MITSUBISHI SPYDER 1990 Service Repair Manual

SPYDER 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57345/w960_57345-0.png

MITSUBISHI SPYDER 1990 Service Repair Manual

Trending: automatic transmission fluid, ad blue, lock, lights, set clock, air conditioning, CD player

Page 331 of 2103

ENGINE OVERHAUL Timing

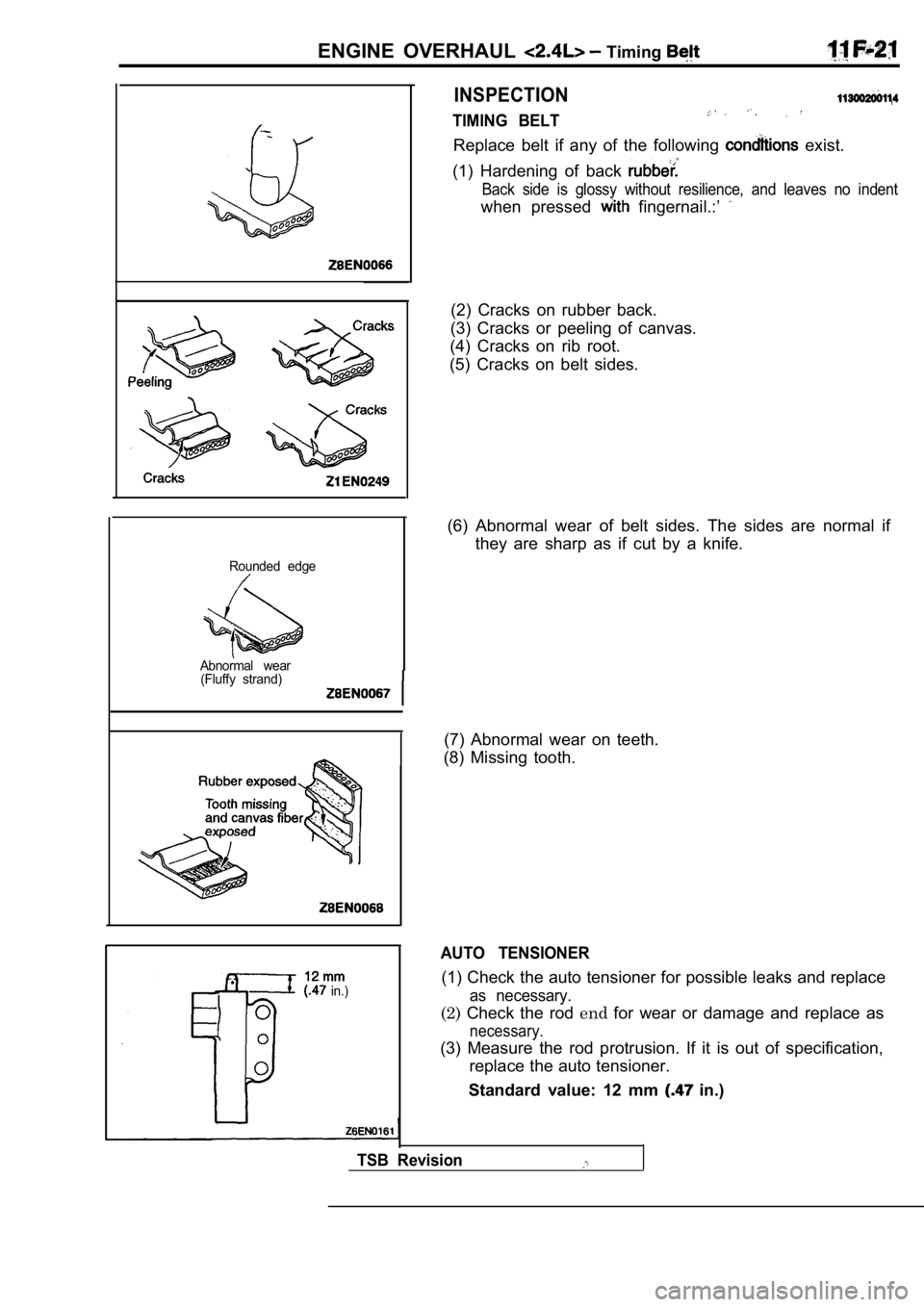

Rounded edge

Abnormal wear (Fluffy strand)

in.)(1) Check the auto tensioner for possible leaks and replace

as necessary.

INSPECTION

TIMING BELT

Replace belt if any of the following exist.

(1) Hardening of back

Back side is glossy without resilience, and leaves no indent

when pressed fingernail.:’

(2) Cracks on rubber back.

(3) Cracks or peeling of canvas.

(4) Cracks on rib root.

(5) Cracks on belt sides.

(6) Abnormal wear of belt sides. The sides are norm al if

they are sharp as if cut by a knife.

(7) Abnormal wear on teeth.

(8) Missing tooth.

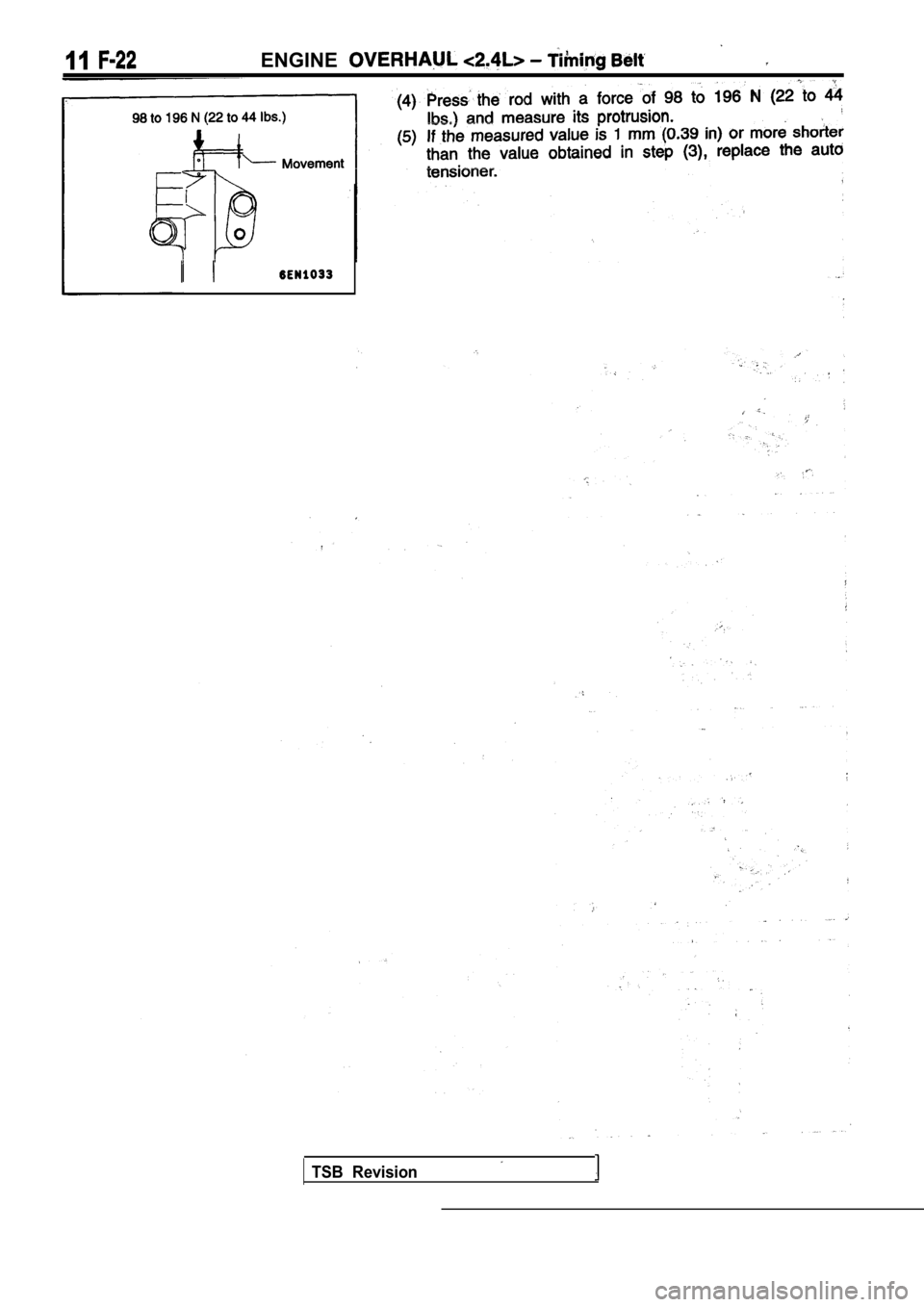

AUTO TENSIONER

(2) Check the rod endfor wear or damage and replace as

necessary.

(3) Measure the rod protrusion. If it is out of spe cification,

replace the auto tensioner.

Standard value: 12 mm

in.)

TSB Revision

Page 332 of 2103

Page 333 of 2103

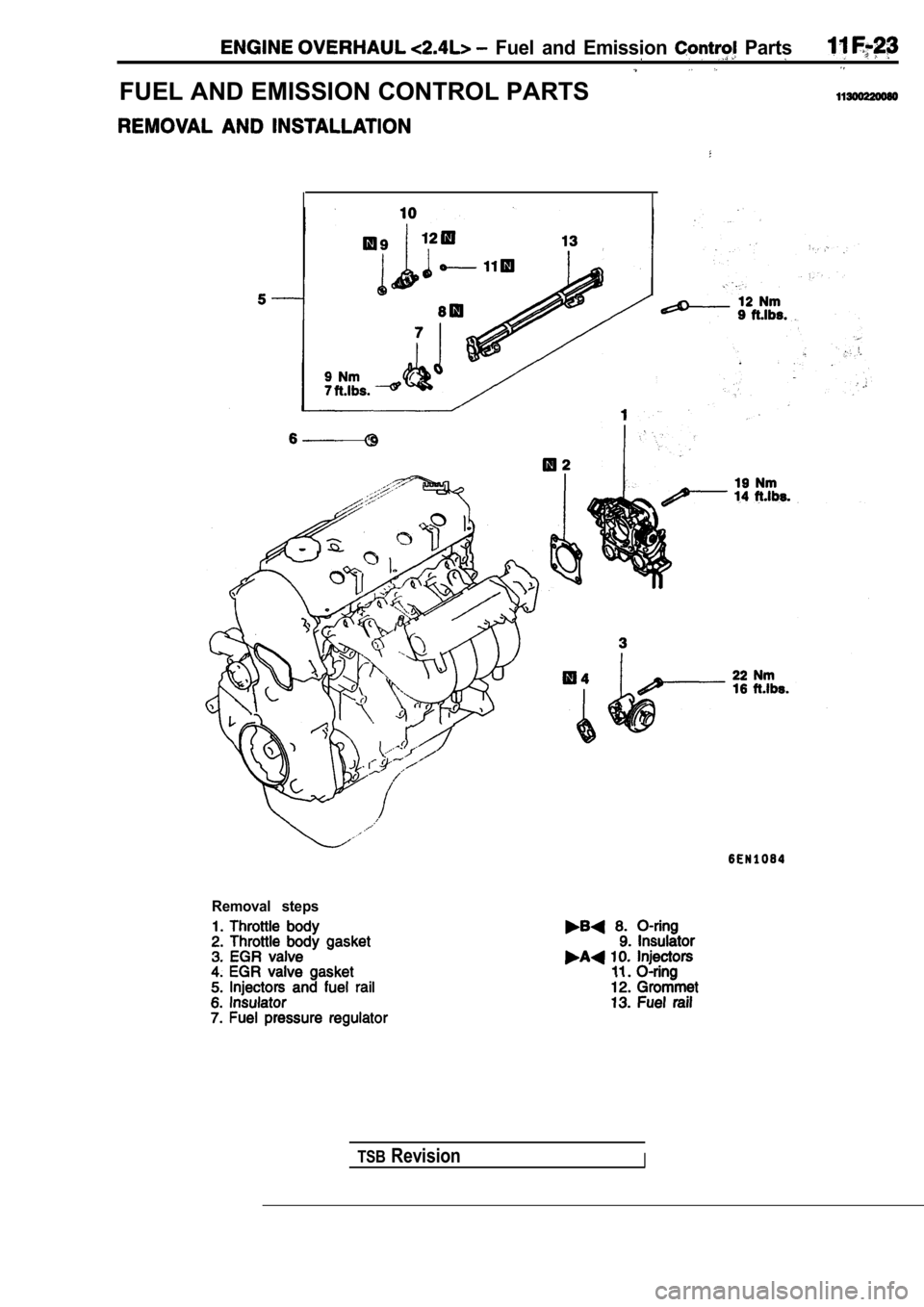

Fuel and Emission Parts

FUEL AND EMISSION CONTROL PARTS

Removal steps

TSBRevisionI

Page 334 of 2103

, . .

11 ENGINE OVERHAUL Fuel and . .

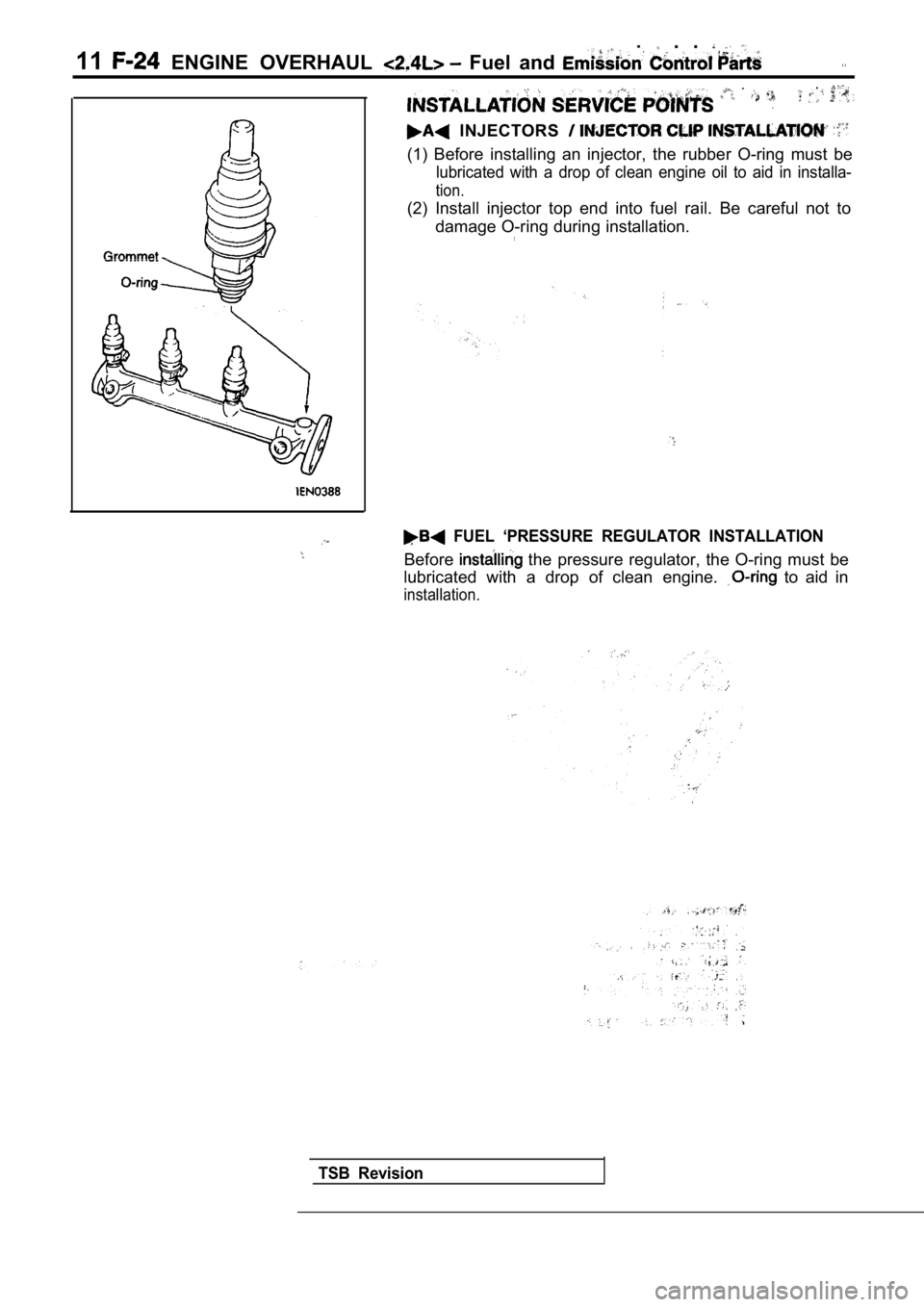

INJECTORS

(1) Before installing an injector, the rubber O-ring must be

lubricated with a drop of clean engine oil to aid in installa-

tion.

(2) Install injector top end into fuel rail. Be careful not to

damage O-ring during installation.

FUEL ‘PRESSURE REGULATOR INSTALLATION

Before the pressure regulator, the O-ring must be

lubricated with a drop of clean engine.

to aid in

installation.

TSB Revision

Page 335 of 2103

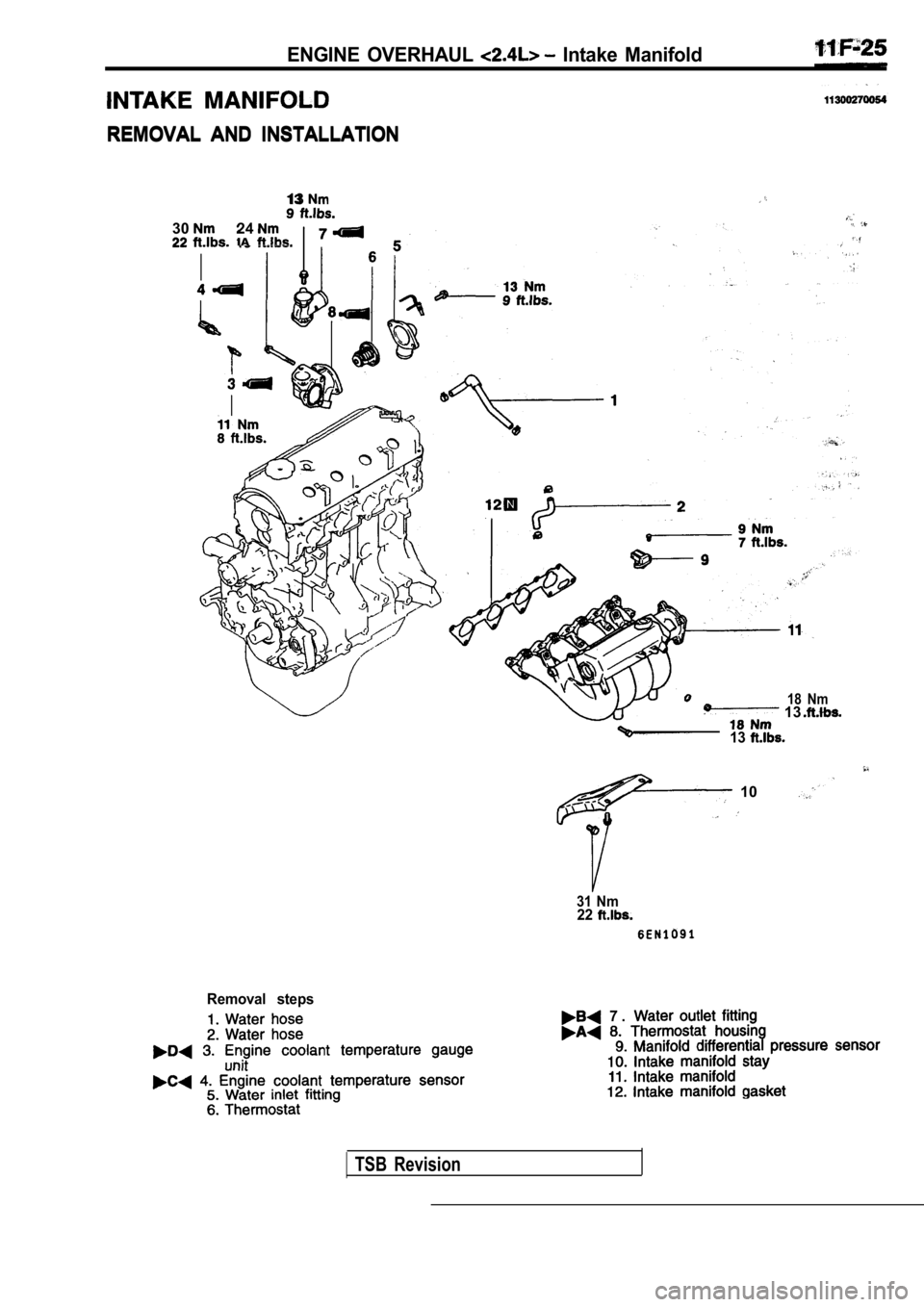

ENGINE OVERHAUL Intake Manifold

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

3024IAI

13

18 Nm 13

13

10

31 Nm22

Removal steps

7 .

TSB Revision

Page 336 of 2103

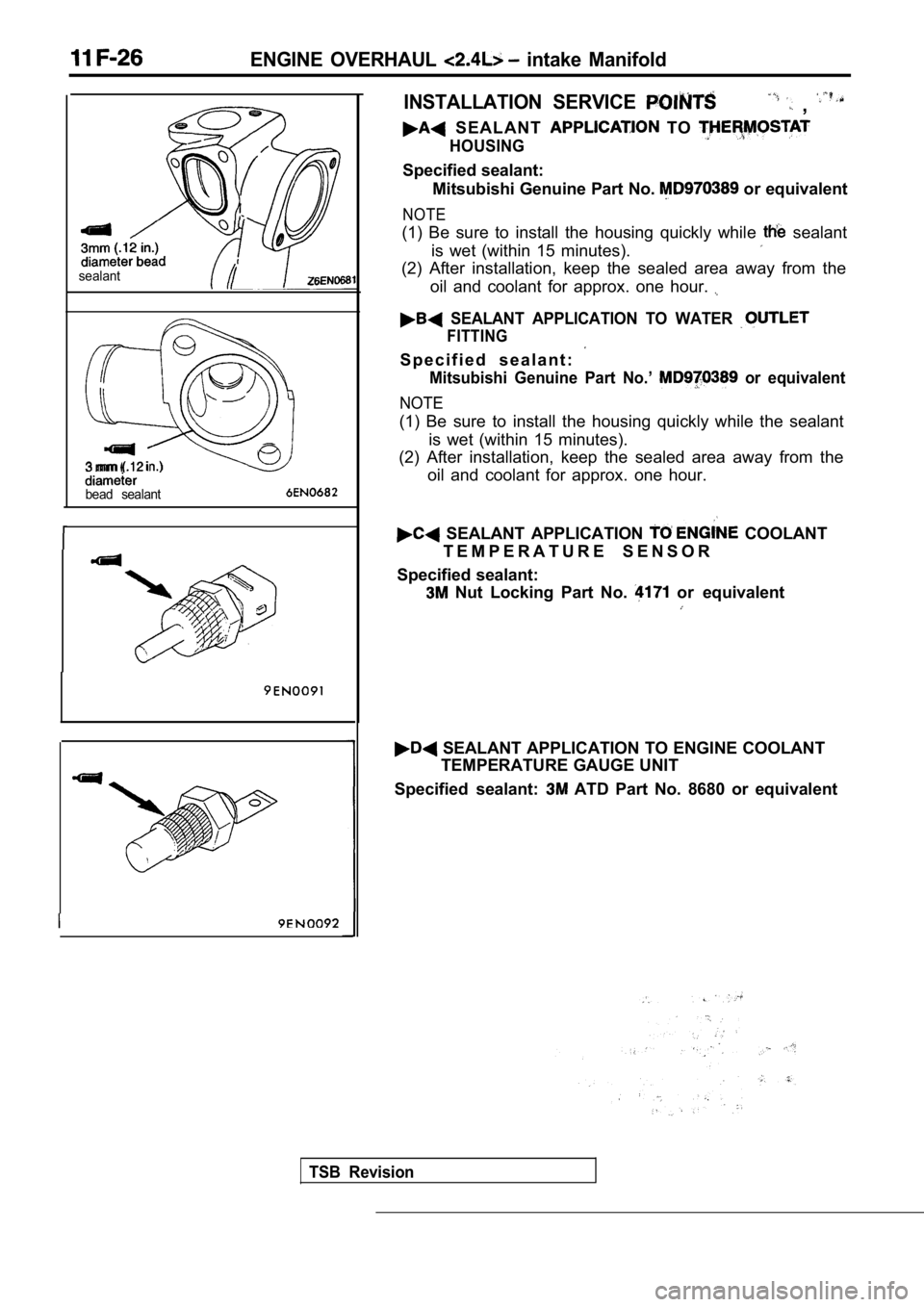

ENGINE OVERHAUL intake Manifold

sealant

3 mm

bead sealant

INSTALLATION SERVICE ,

S E A L A N T TO

HOUSING

Specified sealant:Mitsubishi Genuine Part No.

or equivalent

NOTE

(1) Be sure to install the housing quickly while sealant

is wet (within 15 minutes).

(2) After installation, keep the sealed area away f rom the

oil and coolant for approx. one hour.

SEALANT APPLICATION TO WATER

FITTING

S p e c i f i e d s e a l a n t :

Mitsubishi Genuine Part No.’ or equivalent

NOTE

(1) Be sure to install the housing quickly while th e sealant

is wet (within 15 minutes).

(2) After installation, keep the sealed area away f rom the

oil and coolant for approx. one hour.

SEALANT APPLICATION COOLANT

T E M P E R A T U R E S E N S O R

Specified sealant:

Nut Locking Part No. or equivalent

SEALANT APPLICATION TO ENGINE COOLANT TEMPERATURE GAUGE UNIT

Specified sealant:

ATD Part No. 8680 or equivalent

TSB Revision

Page 337 of 2103

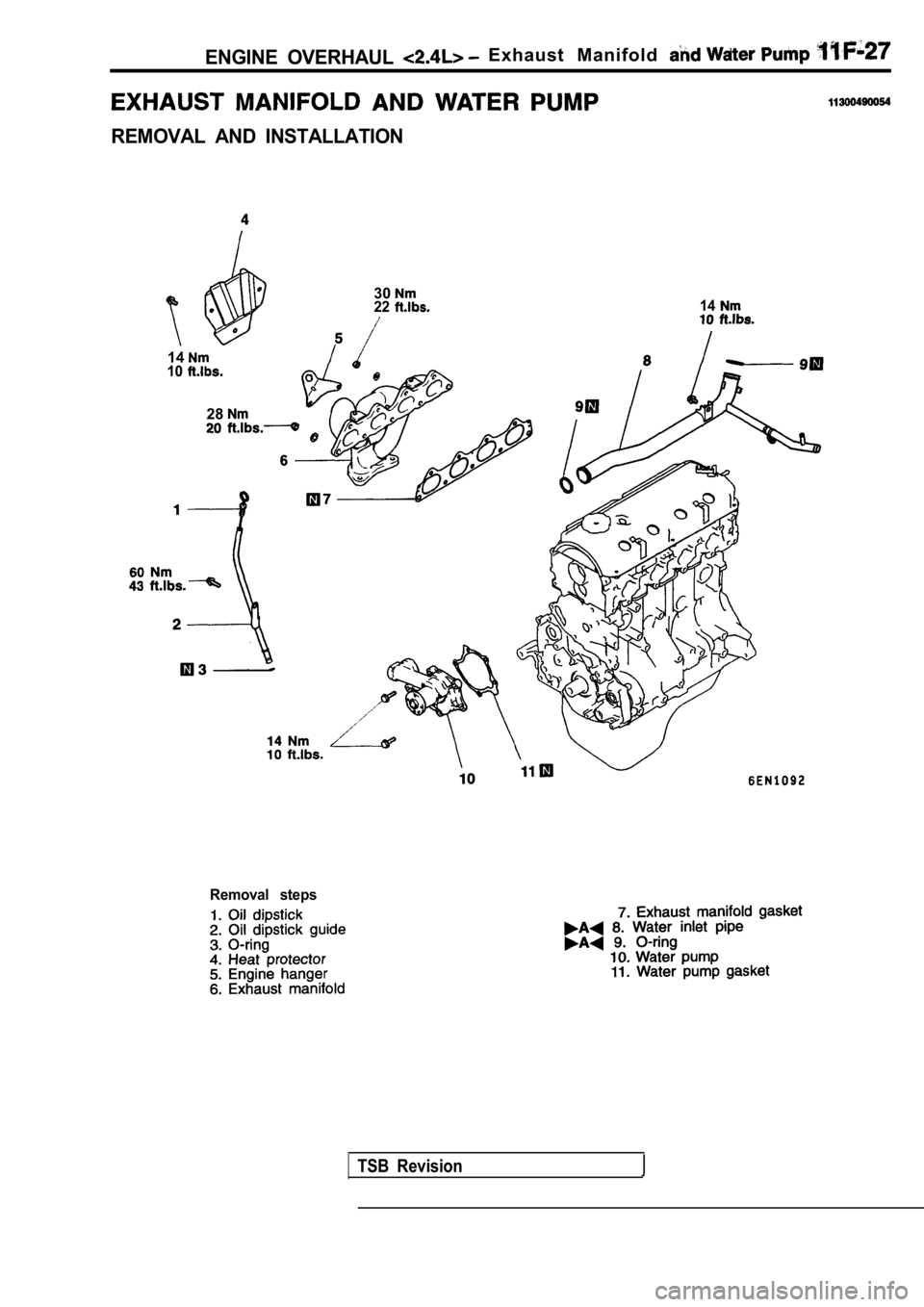

ENGINE OVERHAUL Exhaust Manifold

REMOVAL AND INSTALLATION

3022

1410

28

14

Removal steps

TSB Revision

Page 338 of 2103

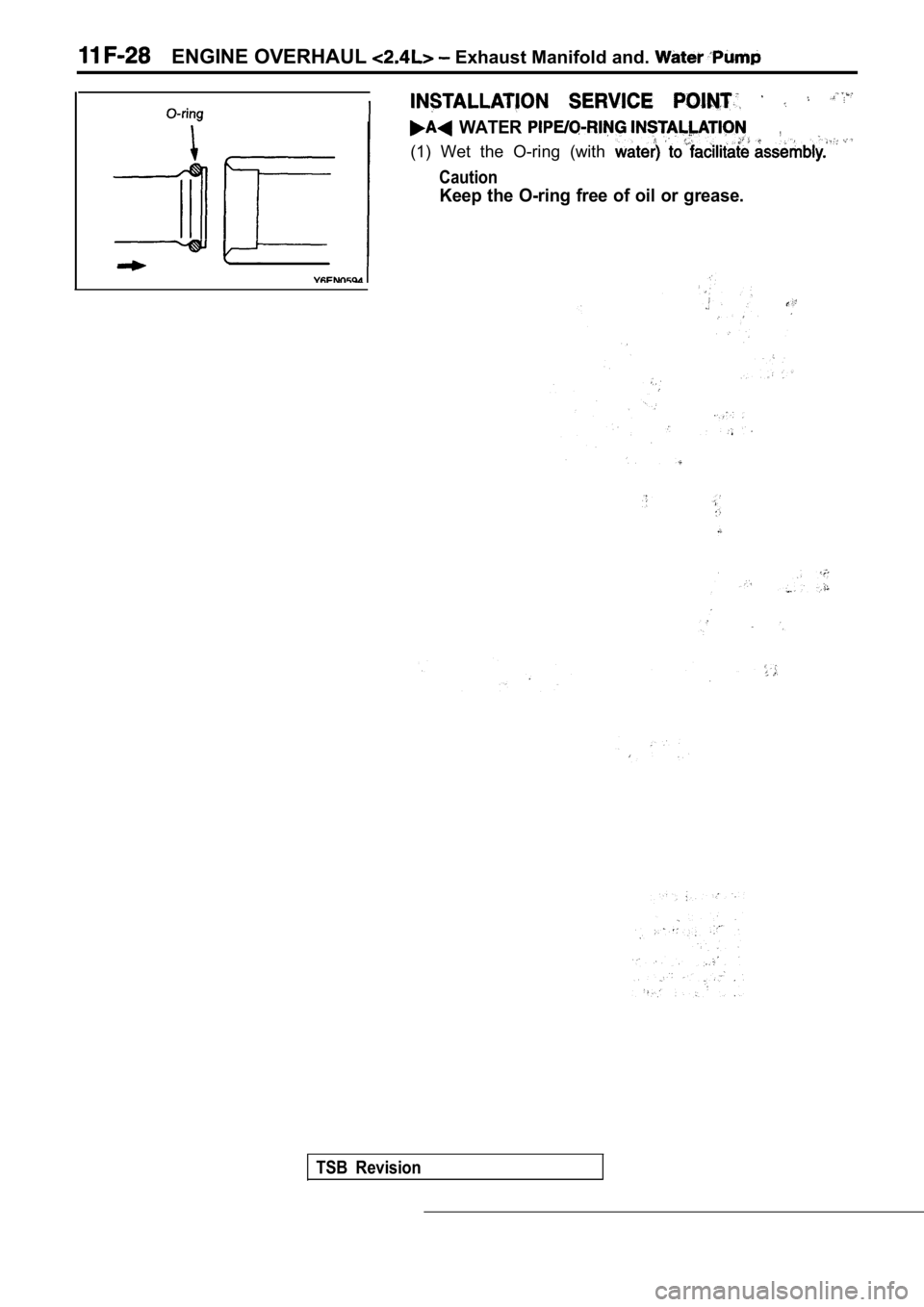

ENGINE OVERHAUL Exhaust Manifold and.

WATER ,

(1) Wet the O-ring (with

Caution

Keep the O-ring free of oil or grease.

TSB Revision

Page 339 of 2103

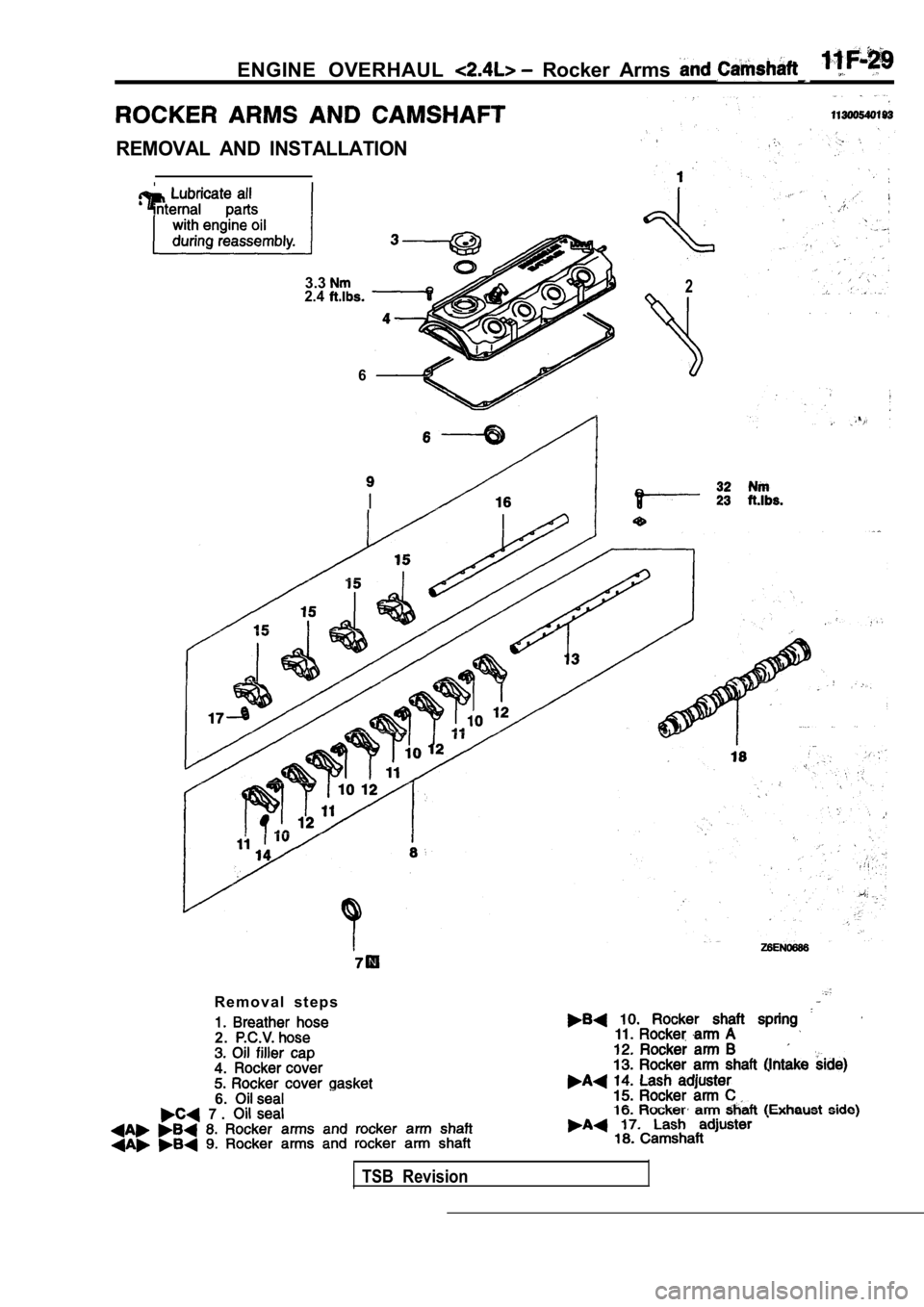

ENGINE OVERHAUL Rocker Arms

REMOVAL AND INSTALLATION

3.32.4

6

2

R e m o v a l s t e p s

2.

4.

6. 7 .

TSB Revision

Page 340 of 2103

ENGINE OVERHAUL Rocker Arms and Camshaft

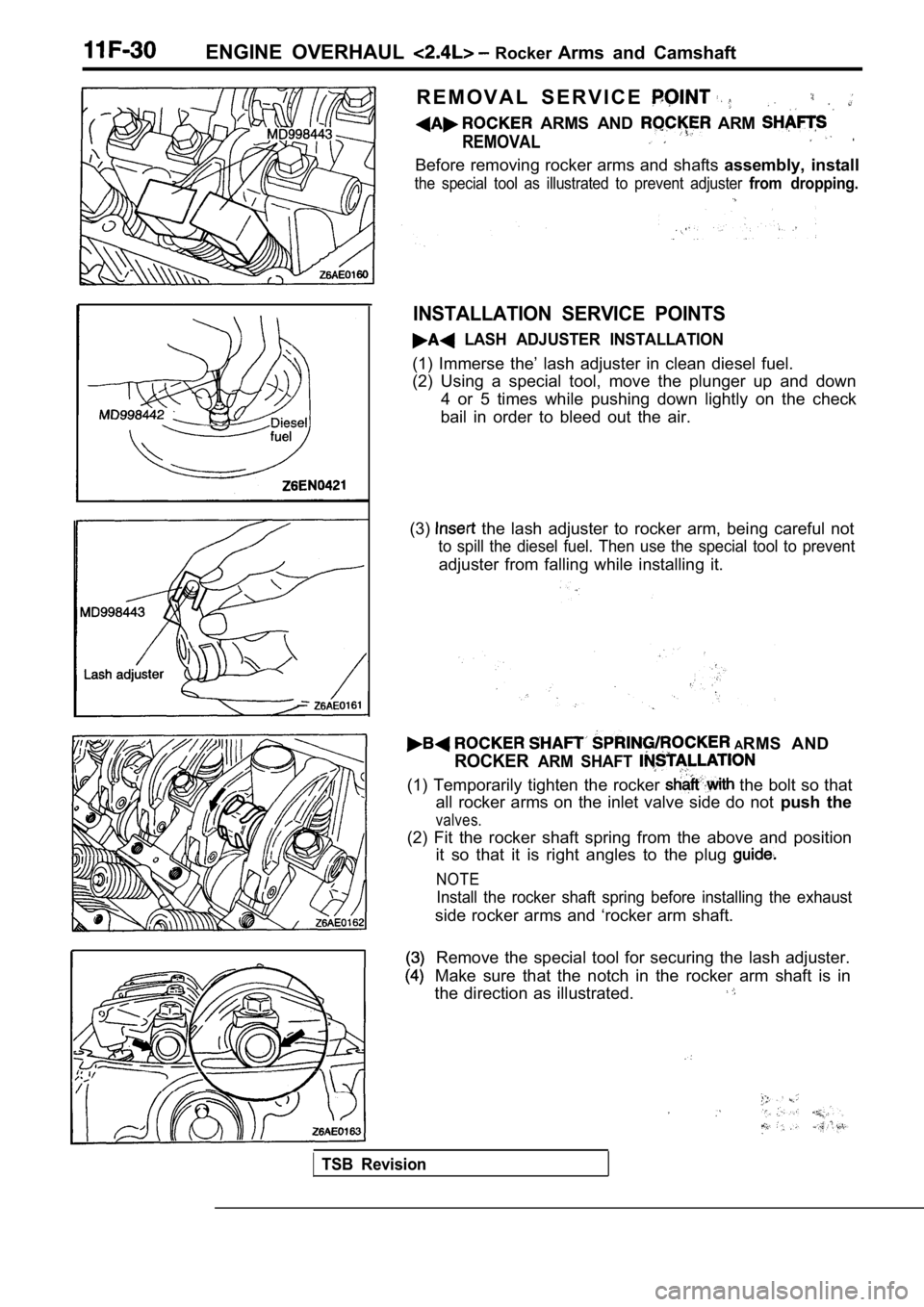

R E M O V A L S E R V I C E

ARMS AND ARM

REMOVAL.

Before removing rocker arms and shafts assembly, install

the special tool as illustrated to prevent adjuster from dropping.

INSTALLATION SERVICE POINTS

LASH ADJUSTER INSTALLATION

(1) Immerse the’ lash adjuster in clean diesel fuel .

(2) Using a special tool, move the plunger up and d own

4 or 5 times while pushing down lightly on the chec k

bail in order to bleed out the air.

(3)

the lash adjuster to rocker arm, being careful not

to spill the diesel fuel. Then use the special tool to prevent

adjuster from falling while installing it.

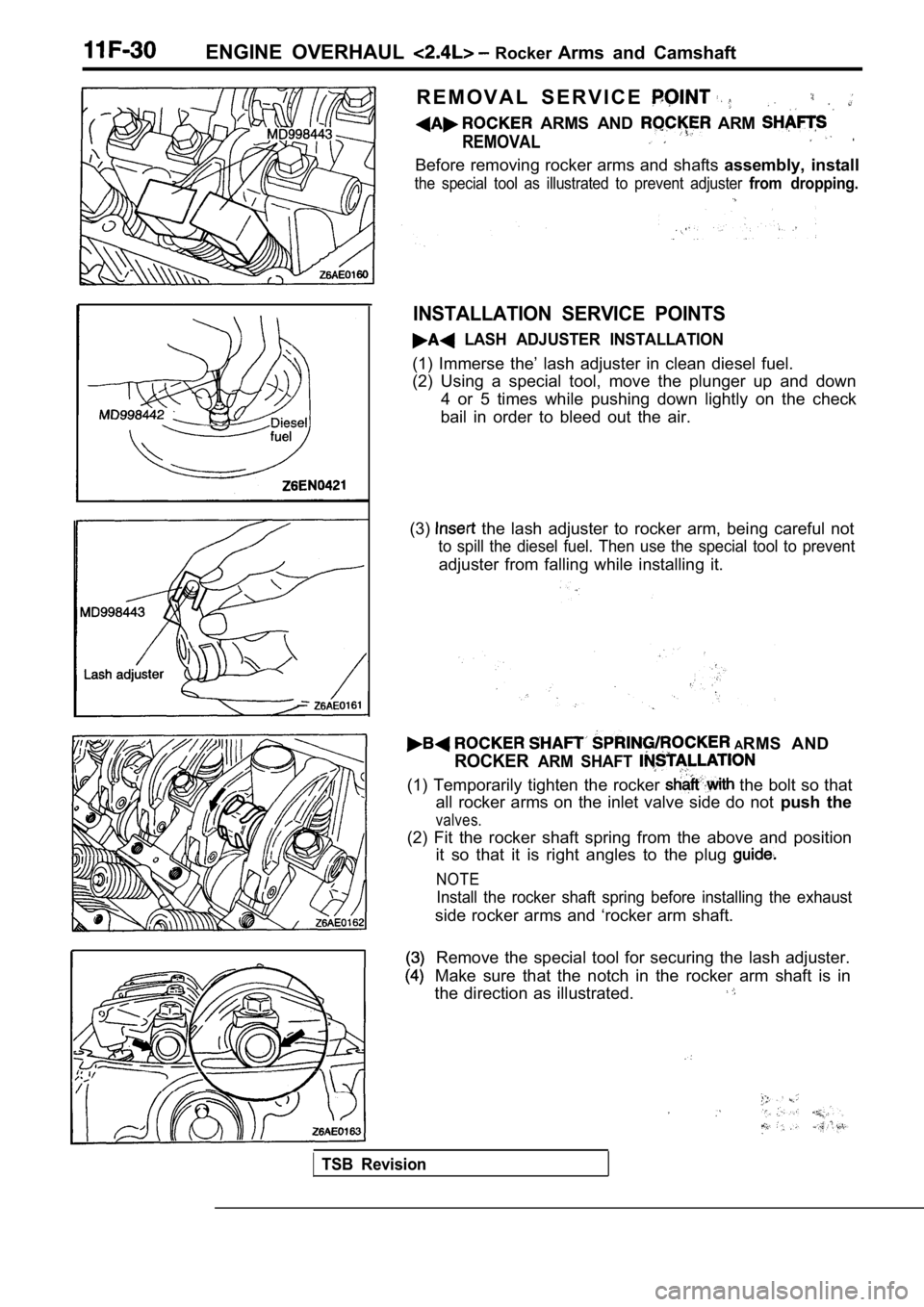

ARMS AND

ROCKERARM SHAFT

(1) Temporarily tighten the rocker the bolt so that

all rocker arms on the inlet valve side do not push the

valves.

(2) Fit the rocker shaft spring from the above and position

it so that it is right angles to the plug

NOTE

Install the rocker shaft spring before installing t he exhaust

side rocker arms and ‘rocker arm shaft.

Remove the special tool for securing the lash adjus ter.

Make sure that the notch in the rocker arm shaft is in

the direction as illustrated.

TSB Revision

Trending: maintenance schedule, MPG, heater, engine, glove box, parking sensors, wheel bolts