MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 551 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND ENGINE>

Code No. (Heated Oxygen) Sensor Heater Circuit

Malfunction (Bank 1 Sensor 2)

[Comment]

Background

lThe engine control module checks whether the heater curre MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND ENGINE>

Code No. (Heated Oxygen) Sensor Heater Circuit

Malfunction (Bank 1 Sensor 2)

[Comment]

Background

lThe engine control module checks whether the heater curre](/img/19/57345/w960_57345-550.png)

ENGINE (TURBO)

AND ENGINE>

Code No. (Heated Oxygen) Sensor Heater Circuit

Malfunction (Bank 1 Sensor 2)

[Comment]

Background

lThe engine control module checks whether the heater current is within a specified range

when the is energized.

Check Area

l Battery voltage is between 11 and 16

Judgement CriterialHeater current of the front heated oxygen sensor he ater (Bank 1 Sensor 2) has continuedto be not higher than 0.2 A or not lower than 3.5 A for sec.

l Monitored once trio.

NG Replace

(Refer to

Measure at the heated oxygen sensor

(rear) connector

lDisconnect the connector, heated oxygen sensor (rear) and the relay connector. Repair, if sure at the harness side.IlVoltage between ground (Igni-tion switch: ON)

OK: Battery positive voltage

Measure at the ECM connector

OK

Check the following connector:NG

cause

lOpenorshorted oxygen sensor in oxygen sensor heater’

l Engine control module failed

NG Check the following connector: Repair

OK

Check trouble symptom.

Check trouble symptom. ECM and the heated

oxygen sensor

(rear) connector. Repair, necessary.,

NG

Replace the ECM.

TSB RevisionI

Page 552 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND ENGINE> Troubleshooting

Code No. Fuel Trim Malfunction (Bank 1)

[Comment]

Background

lIf a malfunction occurs in the fuel system, the fue l compensation value MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND ENGINE> Troubleshooting

Code No. Fuel Trim Malfunction (Bank 1)

[Comment]

Background

lIf a malfunction occurs in the fuel system, the fue l compensation value](/img/19/57345/w960_57345-551.png)

ENGINE (TURBO)

AND ENGINE> Troubleshooting

Code No. Fuel Trim Malfunction (Bank 1)

[Comment]

Background

lIf a malfunction occurs in the fuel system, the fue l compensation value becomes too largeor too small.lThe engine control module checks whether the fuel c ompensation value is within a specified

range.

Check Areal Under the closed loop air-fuel ratio control

l Intake air temperature is or higher

l Barometric pressure is 76 (11 psi.) or higher.

Judgement CriterialLong-range fuel correction has continued to be not lower than or not higher than

-12.5% for 10 sec.

lShort-range fuel correction has continued to be not lower than or not higher than-10.0% for 10 sec.

SCAN TOOL Data list 13 Intake air temperature sensor (Refer to

Probable

l V o l u m e ‘ a i r l Injector failed .Incorrect fuel pressure

Air drawn gaps seals,’ etc.

Heated oxygen sensor

Engine coolant temperature sensor failed, Intake air, temperature sensor f a i l e d Exhaust gas leaks

E n g i n e

NG Check the intake air temperature circuit malfuncti on. (Refer to INSPECTION PROCEDURE TROUBLE CODE

NGSCAN TOOL Data list Check the engine coolant malfunction (Refer

21 Engine coolant temperature sensor (Refer to to INSPECTION PROCEDURE

OKTROUBLE CODE

SCAN TOOL Data list

25 Barometric pressure sensor (Refer to

OK

NG Check the barometric pressure circuit INSPECTION PROCEDURE D I A G N O S T I C

TROUBLE CODE

NGCheck the injector (Refer to Replace

OK N G

Check the following connectors: Repair

NG Repair

OK

Check the fuel pressure (Refer to

OK

SCAN TOOL Data list

Morethan zero Check if air was drawn N G Repair81 Long-term fuel compensation (Refer to l fuel trim more or less than zero?I

sensor(Refer to l Does the tester indi-

cate more than the

standard value?

Yes

Replace the volume airflow sensor.

TSB Revision1

lCheck for fuel leakingfrom injectors.lCheck for contamina-

tion (water, kerosene,

etc.) in the fuel.

OK

Replace the ECM

into the intake

OK

SCAN No

12 Volume air flow sensor(Refer to l Does the tester indi-

cate less than the

standard value?

l Check for blockedinjectors.l Check for fuel filter

and fuel line block-

ages.l Check the fuel pump(insufficientdis-charge).l Check for exhaust

gas leaks (oxygen

sensorfitting, exhaust

manifold cracks, front

pipe cracks, etc.)lCheck for contamina-

tion (water, kerosene,

etc.) in the

OK

Replace

Page 553 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE

AND ENGINE> Troubleshootina

Code No. Injector Circuit P r o b a b l e c a u s e

function (Cylinder-l,

[Comment]l Injector failedBackgroundl con-l A surge voltage is generated MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE

AND ENGINE> Troubleshootina

Code No. Injector Circuit P r o b a b l e c a u s e

function (Cylinder-l,

[Comment]l Injector failedBackgroundl con-l A surge voltage is generated](/img/19/57345/w960_57345-552.png)

ENGINE

AND ENGINE> Troubleshootina

Code No. Injector Circuit P r o b a b l e c a u s e

function (Cylinder-l,

[Comment]l Injector failedBackgroundl con-l A surge voltage is generated when the injectors are driven and the current flowing tothe injector coil is shut off.

l Engine control module failed

l The engine control module checks this surge voltage .

Check Areal Engine speed is between and 1000 l Throttle position sensor output voltage is not high er than 1.16 l Monitoring Time: 4

Judgement Criterial Injector coil surge voltage (system voltage V) has not been detected for 4 sec.

Engine (Turbo)>

Check the injector. (Refer to Replace

NGCheck the resister. (Refer to

N GMeasure at the resistor connector l Disconnect the connector, and measure at the harnes s side.Check harness wire between the relay and the

l Voltage between 3 and ground. (Ignition switch: ON) tor. Repair, if necessary.

OK: Battery positive voltage

OK

Measure at the injector connectors lDisconnect the connector, and measure at the harnes s side.

l Voltage between 1 and ground. (Ignition switch: ON)

OK: Battery positive voltage

OK

Check the injector control circuit.

(Refer to INSPECTION PROCEDURE 49.)

Engine> connector:

N G Repair

OK

Check trouble I

NG

Check wire between the the injector connector.Repair, if

Check the injector. (Refer to N G

I Replace

Measure at the injector connector.

l Disconnect the connector, and measure at the harnes s side.

l Voltage between 1 and ground (Ignition switch: ON)

OK: Battery positive voltage

OK

PROCEDURE 49.)

TSB Revision

Page 554 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual E N G I N E ( T U R B O ) .

AND ENGINE> ,

Code No. Random Misfire Detected

[Comment]l Ignition system related part(s) BackgroundlIf a misfiring occurs while the engine is runni MITSUBISHI SPYDER 1990 Service Repair Manual E N G I N E ( T U R B O ) .

AND ENGINE> ,

Code No. Random Misfire Detected

[Comment]l Ignition system related part(s) BackgroundlIf a misfiring occurs while the engine is runni](/img/19/57345/w960_57345-553.png)

E N G I N E ( T U R B O ) .

AND ENGINE> ,

Code No. Random Misfire Detected

[Comment]l Ignition system related part(s) BackgroundlIf a misfiring occurs while the engine is running, the engine speed suddenly changes.l

Poor crankshaft sensor l Incorrect air/fuel ratiol The engine control module checks for changes in the engine speed.

l Low compression

Check ArealEngine coolant sensor: l 5 or more have passed after the engine was started. l

liming belt broken

l Engine speed is at between 500 and 6000 l Injector failedl Engine coolant temperature is or higher, l

EGR valve failed

l Intake air temperature is or higherlEngine control l Barometric pressure is 76 (11 psi.) or higher.l Running free from sudden accelerations/deceleration s such as shift change.

Judgement Criteria. .

(change in the angular acceleration of the crankshaft is used for misfire detection.)lMisfire has occurred more frequently than allowed during the last 200 revolutions [when

the catalyst temperature is higher than

orlMisfire has occurred in 20 or more of the last 1000 revolutions (corresponding to 1.5

times the limit of emission standard.) I,

SCAN TOOL Data list

22 Crankshaft position sensor (Refer to

l Crankshaft position sensor wave form check

l Engine speed: stable

OK: Constant pulse range

OK

position sensor and

Check the injector (Refer toNG Replace

Check the fuel trim malfunction (bank 1) (Refer to IN-SPECTION PROCEDURE FOR DIAGNOSTIC TROUBLE

OK

SCAN TOOL list

21 Engine coolant temperature sensor (Refer to

OK

Check the engine coolant temperature circuit malfu nction (Refer

to INSPECTION PROCEDURE FOR DIAGNOSTICTROUBLE CODE 5.)

Check the following items.

l Check the ignition coil, spark plugs, spark plug ca bles.

l Check the compression pressure.

l Check for broken timing belt teeth.

l Check the EGR system and the EGR valve.

TSB Revision

Page 555 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

ENGINE>

Code No. Misfire Detected (Cylin-

der-l,

[Comment]Background

lif a misfiring occurs while the engine is running, the engine speed suddenly changes.

l Th MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

ENGINE>

Code No. Misfire Detected (Cylin-

der-l,

[Comment]Background

lif a misfiring occurs while the engine is running, the engine speed suddenly changes.

l Th](/img/19/57345/w960_57345-554.png)

ENGINE (TURBO)

ENGINE>

Code No. Misfire Detected (Cylin-

der-l,

[Comment]Background

lif a misfiring occurs while the engine is running, the engine speed suddenly changes.

l The engine control module checks for changes in the engine speed.

Check Areal 5 or more have passed after the engine was started.l Engine speed is at between 500 and 6000 l Engine coolant temperature is or higher.

l Intake air temperature is or higher

l Barometric pressure is 76 (11 psi.) or higher.

l Running free from sudden accelerations/deceleration s such as shift change.

Judgement Criteria(change in the angular acceleration of the crankshaft is used for misfire detection.)lMisfire has occurred more frequently than allowed during the last 200 revolutions [when

the catalyst temperature is higher than

or l Misfire has occurred in 20 or more of the last 1000 revolutions (corresponding to 1.5

times the limit of emission standard.)

l l Low compression l Injector failed

l Engine

Check the injector (Refer

OK

Replace

Check the following connectors: __ Repair,OK

[Check the harness wire between the ECM and the inj ectorNG ,

connector

Check the following items.

l Check the spark plugs, spark plug cables.

l Check the compression pressure

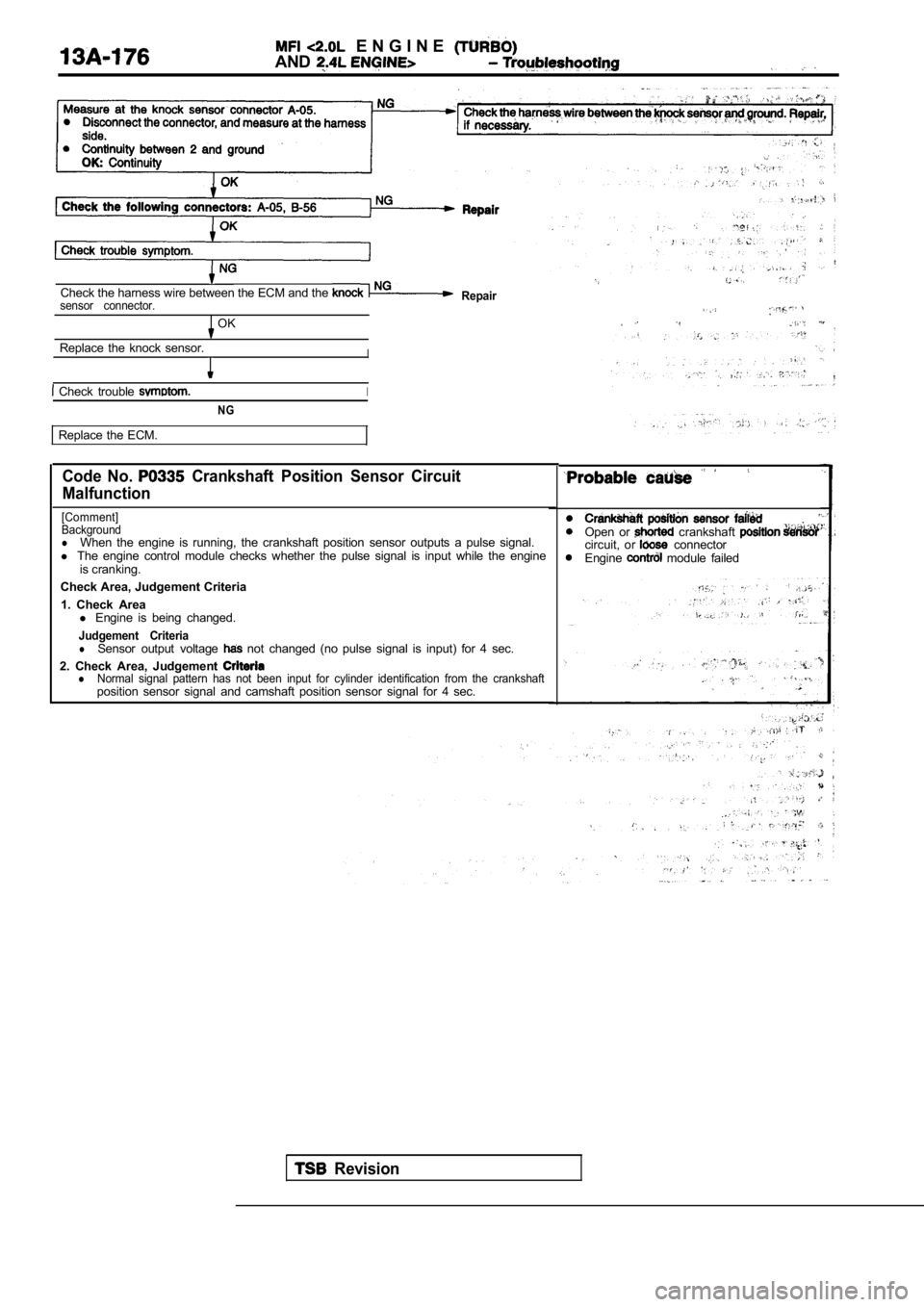

Code No. Knock Sensor 1 Circuit Malfunction

Engine (Turbo)>

l sensor failed BackgroundlThe knock sensor converts the vibration of the cyli nder block into a voltage and outputs

it. If there is a malfunction of the knock sensor, the voltage output will not change.

l The engine control module checks whether the voltag e output changes.

Check Areal Ignition switch: ONl60 or more have passed after the ignition switch was turned on or the starting sequencewasl Engine speed is higher than 2000

Judgement CriterialKnock sensor output voltage (knock sensor peak volt age in each deg period of the

crankshaft) has not changed more than 0.06 in the last consecutive 200 periods.

lOpen or shorted knock sensor circuit, or connector

l Engine control module failed

Revision

Page 556 of 2103

E N G I N E

AND

Check the harness wire between the ECM and the sensor connector.Repair

OK

Replace the knock sensor.I

Check trouble I

NG

Replace the ECM.

Code No. Crankshaft Position Sensor Circuit

Malfunction

[Comment]

Background

lWhen the engine is running, the crankshaft position sensor outputs a pulse signal.

l The engine control module checks whether the pulse signal is input while the engine

is cranking.

Check Area, Judgement Criteria

1. Check Area l Engine is being changed.

Judgement CriterialSensor output voltage not changed (no pulse signal is input) for 4 sec.

2. Check Area, Judgement

lNormal signal pattern has not been input for cylind er identification from the crankshaftposition sensor signal and camshaft position sensor signal for 4 sec.

Revision

.Open or crankshaft circuit, or connector

Engine module failed

Page 557 of 2103

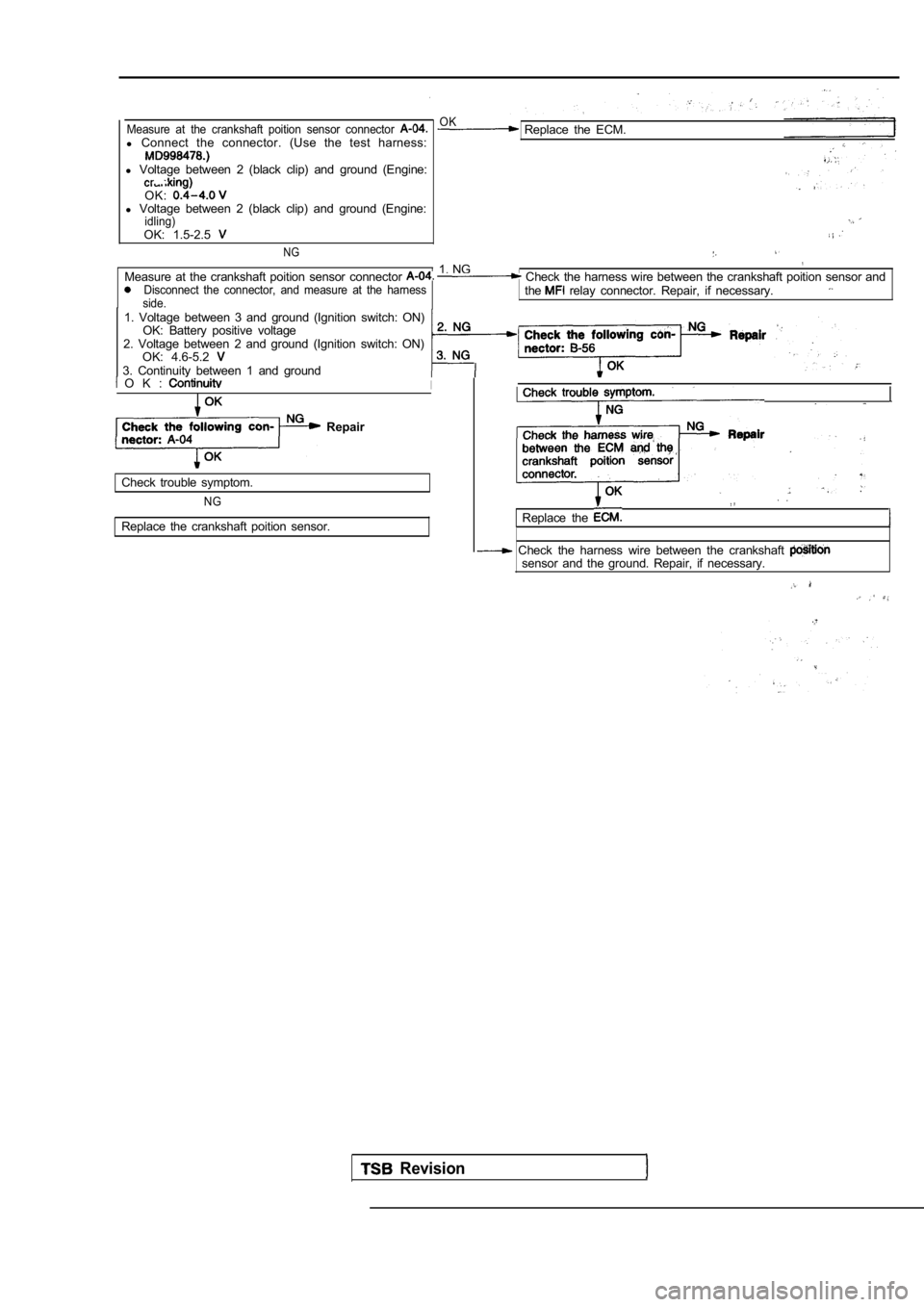

Measure at the crankshaft poition sensor connector l Connect the connector. (Use the test harness:

l Voltage between 2 (black clip) and ground (Engine:

OK:l Voltage between 2 (black clip) and ground (Engine:idling)OK: 1.5-2.5

NG

OK Replace the ECM.

1. NG

Measure at the crankshaft poition sensor connector Check the harness wire between the crankshaft poit ion sensor andDisconnect the connector, and measure at the harnes sthe relay connector. Repair, if necessary.side.1. Voltage between 3 and ground (Ignition switch: ON)

OK: Battery positive voltage

2. Voltage between 2 and ground (Ignition switch: O N)

OK: 4.6-5.2

3. Continuity between 1 and ground O K : I

Repair

Check trouble symptom.

NG

Replace the crankshaft poition sensor. Check trouble symptom. Replace the

Check the harness wire between the crankshaft sensor and the ground. Repair, if necessary.

Revision

Page 558 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND ENGINE>

Code No. Camshaft Position Sensor Circuit

Malfunction

[Comment]

Background

l When the engine is running, the camshaft position s ensor outputs a pulse MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND ENGINE>

Code No. Camshaft Position Sensor Circuit

Malfunction

[Comment]

Background

l When the engine is running, the camshaft position s ensor outputs a pulse](/img/19/57345/w960_57345-557.png)

ENGINE (TURBO)

AND ENGINE>

Code No. Camshaft Position Sensor Circuit

Malfunction

[Comment]

Background

l When the engine is running, the camshaft position s ensor outputs a pulse signal. The engine control module checks whether the pulse signal is input.

Check Area,

Criteria

1. Check Area, Judgement Criteria l Sensor output voltage has not changed (no pulse sig nal is input) for 4 sec.

2. Check Area, Judgement Criteria l

Normal signal pattern has not been input for cylind er identification from the crankshaftposition sensor and camshaft position sensor signal for 4 sec.

Measure at the camshaft position sensor connector l Connect the connector. Voltage between 2 and ground (Engine: cranking)

OK:

l Voltage between 2 and ground (Engine: idling)

OK:

NG

Measure at the camshaft position sensor connector lDisconnect the connector. and measure at the harnes s

side.

1. Voltage between 3 and ground (Ignition switch: O N)

O K :

2. Voltage between 2 and (Ignition switch: ON)

OK:

3. Continuity between 1 and ground

OK: Continuity

OK

Probable cause

Camshaft position sensor lOpen or position cir-cuit or loose connector Engine control module failed

OK Replace the ECM.

1. NG Check the harness wire the camshaft position’ the relay connector. Repair, if necessary.

Repair

Check trouble symptom.

Repair

Check trouble II tor.

TSB Revision

NG

the camshaft oosition sensor.

OK

Replace the ECM.

Check the harness wire between the camshaft positi on sensor and

the ground. Repair, if necessary.

Page 559 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND ENGINE> Troubleshooting

Code No. Exhaust Gas Recirculation Flow MalfunctionProbable

[Comment]l EGR valve does not openBackgroundl EGR control vacuum is too lowl MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND ENGINE> Troubleshooting

Code No. Exhaust Gas Recirculation Flow MalfunctionProbable

[Comment]l EGR valve does not openBackgroundl EGR control vacuum is too lowl](/img/19/57345/w960_57345-558.png)

ENGINE (TURBO)

AND ENGINE> Troubleshooting

Code No. Exhaust Gas Recirculation Flow MalfunctionProbable

[Comment]l EGR valve does not openBackgroundl EGR control vacuum is too lowlWhen the EGR solenoid switches from OFF to ON while the engine is running, EGRl EGR solenoid failedgas flows.lOpen or shorted EGR solenoid circuit, or l The engine control module checks how the EGR gas fl ow signal changes.connector

Check Areal Manifold differential pressure sensor failed

l Engine coolant temperature is higher than l Engine control failedl Engine speed is between 1000 and 2000 l Engine speed is between 940 and 2000 .

l Intake air temperature is

or higher.

l Barometric pressure is 76 (11 psi.) or higher.

l Closed throttle position switch: ON

l Volumetric efficiency is 15%

or 27% or lower. engine l Volumetric efficiency is 15% or 20% or lower. engine>

l Monitoring Time: 2

Judgement Criterial There is no change in the condition of the air inta ke system when the EGR solenoid

is turned on.

l Monitored only once per trip.

Check the EGR system (Refer to GROUP 17 Emission Control(Refer to GROUP 17 Emission System) Engine EGR solenoid

(Refer to GROUP 17 Emission Control System)

OK

Replace,

Check the following items.

l Vacuum hoses

l EGR

vacuum7

l EGR valve

Check the manifold differential pressure sensor malfunction95 Manifold differential pressure sensor (Refer to (Refer to INSPECTION PROCEDURE FOR TROUBLE CODE

Check for EGR valve and EGR line blockages, and cle an if

TSB Revision

Page 560 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND ENGINE> Troubleshooting

Code No. Exhaust Gas Recirculation Solenoid cause

Malfunction

[Comment]Backgroundl EGR solenoid lOpen or shorted lThe engine control module MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND ENGINE> Troubleshooting

Code No. Exhaust Gas Recirculation Solenoid cause

Malfunction

[Comment]Backgroundl EGR solenoid lOpen or shorted lThe engine control module](/img/19/57345/w960_57345-559.png)

ENGINE (TURBO)

AND ENGINE> Troubleshooting

Code No. Exhaust Gas Recirculation Solenoid cause

Malfunction

[Comment]Backgroundl EGR solenoid lOpen or shorted lThe engine control module checks current flows in t he EGR solenoid circuit whenconnector.the solenoid is on and off.

l Engine control module failed.

Check Area Battery voltage is not lower than 10 V.

Judgement Criteria, ,lSolenoid coil surge voltage (system voltage V) is not detected when the EGR solenoidis turned on/off.

NG

Check the EGR solenoid. (Refer to GROUP Emission

Control System) Engine (Turbo)> (Refer toGROUP17 Emission Control System) Engine>

I

Replace

Measure at the EGR solenoid connector lDisconnect the connector and measure at the harness

l Voltage between 1 and ground (Ignition switch: ON) positive

NG

Repair, if necessary. ,

Disconnect the connector and measure at the harness

Check trouble symptom.

NG

Check the harness wire between ECM and solenoid val ve connector.Repair, if necessary.

Replace the ECM.

TSB Revision