NISSAN PICK-UP 1998 Repair Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 1231 of 1659

![NISSAN PICK-UP 1998 Repair Manual Steering Wheel

REMOVAL AND INSTALLATION

1. Remove air bag module and spiral cable. Refer to RS sec-

tion [``Air Bag Module and Spiral Cable, ``SUPPLEMENTAL

RESTRAINT SYSTEM (SRS)]. (With air bag)

NISSAN PICK-UP 1998 Repair Manual Steering Wheel

REMOVAL AND INSTALLATION

1. Remove air bag module and spiral cable. Refer to RS sec-

tion [``Air Bag Module and Spiral Cable, ``SUPPLEMENTAL

RESTRAINT SYSTEM (SRS)]. (With air bag)](/img/5/57374/w960_57374-1230.png)

Steering Wheel

REMOVAL AND INSTALLATION

1. Remove air bag module and spiral cable. Refer to RS sec-

tion [``Air Bag Module and Spiral Cable'', ``SUPPLEMENTAL

RESTRAINT SYSTEM (SRS)'']. (With air bag)

Remove horn pad. (Without air bag)

2. Disconnect horn connector and remove steering wheel nut.

SST721C

SBF812EC

SST730C

STEERING WHEEL AND STEERING COLUMN

ST-9

Page 1232 of 1659

![NISSAN PICK-UP 1998 Repair Manual 3. Remove steering wheel using Tool.

lFor installation, refer to RS section [``Air Bag Module and

Spiral Cable, ``SUPPLEMENTAL RESTRAINT SYSTEM

(SRS)].

Steering Column

REMOVAL

CAUTION:

lThe rotati NISSAN PICK-UP 1998 Repair Manual 3. Remove steering wheel using Tool.

lFor installation, refer to RS section [``Air Bag Module and

Spiral Cable, ``SUPPLEMENTAL RESTRAINT SYSTEM

(SRS)].

Steering Column

REMOVAL

CAUTION:

lThe rotati](/img/5/57374/w960_57374-1231.png)

3. Remove steering wheel using Tool.

lFor installation, refer to RS section [``Air Bag Module and

Spiral Cable'', ``SUPPLEMENTAL RESTRAINT SYSTEM

(SRS)''].

Steering Column

REMOVAL

CAUTION:

lThe rotation of the spiral cable (SRS ``Air bag'' compo-

nent part) is limited. If the steering gear must be

removed, set the front wheels in the straight-ahead

direction.

Do not rotate the steering column while the steering gear

is removed.

lRemove the steering wheel before removing the steering

lower joint to avoid damaging the SRS spiral cable. Refer

to ST-9.

1. Remove steering wheel, refer to ST-9.

2. Remove steering column cover.

3. Remove instrument lower panel.

4. Disconnect combination switch electrical connectors and air

bag harness connector.

5. Remove dash insulator.

6. Remove bolt from lower joint.

7. Remove two steering column bolts and remove steering col-

umn.

INSTALLATION

lWhen installing steering column, finger-tighten all lower

bracket and clamp retaining bolts; then tighten them

securely. Make sure that undue stress is not applied to steer-

ing column.

lWhen fitting steering lower joint, be sure tightening bolt faces

cutout portion.

lAlign spiral cable correctly when installing steering wheel.

Refer to RS section [``Air Bag Module and Spiral Cable'',

``SUPPLEMENTAL RESTRAINT SYSTEM (SRS)''].

CAUTION:

After installation, turn steering wheel to make sure it moves

smoothly. Ensure the number of turns from the straight for-

ward position to left and right locks are the same. Be sure

that the steering wheel is in a neutral position when driving

straight ahead.

SST515B

SST666A

STEERING WHEEL AND STEERING COLUMN

Steering Wheel (Cont'd)

ST-10

Page 1233 of 1659

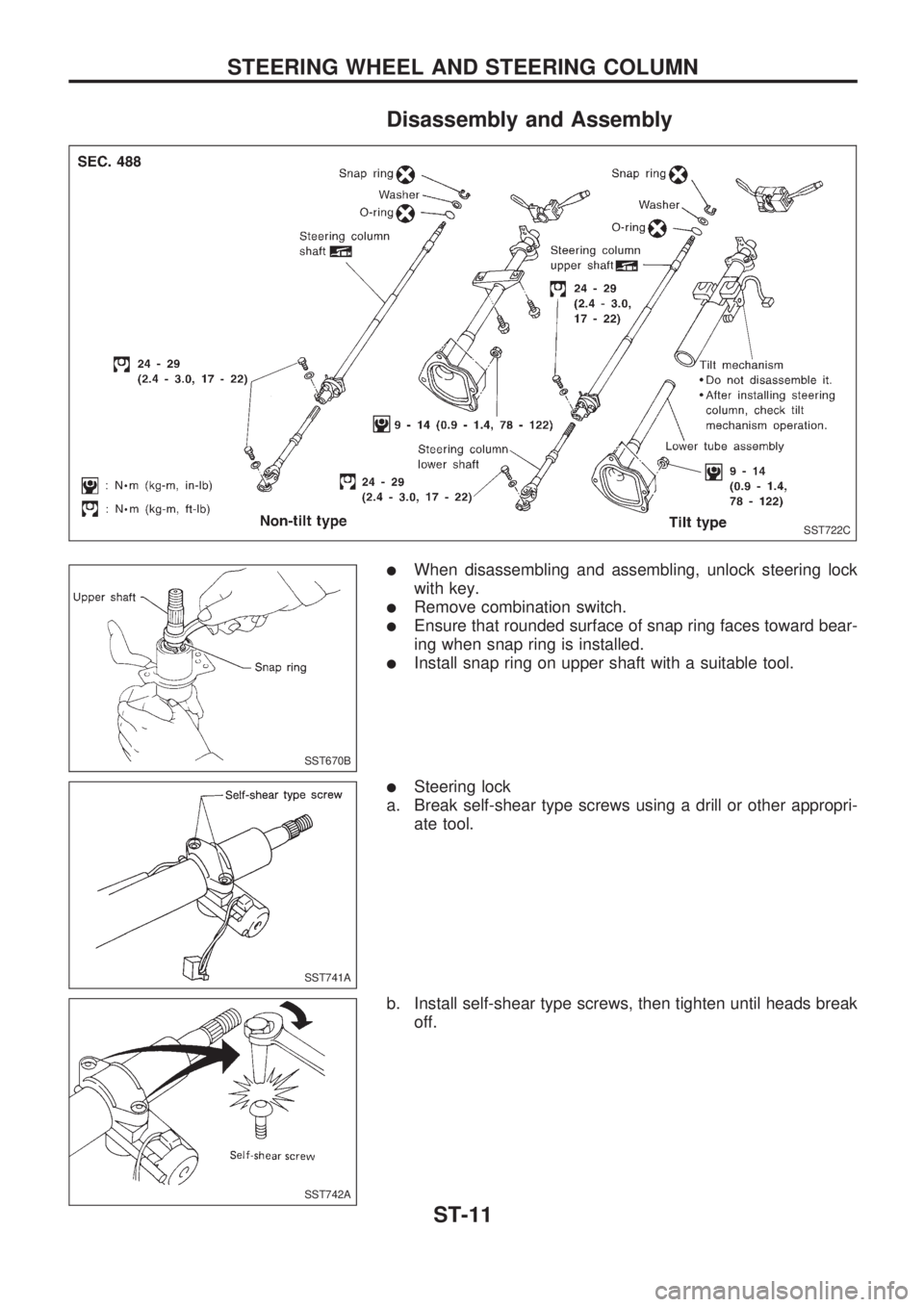

Disassembly and Assembly

lWhen disassembling and assembling, unlock steering lock

with key.

lRemove combination switch.

lEnsure that rounded surface of snap ring faces toward bear-

ing when snap ring is installed.

lInstall snap ring on upper shaft with a suitable tool.

lSteering lock

a. Break self-shear type screws using a drill or other appropri-

ate tool.

b. Install self-shear type screws, then tighten until heads break

off.

SST722C

SST670B

SST741A

SST742A

STEERING WHEEL AND STEERING COLUMN

ST-11

Page 1234 of 1659

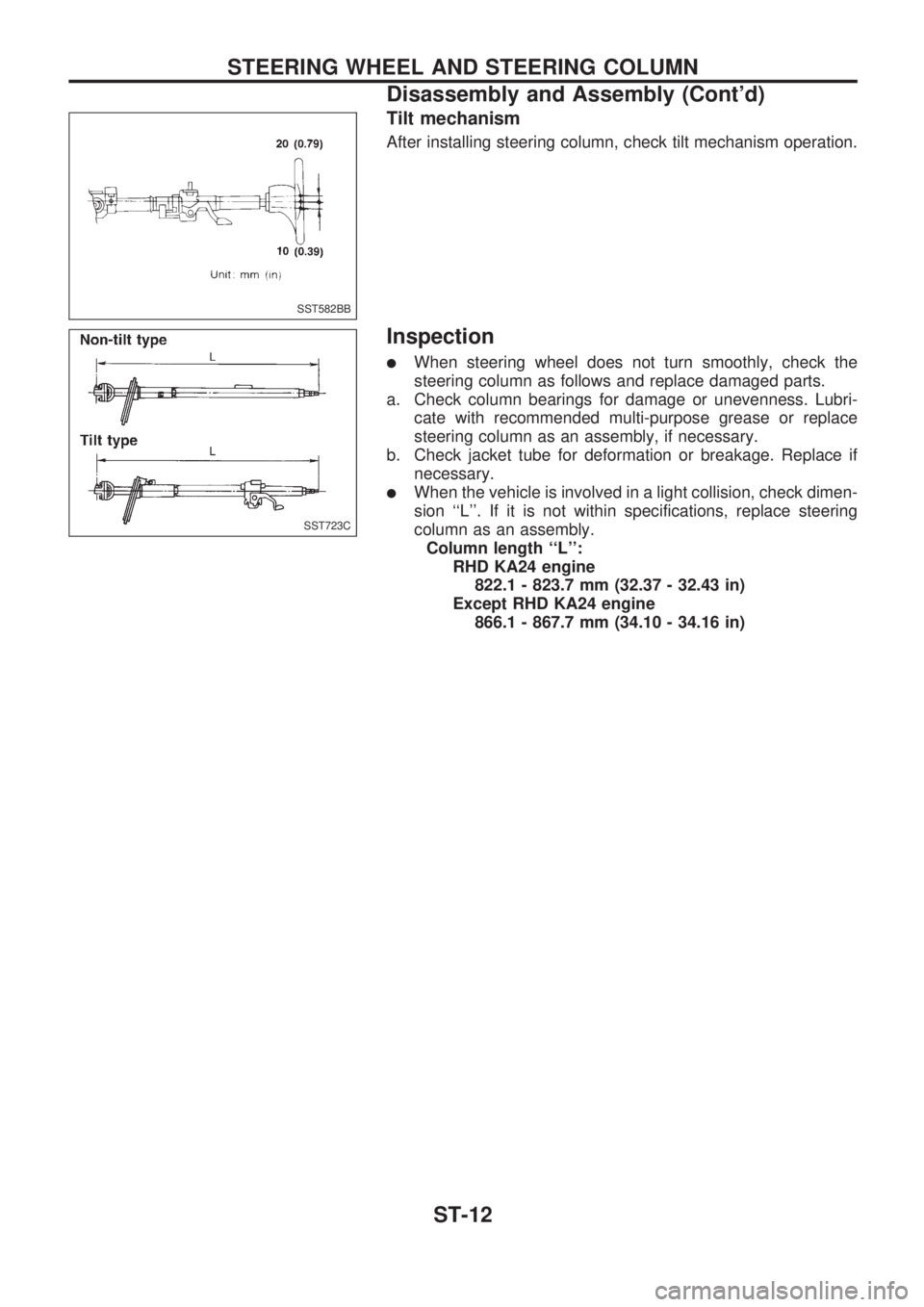

Tilt mechanism

After installing steering column, check tilt mechanism operation.

Inspection

lWhen steering wheel does not turn smoothly, check the

steering column as follows and replace damaged parts.

a. Check column bearings for damage or unevenness. Lubri-

cate with recommended multi-purpose grease or replace

steering column as an assembly, if necessary.

b. Check jacket tube for deformation or breakage. Replace if

necessary.

lWhen the vehicle is involved in a light collision, check dimen-

sion ``L''. If it is not within specifications, replace steering

column as an assembly.

Column length ``L'':

RHD KA24 engine

822.1 - 823.7 mm (32.37 - 32.43 in)

Except RHD KA24 engine

866.1 - 867.7 mm (34.10 - 34.16 in)

SST582BB

SST723C

STEERING WHEEL AND STEERING COLUMN

Disassembly and Assembly (Cont'd)

ST-12

Page 1235 of 1659

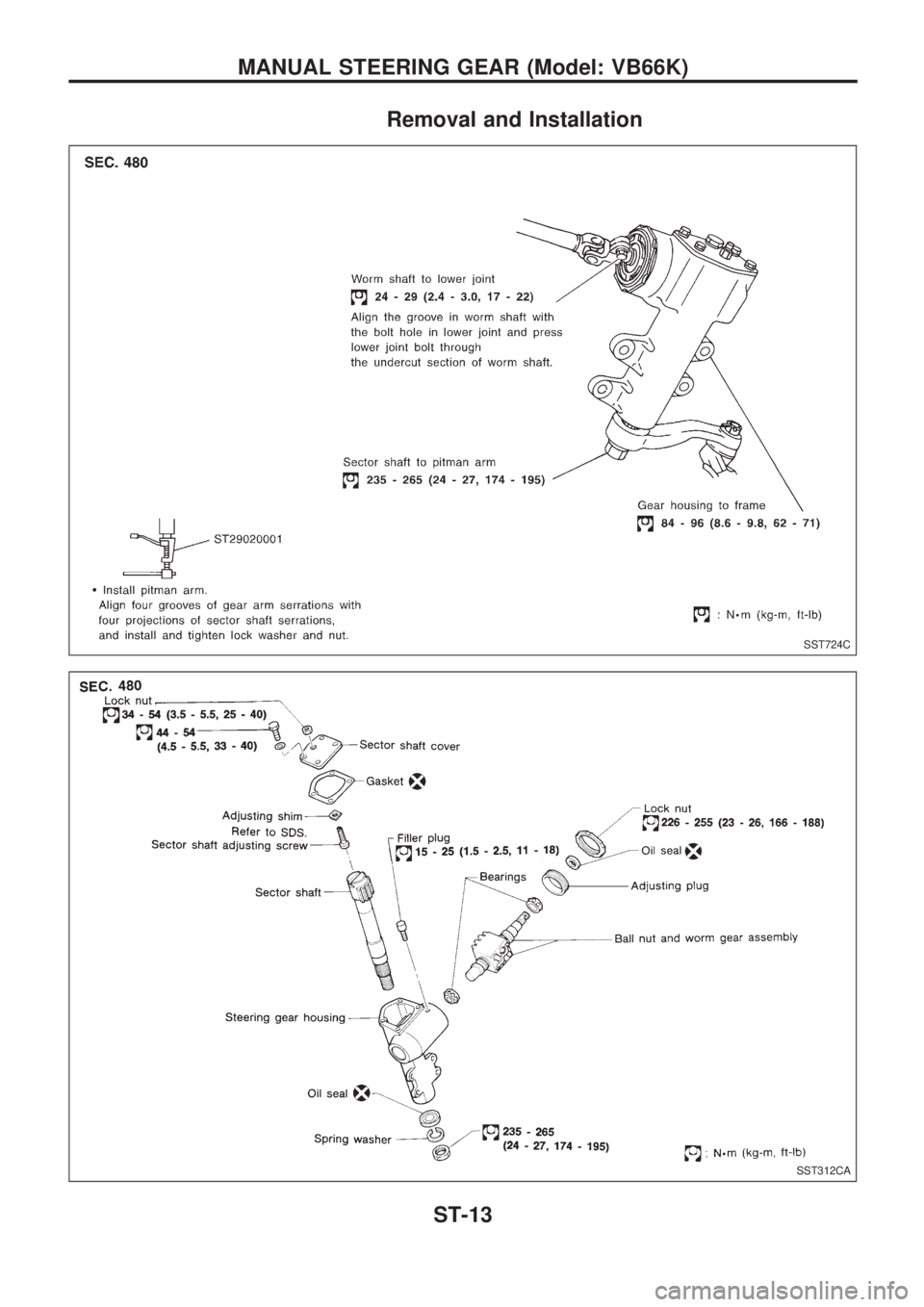

Removal and Installation

SST724C

SST312CA

MANUAL STEERING GEAR (Model: VB66K)

ST-13

Page 1236 of 1659

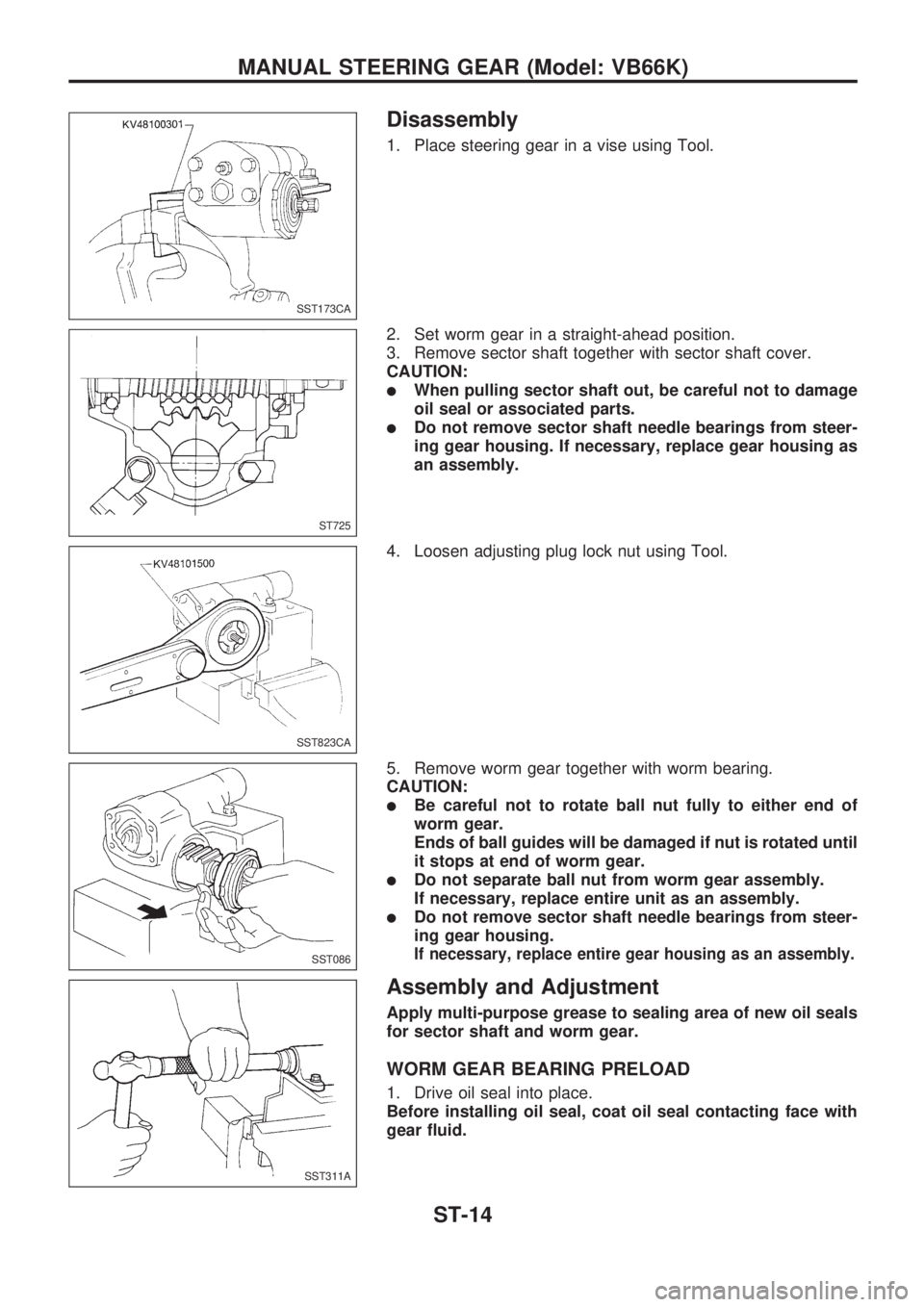

Disassembly

1. Place steering gear in a vise using Tool.

2. Set worm gear in a straight-ahead position.

3. Remove sector shaft together with sector shaft cover.

CAUTION:

lWhen pulling sector shaft out, be careful not to damage

oil seal or associated parts.

lDo not remove sector shaft needle bearings from steer-

ing gear housing. If necessary, replace gear housing as

an assembly.

4. Loosen adjusting plug lock nut using Tool.

5. Remove worm gear together with worm bearing.

CAUTION:

lBe careful not to rotate ball nut fully to either end of

worm gear.

Ends of ball guides will be damaged if nut is rotated until

it stops at end of worm gear.

lDo not separate ball nut from worm gear assembly.

If necessary, replace entire unit as an assembly.

lDo not remove sector shaft needle bearings from steer-

ing gear housing.

If necessary, replace entire gear housing as an assembly.

Assembly and Adjustment

Apply multi-purpose grease to sealing area of new oil seals

for sector shaft and worm gear.

WORM GEAR BEARING PRELOAD

1. Drive oil seal into place.

Before installing oil seal, coat oil seal contacting face with

gear fluid.

SST173CA

ST725

SST823CA

SST086

SST311A

MANUAL STEERING GEAR (Model: VB66K)

ST-14

Page 1237 of 1659

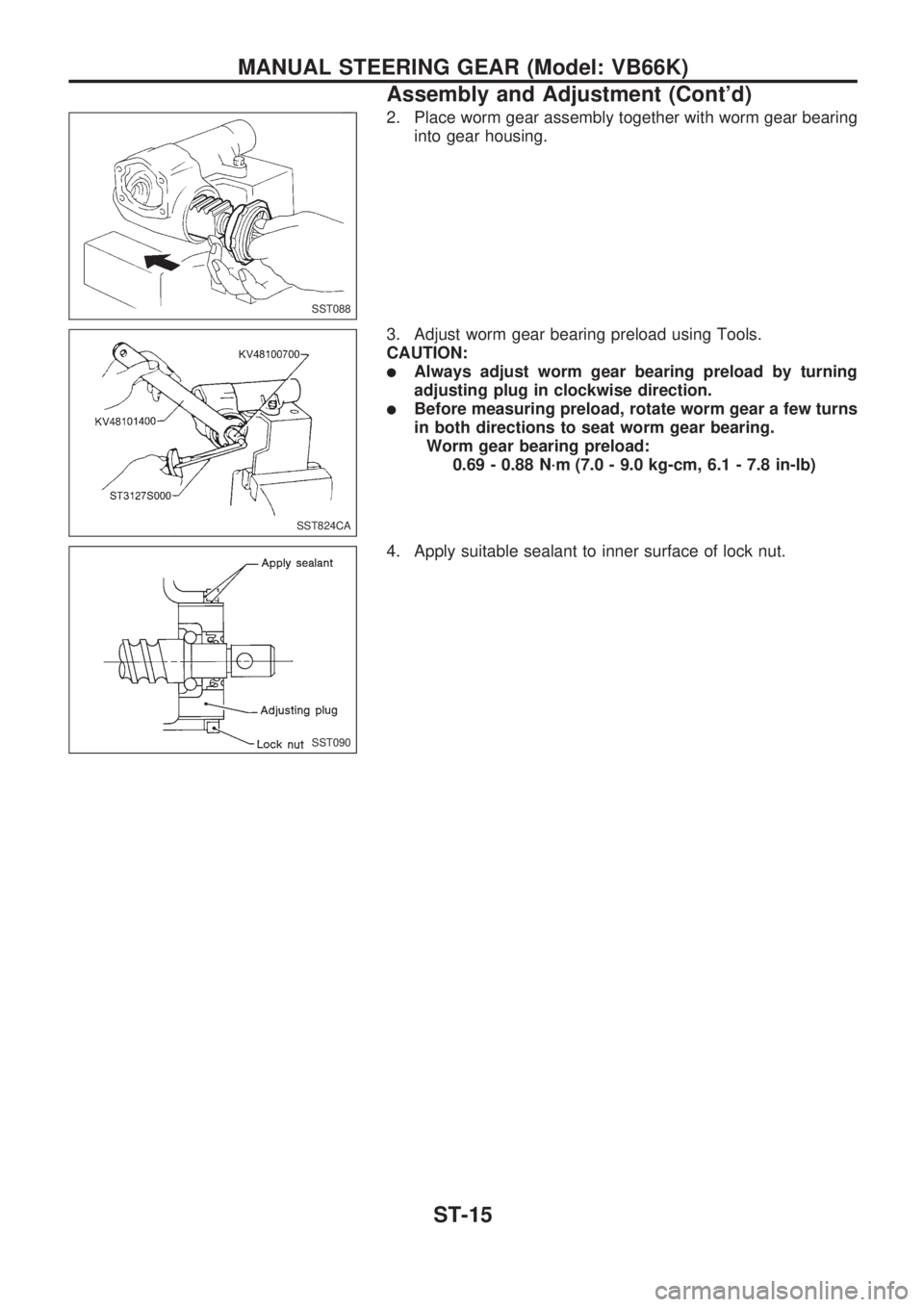

2. Place worm gear assembly together with worm gear bearing

into gear housing.

3. Adjust worm gear bearing preload using Tools.

CAUTION:

lAlways adjust worm gear bearing preload by turning

adjusting plug in clockwise direction.

lBefore measuring preload, rotate worm gear a few turns

in both directions to seat worm gear bearing.

Worm gear bearing preload:

0.69 - 0.88 N´m (7.0 - 9.0 kg-cm, 6.1 - 7.8 in-lb)

4. Apply suitable sealant to inner surface of lock nut.

SST088

SST824CA

SST090

MANUAL STEERING GEAR (Model: VB66K)

Assembly and Adjustment (Cont'd)

ST-15

Page 1238 of 1659

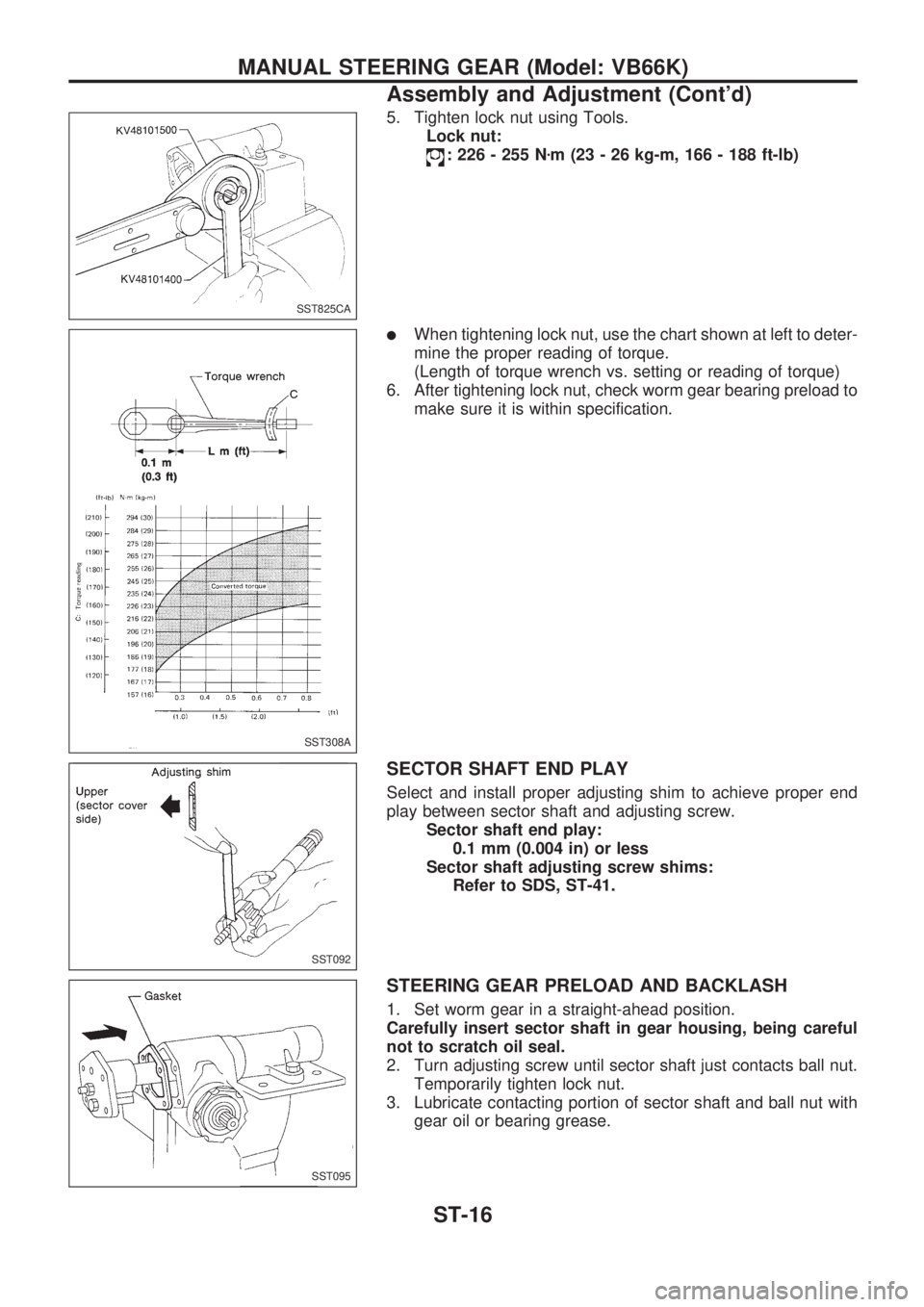

5. Tighten lock nut using Tools.

Lock nut:

: 226 - 255 Nzm (23 - 26 kg-m, 166 - 188 ft-lb)

lWhen tightening lock nut, use the chart shown at left to deter-

mine the proper reading of torque.

(Length of torque wrench vs. setting or reading of torque)

6. After tightening lock nut, check worm gear bearing preload to

make sure it is within specification.

SECTOR SHAFT END PLAY

Select and install proper adjusting shim to achieve proper end

play between sector shaft and adjusting screw.

Sector shaft end play:

0.1 mm (0.004 in) or less

Sector shaft adjusting screw shims:

Refer to SDS, ST-41.

STEERING GEAR PRELOAD AND BACKLASH

1. Set worm gear in a straight-ahead position.

Carefully insert sector shaft in gear housing, being careful

not to scratch oil seal.

2. Turn adjusting screw until sector shaft just contacts ball nut.

Temporarily tighten lock nut.

3. Lubricate contacting portion of sector shaft and ball nut with

gear oil or bearing grease.

SST825CA

SST308A

SST092

SST095

MANUAL STEERING GEAR (Model: VB66K)

Assembly and Adjustment (Cont'd)

ST-16

Page 1239 of 1659

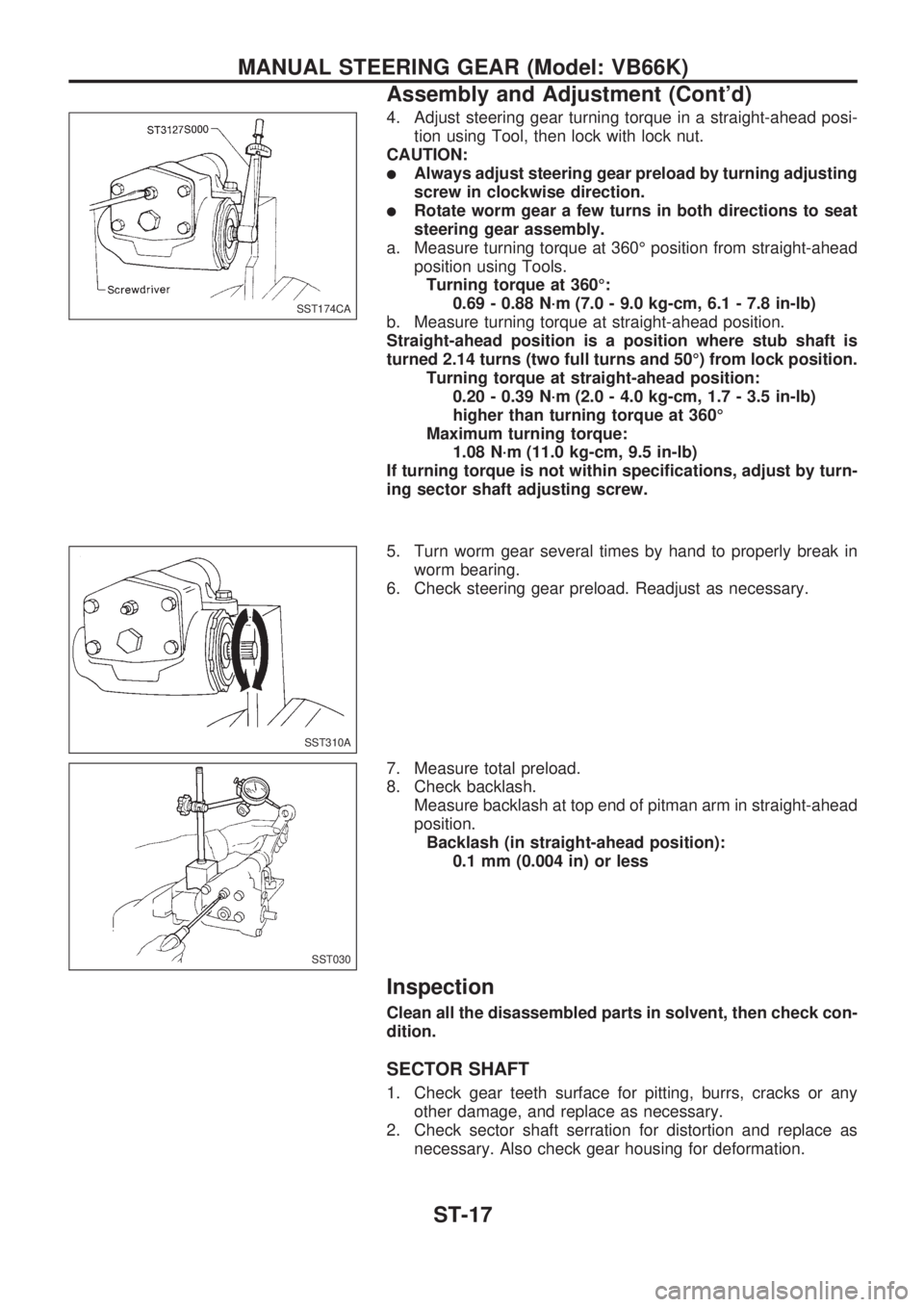

4. Adjust steering gear turning torque in a straight-ahead posi-

tion using Tool, then lock with lock nut.

CAUTION:

lAlways adjust steering gear preload by turning adjusting

screw in clockwise direction.

lRotate worm gear a few turns in both directions to seat

steering gear assembly.

a. Measure turning torque at 360É position from straight-ahead

position using Tools.

Turning torque at 360É:

0.69 - 0.88 N´m (7.0 - 9.0 kg-cm, 6.1 - 7.8 in-lb)

b. Measure turning torque at straight-ahead position.

Straight-ahead position is a position where stub shaft is

turned 2.14 turns (two full turns and 50É) from lock position.

Turning torque at straight-ahead position:

0.20 - 0.39 N´m (2.0 - 4.0 kg-cm, 1.7 - 3.5 in-lb)

higher than turning torque at 360É

Maximum turning torque:

1.08 N´m (11.0 kg-cm, 9.5 in-lb)

If turning torque is not within specifications, adjust by turn-

ing sector shaft adjusting screw.

5. Turn worm gear several times by hand to properly break in

worm bearing.

6. Check steering gear preload. Readjust as necessary.

7. Measure total preload.

8. Check backlash.

Measure backlash at top end of pitman arm in straight-ahead

position.

Backlash (in straight-ahead position):

0.1 mm (0.004 in) or less

Inspection

Clean all the disassembled parts in solvent, then check con-

dition.

SECTOR SHAFT

1. Check gear teeth surface for pitting, burrs, cracks or any

other damage, and replace as necessary.

2. Check sector shaft serration for distortion and replace as

necessary. Also check gear housing for deformation.

SST174CA

SST310A

SST030

MANUAL STEERING GEAR (Model: VB66K)

Assembly and Adjustment (Cont'd)

ST-17

Page 1240 of 1659

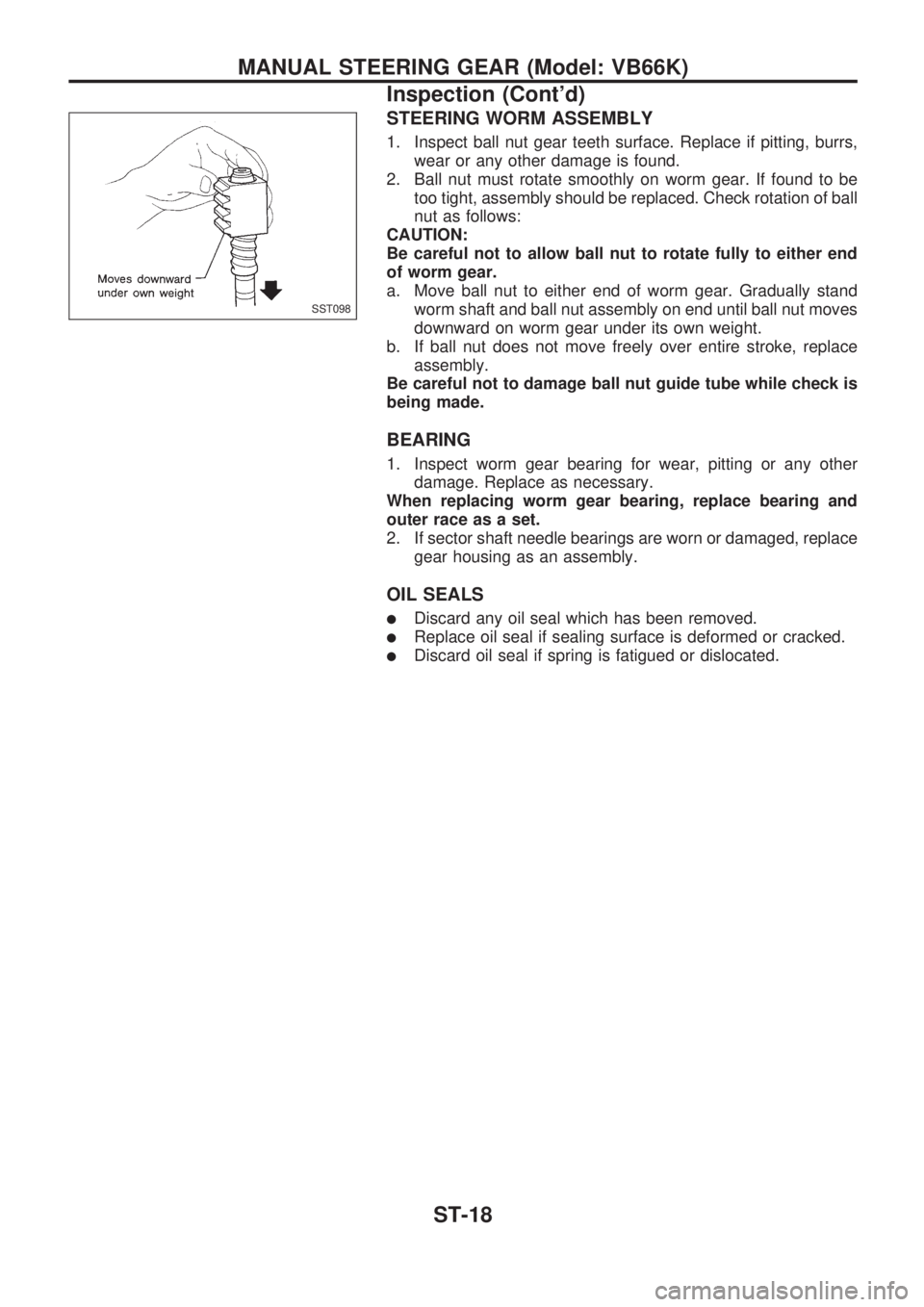

STEERING WORM ASSEMBLY

1. Inspect ball nut gear teeth surface. Replace if pitting, burrs,

wear or any other damage is found.

2. Ball nut must rotate smoothly on worm gear. If found to be

too tight, assembly should be replaced. Check rotation of ball

nut as follows:

CAUTION:

Be careful not to allow ball nut to rotate fully to either end

of worm gear.

a. Move ball nut to either end of worm gear. Gradually stand

worm shaft and ball nut assembly on end until ball nut moves

downward on worm gear under its own weight.

b. If ball nut does not move freely over entire stroke, replace

assembly.

Be careful not to damage ball nut guide tube while check is

being made.

BEARING

1. Inspect worm gear bearing for wear, pitting or any other

damage. Replace as necessary.

When replacing worm gear bearing, replace bearing and

outer race as a set.

2. If sector shaft needle bearings are worn or damaged, replace

gear housing as an assembly.

OIL SEALS

lDiscard any oil seal which has been removed.

lReplace oil seal if sealing surface is deformed or cracked.

lDiscard oil seal if spring is fatigued or dislocated.

SST098

MANUAL STEERING GEAR (Model: VB66K)

Inspection (Cont'd)

ST-18