MITSUBISHI SPYDER 1990 Service Repair Manual

SPYDER 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57345/w960_57345-0.png

MITSUBISHI SPYDER 1990 Service Repair Manual

Trending: display, seats, horn, wheel torque, engine overheat, timing belt, steering wheel adjustment

Page 1391 of 2103

AUTOMATIC TRANSAXLE

-Transfer

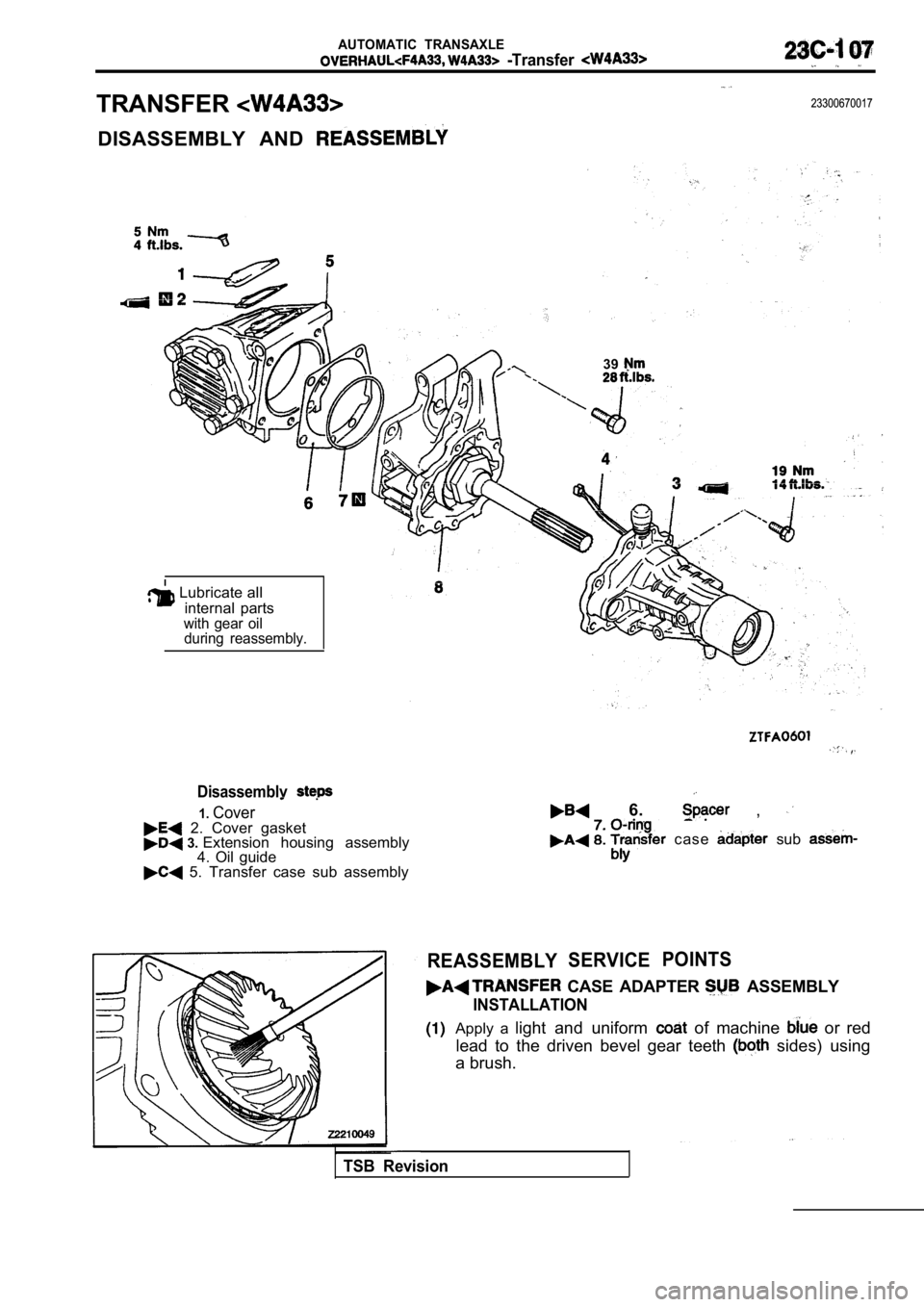

TRANSFER23300670017

DISASSEMBLY AND

39

Lubricate all internal parts

with gear oilduring reassembly.

Disassemblv .

1.Cover 2. Cover gasket 3. Extension housing assembly

4. Oil guide

5. Transfer case sub assembly

6. ,

c a s e sub

REASSEMBLYSERVICE POINTS

CASE ADAPTER ASSEMBLY

INSTALLATION

Apply a

light and uniform of machine or red

lead to the driven bevel gear teeth

sides) using

a brush.

TSB Revision

Page 1392 of 2103

AUTOMATIC TRANSAXLE

Transfer .

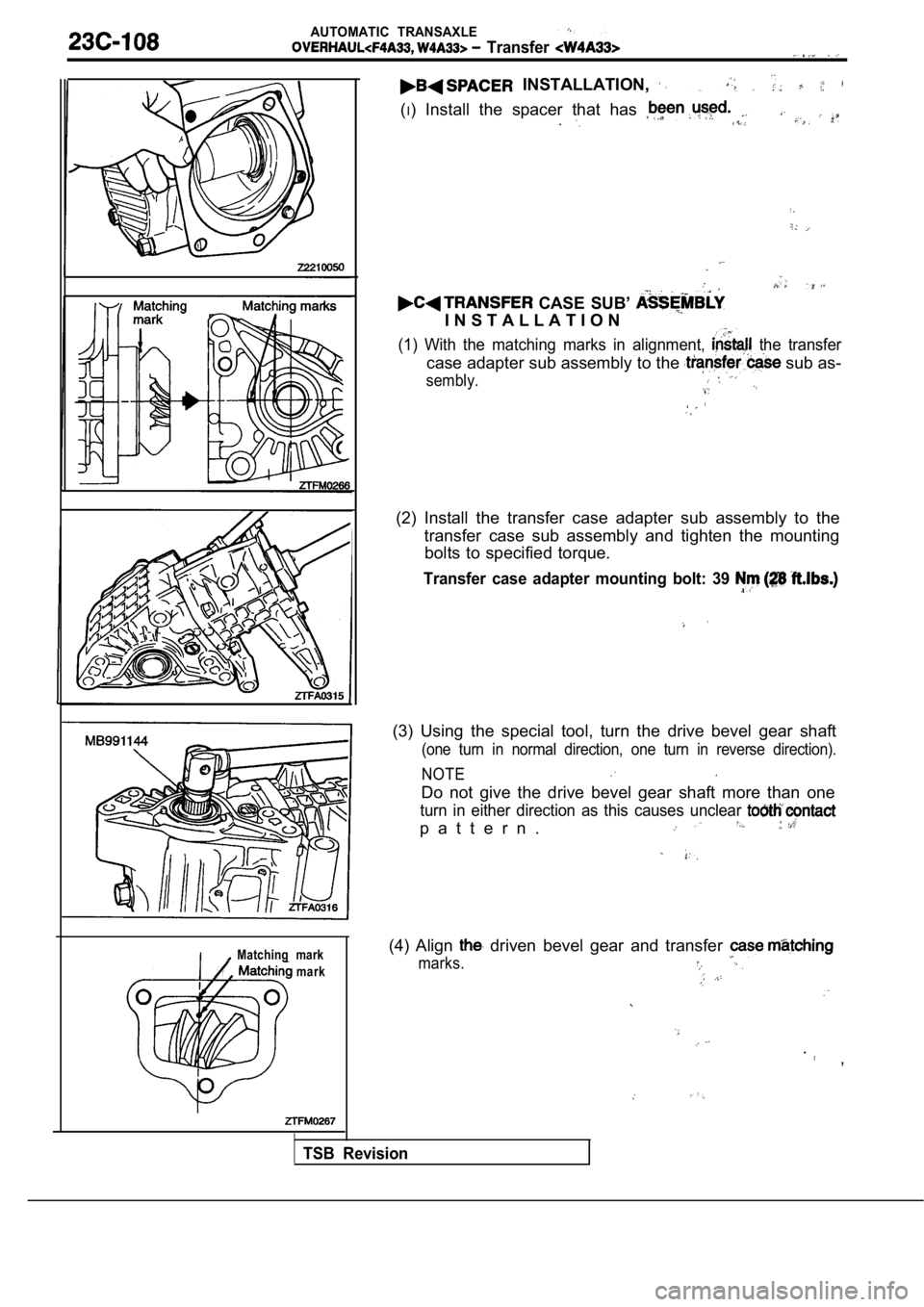

INSTALLATION,

(I) Install the spacer that has

CASE SUB’

I N S T A L L A T I O N

(1) With the matching marks in alignment, the transfer

case adapter sub assembly to the sub as-

sembly.

(2) Install the transfer case adapter sub assembly to the

transfer case sub assembly and tighten the mounting bolts to specified torque.

Transfer case adapter mounting bolt: 39

(3) Using the special tool, turn the drive bevel ge ar shaft

(one turn in normal direction, one turn in reverse direction).

NOTE

Do not give the drive bevel gear shaft more than on e

turn in either direction as this causes unclear

p a t t e r n .

Matching mark

mark(4) Align driven bevel gear and transfer

marks.

. ,

TSB Revision

Page 1393 of 2103

00

0

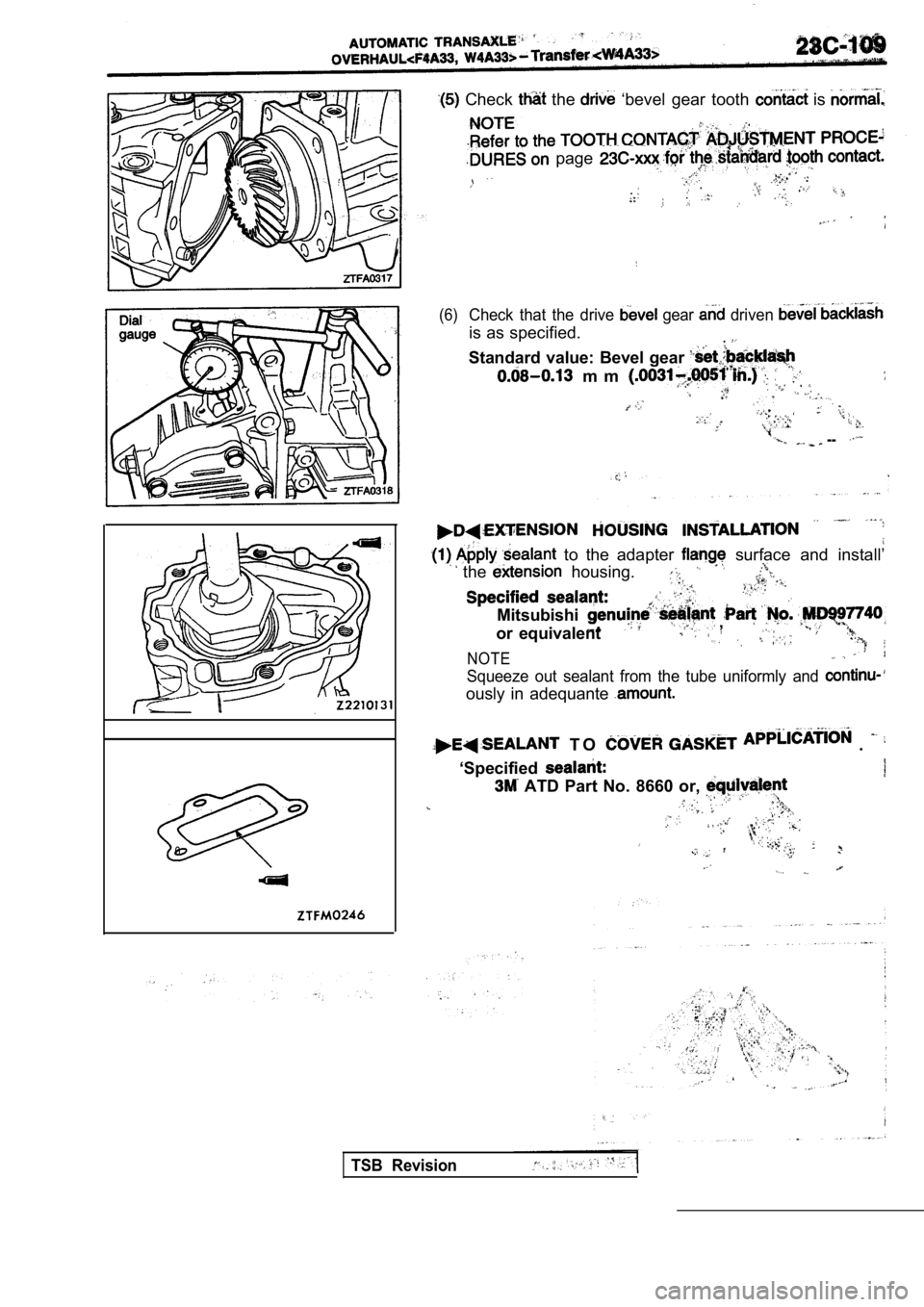

Check the ‘bevel gear tooth is

page

..

(6)Check that the drive gear driven

is as specified. .

Standard value: Bevel gear

m m

--

to the adapter surface and install’

the housing.

Mitsubishi

or equivalent ,

NOTE

Squeeze out sealant from the tube uniformly and

ously in adequante

T O .

‘Specified

ATD Part No. 8660 or,

TSB Revision

Page 1394 of 2103

A U T O M A T I C T R A N S A X L E

Transfer

I

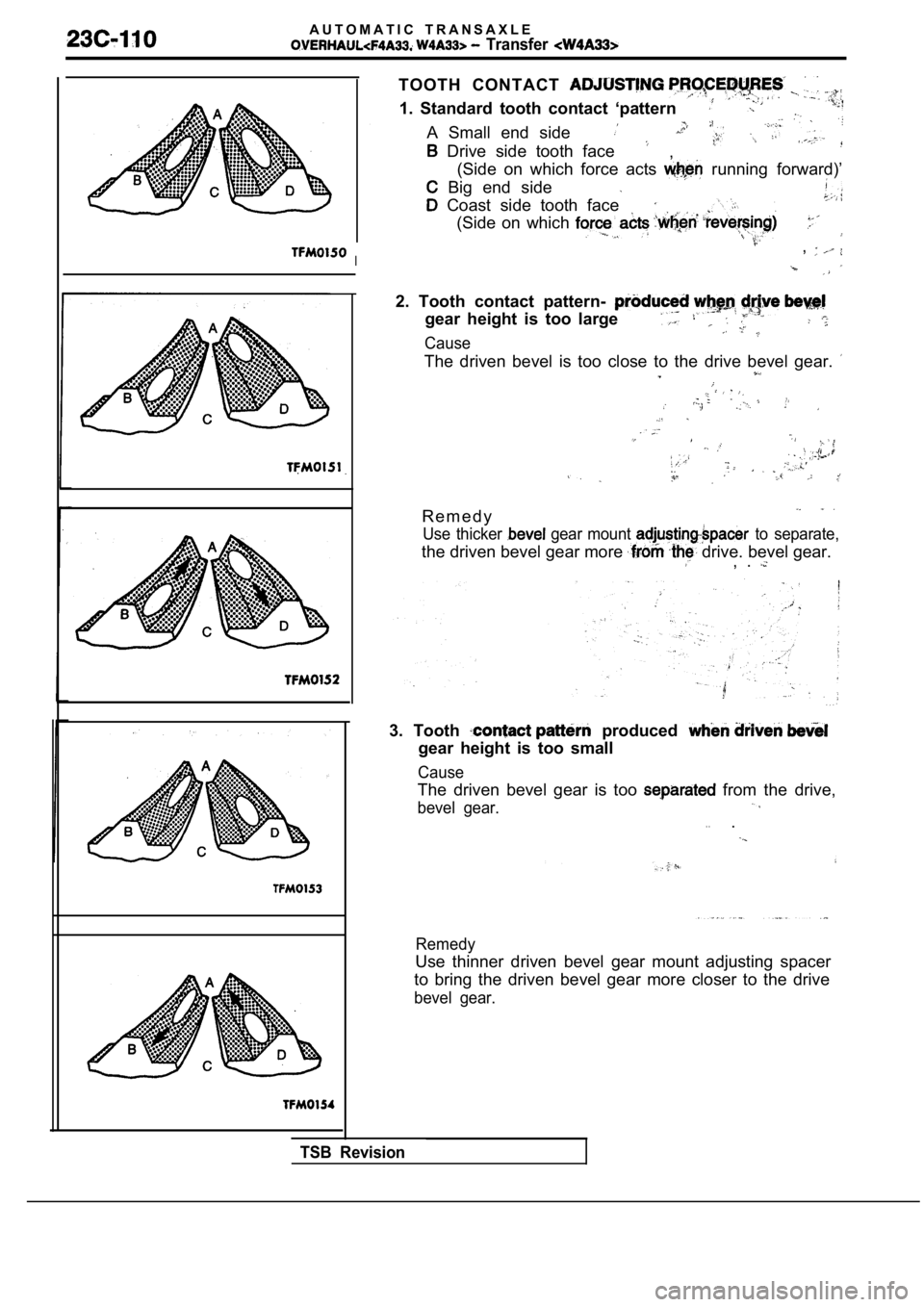

TOOTH CONTACT

1. Standard tooth contact ‘pattern

A Small end side

Drive side tooth face,

(Side on which force acts

running forward)’

Big end side

Coast side tooth face

(Side on which

,

2. Tooth contact pattern-

gear height is too large

Cause

The driven bevel is too close to the drive bevel ge ar.

R e m e d y

Use thicker gear mount to separate,

the driven bevel gear more drive. bevel gear., .

3. Tooth produced

gear height is too small

Cause

The driven bevel gear is too from the drive,

bevel gear.. ..

Remedy

Use thinner driven bevel gear mount adjusting space r

to bring the driven bevel gear more closer to the d rive

bevel gear.

TSB Revision

Page 1395 of 2103

AUTOMATIC TRANSAXLE

Transfer

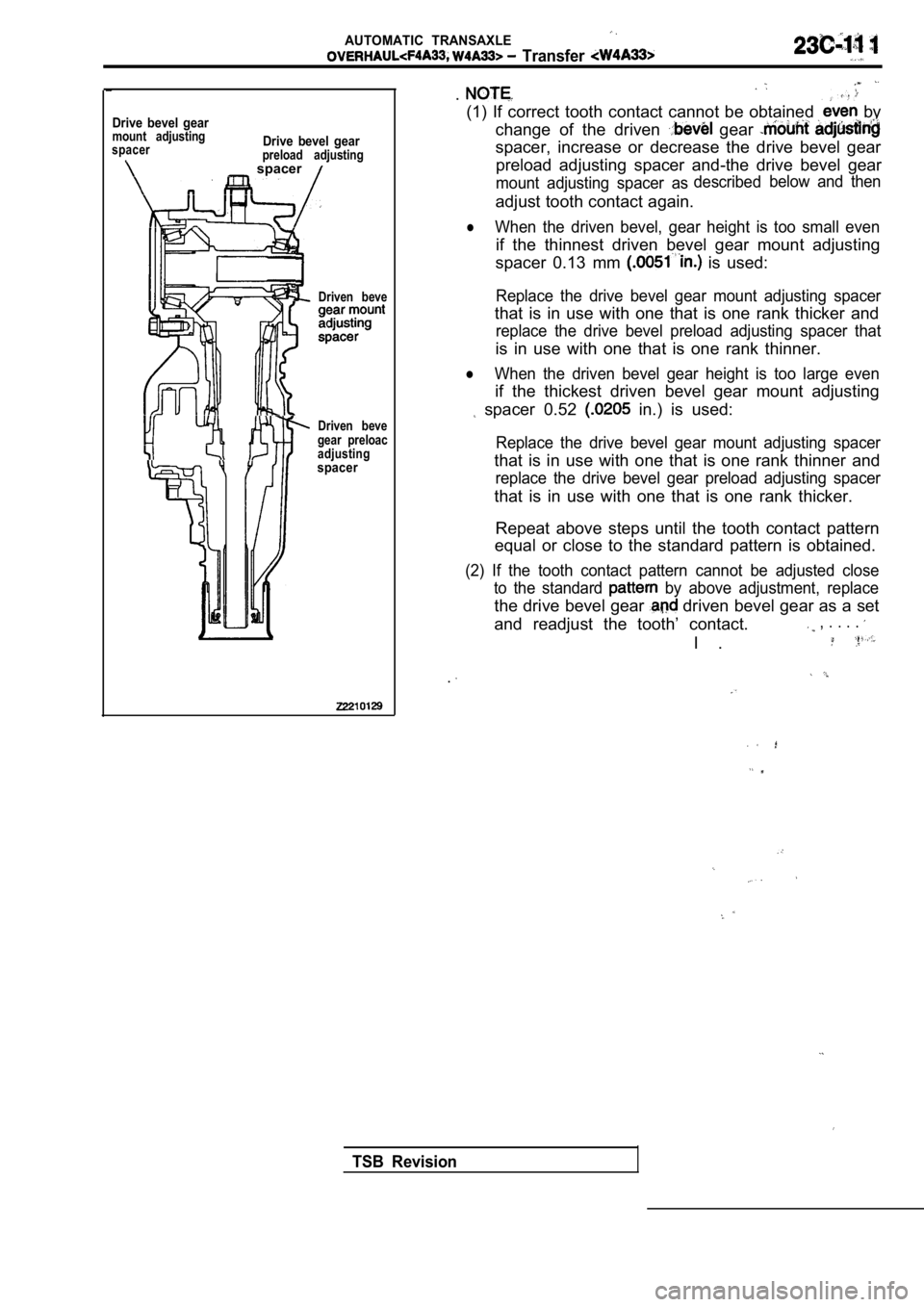

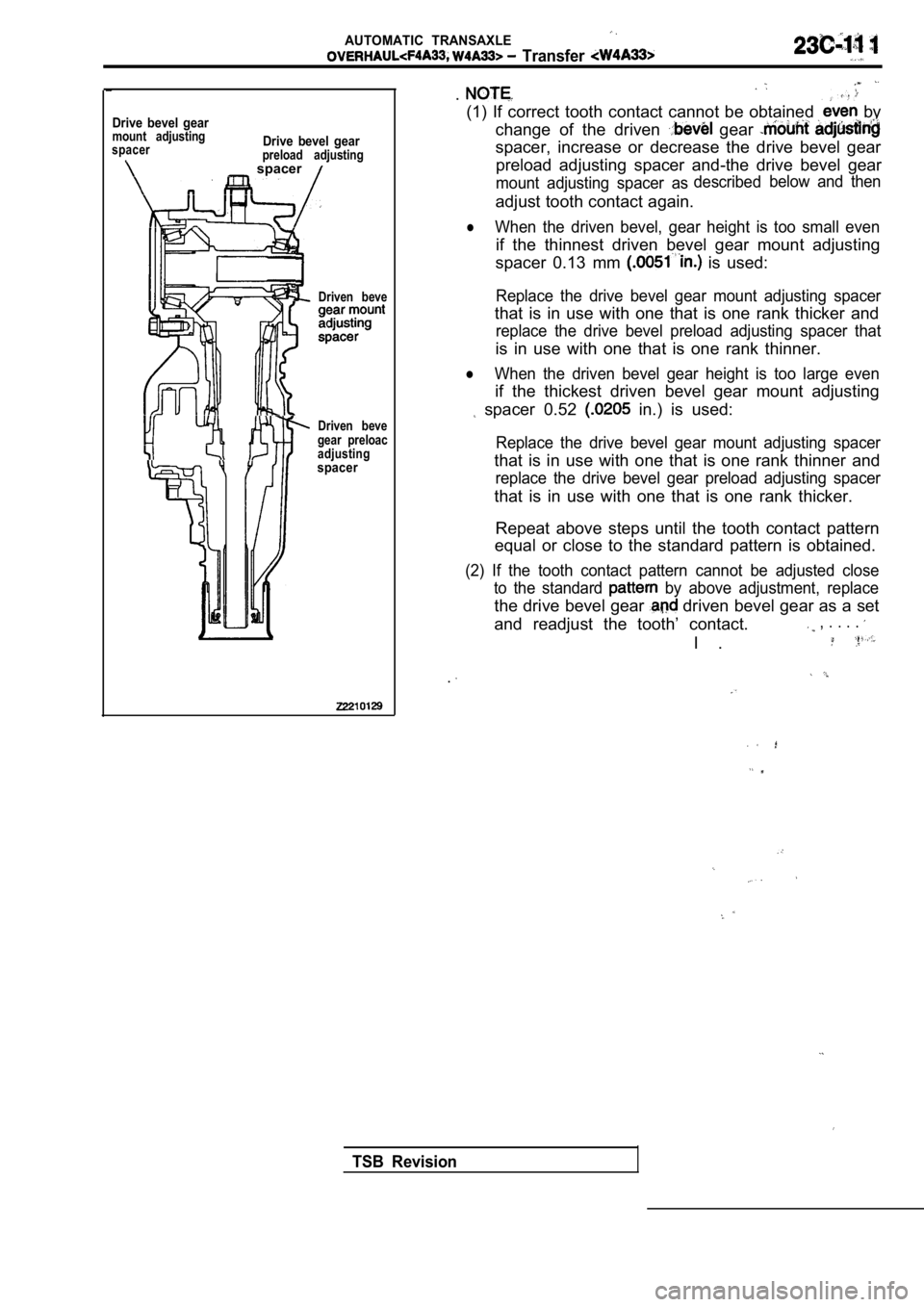

Drive bevel gearmount adjusting

spacer

.

Drive bevel gearpreload adjusting spacer

Driven beve

Driven beve

gear preloac

adjustingspacer

.

(1) If correct tooth contact cannot be obtained by

change of the driven

gear

spacer, increase or decrease the drive bevel gear preload adjusting spacer and-the drive bevel gear

mount adjusting spacer as described

below and then

adjust tooth contact again.

lWhen the driven bevel, gear height is too small eve

n

if the thinnest driven bevel gear mount adjusting

spacer 0.13 mm

is used:

Replace the drive bevel gear mount adjusting spacer

that is in use with one that is one rank thicker an d

replace the drive bevel preload adjusting spacer th at

is in use with one that is one rank thinner.

lWhen the driven bevel gear height is too large even

if the thickest driven bevel gear mount adjusting

spacer 0.52 in.) is used:

Replace the drive bevel gear mount adjusting spacer

that is in use with one that is one rank thinner and

replace the drive bevel gear preload adjusting spac er

that is in use with one that is one rank thicker.

Repeat above steps until the tooth contact pattern

equal or close to the standard pattern is obtained.

(2) If the tooth contact pattern cannot be adjusted close

to the standard

by above adjustment, replace

the drive bevel gear driven bevel gear as a set

and readjust the tooth’ contact.

, . . . .

I .

.

TSB Revision

Page 1396 of 2103

AUTOMATIC TRANSAXLE

-Transfer

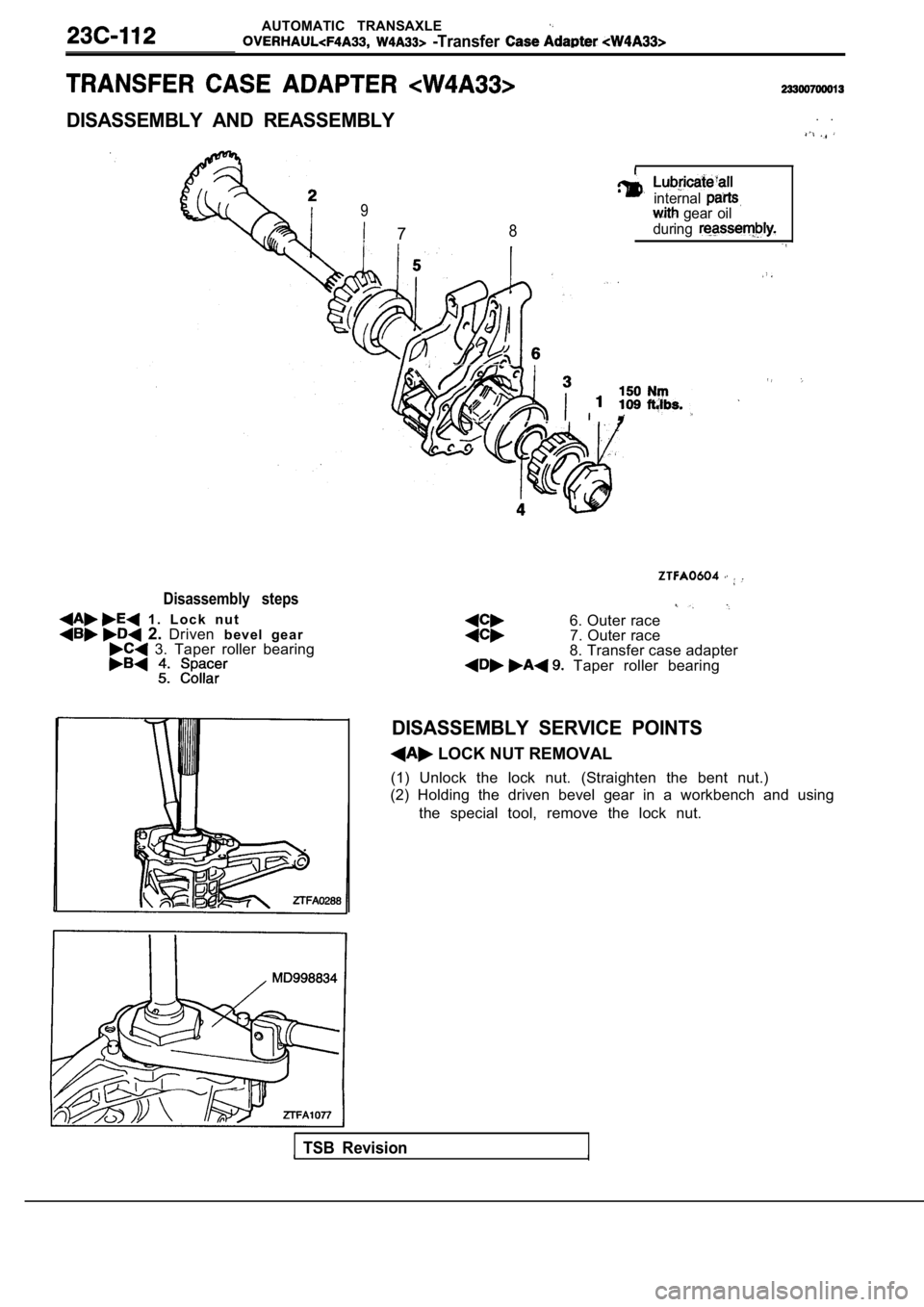

DISASSEMBLY AND REASSEMBLY

9

78

. .

internal gear oil

during

Disassembly steps

1 . L o c k n u t 2. Driven b e v e l g e a r 3. Taper roller bearing

,

,

6. Outer race7. Outer race

8. Transfer case adapter

Taper roller bearing

DISASSEMBLY SERVICE POINTS

LOCK NUT REMOVAL

(1) Unlock the lock nut. (Straighten the bent nut.)

(2) Holding the driven bevel gear in a workbench an d using

the special tool, remove the lock nut.

TSB Revision

Page 1397 of 2103

AUTOMATIC TRANSAXLE

-Transfer Case Adapter

2

4

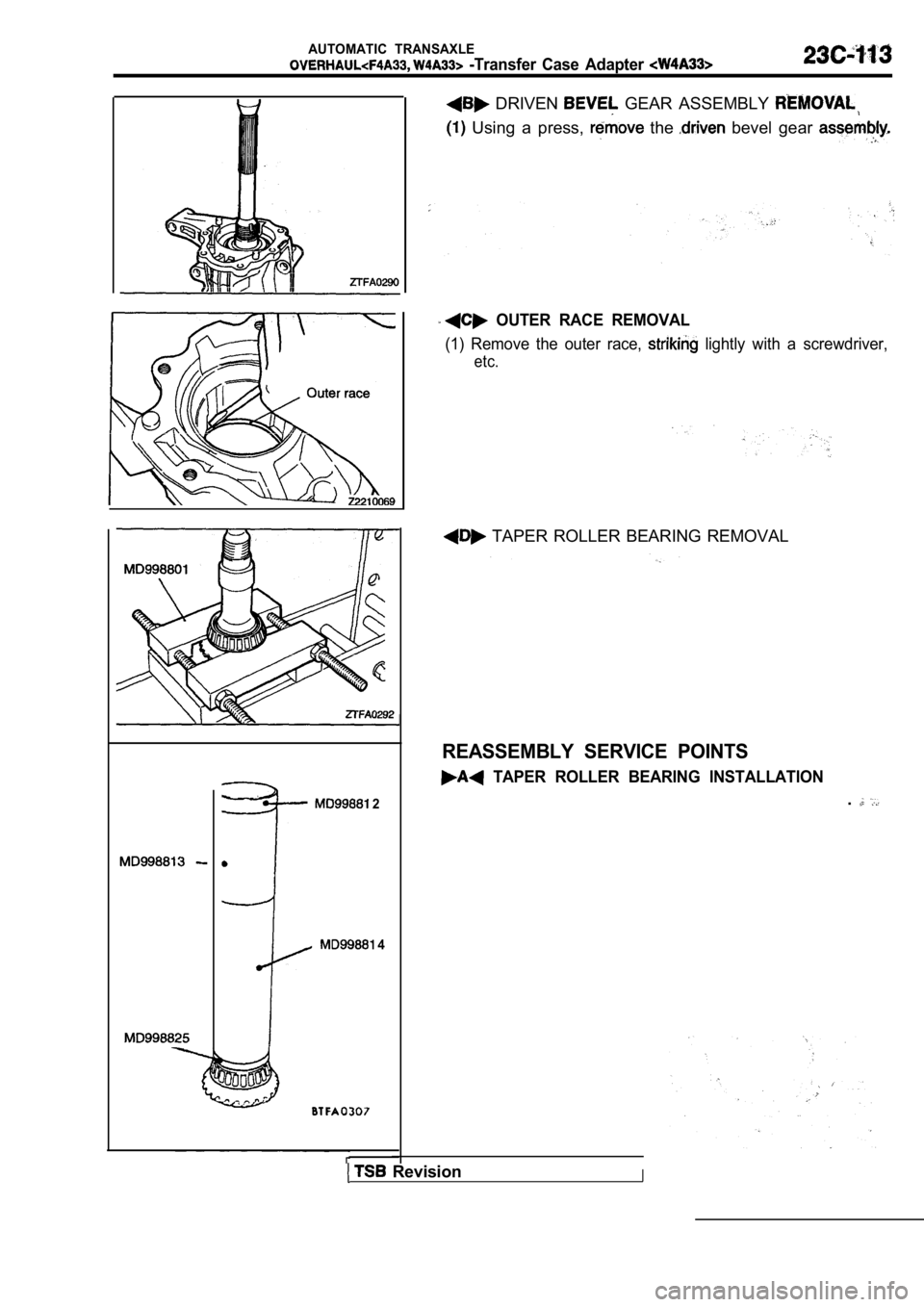

DRIVEN GEAR ASSEMBLY

Using a press, the bevel gear

OUTER RACE REMOVAL

(1) Remove the outer race, lightly with a screwdriver,

etc.

TAPER ROLLER BEARING REMOVAL

REASSEMBLY SERVICE POINTS

TAPER ROLLER BEARING INSTALLATION

.

RevisionI

Page 1398 of 2103

AUTOMATIC TRANSAXLE

Transfer Case Adapter

2

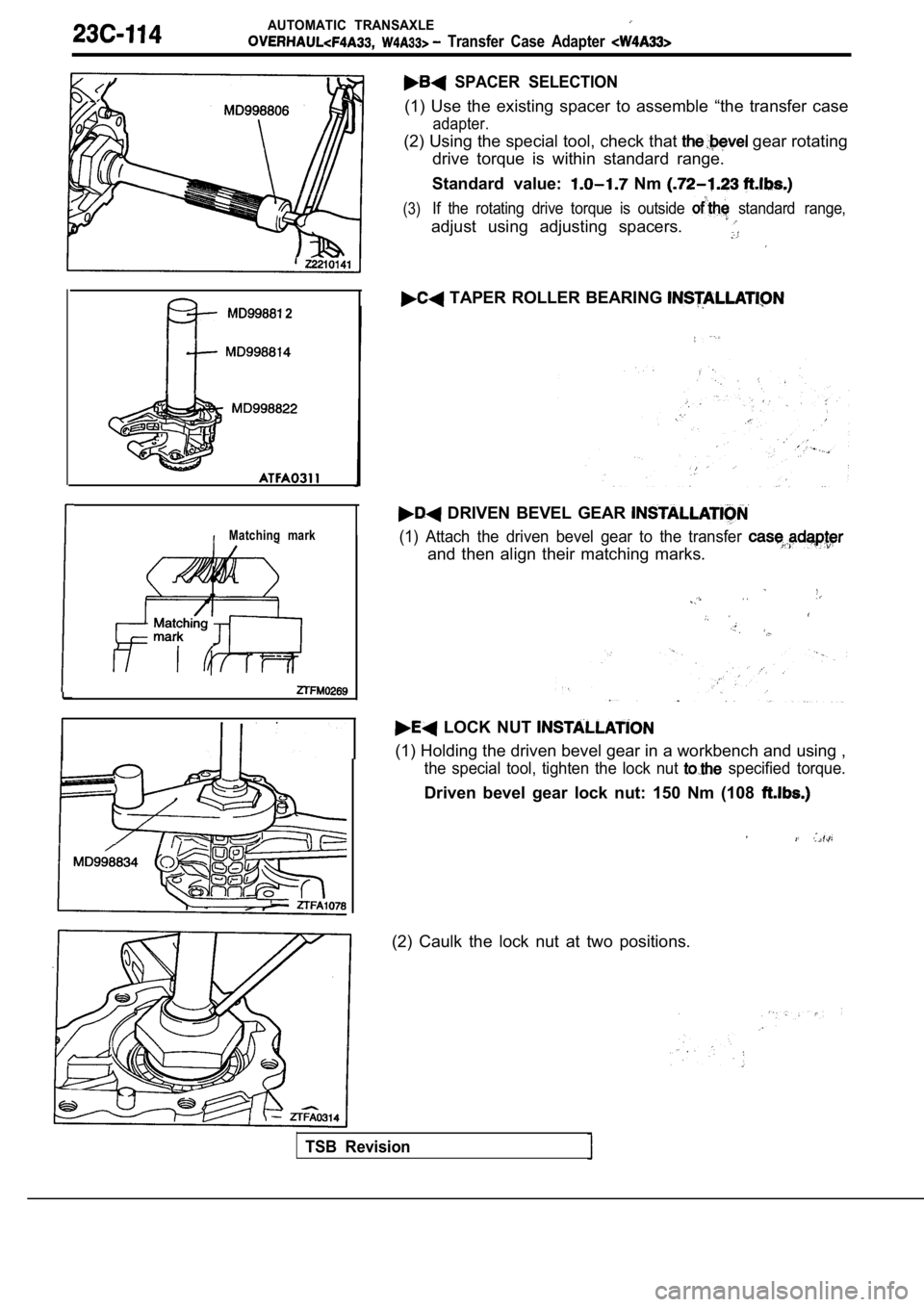

Matching mark

SPACER SELECTION

(1) Use the existing spacer to assemble “the transfer case

adapter.

(2) Using the special tool, check that gear rotating

drive torque is within standard range.

Standard value:

Nm

(3)If the rotating drive torque is outside standard range,

adjust using adjusting spacers.

TAPER ROLLER BEARING

DRIVEN BEVEL GEAR

(1) Attach the driven bevel gear to the transfer

and then align their matching marks.

. .

LOCK NUT

(1) Holding the driven bevel gear in a workbench an d using ,

the special tool, tighten the lock nut specified torque.

Driven bevel gear lock nut: 150 Nm (108

(2) Caulk the lock nut at two positions.

TSB Revision

Page 1399 of 2103

A U T O M A T I C T R A N S A X L E.

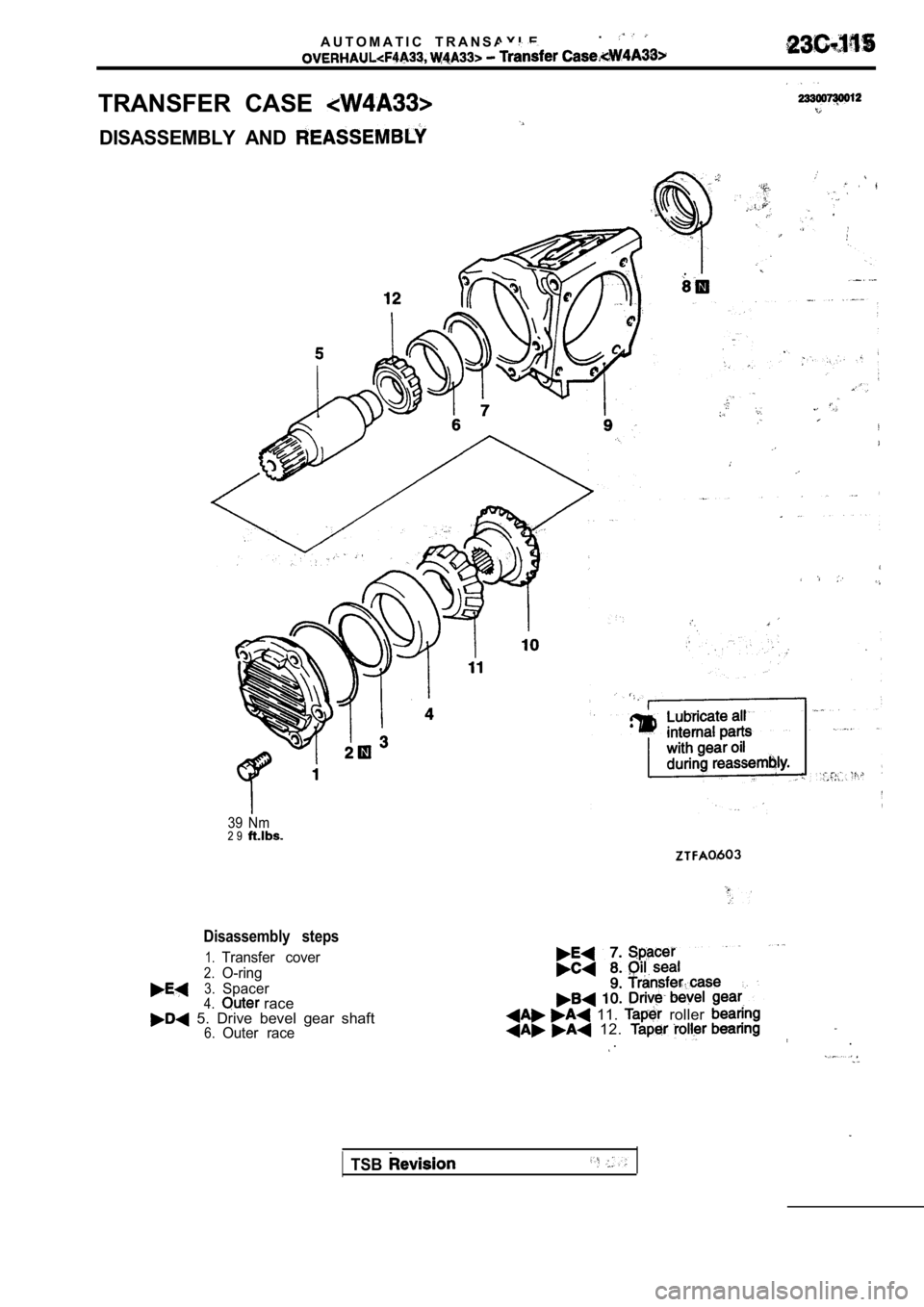

TRANSFER CASE

DISASSEMBLY AND

39 Nm2 9

Disassembly steps

1.Transfer cover

2.O-ring

3.Spacer4. race 5. Drive bevel gear shaft6.Outer race

11. roller 12. .

.

TSB

Page 1400 of 2103

AUTOMATIC TRANSAXLE

Case

1II I

8

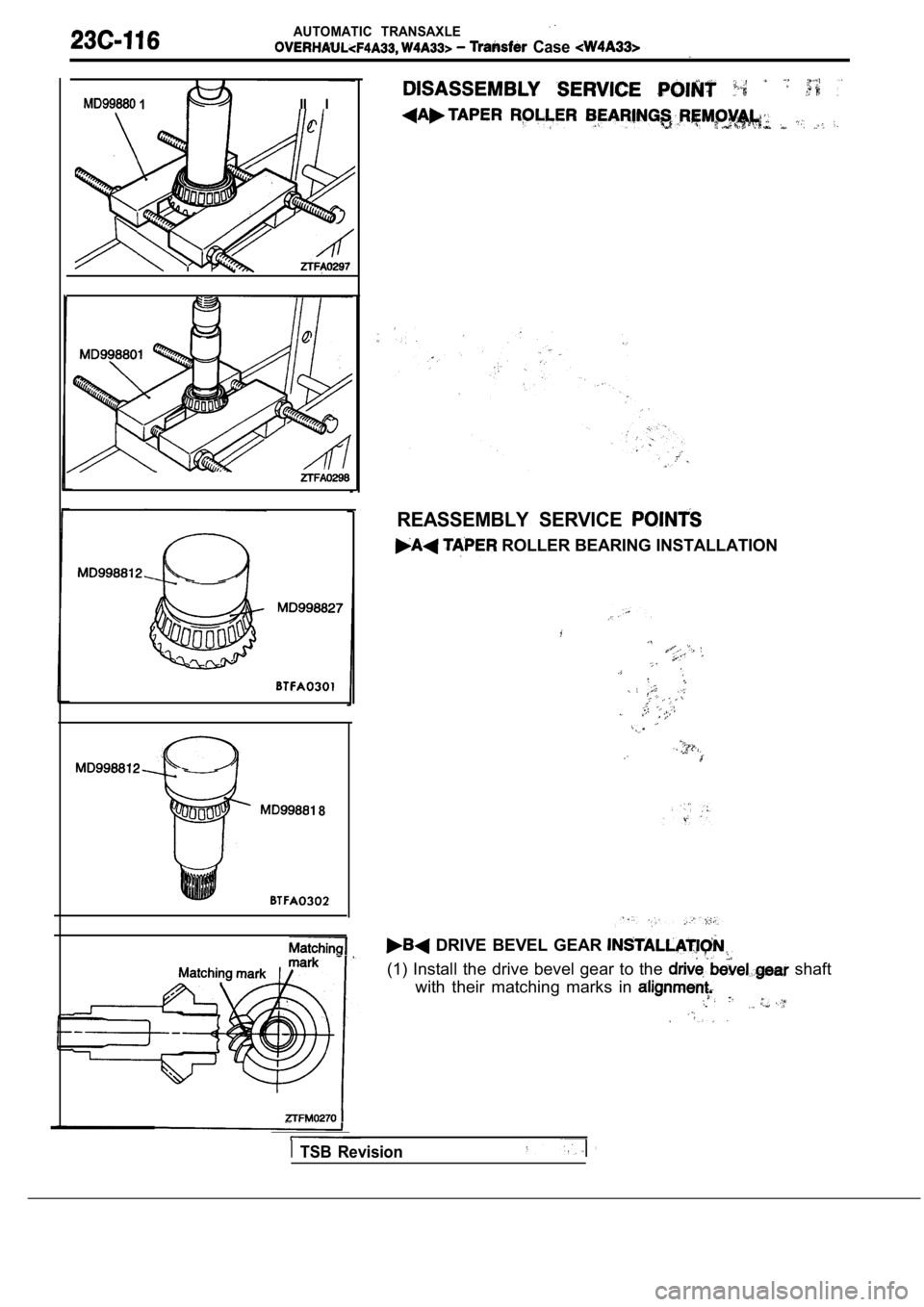

REASSEMBLY SERVICE

ROLLER BEARING INSTALLATION

DRIVE BEVEL GEAR

(1) Install the drive bevel gear to the shaft

with their matching marks in

TSB Revision

Trending: clutch, turn signal, power steering, check engine, clock, brake pads replacement, warning