NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1771 of 3171

IP-12

INSTRUMENT PANEL ASSEMBLY

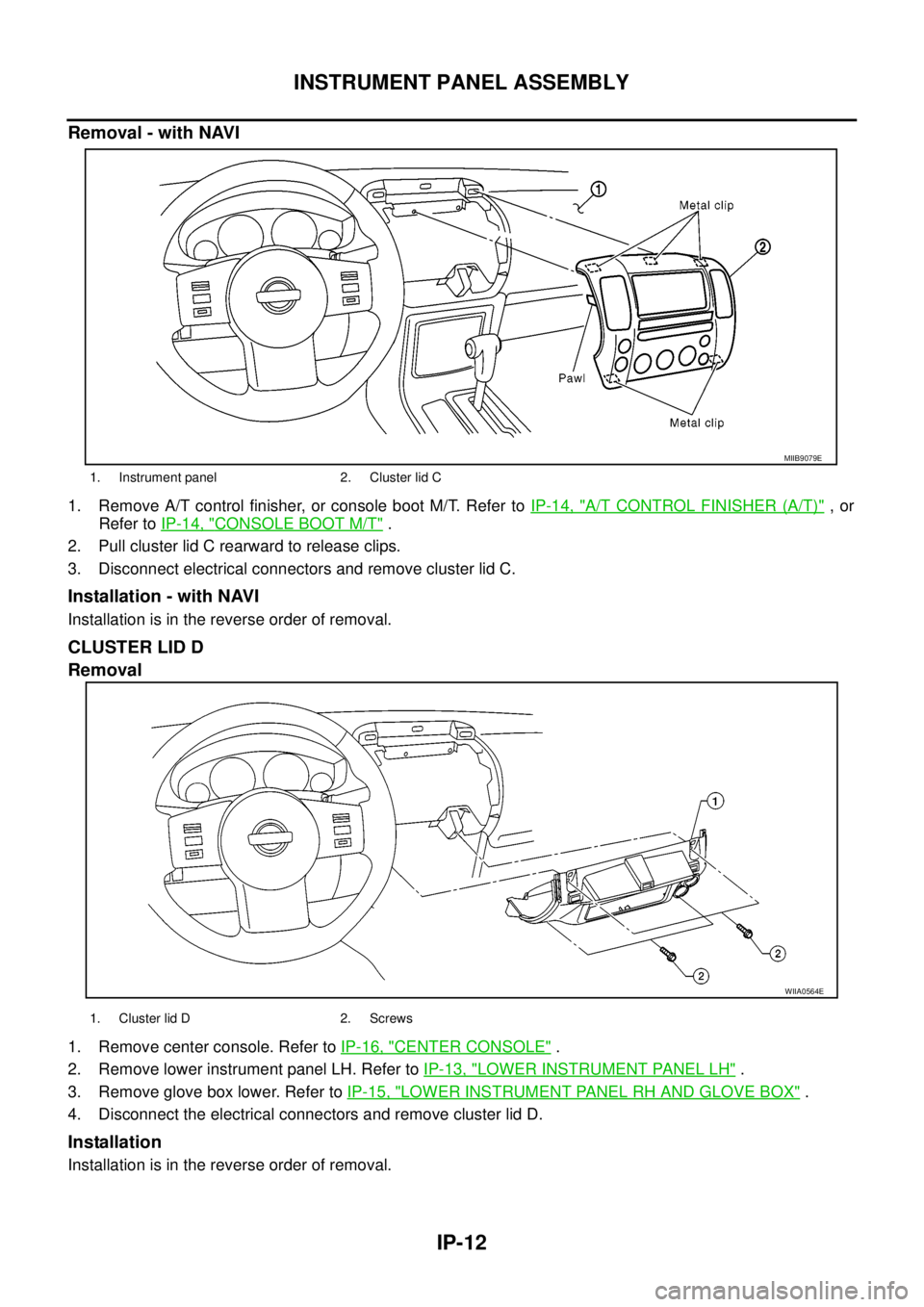

Removal - with NAVI

1. Remove A/T control finisher, or console boot M/T. Refer toIP-14, "A/T CONTROL FINISHER (A/T)",or

Refer toIP-14, "

CONSOLE BOOT M/T".

2. Pull cluster lid C rearward to release clips.

3. Disconnect electrical connectors and remove cluster lid C.

Installation - with NAVI

Installation is in the reverse order of removal.

CLUSTER LID D

Removal

1. Remove center console. Refer toIP-16, "CENTER CONSOLE".

2. Remove lower instrument panel LH. Refer toIP-13, "

LOWER INSTRUMENT PANEL LH".

3. Remove glove box lower. Refer toIP-15, "

LOWER INSTRUMENT PANEL RH AND GLOVE BOX".

4. Disconnect the electrical connectors and remove cluster lid D.

Installation

Installation is in the reverse order of removal.

1. Instrument panel 2. Cluster lid C

MIIB9079E

WIIA0564E

1. Cluster lid D 2. Screws

Page 1772 of 3171

INSTRUMENT PANEL ASSEMBLY

IP-13

C

D

E

F

G

H

J

K

L

MA

B

IP

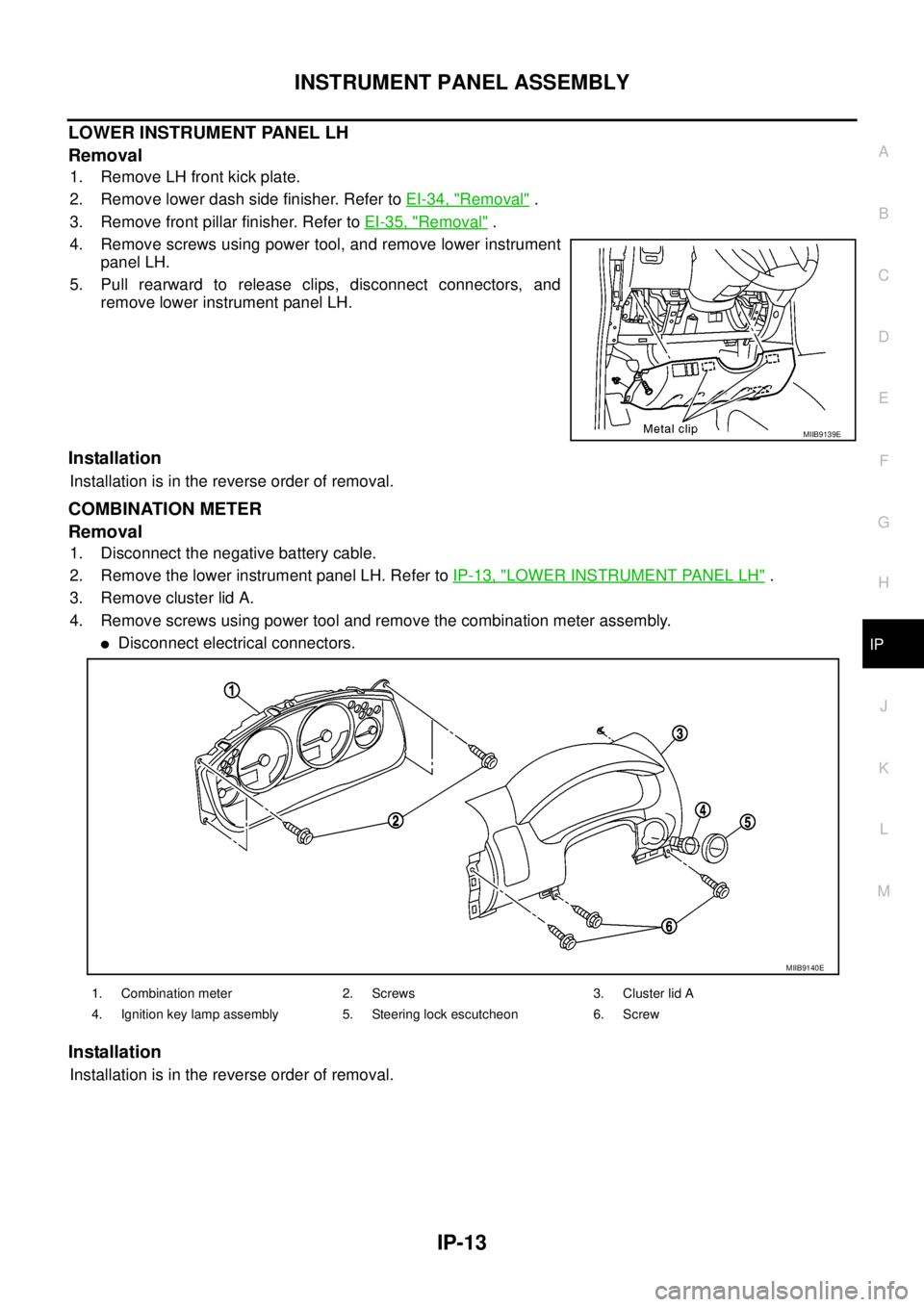

LOWER INSTRUMENT PANEL LH

Removal

1. Remove LH front kick plate.

2. Remove lower dash side finisher. Refer toEI-34, "

Removal".

3. Remove front pillar finisher. Refer toEI-35, "

Removal".

4. Remove screws using power tool, and remove lower instrument

panel LH.

5. Pull rearward to release clips, disconnect connectors, and

remove lower instrument panel LH.

Installation

Installation is in the reverse order of removal.

COMBINATION METER

Removal

1. Disconnect the negative battery cable.

2. Remove the lower instrument panel LH. Refer toIP-13, "

LOWER INSTRUMENT PANEL LH".

3. Remove cluster lid A.

4. Remove screws using power tool and remove the combination meter assembly.

lDisconnect electrical connectors.

Installation

Installation is in the reverse order of removal.

MIIB9139E

1. Combination meter 2. Screws 3. Cluster lid A

4. Ignition key lamp assembly 5. Steering lock escutcheon 6. Screw

MIIB9140E

Page 1773 of 3171

IP-14

INSTRUMENT PANEL ASSEMBLY

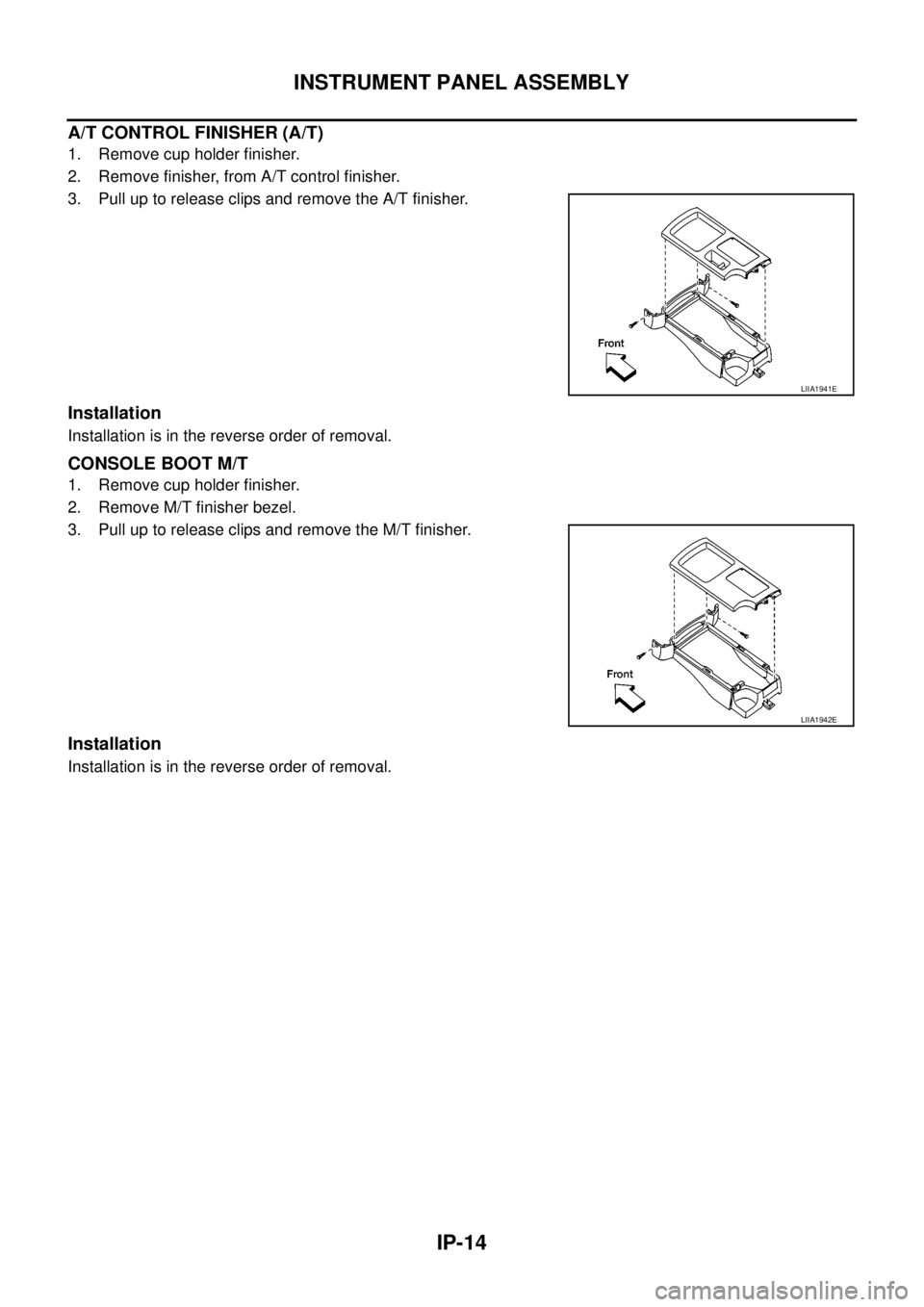

A/T CONTROL FINISHER (A/T)

1. Remove cup holder finisher.

2. Remove finisher, from A/T control finisher.

3. Pull up to release clips and remove the A/T finisher.

Installation

Installation is in the reverse order of removal.

CONSOLE BOOT M/T

1. Remove cup holder finisher.

2. Remove M/T finisher bezel.

3. Pull up to release clips and remove the M/T finisher.

Installation

Installation is in the reverse order of removal.

LIIA1941E

LIIA1942E

Page 1774 of 3171

INSTRUMENT PANEL ASSEMBLY

IP-15

C

D

E

F

G

H

J

K

L

MA

B

IP

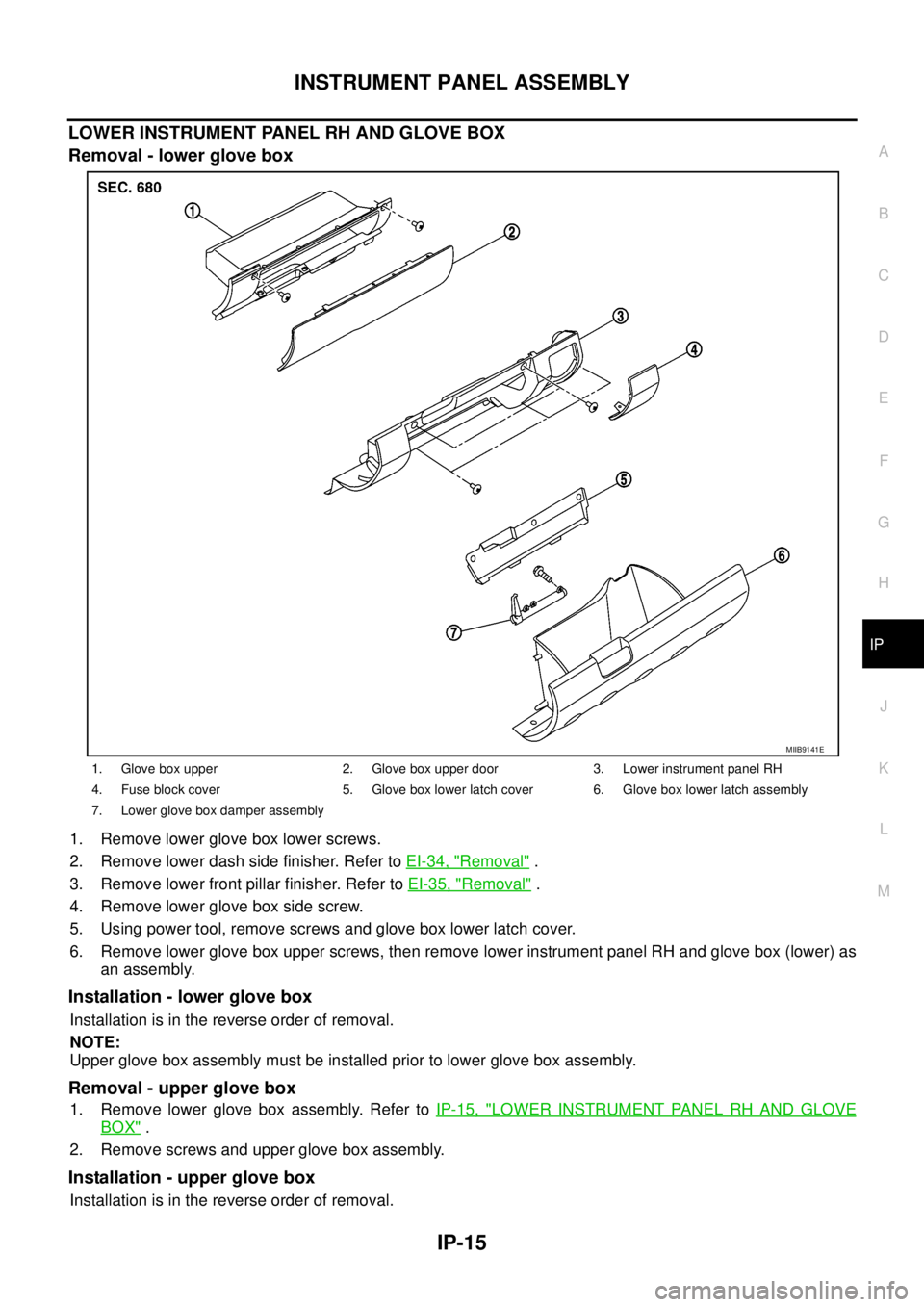

LOWER INSTRUMENT PANEL RH AND GLOVE BOX

Removal - lower glove box

1. Remove lower glove box lower screws.

2. Remove lower dash side finisher. Refer toEI-34, "

Removal".

3. Remove lower front pillar finisher. Refer toEI-35, "

Removal".

4. Remove lower glove box side screw.

5. Using power tool, remove screws and glove box lower latch cover.

6. Remove lower glove box upper screws, then remove lower instrument panel RH and glove box (lower) as

an assembly.

Installation - lower glove box

Installation is in the reverse order of removal.

NOTE:

Upper glove box assembly must be installed prior to lower glove box assembly.

Removal - upper glove box

1. Remove lower glove box assembly. Refer toIP-15, "LOWER INSTRUMENT PANEL RH AND GLOVE

BOX".

2. Remove screws and upper glove box assembly.

Installation - upper glove box

Installation is in the reverse order of removal.

1. Glove box upper 2. Glove box upper door 3. Lower instrument panel RH

4. Fuse block cover 5. Glove box lower latch cover 6. Glove box lower latch assembly

7. Lower glove box damper assembly

MIIB9141E

Page 1775 of 3171

IP-16

INSTRUMENT PANEL ASSEMBLY

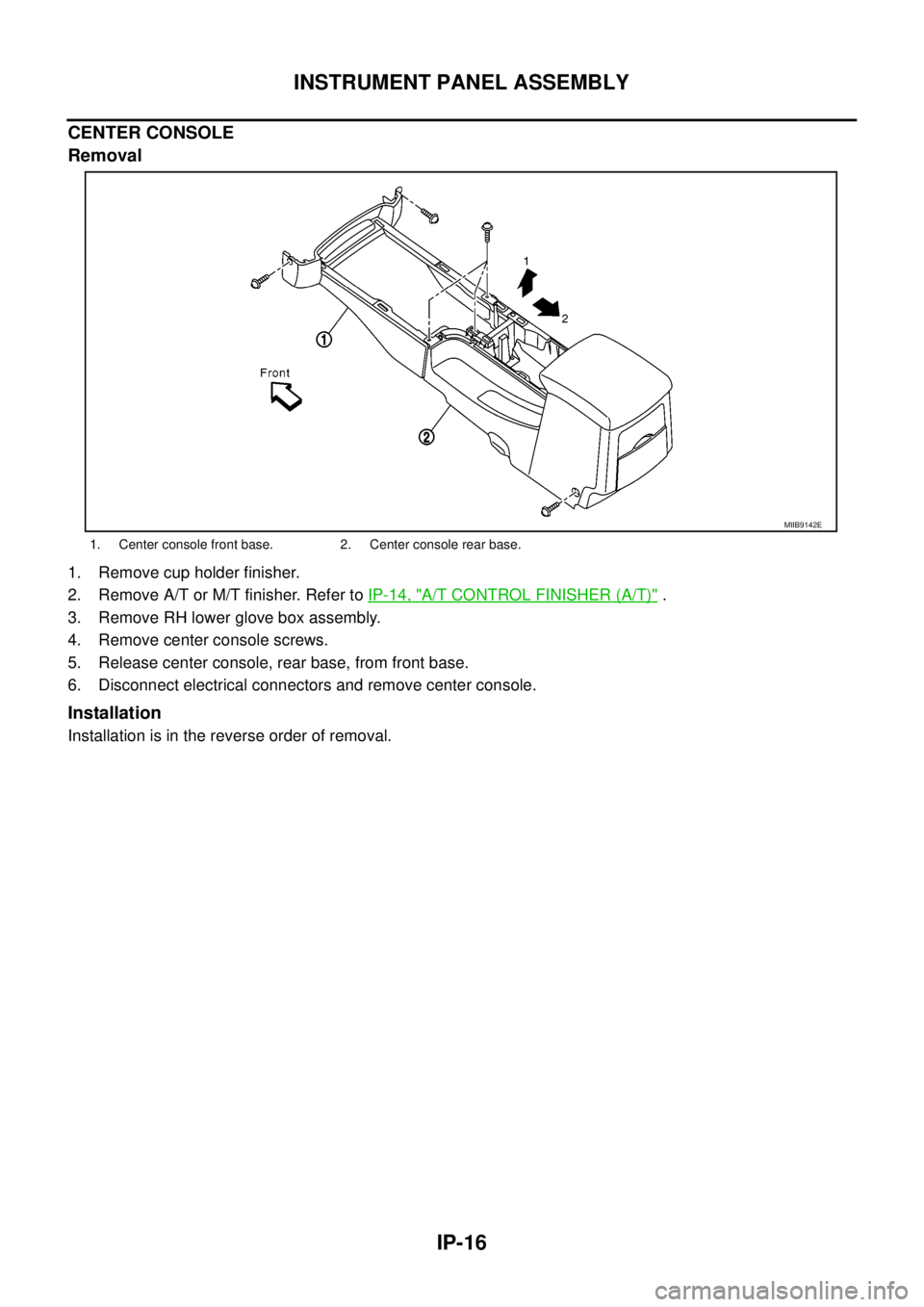

CENTER CONSOLE

Removal

1. Remove cup holder finisher.

2. Remove A/T or M/T finisher. Refer toIP-14, "

A/T CONTROL FINISHER (A/T)".

3. Remove RH lower glove box assembly.

4. Remove center console screws.

5. Release center console, rear base, from front base.

6. Disconnect electrical connectors and remove center console.

Installation

Installation is in the reverse order of removal.

1. Center console front base. 2. Center console rear base.

MIIB9142E

Page 1776 of 3171

INSTRUMENT PANEL ASSEMBLY

IP-17

C

D

E

F

G

H

J

K

L

MA

B

IP

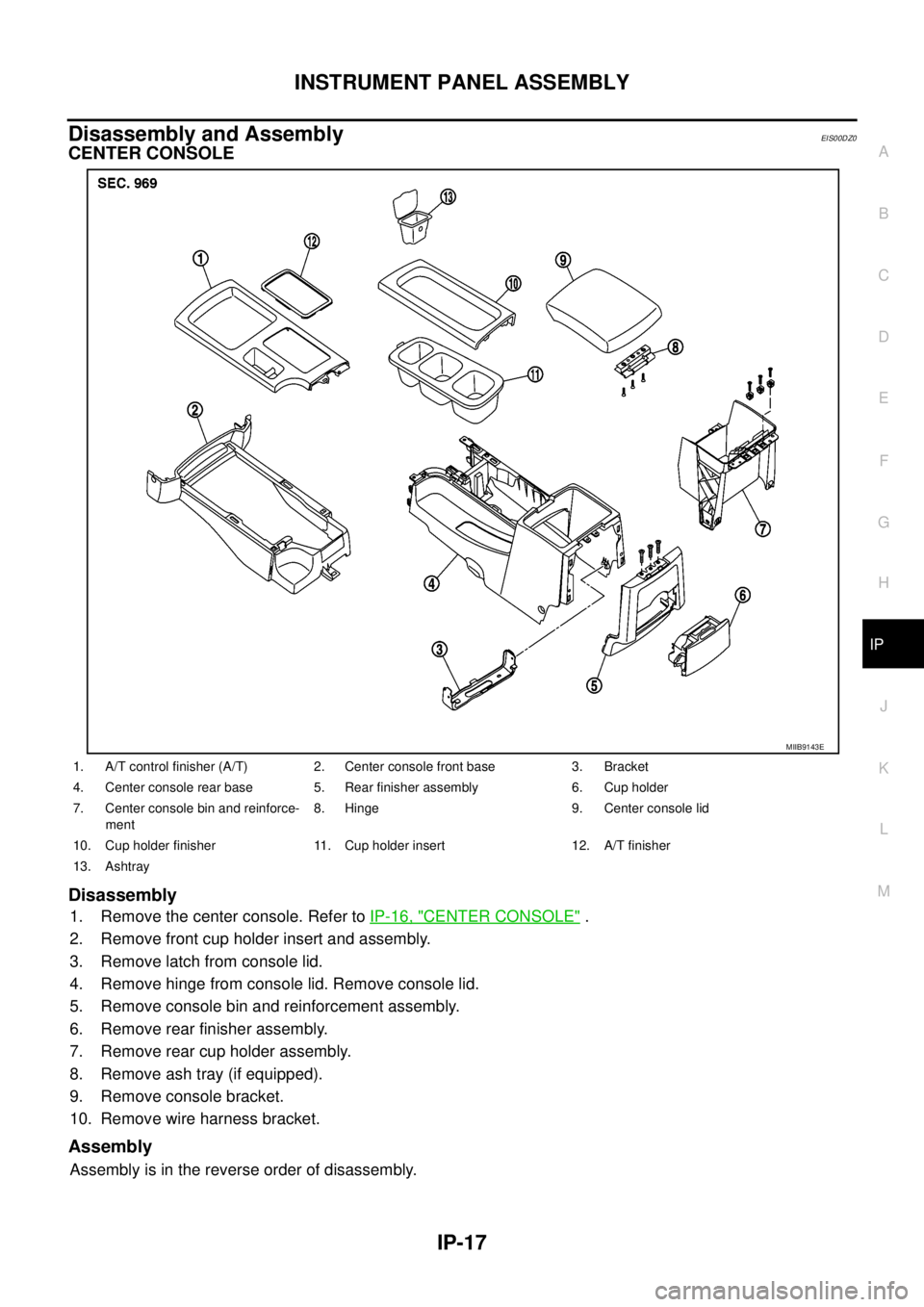

Disassembly and AssemblyEIS00DZ0

CENTER CONSOLE

Disassembly

1. Remove the center console. Refer toIP-16, "CENTER CONSOLE".

2. Remove front cup holder insert and assembly.

3. Remove latch from console lid.

4. Remove hinge from console lid. Remove console lid.

5. Remove console bin and reinforcement assembly.

6. Remove rear finisher assembly.

7. Remove rear cup holder assembly.

8. Remove ash tray (if equipped).

9. Remove console bracket.

10. Remove wire harness bracket.

Assembly

Assembly is in the reverse order of disassembly.

MIIB9143E

1. A/T control finisher (A/T) 2. Center console front base 3. Bracket

4. Center console rear base 5. Rear finisher assembly 6. Cup holder

7. Center console bin and reinforce-

ment8. Hinge 9. Center console lid

10. Cup holder finisher 11. Cup holder insert 12. A/T finisher

13. Ashtray

Page 1777 of 3171

IP-18

INSTRUMENT PANEL ASSEMBLY

Page 1778 of 3171

LAN-1

LAN SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTIONLAN

A

B

LAN

LAN SYSTEM

CAN

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Precautions When Using CONSULT-II ..................... 3

CHECK POINTS FOR USING CONSULT-II ......... 3

Precautions For Trouble Diagnosis .......................... 3

CAN SYSTEM ....................................................... 3

Precautions For Harness Repair .............................. 3

CAN SYSTEM ....................................................... 3

TROUBLE DIAGNOSES WORK FLOW .................... 5

When Displaying CAN Communication System

Errors ....................................................................... 5

WHEN A MALFUNCTION IS DETECTED BY

CAN COMMUNICATION SYSTEM ....................... 5

WHEN A MALFUNCTION IS DETECTED

EXCEPT CAN COMMUNICATION SYSTEM ........ 5

TROUBLE DIAGNOSIS FLOW CHART ............... 6

Diagnosis Procedure ................................................ 7

SELECTING CAN SYSTEM TYPE (HOW TO

USE SPECIFICATION TABLE) ............................. 7

ACQUISITION OF DATA BY CONSULT-II ............ 8

HOW TO USE CHECK SHEET TABLE ................ 9

CAN Diagnostic Support Monitor ........................... 15

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR ECM ............................... 15

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR TCM ............................... 16

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR NAVI CONTROL UNIT ... 17

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR DIFFERENTIAL LOCK

CONTROL UNIT ................................................. 18

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR FRONT AIR CONTROL... 19

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR BCM ............................... 20

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR TRANSFER CONTROLUNIT .................................................................... 21

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR ABS ACTUATOR AND

ELECTRIC UNIT (CONTROL UNIT) ................... 21

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR IPDM E/R ....................... 22

CAN COMMUNICATION ........................................... 23

System Description ................................................. 23

Component Parts and Harness Connector Location... 23

LHD MODELS ..................................................... 23

RHD MODELS .................................................... 24

Schematic ............................................................... 25

Wiring Diagram — CAN — ..................................... 26

CAN Communication Unit ....................................... 30

TYPE 1/ TYPE 2/ TYPE 3 ................................... 32

TYPE 4/ TYPE 5 .................................................. 34

TYPE 6/ TYPE 7/ TYPE 8/ TYPE 9/ TYPE 10/

TYPE 11/ TYPE 16/ TYPE 17 .............................. 36

TYPE 12/ TYPE 13/ TYPE 14/ TYPE 15 ............. 40

CAN SYSTEM (TYPE 1) ........................................... 44

Component Parts and Harness Connector Location... 44

Schematic ............................................................... 44

Wiring Diagram — CAN — ..................................... 44

Check Sheet ........................................................... 45

CHECK SHEET RESULTS (EXAMPLE) ............. 47

CAN SYSTEM (TYPE 2) ........................................... 56

Component Parts and Harness Connector Location... 56

Schematic ............................................................... 56

Wiring Diagram — CAN — ..................................... 56

Check Sheet ........................................................... 57

CHECK SHEET RESULTS (EXAMPLE) ............. 59

CAN SYSTEM (TYPE 3) ........................................... 68

Component Parts and Harness Connector Location... 68

Schematic ............................................................... 68

Wiring Diagram — CAN — ..................................... 68

Check Sheet ........................................................... 69

CHECK SHEET RESULTS (EXAMPLE) ............. 71

CAN SYSTEM (TYPE 4) ........................................... 82

Component Parts and Harness Connector Location... 82

Schematic ............................................................... 82

Page 1779 of 3171

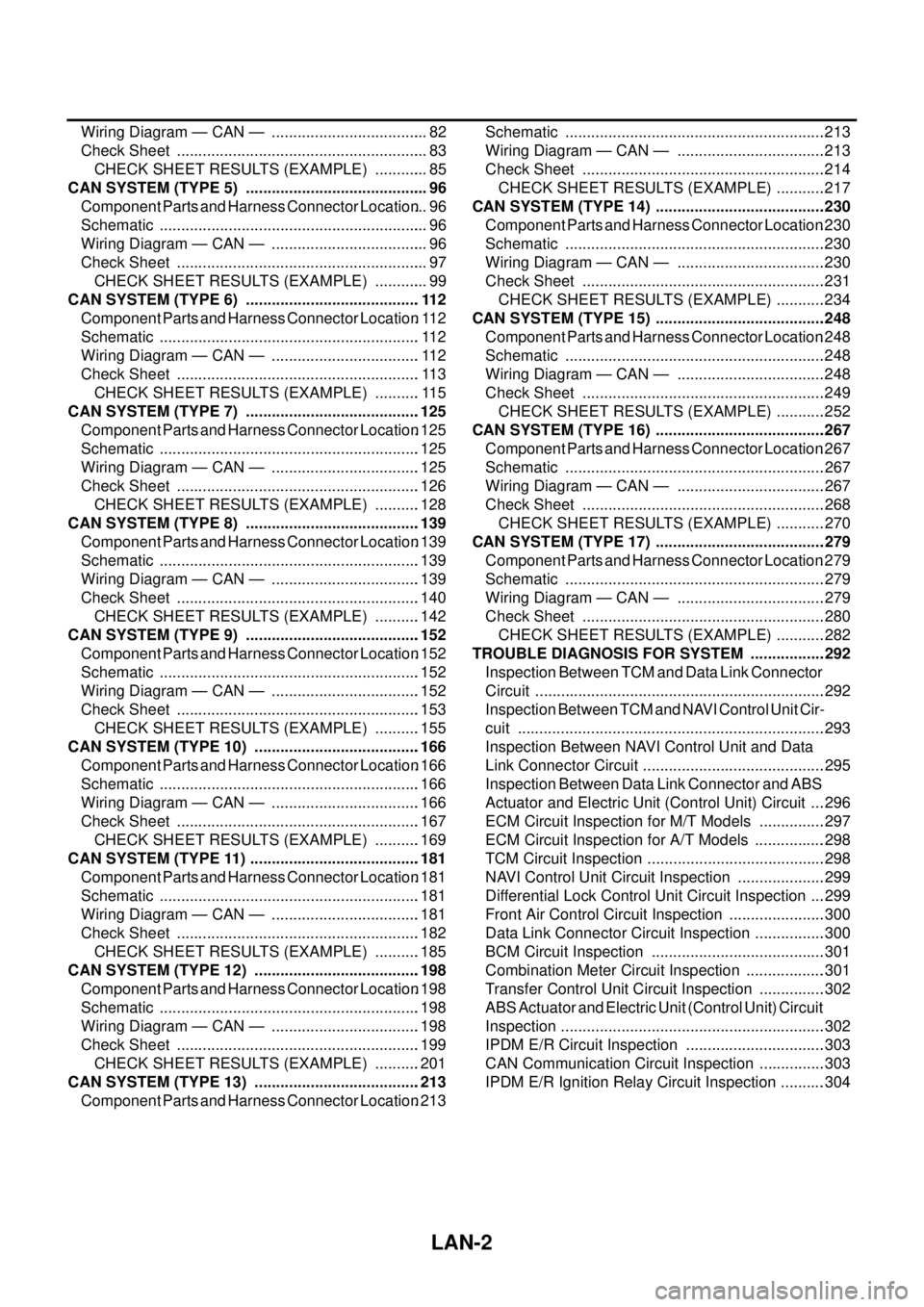

LAN-2

Wiring Diagram — CAN — ..................................... 82

Check Sheet ........................................................... 83

CHECK SHEET RESULTS (EXAMPLE) ............. 85

CAN SYSTEM (TYPE 5) ........................................... 96

Component Parts and Harness Connector Location... 96

Schematic ............................................................... 96

Wiring Diagram — CAN — ..................................... 96

Check Sheet ........................................................... 97

CHECK SHEET RESULTS (EXAMPLE) ............. 99

CAN SYSTEM (TYPE 6) .........................................112

Component Parts and Harness Connector Location.112

Schematic .............................................................112

Wiring Diagram — CAN — ...................................112

Check Sheet .........................................................113

CHECK SHEET RESULTS (EXAMPLE) ...........115

CAN SYSTEM (TYPE 7) .........................................125

Component Parts and Harness Connector Location.125

Schematic .............................................................125

Wiring Diagram — CAN — ...................................125

Check Sheet .........................................................126

CHECK SHEET RESULTS (EXAMPLE) ...........128

CAN SYSTEM (TYPE 8) .........................................139

Component Parts and Harness Connector Location.139

Schematic .............................................................139

Wiring Diagram — CAN — ...................................139

Check Sheet .........................................................140

CHECK SHEET RESULTS (EXAMPLE) ...........142

CAN SYSTEM (TYPE 9) .........................................152

Component Parts and Harness Connector Location.152

Schematic .............................................................152

Wiring Diagram — CAN — ...................................152

Check Sheet .........................................................153

CHECK SHEET RESULTS (EXAMPLE) ...........155

CAN SYSTEM (TYPE 10) .......................................166

Component Parts and Harness Connector Location.166

Schematic .............................................................166

Wiring Diagram — CAN — ...................................166

Check Sheet .........................................................167

CHECK SHEET RESULTS (EXAMPLE) ...........169

CAN SYSTEM (TYPE 11) ........................................181

Component Parts and Harness Connector Location.181

Schematic .............................................................181

Wiring Diagram — CAN — ...................................181

Check Sheet .........................................................182

CHECK SHEET RESULTS (EXAMPLE) ...........185

CAN SYSTEM (TYPE 12) .......................................198

Component Parts and Harness Connector Location.198

Schematic .............................................................198

Wiring Diagram — CAN — ...................................198

Check Sheet .........................................................199

CHECK SHEET RESULTS (EXAMPLE) ...........201

CAN SYSTEM (TYPE 13) .......................................213

Component Parts and Harness Connector Location.213Schematic .............................................................213

Wiring Diagram — CAN — ...................................213

Check Sheet .........................................................214

CHECK SHEET RESULTS (EXAMPLE) ............217

CAN SYSTEM (TYPE 14) ........................................230

Component Parts and Harness Connector Location.230

Schematic .............................................................230

Wiring Diagram — CAN — ...................................230

Check Sheet .........................................................231

CHECK SHEET RESULTS (EXAMPLE) ............234

CAN SYSTEM (TYPE 15) ........................................248

Component Parts and Harness Connector Location.248

Schematic .............................................................248

Wiring Diagram — CAN — ...................................248

Check Sheet .........................................................249

CHECK SHEET RESULTS (EXAMPLE) ............252

CAN SYSTEM (TYPE 16) ........................................267

Component Parts and Harness Connector Location.267

Schematic .............................................................267

Wiring Diagram — CAN — ...................................267

Check Sheet .........................................................268

CHECK SHEET RESULTS (EXAMPLE) ............270

CAN SYSTEM (TYPE 17) ........................................279

Component Parts and Harness Connector Location.279

Schematic .............................................................279

Wiring Diagram — CAN — ...................................279

Check Sheet .........................................................280

CHECK SHEET RESULTS (EXAMPLE) ............282

TROUBLE DIAGNOSIS FOR SYSTEM ..................292

Inspection Between TCM and Data Link Connector

Circuit ....................................................................292

Inspection Between TCM and NAVI Control Unit Cir-

cuit ........................................................................293

Inspection Between NAVI Control Unit and Data

Link Connector Circuit ...........................................295

Inspection Between Data Link Connector and ABS

Actuator and Electric Unit (Control Unit) Circuit ....296

ECM Circuit Inspection for M/T Models ................297

ECM Circuit Inspection for A/T Models .................298

TCM Circuit Inspection ..........................................298

NAVI Control Unit Circuit Inspection .....................299

Differential Lock Control Unit Circuit Inspection ....299

Front Air Control Circuit Inspection .......................300

Data Link Connector Circuit Inspection .................300

BCM Circuit Inspection .........................................301

Combination Meter Circuit Inspection ...................301

Transfer Control Unit Circuit Inspection ................302

ABS Actuator and Electric Unit (Control Unit) Circuit

Inspection ..............................................................302

IPDM E/R Circuit Inspection .................................303

CAN Communication Circuit Inspection ................303

IPDM E/R Ignition Relay Circuit Inspection ...........304

Page 1780 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual PRECAUTIONS

LAN-3

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

[CAN]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EKS00Q9Y

The Supplement NISSAN NAVARA 2005 Repair Workshop Manual PRECAUTIONS

LAN-3

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

[CAN]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EKS00Q9Y

The Supplement](/img/5/57362/w960_57362-1779.png)

PRECAUTIONS

LAN-3

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

[CAN]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EKS00Q9Y

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions When Using CONSULT-IIEKS00LBE

When connecting CONSULT-II to data link connector, connect them through CONSULT-II CONVERTER.

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

CHECK POINTS FOR USING CONSULT-II

1. Has CONSULT-II been used without connecting CONSULT-II CONVERTER on this vehicle?

–If YES, GO TO 2.

–If NO, GO TO 5.

2. Is there any indication other than indications relating to CAN communication system in the self-diagnosis

results?

–If YES, GO TO 3.

–If NO, GO TO 4.

3. Based on self-diagnosis results unrelated to CAN communication, carry out the inspection.

4. Malfunctions may be detected in self-diagnosis depending on control units carrying out CAN communica-

tion. Therefore, erase the self-diagnosis results.

5. Diagnose CAN communication system. Refer toLAN-5, "

TROUBLE DIAGNOSES WORK FLOW".

Precautions For Trouble DiagnosisEKS00LBF

CAN SYSTEM

lDo not apply voltage of 7.0 V or higher to the measurement terminals.

lUse the tester with its open terminal voltage being 7.0 V or less.

lBe sure to turn ignition switch off and disconnect negative battery terminal before checking the circuit.

Precautions For Harness RepairEKS00LBG

CAN SYSTEM

lSolder the repaired parts, and wrap with tape. [Frays of twisted

line must be within 110 mm (4.33 in).]

PKIA0306E