NISSAN ALMERA N15 1995 Service Manual

ALMERA N15 1995

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57349/w960_57349-0.png

NISSAN ALMERA N15 1995 Service Manual

Trending: air bag, bolt pattern, steering wheel, jacking, jump start, warning lights, hood open

Page 121 of 1701

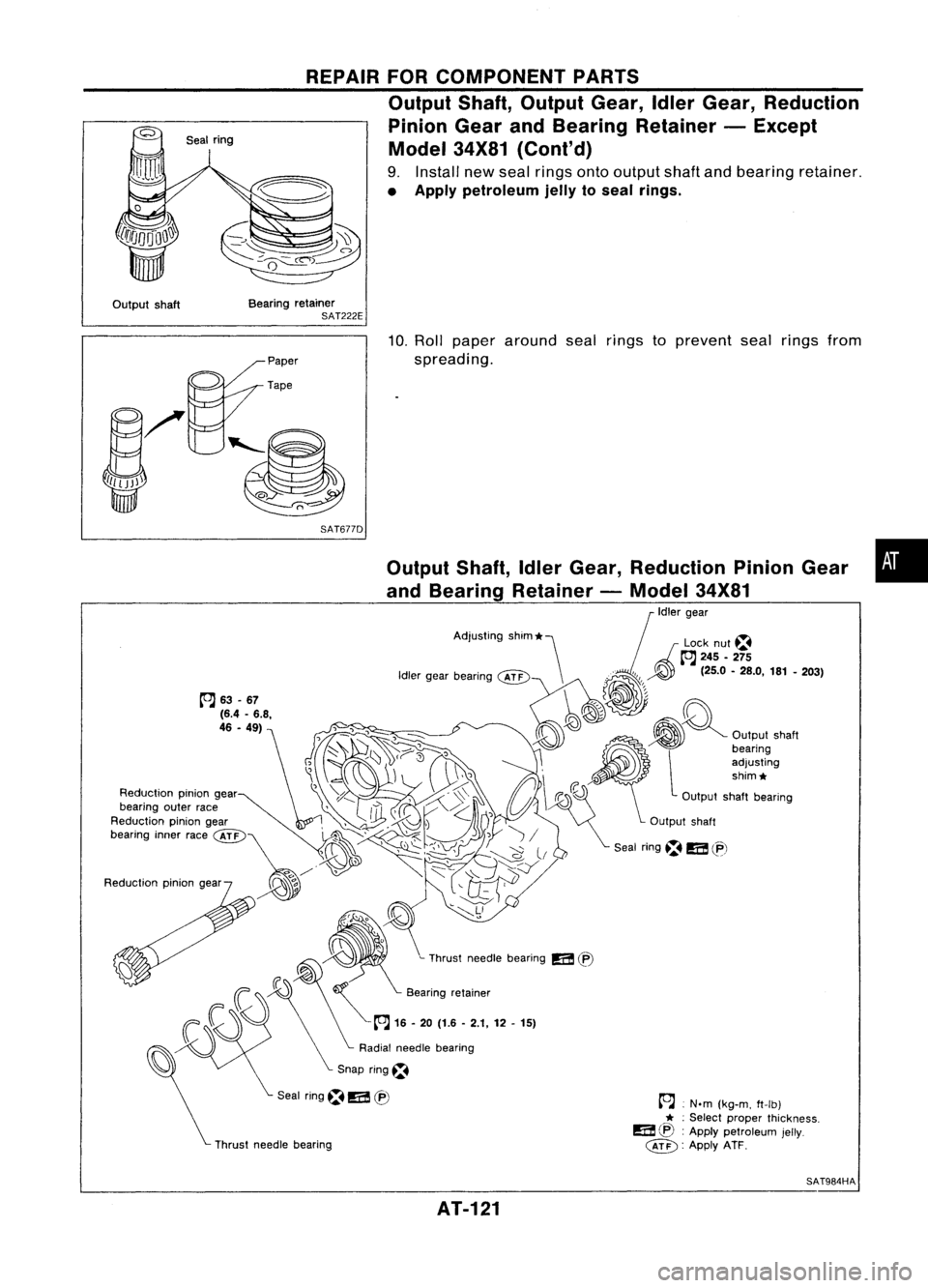

Sealring

REPAIR

FORCOMPONENT PARTS

Output Shaft,Output Gear,IdlerGear, Reduction

Pinion GearandBearing Retainer -Except

Model 34X81(Cont'd)

9. Install newseal rings ontooutput shaftandbearing retainer.

• Apply petroleum jellytoseal rings.

Output shaft Bearing

retainer

SAT222E

SAT677D

Thrust needle bearing

•

~ .N.m (kg-m, ft-Ib)

* :

Select proper thickness.

a ~:

Apply petroleum jelly.

@) :

Apply ATF.

~

Thrust needle beanng

!i:i!I

(EJ

10.

Roll paper around sealrings toprevent sealrings from

spreading.

Seal ring~

!i:i!I

tB

~63-67

(6.4 -6.8,

46 .49)

Reduclron piniongear

SAT984HA

AT-121

Page 122 of 1701

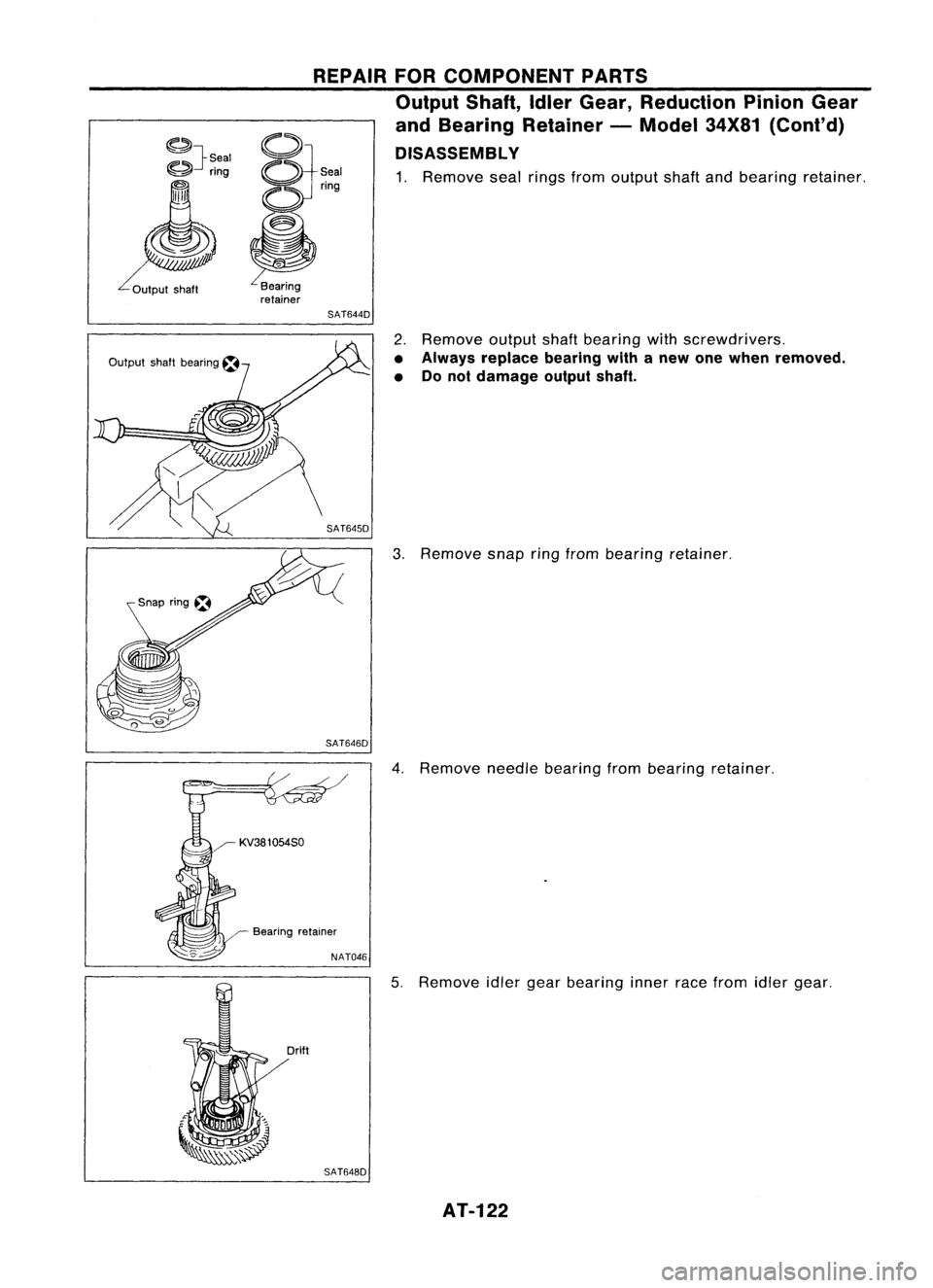

Sealring

~}~eal

~ nng

Output shaftbearing ~ REPAIR

FORCOMPONENT PARTS

Output Shaft,IdlerGear, Reduction PinionGear

and Bearing Retainer -Model 34X81(Cont'd)

DISASSEMBL Y

1. Remove sealrings fromoutput shaftandbearing retainer.

SAT644D

2.Remove outputshaftbearing withscrewdrivers.

• Always replace bearingwithanew onewhen removed.

• Donot damage outputshaft.

3. Remove snapringfrom bearing retainer.

SAT646D

4.Remove needlebearing frombearing retainer.

~ KV381054S0

Bearing retainer

NAT046

5.Remove idlergearbearing innerracefrom idlergear.

SAT648D AT-122

Page 123 of 1701

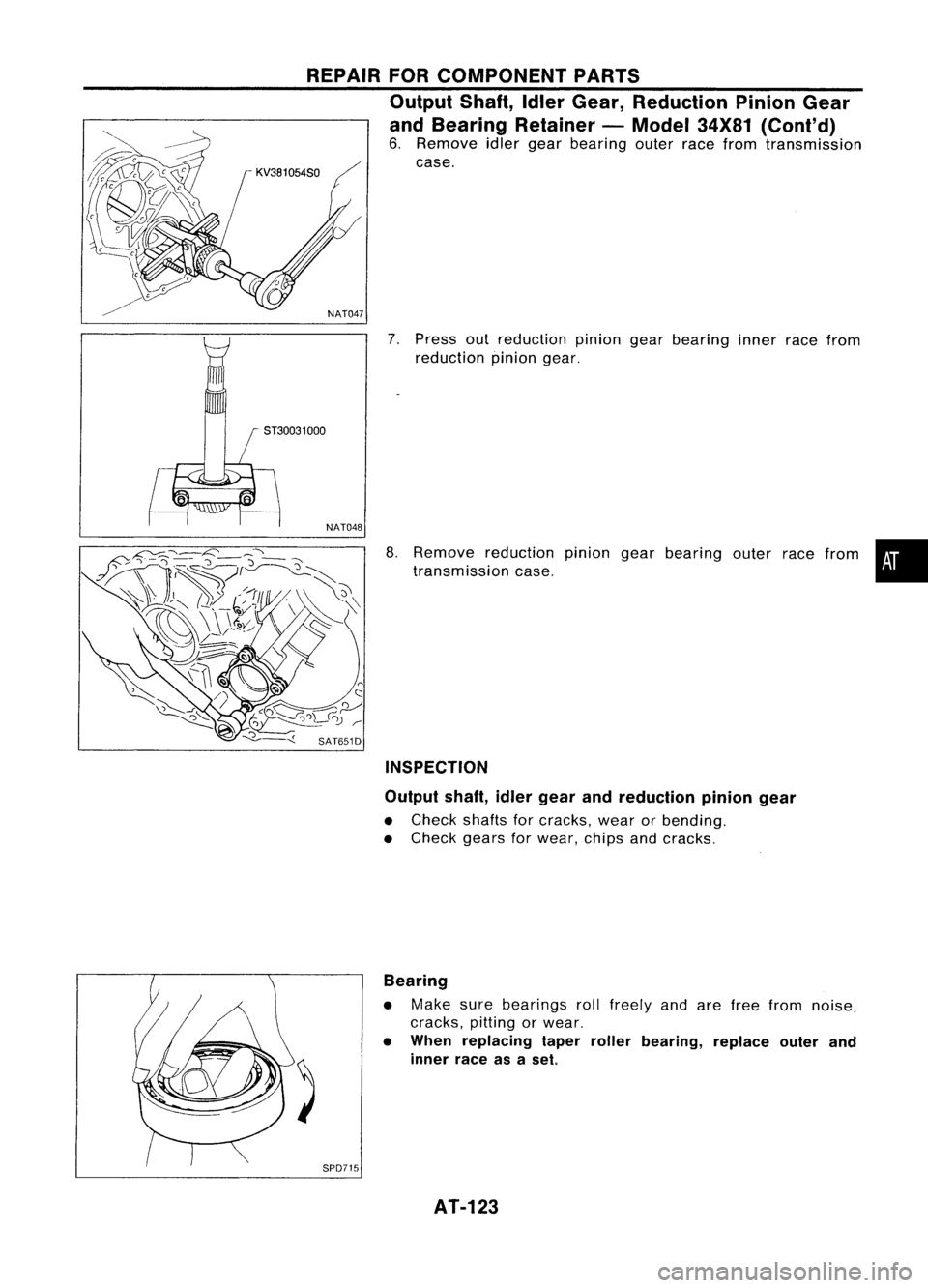

REPAIRFORCOMPONENT PARTS

Output Shaft,IdlerGear, Reduction PinionGear

and Bearing Retainer -Model 34X81(Cont'd)

6. Remove idlergear bearing outerracefrom transmission

case.

NAT047

7.Press outreduction piniongearbearing innerracefrom

reduction piniongear.

8. Remove reduction piniongearbearing outerracefrom •

transmission case.

INSPECTION

Output shaft,idlergear andreduction piniongear

• Check shaftsforcracks, wearorbending.

• Check gearsforwear, chipsandcracks.

Bearing

• Make surebearings rollfreely andarefree from noise,

cracks, pittingorwear.

• When replacing taperroller bearing, replaceouterand

inner raceasaset

SPD715 AT-123

Page 124 of 1701

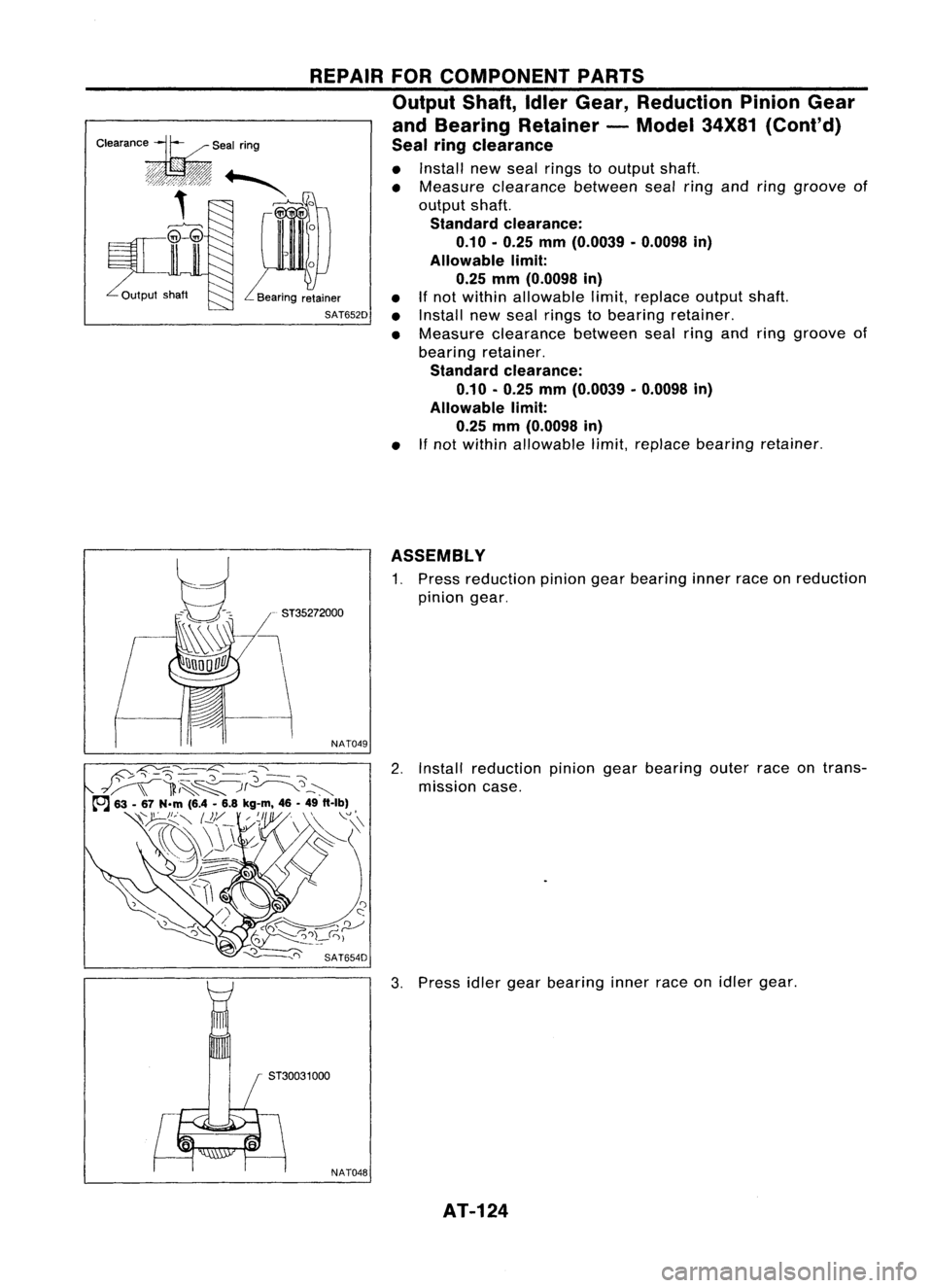

REPAIRFORCOMPONENT PARTS

Output Shaft,IdlerGear, Reduction PinionGear

and Bearing Retainer -Model 34X81(Cont'd)

Seal ringclearance

............ •Install newseal rings tooutput shaft.

""""'" •Measure clearance betweensealringandring groove of

output shaft.

Standard clearance:

0.10.0.25 mm(0.0039 .0.0098 in)

Allowable limit:

0.25 mm(0.0098 in)

Bearing retainer •

Ifnot within allowable limit,replace outputshaft.

SAT652D •

Install newseal rings tobearing retainer.

• Measure clearance betweensealringandring groove of

bearing retainer.

Standard clearance:

0.10 .0.25 mm(0.0039 .0.0098 in)

Allowable limit:

0.25 mm(0.0098 in)

• If

not within allowable limit,replace bearing retainer.

ASSEMBLY

1. Press reduction piniongearbearing innerraceonreduction

pinion gear.

- ST35272000

NAT049

2.Install reduction piniongearbearing outerraceontrans-

mission case.

3. Press idlergear bearing innerraceonidler gear.

NAT048 AT-124

Page 125 of 1701

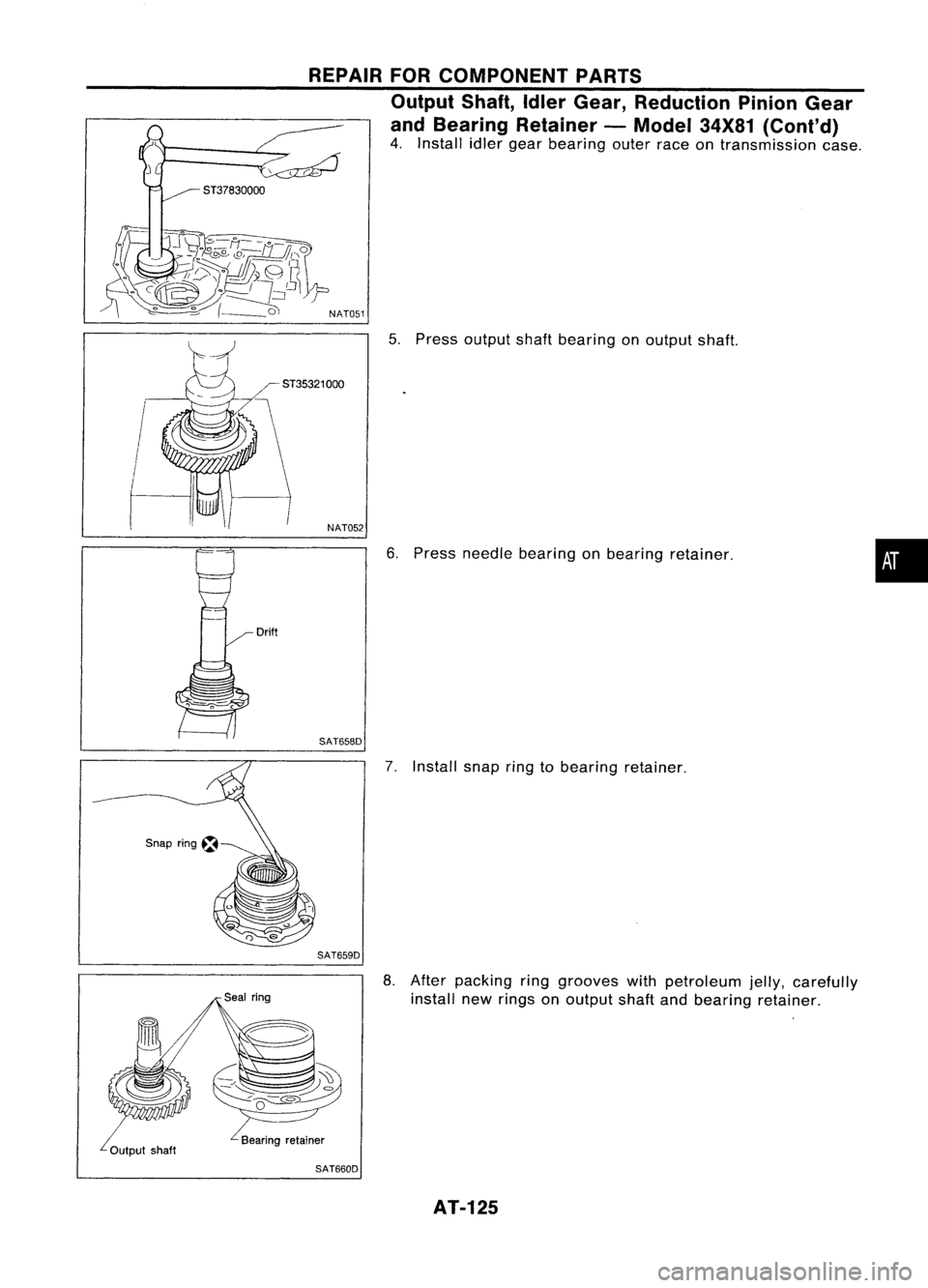

5T37830000

REPAIR

FORCOMPONENT PARTS

Output Shaft,IdlerGear, Reduction PinionGear

and Bearing Retainer -Model 34X81(Cont'd)

4. Install idlergear bearing outerraceontransmission case.

NAT051

5.Press output shaftbearing onoutput shaft.

NAT052

6.Press needle bearing onbearing retainer.

SAT658D

7.Install snapringtobearing retainer.

SAT659D

•

8. After packing ringgrooves withpetroleum jelly,carefully

install newrings onoutput shaftandbearing retainer.

SAT660D AT-125

Page 126 of 1701

REPAIRFORCOMPONENT PARTS

Output Shaft,IdlerGear, Reduction PinionGear

and Bearing Retainer -Model 34X81(Cont'd)

• Roll paper around sealrings toprevent sealrings from

spreading.

B:

paper

Tape

0/ ~

,~

~ SAT661D

n :

Adjustment isrequired.

cED:

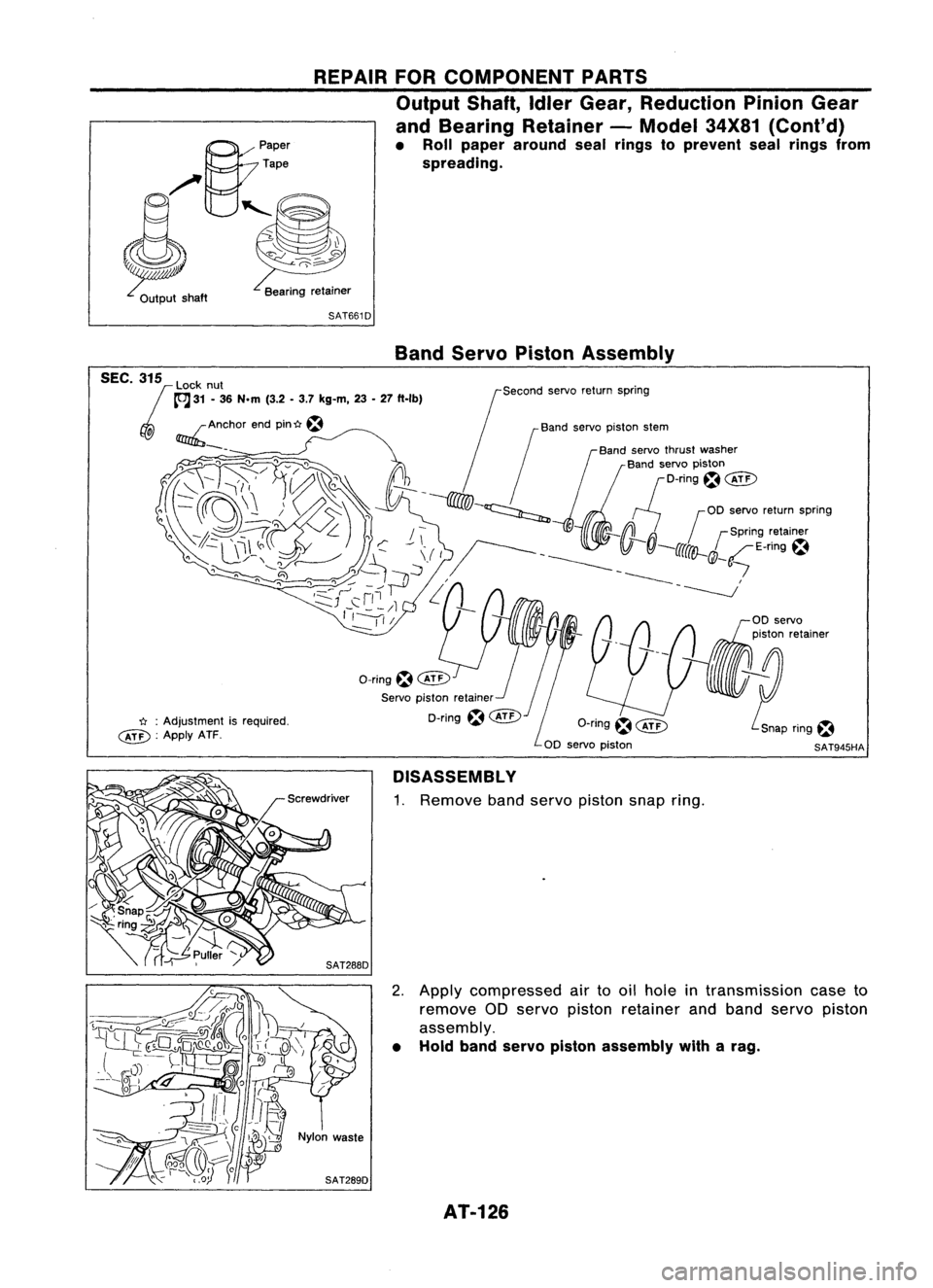

ApplyATF. Band

Servo Piston Assembly

Second servoreturn spring

SAT945HA

DISASSEMBL Y

1. Remove bandservo piston snapring.

2. Apply compressed airtooil hole intransmission caseto

remove 00servo piston retainer andband servo piston

assembly.

• Hold band servo piston assembly witharag.

AT-126

Page 127 of 1701

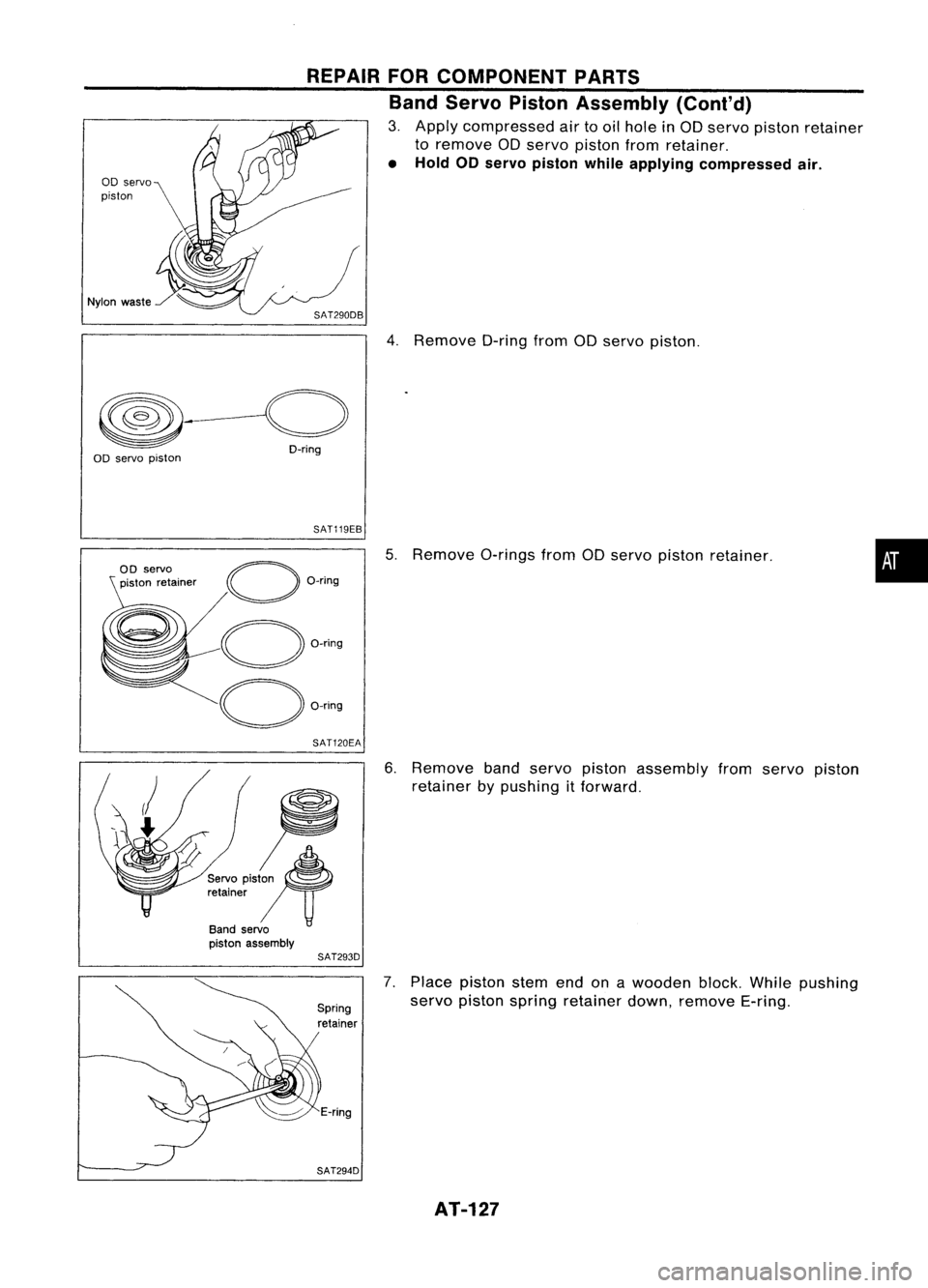

REPAIRFORCOMPONENT PARTS

Band Servo Piston Assembly (Cont'd)

3. Apply compressed airtooil hole inaD servo piston retainer

to remove aDservo piston fromretainer.

• Hold 00servo piston whileapplying compressed air.

00 servo

piston

Nylon waste

4.Remove D-ringfromaDservo piston.

~~----o

O-ring

00 servo piston

SAT119EB

00 servo

piston retainer

SAT120EA

5.

Remove a-ringsfromaDservo piston retainer.

•

~;!

Servo

PiS' ~

retainer

IT

Band servo

piston assembly

SAT293D

6.

Remove bandservo piston assembly fromservo piston

retainer bypushing itforward.

7. Place piston stemendonawooden block.Whilepushing

servo piston spring retainer down,remove E-ring.

AT-127

Page 128 of 1701

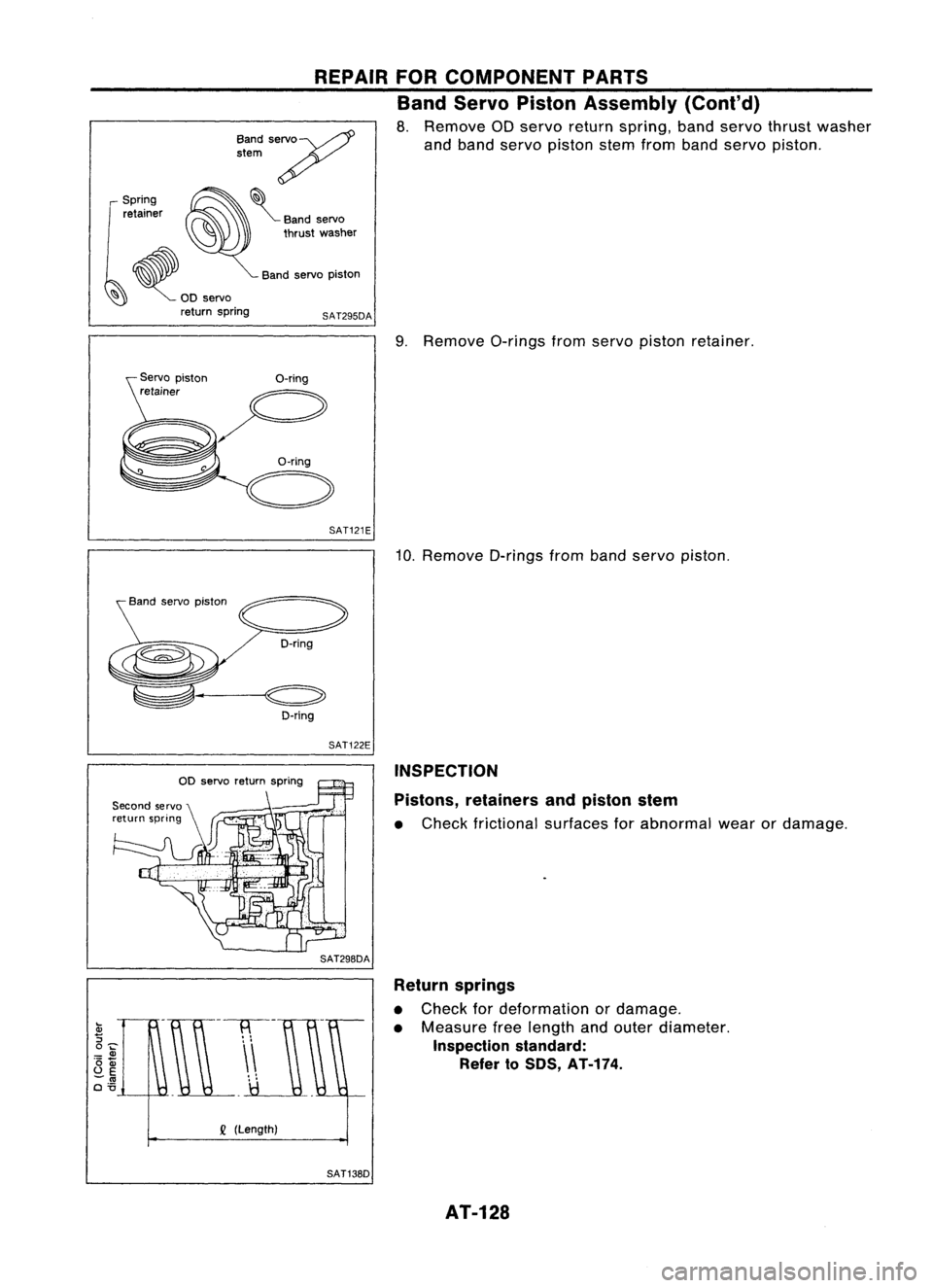

SAT295DA

REPAIR

FORCOMPONENT PARTS

Band Servo Piston Assembly (Cont'd)

8. Remove aDservo return spring, bandservo thrust washer

and band servo piston stemfromband servo piston.

Band

servo~

stem ~

~~:~~r ~~ Bandservo

~ thrustwasher

~ Bandservo piston

~ ~OO servo

return spring

9.Remove a-ringsfromservo piston retainer.

SAT121E

10.Remove D-ringsfromband servo piston.

O-ring SAT122E INSPECTION

Pistons, retainers andpiston stem

• Check frictional surfacesforabnormal wearordamage.

Return springs

• Check fordeformation ordamage.

• Measure freelength andouter diameter.

Inspection standard:

Refer toSOS, AT-174.

Q

(Length)

SAT138D AT-128

Page 129 of 1701

Unit:mm(in)

Inner diameter

O-ring Exceptmodel34X81 Model

34X81

G)

53.8

(2.118) 51.9(2.043)

@

31.7(1.248) 29.8

(1.173)

REPAIR

FORCOMPONENT PARTS

Band Servo Piston Assembly (Cont'd)

ASSEMBLY

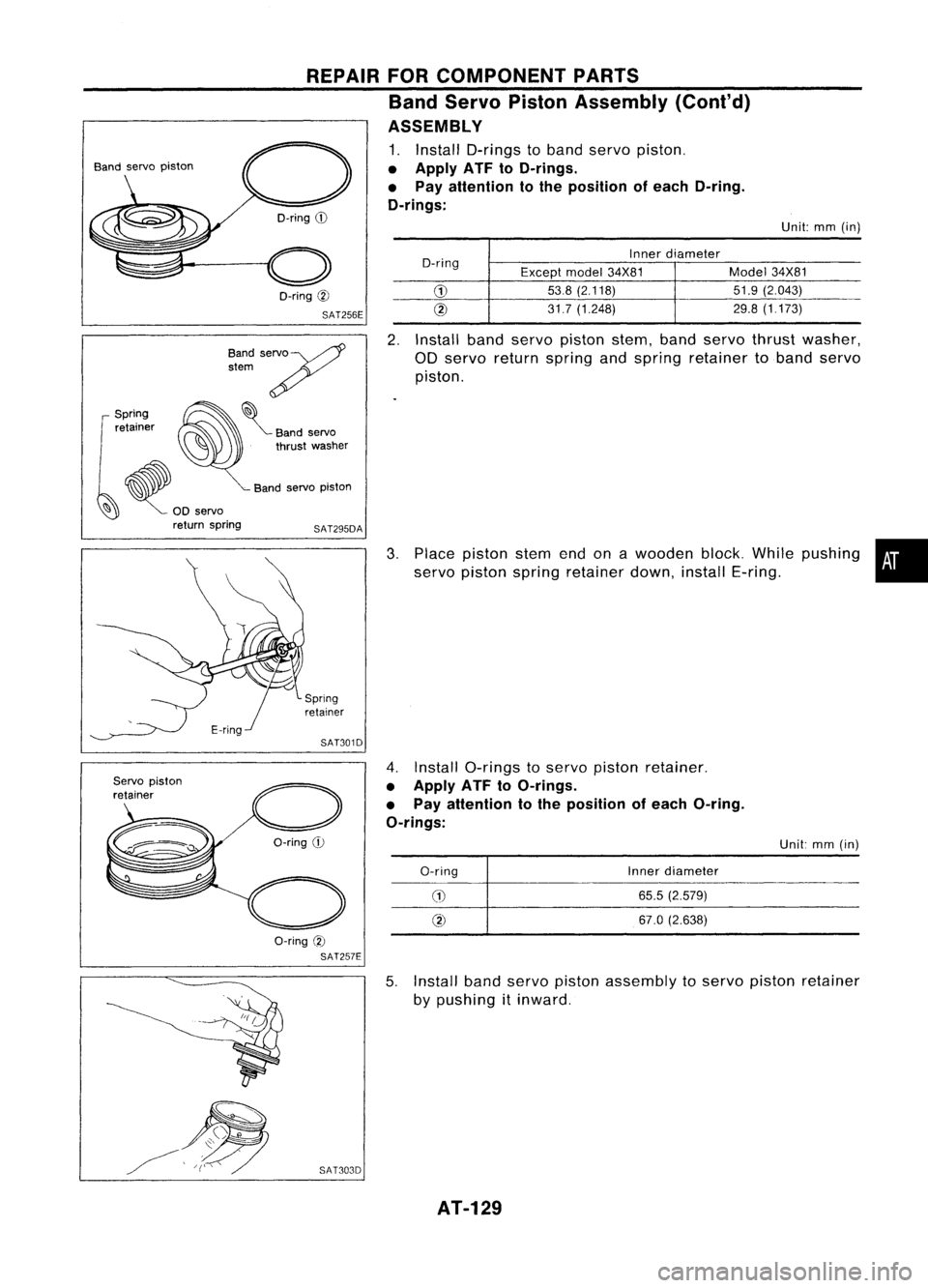

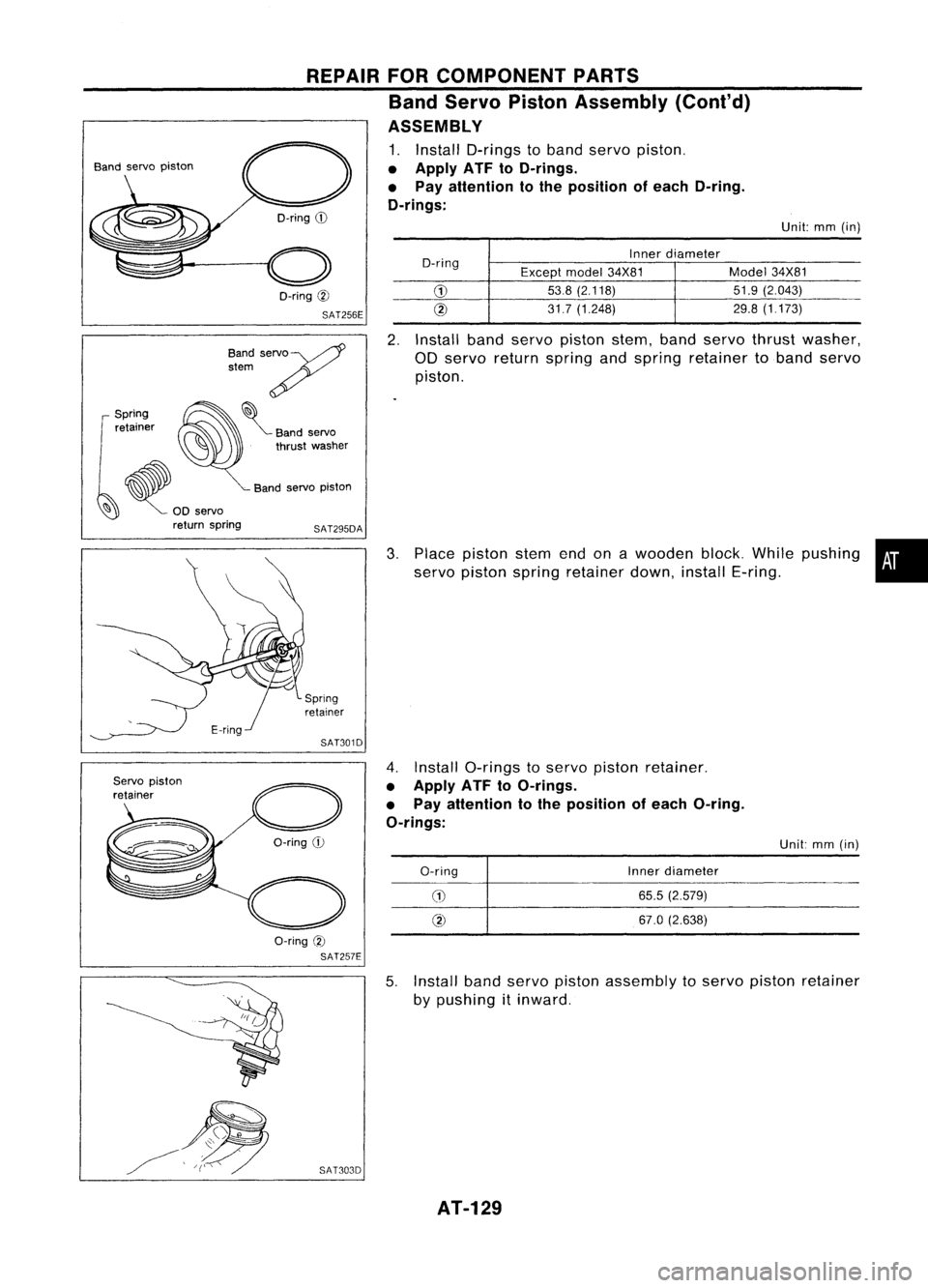

1. Install D-rings toband servo piston.

• Apply ATF toO-rings.

• Pay attention tothe position ofeach O-ring.

O-rings:

O-ring

!IJ

SAT256E

O-ring

CD

o

Band

servo piston

BandservoW

stem?

~~:~~r ~~ Bandservo

~ .thrust washer

• .Band servo piston

~ ~ 00servo

return spring

SAT295DA

2.

Install bandservo piston stem,bandservo thrust washer,

OD servo return spring andspring retainer tabandservo

piston.

3. Place piston stemendonawooden block.Whilepushing •

servo piston spring retainer down,installE-ring.

SAT301D

4.Install O-rings toservo piston retainer.

• Apply ATFtoO-rings.

• Pay attention tothe position ofeach O-ring.

O-rings:

Servo

piston

retainer

a-ring

CD

O-ring

CD

@

Inner

diameter

65.5 (2.579)

67.0 (2.638) Unit:

mm(in)

a-ring

@

SAT257E

5.Install bandservo piston assembly toservo piston retainer

by pushing

it

inward.

SAT303D AT-129

Page 130 of 1701

REPAIRFORCOMPONENT PARTS

Band Servo Piston Assembly (Cont'd)

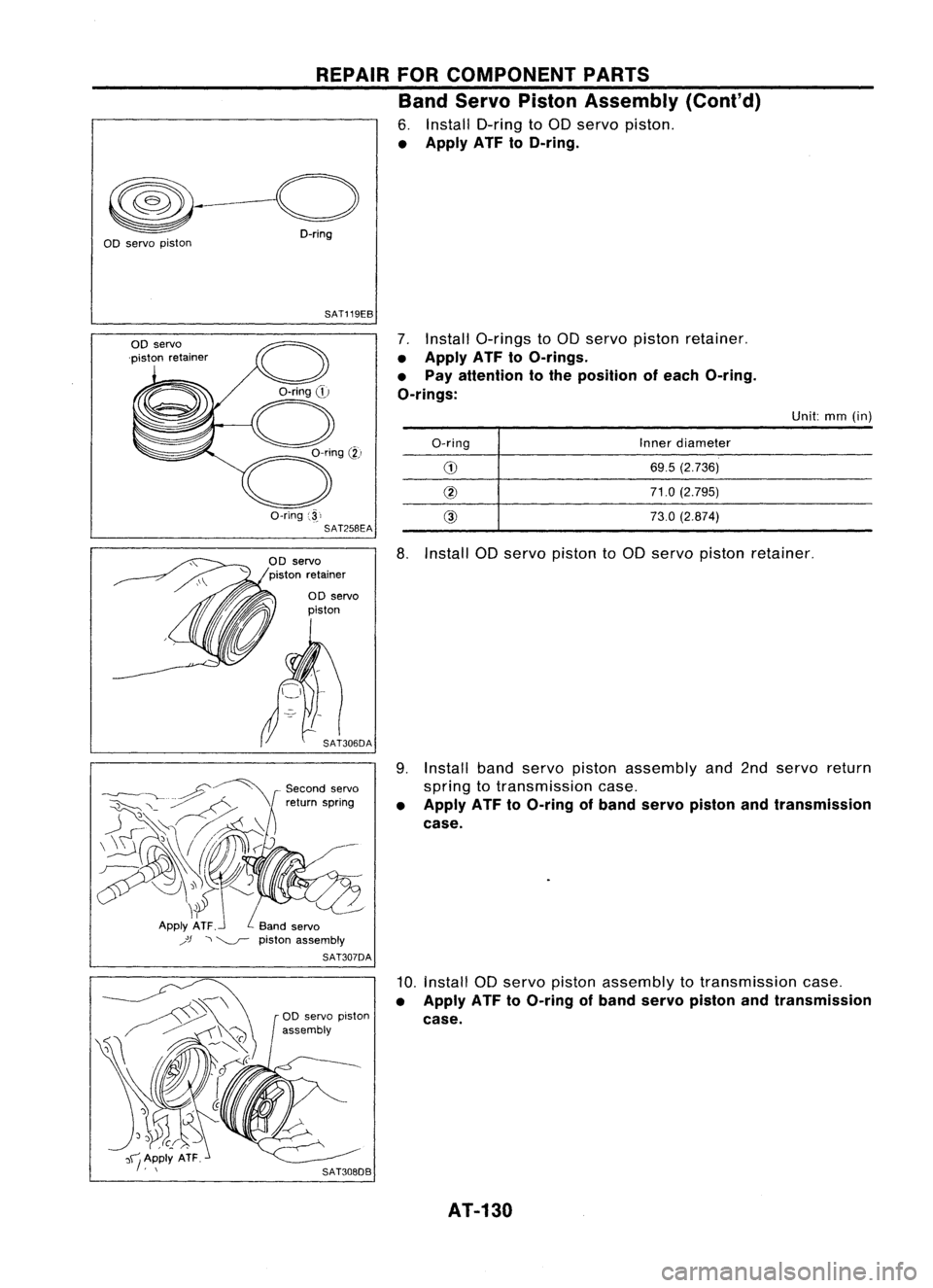

6. Install O-ring to00 servo piston.

• Apply ATFtoO-ring.

~---o

D-ring

aD servo piston

SAT119EB

7.Install a-rings toaD servo piston retainer.

• Apply ATFtoO-rings.

• Pay attention tothe position ofeach O-ring.

O-rings:

OD

servo

'piston retainer

a-ring

,j.,

SAT258EA

O-ring

Inner

diameter

69.5 (2.736)

71.0 (2.795)

73.0 (2.874)

Unit:

mm(in)

aD servo

piston

Second servo

return spring

jJ --,~

pistonassembly

SAT307DA

8.

Install aDservo piston to00 servo piston retainer.

9. Install bandservo piston assembly and2ndservo return

spring totransmission case.

• Apply ATFtoO-ring ofband servo piston andtransmission

case.

10.

Install aDservo piston assembly totransmission case.

• Apply ATFtoO-ring ofband servo piston andtransmission

case.

AT-130

Trending: roof rack, oil level, automatic transmission fluid, steering, lug pattern, refer to last page, spark plugs