NISSAN ALMERA N15 1995 Service Manual

ALMERA N15 1995

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57349/w960_57349-0.png

NISSAN ALMERA N15 1995 Service Manual

Trending: tow bar, Check engine light wiring, load capacity, coolant reservoir, adding oil, hood release, immo

Page 131 of 1701

REPAIRFORCOMPONENT PARTS

Band Servo Piston Assembly (Cont'd)

11. Install bandservo piston snapringtotransmission case.

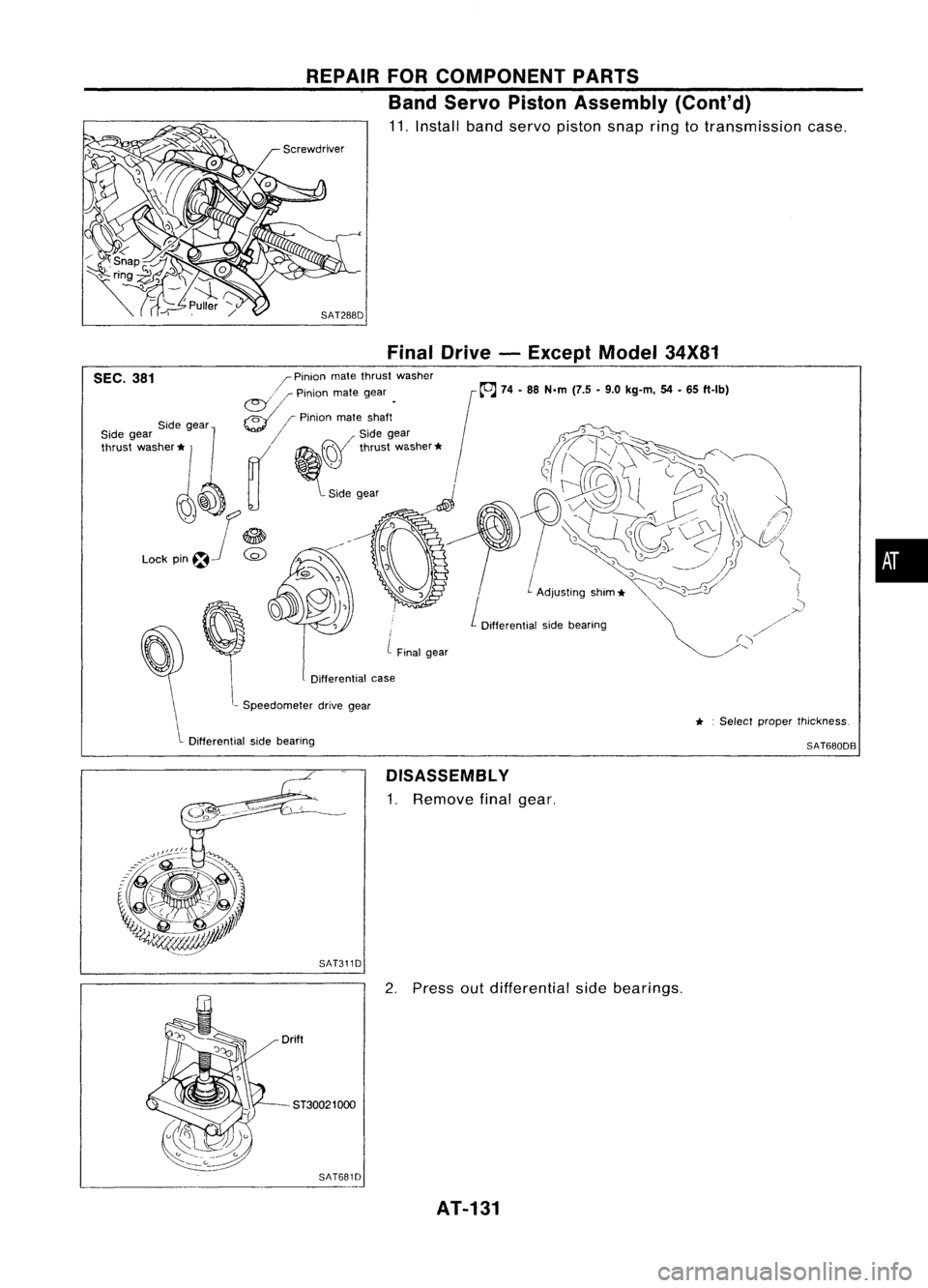

SAT288D FinalDrive -Except Model34X81

I

L

Final gear

SEC.

381

OJ

\ Differentialcase

\ -Speedometer drivegear

~ Differential sidebearing

*

:

Select proper thickness.

SAT680DB

•

DISASSEMBL Y

1. Remove finalgear.

SAT311D

2.Press outdifferential sidebearings.

ST30021000

SAT681D AT-131

Page 132 of 1701

REPAIRFORCOMPONENT PARTS

Final Drive -Except Model34X81(Cont'd)

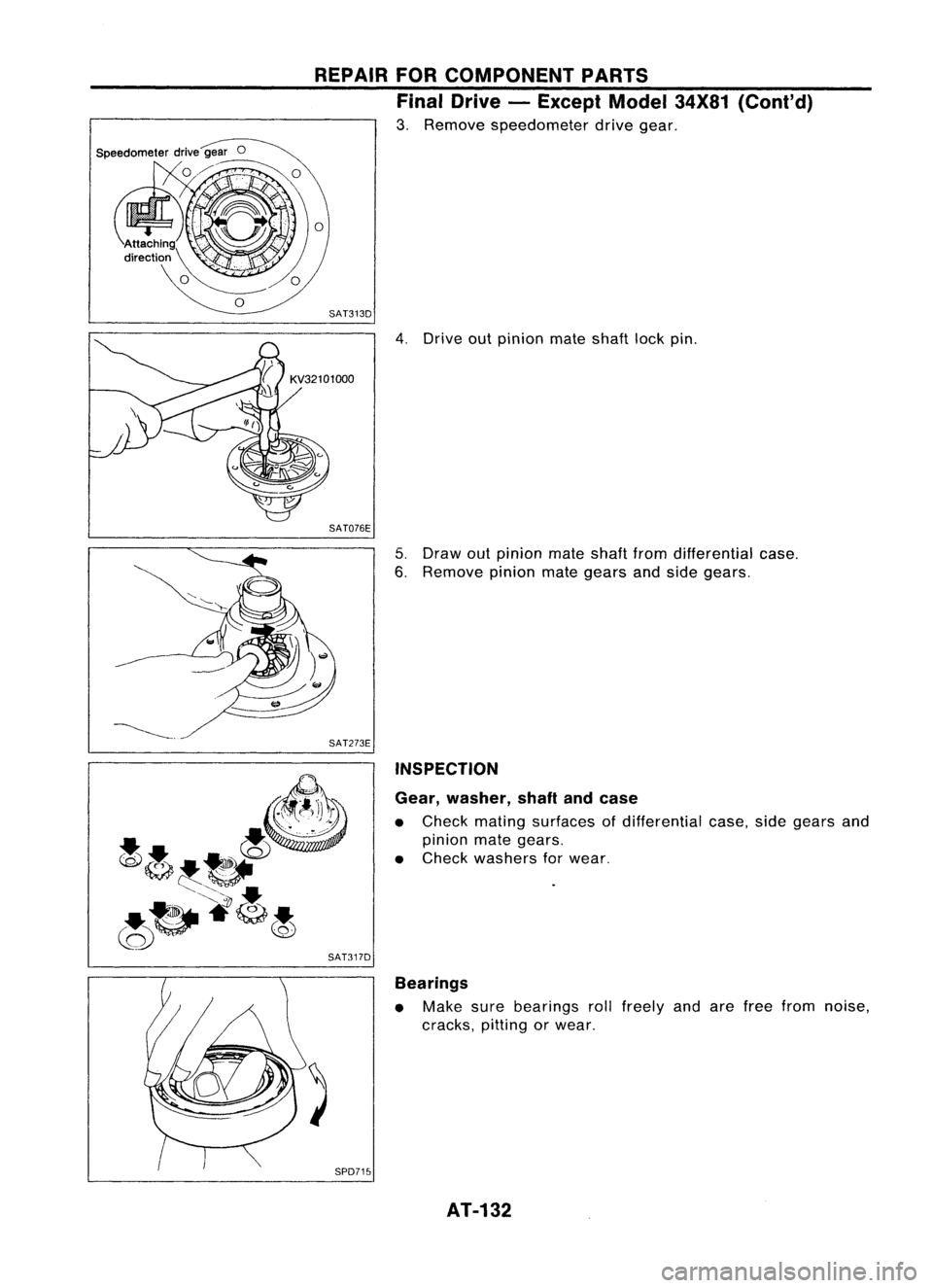

3. Remove speedometer drivegear.

4. Drive outpinion mateshaft lockpin.

SAT076E

5.Draw outpinion mateshaftfromdifferential case.

6. Remove pinionmategears andside gears.

SAT273E INSPECTION

Gear, washer, shaftandcase

• Check mating surfaces ofdifferential case,sidegears and

pinion mategears.

• Check washers forwear.

SAT317D Bearings

• Make surebearings rollfreely andarefree from noise,

cracks, pittingorwear.

SPD715 AT-132

Page 133 of 1701

Pinionmateshaft

r= REPAIR

FORCOMPONENT PARTS

Final Drive -Except Model34X81(Cont'd)

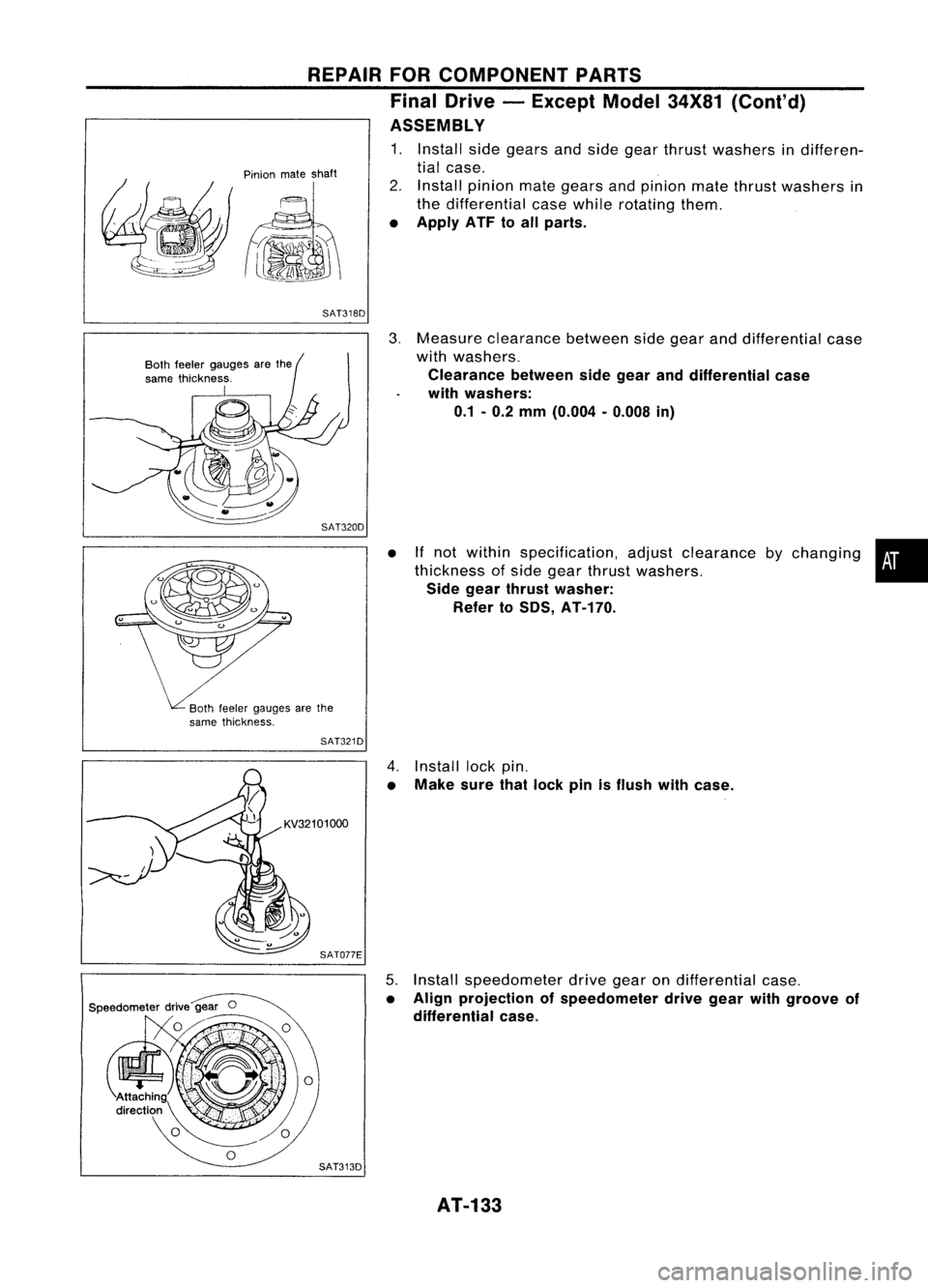

ASSEMBLY

1. Install sidegears andside gear thrust washers indifferen-

tial case.

2. Install pinion mategears andpinion matethrust washers in

the differential casewhile rotating them.

• Apply ATF toall parts.

SAT318D

Both feeler gauges arethe

same thickness.

3.

Measure clearance betweensidegear anddifferential case

with washers.

Clearance betweensidegear anddifferential case

with washers:

0.1 -0.2 mm (0.004 -0.008 in)

SAT321D •

If

not within specification, adjustclearance bychanging •

thickness ofside gear thrust washers.

Side gear thrust washer:

Refer to50S, AT-170.

KV32101000

SAT077E

4.

Install lockpin.

• Make surethatlock pinisflush withcase.

5. Install speedometer drivegearondifferential case.

• Align projection ofspeedometer drivegearwithgroove of

differential

case.

AT-133

Page 134 of 1701

REPAIRFORCOMPONENT PARTS

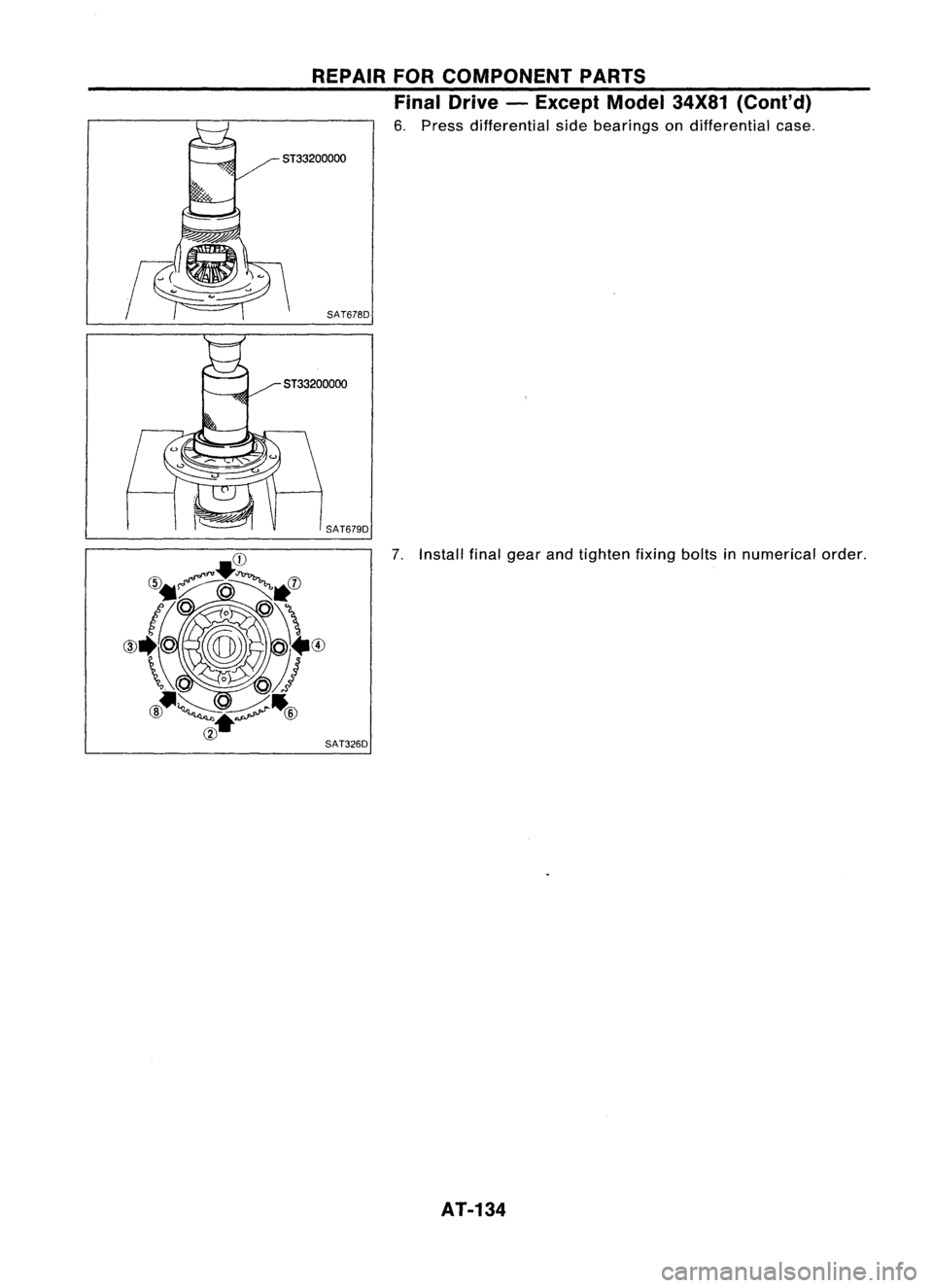

Final Drive -Except Model34X81(Cont'd)

6. Press differential sidebearings ondifferential case.

ST33200000

SAT678D

5T33200000

SAT679D

7.Install finalgear andtighten fixingboltsinnumerical order.

SAT326D

AT-134

Page 135 of 1701

REPAIRFORCOMPONENT PARTS

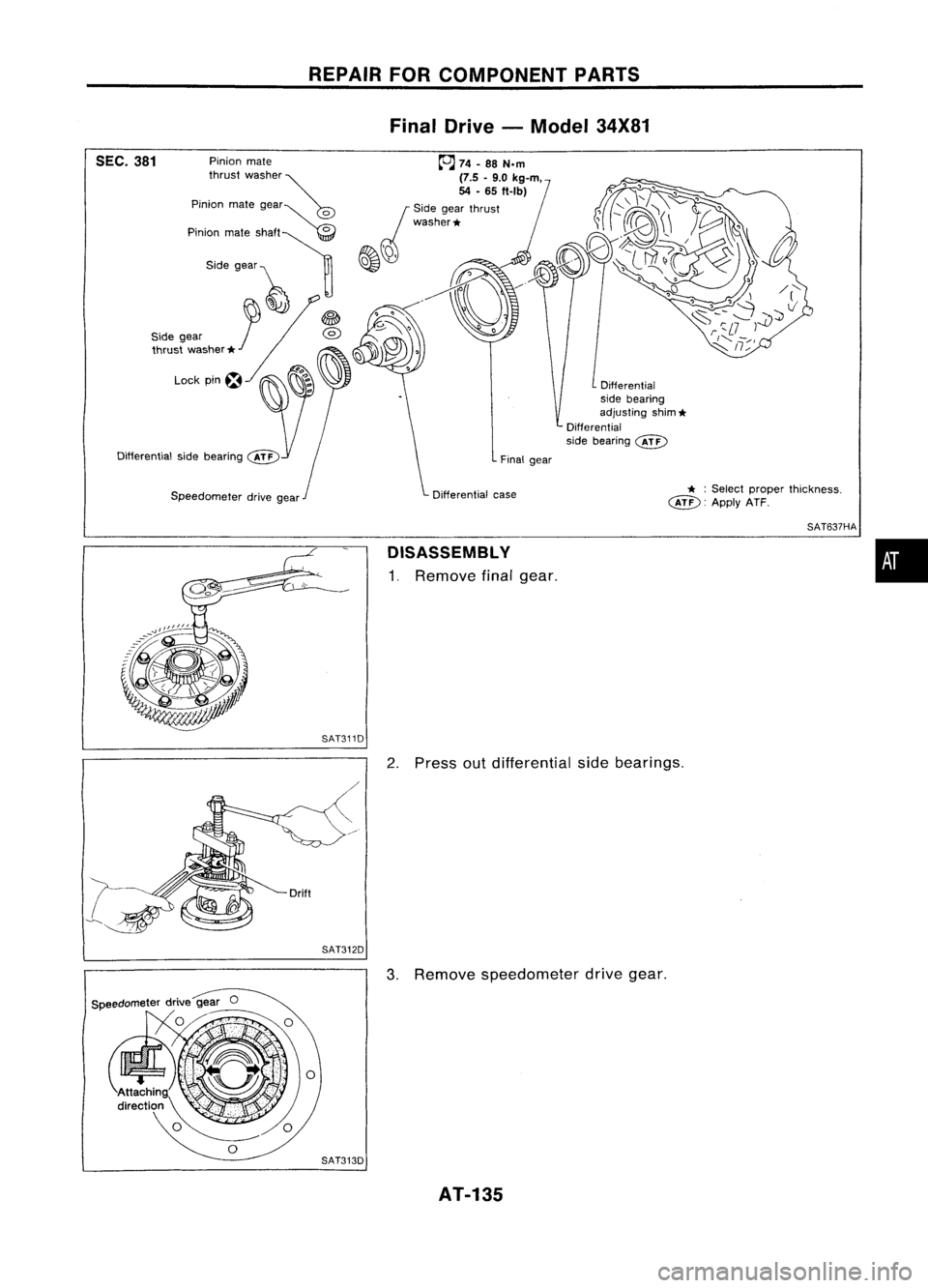

Final Drive -Model 34X81

•

SAT637HA

*

:

Select proper thickness.

@):

ApplyATF.

Differential

side bearing

adjusting shim

*

Differential

side bearing

@)

Final gear

Differential case

DISASSEMBL Y

1. Remove finalgear.

Speedometer

drivegear

SEC.

381

Pinionmate

thrust washer ""

Pinion mategear~

'@

Pinion mateShaft~

Sid, ""~ _~

Z~

Side gear )

@

thrust washer

*

q"

L~k~O~ ~,~

om""".,

,Id,

b"do,

~v .

SAT311D

2.Press outdifferential sidebearings.

SAT312D

3.Remove speedometer drivegear.

Speedometer drivegear 0

o

SAT313DAT-135

Page 136 of 1701

REPAIRFORCOMPONENT PARTS

Final Drive -Model 34X81

(Coni'd)

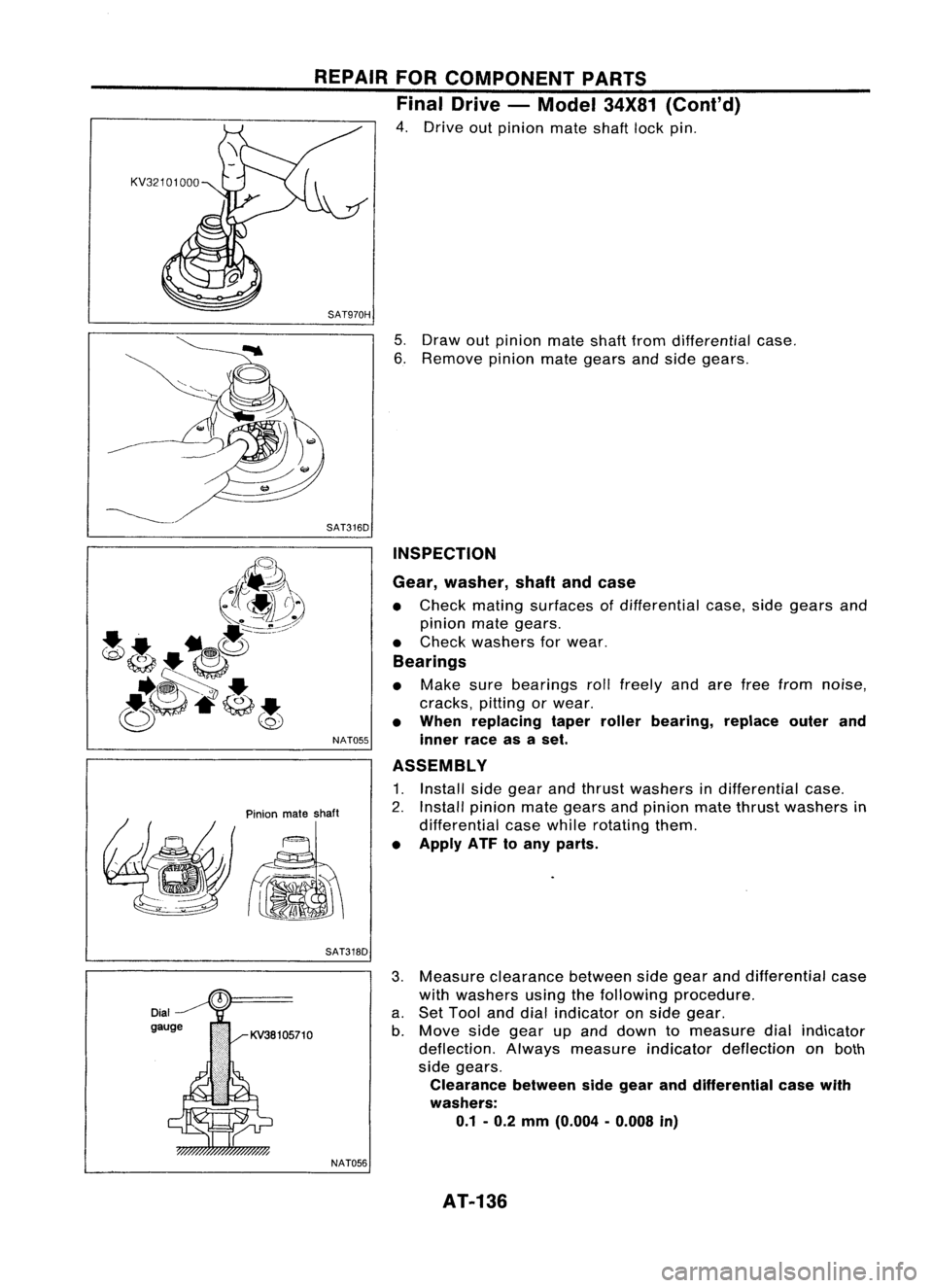

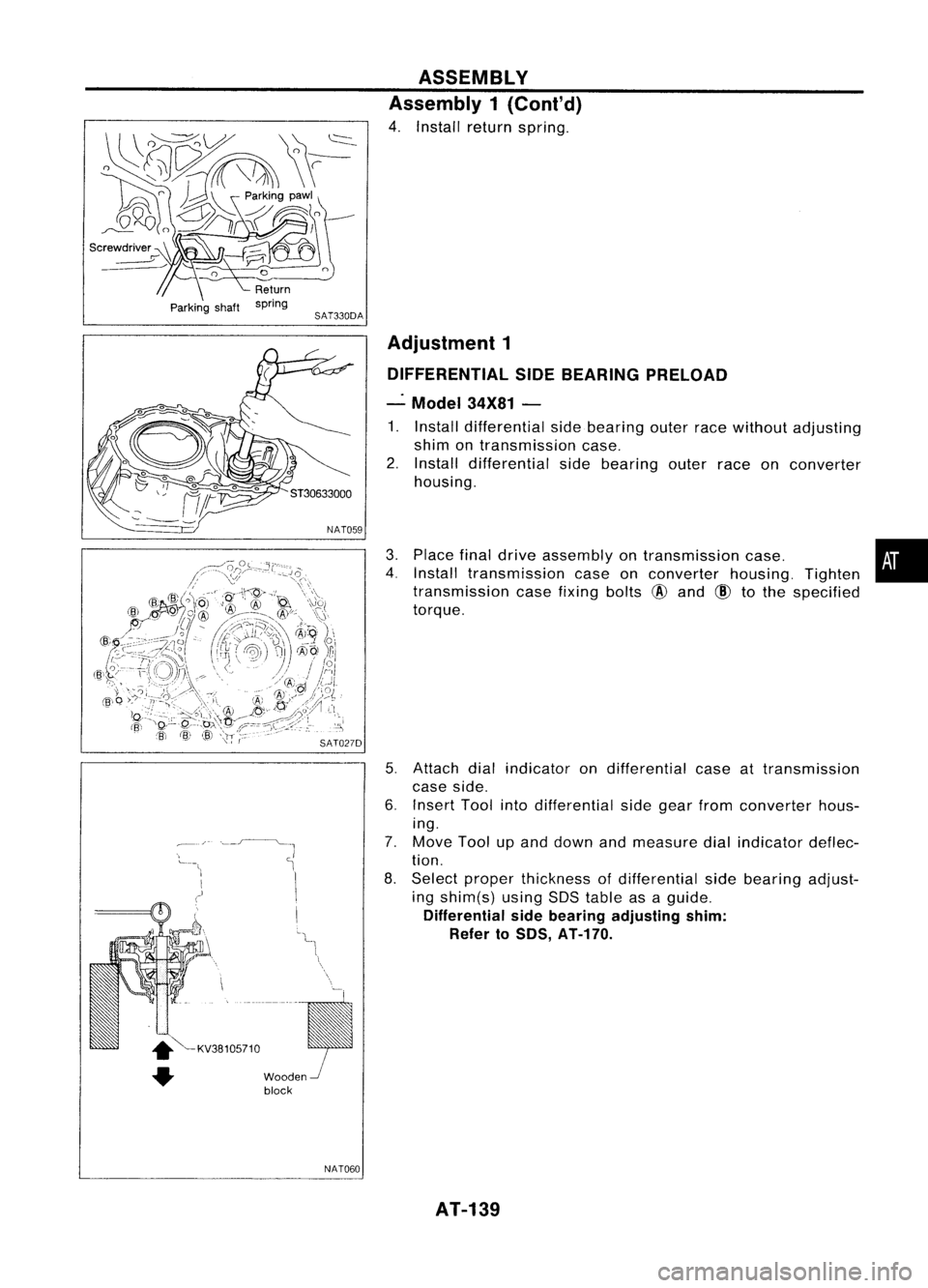

4. Drive outpinion mateshaftlockpin.

SAT970H

5.Draw outpinion mateshaftfromdifferential case.

6. Remove pinionmategears andside gears.

SAT316D INSPECTION

Gear, washer, shaftandcase

• Check mating surfaces ofdifferential case,sidegears and

pinion mategears.

• Check washers forwear.

Bearings

• Make surebearings rollfreely andarefree from noise,

cracks, pittingorwear.

• When replacing taperroller bearing, replaceouterand

NAT055

innerraceasaset.

'----------------'

Dial

gauge

Pinion

mateshaft

SAT318D

NAT056 ASSEMBLY

1. Install sidegear andthrust washers indifferential case.

2. Install pinion mategears andpinion matethrust washers in

differential casewhile rotating them.

• Apply ATFtoany parts.

3. Measure clearance betweensidegear anddifferential case

with washers usingthefollowing procedure.

a. Set Tool anddial indicator onside gear.

b. Move sidegear upand down tomeasure dialindicator

deflection. Alwaysmeasure indicatordeflection onboth

side gears.

Clearance betweensidegear anddifferential casewith

washers:

0.1 -0.2 mm (0.004 -0.008 in)

AT-136

Page 137 of 1701

REPAIRFORCOMPONENT PARTS

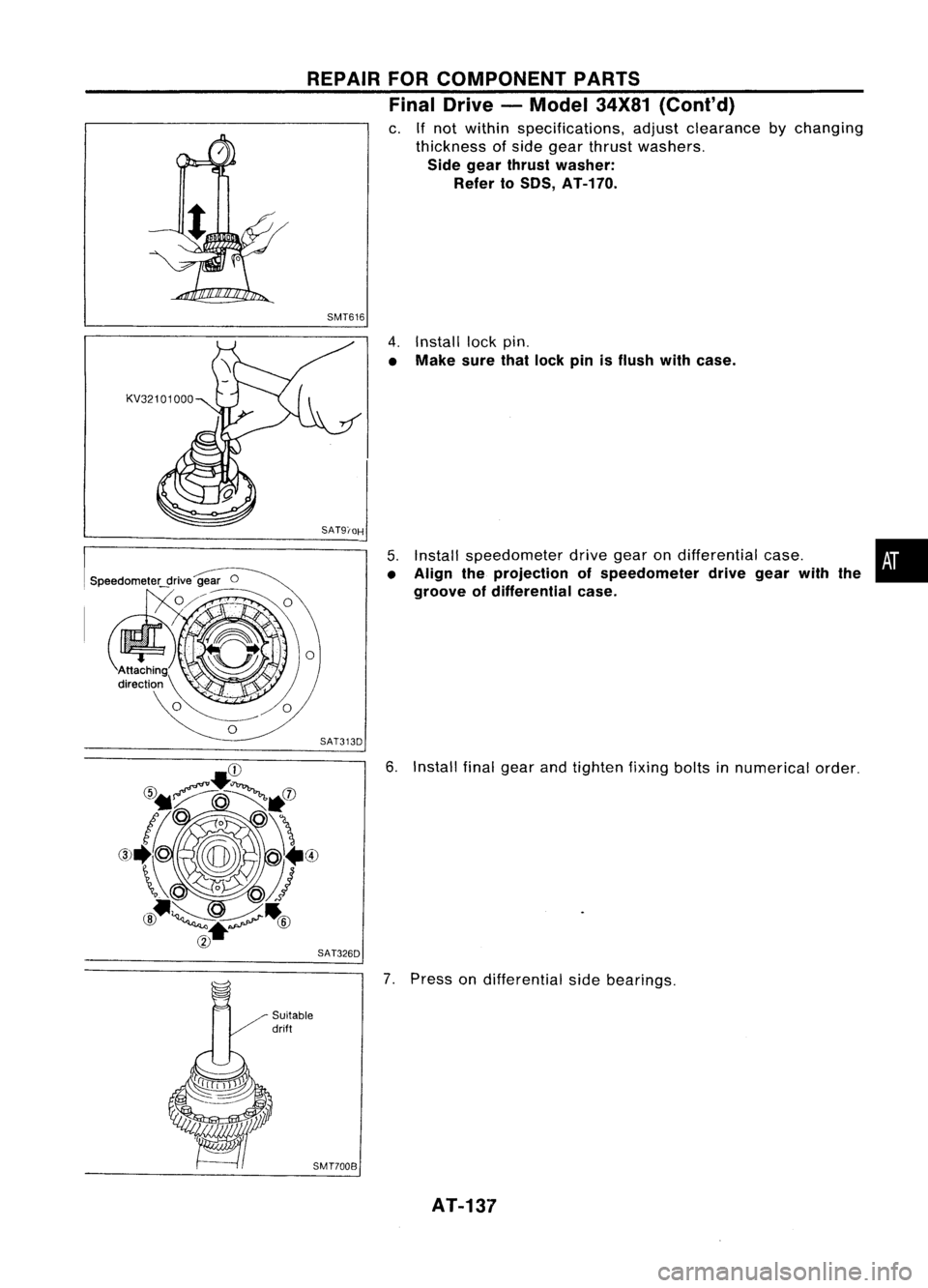

Final Drive -Model 34X81(Cont'd)

c. Ifnot within specifications, adjustclearance bychanging

thickness ofside gear thrust washers.

Side gear thrust washer:

Refer to50S, AT-170.

SMT616

4.Install lockpin.

• Make surethatlock pinisflush withcase.

I

Speedometer:..slrive gear0

~//

5.

Install speedometer drivegearondifferential case. •

• Align theprojection ofspeedometer drivegearwiththe

groove ofdifferential case.

SAT313D

6.Install finalgear andtighten fixingboltsinnumerical order.

SAT326D

7.Press ondifferential sidebearings.

Suitable

drift

SMT700B AT-137

Page 138 of 1701

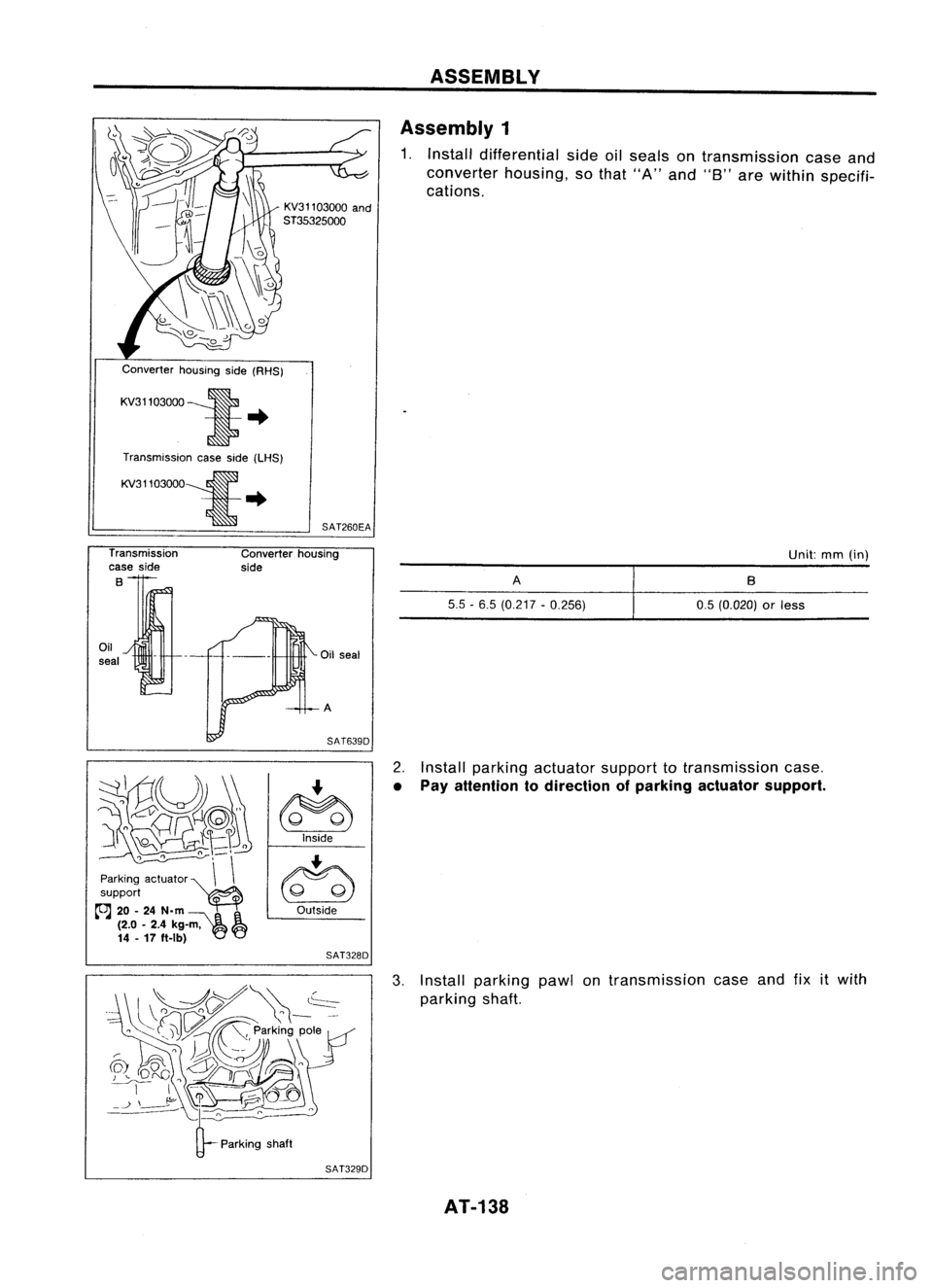

ASSEMBLY

KV31103000 and

ST35325000

Assembly

1

1. Install differential side.

converter

housing

011

seals ontransmiss,'on

cations. 'so that "A" and "8" caseand

are within specifi-

Converter housings'd

Ie

(RHS)

KV31103000 -J..

Transmission caseside(LHS)

KV'"03000~ ..

Unit:mm(in)

B

0.5 (0.020)

or

less

A

5.5 -6.5 (0.217 -0.256)

Install parking actuator su

Pay attention todirection

Pfortt?transmission case.

o parkmg actuator support.

SAT260EA

Converter housing

side

Transmission

case side

B

Oil

seal Oil

seal

A

SAT6390 2.

..

•

~ Inside

...

~ Outside

SAT328D 3.

Install parking

parking shaft.pawlontransmission caseand

fixitwith

SAT3290 AT-138

Page 139 of 1701

~-_./-'--.~.-l

~

1I

-~------~._--~

.

• ~KV38105710

• Wooden

block

NAT060 ASSEMBLY

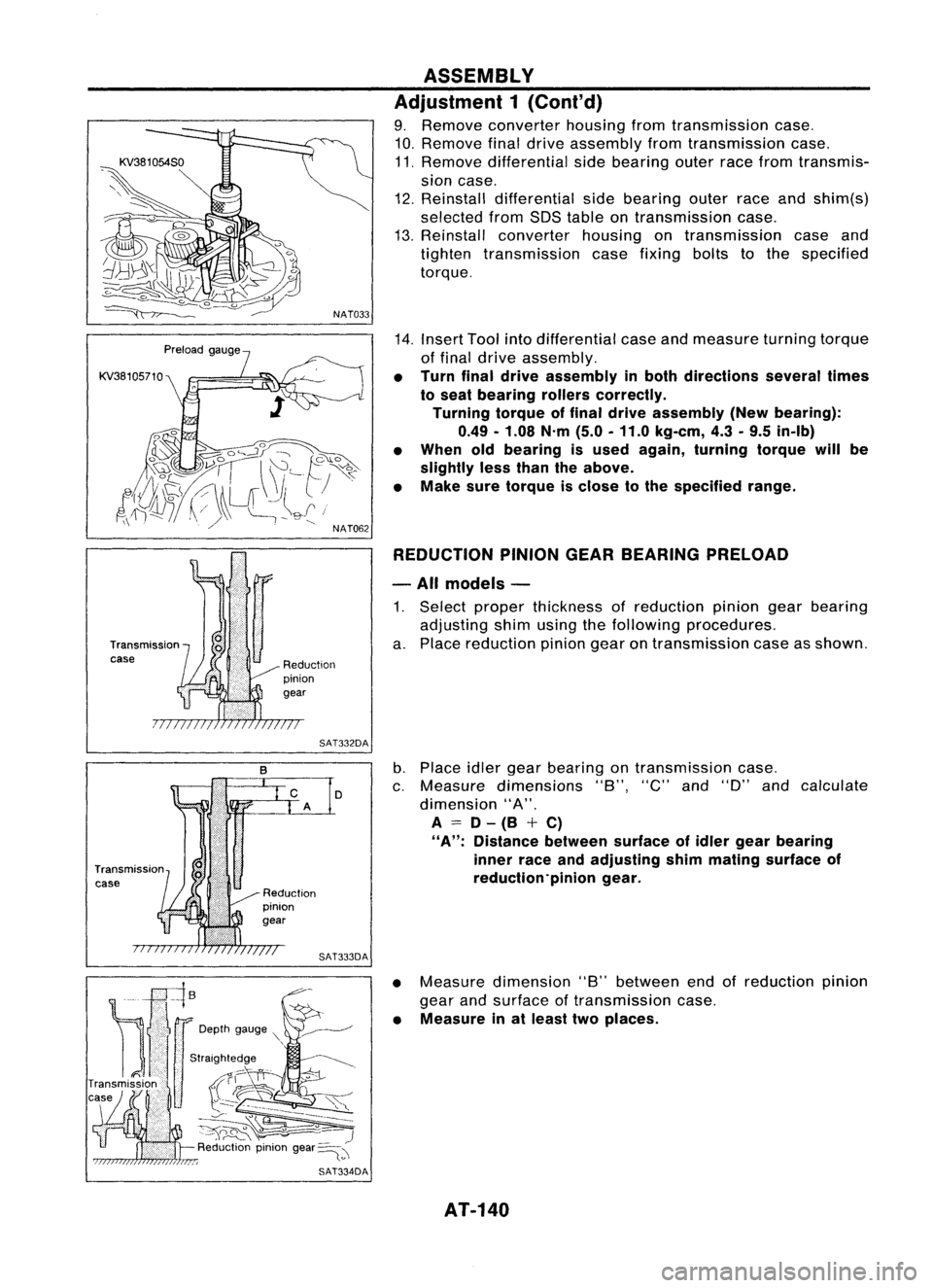

Assembly 1(Cont'd)

4. Install returnspring.

Adjustment 1

DIFFERENTIAL SIDEBEARING PRELOAD

-" Model 34X81-

1. Install differential sidebearing outerracewithout adjusting

shim ontransmission case.

2. Install differential sidebearing outerraceonconverter

housing.

3. Place finaldrive assembly ontransmission case. •

4. Install transmission caseonconverter housing.Tighten

transmission casefixing bolts

@

and

CID

tothe specified

torque.

5. Attach dialindicator ondifferential caseattransmission

case side.

6. Insert Toolintodifferential sidegear from converter hous-

ing.

7. Move Toolupand down andmeasure dialindicator deflec-

tion.

8. Select proper thickness ofdifferential sidebearing adjust-

ing shim(s) usingSDStable asaguide.

Differential sidebearing adjusting shim:

Refer to50S, AT-HO.

AT-139

Page 140 of 1701

KV38105710

Transmission

case

NAT033

Reduction

pinion

gear

SAT332DA

D

SAT333DA ASSEMBLY

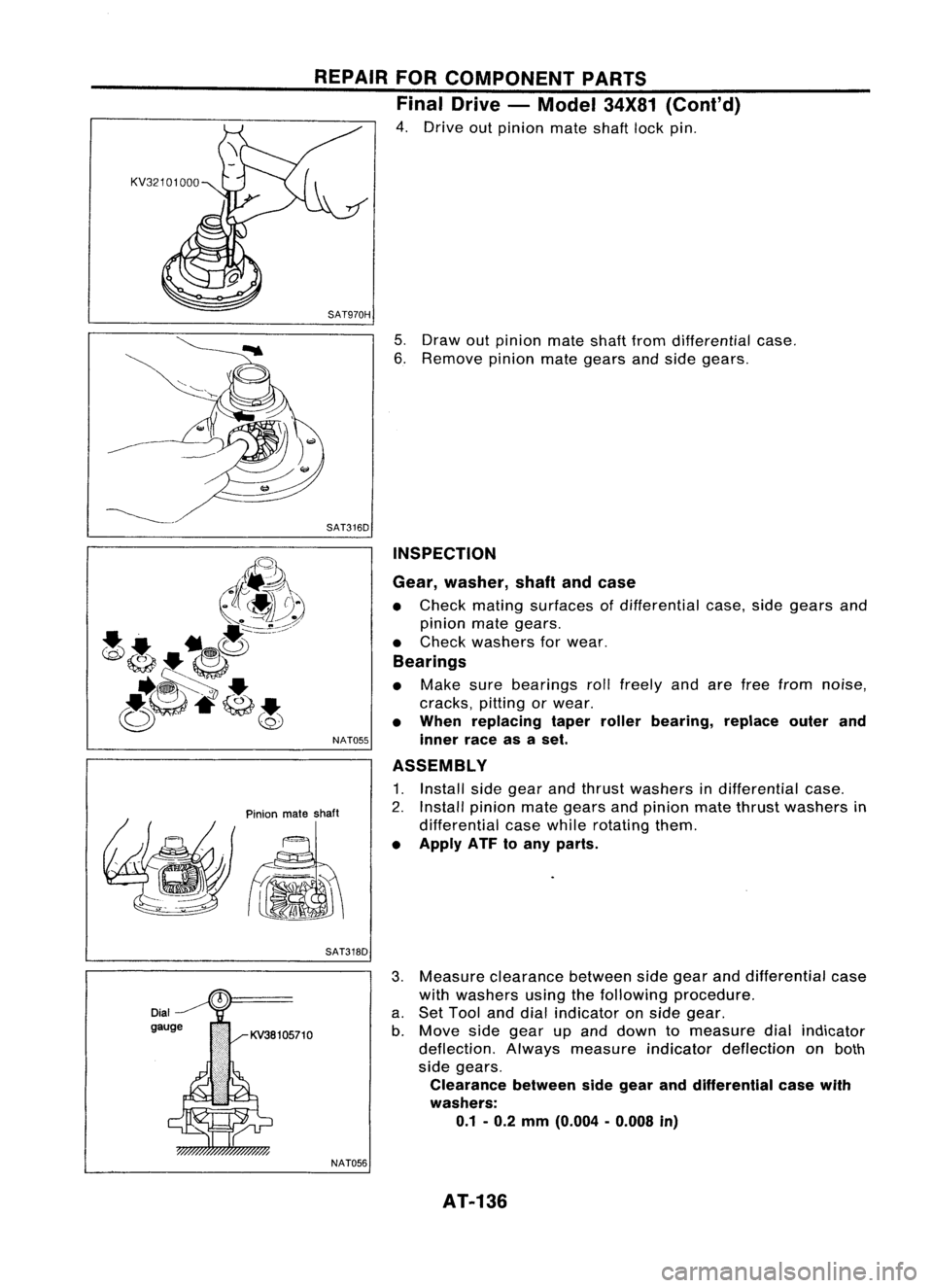

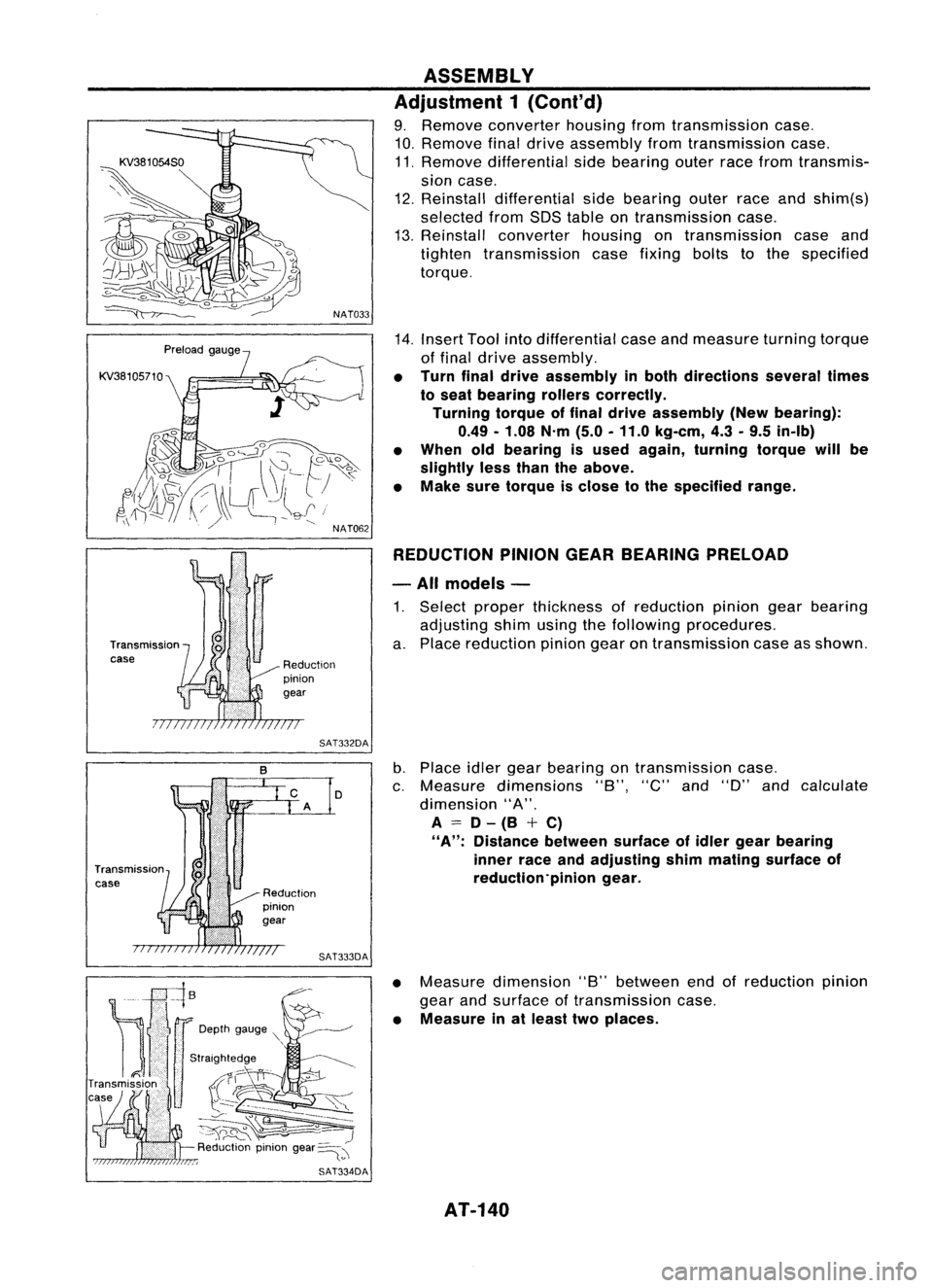

Adjustment 1(Cont'd)

9. Remove converter housingfromtransmission case.

10. Remove finaldrive assembly fromtransmission case.

11. Remove differential sidebearing outerracefrom transmis-

sion case.

12. Reinstall differential sidebearing outerraceandshim(s)

selected fromSDStable ontransmission case.

13. Reinstall converter housingontransmission caseand

tighten transmission casefixing boltstothe specified

torque.

14. Insert Toolintodifferential caseandmeasure turningtorque

of final drive assembly.

• Turn finaldrive assembly inboth directions severaltimes

to seat bearing rollerscorrectly.

Turning torqueoffinal drive assembly (Newbearing):

0.49 -1.08 N'm(5.0-11.0 kg-em, 4.3-9.5 in-Ib)

• When oldbearing isused again, turning torquewillbe

slightly lessthan theabove.

• Make suretorque isclose tothe specified range.

REDUCTION PINIONGEARBEARING PRELOAD

- All models -

1. Select proper thickness ofreduction piniongearbearing

adjusting shimusing thefollowing procedures.

a. Place reduction piniongearontransmission caseasshown.

b. Place idlergear bearing ontransmission case.

c. Measure dimensions "8","C"and"D" andcalculate

dimension "A".

A

=

D-(8 +C)

"A":

Distance betweensurfaceofidler gear bearing

inner raceandadjusting shimmating surface of

reduction'pinion gear.

• Measure dimension "8"between endofreduction pinion

gear andsurface oftransmission case.

• Measure inat least twoplaces.

AT-140

Trending: bolt pattern, fuel filter location, wheel, towing, ground clearance, catalytic converter, air filter