NISSAN ALMERA N16 2003 Electronic Repair Manual

ALMERA N16 2003

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57350/w960_57350-0.png

NISSAN ALMERA N16 2003 Electronic Repair Manual

Trending: FLUID, steering wheel adjustment, navigation system, Wiring diagrams, Automatic air, change language, Start

Page 2861 of 3189

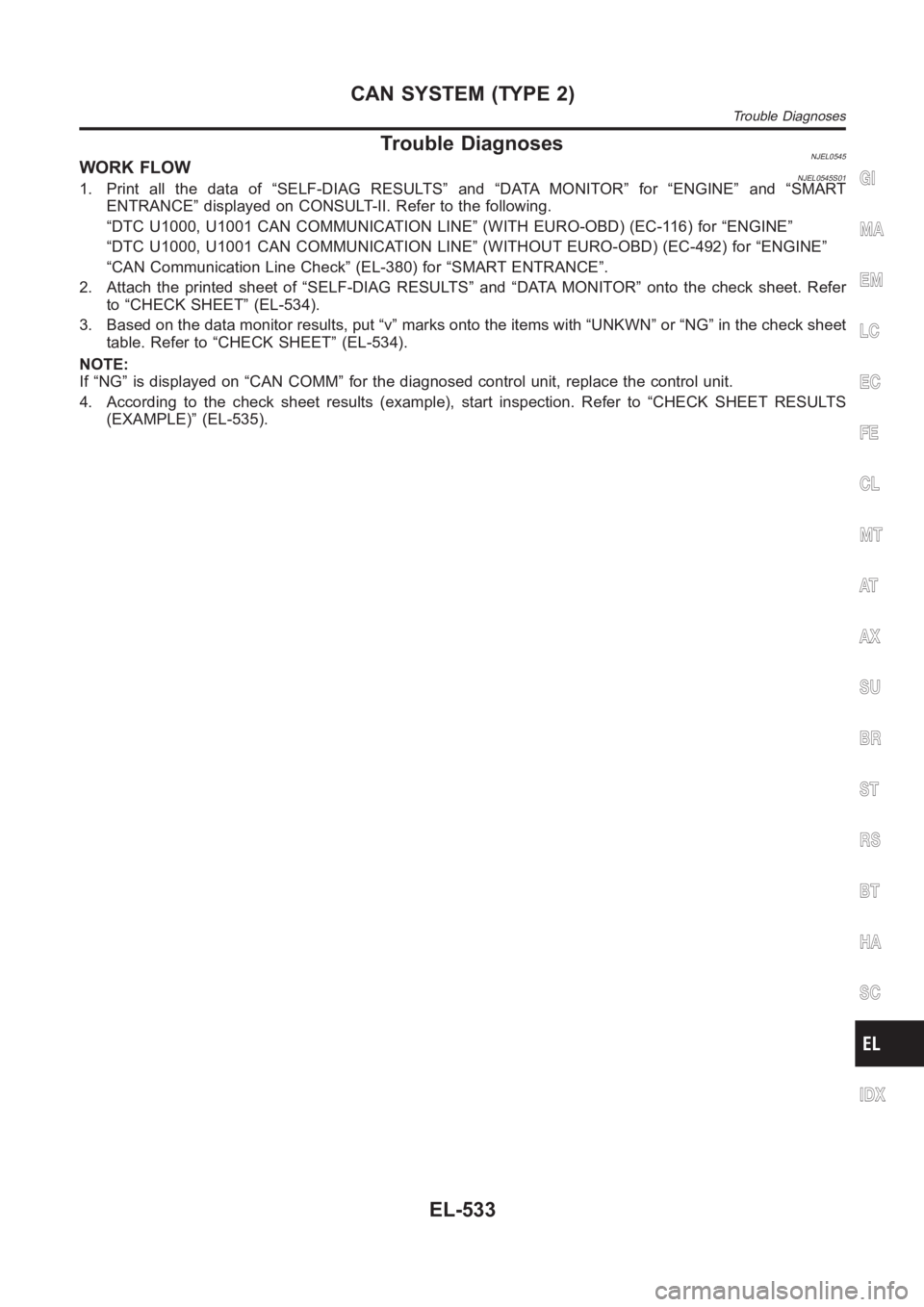

COMBINATION METER CIRCUIT CHECK=NJEL0540S09

1 CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect the negative battery cable.

3. Check following terminals and connector of combination meter for damage, bend and loose connection (meter-side and

harness-side).

OK or NG

OK GO TO 2.

NG Repair terminal or connector.

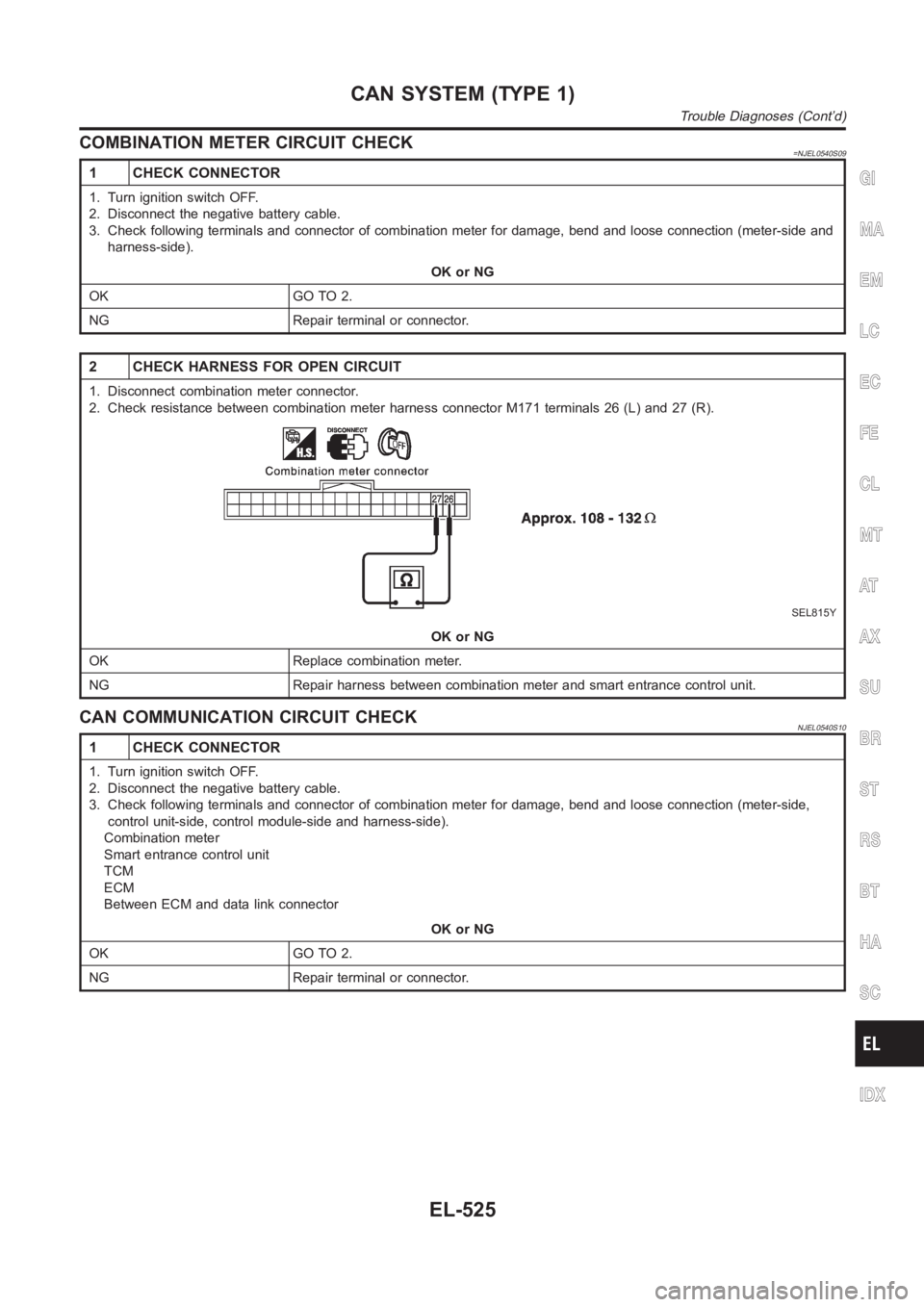

2 CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect combination meter connector.

2. Check resistance between combination meter harness connector M171 terminals 26 (L) and 27 (R).

SEL815Y

OK or NG

OK Replace combination meter.

NG Repair harness between combination meter and smart entrance control unit.

CAN COMMUNICATION CIRCUIT CHECKNJEL0540S10

1 CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect the negative battery cable.

3. Check following terminals and connector of combination meter for damage, bend and loose connection (meter-side,

control unit-side, control module-side and harness-side).

Combination meter

Smart entrance control unit

TCM

ECM

Between ECM and data link connector

OK or NG

OK GO TO 2.

NG Repair terminal or connector.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

CAN SYSTEM (TYPE 1)

Trouble Diagnoses (Cont’d)

EL-525

Page 2862 of 3189

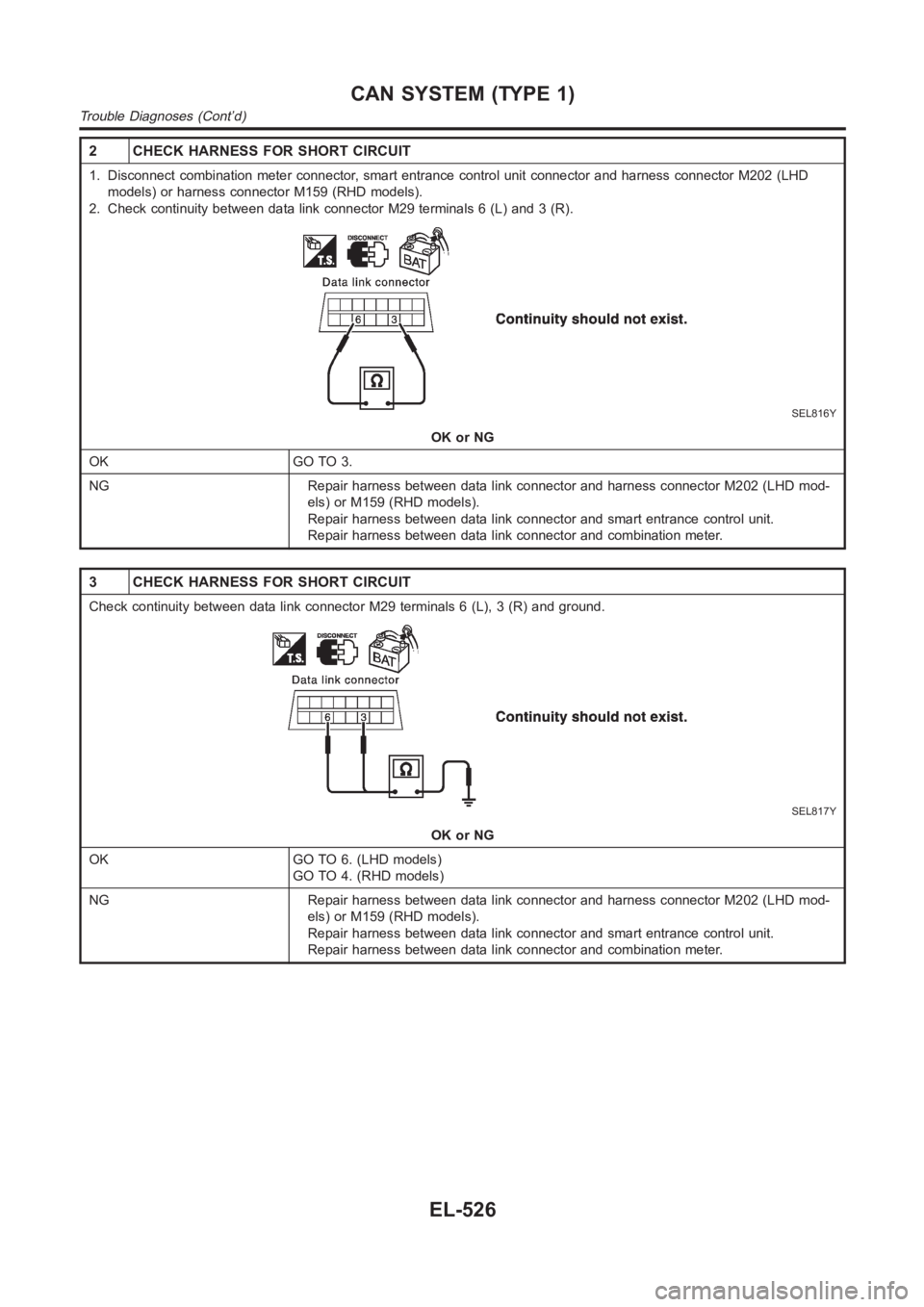

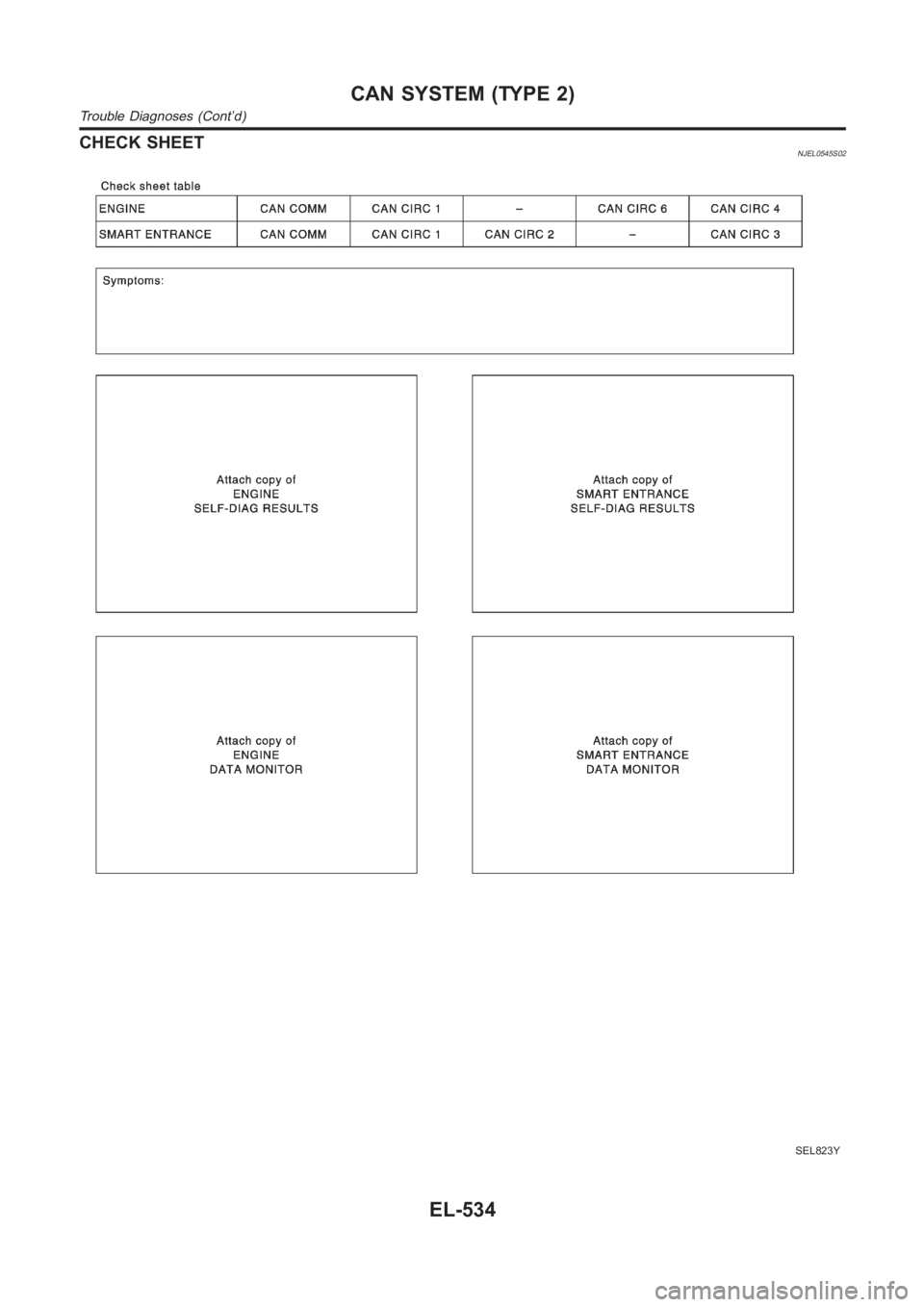

2 CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect combination meter connector, smart entrance control unit connector and harness connector M202 (LHD

models) or harness connector M159 (RHD models).

2. Check continuity between data link connector M29 terminals 6 (L) and 3 (R).

SEL816Y

OK or NG

OK GO TO 3.

NG Repair harness between data link connector and harness connector M202 (LHD mod-

els) or M159 (RHD models).

Repair harness between data link connector and smart entrance control unit.

Repair harness between data link connector and combination meter.

3 CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between data link connector M29 terminals 6 (L), 3 (R) andground.

SEL817Y

OK or NG

OK GO TO 6. (LHD models)

GO TO 4. (RHD models)

NG Repair harness between data link connector and harness connector M202 (LHD mod-

els) or M159 (RHD models).

Repair harness between data link connector and smart entrance control unit.

Repair harness between data link connector and combination meter.

CAN SYSTEM (TYPE 1)

Trouble Diagnoses (Cont’d)

EL-526

Page 2863 of 3189

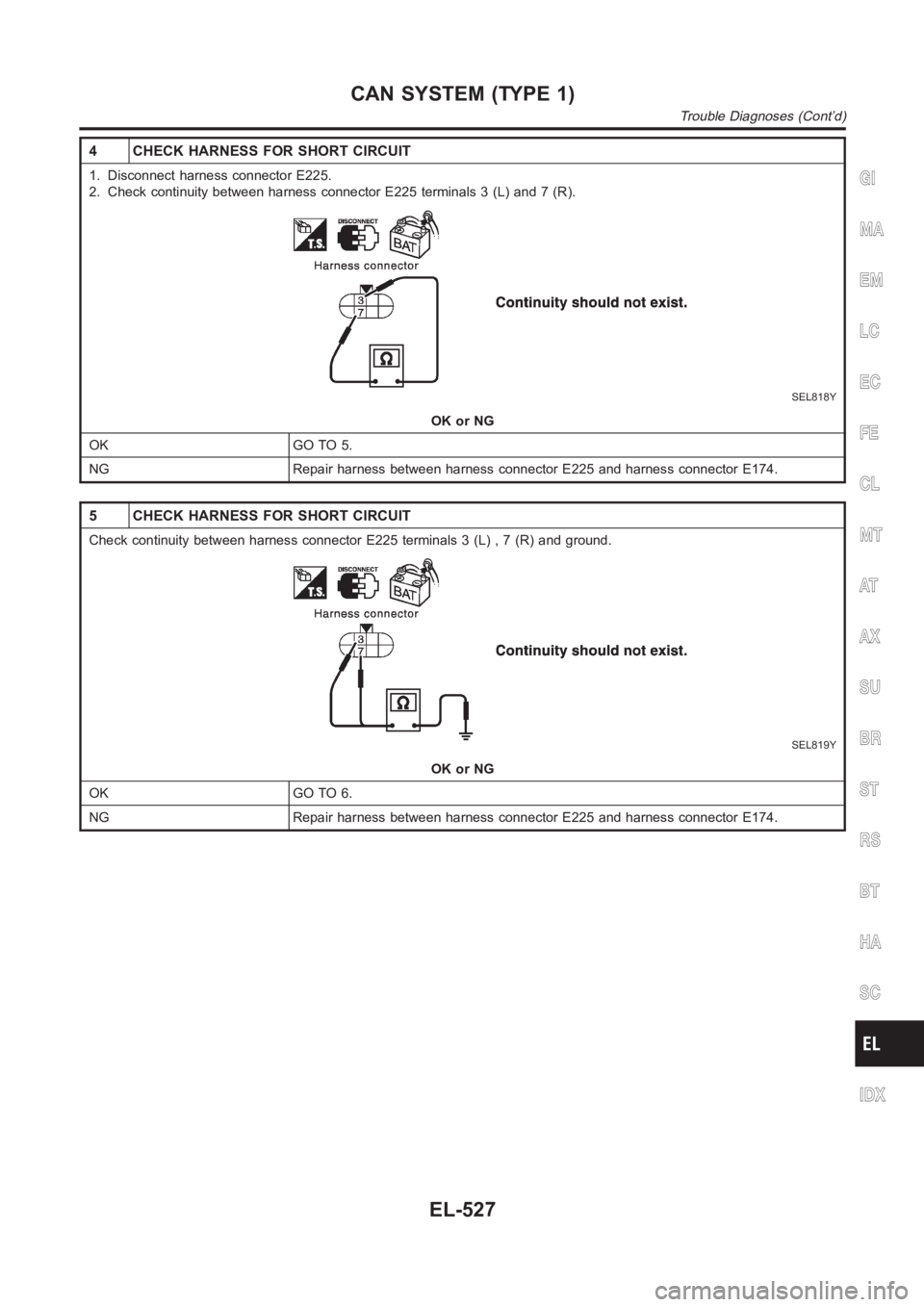

4 CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect harness connector E225.

2. Check continuity between harness connector E225 terminals 3 (L) and 7 (R).

SEL818Y

OK or NG

OK GO TO 5.

NG Repair harness between harness connector E225 and harness connector E174.

5 CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between harness connector E225 terminals 3 (L) , 7 (R) andground.

SEL819Y

OK or NG

OK GO TO 6.

NG Repair harness between harness connector E225 and harness connector E174.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

CAN SYSTEM (TYPE 1)

Trouble Diagnoses (Cont’d)

EL-527

Page 2864 of 3189

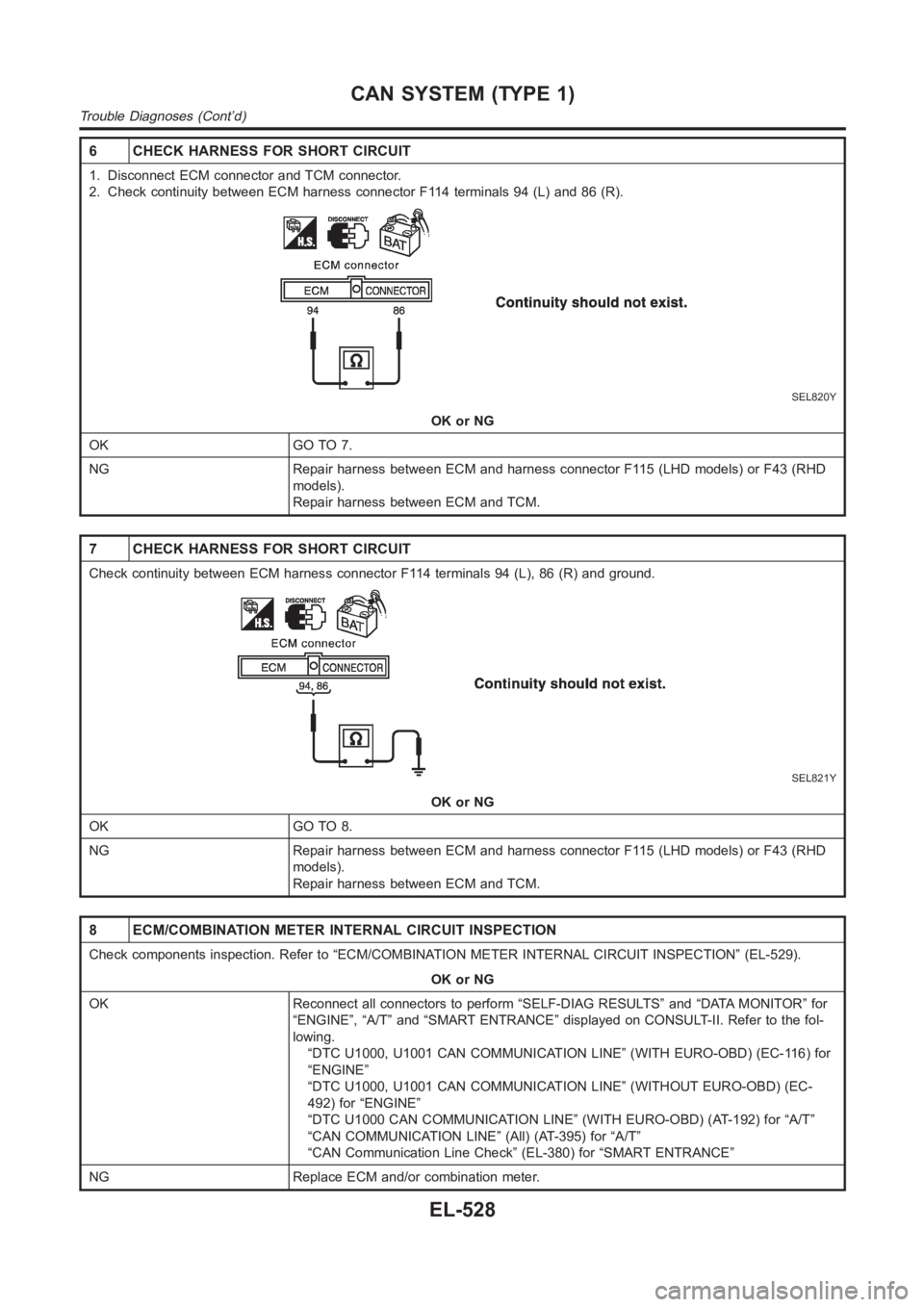

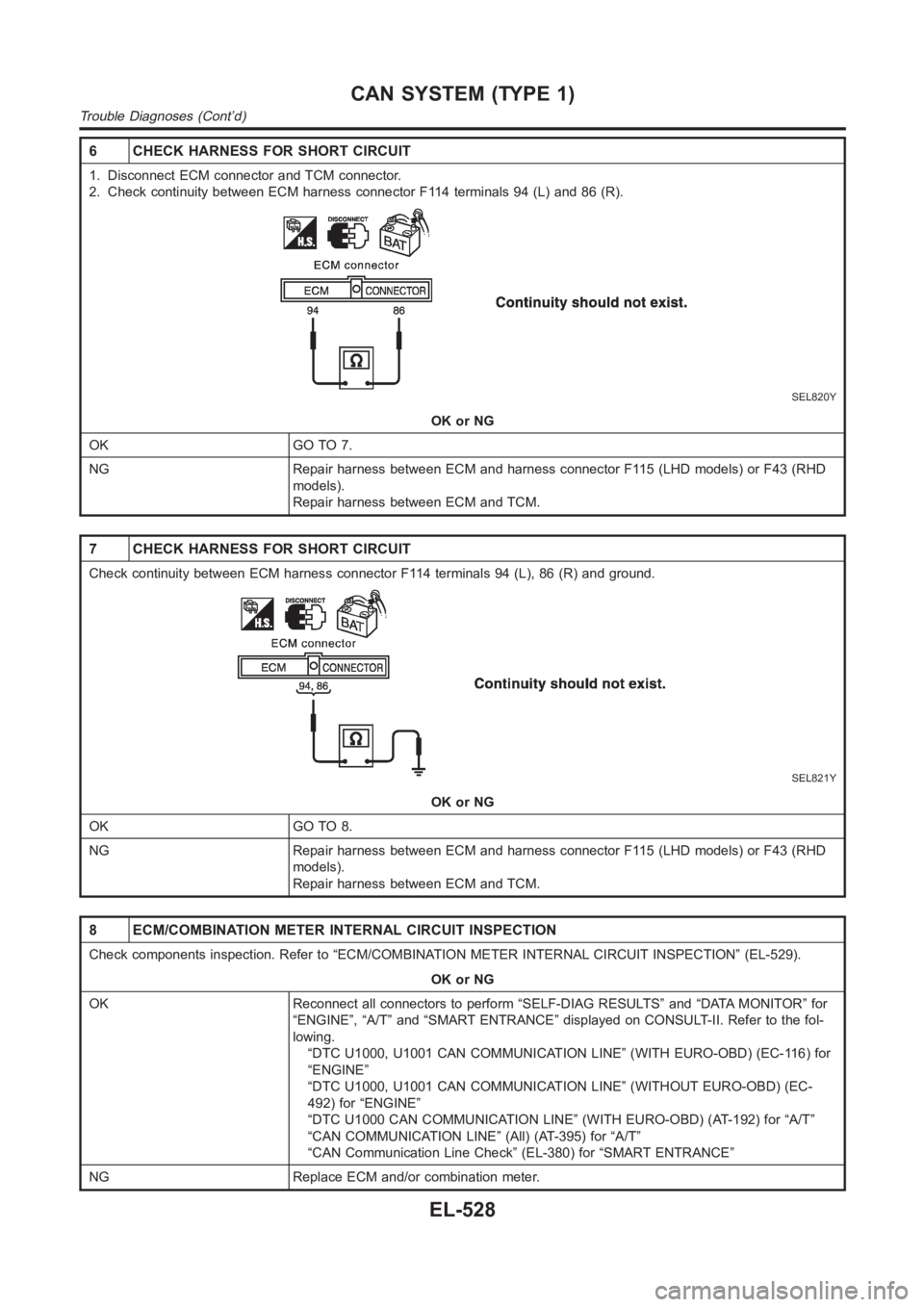

6 CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect ECM connector and TCM connector.

2. Check continuity between ECM harness connector F114 terminals 94 (L) and86(R).

SEL820Y

OK or NG

OK GO TO 7.

NG Repair harness between ECM and harness connector F115 (LHD models) or F43 (RHD

models).

Repair harness between ECM and TCM.

7 CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between ECM harness connector F114 terminals 94 (L), 86 (R) and ground.

SEL821Y

OK or NG

OK GO TO 8.

NG Repair harness between ECM and harness connector F115 (LHD models) or F43 (RHD

models).

Repair harness between ECM and TCM.

8 ECM/COMBINATION METER INTERNAL CIRCUIT INSPECTION

Check components inspection. Refer to “ECM/COMBINATION METER INTERNAL CIRCUIT INSPECTION” (EL-529).

OK or NG

OK Reconnect all connectors to perform “SELF-DIAG RESULTS” and “DATA MONITOR” for

“ENGINE”, “A/T” and “SMART ENTRANCE” displayed on CONSULT-II. Refer to thefol-

lowing.

“DTC U1000, U1001 CAN COMMUNICATION LINE” (WITH EURO-OBD) (EC-116) for

“ENGINE”

“DTC U1000, U1001 CAN COMMUNICATION LINE” (WITHOUT EURO-OBD) (EC-

492) for “ENGINE”

“DTC U1000 CAN COMMUNICATION LINE” (WITH EURO-OBD) (AT-192) for “A/T”

“CAN COMMUNICATION LINE” (All) (AT-395) for “A/T”

“CAN Communication Line Check” (EL-380) for “SMART ENTRANCE”

NG Replace ECM and/or combination meter.

CAN SYSTEM (TYPE 1)

Trouble Diagnoses (Cont’d)

EL-528

Page 2865 of 3189

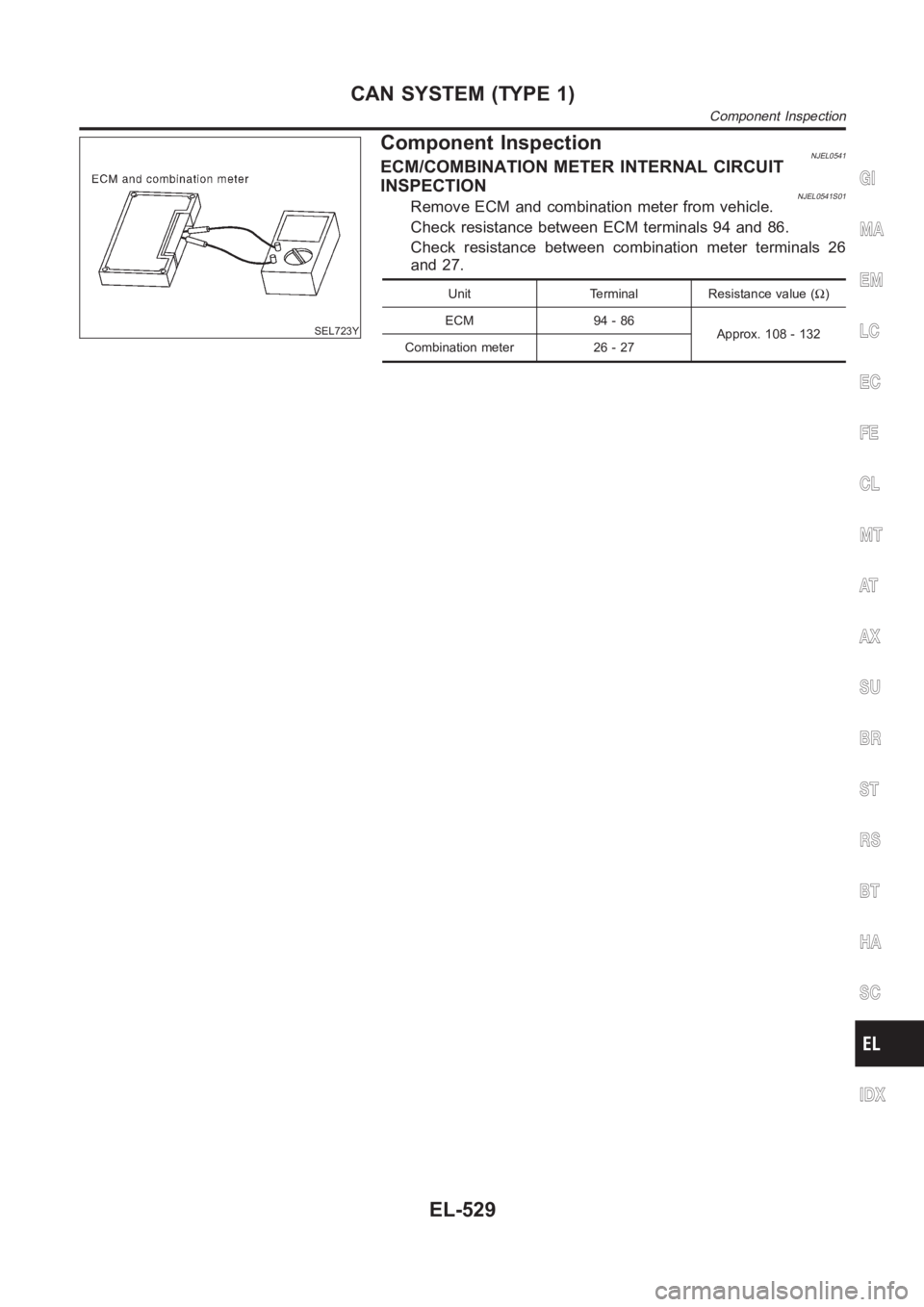

SEL723Y

Component InspectionNJEL0541ECM/COMBINATION METER INTERNAL CIRCUIT

INSPECTION

NJEL0541S01Remove ECM and combination meter from vehicle.

Check resistance between ECM terminals 94 and 86.

Check resistance between combination meter terminals 26

and 27.

Unit Terminal Resistance value (Ω)

ECM 94 - 86

Approx. 108 - 132

Combination meter 26 - 27

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

CAN SYSTEM (TYPE 1)

Component Inspection

EL-529

Page 2866 of 3189

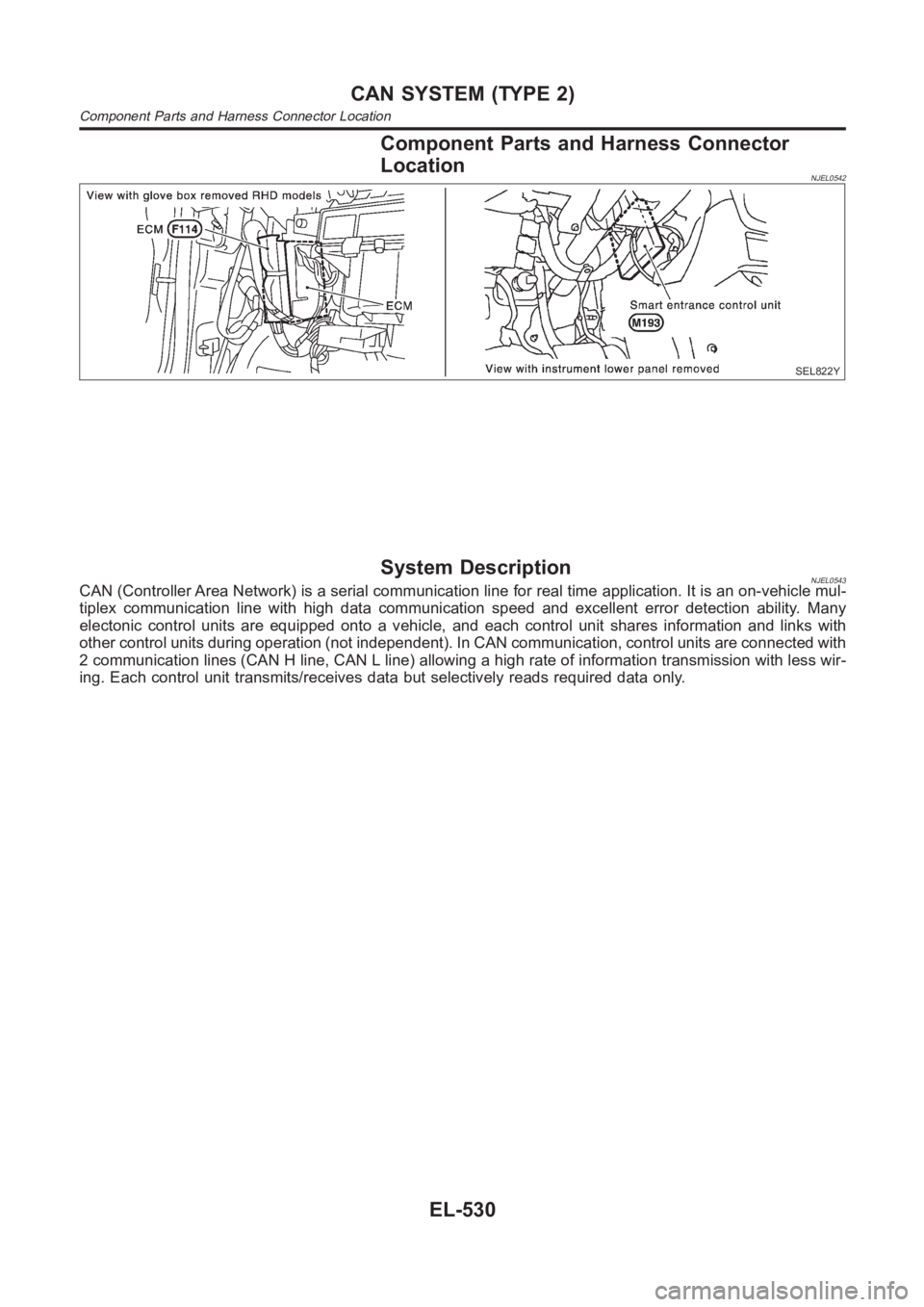

Component Parts and Harness Connector

Location

NJEL0542

SEL822Y

System DescriptionNJEL0543CAN (Controller Area Network) is a serial communication line for real timeapplication. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many

electonic control units are equipped onto a vehicle, and each control unitshares information and links with

other control units during operation (not independent). In CAN communication, control units are connected with

2 communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wir-

ing. Each control unit transmits/receives data but selectively reads requireddataonly.

CAN SYSTEM (TYPE 2)

Component Parts and Harness Connector Location

EL-530

Page 2867 of 3189

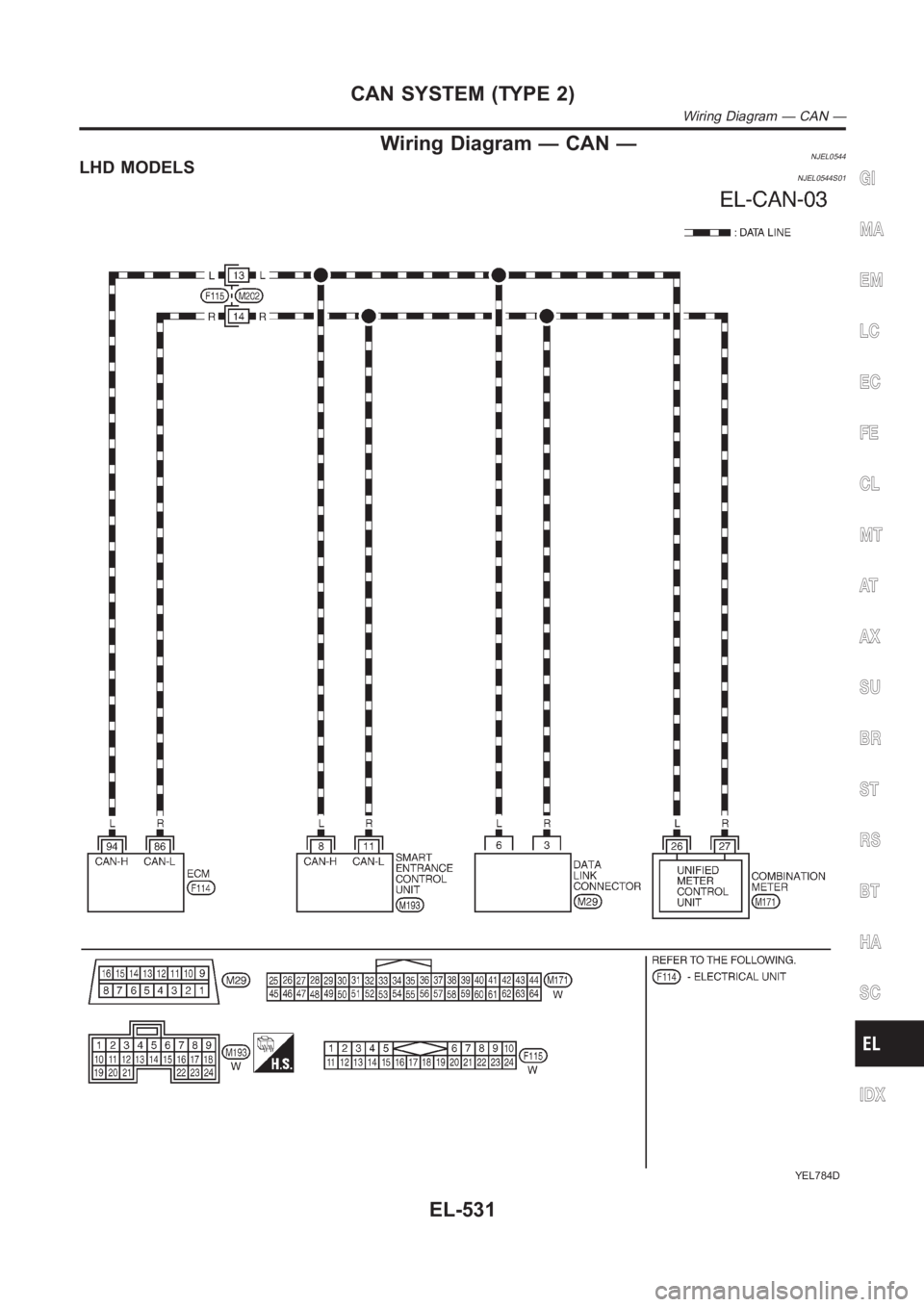

Wiring Diagram — CAN —NJEL0544LHD MODELSNJEL0544S01

YEL784D

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

CAN SYSTEM (TYPE 2)

Wiring Diagram — CAN —

EL-531

Page 2868 of 3189

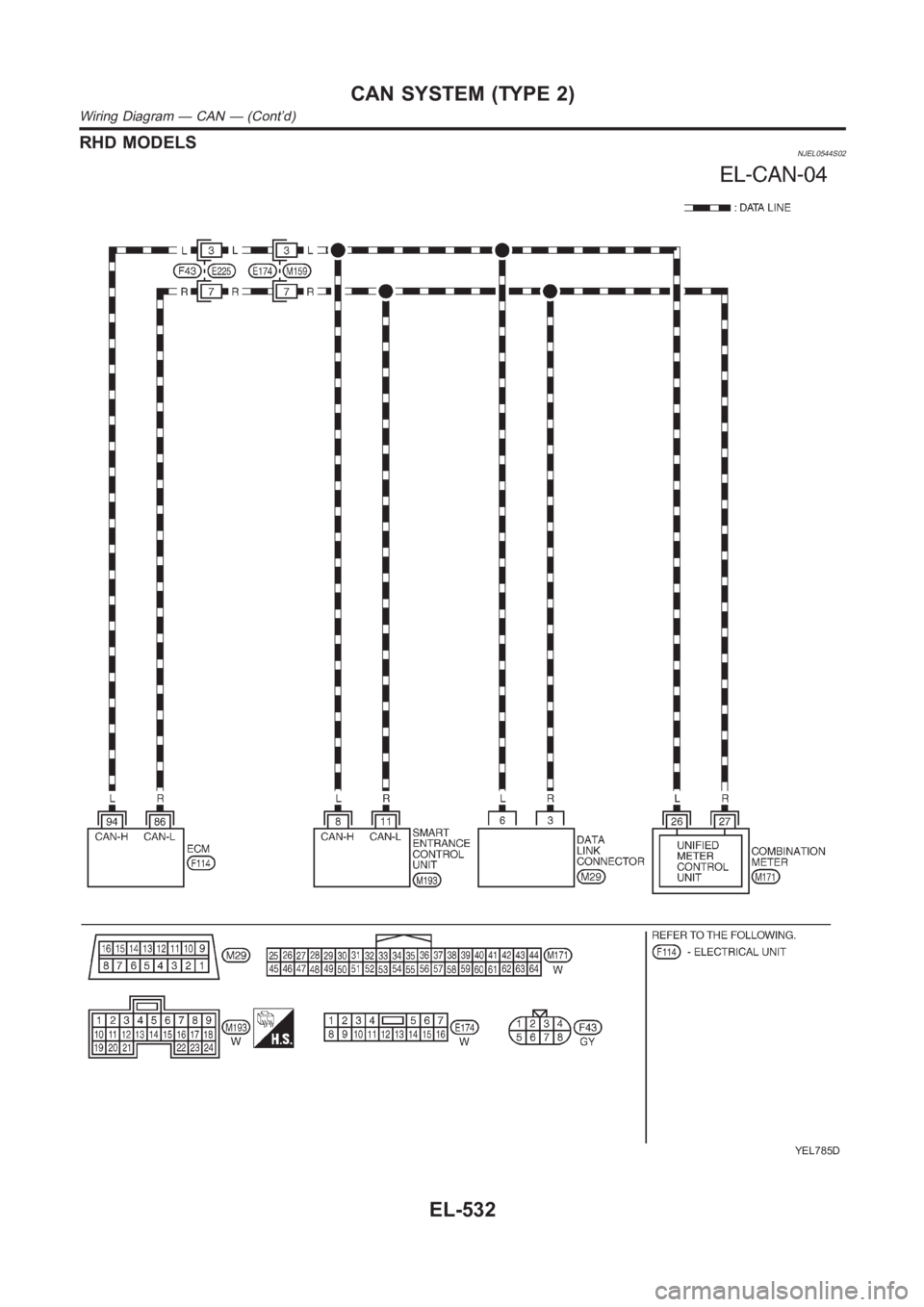

RHD MODELSNJEL0544S02

YEL785D

CAN SYSTEM (TYPE 2)

Wiring Diagram — CAN — (Cont’d)

EL-532

Page 2869 of 3189

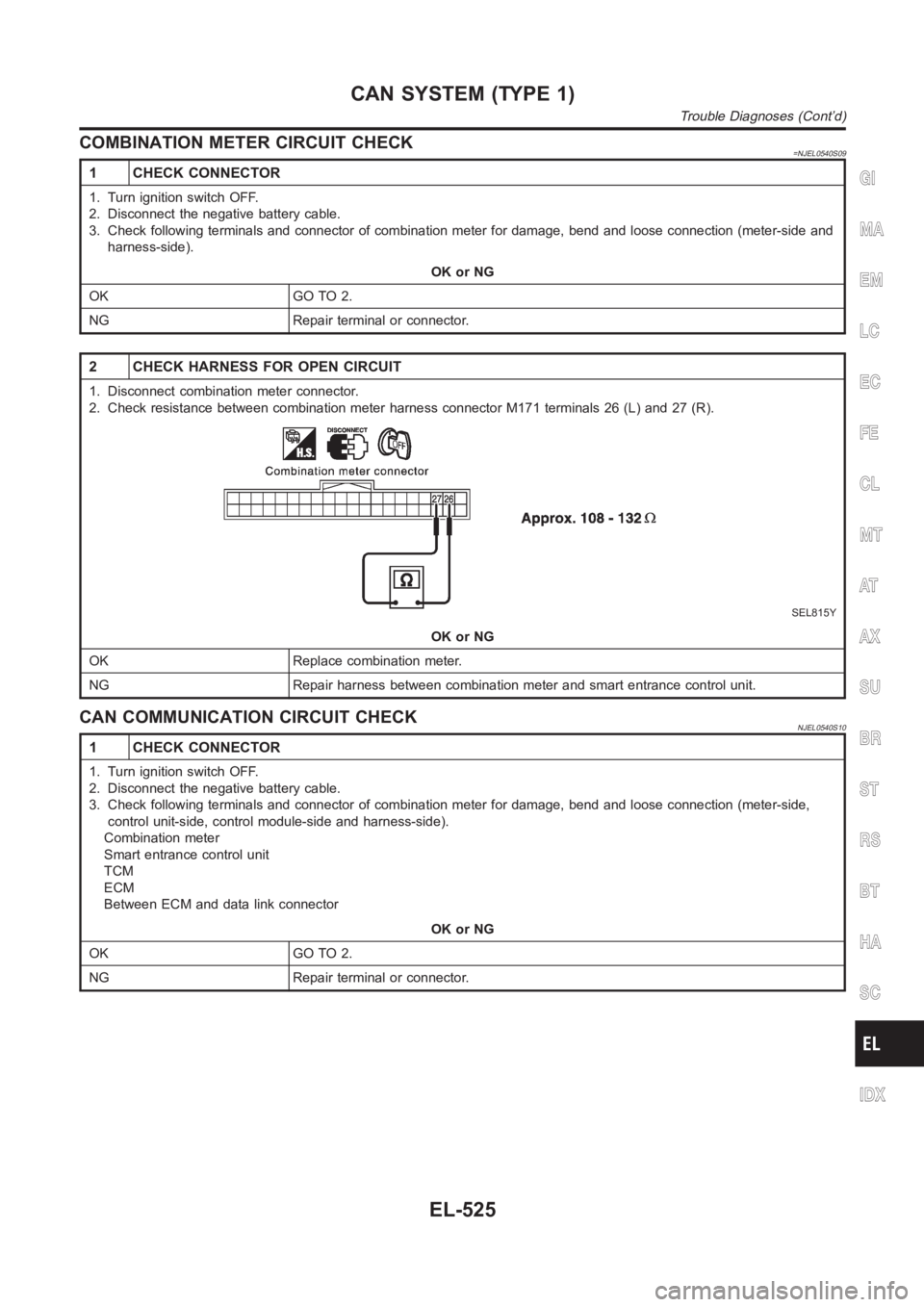

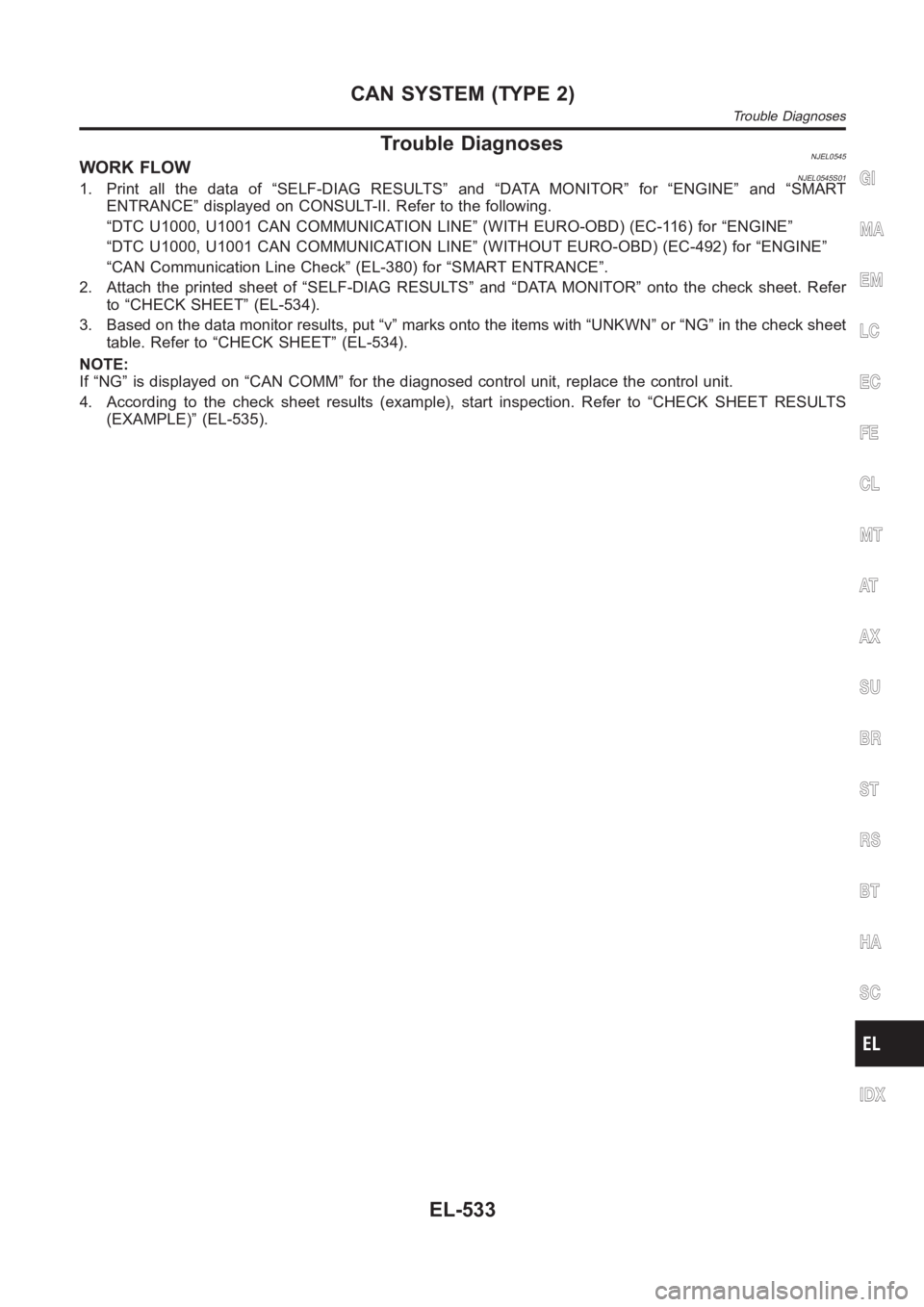

Trouble DiagnosesNJEL0545WORK FLOWNJEL0545S011. Print all the data of “SELF-DIAG RESULTS” and “DATA MONITOR” for “ENGINE” and “SMART

ENTRANCE” displayed on CONSULT-II. Refer to the following.

“DTC U1000, U1001 CAN COMMUNICATION LINE” (WITH EURO-OBD) (EC-116) for “ENGINE”

“DTC U1000, U1001 CAN COMMUNICATION LINE” (WITHOUT EURO-OBD) (EC-492) for “ENGINE”

“CAN Communication Line Check” (EL-380) for “SMART ENTRANCE”.

2. Attach the printed sheet of “SELF-DIAG RESULTS” and “DATA MONITOR” ontothe check sheet. Refer

to “CHECK SHEET” (EL-534).

3. Based on the data monitor results, put “v” marks onto the items with “UNKWN” or “NG” in the check sheet

table. Refer to “CHECK SHEET” (EL-534).

NOTE:

If “NG” is displayed on “CAN COMM” for the diagnosed control unit, replace the control unit.

4. According to the check sheet results (example), start inspection. Refer to “CHECK SHEET RESULTS

(EXAMPLE)” (EL-535).GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

CAN SYSTEM (TYPE 2)

Trouble Diagnoses

EL-533

Page 2870 of 3189

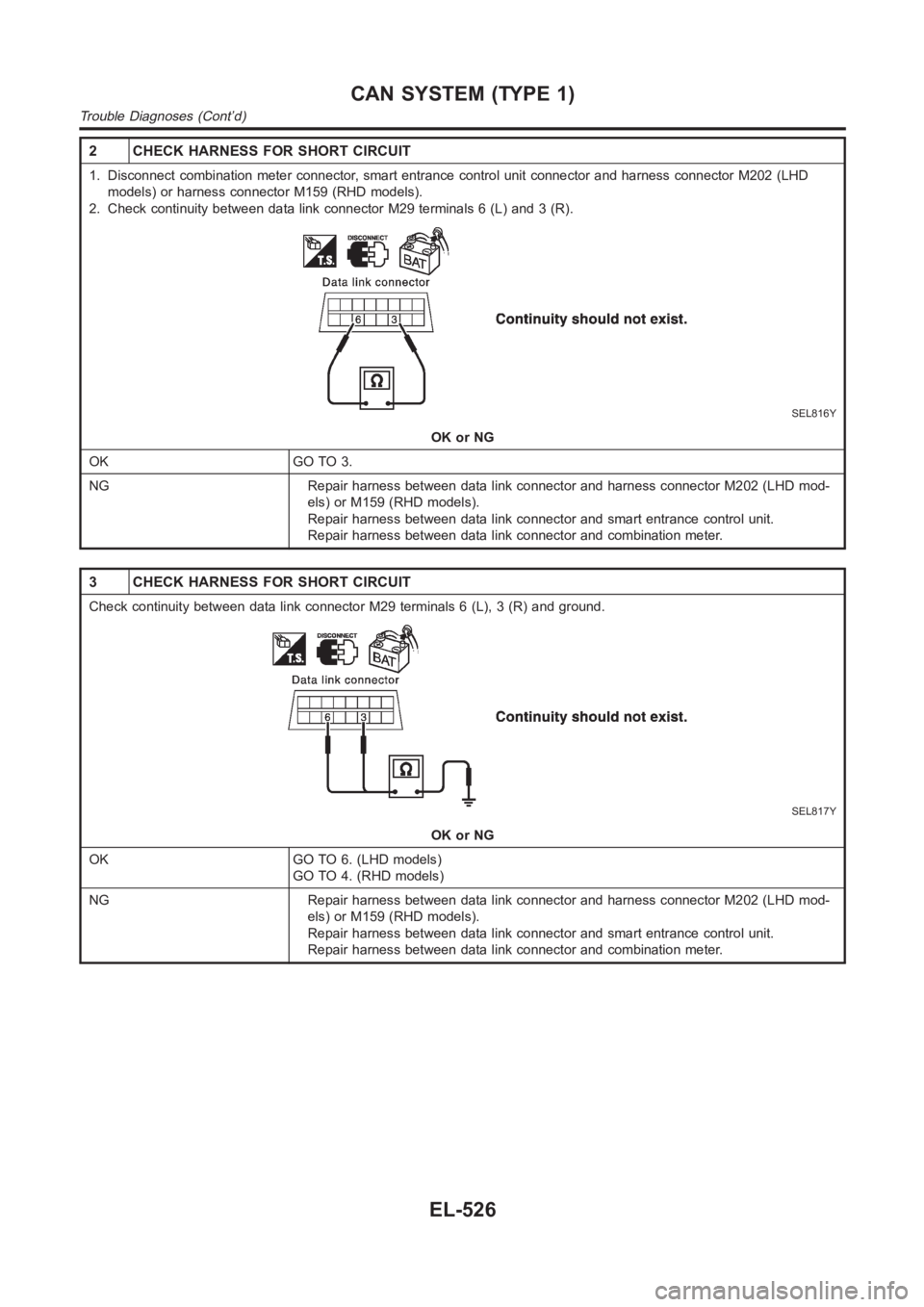

CHECK SHEETNJEL0545S02

SEL823Y

CAN SYSTEM (TYPE 2)

Trouble Diagnoses (Cont’d)

EL-534

Trending: ECO mode, remote start, Air conditioner, trailer, schematic, warning lights, jack points