NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1741 of 3171

REAR WINDOW DEFOGGER

GW-55

C

D

E

F

G

H

J

K

L

MA

B

GW

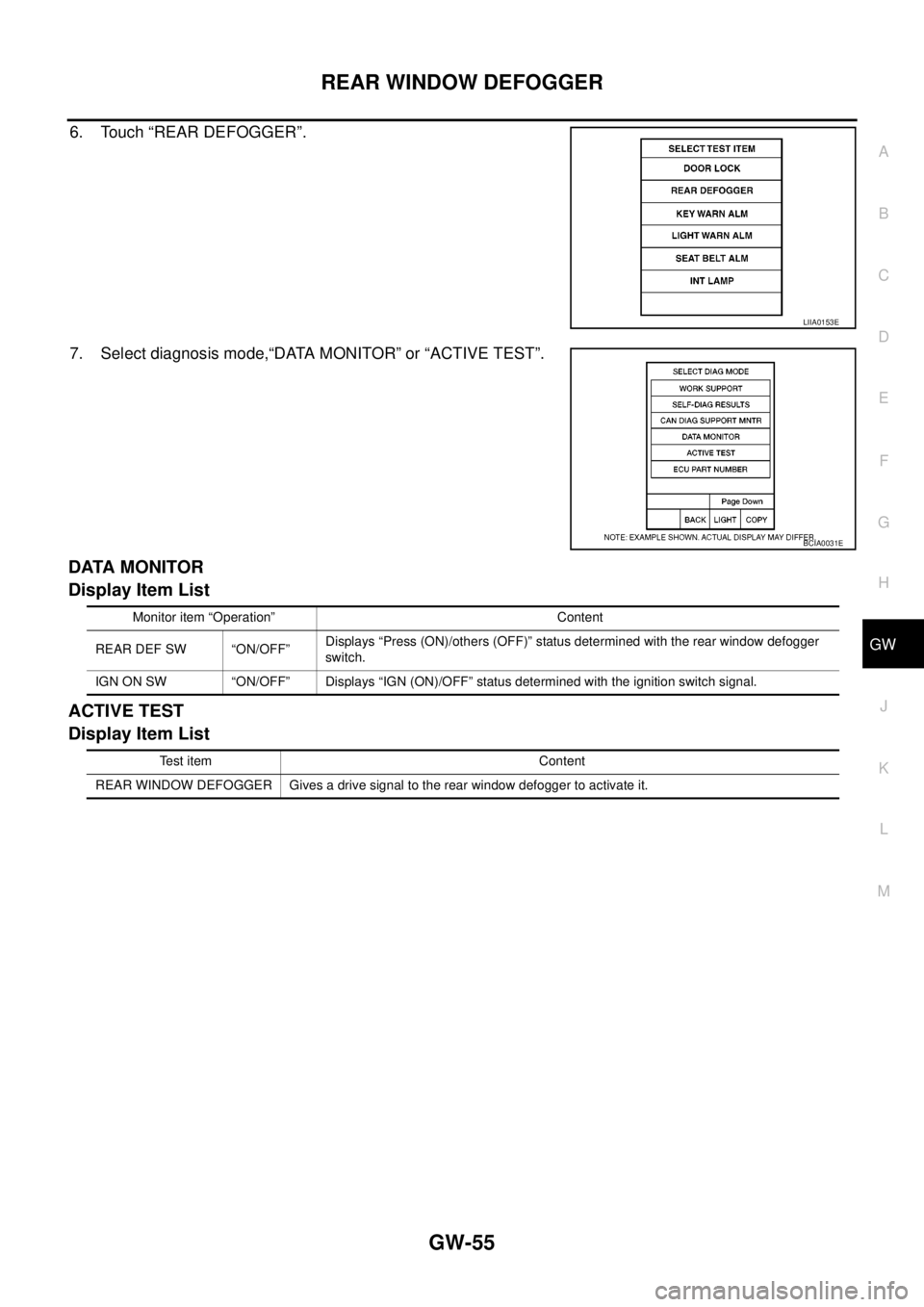

6. Touch “REAR DEFOGGER”.

7. Select diagnosis mode,“DATA MONITOR” or “ACTIVE TEST”.

DATA MONITOR

Display Item List

ACTIVE TEST

Display Item List

LIIA0153E

BCIA0031E

Monitor item “Operation” Content

REAR DEF SW “ON/OFF”Displays “Press (ON)/others (OFF)” status determined with the rear window defogger

switch.

IGN ON SW “ON/OFF” Displays “IGN (ON)/OFF” status determined with the ignition switch signal.

Test item Content

REAR WINDOW DEFOGGER Gives a drive signal to the rear window defogger to activate it.

Page 1742 of 3171

GW-56

REAR WINDOW DEFOGGER

Trouble Diagnoses Symptom Chart

EIS00B8N

lMake sure other systems using the signal of the following systems operate normally.

BCM Power Supply and Ground Circuit CheckEIS00B8O

First perform the “SELF-DIAG RESULTS” in “BCM” with CONSULT-II, when perform the each trouble

diagnosis. Refer toBCS-16, "

CAN Communication Inspection Using CONSULT-II (Self-Diagnosis)".

1.CHECK FUSE

lCheck 10A fuse [No. 1, located in the fuse block (J/B)]

lCheck 50A fusible link (letterGlocated in the fuse and fusible link box)

NOTE:

Refer toGW-47, "

Component Parts and Harness Connector Location".

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse. Refer toPG-

4, "POWER SUPPLY ROUTING CIRCUIT".

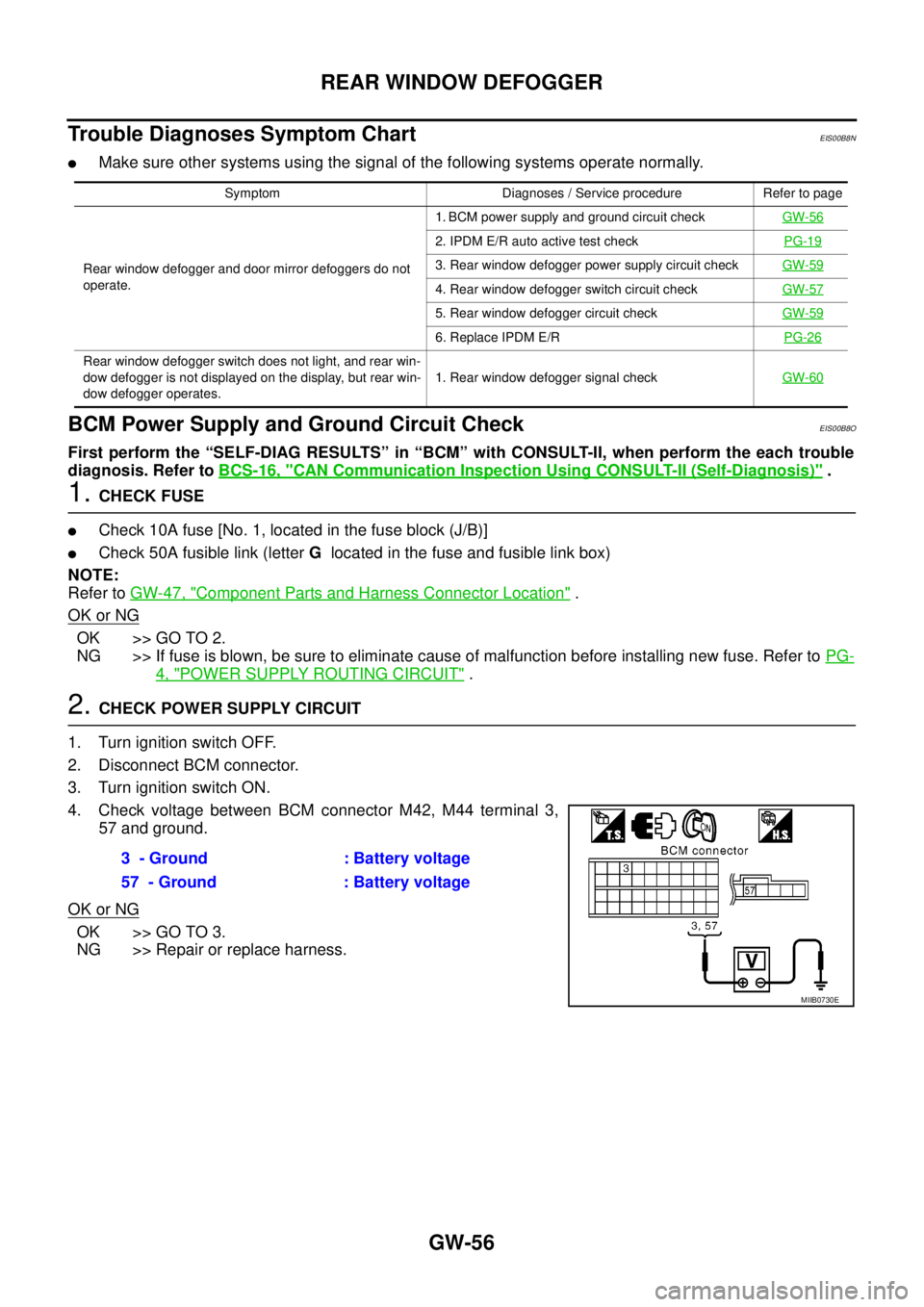

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Turn ignition switch ON.

4. Check voltage between BCM connector M42, M44 terminal 3,

57 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

Symptom Diagnoses / Service procedure Refer to page

Rear window defogger and door mirror defoggers do not

operate.1. BCM power supply and ground circuit checkGW-56

2. IPDM E/R auto active test checkPG-19

3. Rear window defogger power supply circuit checkGW-59

4. Rear window defogger switch circuit checkGW-57

5. Rear window defogger circuit checkGW-59

6. Replace IPDM E/RPG-26

Rear window defogger switch does not light, and rear win-

dow defogger is not displayed on the display, but rear win-

dow defogger operates.1. Rear window defogger signal checkGW-60

3 - Ground : Battery voltage

57 - Ground : Battery voltage

MIIB0730E

Page 1743 of 3171

REAR WINDOW DEFOGGER

GW-57

C

D

E

F

G

H

J

K

L

MA

B

GW

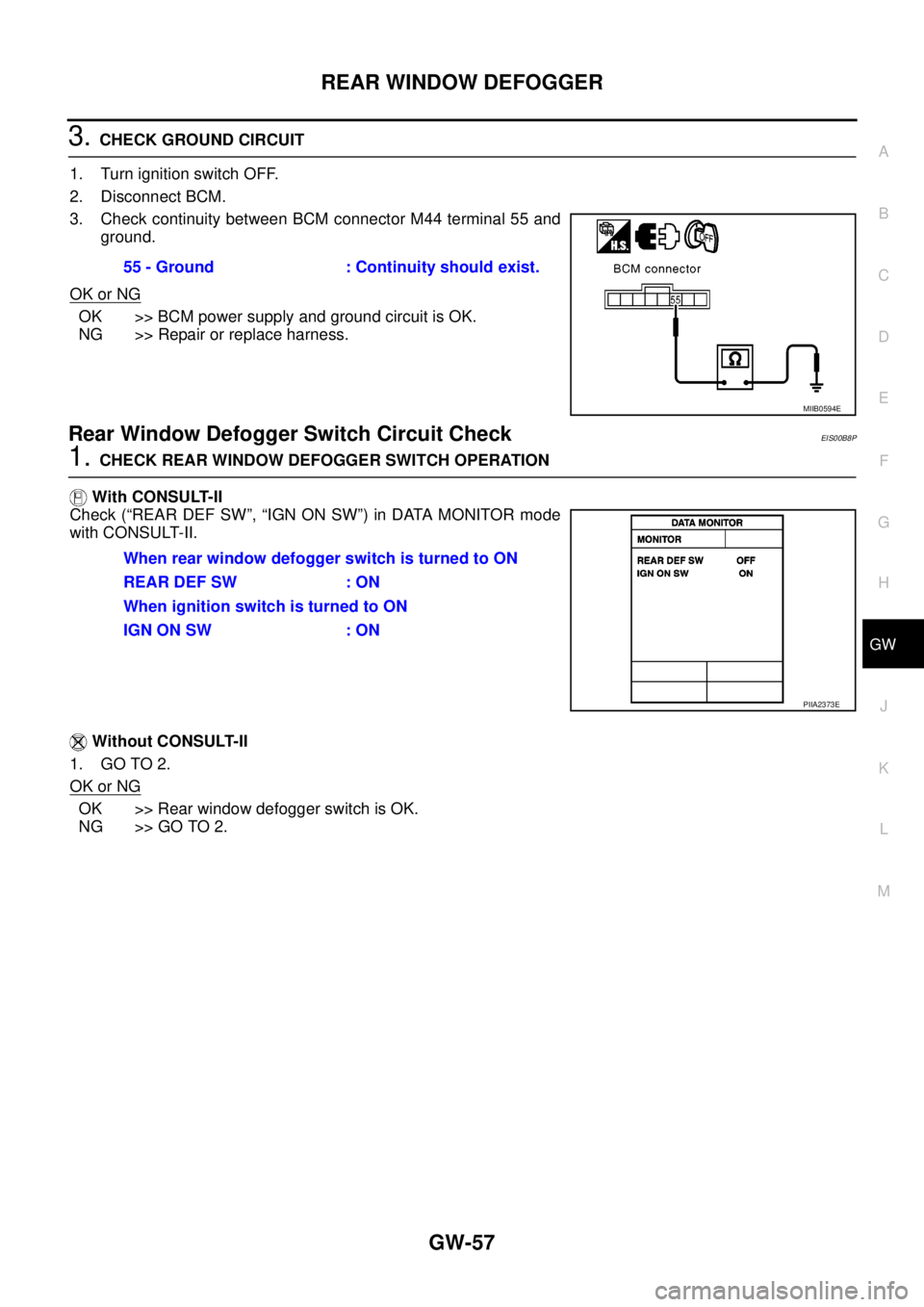

3.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM.

3. Check continuity between BCM connector M44 terminal 55 and

ground.

OK or NG

OK >> BCM power supply and ground circuit is OK.

NG >> Repair or replace harness.

Rear Window Defogger Switch Circuit CheckEIS00B8P

1.CHECK REAR WINDOW DEFOGGER SWITCH OPERATION

With CONSULT-II

Check (“REAR DEF SW”, “IGN ON SW”) in DATA MONITOR mode

with CONSULT-II.

Without CONSULT-II

1. GO TO 2.

OK or NG

OK >> Rear window defogger switch is OK.

NG >> GO TO 2.55 - Ground : Continuity should exist.

MIIB0594E

When rear window defogger switch is turned to ON

REAR DEF SW : ON

When ignition switch is turned to ON

IGNONSW :ON

PIIA2373E

Page 1744 of 3171

GW-58

REAR WINDOW DEFOGGER

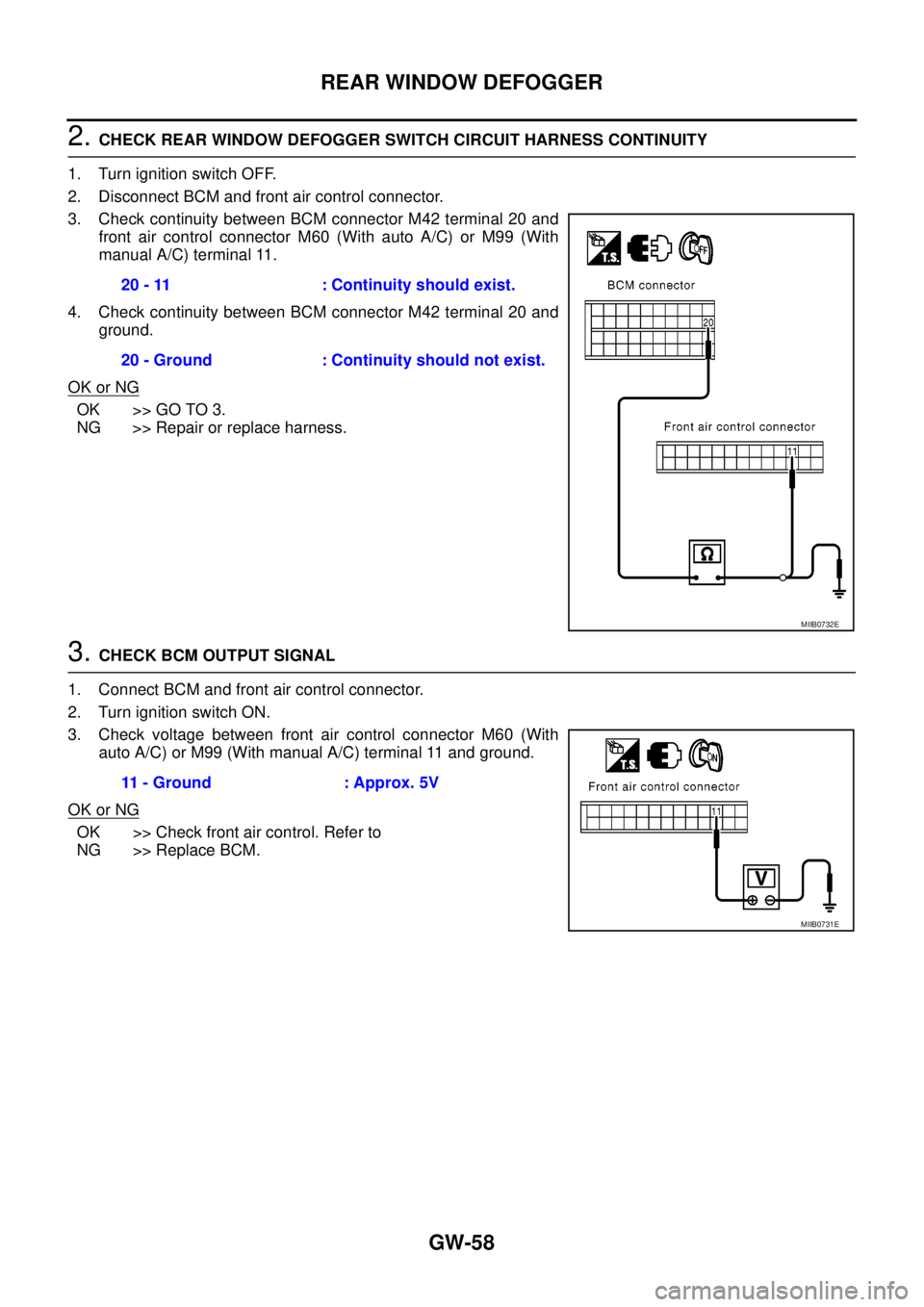

2.CHECK REAR WINDOW DEFOGGER SWITCH CIRCUIT HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect BCM and front air control connector.

3. Check continuity between BCM connector M42 terminal 20 and

front air control connector M60 (With auto A/C) or M99 (With

manual A/C) terminal 11.

4. Check continuity between BCM connector M42 terminal 20 and

ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

3.CHECK BCM OUTPUT SIGNAL

1. Connect BCM and front air control connector.

2. Turn ignition switch ON.

3. Check voltage between front air control connector M60 (With

auto A/C) or M99 (With manual A/C) terminal 11 and ground.

OK or NG

OK >> Check front air control. Refer to

NG >> Replace BCM.20 - 11 : Continuity should exist.

20 - Ground : Continuity should not exist.

MIIB0732E

11 - Ground : Approx. 5V

MIIB0731E

Page 1745 of 3171

REAR WINDOW DEFOGGER

GW-59

C

D

E

F

G

H

J

K

L

MA

B

GW

Rear Window Defogger Power Supply Circuit CheckEIS00B8Q

1.CHECK FUSE

lCheck 15A fuse (No.46, 47, located in the IPDM E/R)

NOTE:

Refer toGW-47, "

Component Parts and Harness Connector Location".

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse, refer toPG-

4, "POWER SUPPLY ROUTING CIRCUIT".

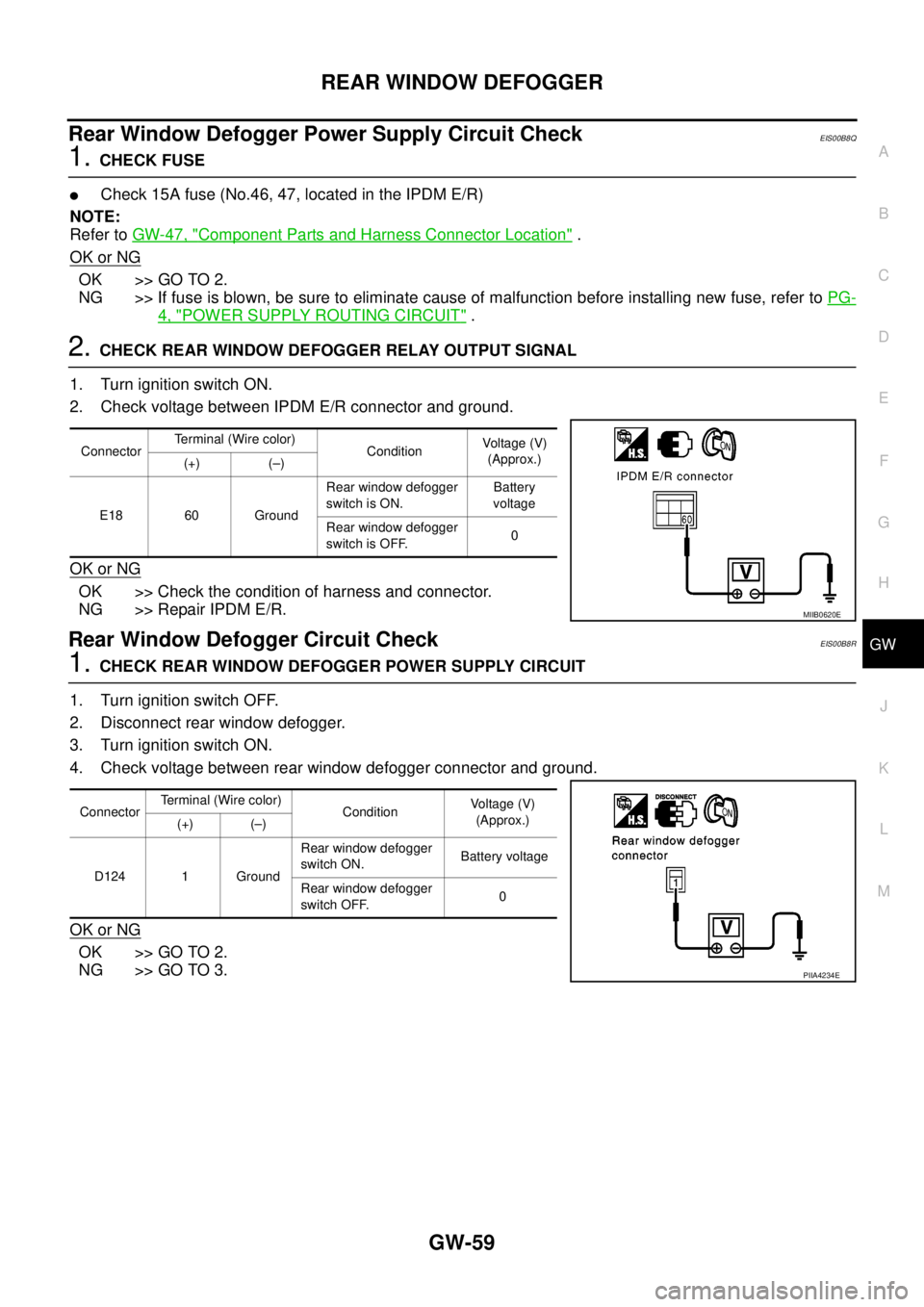

2.CHECK REAR WINDOW DEFOGGER RELAY OUTPUT SIGNAL

1. Turn ignition switch ON.

2. Check voltage between IPDM E/R connector and ground.

OK or NG

OK >> Check the condition of harness and connector.

NG >> Repair IPDM E/R.

Rear Window Defogger Circuit CheckEIS00B8R

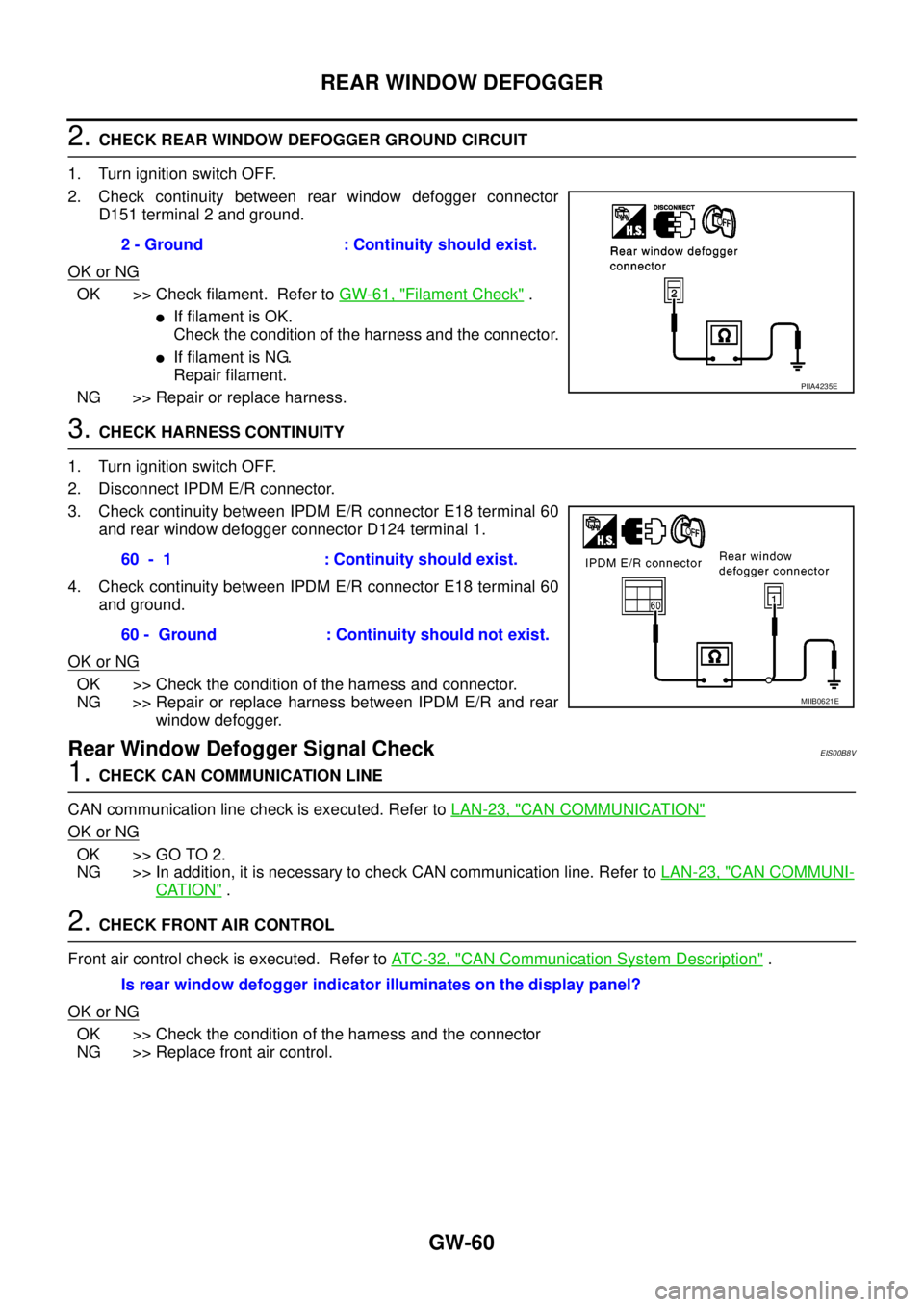

1.CHECK REAR WINDOW DEFOGGER POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear window defogger.

3. Turn ignition switch ON.

4. Check voltage between rear window defogger connector and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

ConnectorTerminal (Wire color)

ConditionVoltag e (V)

(Approx.)

(+) (–)

E18 60 GroundRear window defogger

switch is ON.Battery

voltage

Rear window defogger

switch is OFF.0

MIIB0620E

ConnectorTerminal (Wire color)

ConditionVo l ta g e (V )

(Approx.)

(+) (–)

D124 1 GroundRear window defogger

switch ON.Battery voltage

Rear window defogger

switch OFF.0

PIIA4234E

Page 1746 of 3171

GW-60

REAR WINDOW DEFOGGER

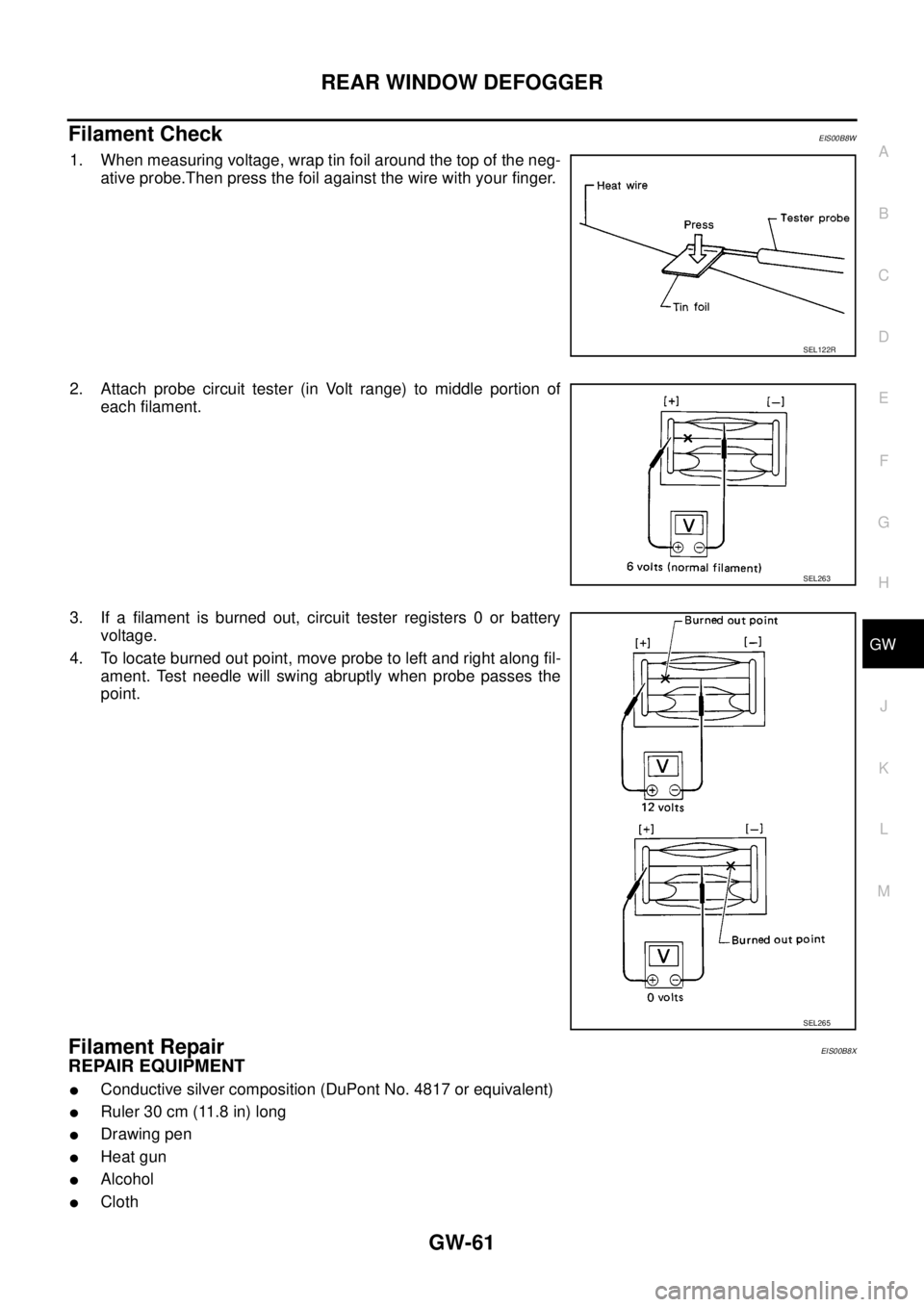

2.CHECK REAR WINDOW DEFOGGER GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between rear window defogger connector

D151 terminal 2 and ground.

OK or NG

OK >> Check filament. Refer toGW-61, "Filament Check".

lIf filament is OK.

Check the condition of the harness and the connector.

lIf filament is NG.

Repair filament.

NG >> Repair or replace harness.

3.CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R connector E18 terminal 60

and rear window defogger connector D124 terminal 1.

4. Check continuity between IPDM E/R connector E18 terminal 60

and ground.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Repair or replace harness between IPDM E/R and rear

window defogger.

Rear Window Defogger Signal CheckEIS00B8V

1.CHECK CAN COMMUNICATION LINE

CAN communication line check is executed. Refer toLAN-23, "

CAN COMMUNICATION"

OK or NG

OK >> GO TO 2.

NG >> In addition, it is necessary to check CAN communication line. Refer toLAN-23, "

CAN COMMUNI-

CATION".

2.CHECK FRONT AIR CONTROL

Front air control check is executed. Refer toAT C - 3 2 , "

CAN Communication System Description".

OK or NG

OK >> Check the condition of the harness and the connector

NG >> Replace front air control.2 - Ground : Continuity should exist.

PIIA4235E

60 - 1 : Continuity should exist.

60 - Ground : Continuity should not exist.

MIIB0621E

Is rear window defogger indicator illuminates on the display panel?

Page 1747 of 3171

REAR WINDOW DEFOGGER

GW-61

C

D

E

F

G

H

J

K

L

MA

B

GW

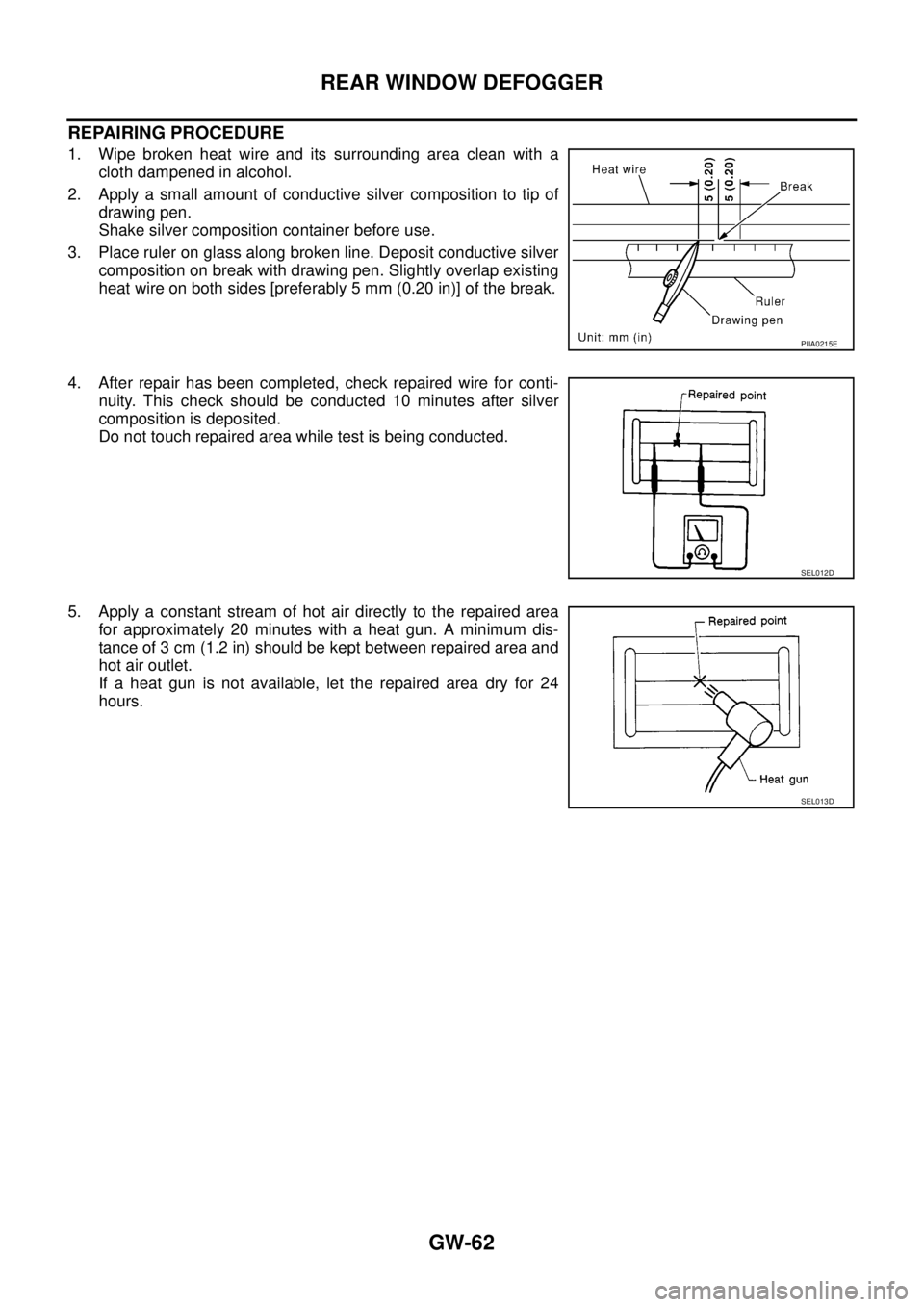

Filament CheckEIS00B8W

1. When measuring voltage, wrap tin foil around the top of the neg-

ative probe.Then press the foil against the wire with your finger.

2. Attach probe circuit tester (in Volt range) to middle portion of

each filament.

3. If a filament is burned out, circuit tester registers 0 or battery

voltage.

4. To locate burned out point, move probe to left and right along fil-

ament. Test needle will swing abruptly when probe passes the

point.

Filament RepairEIS00B8X

REPAIR EQUIPMENT

lConductive silver composition (DuPont No. 4817 or equivalent)

lRuler 30 cm (11.8 in) long

lDrawing pen

lHeat gun

lAlcohol

lCloth

SEL122R

SEL263

SEL265

Page 1748 of 3171

GW-62

REAR WINDOW DEFOGGER

REPAIRING PROCEDURE

1. Wipe broken heat wire and its surrounding area clean with a

cloth dampened in alcohol.

2. Apply a small amount of conductive silver composition to tip of

drawing pen.

Shake silver composition container before use.

3. Place ruler on glass along broken line. Deposit conductive silver

composition on break with drawing pen. Slightly overlap existing

heat wire on both sides [preferably 5 mm (0.20 in)] of the break.

4. After repair has been completed, check repaired wire for conti-

nuity. This check should be conducted 10 minutes after silver

composition is deposited.

Do not touch repaired area while test is being conducted.

5. Apply a constant stream of hot air directly to the repaired area

for approximately 20 minutes with a heat gun. A minimum dis-

tance of 3 cm (1.2 in) should be kept between repaired area and

hot air outlet.

If a heat gun is not available, let the repaired area dry for 24

hours.

PIIA0215E

SEL012D

SEL013D

Page 1749 of 3171

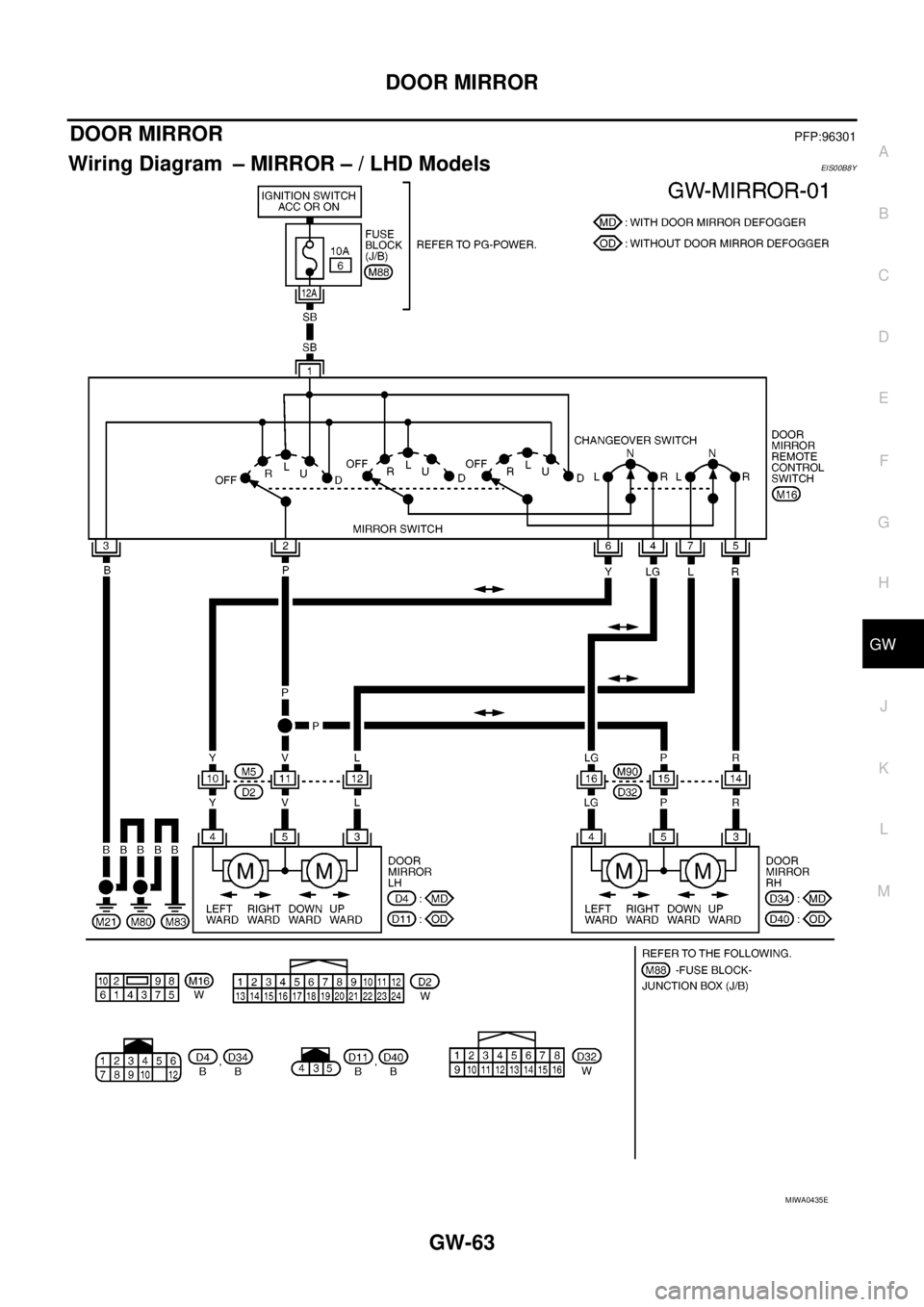

DOOR MIRROR

GW-63

C

D

E

F

G

H

J

K

L

MA

B

GW

DOOR MIRRORPFP:96301

Wiring Diagram – MIRROR – / LHD ModelsEIS00B8Y

MIWA0435E

Page 1750 of 3171

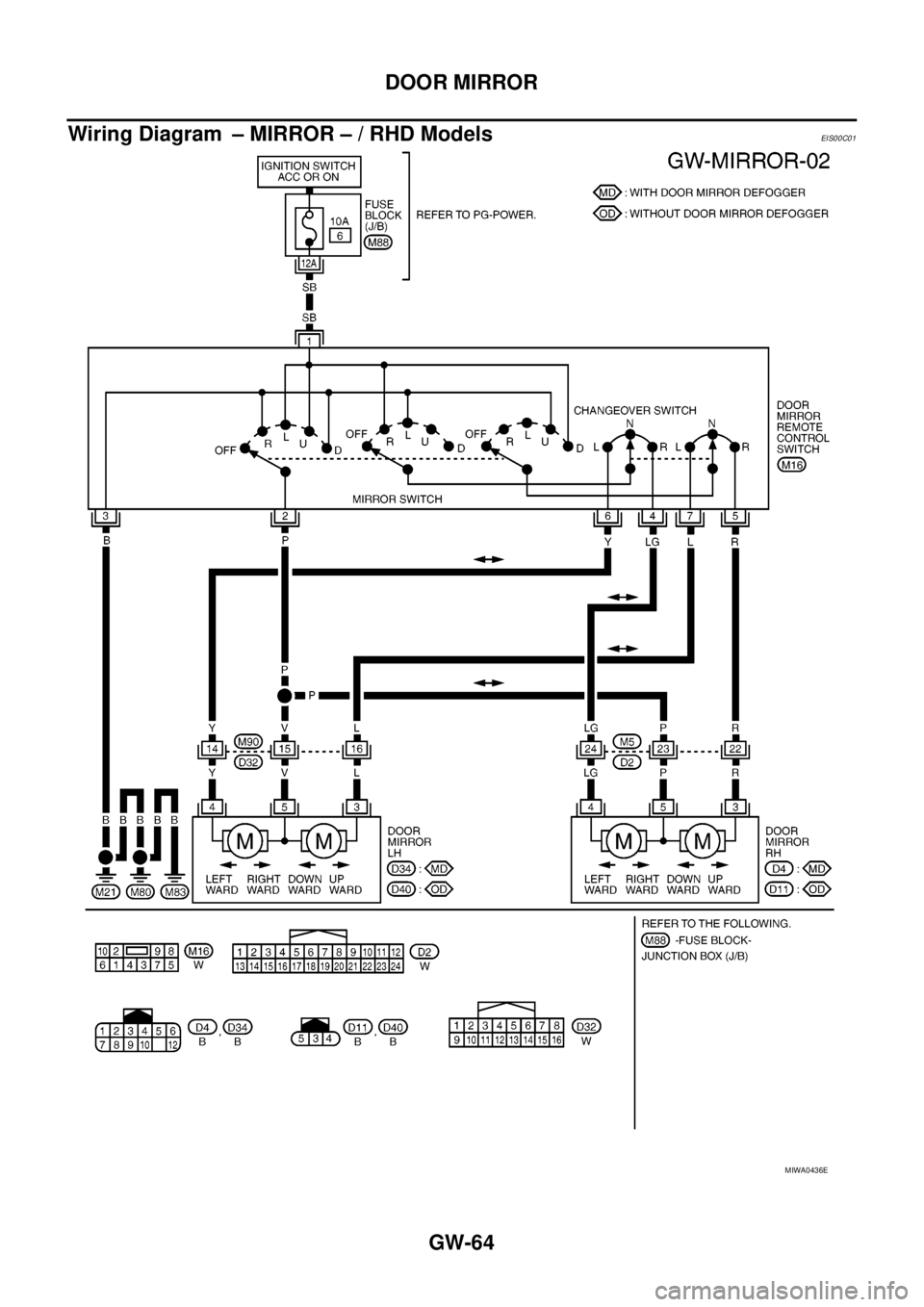

GW-64

DOOR MIRROR

Wiring Diagram – MIRROR – / RHD Models

EIS00C01

MIWA0436E