NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 141 of 1701

SAT336DA

Depth gauge

SAT337D

SAT338DA ASSEMBLY

Adjustment 1(Cont'd)

• Measure dimension "C"between surfaceofidler gear bear-

ing inner raceandconverter housingfittingsurface oftrans-

mission case.

• Measure inat least twoplaces.

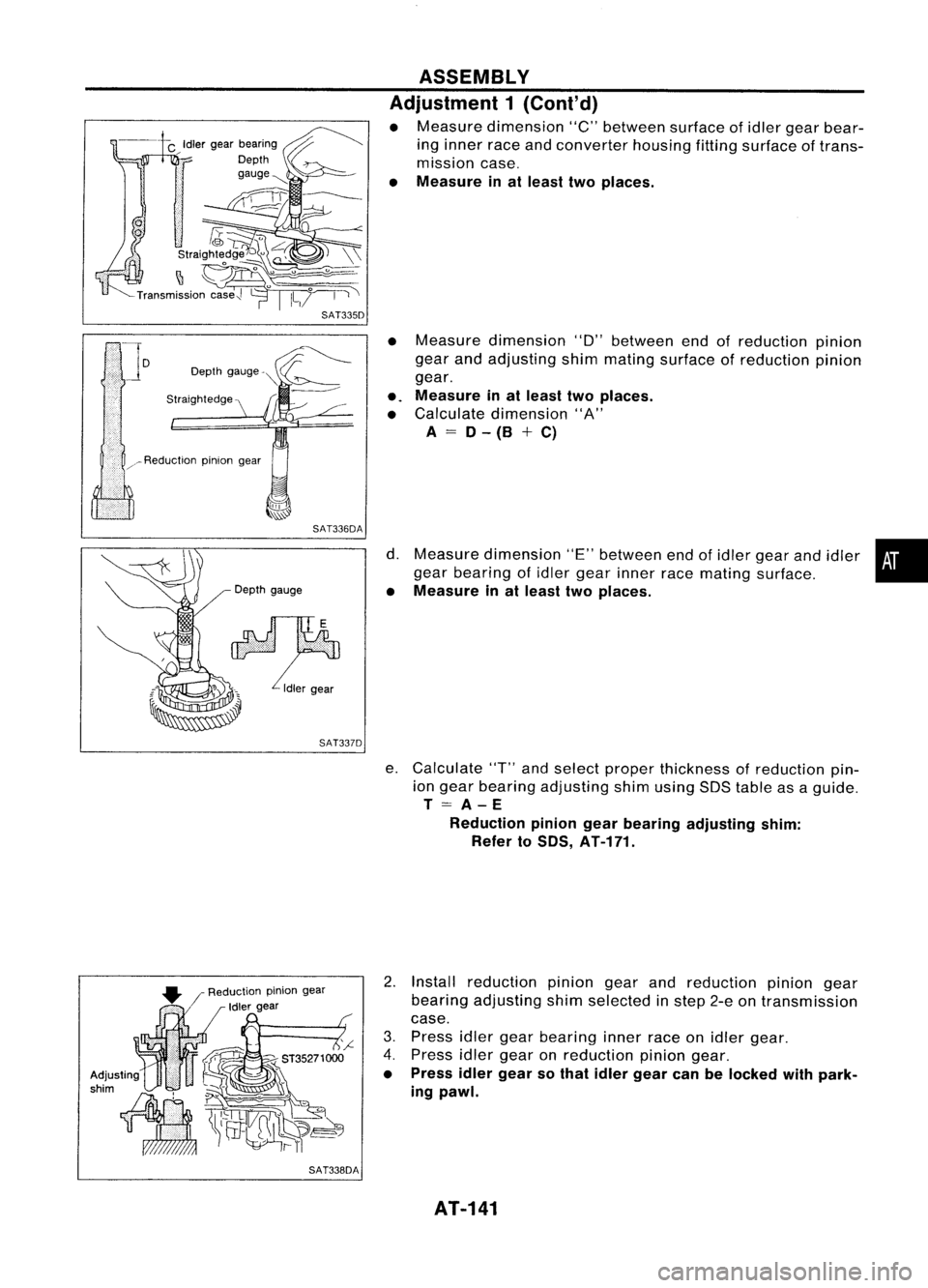

• Measure dimension "D"between endofreduction pinIOn

gear andadjusting shimmating surface ofreduction pinion

gear .

•. Measure inat least twoplaces.

• Calculate dimension "A"

A = 0-(B +C)

d. Measure dimension "E"between endofidler gear andidler •

gear bearing ofidler gear inner racemating surface.

• Measure inat least twoplaces.

e. Calculate "T"andselect proper thickness ofreduction pin-

ion gear bearing adjusting shimusing SDStable asaguide.

T=A-E

Reduction piniongearbearing adjusting shim:

Refer to50S, AT-171.

2. Install reduction piniongearandreduction piniongear

bearing adjusting shimselected instep 2-eontransmission

case.

3. Press idlergearbearing innerraceonidler gear.

4. Press idlergear onreduction piniongear.

• Press idlergearsothat idler gear canbelocked withpark-

ing pawl.

AT-141

Page 142 of 1701

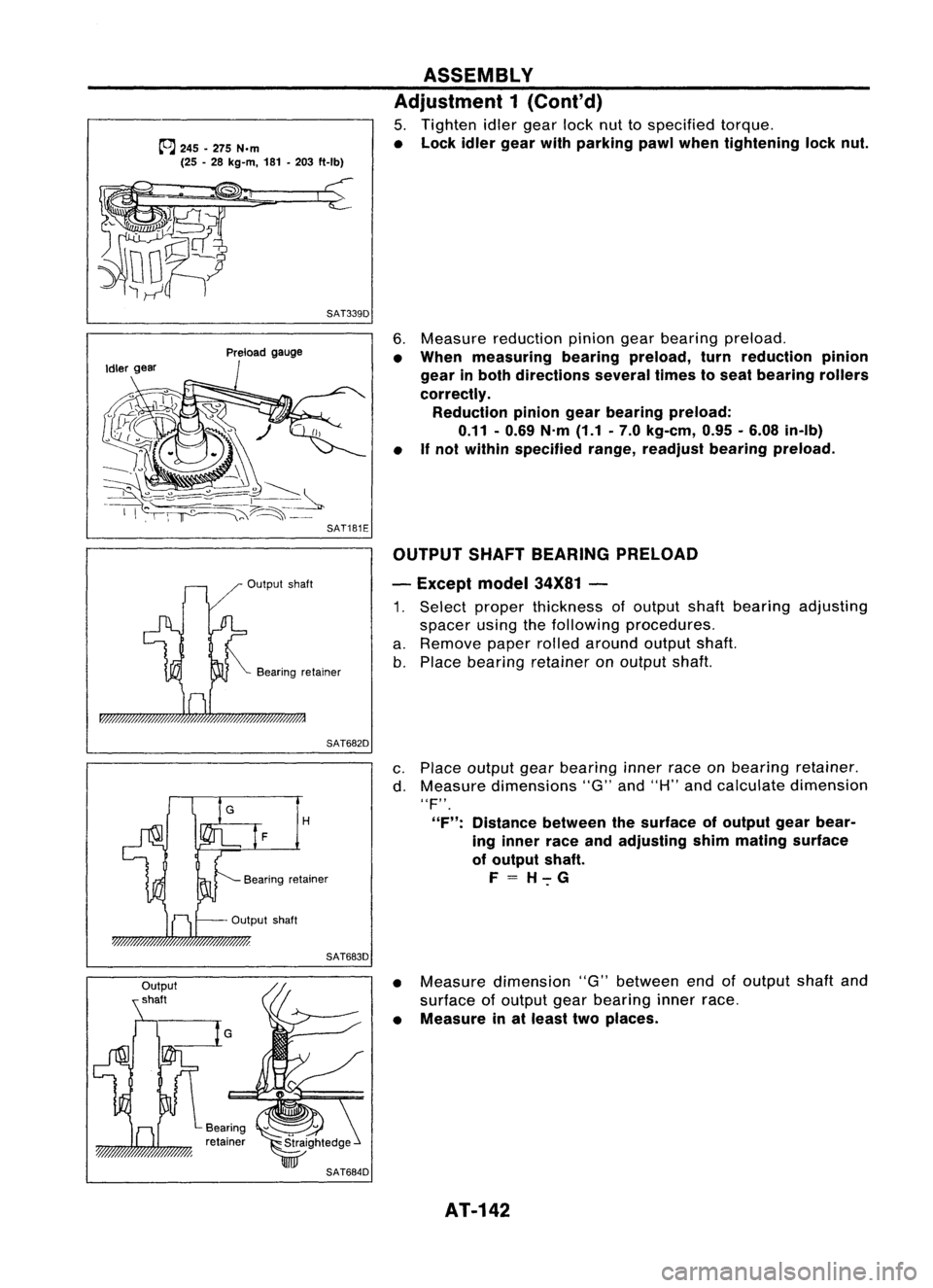

~245 -275 N.m

(25 -28 kg-m, 181-203 ft-Ib)

SAT339D ASSEMBLY

Adjustment 1(Cont'd)

5. Tighten idlergear locknuttospecified torque.

• Lock idlergear withparking pawlwhen tightening locknut.

Output shaft

Preload

gauge

Bearing retainer

6.

Measure reduction piniongearbearing preload.

• When measuring bearingpreload, turnreduction pinion

gear inboth directions severaltimestoseat bearing rollers

correctly. Reduction piniongearbearing preload:

0.11 -0.69 N.m(1.1.7.0 kg-em, 0.95•6.08 in-Ib)

• If

not within specified range,readjust bearingpreload.

OUTPUT SHAFTBEARING PRELOAD

- Except model34X81-

1. Select proper thickness ofoutput shaftbearing adjusting

spacer usingthefollowing procedures.

a. Remove paperrolledaround outputshaft.

b. Place bearing retainer onoutput shaft.

SAT682D

H

F

Output shaft

SAT683D

c.

Place output gearbearing innerraceonbearing retainer.

d. Measure dimensions "G"and"H" andcalculate dimension

"F".

"F": Distance betweenthesurface ofoutput gearbear-

ing inner raceandadjusting shimmating surface

of output shaft.

F=H-:-G

• Measure dimension "G"between endofoutput shaftand

surface ofoutput gearbearing innerrace.

• Measure inat least twoplaces.

AT-142

Page 143 of 1701

Straightedge

SAT685D

~ ..•. I

::~i~:::::: ..-."." ...:::/i \.::;.."... ;.:;:;::{\

Output gear

SAT686D ASSEMBLY

Adjustment 1(Cont'd)

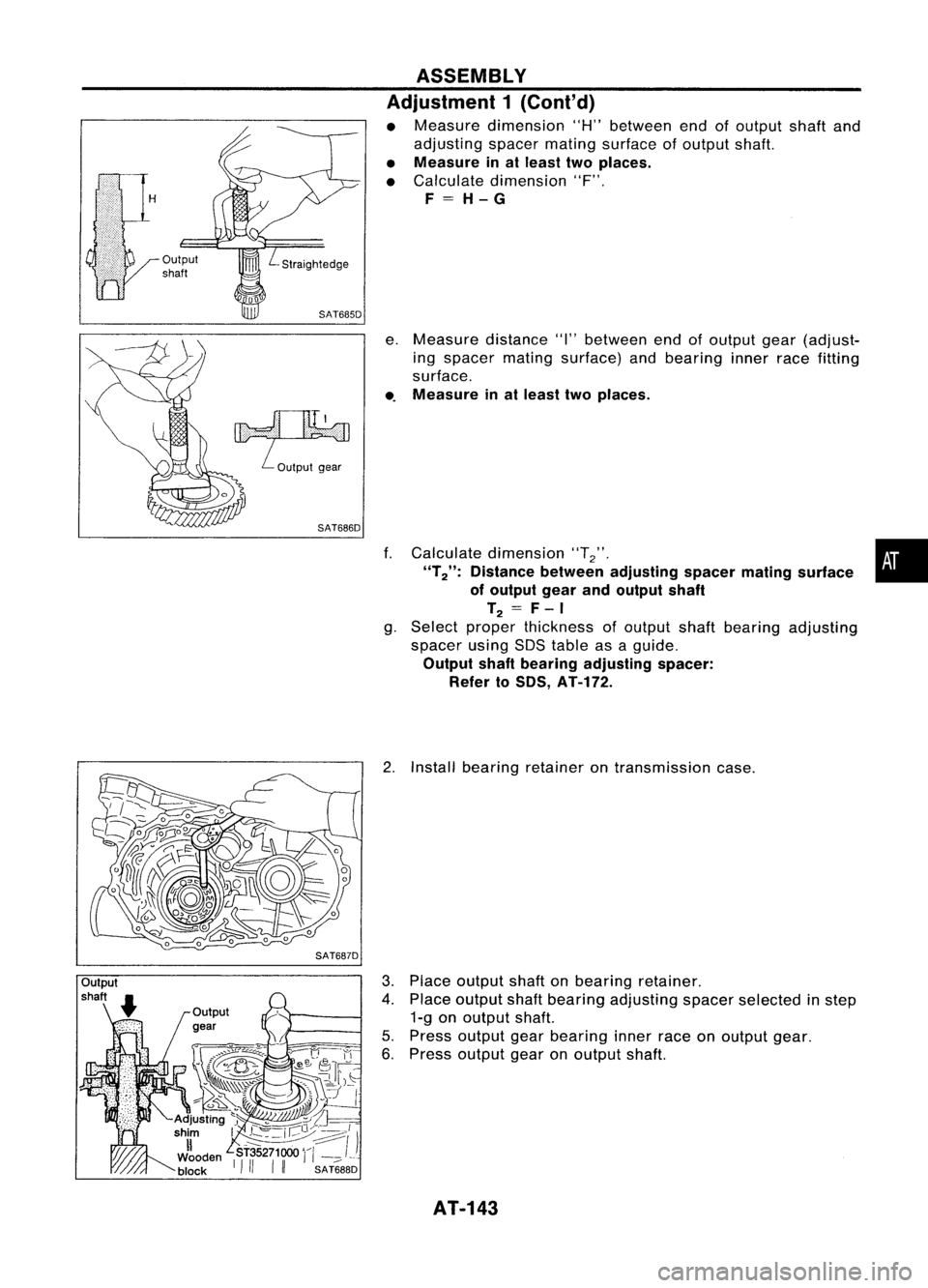

• Measure dimension "H"between endofoutput shaftand

adjusting spacermatingsurface ofoutput shaft.

• Measure inat least twoplaces.

• Calculate dimension "F".

F=H-G

e. Measure distance"I"between endofoutput gear(adjust-

ing spacer matingsurface) andbearing innerracefitting

surface .

• 0

Measure inat least twoplaces.

f. Calculate dimension "T

2". •

"T 2": Distance between adjusting spacermatingsurface

of output gearandoutput shaft

T

2

=

F- I

g. Select proper thickness ofoutput shaftbearing adjusting

spacer usingSOStable asaguide.

Output shaftbearing adjusting spacer:

Refer to50S, AT-172.

2. Install bearing retainer ontransmission case.

3. Place output shaftonbearing retainer.

4. Place output shaftbearing adjusting spacerselected instep

1-g onoutput shaft.

5. Press output gearbearing innerraceonoutput gear.

6. Press output gearonoutput shaft.

AT-143

Page 144 of 1701

SAT689DASSEMBLY

Adjustment 1(Cont'd)

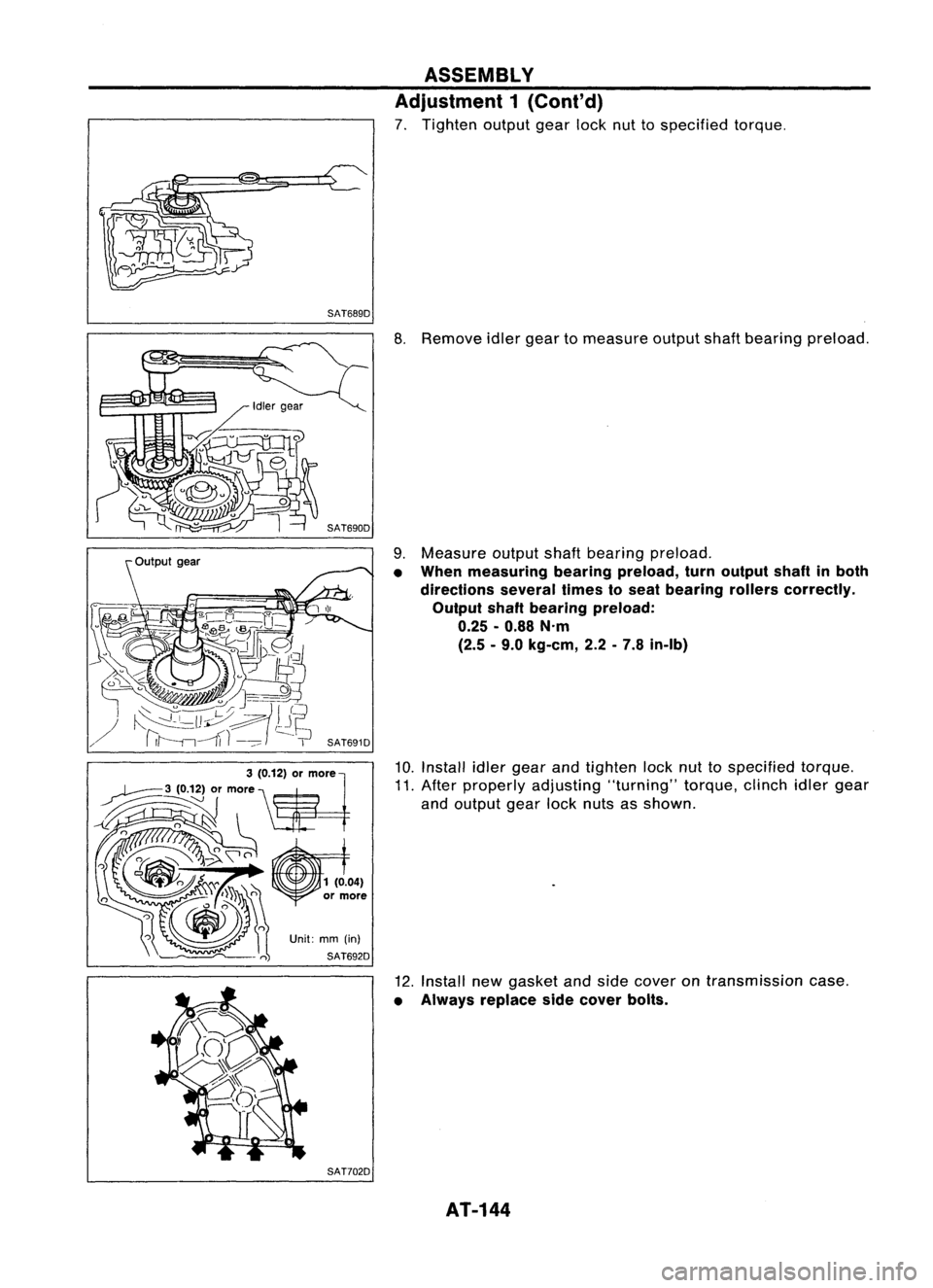

7. Tighten outputgearlocknuttospecified torque.

SAT702D

8.

Remove idlergear tomeasure outputshaftbearing preload.

9. Measure outputshaftbearing preload.

• When measuring bearingpreload, turnoutput shaftinboth

directions severaltimestoseat bearing rollerscorrectly.

Output shaftbearing preload:

0.25 -0.88 N'm

(2.5 -9.0 kg-em, 2.2-7.8 in-Ib)

10. Install idlergear andtighten locknuttospecified torque.

11. After properly adjusting "turning"torque,clinchidlergear

and output gearlocknuts asshown.

12. Install newgasket andside cover ontransmission case.

• Always replace sidecover bolts.

AT-144

Page 145 of 1701

SAT341D

SAT438D

SAT439D

KV31101300 NAT064 ASSEMBLY

Adjustment 1(Cont'd)

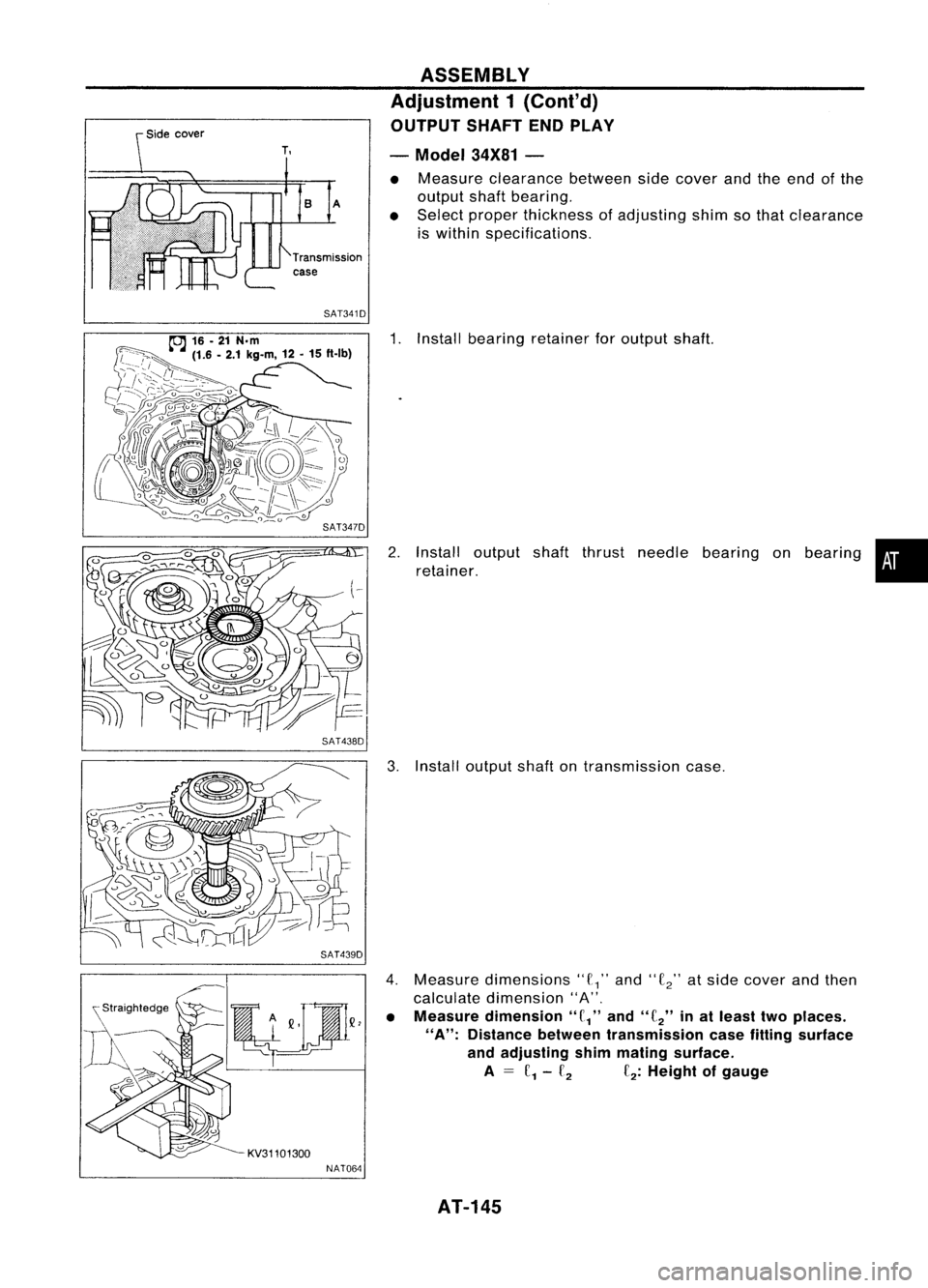

OUTPUT SHAFTENDPLAY

- Model 34X81-

• Measure clearance betweensidecover andtheend ofthe

output shaftbearing.

• Select proper thickness ofadjusting shimsothat clearance

is within specifications.

1. Install bearing retainer foroutput shaft.

2. Install output shaftthrust needle bearing onbearing •

retainer.

3. Install output shaftontransmission case.

4. Measure dimensions"

£1"

and"

£2"

atside cover andthen

calculate dimension "A".

• Measure dimension

"f/'

and

"f

2"

inat least twoplaces.

"A":

Distance betweentransmission casefitting surface

and adjusting shimmating surface.

A

= f

1-£2 £2:

Height ofgauge

AT-145

Page 146 of 1701

SAT440DASSEMBLY

Adjustment 1(Cont'd)

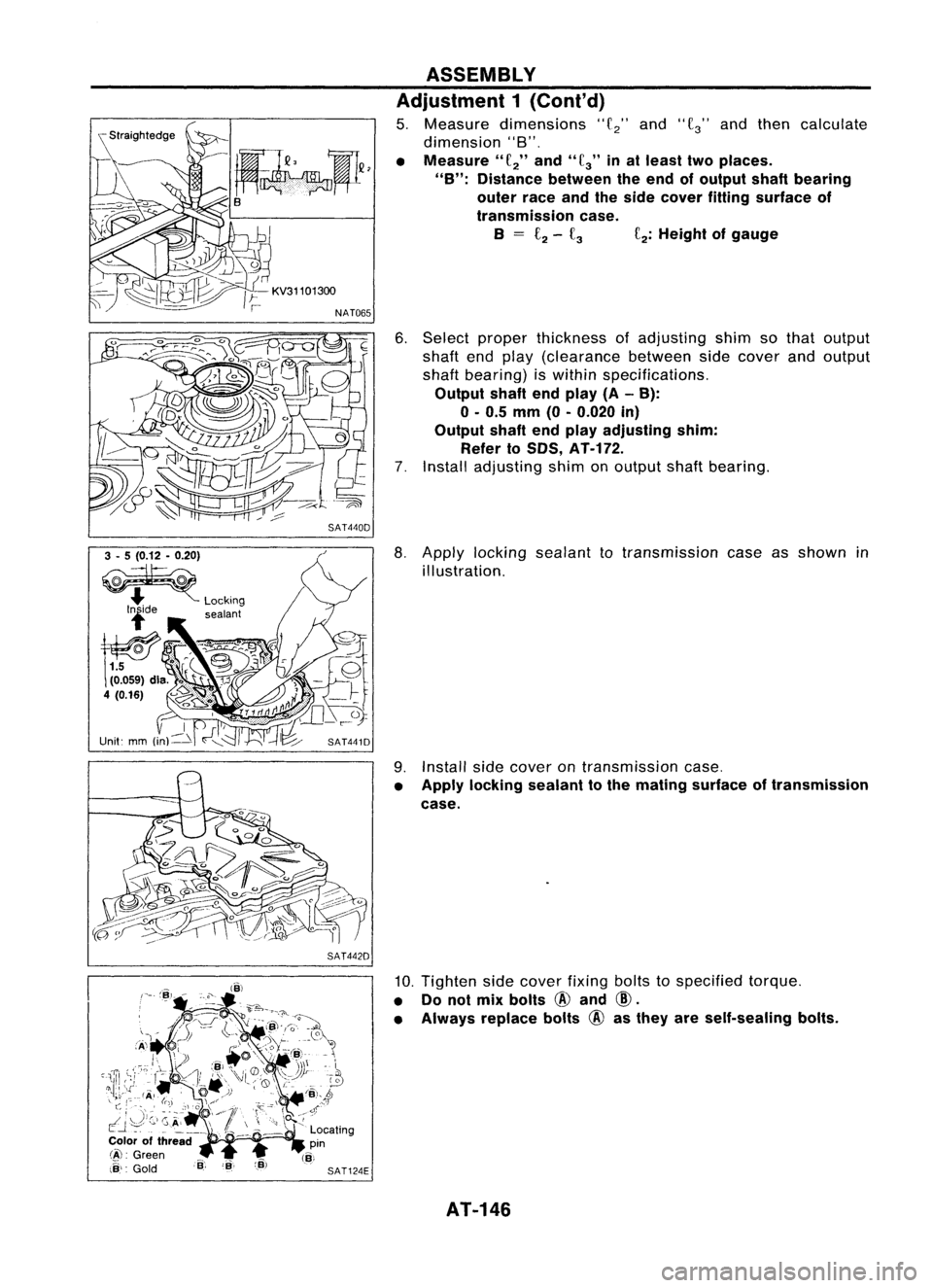

5. Measure dimensions

"f

2"

and

"f

3"

andthen calculate

dimension "8".

• Measure"

f

2"

and"

fa"

inat least twoplaces.

"B": Distance betweentheend ofoutput shaftbearing

outer raceandtheside cover fitting surface of

transmission case.

B

=

£2-

fa

f

2:

Height ofgauge

6. Select proper thickness ofadjusting shimsothat output

shaft endplay (clearance betweensidecover andoutput

shaft bearing) iswithin specifications.

Output shaftendplay (A-B):

o -

0.5

mm

(0-0.020

in)

Output shaftendplay adjusting shim:

Refer to50S,

AT-H2.

7. Install adjusting shimonoutput shaftbearing.

3 -5 (0.12 -0.20)

~

.... Locking

lide sealant

SAT441D

SAT442D

8.

Apply locking sealant totransmission caseasshown in

illustration.

9. Install sidecover ontransmission case.

• Apply locking sealant tothe mating surface oftransmission

case.

10. Tighten sidecover fixingboltstospecified torque.

• Donot mix bolts

@

and

CID.

• Always replace bolts

@

asthey areself-sealing bolts.

AT-146

Page 147 of 1701

Forwardclutch

assembly

Bearing race

m

@

ASSEMBLY

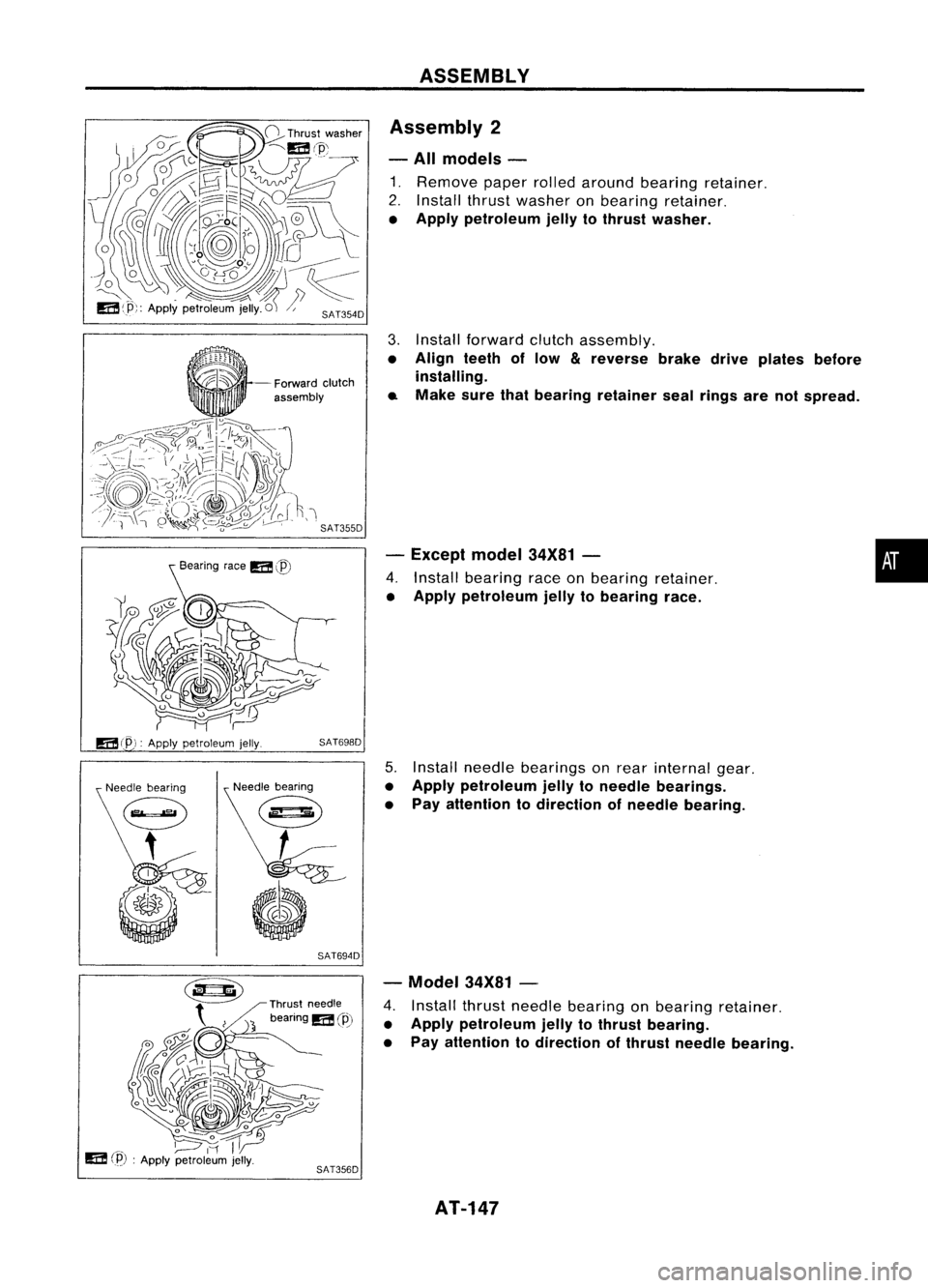

Assembly 2

- All models -

1. Remove paperrolledaround bearing retainer.

2. Install thrustwasher onbearing retainer.

• Apply petroleum jellytothrust washer.

3. Install forward clutchassembly.

• Align teethoflow

&

reverse brakedriveplates before

installing.

.. Make surethatbearing retainer sealrings arenotspread.

- Except model34X81-

4. Install bearing raceonbearing retainer.

• Apply petroleum jellytobearing race.

•

mep,:

Applypetroleum jelly.

SAT698D

Needle bearing

@

'-

(I

SAT694D

5.

Install needle bearings onrear internal gear.

• Apply petroleum jellytoneedle bearings.

• Pay attention todirection ofneedle bearing.

- Model 34X81-

4. Install thrustneedle bearing onbearing retainer.

• Apply petroleum jellytothrust bearing.

• Pay attention todirection ofthrust needle bearing.

AT-147

Page 148 of 1701

~ru,t

,,,dl,

beanng

m@

6

/)/11/

11

~I~u ,

"ill)

ASSEMBLY

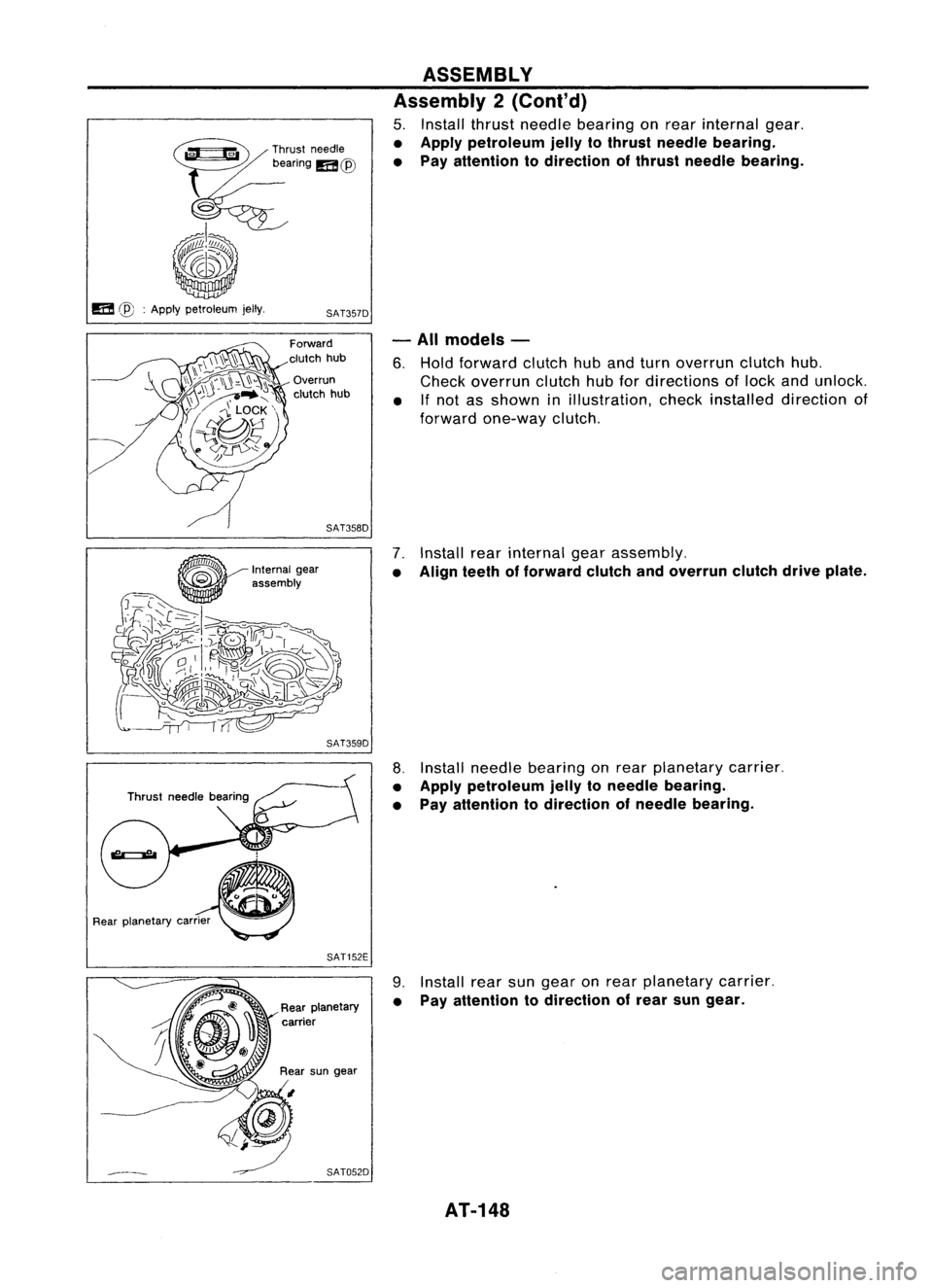

Assembly 2(Cont'd)

5. Install thrustneedle bearing onrear internal gear.

• Apply petroleum jellytothrust needle bearing.

• Pay attention todirection ofthrust needle bearing.

m

@:

Apply petroleum jelly.

SAT357D

Forward

clutch hub

Overrun

clutch hub

SAT358D

SAT359D -

All models -

6. Hold forward clutchhubandturn overrun clutchhub.

Check overrun clutchhubfordirections oflock andunlock.

• If

not asshown inillustration, checkinstalled direction of

forward one-way clutch.

"7.

Install rearinternal gearassembly.

• Align teethofforward clutchandoverrun clutchdriveplate.

,

~

"

u

Rear planetary carner

SAT152E

8.

Install needle bearing onrear planetary carrier.

• Apply petroleum jellytoneedle bearing.

• Pay attention todirection ofneedle bearing.

9. Install rearsungear onrear planetary carrier.

• Pay attention todirection ofrear sungear.

AT-148

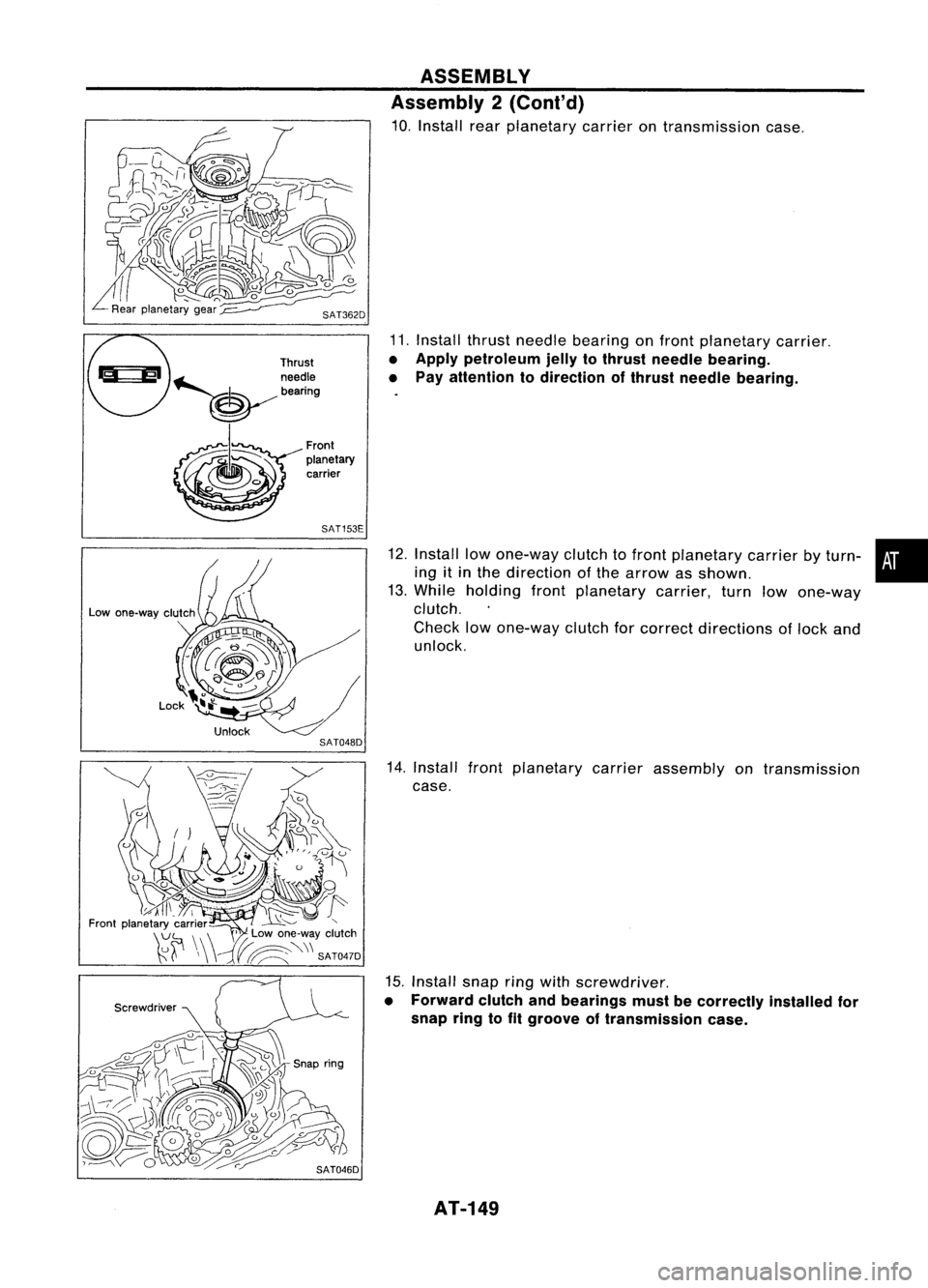

Page 149 of 1701

Thrust

~.-b.. ~needle

~ bearing ASSEMBLY

Assembly 2(Cont'd)

10. Install rearplanetary carrierontransmission case.

11. Install thrustneedle bearing onfront planetary carrier.

• Apply petroleum jellytothrust needle bearing.

• Pay attention todirection ofthrust needle bearing.

Front

planetary carrier

SAT153E

Screwdriver

12.

Install lowone-way clutchtofront planetary carrierbyturn- •

ing itin the direction ofthe arrow asshown.

13. While holding frontplanetary carrier,turnlowone-way

clutch.

Check lowone-way clutchforcorrect directions oflock and

unlock.

14. Install frontplanetary carrierassembly ontransmission

case.

15. Install snapringwith screwdriver.

• Forward clutchandbearings mustbecorrectly installedfor

snap ringtofit groove oftransmission case.

AT-149

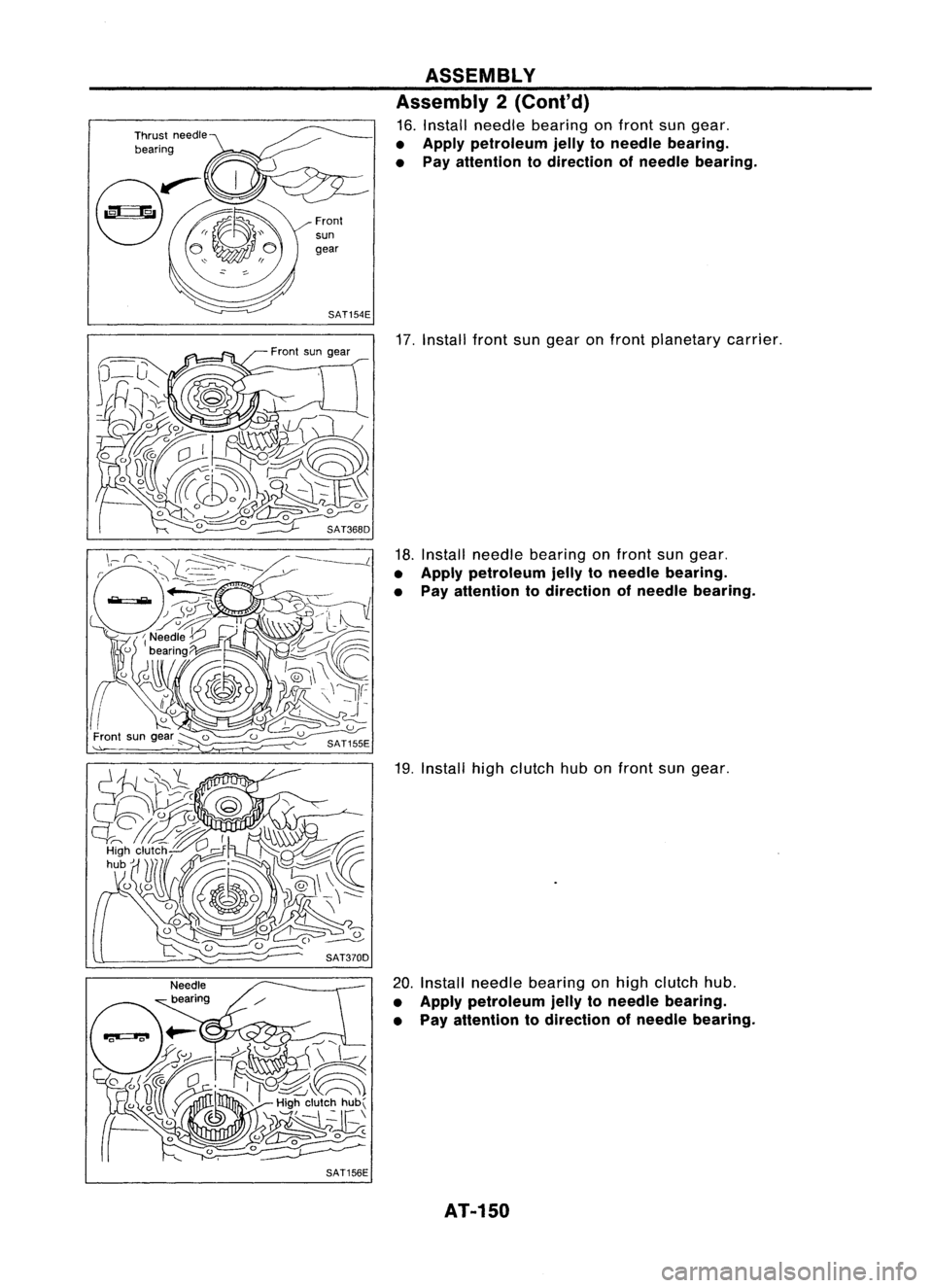

Page 150 of 1701

Front

sun

gear

SAT154E

SAT156E ASSEMBLY

Assembly 2(Cont'd)

16. Install needle bearing onfront sungear.

• Apply petroleum jellytoneedle bearing.

• Pay attention todirection ofneedle bearing.

17. Install frontsungear onfront planetary carrier.

18. Install needle bearing onfront sungear.

• Apply petroleum jellytoneedle bearing.

• Pay attention todirection ofneedle bearing.

19. Install highclutch hubonfront sungear.

20. Install needle bearing onhigh clutch hub.

• Apply petroleum jellytoneedle bearing.

• Pay attention todirection ofneedle bearing.

AT-150