NISSAN NAVARA 2005 Repair Workshop Manual

Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2081 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual LAN-304

[CAN]

TROUBLE DIAGNOSIS FOR SYSTEM

3.CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between data link connector M45 terminals 6, 14

and ground.

OK or NG

OK >> GO TO 4.

NG >>

lRepair harness. NISSAN NAVARA 2005 Repair Workshop Manual LAN-304

[CAN]

TROUBLE DIAGNOSIS FOR SYSTEM

3.CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between data link connector M45 terminals 6, 14

and ground.

OK or NG

OK >> GO TO 4.

NG >>

lRepair harness.](/img/5/57362/w960_57362-2080.png)

LAN-304

[CAN]

TROUBLE DIAGNOSIS FOR SYSTEM

3.CHECK HARNESS FOR SHORT CIRCUIT

Check continuity between data link connector M45 terminals 6, 14

and ground.

OK or NG

OK >> GO TO 4.

NG >>

lRepair harness.

lChange harness if shielded lines are used for the har-

ness.

4.ECM AND IPDM E/R INTERNAL CIRCUIT INSPECTION

1. Remove ECM and IPDM E/R from vehicle.

2. Check resistance between ECM terminals.

3. Check resistance between IPDM E/R terminals.

OK or NG

OK >> GO TO 5.

NG >> Replace ECM and/or IPDM E/R.

5.CHECK SYMPTOM

1. Fill in described symptoms on the column “Symptom” in the check sheet.

2. Connect all connectors, and then make sure that the symptom is reproduced.

OK or NG

OK >> GO TO 6.

NG >> Refer toLAN-13, "

Example of Filling in Check Sheet When Initial Conditions Are Not Reproduced"

.

6.UNIT REPRODUCIBILITY INSPECTION

Perform the following procedure for each unit on the CAN network, and then perform reproducibility test.

1. Turn ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect the unit connector.

4. Connect the battery cable to the negative terminal.

5. Make sure that the symptom filled in the “Symptom” of the check sheet is reproduced. (Do not confuse it

with the symptom related to removed unit.)

6. Make sure that the same symptom is reproduced.

Inspection results

Reproduced>>Install removed unit, and then check the other unit.

Not reproduced>>Replace removed unit.

IPDM E/R Ignition Relay Circuit InspectionEKS00O5C

Check the following. If no malfunction is found, replace the IPDM E/R.

lIPDM E/R power supply circuit. Refer toPG-24, "Check IPDM E/R Power Supply and Ground Circuit". 6 – Ground : Continuity should not exist.

14 – Ground : Continuity should not exist.

PKIA9872E

Terminal Resistance (Approx.)

95 87 108 – 132W

Terminal Resistance (Approx.)

39 40 108 – 132W

LKIA0037E

Page 2082 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYSTEM

LAN-305

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

lIgnition power supply circuit. Refer toPG-12, "IGNITION POWER SUPPLY—IGNITION SW. IN ON

AND/OR START". NISSAN NAVARA 2005 Repair Workshop Manual TROUBLE DIAGNOSIS FOR SYSTEM

LAN-305

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

lIgnition power supply circuit. Refer toPG-12, "IGNITION POWER SUPPLY—IGNITION SW. IN ON

AND/OR START".](/img/5/57362/w960_57362-2081.png)

TROUBLE DIAGNOSIS FOR SYSTEM

LAN-305

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

lIgnition power supply circuit. Refer toPG-12, "IGNITION POWER SUPPLY—IGNITION SW. IN ON

AND/OR START".

Page 2083 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual LAN-306

[CAN]

TROUBLE DIAGNOSIS FOR SYSTEM NISSAN NAVARA 2005 Repair Workshop Manual LAN-306

[CAN]

TROUBLE DIAGNOSIS FOR SYSTEM](/img/5/57362/w960_57362-2082.png)

LAN-306

[CAN]

TROUBLE DIAGNOSIS FOR SYSTEM

Page 2084 of 3171

LT-1

LIGHTING SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTIONLT

A

B

LT

LIGHTING SYSTEM

PRECAUTIONS .......................................................... 4

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 4

General Precautions for Service Operations ............ 4

Wiring Diagrams and Trouble Diagnosis .................. 4

HEADLAMP -CONVENTIONAL TYPE- ..................... 5

Component Parts and Harness Connector Location..... 5

System Description .................................................. 5

OUTLINE ............................................................... 5

FRIENDLY LIGHTING FUNCTION ....................... 6

CAN Communication System Description ................ 6

Schematic ................................................................ 7

Wiring Diagram - H/LAMP - ...................................... 8

Terminals and Reference Value for BCM ............... 12

Terminals and Reference Values for IPDM E/R ..... 12

How to Proceed With Trouble Diagnosis ................ 13

Preliminary Check .................................................. 13

CHECK POWER SUPPLY AND GROUND CIR-

CUIT .................................................................... 13

CONSULT-II Functions (BCM) ............................... 15

CONSULT-II BASIC OPERATION ....................... 15

WORK SUPPORT ............................................... 16

DATA MONITOR ................................................. 16

ACTIVE TEST ..................................................... 17

CONSULT-II Functions (IPDM E/R) ....................... 18

CONSULT-II BASIC OPERATION ....................... 18

DATA MONITOR ................................................. 19

ACTIVE TEST ..................................................... 19

Headlamp High Beam Does Not Illuminate (Both

Sides) ..................................................................... 20

Headlamp HI Beam Does Not Illuminate (One Side)... 22

High Beam Indicator Lamp Does Not Illuminate .... 23

Headlamp LO Beam Does Not Illuminate (Both

Sides) ..................................................................... 23

Headlamp LO Beam Does Not Illuminate (One Side)

... 25

Headlamps Do Not Turn OFF ................................ 26

Aiming Adjustment ................................................. 28

LOW BEAM AND HIGH BEAM ........................... 28Bulb Replacement .................................................. 29

HEADLAMP HIGH/LOW BEAM .......................... 29

FRONT TURN SIGNAL LAMP ............................ 29

CLEARANCE LAMP ............................................ 29

Removal and Installation ........................................ 30

REMOVAL ........................................................... 30

INSTALLATION ................................................... 30

Disassembly and Assembly .................................... 30

DISASSEMBLY ................................................... 30

HEADLAMP - DAYTIME LIGHT SYSTEM - ............. 31

Component Parts and Harness Connector Location... 31

System Description ................................................. 31

OUTLINE ............................................................. 32

DAYTIME LIGHT OPERATION ........................... 32

COMBINATION SWITCH READING FUNCTION... 33

AUTO LIGHT OPERATION ................................. 33

CAN Communication System Description .............. 33

CAN Communication Unit ....................................... 33

Schematic ............................................................... 34

Wiring Diagram — DTRL — ................................... 35

Terminals and Reference Values for BCM .............. 39

Terminals and Reference Values for IPDM E/R ...... 39

How to Proceed With Trouble Diagnosis ................ 40

Preliminary Check .................................................. 40

CHECK POWER SUPPLY AND GROUND CIR-

CUIT .................................................................... 40

CONSULT-II Functions (BCM) ................................ 42

CONSULT-II BASIC OPERATION ....................... 42

DATA MONITOR ................................................. 43

ACTIVE TEST ..................................................... 44

CONSULT-II Functions (IPDM E/R) ........................ 45

CONSULT-II BASIC OPERATION ....................... 45

DATA MONITOR ................................................. 46

ACTIVE TEST ..................................................... 46

Daytime Light Control Does Not Operate Properly

(Normal Headlamps Operate Properly) .................. 47

Aiming Adjustment .................................................. 48

Bulb Replacement .................................................. 48

Removal and Installation ........................................ 48

Disassembly and Assembly .................................... 48

Page 2085 of 3171

LT-2

AUTO LIGHT SYSTEM ............................................. 49

Component Parts and Harness Connector Location... 49

System Description ................................................. 49

OUTLINE ............................................................. 49

COMBINATION SWITCH READING FUNCTION... 50

CAN Communication System Description .............. 50

Major Components and Functions .......................... 50

Schematic ............................................................... 51

Wiring Diagram — AUTO/L — ................................ 52

Terminals and Reference Values for BCM .............. 56

Terminals and Reference Values for IPDM E/R ...... 57

How to Proceed With Trouble Diagnosis ................ 57

Preliminary Check .................................................. 58

SETTING CHANGE FUNCTIONS ....................... 58

CHECK POWER SUPPLY AND GROUND CIR-

CUIT .................................................................... 58

CONSULT-II Function (BCM) .................................. 59

CONSULT-II OPERATION ................................... 59

WORK SUPPORT ............................................... 60

DATA MONITOR .................................................. 60

ACTIVE TEST ..................................................... 61

Trouble Diagnosis Chart by Symptom .................... 62

Lighting Switch Inspection ...................................... 62

Light and Rain Sensor System Inspection .............. 63

Removal and Installation of Light and Rain Sensor... 65

REMOVAL ........................................................... 65

INSTALLATION .................................................... 65

HEADLAMP AIMING CONTROL (MANUAL) ........... 66

Schematic ............................................................... 66

Wiring Diagram — H/AIM — ................................... 67

Removal and Installation ........................................ 70

Switch Circuit Inspection ........................................ 70

FRONT FOG LAMP .................................................. 71

Component Parts and Harness Connector Location... 71

System Description ................................................. 71

OUTLINE ............................................................. 71

COMBINATION SWITCH READING FUNCTION... 72

CAN Communication System Description .............. 72

Schematic ............................................................... 73

Wiring Diagram — F/FOG — .................................. 74

Terminals and Reference Values for BCM .............. 77

Terminals and Reference Values for IPDM E/R ...... 77

How to Proceed With Trouble Diagnosis ................ 78

Preliminary Check .................................................. 78

CHECK POWER SUPPLY AND GROUND CIR-

CUIT .................................................................... 78

CONSULT-II Functions (BCM) ................................ 79

CONSULT-II Functions (IPDM E/R) ........................ 79

Front Fog Lamps Do Not Illuminate (Both Sides) ... 80

Front Fog Lamp Does Not Illuminate (One Side) ... 82

Front Fog Lamp Indicator Lamp Does Not Illuminate... 83

Front Fog Lamps Do Not Turn OFF ........................ 84

Aiming Adjustment .................................................. 85

Bulb Replacement .................................................. 86

Removal and Installation of Front Fog Lamp .......... 86

REMOVAL ........................................................... 86

INSTALLATION .................................................... 86

REAR FOG LAMP ..................................................... 87

Component Parts and Harness Connector Location... 87System Description ................................................. 87

OUTLINE ............................................................. 87

COMBINATION SWITCH READING FUNCTION... 88

CAN Communication System Description .............. 88

CAN Communication Unit ....................................... 88

Wiring Diagram — R/FOG — .................................. 89

Terminals and Reference Values for BCM .............. 91

How to Proceed With Trouble Diagnosis ................ 91

Preliminary Check ................................................... 92

CHECK POWER SUPPLY AND GROUND CIR-

CUIT ..................................................................... 92

CONSULT-II Functions (BCM) ................................ 93

Rear Fog Lamp Does Not Operate ......................... 93

Rear Fog Lamp Indicator Lamp Does Not Illuminate... 95

Rear Fog Lamp Does Not Turn OFF ....................... 96

Bulb Replacement ................................................... 96

Removal and Installation ......................................... 96

TURN SIGNAL AND HAZARD WARNING LAMPS... 97

Component Parts and Harness Connector Location... 97

System Description ................................................. 97

OUTLINE ............................................................. 97

TURN SIGNAL OPERATION ............................... 97

HAZARD LAMP OPERATION ............................. 98

REMOTE KEYLESS ENTRY SYSTEM OPERA-

TION .................................................................... 99

COMBINATION SWITCH READING FUNCTION... 99

CAN Communication System Description .............. 99

Wiring Diagram — TURN — .................................100

Terminals and Reference Values for BCM ............102

How to Proceed With Trouble Diagnosis ..............103

Preliminary Check .................................................103

CHECK POWER SUPPLY AND GROUND CIR-

CUIT ...................................................................103

CONSULT-II Function (BCM) ................................105

CONSULT-II OPERATION .................................105

DATA MONITOR ................................................106

ACTIVE TEST ....................................................106

Turn Signal Lamp Does Not Operate ....................107

Hazard Warning Lamp Does Not Operate But Turn

Signal Lamps Operate ..........................................109

Turn Signal Indicator Lamp Does Not Operate .....110

Bulb Replacement (Front Turn Signal Lamp) ........ 111

Bulb Replacement (Rear Turn Signal Lamp) ........ 111

Bulb Replacement (Side Turn Signal Lamp) ......... 111

Removal and Installation of Front Turn Signal Lamp. 111

Removal and Installation of Rear Turn Signal Lamp. 111

Removal and Installation of Side Turn Signal Lamp. 111

REMOVAL .......................................................... 111

INSTALLATION .................................................. 111

LIGHTING AND TURN SIGNAL SWITCH ..............112

Removal and Installation .......................................112

REMOVAL ..........................................................112

INSTALLATION ..................................................112

HAZARD SWITCH ...................................................113

Removal and Installation .......................................113

REMOVAL ..........................................................113

INSTALLATION ..................................................113

COMBINATION SWITCH ........................................114

Wiring Diagram — COMBSW — ..........................114

Page 2086 of 3171

LT-3

C

D

E

F

G

H

I

J

L

MA

B

LT Combination Switch Reading Function ................. 115

CONSULT-II Function (BCM) ................................ 115

CONSULT-II OPERATION ................................. 115

DATA MONITOR ................................................ 116

Combination Switch Inspection ............................. 118

Removal and Installation ...................................... 120

Switch Circuit Inspection ...................................... 120

STOP LAMP ........................................................... 121

Wiring Diagram — STOP/L — .............................. 121

Bulb Replacement ................................................ 122

Removal and Installation ...................................... 122

BACK-UP LAMP .................................................... 123

Wiring Diagram — BACK/L — ............................. 123

Bulb Replacement ................................................ 124

Removal and Installation ...................................... 124

PARKING, LICENSE PLATE AND TAIL LAMPS ... 125

Component Parts and Harness Connector Location. 125

System Description .............................................. 125

OUTLINE ........................................................... 125

OPERATION BY LIGHTING SWITCH .............. 126

COMBINATION SWITCH READING FUNCTION. 126

CAN Communication System Description ............ 126

Schematic ............................................................ 127

WITHOUT DAYTIME LIGHT SYSTEM ............. 127

Wiring Diagram — TAIL/L — ................................ 128

WITHOUT DAYTIME LIGHT SYSTEM ............. 128

Schematic ............................................................ 131

WITH DAYTIME LIGHT SYSTEM ..................... 131

Wiring Diagram — TAIL/L — ................................ 132

WITH DAYTIME LIGHT SYSTEM ..................... 132

Terminals and Reference Values for BCM ........... 135

Terminals and Reference Values for IPDM E/R ... 135

How to Proceed With Trouble Diagnosis .............. 136

Preliminary Check ................................................ 136

CHECK POWER SUPPLY AND GROUND CIR-

CUIT .................................................................. 136

CONSULT-II Functions (BCM) ............................. 137

CONSULT-II Functions (IPDM E/R) ..................... 137

Clarence, License Plate and Tail Lamps Do Not Illu-

minate .................................................................. 138

Clearance, License Plate and Tail Lamps Do Not

Turn OFF (After Approx. 10 Minutes) ................... 141

Front Clearance Lamp ......................................... 142BULB REPLACEMENT .....................................142

Tail Lamp ..............................................................142

BULB REPLACEMENT .....................................142

REAR COMBINATION LAMP .................................143

Bulb Replacement ................................................143

REMOVAL .........................................................143

INSTALLATION .................................................143

Removal and Installation ......................................144

REMOVAL .........................................................144

INSTALLATION .................................................144

INTERIOR ROOM LAMP ........................................145

Component Parts and Harness Connector Location.145

System Description ...............................................145

POWER SUPPLY AND GROUND ....................145

SWITCH OPERATION ......................................147

ROOM LAMP TIMER OPERATION ..................147

INTERIOR LAMP BATTERY SAVER CONTROL.147

Schematic .............................................................148

Wiring Diagram — INT/L — ..................................149

Terminals and Reference Values for BCM ............154

How to Proceed With Trouble Diagnosis ..............155

Preliminary Check ................................................155

INSPECTION FOR POWER SUPPLY AND

GROUND CIRCUIT ...........................................155

CONSULT-II Function ...........................................157

CONSULT-II OPERATION .................................157

WORK SUPPORT .............................................158

DATA MONITOR ...............................................158

ACTIVE TEST ...................................................159

Map Lamp Control Does Not Operate ..................160

All Interior Room Lamps Do Not Operate .............161

ILLUMINATION .......................................................162

System Description ...............................................162

ILLUMINATION OPERATION BY LIGHTING

SWITCH ............................................................162

CAN Communication System Description ............163

CAN Communication Unit .....................................163

Schematic .............................................................164

Wiring Diagram — ILL — ......................................166

BULB SPECIFICATIONS ........................................173

Headlamp .............................................................173

Exterior Lamp .......................................................173

Interior Lamp/Illumination .....................................173

Page 2087 of 3171

LT-4

PRECAUTIONS

PRECAUTIONS

PFP:00011

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EKS00N1L

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

General Precautions for Service OperationsEKS00L4H

lNever work with wet hands.

lTurn the lighting switch OFF before disconnecting and connecting the connector.

lWhen checking the headlamp on/off operation, check it on vehicle and with the power connected to the

vehicle-side connector.

lDo not touch the headlamp bulb glass surface with bare hands or allow oil or grease to get on it. Do not

touch the headlamp bulb just after the headlamp is turned off, because it is very hot.

lWhen the bulb has burned out, wrap it in a thick vinyl bag and discard. Do not break the bulb.

lLeaving the bulb removed from the headlamp housing for a long period of time can deteriorate the perfor-

mance of the lens and reflector (dirt, clouding). Always prepare a new bulb and have it on hand when

replacing the bulb.

lDo not use organic solvent (paint thinner or gasoline) to clean lamps and to remove old sealant.

Wiring Diagrams and Trouble DiagnosisEKS00L4I

When you read wiring diagrams, refer to the following:

lRefer toGI-15, "How to Read Wiring Diagrams".

lRefer toPG-4, "POWER SUPPLY ROUTING CIRCUIT".

When you perform trouble diagnosis, refer to the following:

lRefer toGI-11, "HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES".

lRefer toGI-24, "How to Perform Efficient Diagnosis for an Electrical Incident".

Page 2088 of 3171

HEADLAMP -CONVENTIONAL TYPE-

LT-5

C

D

E

F

G

H

I

J

L

MA

B

LT

HEADLAMP -CONVENTIONAL TYPE-PFP:26010

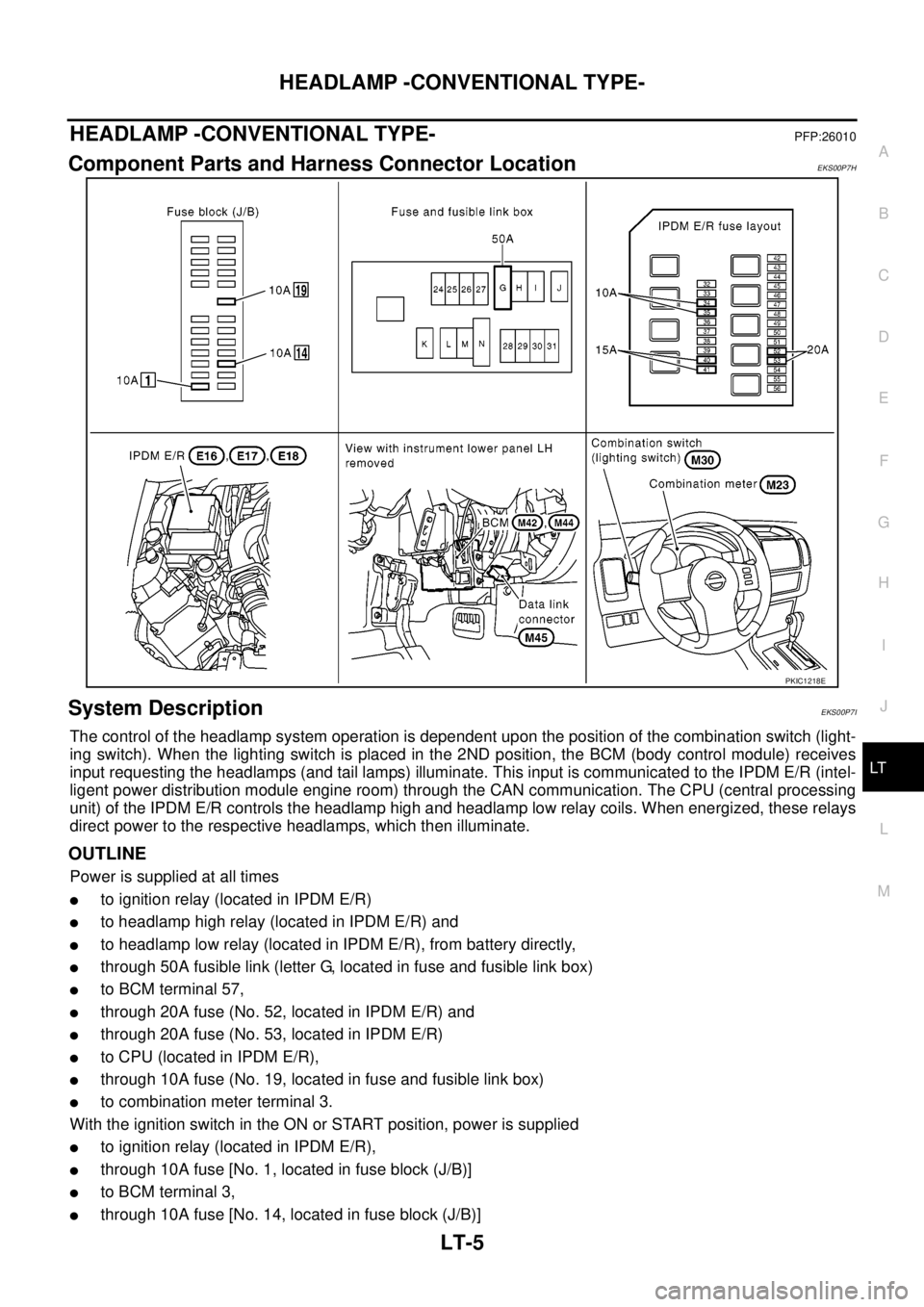

Component Parts and Harness Connector LocationEKS00P7H

System DescriptionEKS00P7I

The control of the headlamp system operation is dependent upon the position of the combination switch (light-

ing switch). When the lighting switch is placed in the 2ND position, the BCM (body control module) receives

input requesting the headlamps (and tail lamps) illuminate. This input is communicated to the IPDM E/R (intel-

ligent power distribution module engine room) through the CAN communication. The CPU (central processing

unit) of the IPDM E/R controls the headlamp high and headlamp low relay coils. When energized, these relays

direct power to the respective headlamps, which then illuminate.

OUTLINE

Power is supplied at all times

lto ignition relay (located in IPDM E/R)

lto headlamp high relay (located in IPDM E/R) and

lto headlamp low relay (located in IPDM E/R), from battery directly,

lthrough 50A fusible link (letter G, located in fuse and fusible link box)

lto BCM terminal 57,

lthrough 20A fuse (No. 52, located in IPDM E/R) and

lthrough 20A fuse (No. 53, located in IPDM E/R)

lto CPU (located in IPDM E/R),

lthrough 10A fuse (No. 19, located in fuse and fusible link box)

lto combination meter terminal 3.

With the ignition switch in the ON or START position, power is supplied

lto ignition relay (located in IPDM E/R),

lthrough 10A fuse [No. 1, located in fuse block (J/B)]

lto BCM terminal 3,

lthrough 10A fuse [No. 14, located in fuse block (J/B)]

PKIC1218E

Page 2089 of 3171

LT-6

HEADLAMP -CONVENTIONAL TYPE-

lto combination meter terminal 16.

Ground is supplied at all times

lto BCM terminal 55 and

lto combination meter terminal 23

lthrough grounds M21, M80 and M83,

lto IPDM E/R terminals 38 and 59

lthrough grounds E21, E41 and E61.

Low Beam Operation

With the lighting switch in 2ND position, the BCM receives input requesting the headlamps to illuminate. This

input is communicated to the IPDM E/R through the CAN communication. The CPU of the IPDM E/R controls

the headlamp low relay coil. When energized, this relay directs power

lthrough 15A fuse (No. 41, located in IPDM E/R)

lthrough IPDM E/R terminal 54

lto front combination lamp RH terminal 1,

lthrough 15A fuse (No. 40, located in IPDM E/R)

lthrough IPDM E/R terminal 52

lto front combination lamp LH terminal 1.

Ground is supplied

lto front combination lamp RH and LH terminals 3

lthrough grounds E21, E41 and E61.

With power and ground supplied, low beam headlamps illuminate.

High Beam Operation/Flash-to-Pass Operation

With the lighting switch in 2ND position and placed in HIGH or PASS position, the BCM receives input request-

ing the headlamp high beams to illuminate. This input is communicated to the IPDM E/R through the CAN

communication. The CPU of the IPDM E/R controls the headlamp high relay coil. When energized, this relay

directs power

lthrough 10A fuse (No. 34, located in IPDM E/R)

lthrough IPDM E/R terminal 56

lto front combination lamp RH terminal 2,

lthrough 10A fuse (No. 35, located in IPDM E/R)

lthrough IPDM E/R terminal 55

lto front combination lamp LH terminal 2.

Ground is supplied

lto front combination lamp RH and LH terminals 3

lthrough grounds E21, E41 and E61.

With power and ground supplied, the high beam headlamps illuminate.

Combination meter that received high beam request signal by BCM through the CAN communication makes a

high beam indicator lamp turn on in combination meter.

FRIENDLY LIGHTING FUNCTION

This function starts timer function of BCM by operating passing switch, and illuminates headlamps (LOW

beam) for a given length of time.

Headlamps (LOW beam) stay ON for a given length of time by operating passing switch when ignition switch is

OFF and lighting switch is OFF.

Headlamps (LOW beam) stays ON for two minutes at a maximum by operating passing switch repeatedly.

CONSULT-II is capable of setting a lighting time. Refer toLT- 1 6 , "

WORK SUPPORT".

CAN Communication System DescriptionEKS00P7J

Refer toLAN-23, "CAN COMMUNICATION".

Page 2090 of 3171

HEADLAMP -CONVENTIONAL TYPE-

LT-7

C

D

E

F

G

H

I

J

L

MA

B

LT

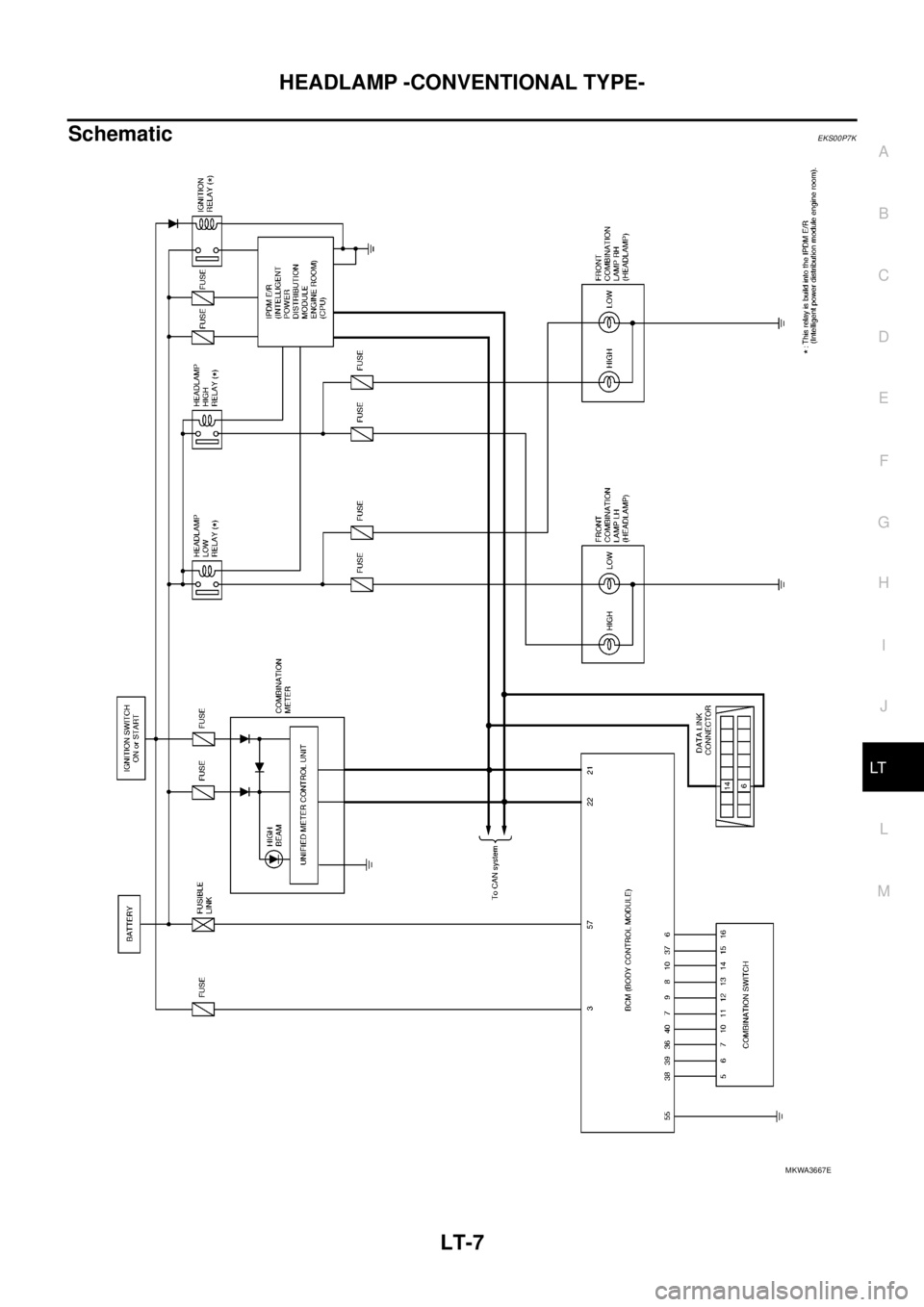

SchematicEKS00P7K

MKWA3667E