NISSAN PATROL 1998 Y61 / 5.G Electrical System Workshop Manual

PATROL 1998 Y61 / 5.G

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/616/w960_616-0.png

NISSAN PATROL 1998 Y61 / 5.G Electrical System Workshop Manual

Trending: Ac switch, brake, Engine room harness, Starter motor, sen, check engine, sub tank control system

Page 161 of 326

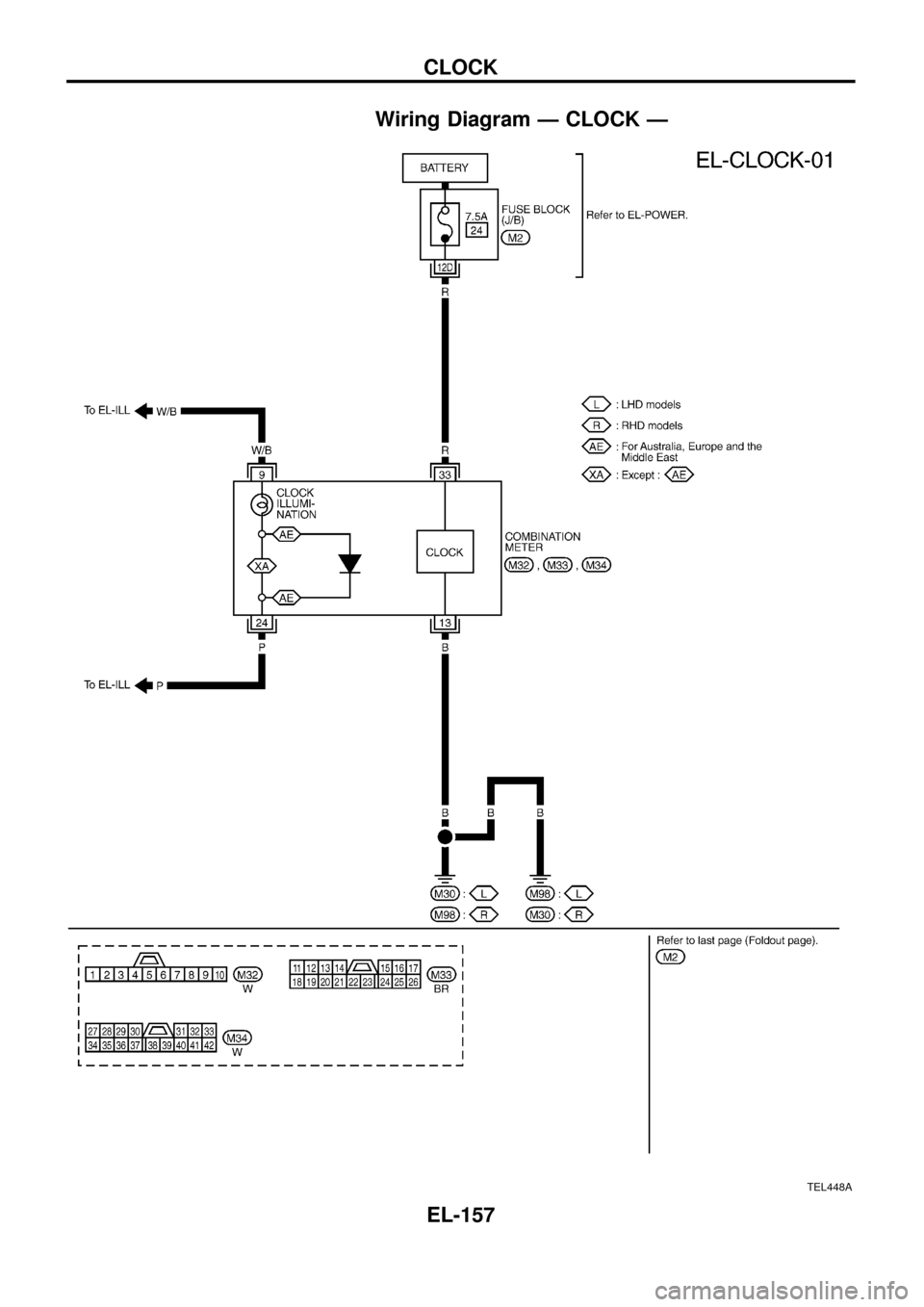

Wiring Diagram Ð CLOCK Ð

TEL448A

CLOCK

EL-157

Page 162 of 326

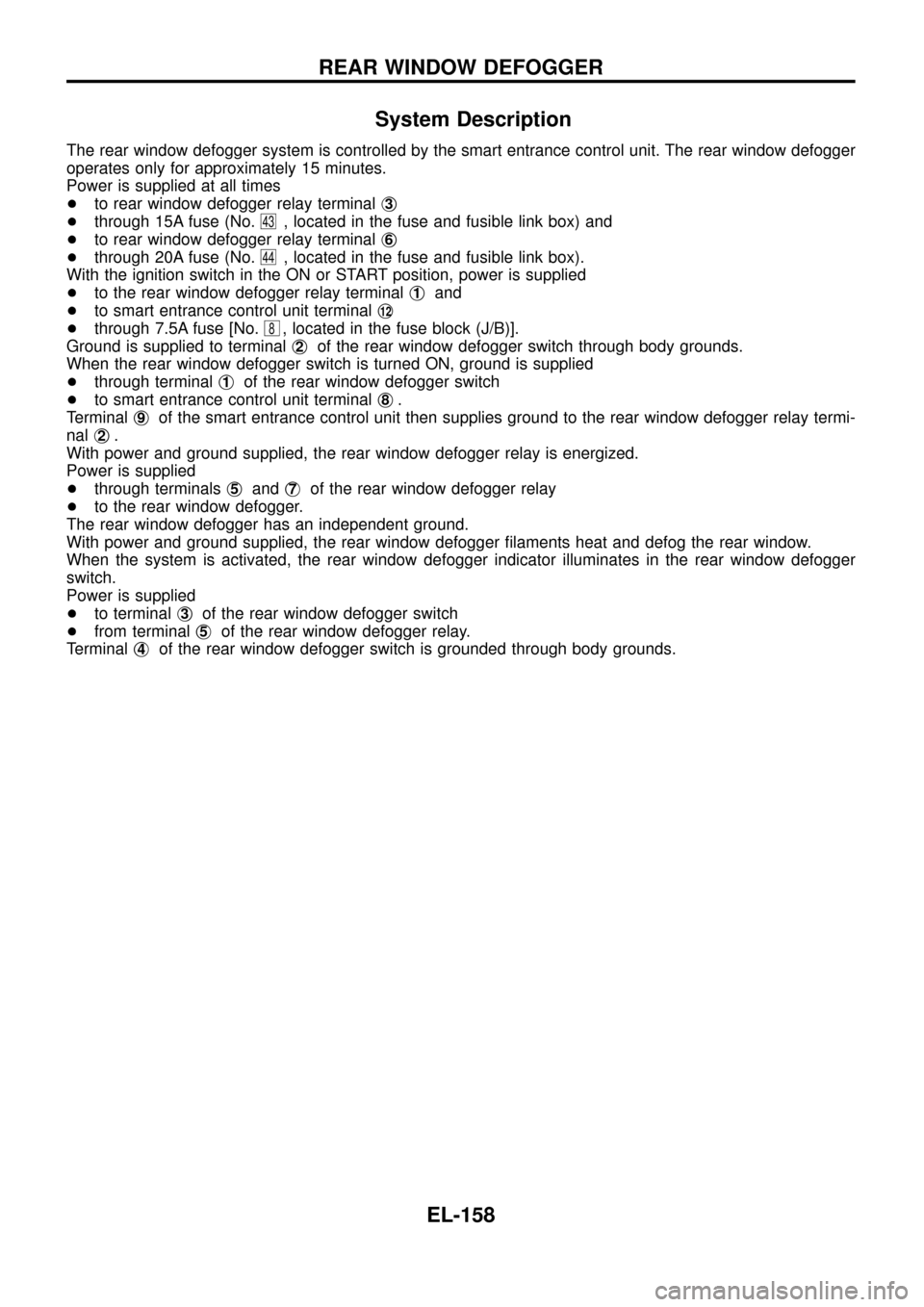

System Description

The rear window defogger system is controlled by the smart entrance control unit. The rear window defogger

operates only for approximately 15 minutes.

Power is supplied at all times

+to rear window defogger relay terminalj

3

+through 15A fuse (No.43, located in the fuse and fusible link box) and

+to rear window defogger relay terminalj

6

+through 20A fuse (No.44, located in the fuse and fusible link box).

With the ignition switch in the ON or START position, power is supplied

+to the rear window defogger relay terminalj

1and

+to smart entrance control unit terminalj

12

+through 7.5A fuse [No.8, located in the fuse block (J/B)].

Ground is supplied to terminalj

2of the rear window defogger switch through body grounds.

When the rear window defogger switch is turned ON, ground is supplied

+through terminalj

1of the rear window defogger switch

+to smart entrance control unit terminalj

8.

Terminalj

9of the smart entrance control unit then supplies ground to the rear window defogger relay termi-

nalj

2.

With power and ground supplied, the rear window defogger relay is energized.

Power is supplied

+through terminalsj

5andj7of the rear window defogger relay

+to the rear window defogger.

The rear window defogger has an independent ground.

With power and ground supplied, the rear window defogger ®laments heat and defog the rear window.

When the system is activated, the rear window defogger indicator illuminates in the rear window defogger

switch.

Power is supplied

+to terminalj

3of the rear window defogger switch

+from terminalj

5of the rear window defogger relay.

Terminalj

4of the rear window defogger switch is grounded through body grounds.

REAR WINDOW DEFOGGER

EL-158

Page 163 of 326

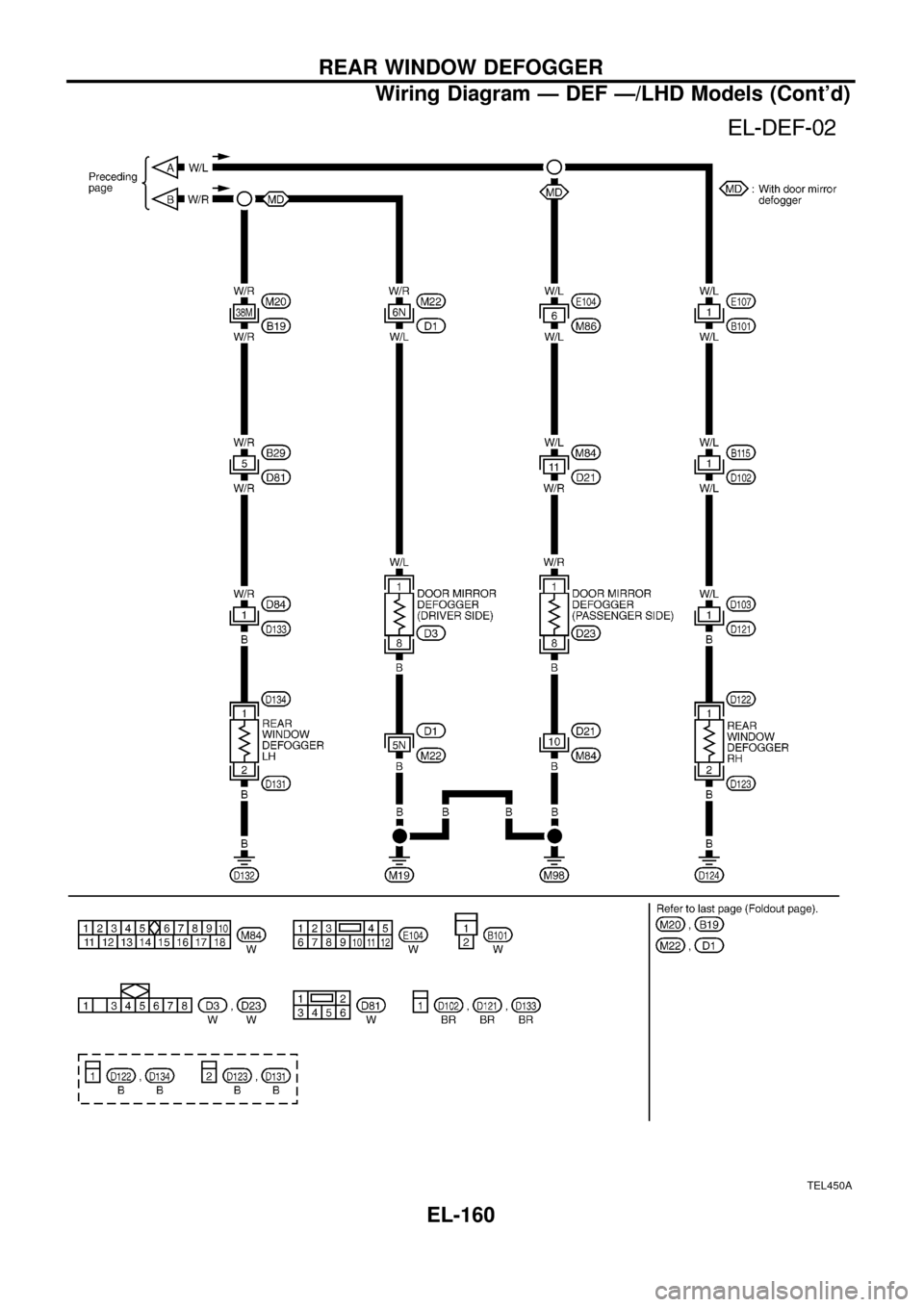

Wiring Diagram Ð DEF Ð/LHD Models

TEL449A

REAR WINDOW DEFOGGER

EL-159

Page 164 of 326

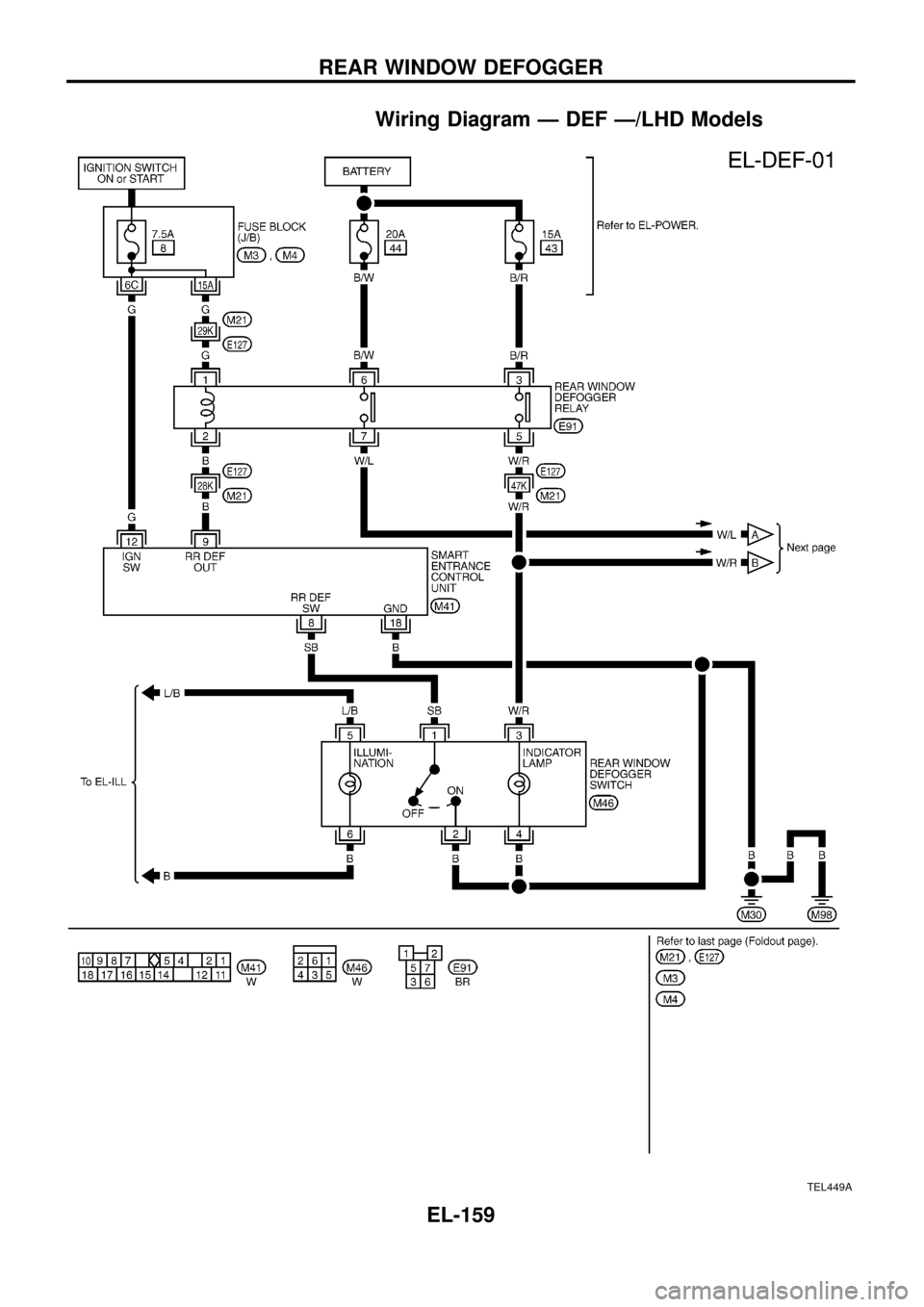

TEL450A

REAR WINDOW DEFOGGER

Wiring Diagram Ð DEF Ð/LHD Models (Cont'd)

EL-160

Page 165 of 326

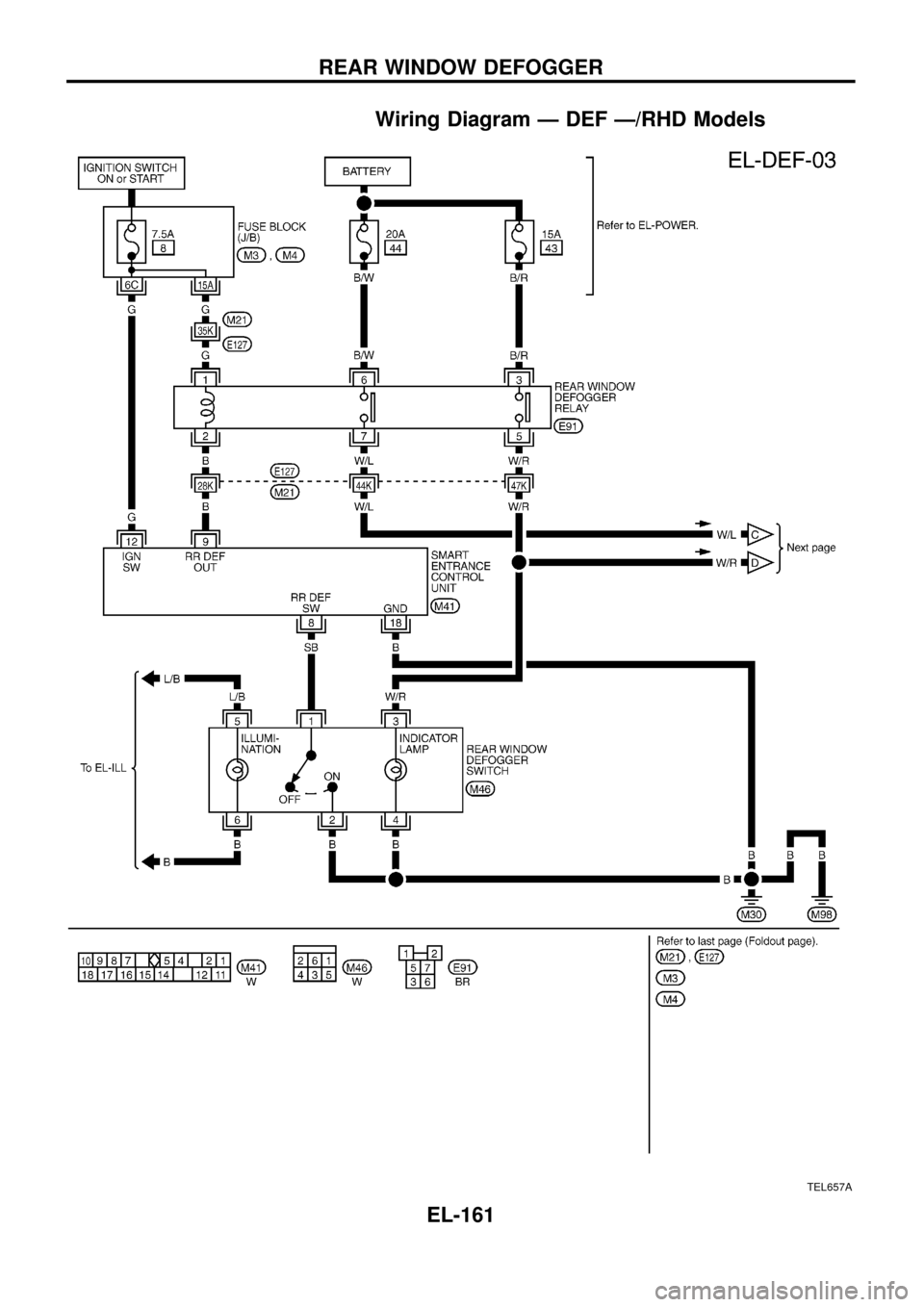

Wiring Diagram Ð DEF Ð/RHD Models

TEL657A

REAR WINDOW DEFOGGER

EL-161

Page 166 of 326

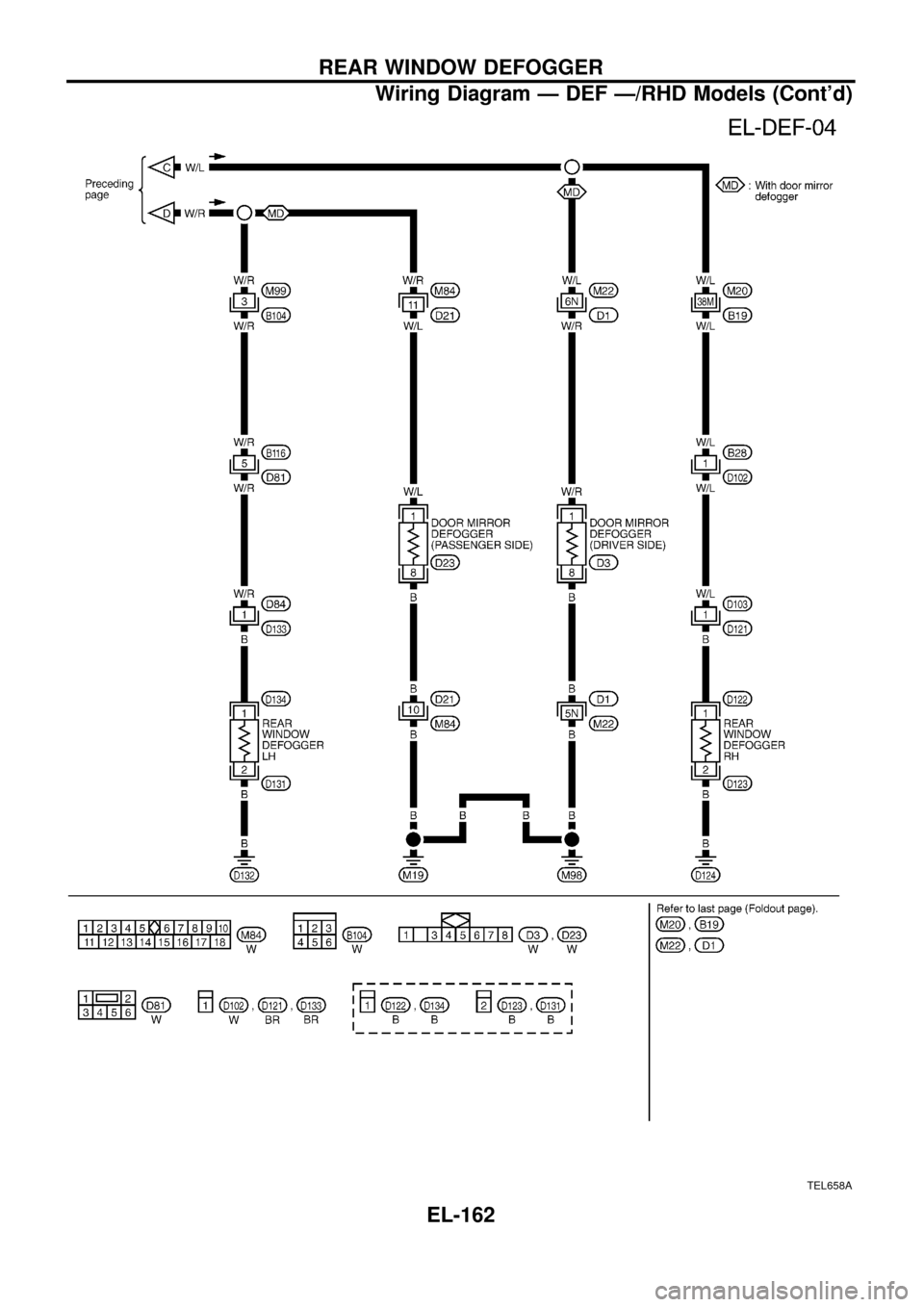

TEL658A

REAR WINDOW DEFOGGER

Wiring Diagram Ð DEF Ð/RHD Models (Cont'd)

EL-162

Page 167 of 326

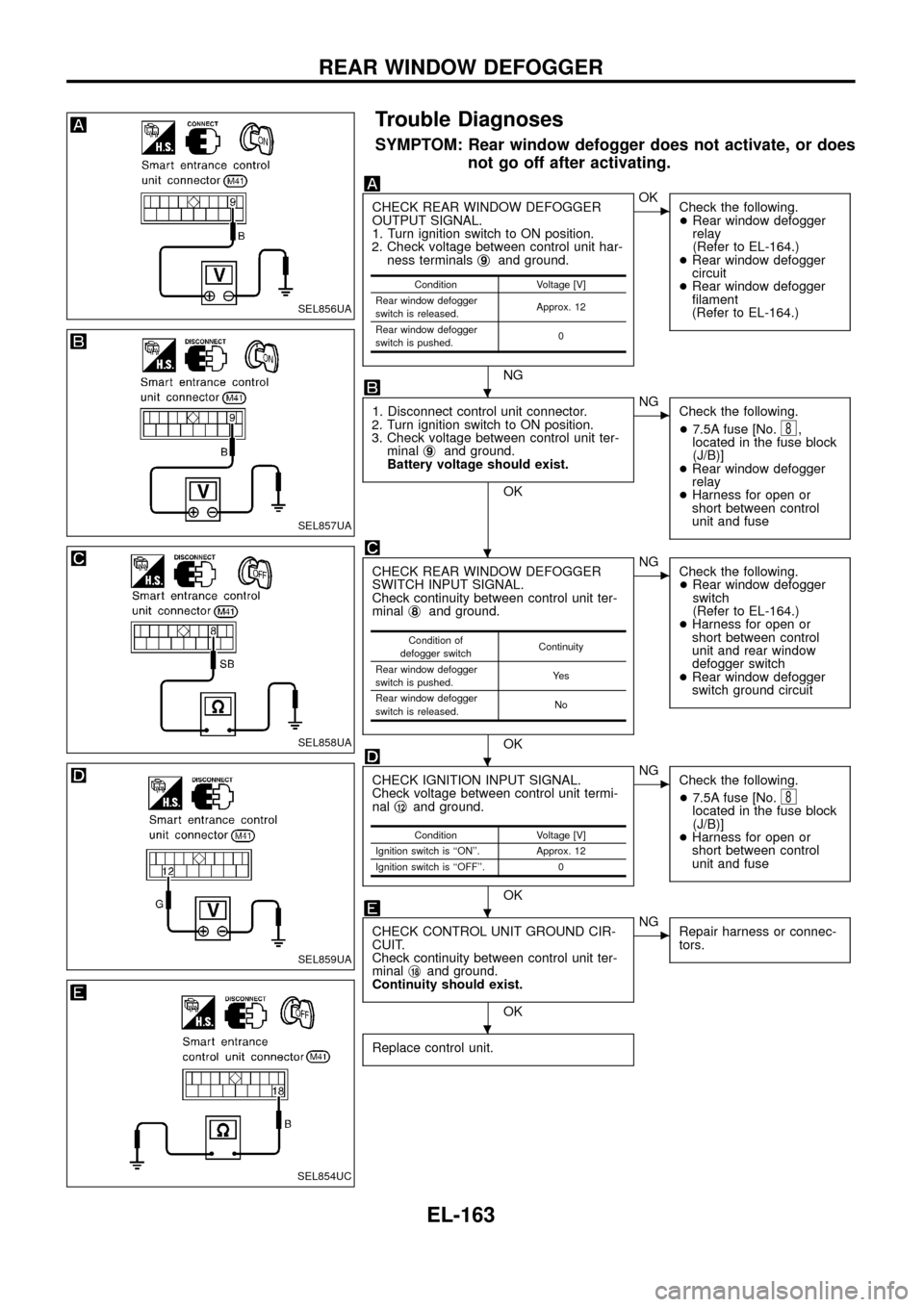

Trouble Diagnoses

SYMPTOM: Rear window defogger does not activate, or does

not go off after activating.

CHECK REAR WINDOW DEFOGGER

OUTPUT SIGNAL.

1. Turn ignition switch to ON position.

2. Check voltage between control unit har-

ness terminalsj

9and ground.

NG

cOK

Check the following.

+Rear window defogger

relay

(Refer to EL-164.)

+Rear window defogger

circuit

+Rear window defogger

®lament

(Refer to EL-164.)

1. Disconnect control unit connector.

2. Turn ignition switch to ON position.

3. Check voltage between control unit ter-

minalj

9and ground.

Battery voltage should exist.

OK

cNG

Check the following.

+7.5A fuse [No.

8,

located in the fuse block

(J/B)]

+Rear window defogger

relay

+Harness for open or

short between control

unit and fuse

CHECK REAR WINDOW DEFOGGER

SWITCH INPUT SIGNAL.

Check continuity between control unit ter-

minalj

8and ground.

OK

cNG

Check the following.

+Rear window defogger

switch

(Refer to EL-164.)

+Harness for open or

short between control

unit and rear window

defogger switch

+Rear window defogger

switch ground circuit

CHECK IGNITION INPUT SIGNAL.

Check voltage between control unit termi-

nalj

12and ground.

OK

cNG

Check the following.

+7.5A fuse [No.

8located in the fuse block

(J/B)]

+Harness for open or

short between control

unit and fuse

CHECK CONTROL UNIT GROUND CIR-

CUIT.

Check continuity between control unit ter-

minalj

18and ground.

Continuity should exist.

OK

cNG

Repair harness or connec-

tors.

Replace control unit.

Condition Voltage [V]

Rear window defogger

switch is released.Approx. 12

Rear window defogger

switch is pushed.0

Condition of

defogger switchContinuity

Rear window defogger

switch is pushed.Ye s

Rear window defogger

switch is released.No

Condition Voltage [V]

Ignition switch is ``ON''. Approx. 12

Ignition switch is ``OFF''. 0

SEL856UA

SEL857UA

SEL858UA

SEL859UA

SEL854UC

.

.

.

.

.

REAR WINDOW DEFOGGER

EL-163

Page 168 of 326

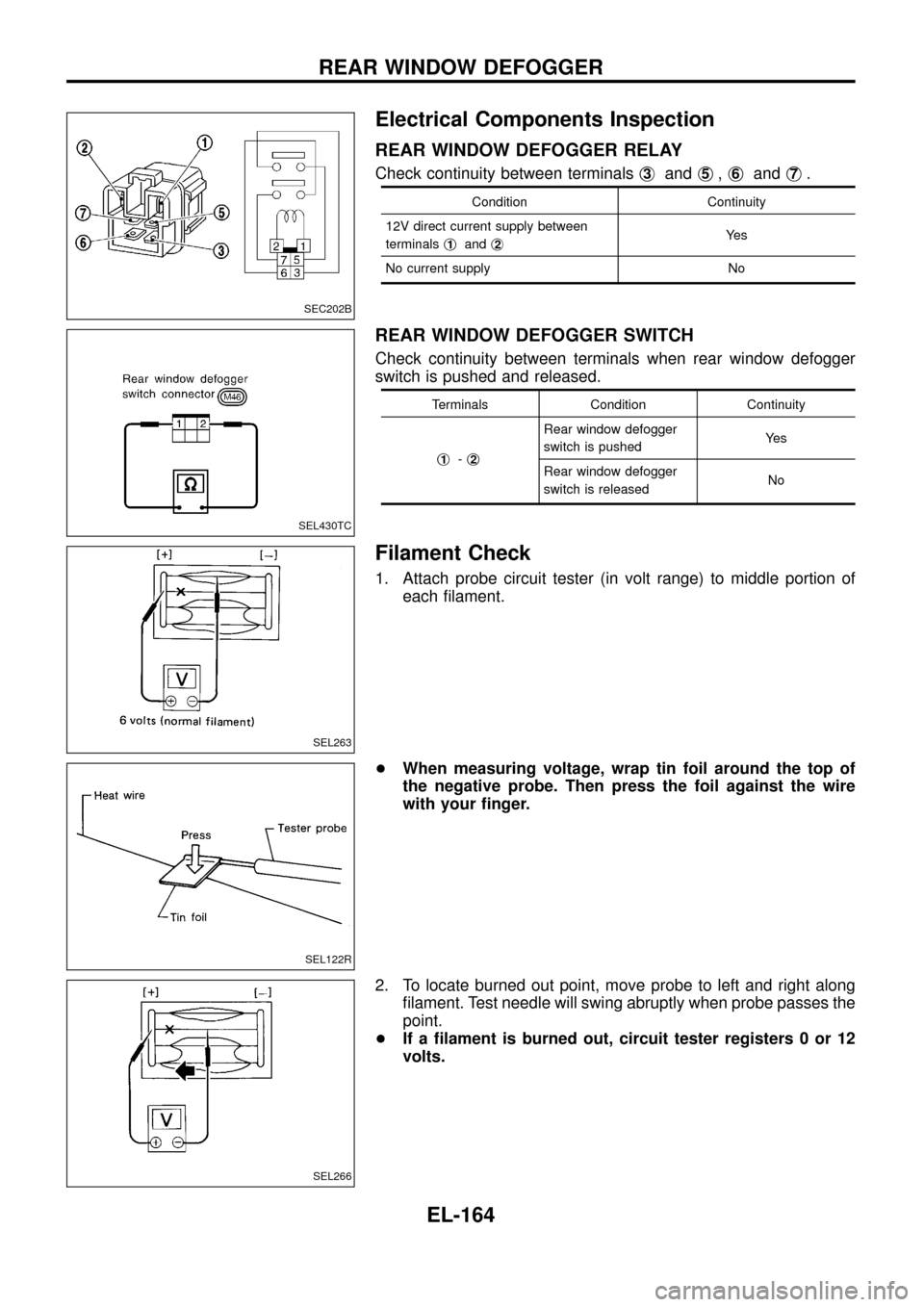

Electrical Components Inspection

REAR WINDOW DEFOGGER RELAY

Check continuity between terminalsj3andj5,j6andj7.

Condition Continuity

12V direct current supply between

terminalsj

1andj2Ye s

No current supply No

REAR WINDOW DEFOGGER SWITCH

Check continuity between terminals when rear window defogger

switch is pushed and released.

Terminals Condition Continuity

j

1-j2

Rear window defogger

switch is pushedYe s

Rear window defogger

switch is releasedNo

Filament Check

1. Attach probe circuit tester (in volt range) to middle portion of

each ®lament.

+When measuring voltage, wrap tin foil around the top of

the negative probe. Then press the foil against the wire

with your ®nger.

2. To locate burned out point, move probe to left and right along

®lament. Test needle will swing abruptly when probe passes the

point.

+If a ®lament is burned out, circuit tester registers 0 or 12

volts.

SEC202B

SEL430TC

SEL263

SEL122R

SEL266

REAR WINDOW DEFOGGER

EL-164

Page 169 of 326

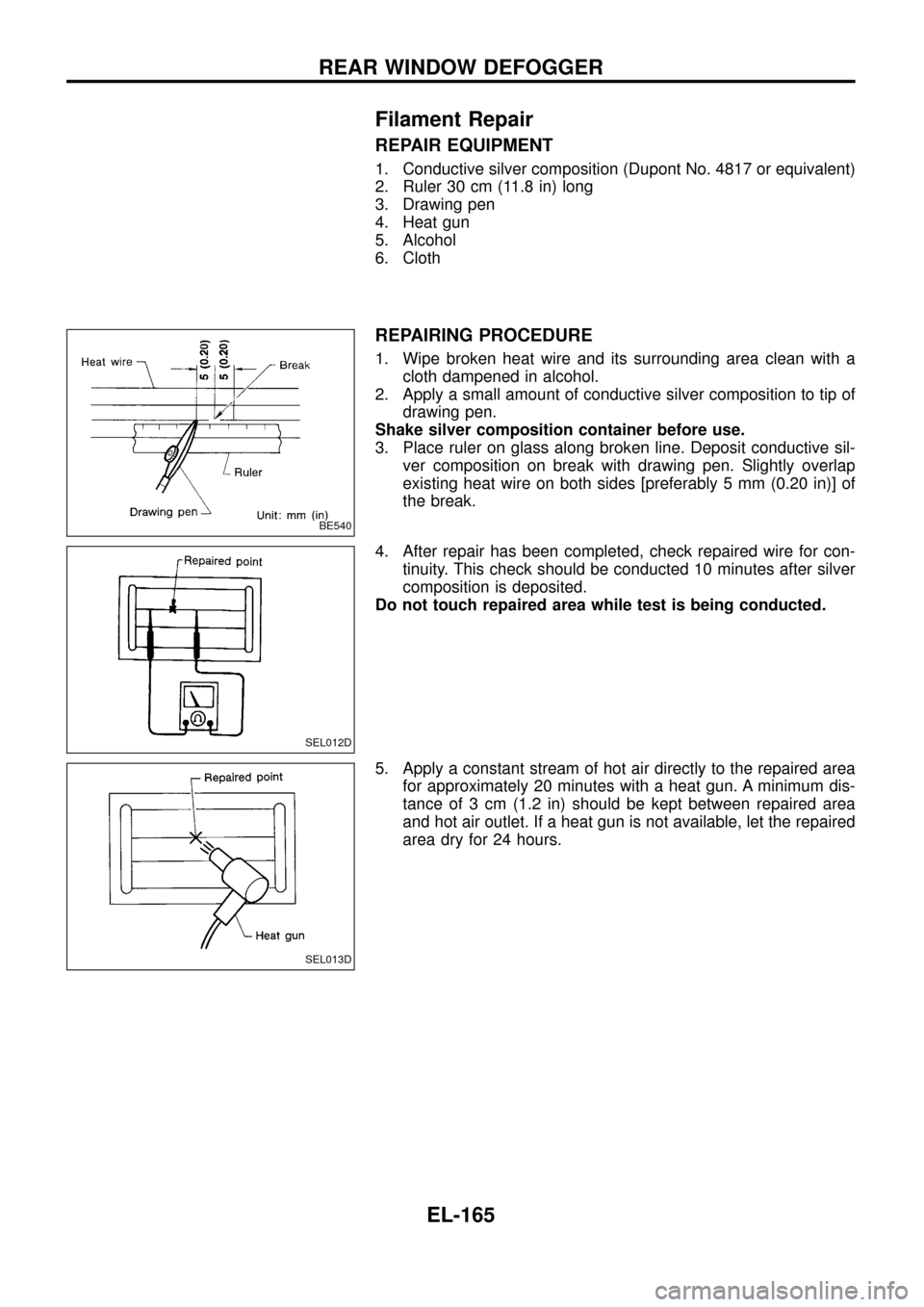

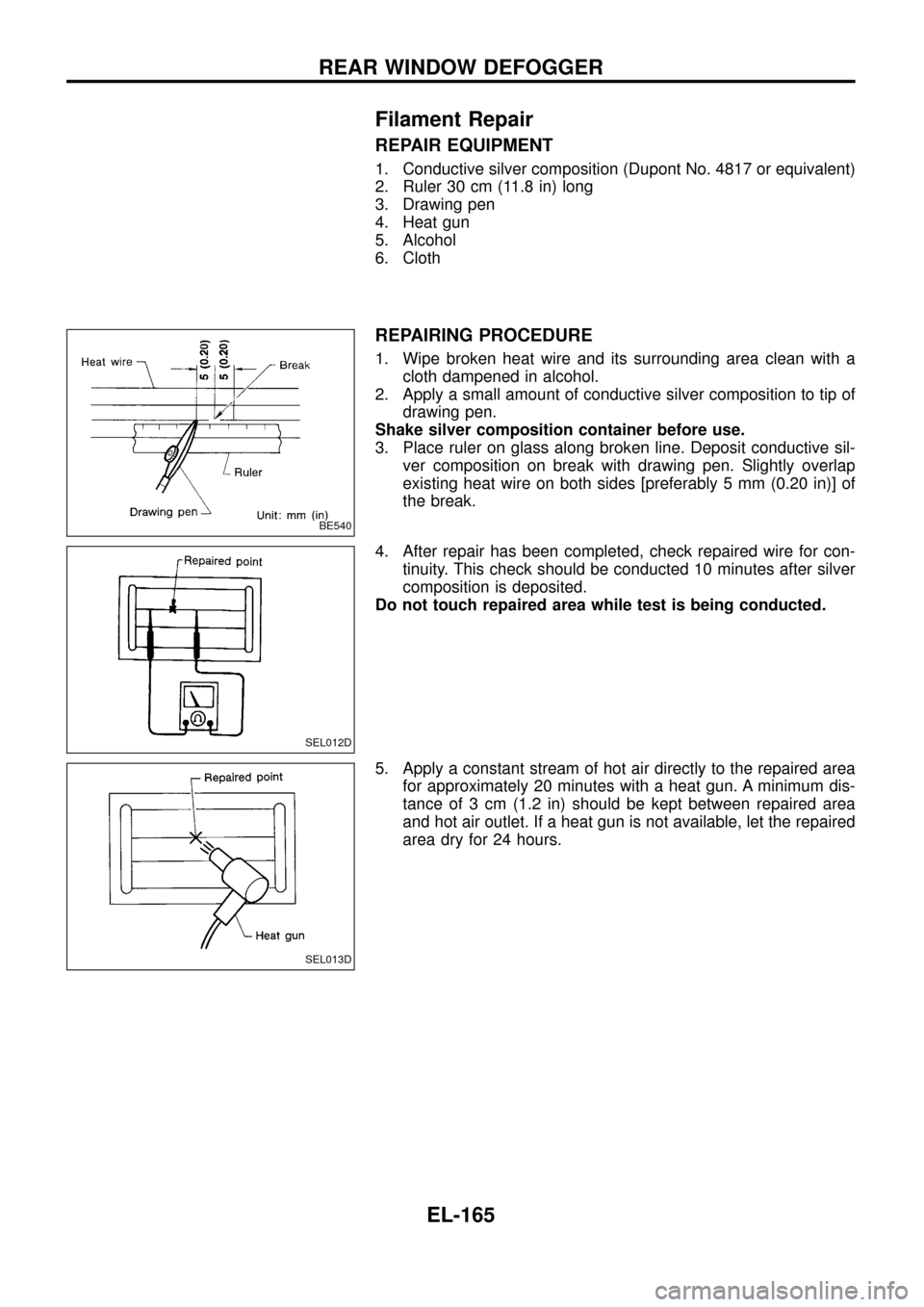

Filament Repair

REPAIR EQUIPMENT

1. Conductive silver composition (Dupont No. 4817 or equivalent)

2. Ruler 30 cm (11.8 in) long

3. Drawing pen

4. Heat gun

5. Alcohol

6. Cloth

REPAIRING PROCEDURE

1. Wipe broken heat wire and its surrounding area clean with a

cloth dampened in alcohol.

2. Apply a small amount of conductive silver composition to tip of

drawing pen.

Shake silver composition container before use.

3. Place ruler on glass along broken line. Deposit conductive sil-

ver composition on break with drawing pen. Slightly overlap

existing heat wire on both sides [preferably 5 mm (0.20 in)] of

the break.

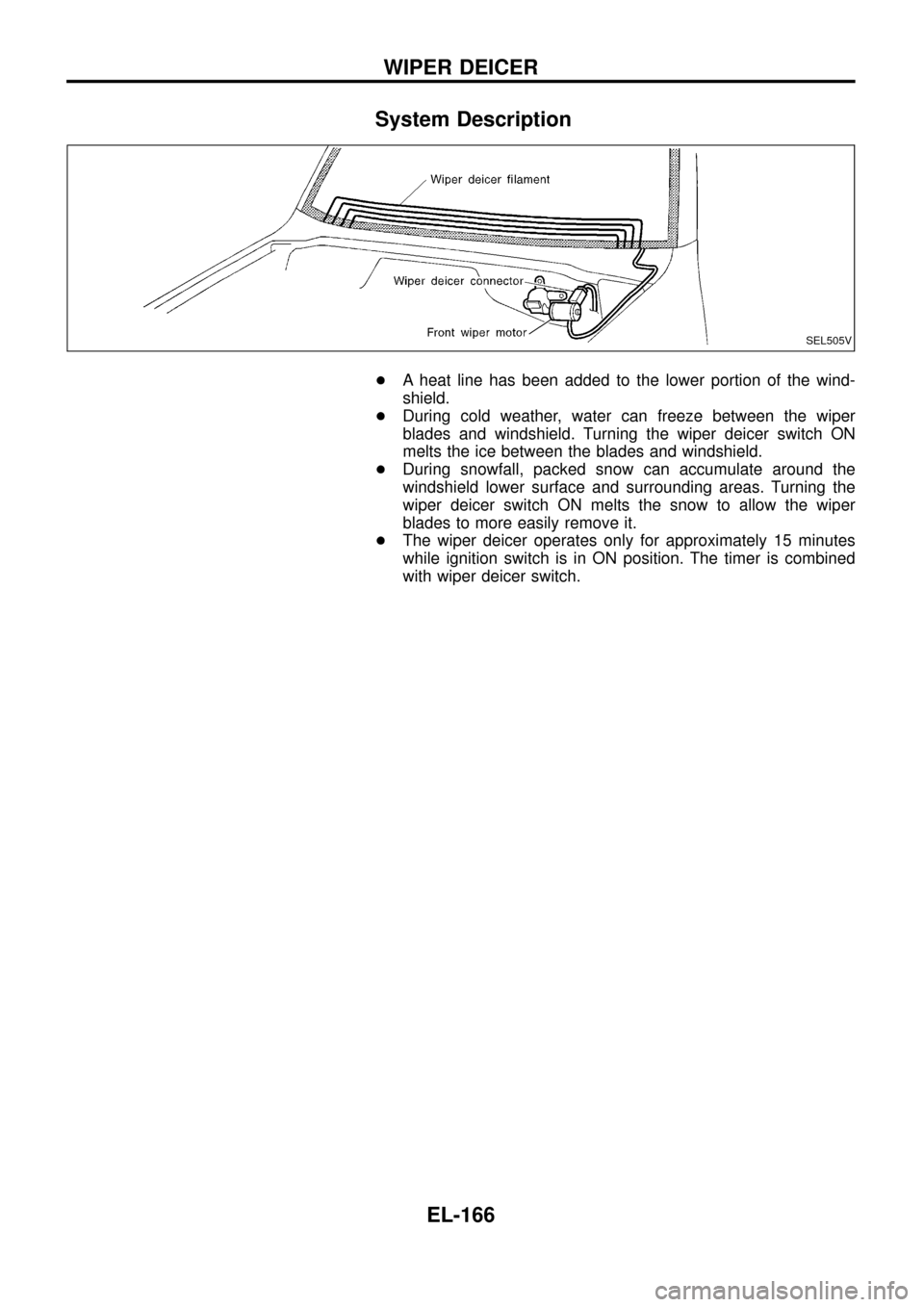

4. After repair has been completed, check repaired wire for con-

tinuity. This check should be conducted 10 minutes after silver

composition is deposited.

Do not touch repaired area while test is being conducted.

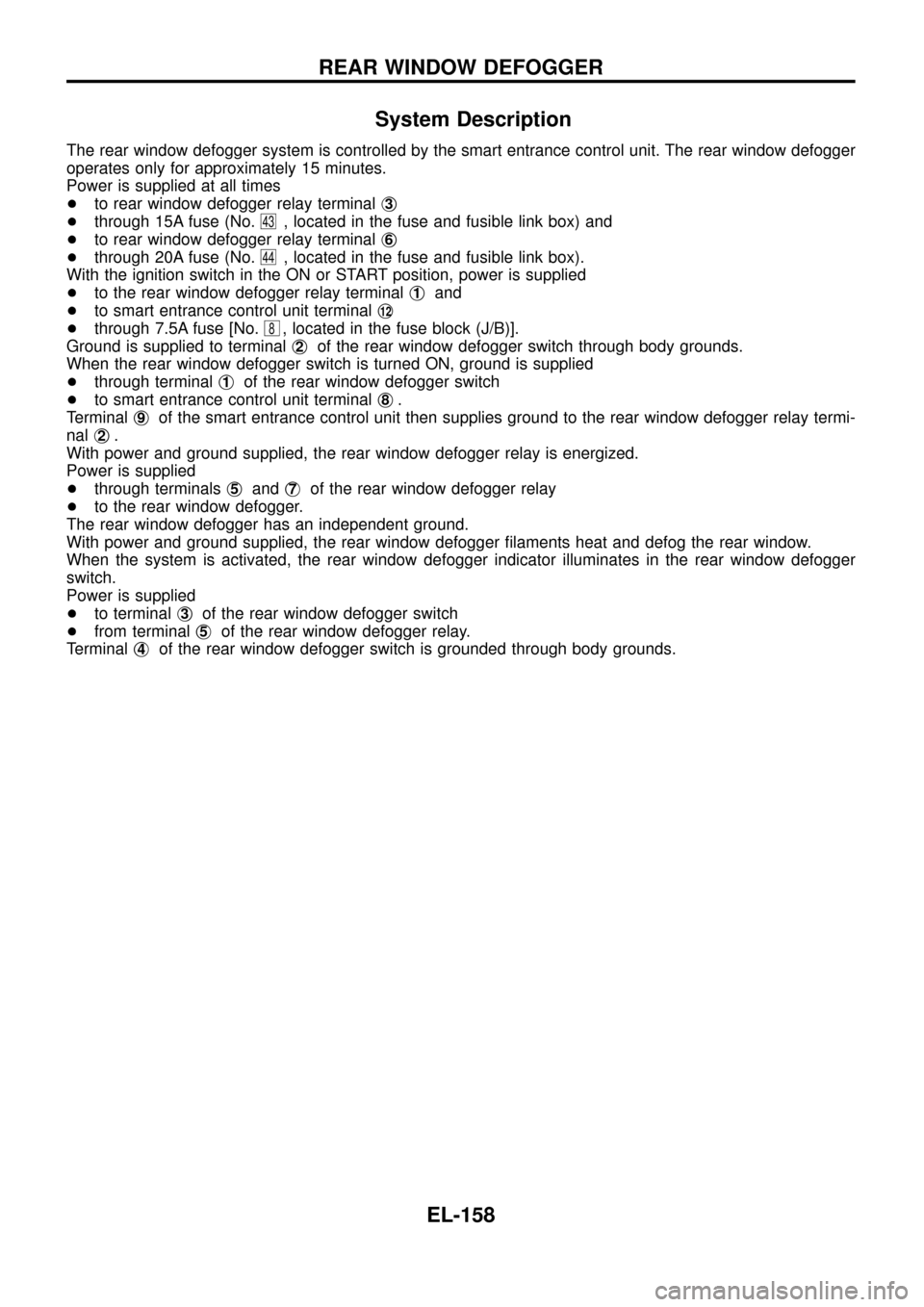

5. Apply a constant stream of hot air directly to the repaired area

for approximately 20 minutes with a heat gun. A minimum dis-

tance of 3 cm (1.2 in) should be kept between repaired area

and hot air outlet. If a heat gun is not available, let the repaired

area dry for 24 hours.

BE540

SEL012D

SEL013D

REAR WINDOW DEFOGGER

EL-165

Page 170 of 326

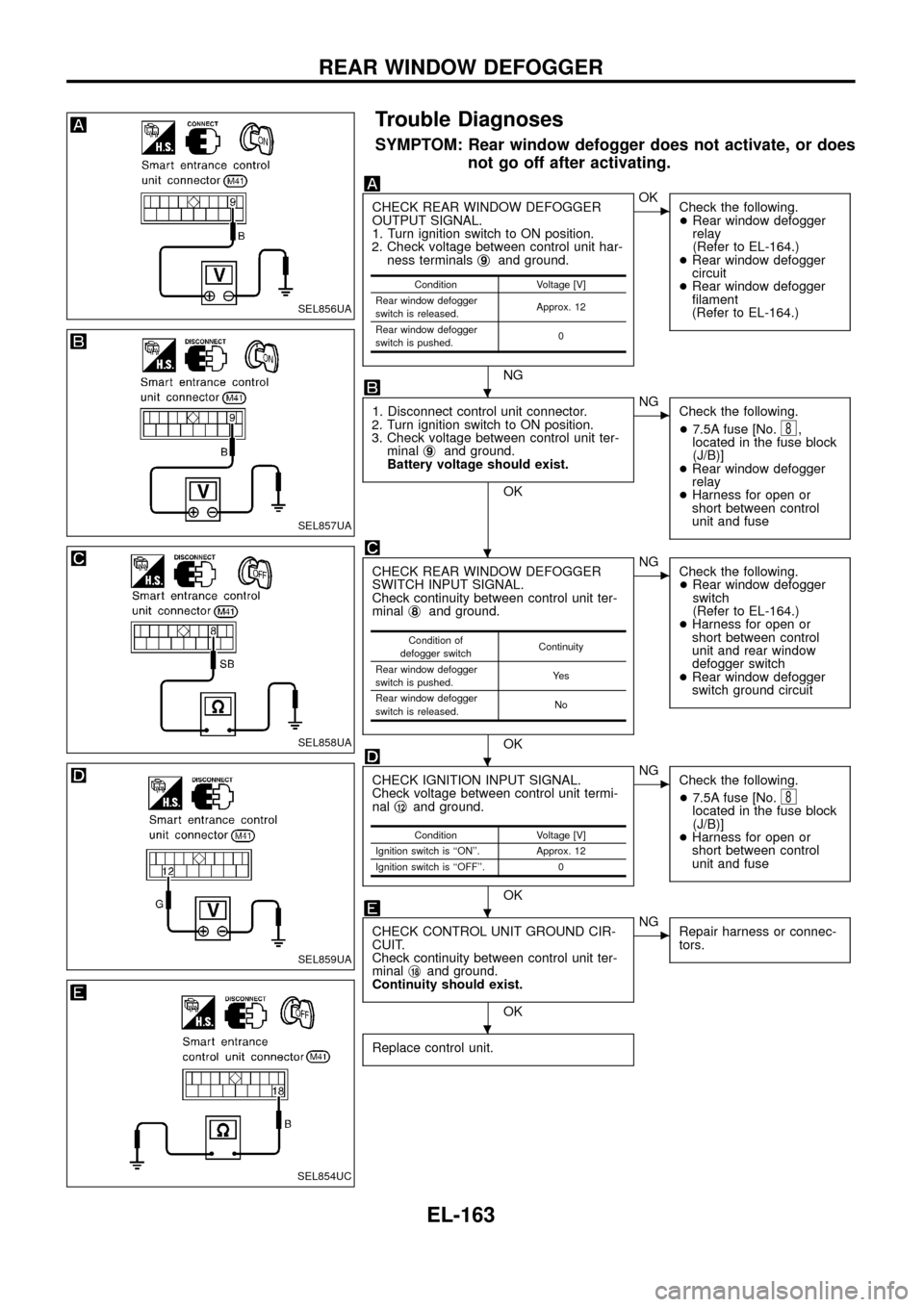

System Description

+A heat line has been added to the lower portion of the wind-

shield.

+During cold weather, water can freeze between the wiper

blades and windshield. Turning the wiper deicer switch ON

melts the ice between the blades and windshield.

+During snowfall, packed snow can accumulate around the

windshield lower surface and surrounding areas. Turning the

wiper deicer switch ON melts the snow to allow the wiper

blades to more easily remove it.

+The wiper deicer operates only for approximately 15 minutes

while ignition switch is in ON position. The timer is combined

with wiper deicer switch.

SEL505V

WIPER DEICER

EL-166

Trending: Park light wiring, section EC, service reset, battery location, Meter control unit, Wiring fuel, tow