MITSUBISHI SPYDER 1990 Service Repair Manual

SPYDER 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57345/w960_57345-0.png

MITSUBISHI SPYDER 1990 Service Repair Manual

Trending: wipers, wheel alignment, horn, airbag, washer fluid, water pump, length

Page 321 of 2103

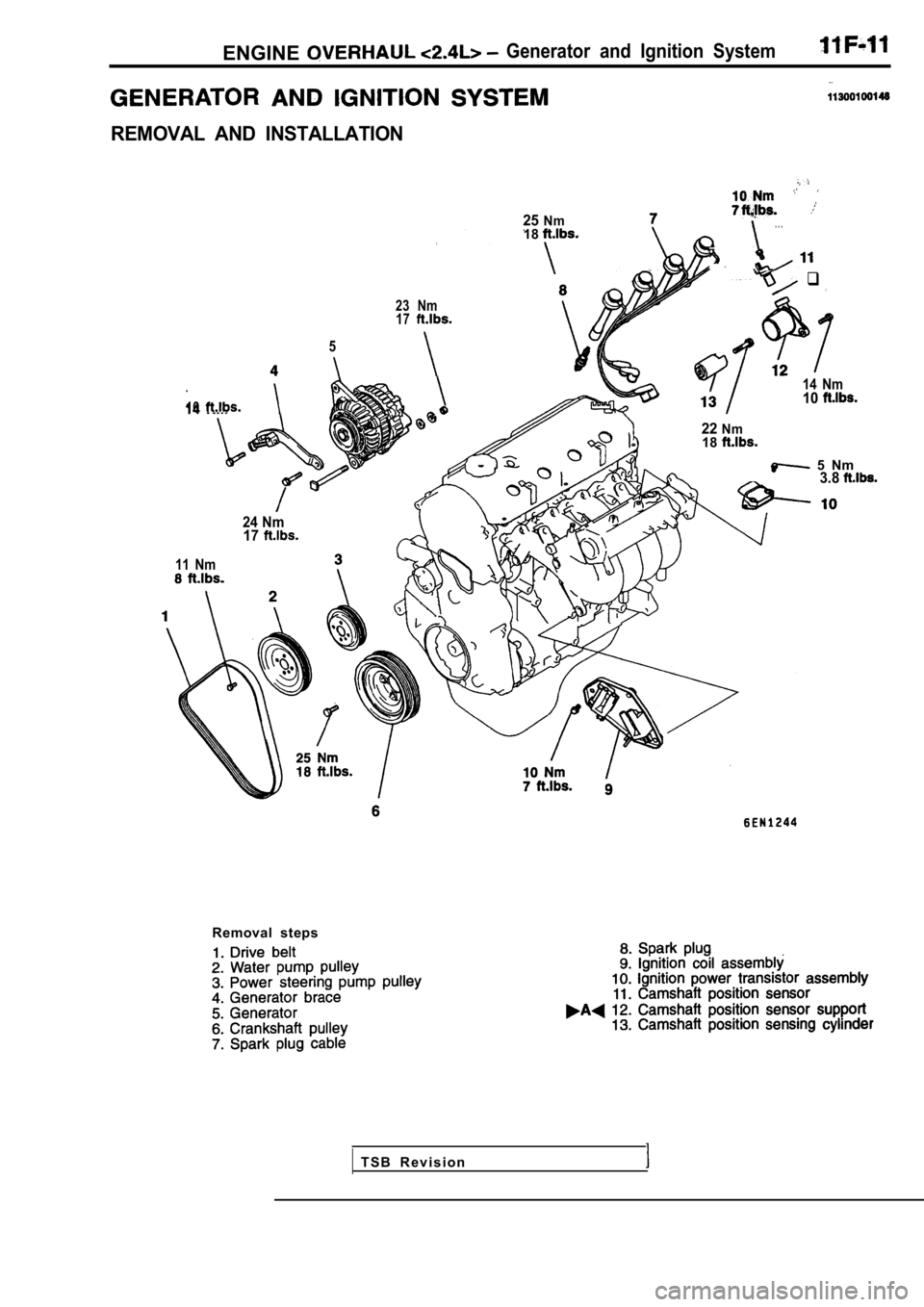

ENGINEGenerator and Ignition System

REMOVAL AND INSTALLATION

23 Nm17

5

10

25Nm18. . .

q

14 Nm10

22Nm18

5 Nm3.8

Removal steps

24 Nm17

11 Nm

T S B R e v i s i o n

Page 322 of 2103

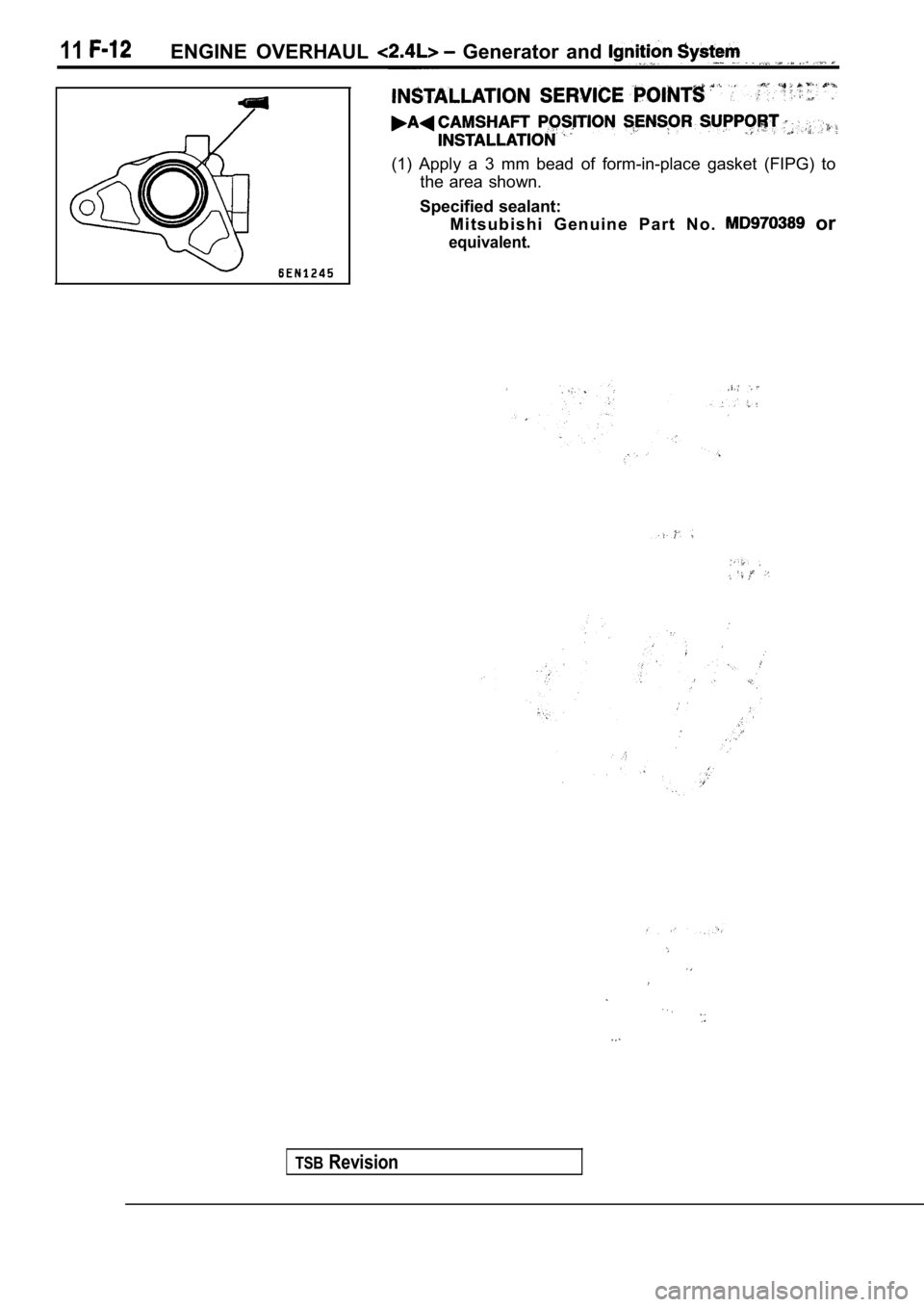

11ENGINE OVERHAUL Generator and

TSBRevision

(1) Apply a 3 mm bead of form-in-place gasket (FIPG) to

the area shown.

Specified sealant: M i t s u b i s h i G e n u i n e P a r t N o .

or

equivalent.

Page 323 of 2103

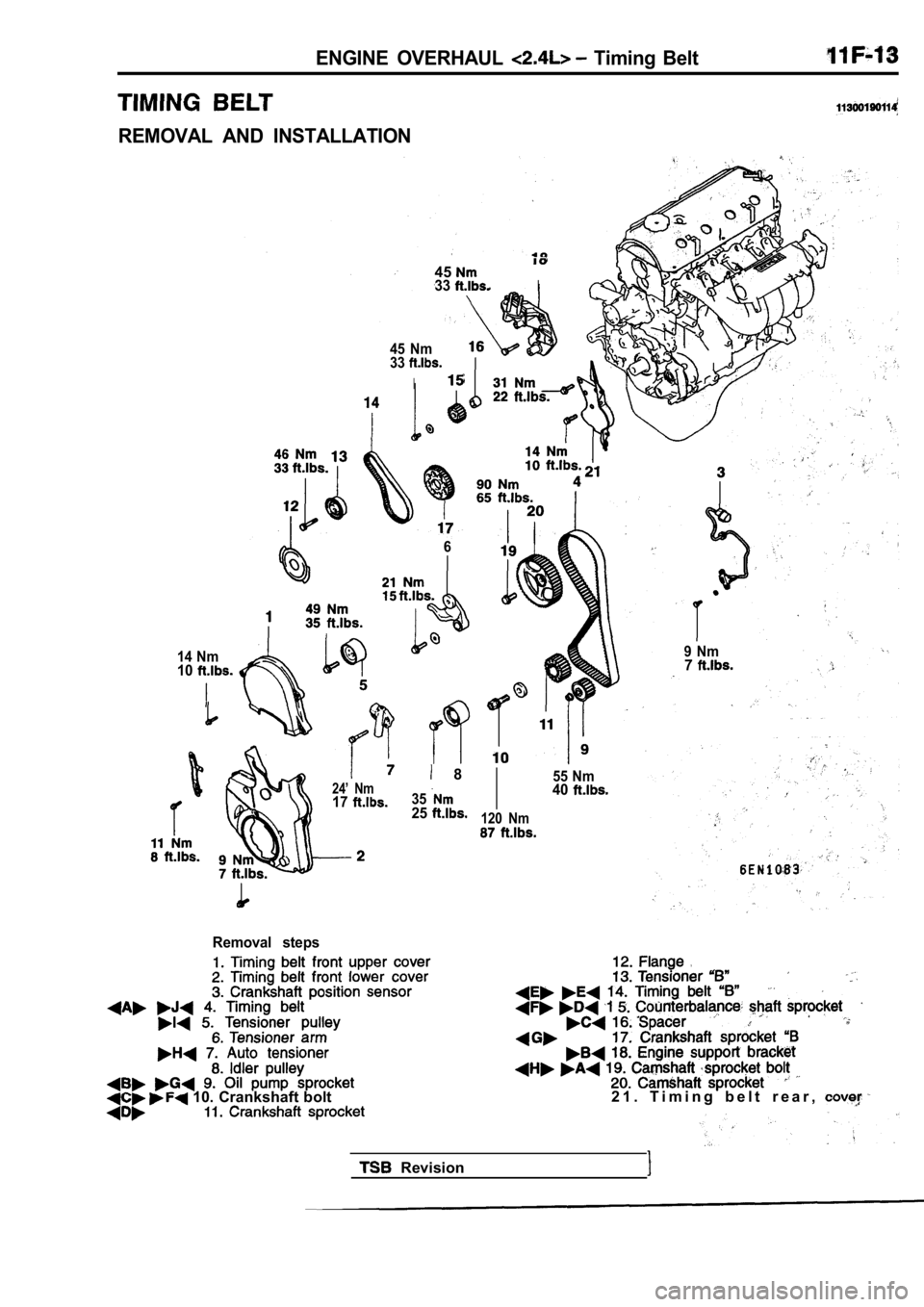

ENGINE OVERHAUL Timing Belt

REMOVAL AND INSTALLATION

4533I

45 Nm

33

I

24’ Nm17

55 Nm40

120 Nm

6

14 Nm

10

8

3525

9 Nm7

Removal steps

10. Crankshaft bolt2 1 . T i m i n g b e l t r e a r ,

Revision

Page 324 of 2103

ENGINE OVERHAUL Timing Belt , ,

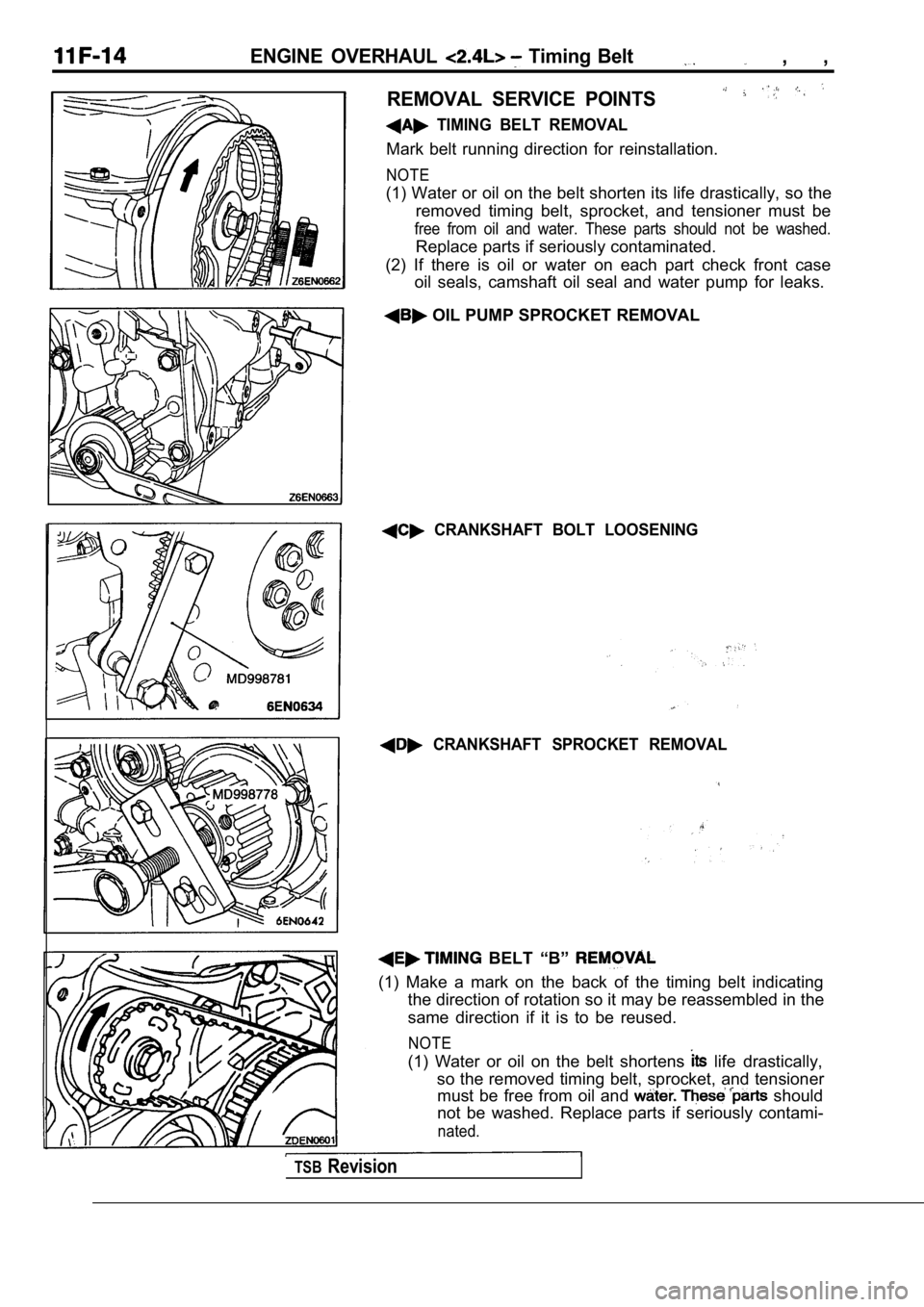

REMOVAL SERVICE POINTS

TIMING BELT REMOVAL

Mark belt running direction for reinstallation.

NOTE

(1) Water or oil on the belt shorten its life drastically, so the

removed timing belt, sprocket, and tensioner must b e

free from oil and water. These parts should not be washed.

Replace parts if seriously contaminated.

(2) If there is oil or water on each part check fro nt case

oil seals, camshaft oil seal and water pump for lea ks.

OIL PUMP SPROCKET REMOVAL

CRANKSHAFT BOLT LOOSENING

CRANKSHAFT SPROCKET REMOVAL

BELT “B”

(1) Make a mark on the back of the timing belt indi cating

the direction of rotation so it may be reassembled in the

same direction if it is to be reused.

NOTE

(1) Water or oil on the belt shortens life drastically,

so the removed timing belt, sprocket, and tensioner must be free from oil and

should

not be washed. Replace parts if seriously contami-

nated.

TSBRevision

Page 325 of 2103

ENGINE OVERHAUL Timing Belt

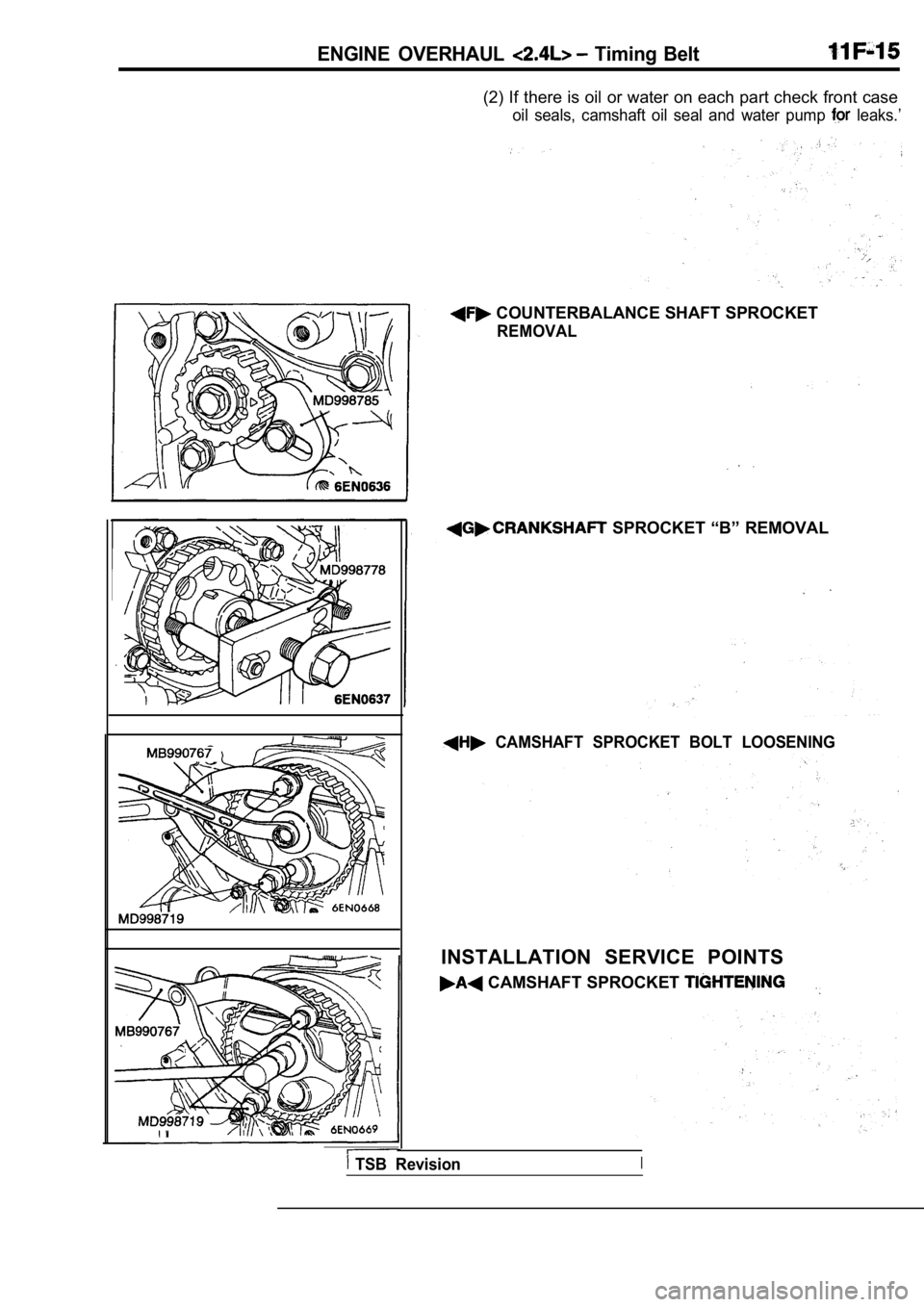

(2) If there is oil or water on each part check front case

oil seals, camshaft oil seal and water pump leaks.’

COUNTERBALANCE SHAFT SPROCKET

REMOVAL

SPROCKET “B” REMOVAL

CAMSHAFT SPROCKET BOLT LOOSENING

INSTALLATION SERVICE POINTS

CAMSHAFT SPROCKET

TSB RevisionI

Page 326 of 2103

ENGINE OVERHAUL Timing,

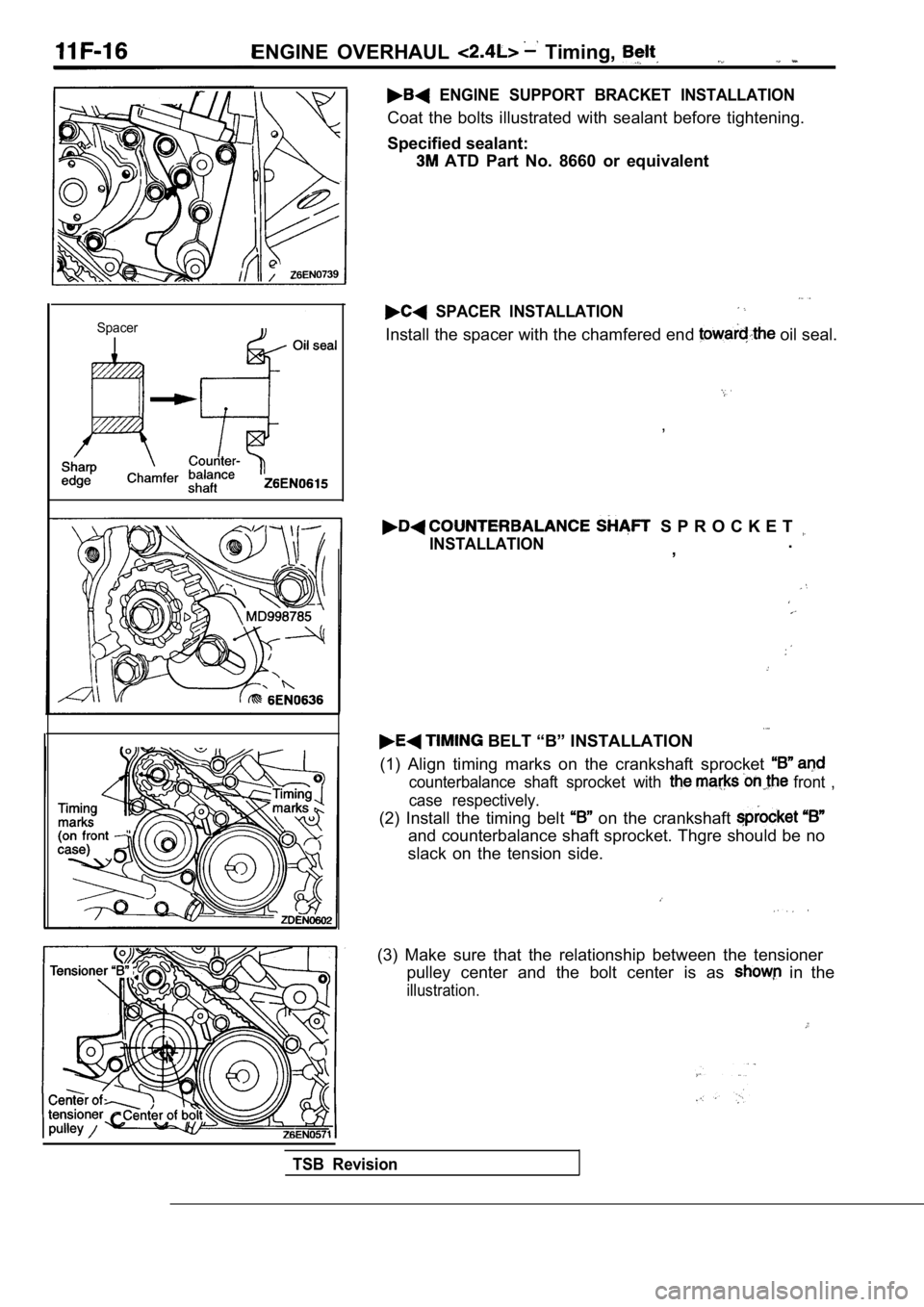

ENGINE SUPPORT BRACKET INSTALLATION

Spacer

Coat the bolts illustrated with sealant before tightening.

Specified sealant:

ATD Part No. 8660 or equivalent

SPACER INSTALLATION

Install the spacer with the chamfered end oil seal.

,

S P R O C K E T

INSTALLATION.

,

BELT “B” INSTALLATION

(1) Align timing marks on the crankshaft sprocket

counterbalance shaft sprocket with front ,

case respectively.

(2) Install the timing belt on the crankshaft

and counterbalance shaft sprocket. Thgre should be no

slack on the tension side.

(3) Make sure that the relationship between the ten sioner

pulley center and the bolt center is as

in the

illustration.

TSB Revision

Page 327 of 2103

ENGINE OVERHAUL Timing Belt

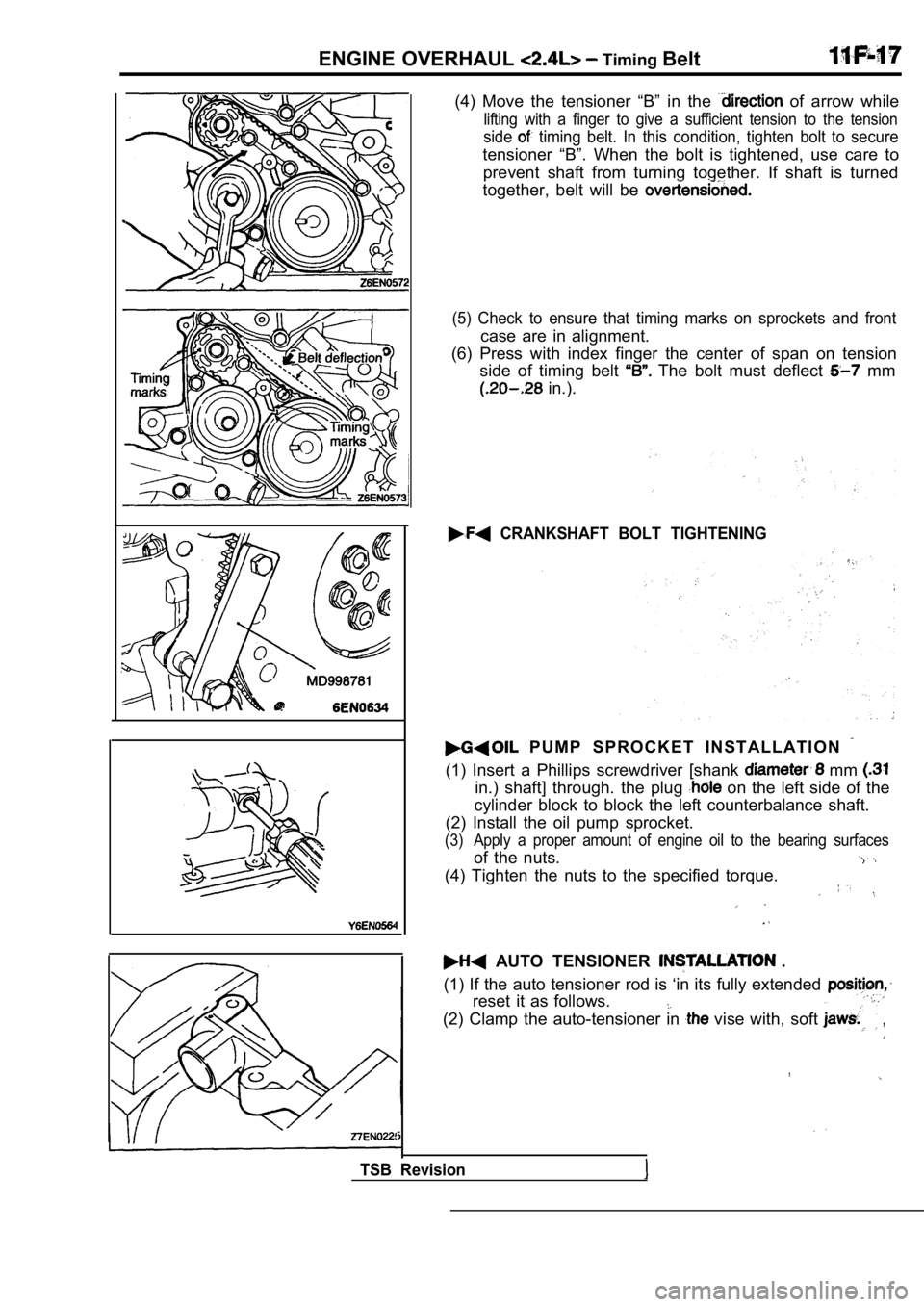

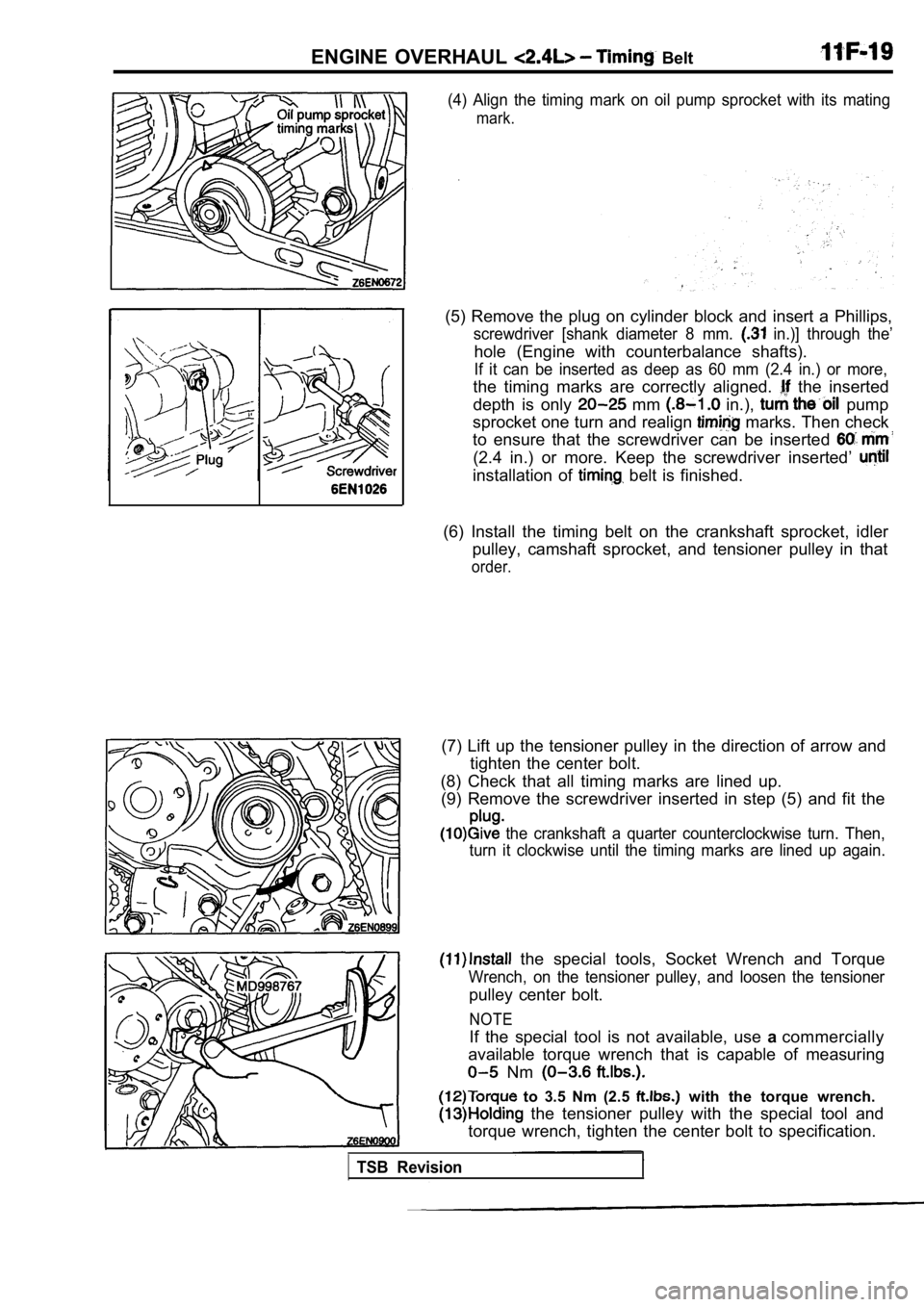

(4) Move the tensioner “B” in the of arrow while

lifting with a finger to give a sufficient tension to the tension

side timing belt. In this condition, tighten bolt to secure

tensioner “B”. When the bolt is tightened, use care to

prevent shaft from turning together. If shaft is tu rned

together, belt will be

(5) Check to ensure that timing marks on sprockets and front

case are in alignment.

(6) Press with index finger the center of span on t ension

side of timing belt

The bolt must deflect mm

in.).

CRANKSHAFT BOLT TIGHTENING

P U M P S P R O C K E T I N S T A L L A T I O N

(1) Insert a Phillips screwdriver [shank mm

in.) shaft] through. the plug on the left side of the

cylinder block to block the left counterbalance sha ft.

(2) Install the oil pump sprocket.

(3) Apply a proper amount of engine oil to the beari ng surfaces

of the nuts.

(4) Tighten the nuts to the specified torque.

AUTO TENSIONER .

(1) If the auto tensioner rod is ‘in its fully exte nded

reset it as follows.

(2) Clamp the auto-tensioner in vise with, soft ,

TSB Revision

Page 328 of 2103

E N G I N E O V E R H A U L Belt

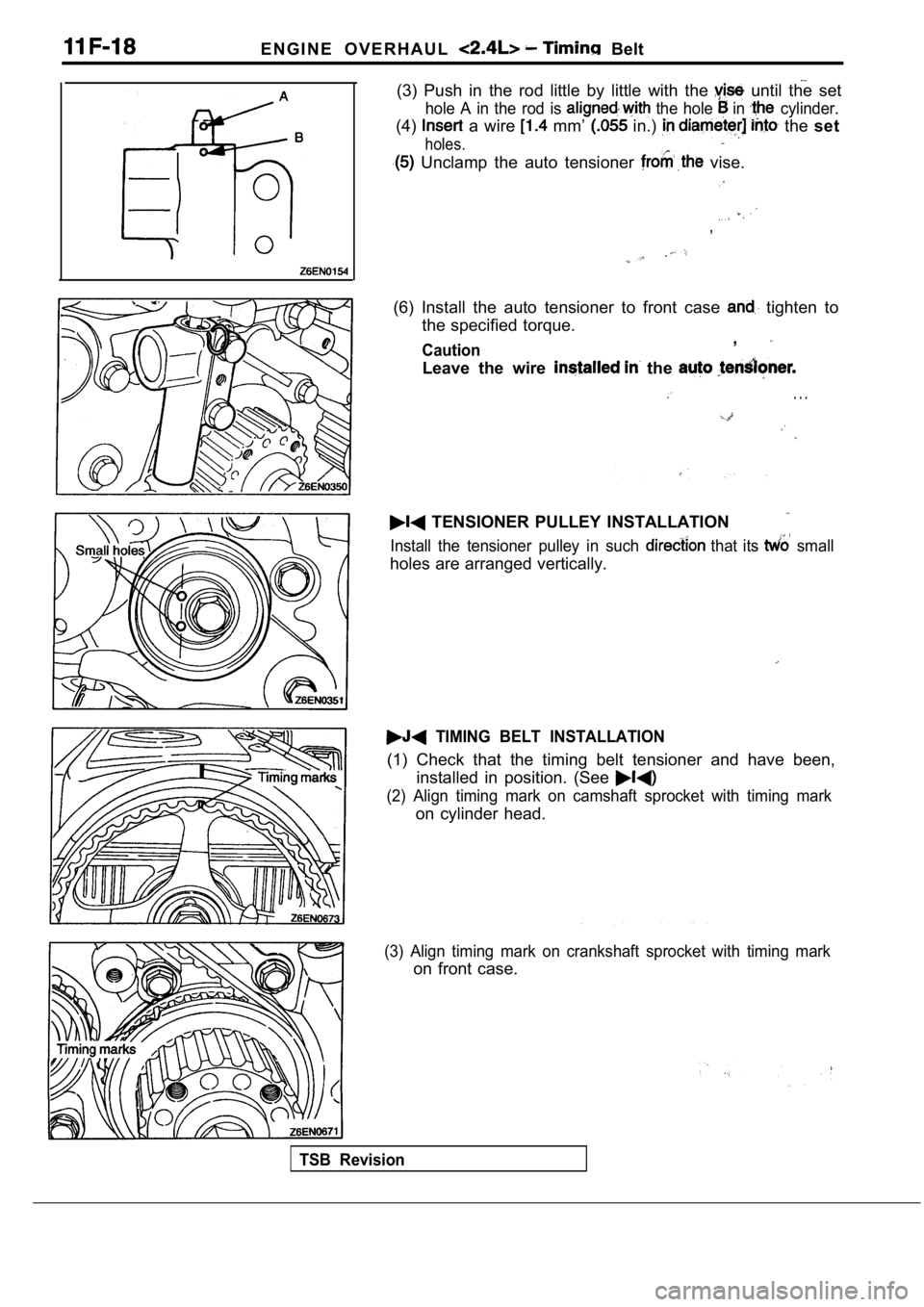

(3) Push in the rod little by little with the until the set

hole A in the rod is the hole in cylinder.

(4) a wire mm’ in.) the set

holes.

Unclamp the auto tensioner vise.

,

(6) Install the auto tensioner to front case tighten to

the specified torque.

Caution,

Leave the wire the

. . .

TENSIONER PULLEY INSTALLATION

Install the tensioner pulley in such that its small

holes are arranged vertically.

TIMING BELT INSTALLATION

(1) Check that the timing belt tensioner and have b een,

installed in position. (See

(2) Align timing mark on camshaft sprocket with tim ing mark

on cylinder head.

(3) Align timing mark on crankshaft sprocket with timing mark

on front case.

TSB Revision

Page 329 of 2103

ENGINE OVERHAUL Belt

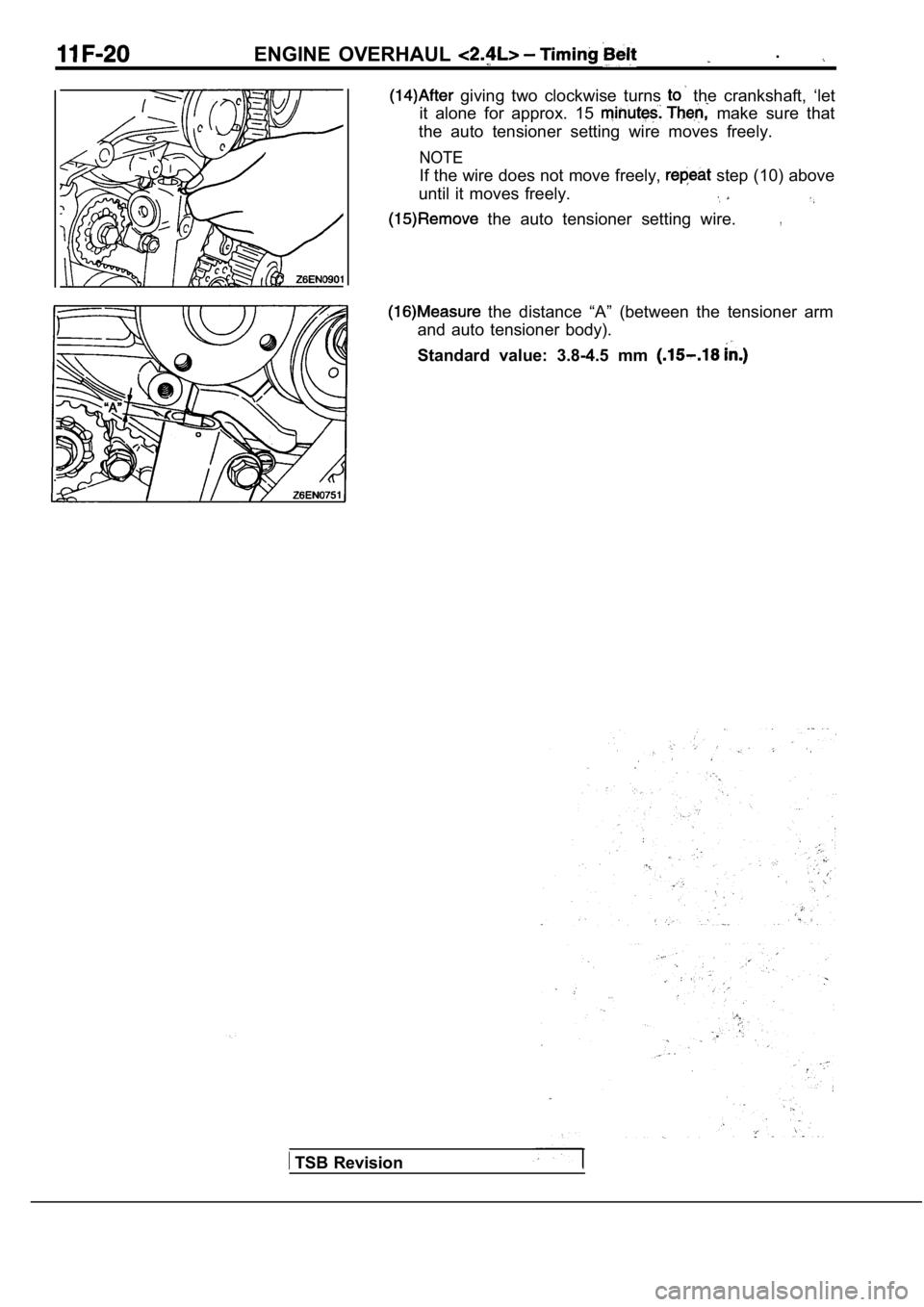

(4) Align the timing mark on oil pump sprocket with its mating

mark.

(5) Remove the plug on cylinder block and insert a Phillips,

screwdriver [shank diameter 8 mm. in.)] through the’

hole (Engine with counterbalance shafts).

If it can be inserted as deep as 60 mm (2.4 in.) or more,

the timing marks are correctly aligned. the inserted

depth is only

mm in.), pump

sprocket one turn and realign

marks. Then check

to ensure that the screwdriver can be inserted

(2.4 in.) or more. Keep the screwdriver inserted’

installation of belt is finished.

(6) Install the timing belt on the crankshaft sproc ket, idler

pulley, camshaft sprocket, and tensioner pulley in that

order.

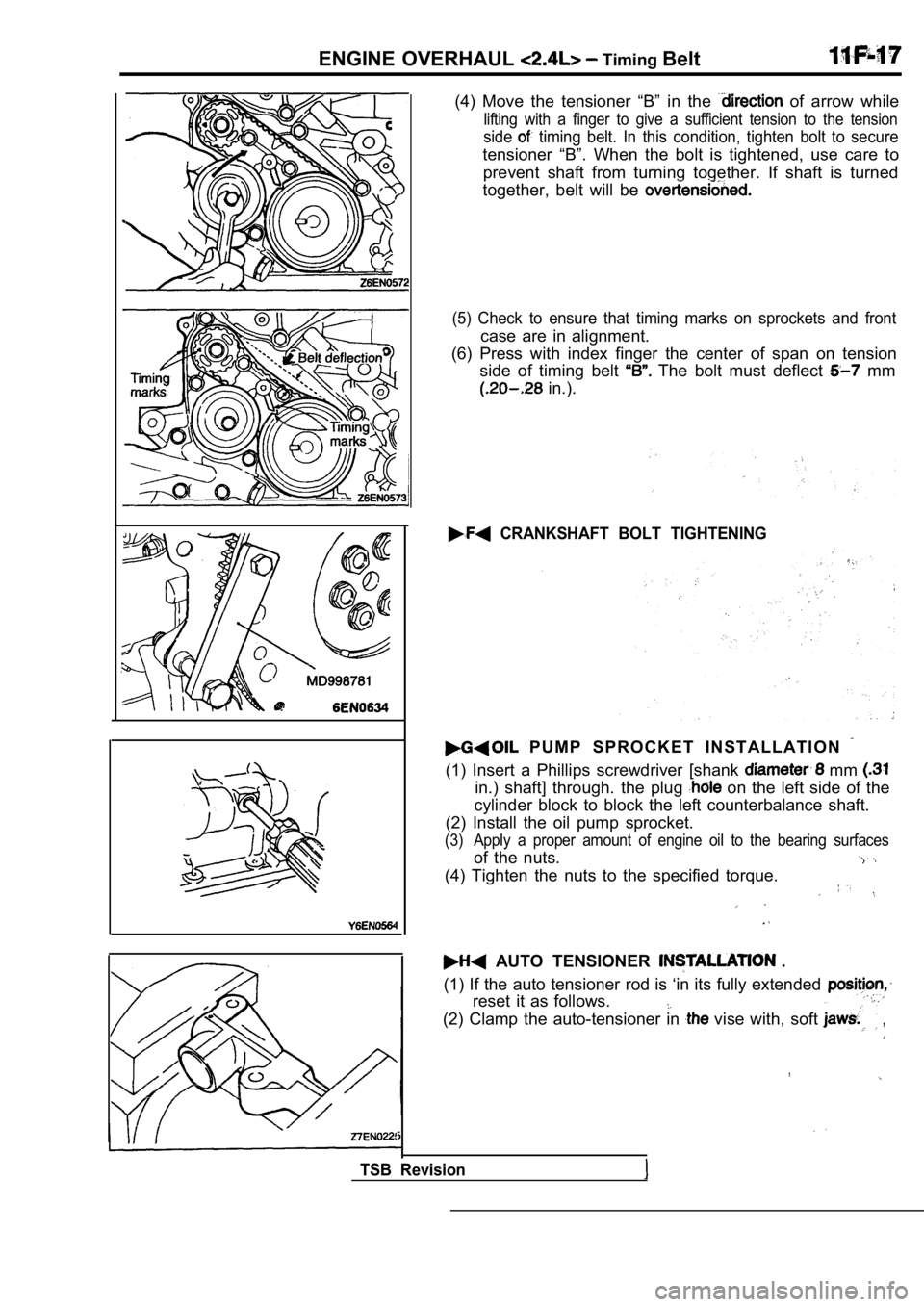

(7) Lift up the tensioner pulley in the direction of arrow and

tighten the center bolt.

(8) Check that all timing marks are lined up. (9) Remove the screwdriver inserted in step (5) and fit the

the crankshaft a quarter counterclockwise turn. Then,

turn it clockwise until the timing marks are lined up again.

the special tools, Socket Wrench and Torque

Wrench, on the tensioner pulley, and loosen the ten sioner

pulley center bolt.

to 3.5 Nm (2.5 with the torque wrench.

the tensioner pulley with the special tool and

torque wrench, tighten the center bolt to specifica tion.

NOTE

If the special tool is not available, use acommercially

available torque wrench that is capable of measurin g

Nm

TSB Revision

Page 330 of 2103

ENGINE OVERHAUL .

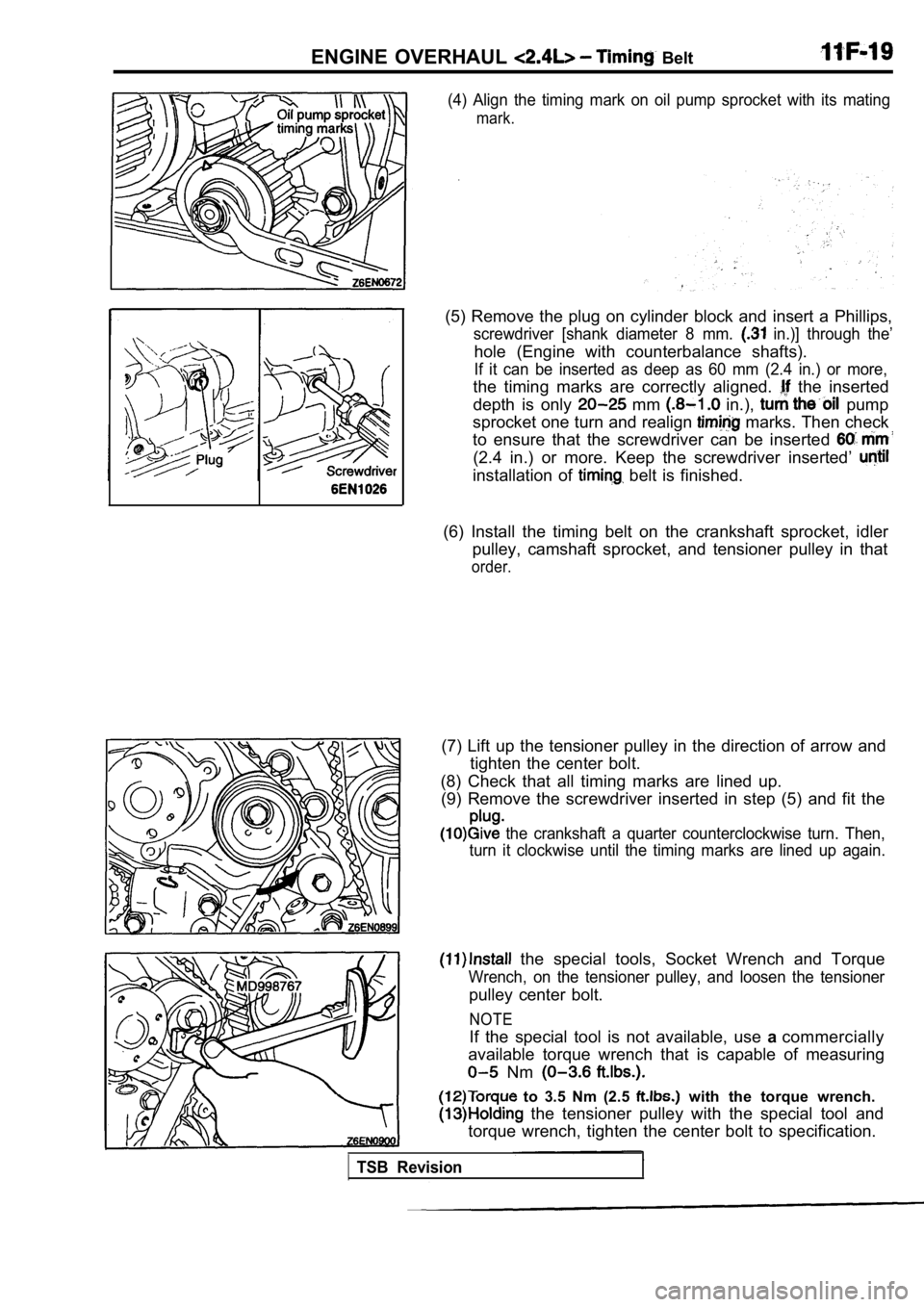

giving two clockwise turns the crankshaft, ‘let

it alone for approx. 15

make sure that

the auto tensioner setting wire moves freely.

NOTE

If the wire does not move freely, step (10) above

until it moves freely.

the auto tensioner setting wire.,

TSB Revision

the distance “A” (between the tensioner arm

and auto tensioner body).

Standard value: 3.8-4.5 mm

Trending: seat memory, brake fluid, oil, recommended oil, octane, spark plugs replace, fuel tank removal