NISSAN ALMERA N16 2003 Electronic Repair Manual

ALMERA N16 2003

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57350/w960_57350-0.png

NISSAN ALMERA N16 2003 Electronic Repair Manual

Trending: ydec, EC-265, brake light, spark plugs replace, load capacity, bolt pattern, air condition

Page 2871 of 3189

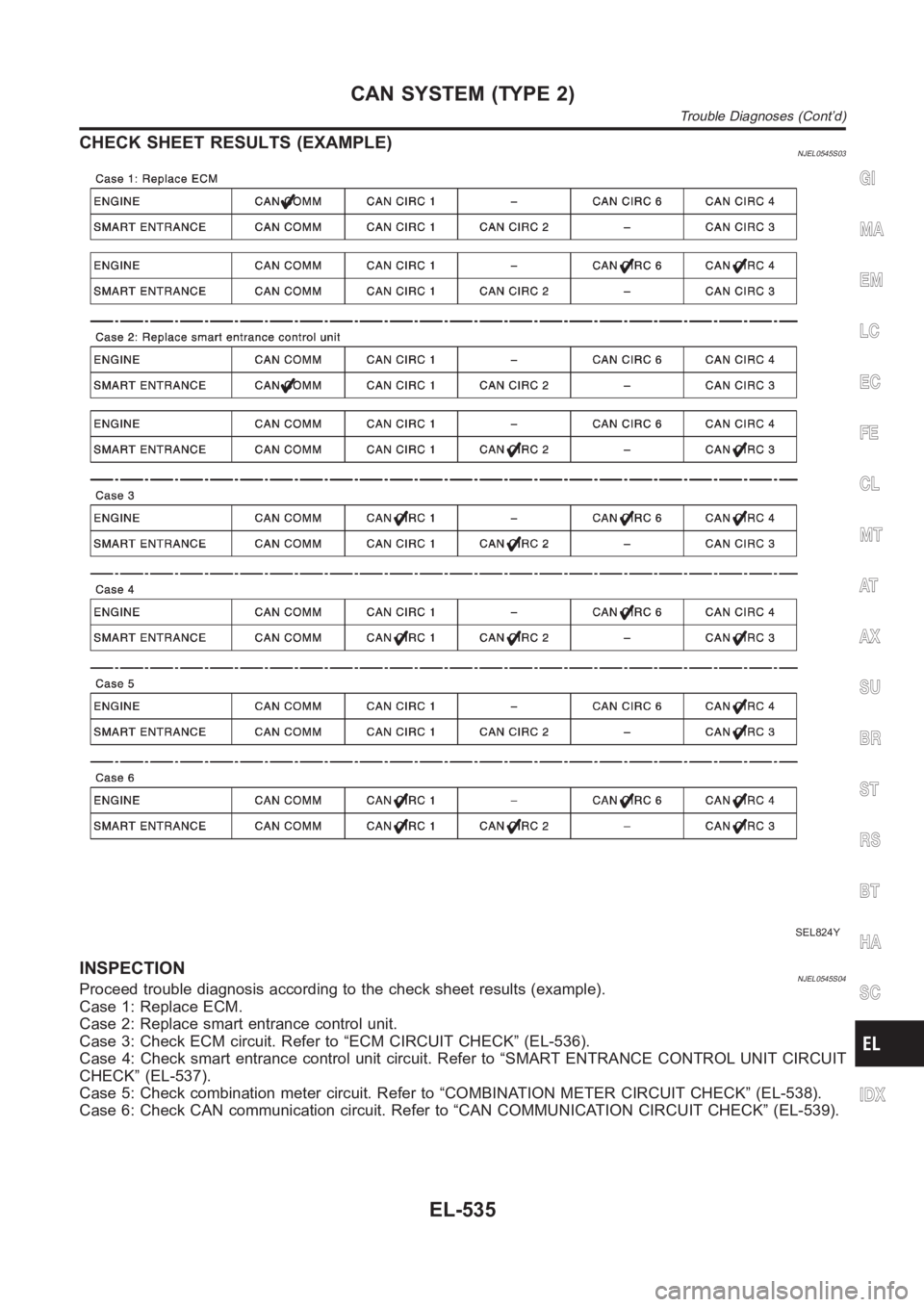

CHECK SHEET RESULTS (EXAMPLE)NJEL0545S03

SEL824Y

INSPECTIONNJEL0545S04Proceed trouble diagnosis according to the check sheet results (example).

Case 1: Replace ECM.

Case 2: Replace smart entrance control unit.

Case 3: Check ECM circuit. Refer to “ECM CIRCUIT CHECK” (EL-536).

Case 4: Check smart entrance control unit circuit. Refer to “SMART ENTRANCE CONTROL UNIT CIRCUIT

CHECK” (EL-537).

Case 5: Check combination meter circuit. Refer to “COMBINATION METER CIRCUIT CHECK” (EL-538).

Case 6: Check CAN communication circuit. Refer to “CAN COMMUNICATION CIRCUIT CHECK” (EL-539).

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

CAN SYSTEM (TYPE 2)

Trouble Diagnoses (Cont’d)

EL-535

Page 2872 of 3189

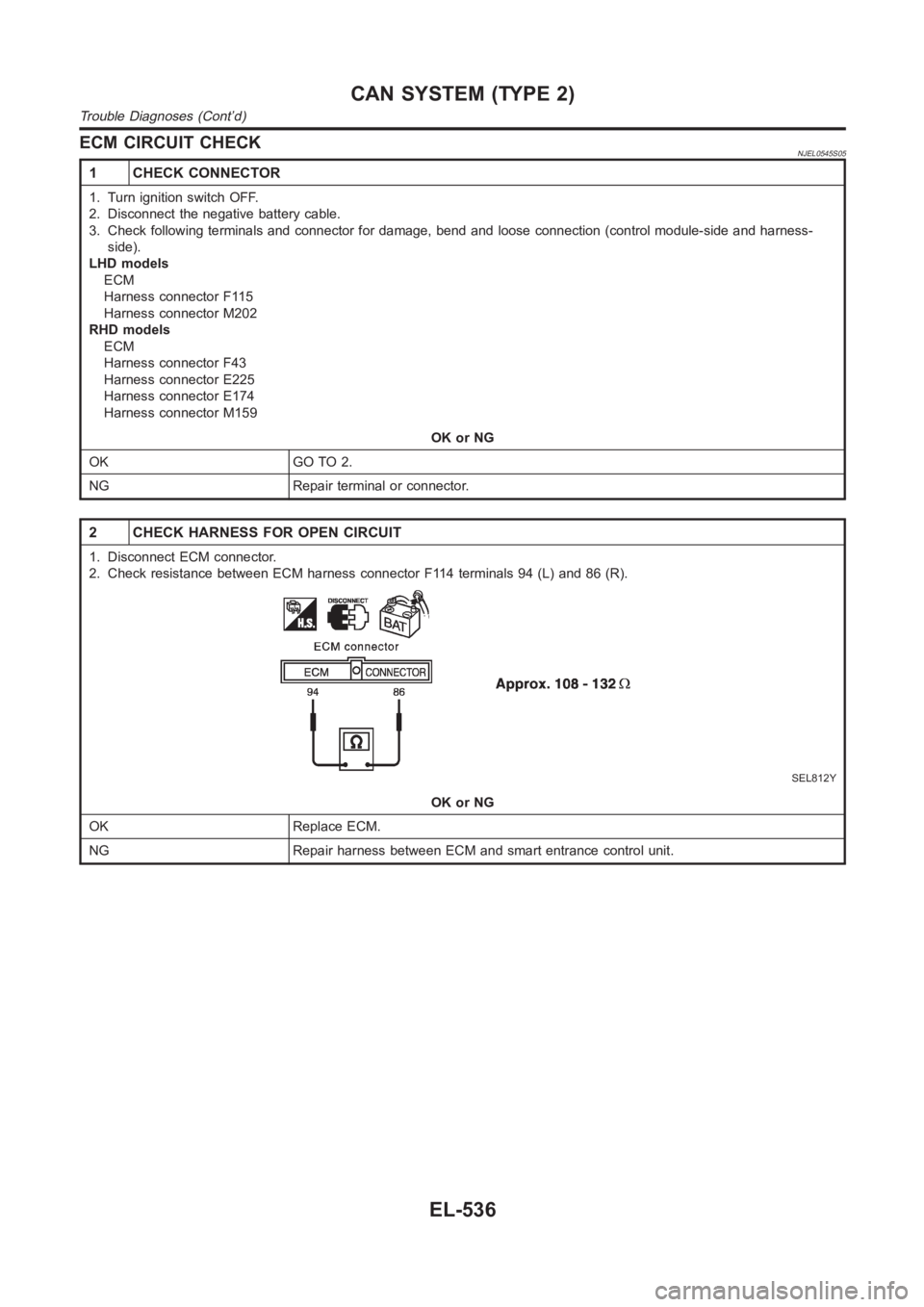

ECM CIRCUIT CHECKNJEL0545S05

1 CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect the negative battery cable.

3. Check following terminals and connector for damage, bend and loose connection (control module-side and harness-

side).

LHD models

ECM

Harness connector F115

Harness connector M202

RHD models

ECM

Harness connector F43

Harness connector E225

Harness connector E174

Harness connector M159

OK or NG

OK GO TO 2.

NG Repair terminal or connector.

2 CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect ECM connector.

2. Check resistance between ECM harness connector F114 terminals 94 (L) and86(R).

SEL812Y

OK or NG

OK Replace ECM.

NG Repair harness between ECM and smart entrance control unit.

CAN SYSTEM (TYPE 2)

Trouble Diagnoses (Cont’d)

EL-536

Page 2873 of 3189

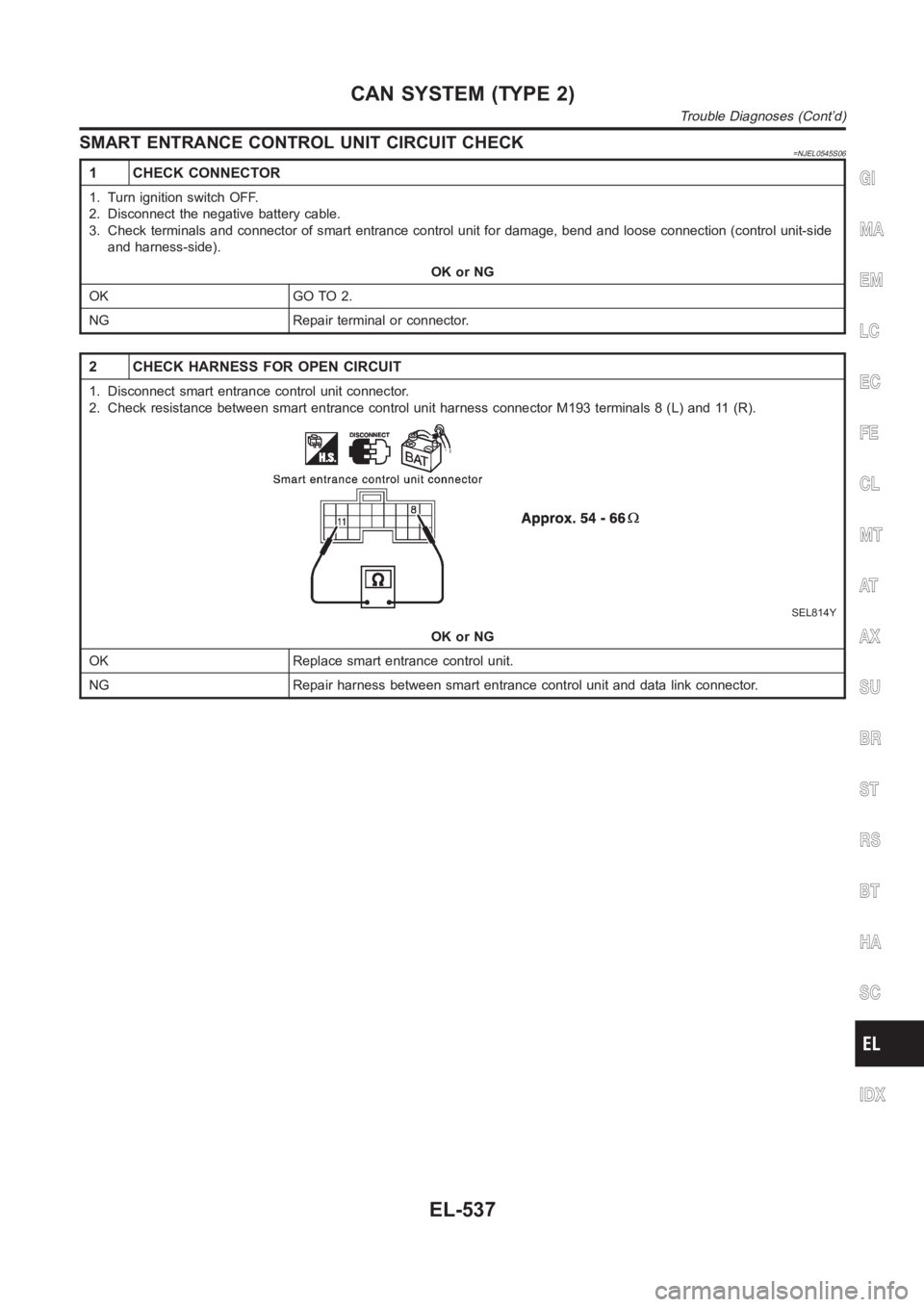

SMART ENTRANCE CONTROL UNIT CIRCUIT CHECK=NJEL0545S06

1 CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect the negative battery cable.

3. Check terminals and connector of smart entrance control unit for damage, bend and loose connection (control unit-side

and harness-side).

OK or NG

OK GO TO 2.

NG Repair terminal or connector.

2 CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect smart entrance control unit connector.

2. Check resistance between smart entrance control unit harness connector M193 terminals 8 (L) and 11 (R).

SEL814Y

OK or NG

OK Replace smart entrance control unit.

NG Repair harness between smart entrance control unit and data link connector.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

CAN SYSTEM (TYPE 2)

Trouble Diagnoses (Cont’d)

EL-537

Page 2874 of 3189

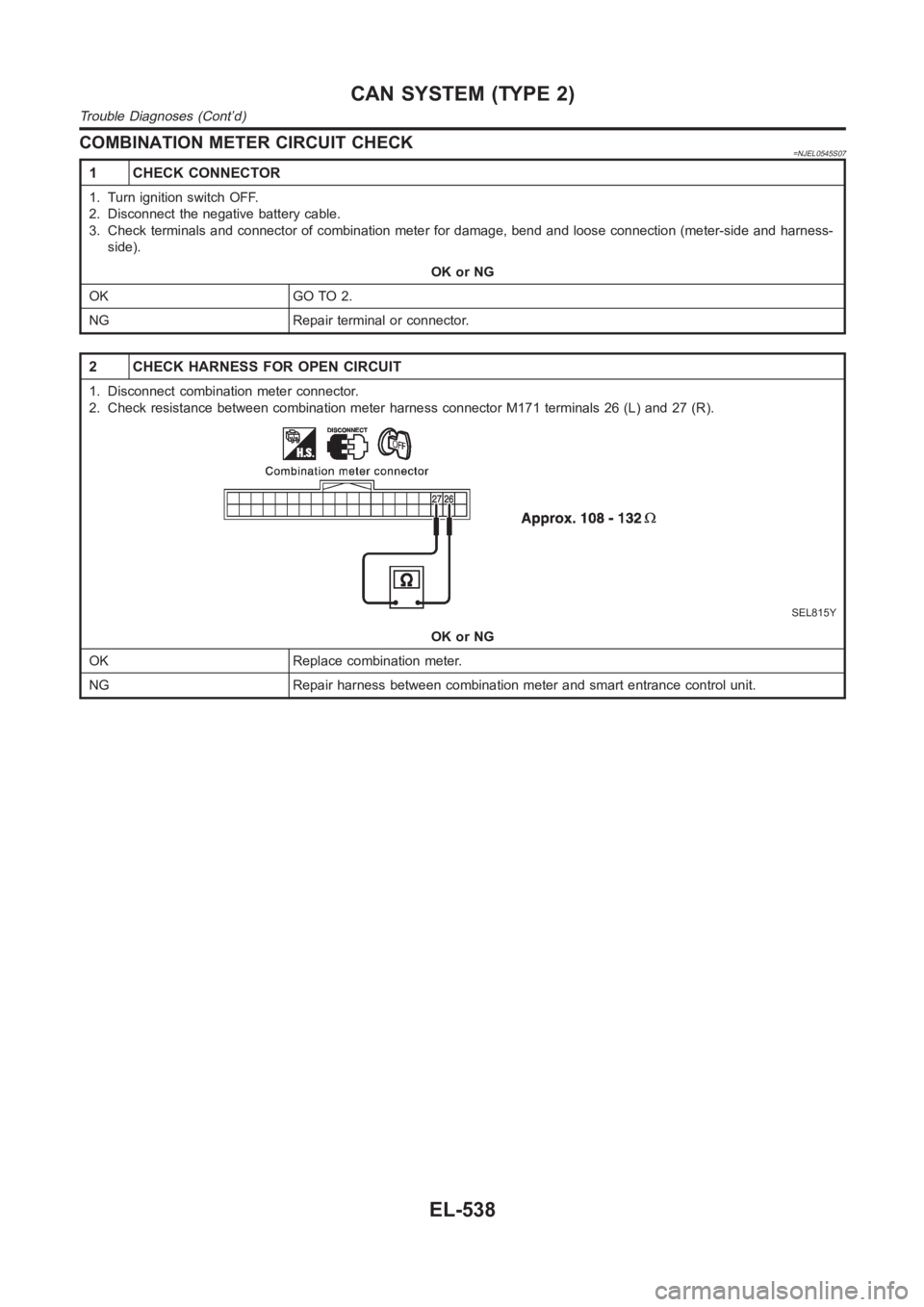

COMBINATION METER CIRCUIT CHECK=NJEL0545S07

1 CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect the negative battery cable.

3. Check terminals and connector of combination meter for damage, bend andloose connection (meter-side and harness-

side).

OK or NG

OK GO TO 2.

NG Repair terminal or connector.

2 CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect combination meter connector.

2. Check resistance between combination meter harness connector M171 terminals 26 (L) and 27 (R).

SEL815Y

OK or NG

OK Replace combination meter.

NG Repair harness between combination meter and smart entrance control unit.

CAN SYSTEM (TYPE 2)

Trouble Diagnoses (Cont’d)

EL-538

Page 2875 of 3189

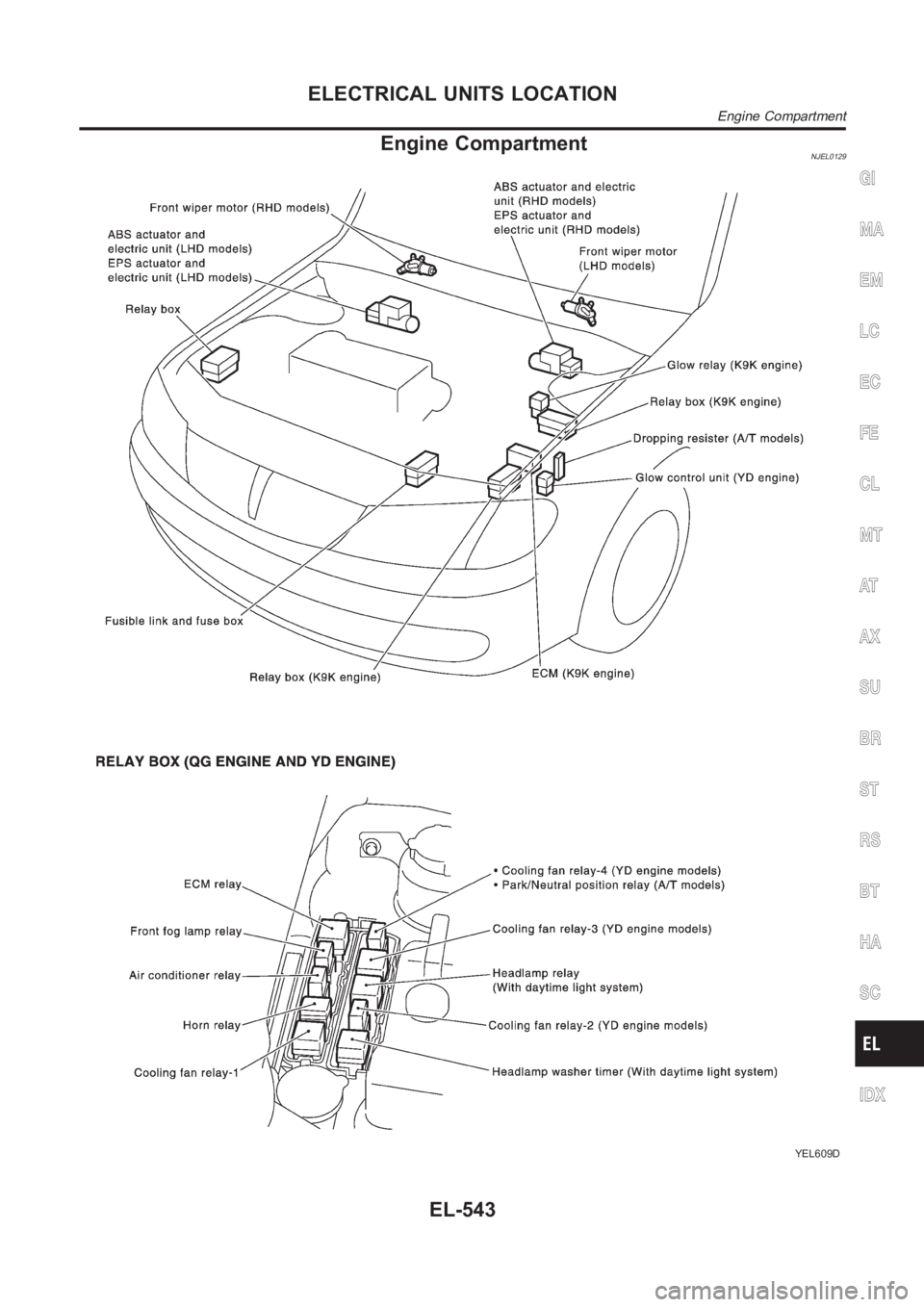

CAN COMMUNICATION CIRCUIT CHECK=NJEL0545S08

1 CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect the negative battery cable.

3. Check following terminals and connector for damage, bend and loose connection (meter-side, control unit-side, control

module-side and harness-side).

Combination meter

Smart entrance control unit

ECM

Between ECM and smart entrance control unit

OK or NG

OK GO TO 2.

NG Repair terminal or connector.

2 CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect combination meter connector, smart entrance control unit connector and harness connector M202 (LHD

models) or harness connector M159 (RHD models).

2. Check continuity between data link connector M29 terminals 6 (L) and 3 (R).

SEL816Y

OK or NG

OK GO TO 3.

NG Repair harness between data link connector and harness connector M202 (LHD mod-

els) or M159 (RHD models).

Repair harness between data link connector and smart entrance control unit.

Repair harness between data link connector and combination meter.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

CAN SYSTEM (TYPE 2)

Trouble Diagnoses (Cont’d)

EL-539

Page 2876 of 3189

3 CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between data link connector M29 terminals 6 (L), 3 (R) andground.

SEL817Y

OK or NG

OK GO TO 6. (LHD models)

GO TO 4. (RHD models)

NG Repair harness between data link connector and harness connector M202 (LHD mod-

els) or M159 (RHD models).

Repair harness between data link connector and smart entrance control unit.

Repair harness between data link connector and combination meter.

4 CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect harness connector E225.

2. Check continuity between harness connector E225 terminals 3 (L) and 7 (R).

SEL818Y

OK or NG

OK GO TO 5.

NG Repair harness between harness connector E225 and harness connector E174.

CAN SYSTEM (TYPE 2)

Trouble Diagnoses (Cont’d)

EL-540

Page 2877 of 3189

5 CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between harness connector E225 terminals 3 (L) , 7 (R) andground.

SEL819Y

OK or NG

OK GO TO 6.

NG Repair harness between harness connector E225 and harness connector E174.

6 CHECK HARNESS FOR SHORT CIRCUIT

1. Disconnect ECM connector.

2. Check continuity between ECM harness connector F114 terminals 94 (L) and86(R).

SEL820Y

OK or NG

OK GO TO 7.

NG Repair harness between ECM and harness connector F115 (LHD models) or F43 (RHD

models).

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

CAN SYSTEM (TYPE 2)

Trouble Diagnoses (Cont’d)

EL-541

Page 2878 of 3189

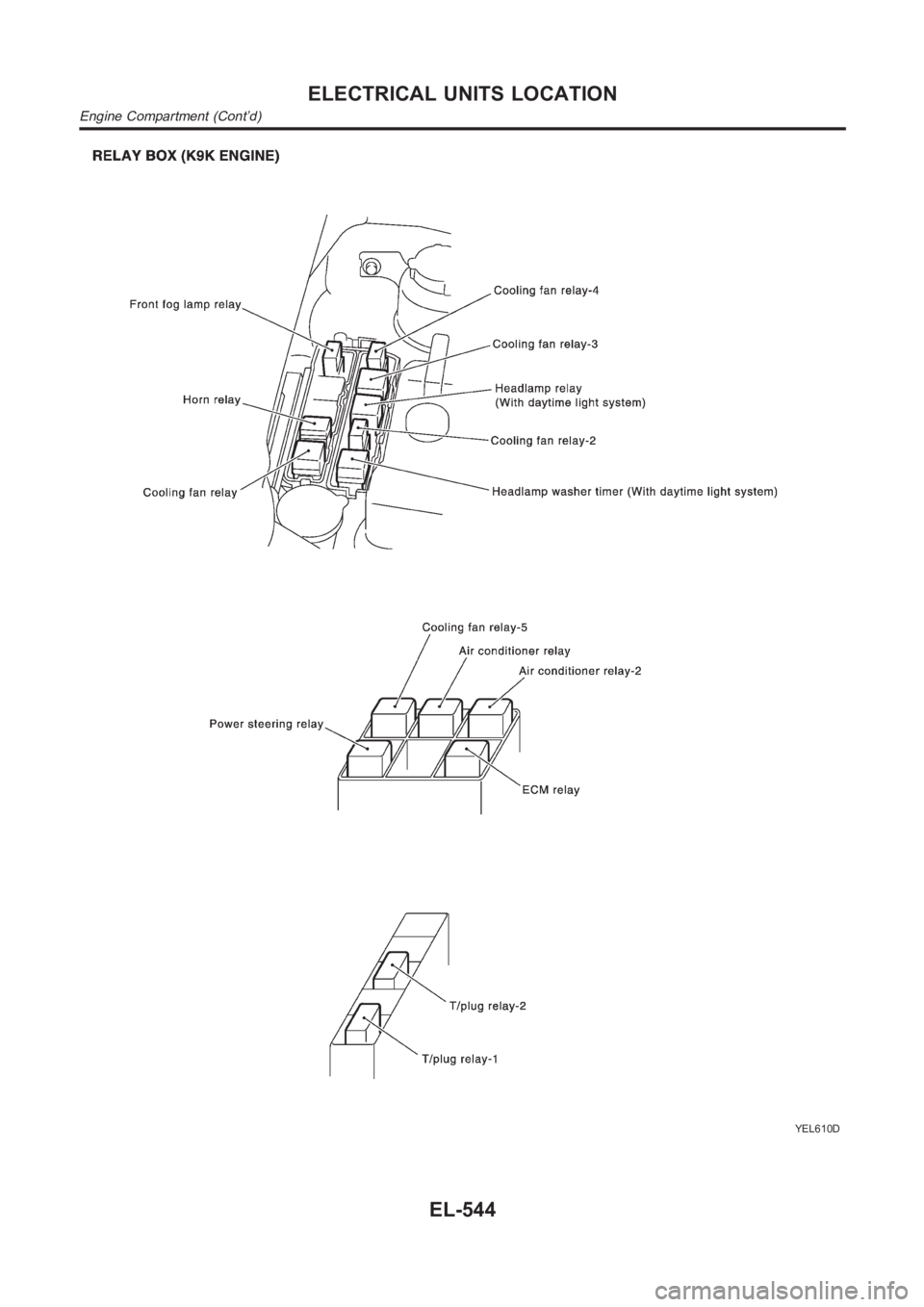

7 CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between ECM harness connector F114 terminals 94 (L), 86 (R) and ground.

SEL821Y

OK or NG

OK GO TO 8.

NG Repair harness between ECM and harness connector F115 (LHD models) or F43 (RHD

models).

8 ECM/COMBINATION METER INTERNAL CIRCUIT INSPECTION

Check components inspection. Refer to “ECM/COMBINATION METER INTERNAL CIRCUIT INSPECTION” (EL-542).

OK or NG

OK Reconnect all connectors to perform “SELF-DIAG RESULTS” and “DATA MONITOR” for

“ENGINE” and “SMART ENTRANCE” displayed on CONSULT-II. Refer to the following.

“DTC U1000, U1001 CAN COMMUNICATION LINE” (WITH EURO-OBD) (EC-116) for

“ENGINE”

“DTC U1000, U1001 CAN COMMUNICATION LINE” (WITHOUT EURO-OBD) (EC-

492) for “ENGINE”

“CAN Communication Line Check” (EL-380) for “SMART ENTRANCE”

NG Replace ECM and/or combination meter.

SEL723Y

Component InspectionNJEL0546ECM/COMBINATION METER INTERNAL CIRCUIT

INSPECTION

NJEL0546S01Remove ECM and combination meter from vehicle.

Check resistance between ECM terminals 94 and 86.

Check resistance between combination meter terminals 26

and 27.

Unit Terminal Resistance value (Ω)

ECM 94 - 86

Approx. 108 - 132

Combination meter 26 - 27

CAN SYSTEM (TYPE 2)

Trouble Diagnoses (Cont’d)

EL-542

Page 2879 of 3189

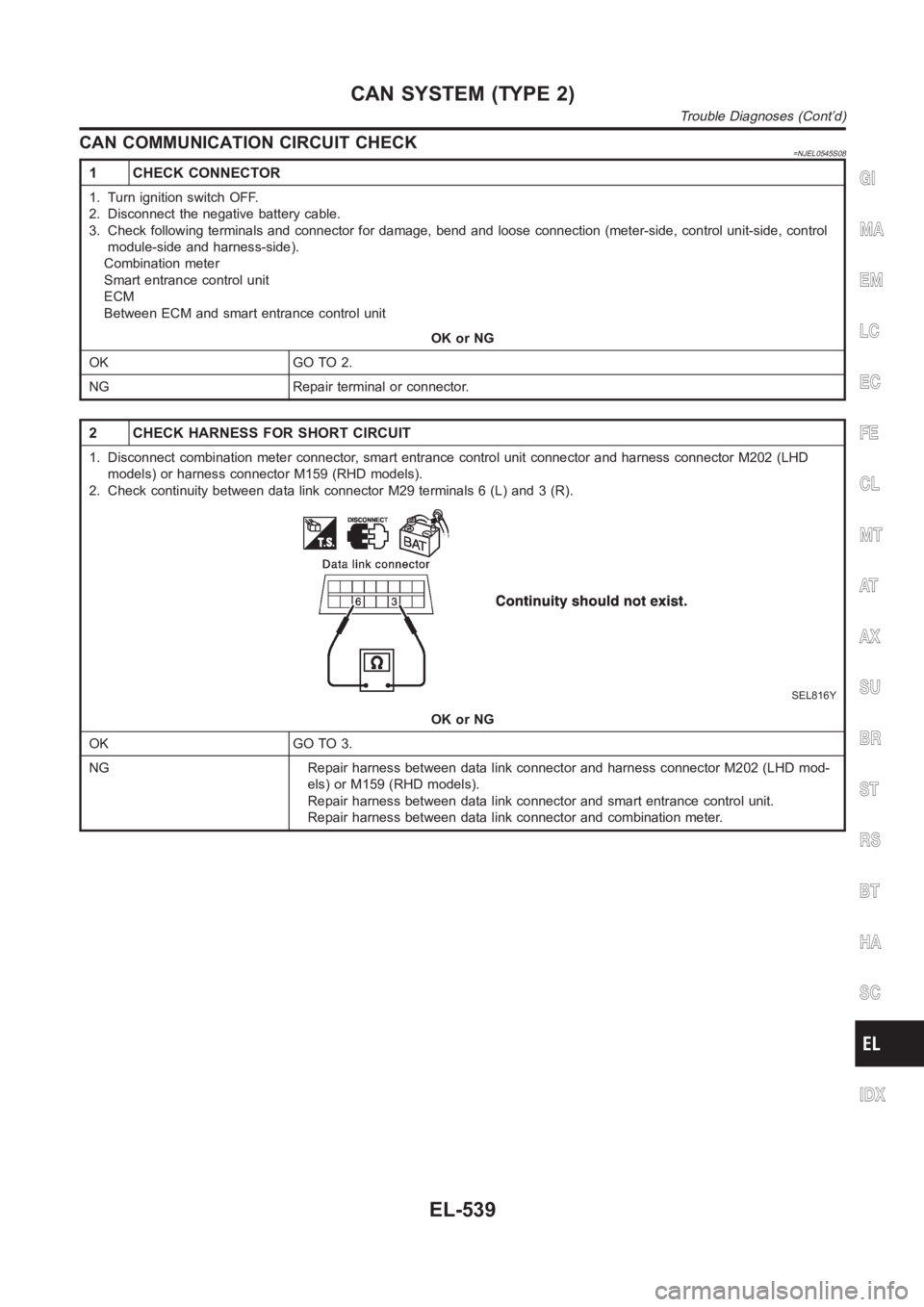

Engine CompartmentNJEL0129

YEL609D

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

ELECTRICAL UNITS LOCATION

Engine Compartment

EL-543

Page 2880 of 3189

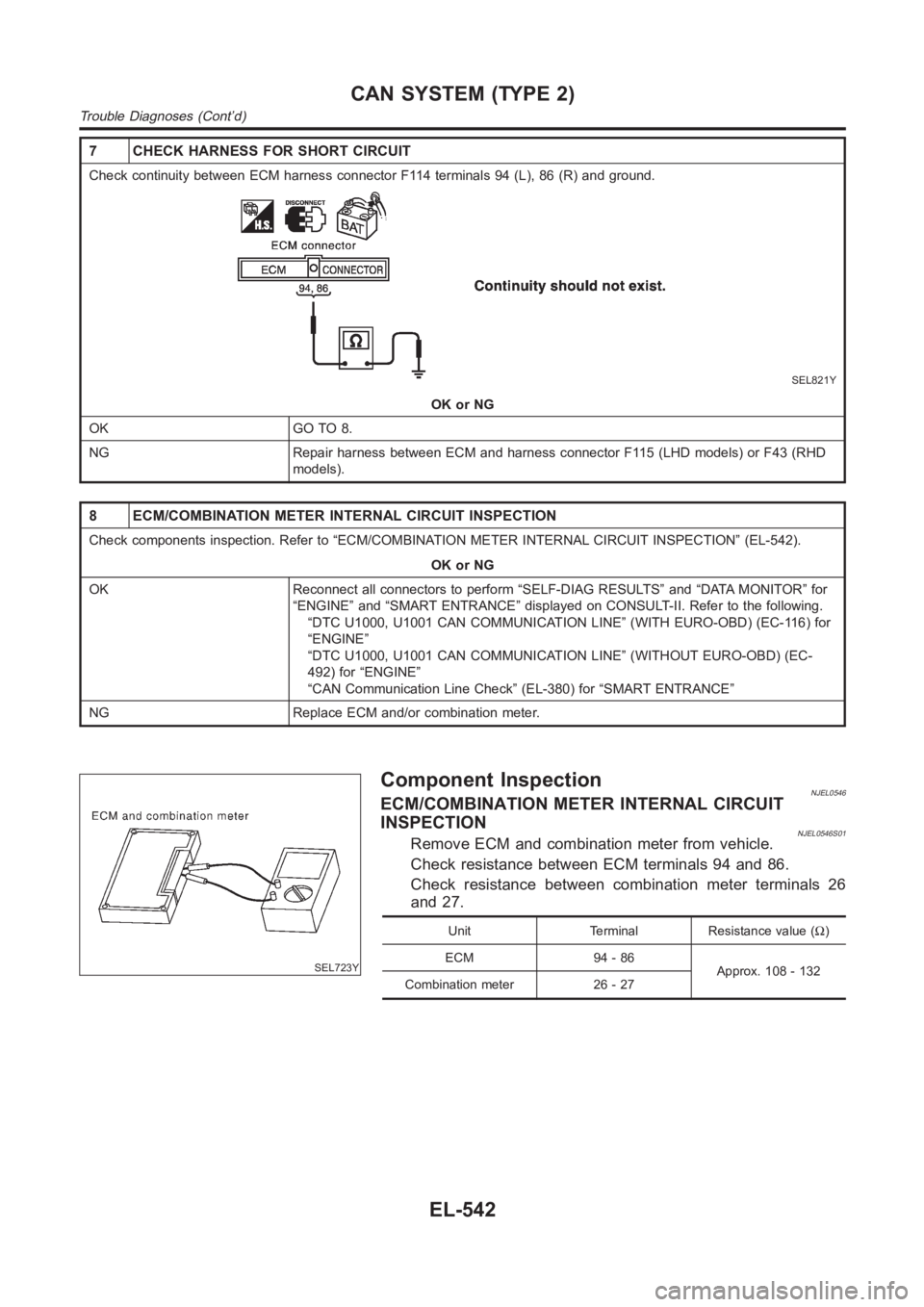

YEL610D

ELECTRICAL UNITS LOCATION

Engine Compartment (Cont’d)

EL-544

Trending: brake light, cooling, immobilize, trunk, service schedule, Speaker, Window defogger