MITSUBISHI SPYDER 1990 Service Repair Manual

SPYDER 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57345/w960_57345-0.png

MITSUBISHI SPYDER 1990 Service Repair Manual

Trending: sensor, oil reset, fuel tank removal, diagram, flat tire, roof rack, ECO mode

Page 291 of 2103

ENGINECamshaft

Install the rocker spring installing,

Remove the the

.

.,

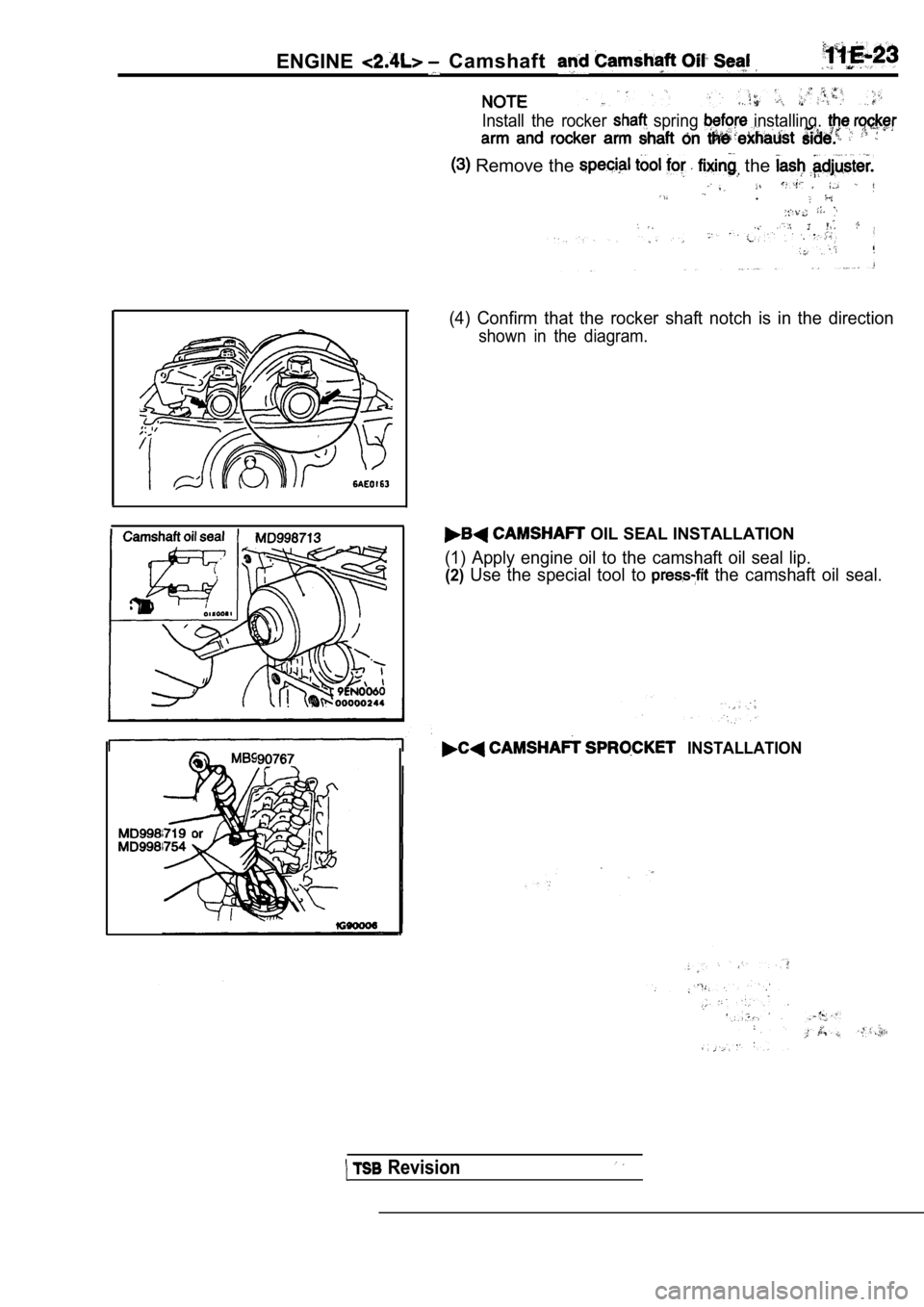

(4) Confirm that the rocker shaft notch is in the direction

shown in the diagram.

OIL SEAL INSTALLATION

(1) Apply engine oil to the camshaft oil seal lip.

(2)Use the special tool to the camshaft oil seal.

INSTALLATION

Revision

Page 292 of 2103

11ENGINE Pan and Oil Screen

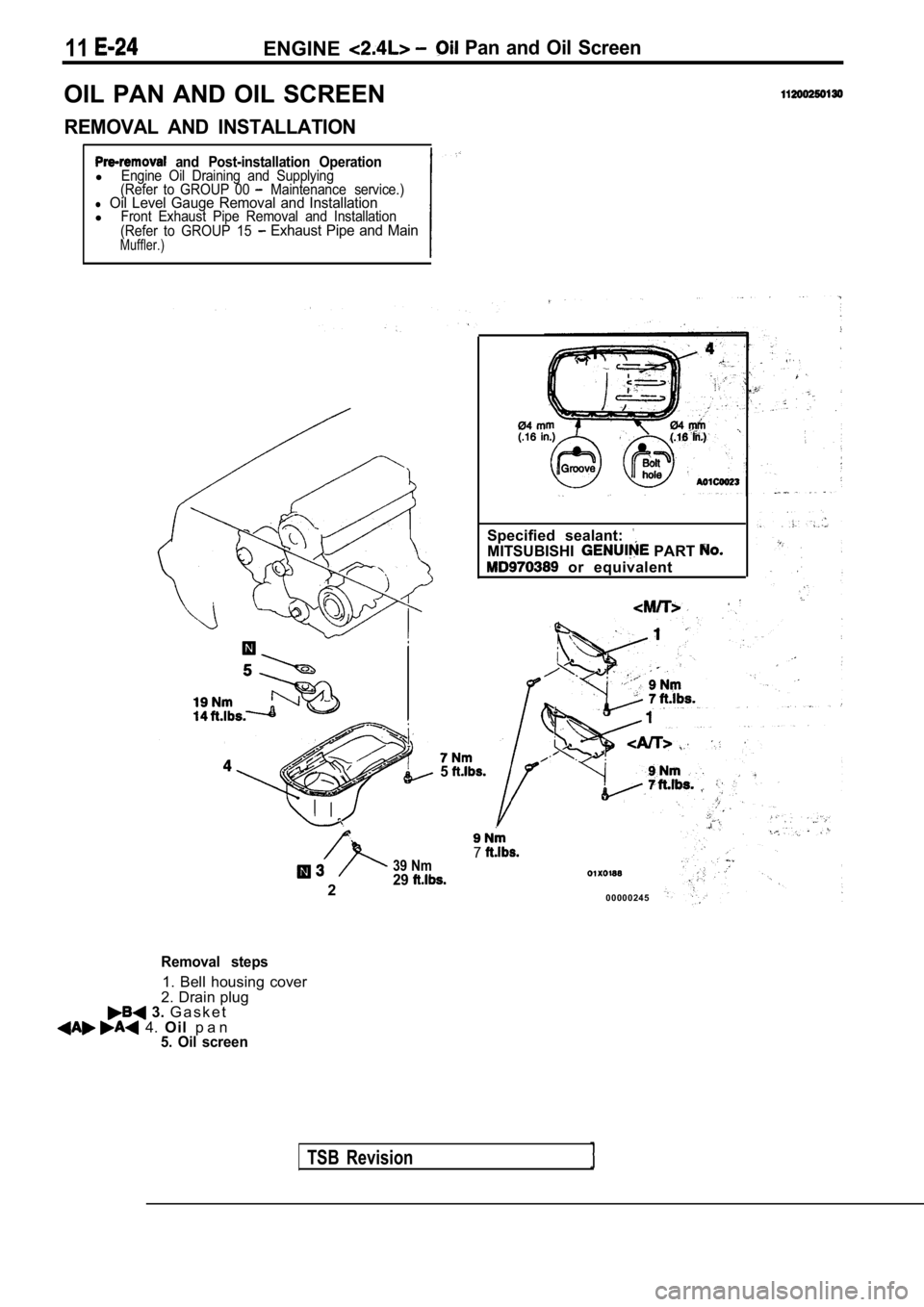

OIL PAN AND OIL SCREEN

REMOVAL AND INSTALLATION

and Post-installation OperationlEngine Oil Draining and Supplying

(Refer to GROUP 00 Maintenance service.)l Oil Level Gauge Removal and InstallationlFront Exhaust Pipe Removal and Installation

(Refer to GROUP 15 Exhaust Pipe and MainMuffler.)

TSB Revision

5

Specified sealant:

MITSUBISHI PART

or equivalent

739 Nm

229

0 0 0 0 0 2 4 5

Removal steps

1. Bell housing cover

2. Drain plug

3. G a s k e t 4. Oil p a n5. Oil screen

Page 293 of 2103

ENGINE Oil Pan and Oil

Draingasket Oil pan side

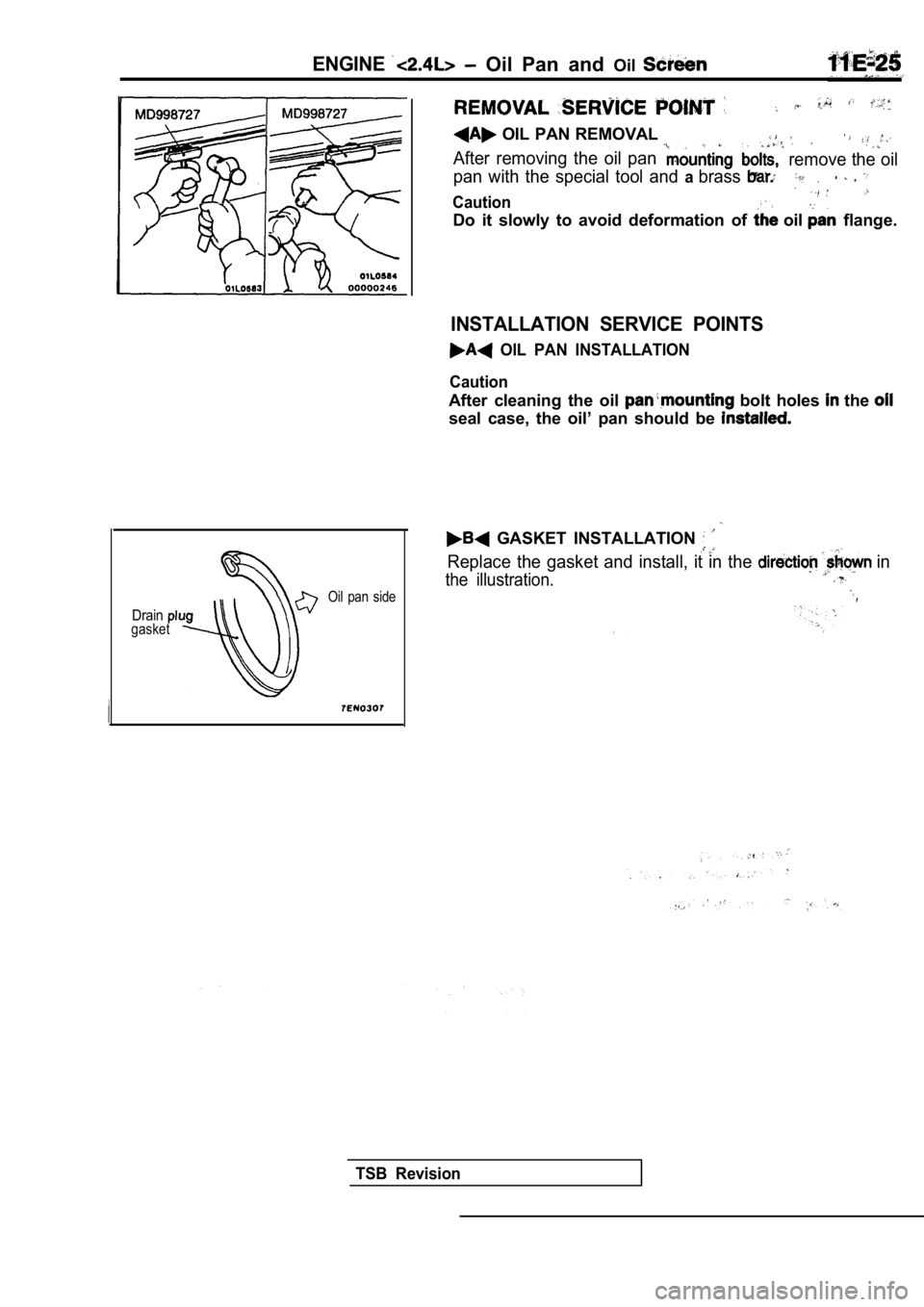

OIL PAN REMOVAL

After removing the oil pan remove the oil

pan with the special tool and

abrass

Caution

Do it slowly to avoid deformation of oil flange.

INSTALLATION SERVICE POINTS

OIL PAN INSTALLATION

Caution

After cleaning the oil bolt holes the

seal case, the oil’ pan should be

GASKET INSTALLATION

Replace the gasket and install, it in the in

the illustration.

TSB Revision

Page 294 of 2103

11ENGINE Crankshaft Front Oil Seal

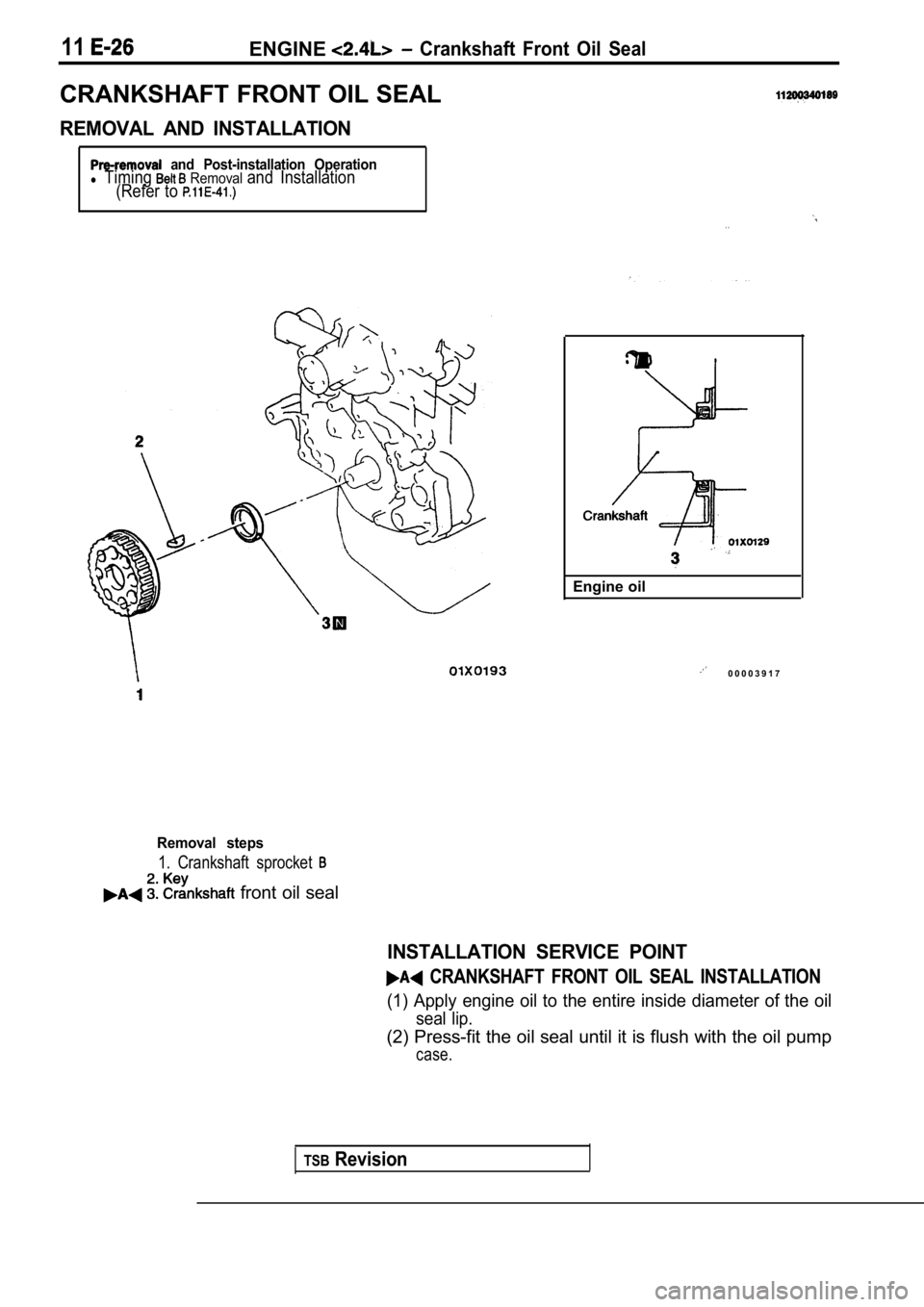

CRANKSHAFT FRONT OIL SEAL

REMOVAL AND INSTALLATION

and Post-installation Operationl Timing Removal and Installation

(Refer to

. .

TSBRevision

Engine oil

0 0 0 0 3 9 1 7

Removal steps

1. Crankshaft sprocket

front oil seal

INSTALLATION SERVICE POINT

CRANKSHAFT FRONT OIL SEAL INSTALLATION

(1) Apply engine oil to the entire inside diameter of the oil

seal lip.

(2) Press-fit the oil seal until it is flush with the oil pump

case.

Page 295 of 2103

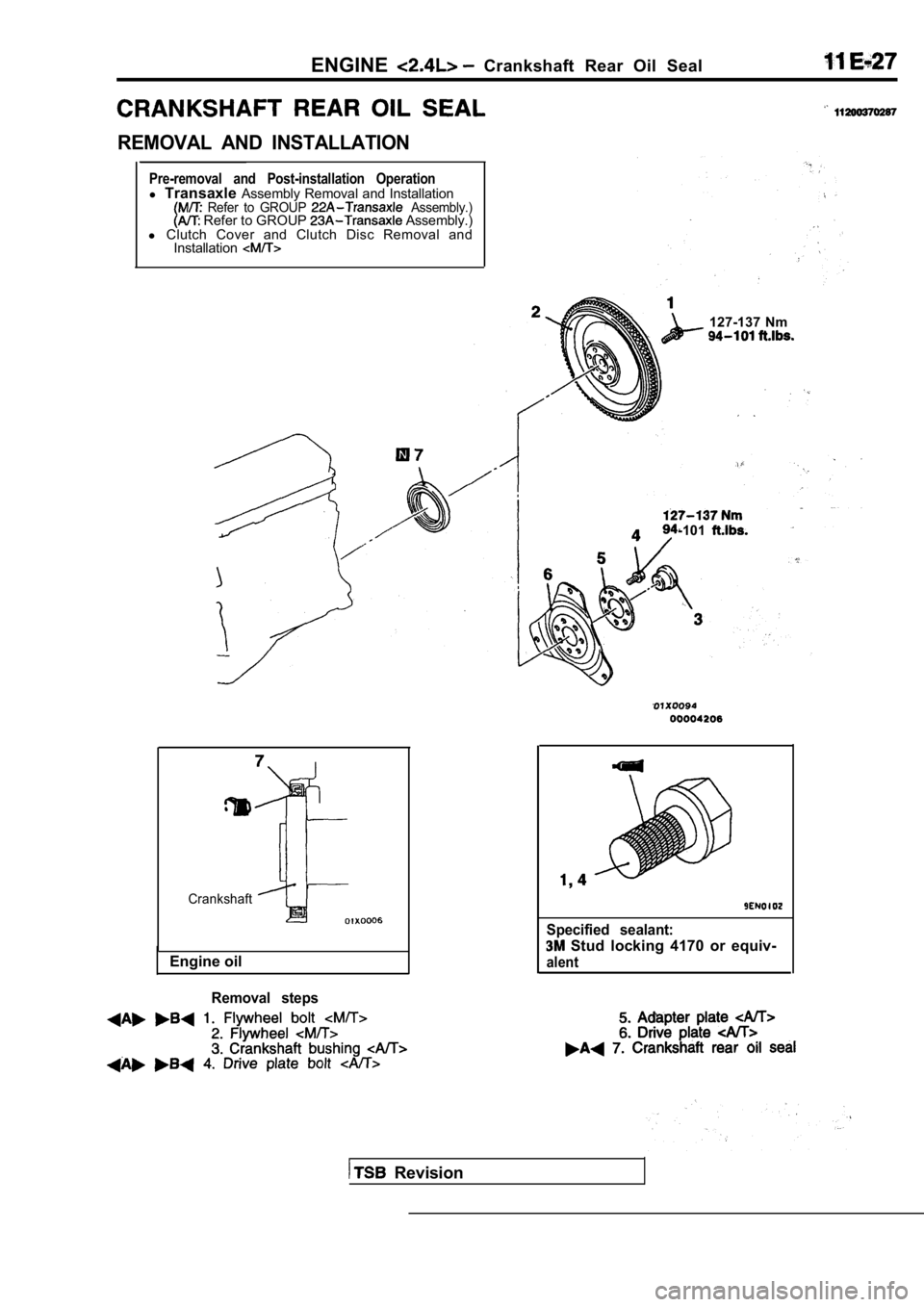

ENGINECrankshaft Rear Oil Seal

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operationl Transaxle Assembly Removal and Installation Refer to GROUP Assembly.) Refer to GROUP Assembly.)

l Clutch Cover and Clutch Disc Removal and

Installation

127-137 Nm

-101

Crankshaft

Engine oil

Removal steps

Specified sealant:

Stud locking 4170 or equiv-

alent

Revision

Page 296 of 2103

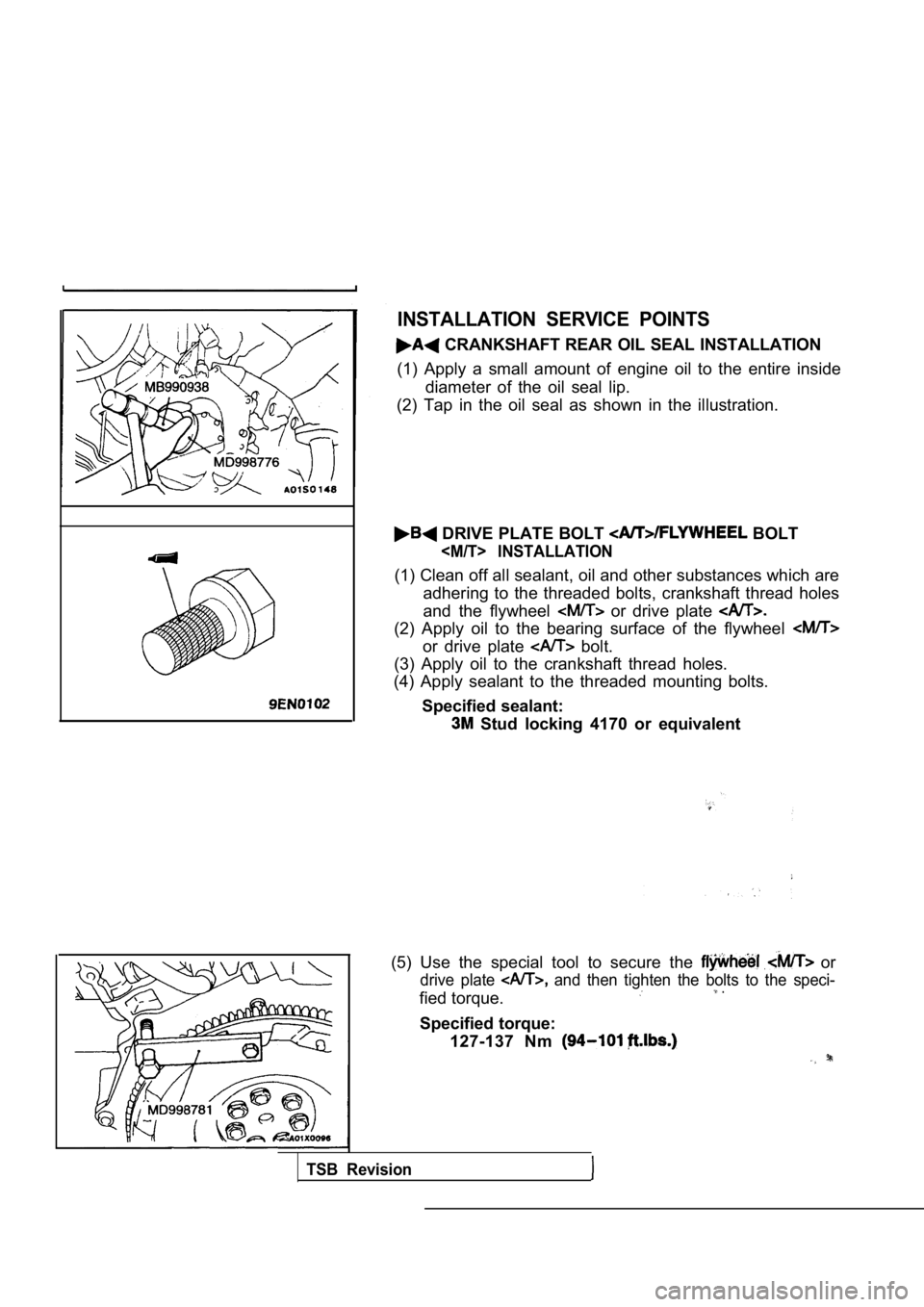

INSTALLATION SERVICE POINTS

CRANKSHAFT REAR OIL SEAL INSTALLATION

(1) Apply a small amount of engine oil to the entir e inside

diameter of the oil seal lip.

(2) Tap in the oil seal as shown in the illustratio n.

DRIVE PLATE BOLT BOLT

INSTALLATION

(1) Clean off all sealant, oil and other substances which are

adhering to the threaded bolts, crankshaft thread h oles

and the flywheel

or drive plate

(2) Apply oil to the bearing surface of the flywhee l

or drive plate bolt.

(3) Apply oil to the crankshaft thread holes.

(4) Apply sealant to the threaded mounting bolts.

Specified sealant:

Stud locking 4170 or equivalent

(5) Use the special tool to secure the

or

drive plate and then tighten the bolts to the speci-

fied torque. .

Specified torque: 127-137 Nm

TSB Revision

Page 297 of 2103

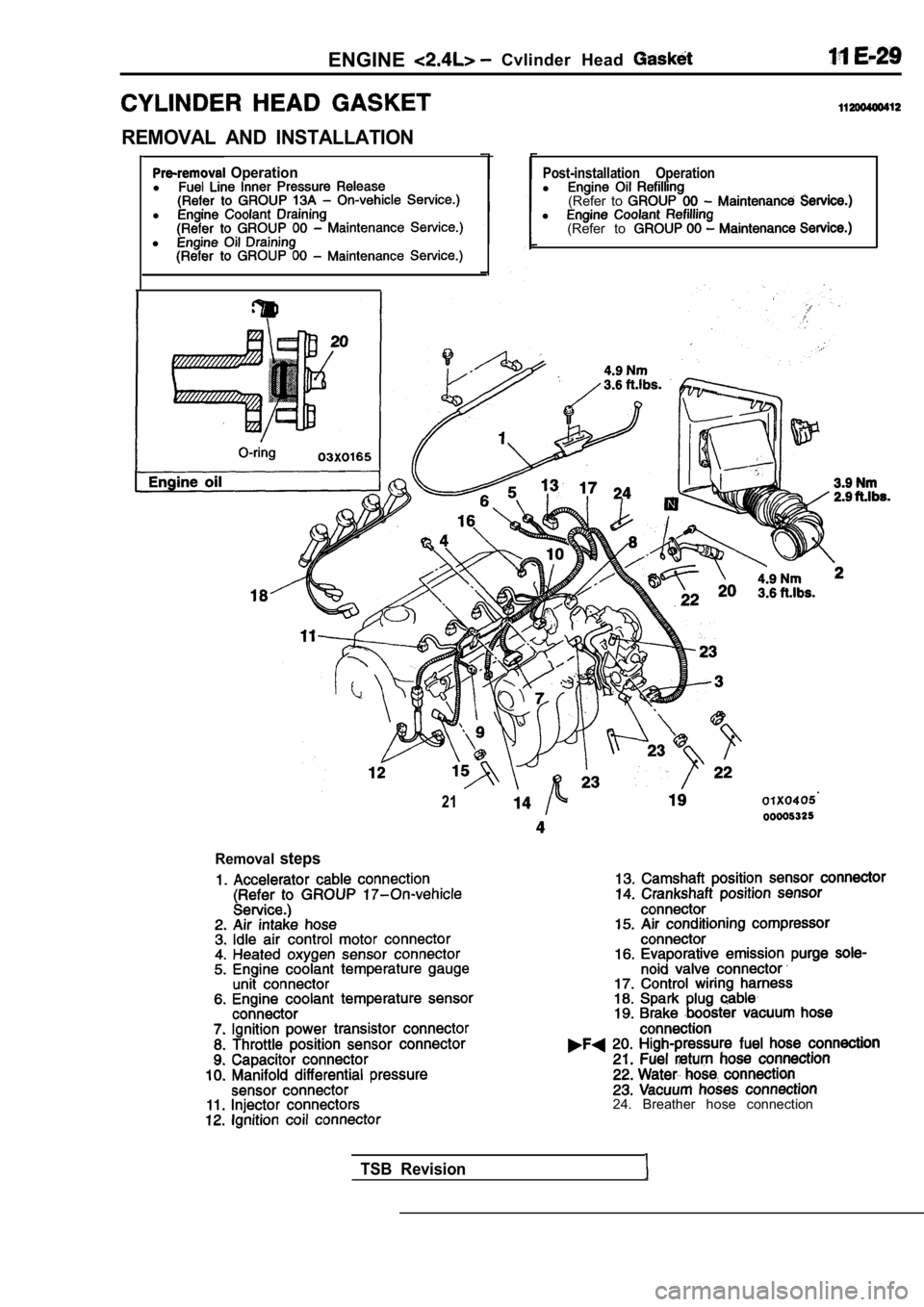

ENGINECvlinder Head

REMOVAL AND INSTALLATION

Operationl

l

l

Post-installation Operationl (Refer to l (Refer to

21

Removalsteps

24. Breather hose connection

TSB Revision

Page 298 of 2103

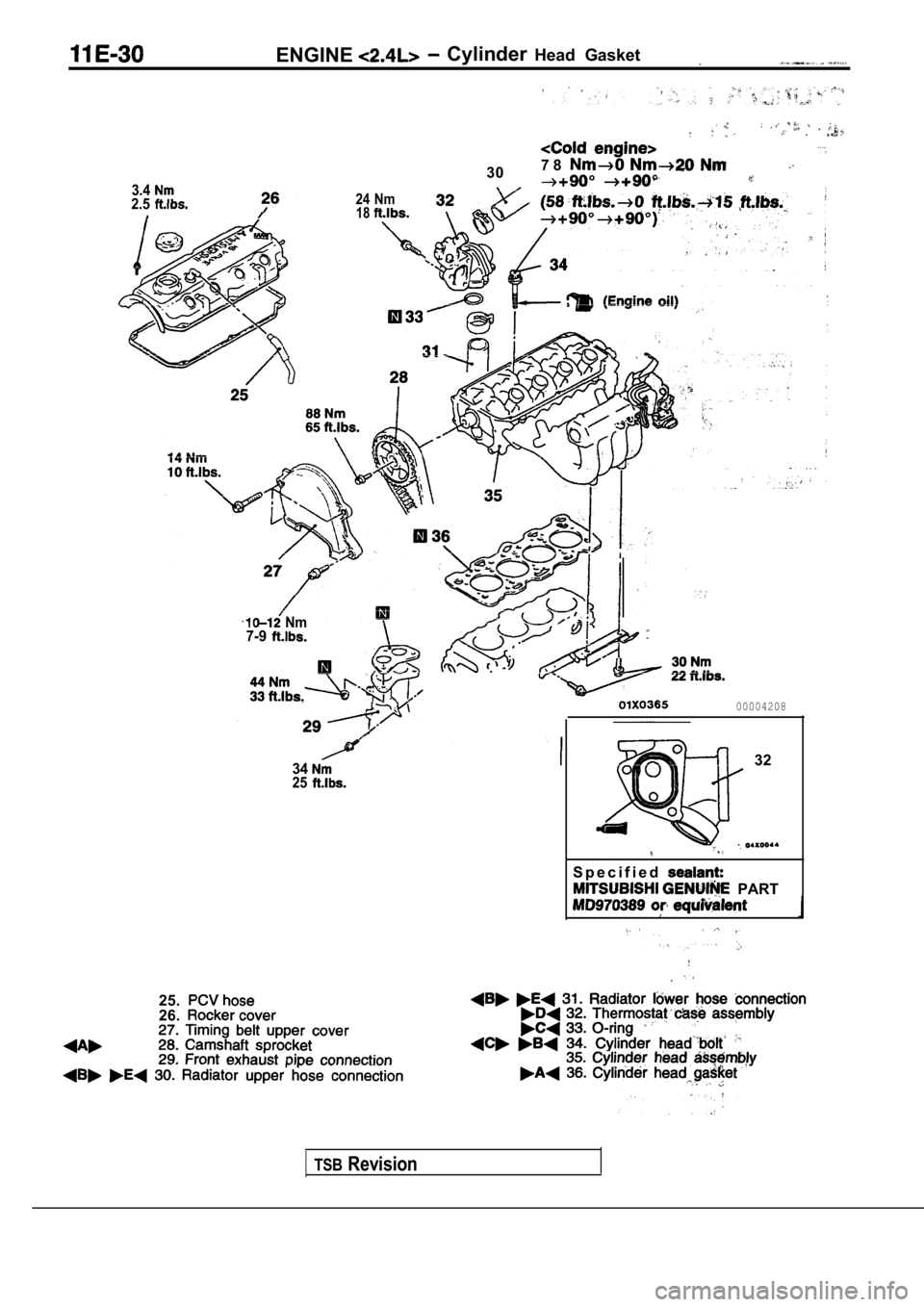

ENGINE Cylinder Head Gasket

3.42.524 Nm18

307 8

Nm7-9

3425

00004208

32

S p e c i f i e d

PART

25.26.

TSBRevision

Page 299 of 2103

ENGINE Cylinder Head

sprocketCamshaft

sprocket

REMOVAL SERVICE POINTS

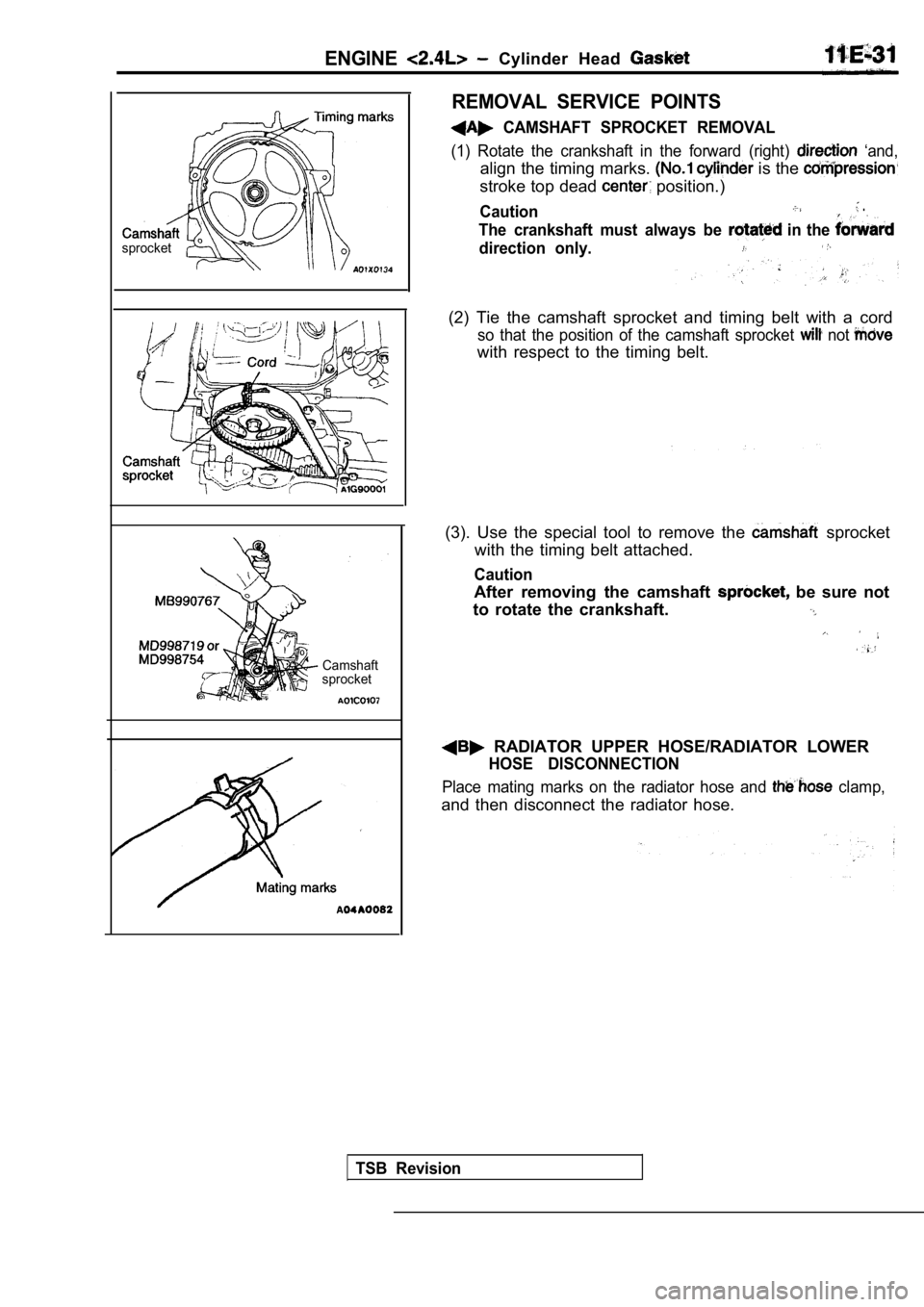

CAMSHAFT SPROCKET REMOVAL

(1) Rotate the crankshaft in the forward (right) ‘and,

align the timing marks. is the

stroke top dead position.)

Caution .

The crankshaft must always be in the

direction only.

(2) Tie the camshaft sprocket and timing belt with a cord

so that the position of the camshaft sprocket not

with respect to the timing belt.

(3). Use the special tool to remove the

sprocket

with the timing belt attached.

Caution

After removing the camshaft be sure not

to rotate the crankshaft.

RADIATOR UPPER HOSE/RADIATOR LOWER

HOSE DISCONNECTION

Place mating marks on the radiator hose and clamp,

and then disconnect the radiator hose.

TSB Revision

Page 300 of 2103

ENGINE Cylinder Head Gasket

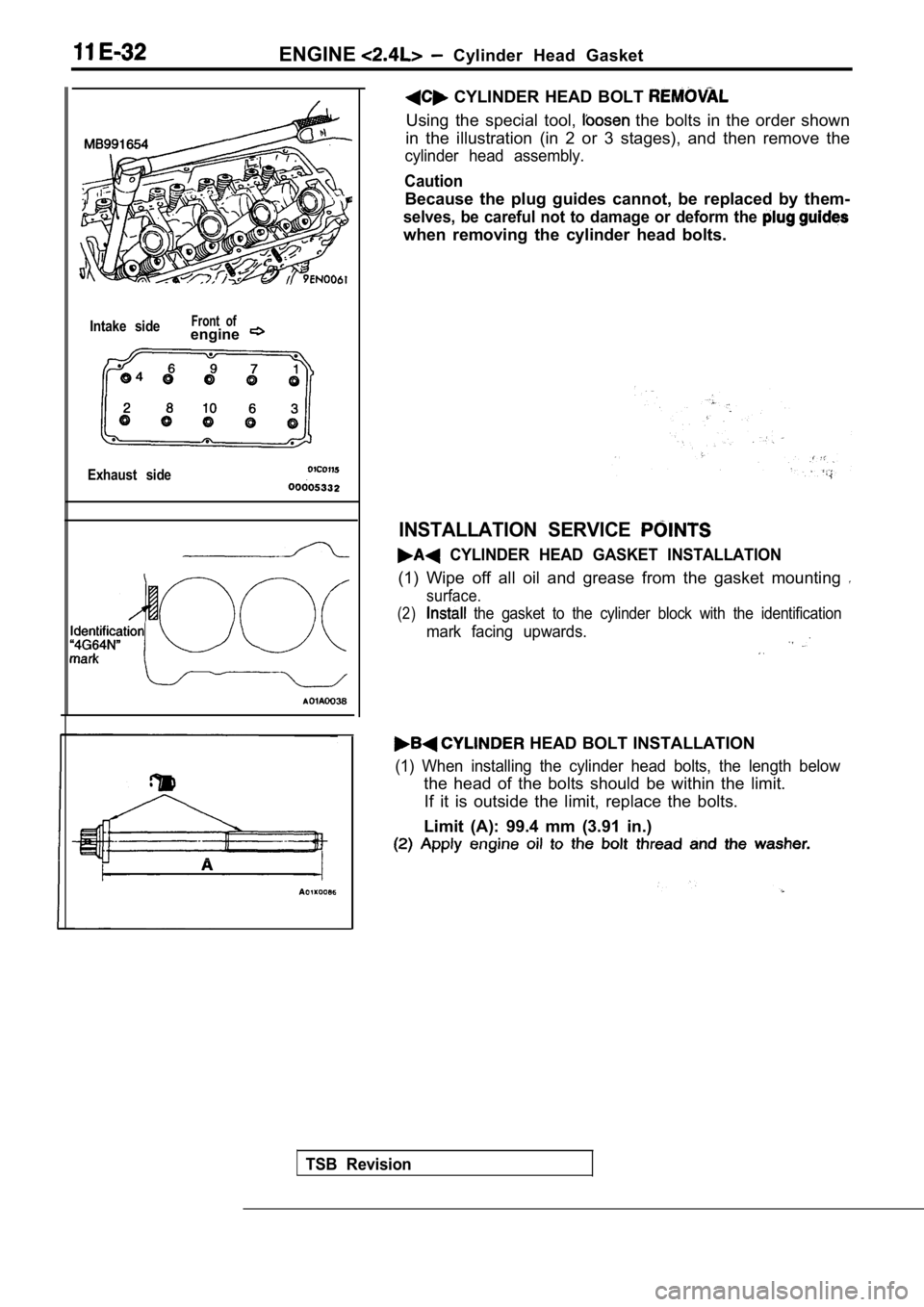

Intake sideFront ofengine

Exhaust side

TSB Revision

CYLINDER HEAD BOLT

Using the special tool, the bolts in the order shown

in the illustration (in 2 or 3 stages), and then re move the

cylinder head assembly.

Caution

Because the plug guides cannot, be replaced by them -

selves, be careful not to damage or deform the

when removing the cylinder head bolts.

INSTALLATION SERVICE

CYLINDER HEAD GASKET INSTALLATION

(1) Wipe off all oil and grease from the gasket mounting

surface.

(2) the gasket to the cylinder block with the identification

mark facing upwards.

HEAD BOLT INSTALLATION

(1) When installing the cylinder head bolts, the le ngth below

the head of the bolts should be within the limit.

If it is outside the limit, replace the bolts.

Limit (A): 99.4 mm (3.91 in.)

Trending: engine coolant, suspension, reset, airbag, jacking, change time, radiator