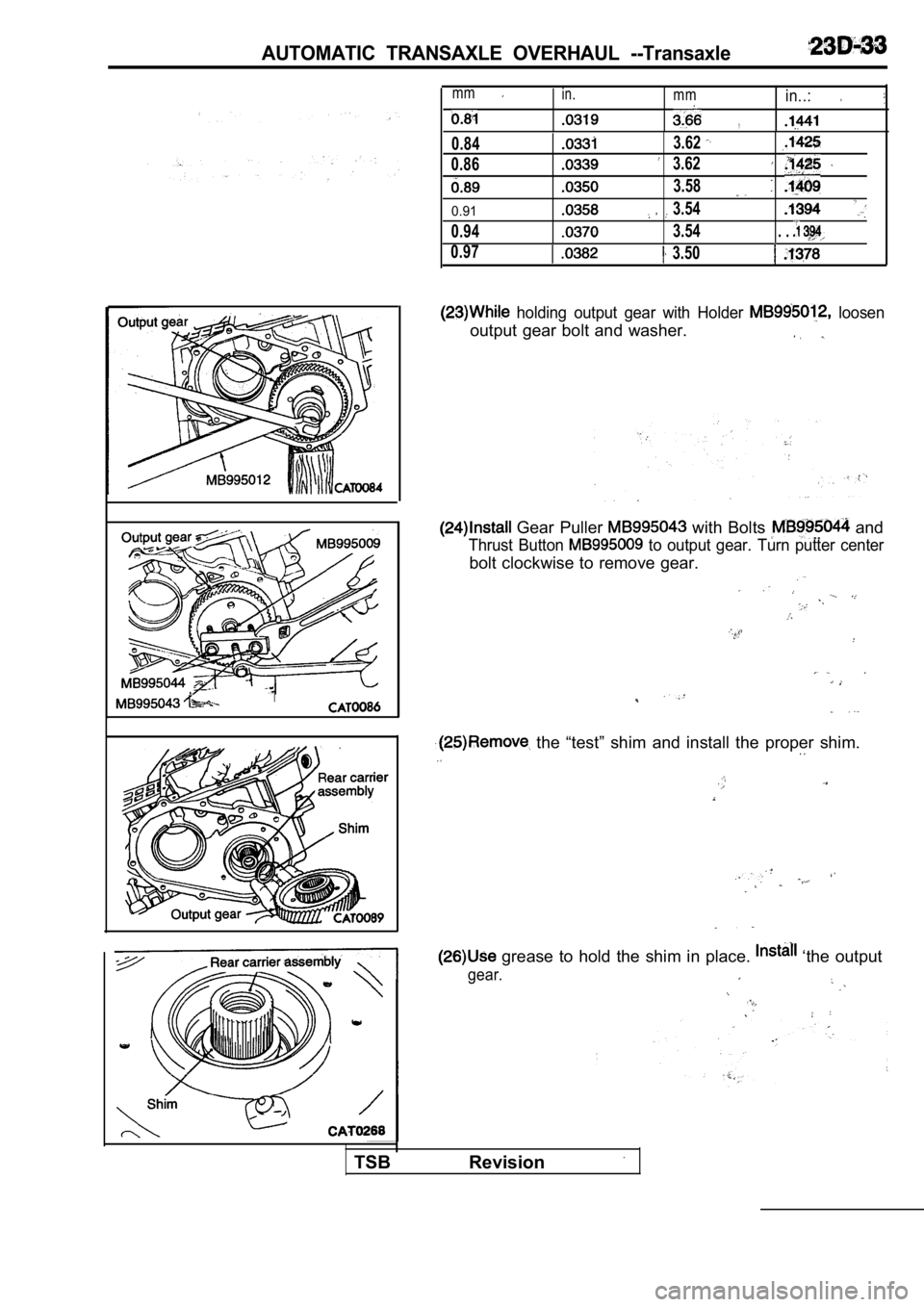

AUTOMATIC TRANSAXLE OVERHAUL --Transaxle

I

mmin.in..:m m

,

0.843.62

0.863.62

3.58

0.91.3.54

0.943.54. .

0.973.50

holding output gear with Holder loosen

output gear bolt and washer.

Gear Puller with Bolts and

Thrust Button to output gear. Turn putter center

bolt clockwise to remove gear.

the “test” shim and install the proper shim.. .

grease to hold the shim in place. ‘the output

gear.

TSB Revision

Page 1436 of 2103

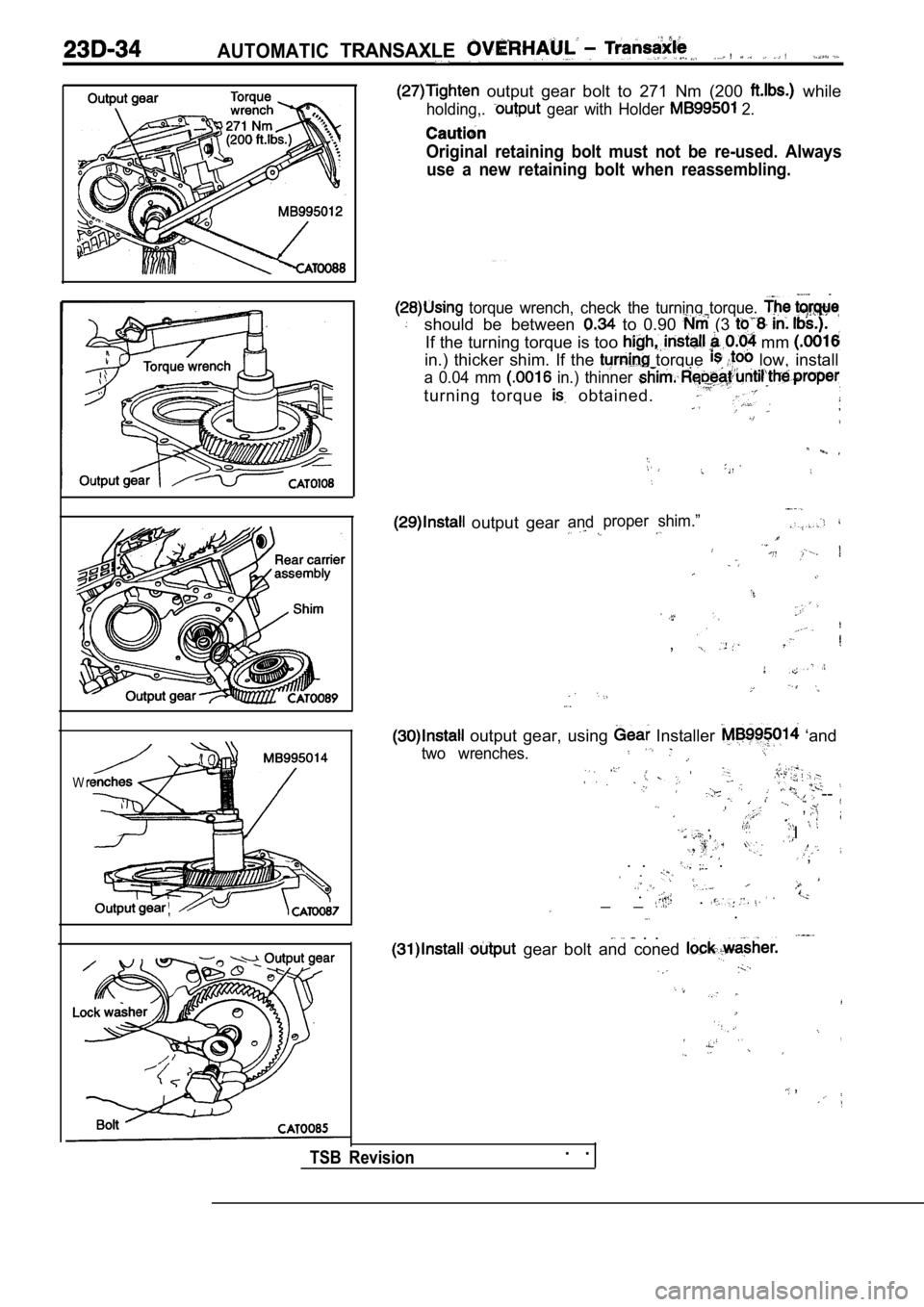

AUTOMATICTRANSAXLE,,

W r

output gear bolt to 271 Nm (200 while

holding,. gear with Holder 2.

Original retaining bolt must not be re-used. Alwaysuse a new retaining bolt when reassembling.

torque wrench, check the turning torque.

should be between to 0.90 (3

If the turning torque is too mm

in.) thicker shim. If the torque low, install

a 0.04 mm in.) thinner

turning torque obtained.

output gearand

TSB Revision. .

proper shim.”

,

output gear, using Installer ‘and

two wrenches.

-- ,

. ,I

. . , .

.

_ _..

. .

gear bolt and coned

,

,

Page 1437 of 2103

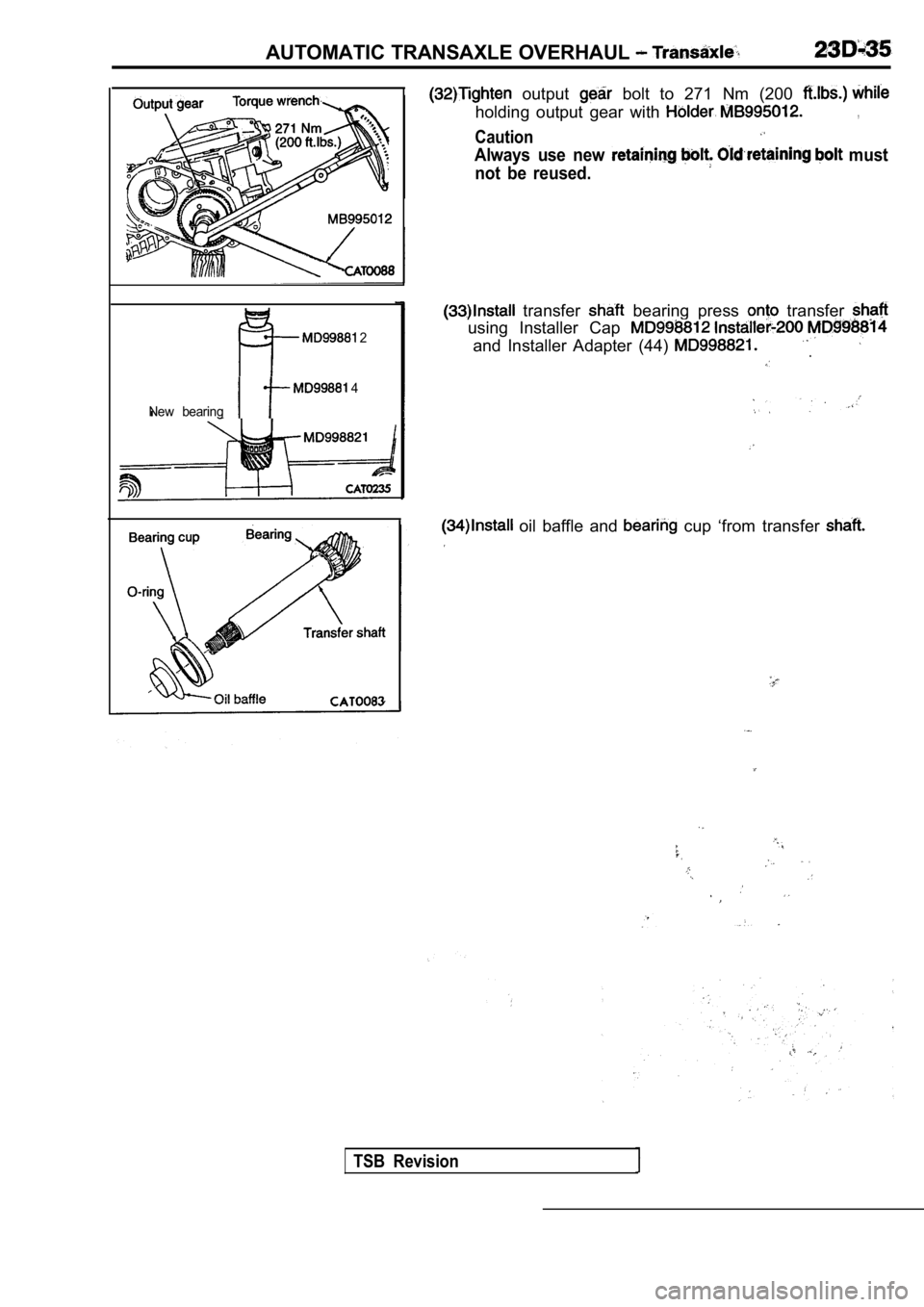

AUTOMATIC TRANSAXLE OVERHAUL

2

4

New bearing

output bolt to 271 Nm (200

holding output gear with ,

Caution

Always use new must

not be reused.

transfer bearing press transfer

using Installer Cap

and Installer Adapter (44) .

oil baffle and cup ‘from transfer

TSB Revision

Page 1438 of 2103

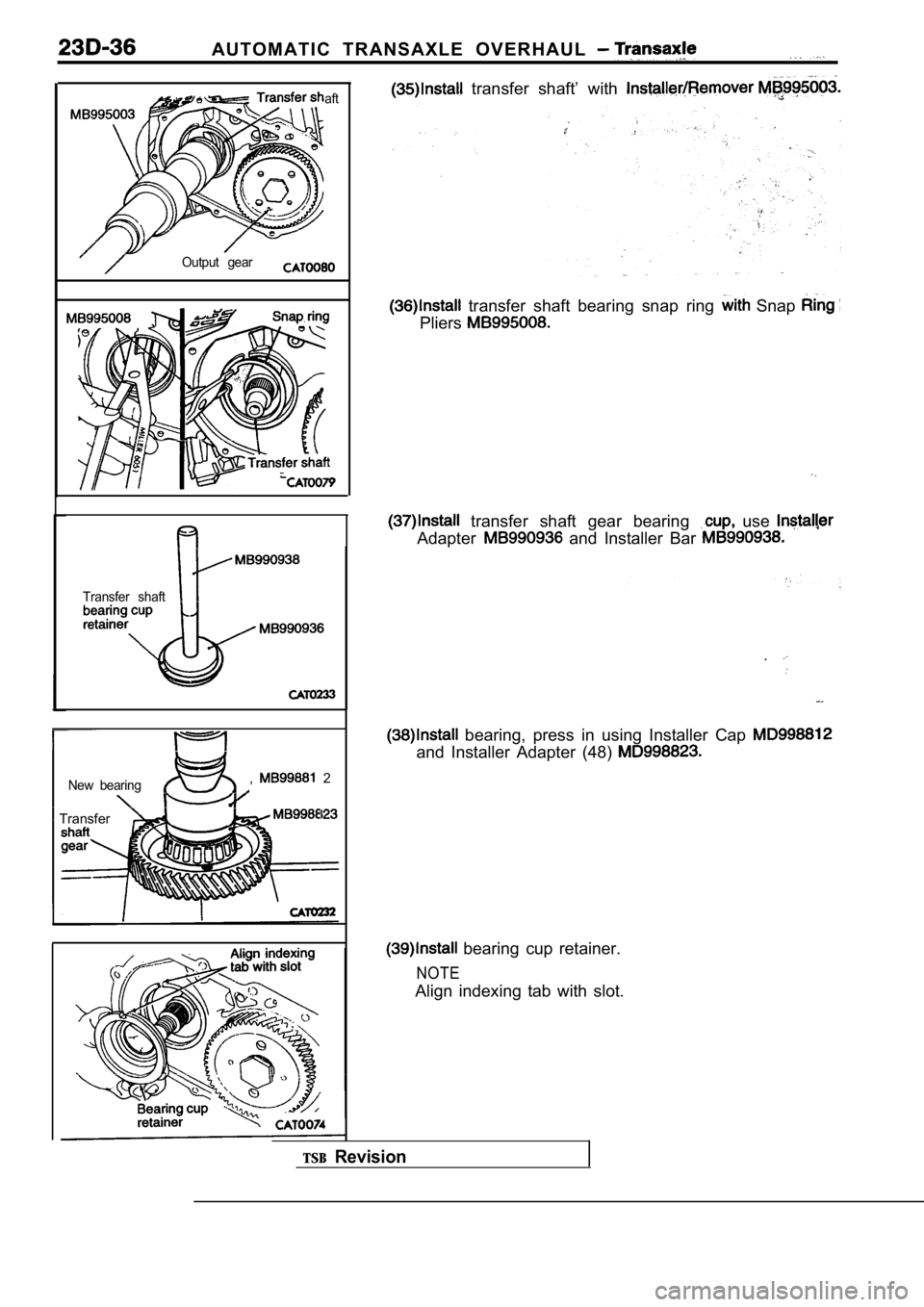

A U T O M A T I C T R A N S A X L E O V E R H A U L

aft

Output gear

Transfer shaft

New bearing, 2

Transfer

transfer shaft’ with

transfer shaft bearing snap ring Snap

Pliers

transfer shaft gear bearing use

Adapter and Installer Bar

bearing, press in using Installer Cap

and Installer Adapter (48)

bearing cup retainer.

NOTE

Align indexing tab with slot.

TSBRevision

Page 1439 of 2103

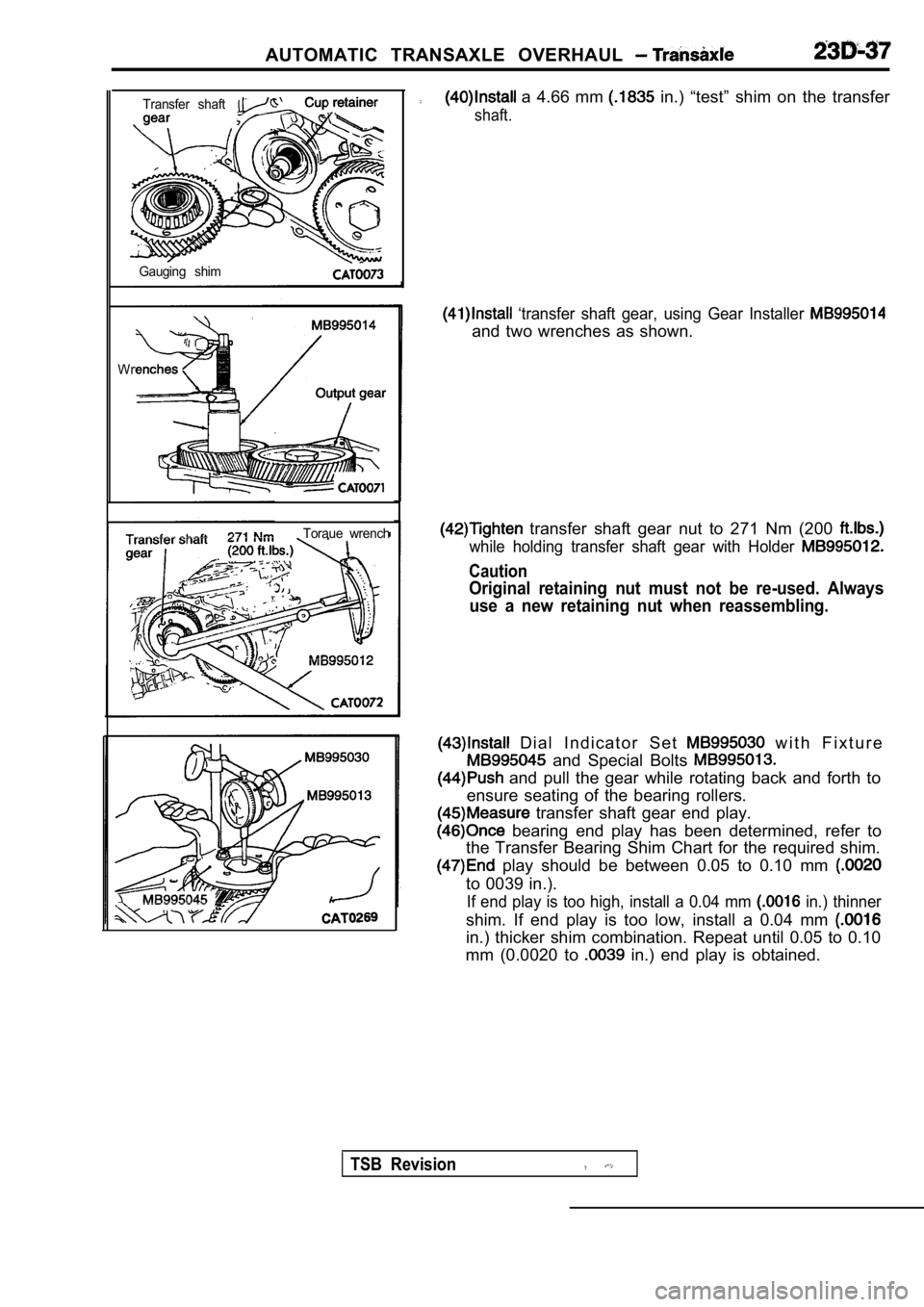

AUTOMATIC TRANSAXLE OVERHAUL

Transfer shaft

Gauging shim

Wr Toraue wrench

a 4.66 mm in.) “test” shim on the transfer

shaft.

‘transfer shaft gear, using Gear Installer

and two wrenches as shown.

transfer shaft gear nut to 271 Nm (200

while holding transfer shaft gear with Holder

Caution

Original retaining nut must not be re-used. Alwaysuse a new retaining nut when reassembling.

D i a l I n d i c a t o r S e t w i t h F i x t u r e

and Special Bolts

and pull the gear while rotating back and forth to

ensure seating of the bearing rollers.

transfer shaft gear end play.

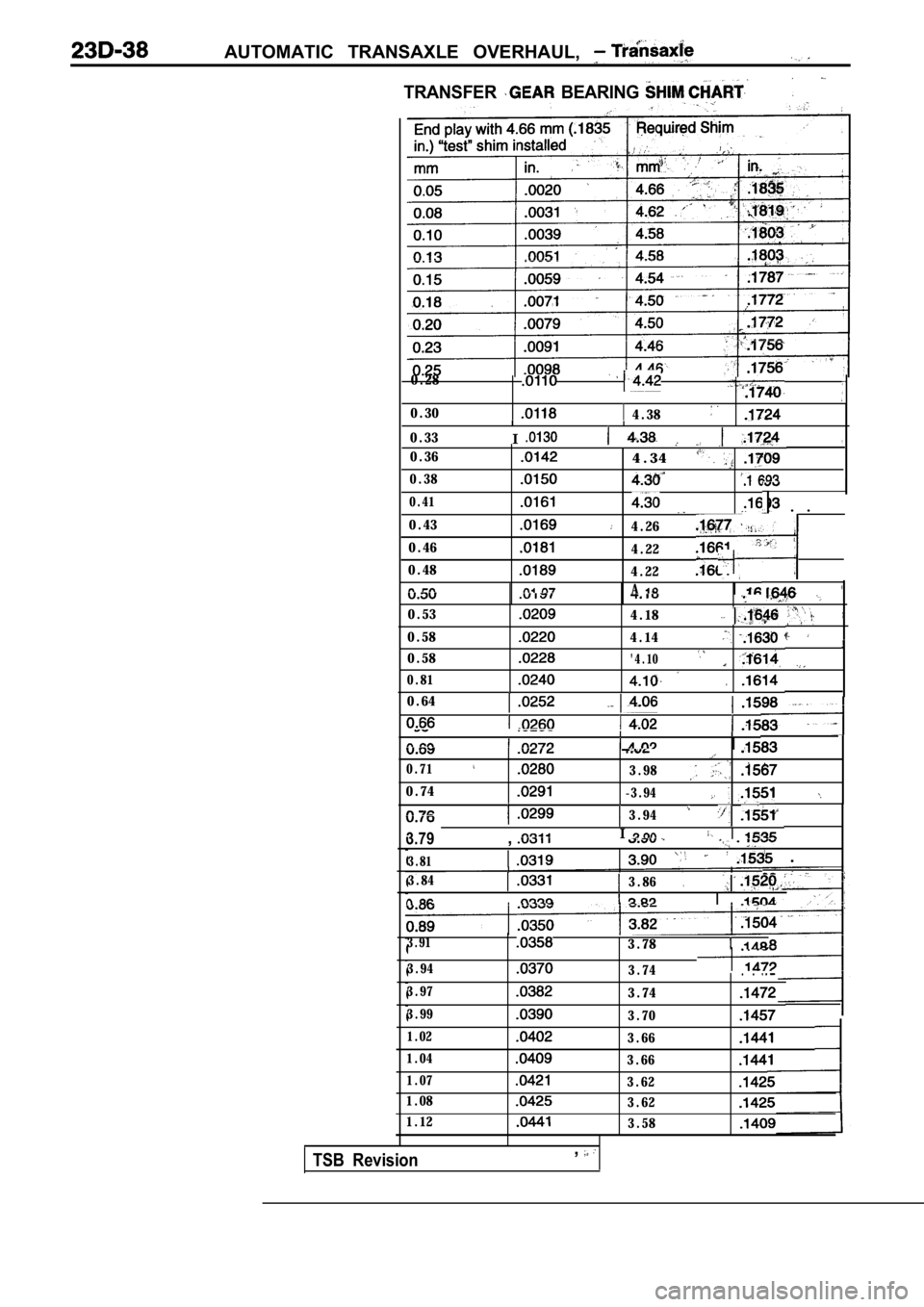

bearing end play has been determined, refer to

the Transfer Bearing Shim Chart for the required sh im.

play should be between 0.05 to 0.10 mm

to 0039 in.).

If end play is too high, install a 0.04 mm in.) thinner

shim. If end play is too low, install a 0.04 mm

in.) thicker shim combination. Repeat until 0.05 to 0.10

mm (0.0020 to

in.) end play is obtained.

TSB Revision

Page 1440 of 2103

AUTOMATIC TRANSAXLE OVERHAUL,

TRANSFER BEARING

0.28

0.30 4.38

0.33I,

0.364.34

0.38I

. .0.41

0.434.26

0.464.22

0.484.22,

AI

0.534.18

0.584.14

0.58©4.10

.0.81

0.64

I

0.713.98

0.74-3.94

3.94

II3.79,

3.81 .

3.843.86.

I

3.913.78

3.943.74. .

3.973.74

3.993.70

1.023.66

1.043.66

1.073.62

1.083.62

1.123.58

TSB Revision,

Trending: wipers, brake, remove seats, tire type, wheelbase, sunroof, lights