NISSAN PICK-UP 1998 Repair Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 881 of 1659

Precautions for Service Equipment

RECOVERY/RECYCLING EQUIPMENT

Be certain to follow the manufacturers instructions for machine

operation and machine maintenance. Never introduce any refrig-

erant other than that specified into the machine.

ELECTRONIC LEAK DETECTOR

Be certain to follow the manufacturer's instructions for tester

operation and tester maintenance.

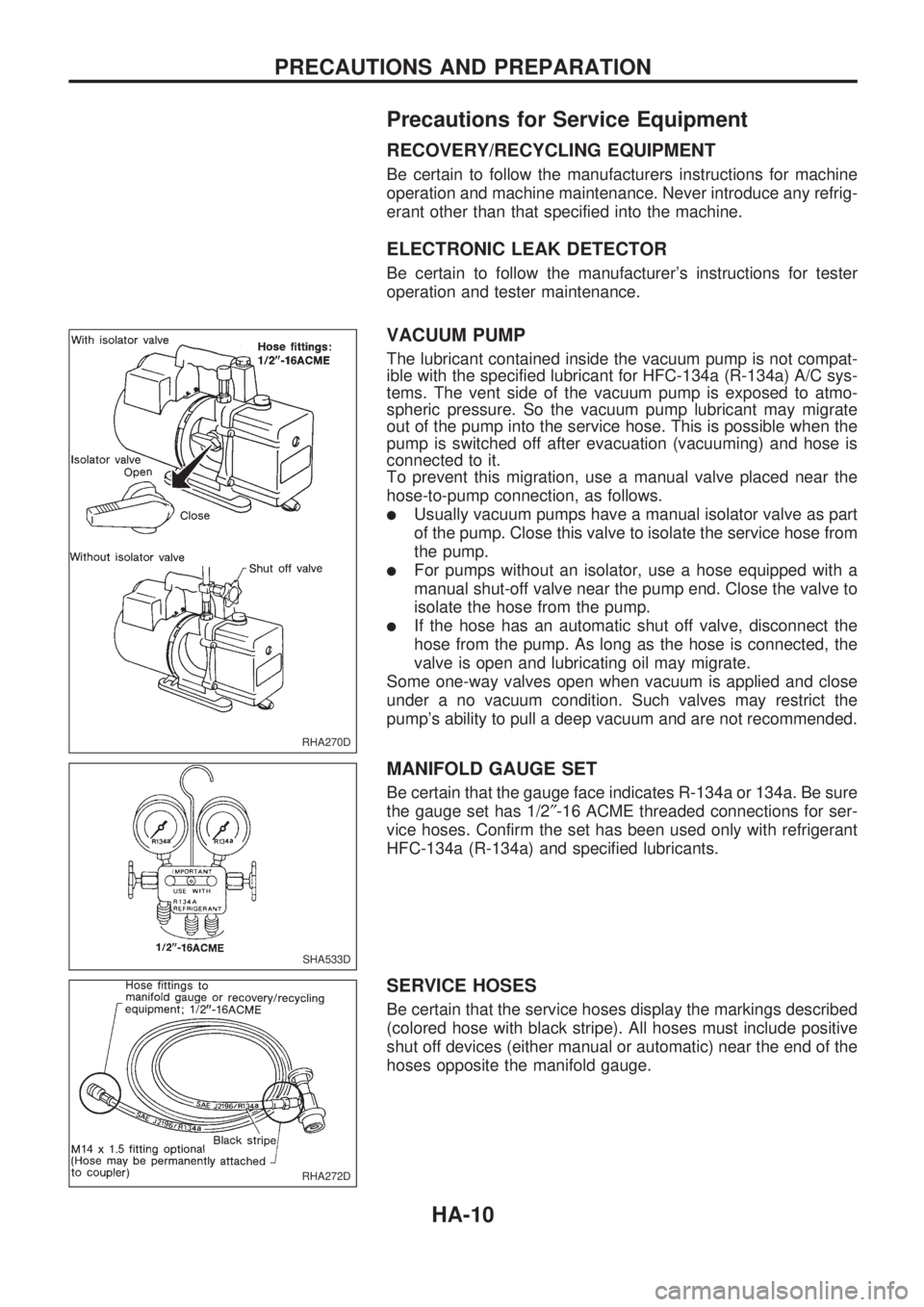

VACUUM PUMP

The lubricant contained inside the vacuum pump is not compat-

ible with the specified lubricant for HFC-134a (R-134a) A/C sys-

tems. The vent side of the vacuum pump is exposed to atmo-

spheric pressure. So the vacuum pump lubricant may migrate

out of the pump into the service hose. This is possible when the

pump is switched off after evacuation (vacuuming) and hose is

connected to it.

To prevent this migration, use a manual valve placed near the

hose-to-pump connection, as follows.

lUsually vacuum pumps have a manual isolator valve as part

of the pump. Close this valve to isolate the service hose from

the pump.

lFor pumps without an isolator, use a hose equipped with a

manual shut-off valve near the pump end. Close the valve to

isolate the hose from the pump.

lIf the hose has an automatic shut off valve, disconnect the

hose from the pump. As long as the hose is connected, the

valve is open and lubricating oil may migrate.

Some one-way valves open when vacuum is applied and close

under a no vacuum condition. Such valves may restrict the

pump's ability to pull a deep vacuum and are not recommended.

MANIFOLD GAUGE SET

Be certain that the gauge face indicates R-134a or 134a. Be sure

the gauge set has 1/2²-16 ACME threaded connections for ser-

vice hoses. Confirm the set has been used only with refrigerant

HFC-134a (R-134a) and specified lubricants.

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe). All hoses must include positive

shut off devices (either manual or automatic) near the end of the

hoses opposite the manifold gauge.

RHA270D

SHA533D

RHA272D

PRECAUTIONS AND PREPARATION

HA-10

Page 882 of 1659

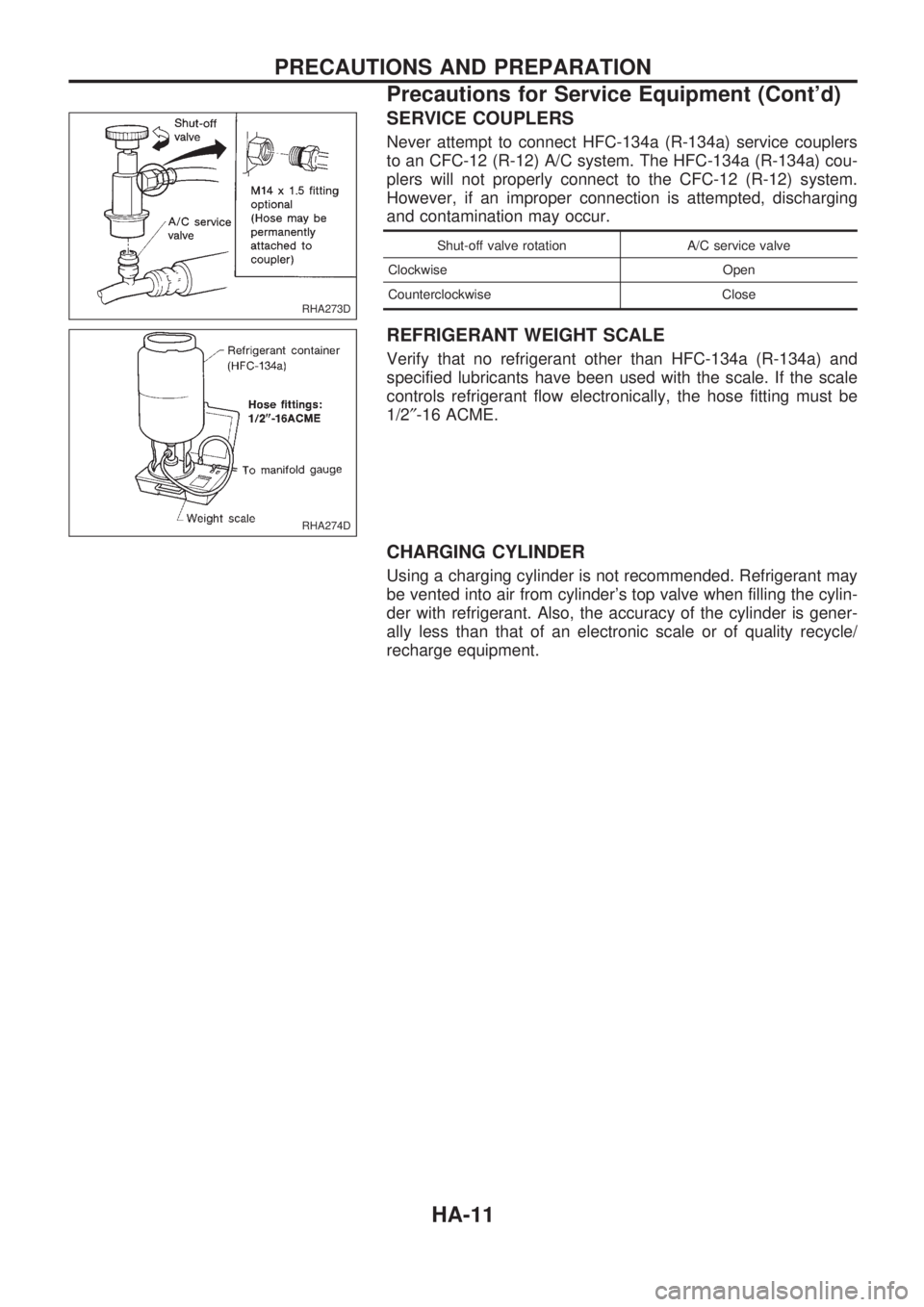

SERVICE COUPLERS

Never attempt to connect HFC-134a (R-134a) service couplers

to an CFC-12 (R-12) A/C system. The HFC-134a (R-134a) cou-

plers will not properly connect to the CFC-12 (R-12) system.

However, if an improper connection is attempted, discharging

and contamination may occur.

Shut-off valve rotation A/C service valve

Clockwise Open

Counterclockwise Close

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and

specified lubricants have been used with the scale. If the scale

controls refrigerant flow electronically, the hose fitting must be

1/2²-16 ACME.

CHARGING CYLINDER

Using a charging cylinder is not recommended. Refrigerant may

be vented into air from cylinder's top valve when filling the cylin-

der with refrigerant. Also, the accuracy of the cylinder is gener-

ally less than that of an electronic scale or of quality recycle/

recharge equipment.

RHA273D

RHA274D

PRECAUTIONS AND PREPARATION

Precautions for Service Equipment (Cont'd)

HA-11

Page 883 of 1659

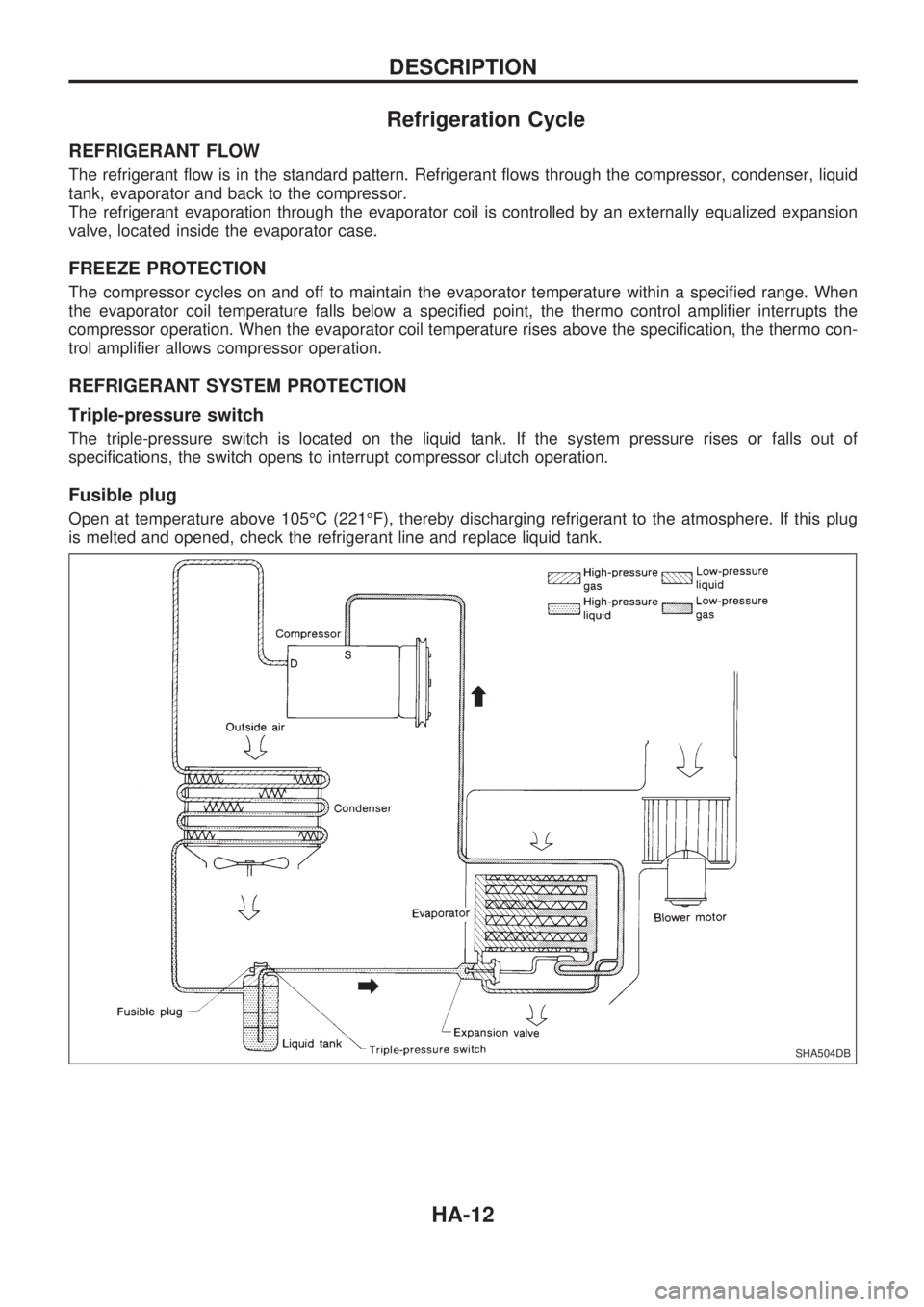

Refrigeration Cycle

REFRIGERANT FLOW

The refrigerant flow is in the standard pattern. Refrigerant flows through the compressor, condenser, liquid

tank, evaporator and back to the compressor.

The refrigerant evaporation through the evaporator coil is controlled by an externally equalized expansion

valve, located inside the evaporator case.

FREEZE PROTECTION

The compressor cycles on and off to maintain the evaporator temperature within a specified range. When

the evaporator coil temperature falls below a specified point, the thermo control amplifier interrupts the

compressor operation. When the evaporator coil temperature rises above the specification, the thermo con-

trol amplifier allows compressor operation.

REFRIGERANT SYSTEM PROTECTION

Triple-pressure switch

The triple-pressure switch is located on the liquid tank. If the system pressure rises or falls out of

specifications, the switch opens to interrupt compressor clutch operation.

Fusible plug

Open at temperature above 105ÉC (221ÉF), thereby discharging refrigerant to the atmosphere. If this plug

is melted and opened, check the refrigerant line and replace liquid tank.

SHA504DB

DESCRIPTION

HA-12

Page 884 of 1659

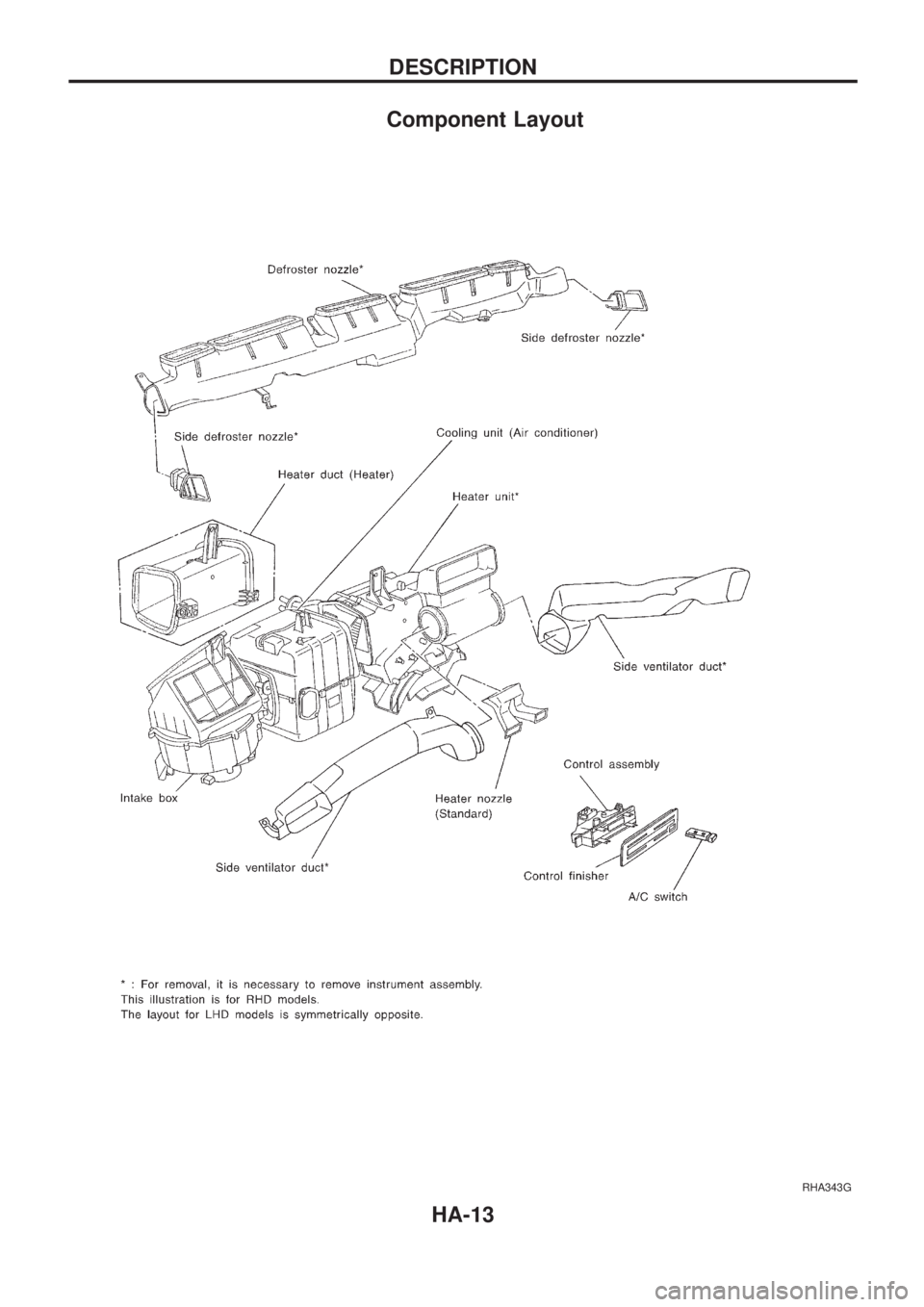

Component Layout

RHA343G

DESCRIPTION

HA-13

Page 885 of 1659

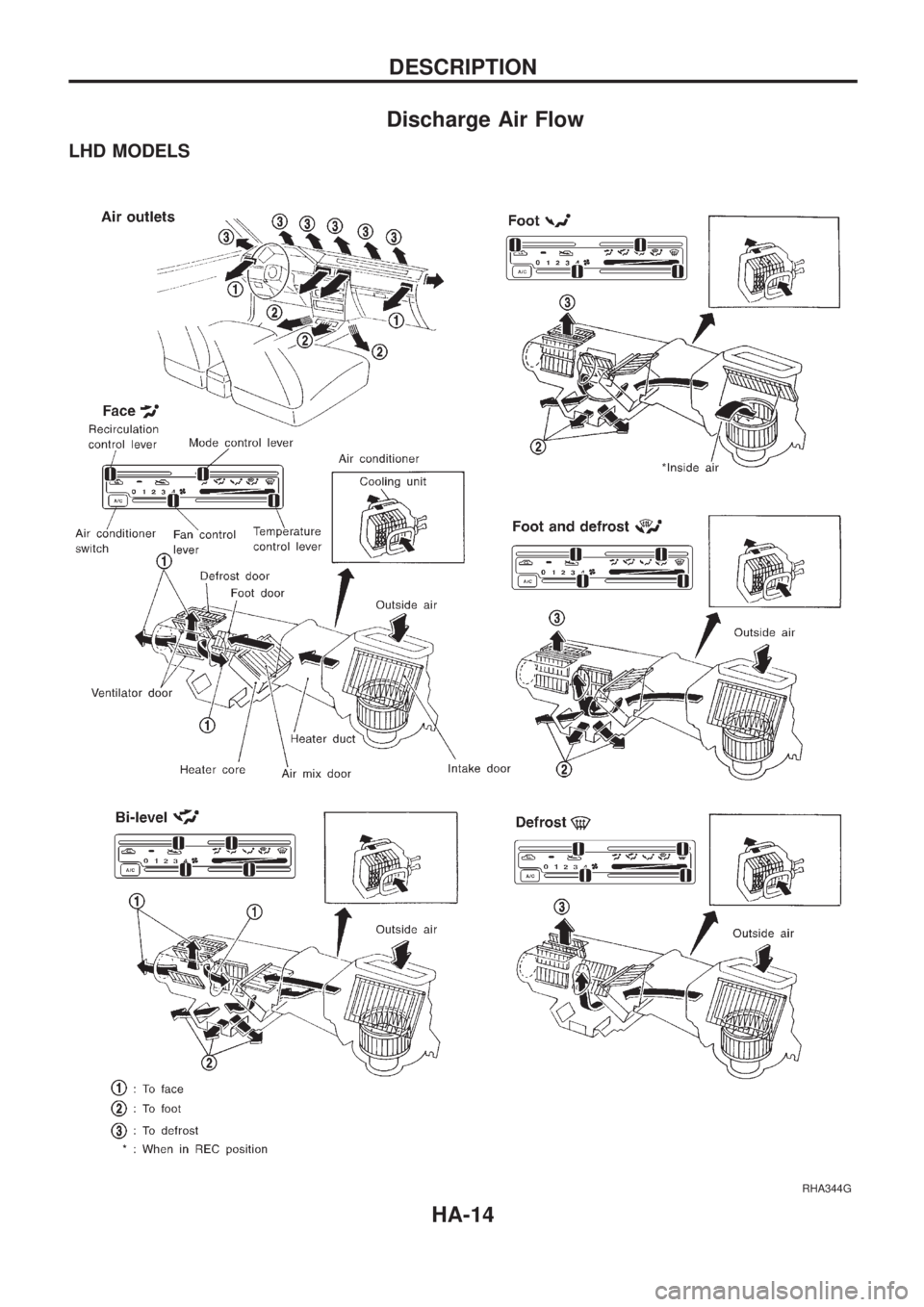

Discharge Air Flow

LHD MODELS

RHA344G

DESCRIPTION

HA-14

Page 886 of 1659

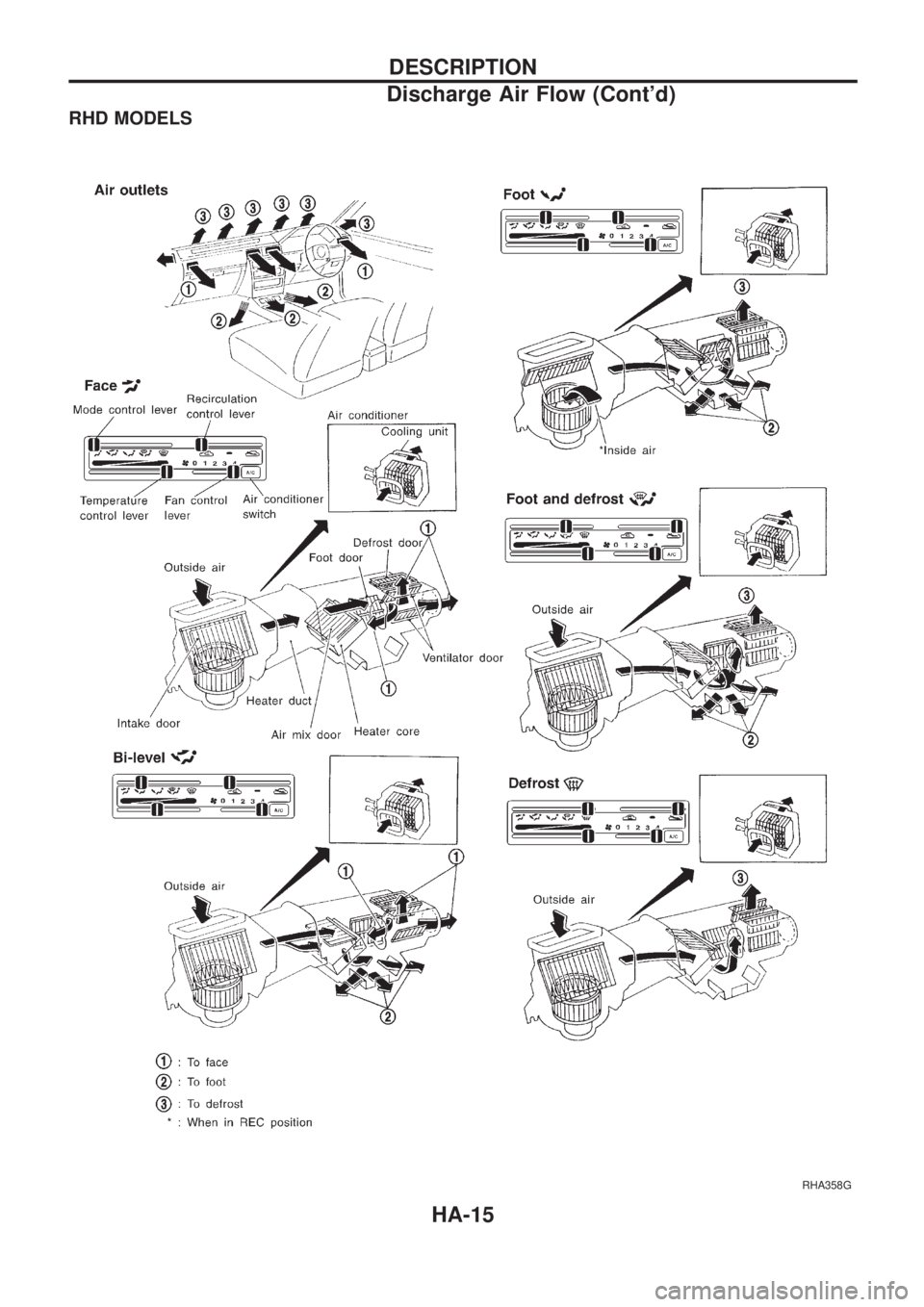

RHD MODELS

RHA358G

DESCRIPTION

Discharge Air Flow (Cont'd)

HA-15

Page 887 of 1659

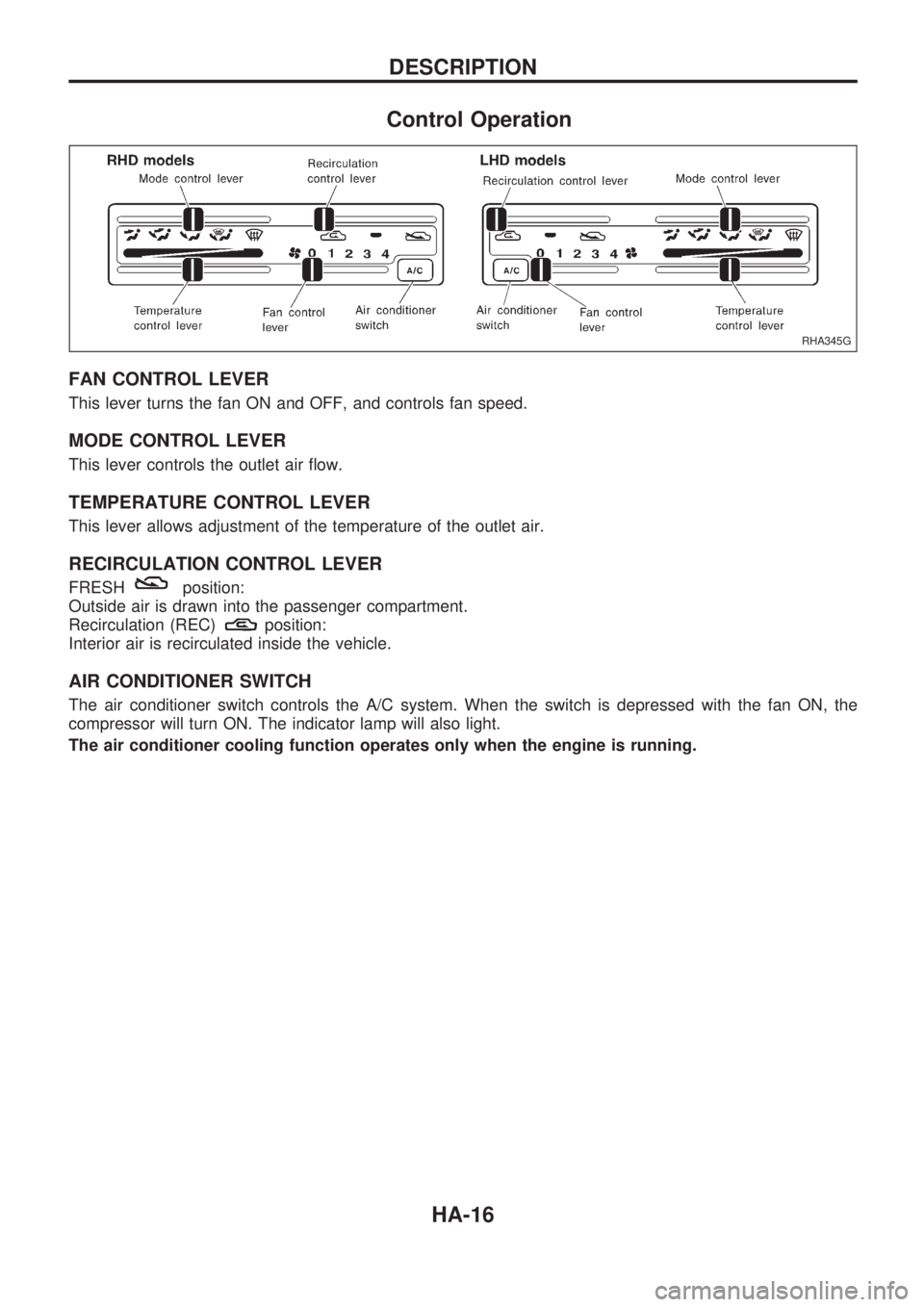

Control Operation

FAN CONTROL LEVER

This lever turns the fan ON and OFF, and controls fan speed.

MODE CONTROL LEVER

This lever controls the outlet air flow.

TEMPERATURE CONTROL LEVER

This lever allows adjustment of the temperature of the outlet air.

RECIRCULATION CONTROL LEVER

FRESHposition:

Outside air is drawn into the passenger compartment.

Recirculation (REC)

position:

Interior air is recirculated inside the vehicle.

AIR CONDITIONER SWITCH

The air conditioner switch controls the A/C system. When the switch is depressed with the fan ON, the

compressor will turn ON. The indicator lamp will also light.

The air conditioner cooling function operates only when the engine is running.

RHA345G

DESCRIPTION

HA-16

Page 888 of 1659

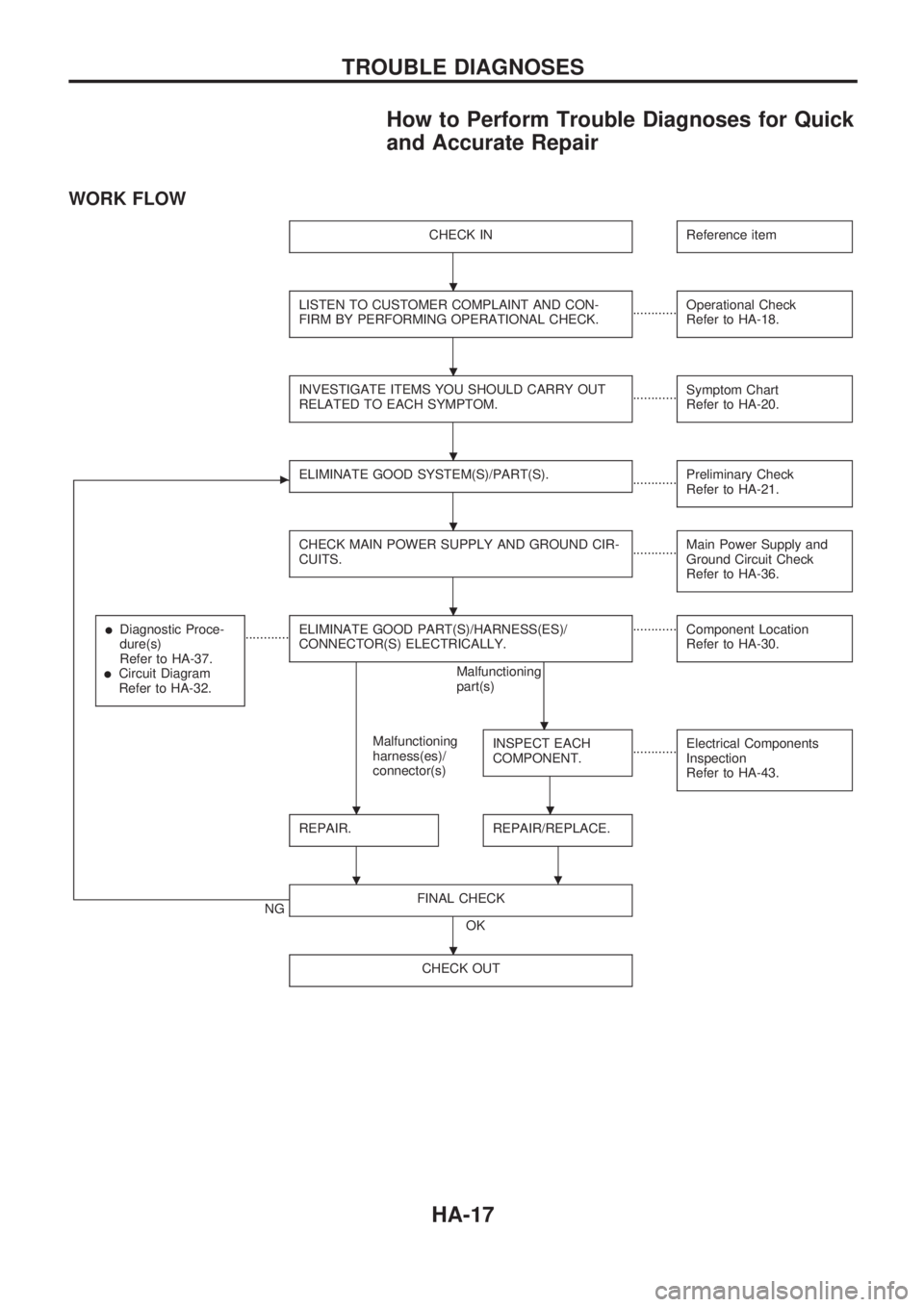

How to Perform Trouble Diagnoses for Quick

and Accurate Repair

WORK FLOW

CHECK INReference item

LISTEN TO CUSTOMER COMPLAINT AND CON-

FIRM BY PERFORMING OPERATIONAL CHECK.............Operational Check

Refer to HA-18.

INVESTIGATE ITEMS YOU SHOULD CARRY OUT

RELATED TO EACH SYMPTOM.............Symptom Chart

Refer to HA-20.

cELIMINATE GOOD SYSTEM(S)/PART(S).............Preliminary Check

Refer to HA-21.

CHECK MAIN POWER SUPPLY AND GROUND CIR-

CUITS.............Main Power Supply and

Ground Circuit Check

Refer to HA-36.

lDiagnostic Proce-

dure(s)

Refer to HA-37.

lCircuit Diagram

Refer to HA-32.

............ELIMINATE GOOD PART(S)/HARNESS(ES)/

CONNECTOR(S) ELECTRICALLY.

Malfunctioning

harness(es)/

connector(s)Malfunctioning

part(s)............

Component Location

Refer to HA-30.INSPECT EACH

COMPONENT.............Electrical Components

Inspection

Refer to HA-43.

REPAIR.REPAIR/REPLACE.

.

NGFINAL CHECK

OK

CHECK OUT

.

.

.

.

.

.

..

.

.

TROUBLE DIAGNOSES

HA-17

Page 889 of 1659

Operational Check

The purpose of the operational check is to confirm that the sys-

tem operates properly.

CONDITIONS:

lEngine running at normal operating temperature.

PROCEDURE:

1. Check blower

a. Slide fan control lever to 1-speed.

Blower should operate on 1-speed.

b. Slide fan control lever to 2-speed and continue checking

blower speed until all speeds are checked.

c. Leave blower on 4-speed.

2. Check discharge air

a. Slide mode control lever to

position.

b. Confirm that all discharge air comes out of face vents.

c. Slide mode control lever to

position.

d. Confirm that discharge air comes out of face vents and foot

vents.

e. Slide mode control lever to

position.

f. Confirm that discharge air comes out of foot vents, with some

air from defrost vents.

g. Slide mode control lever to

position.

h. Confirm that discharge air comes out of foot vents with some

air from defrost vents.

i. Slide mode control lever to

position.

j. Confirm that all discharge air comes out of defrost vents.

3. Check recirculation

a. Slide recirculation control lever to the REC

position.

b. Listen for intake door position change (you should hear

blower sound change slightly).

RHA346G

RHA347G

RHA348G

TROUBLE DIAGNOSES

HA-18

Page 890 of 1659

4. Check temperature decrease

a. Slide temperature control lever to full cold.

b. Check for cold air at discharge air outlets.

5. Check temperature increase

a. Slide temperature control lever to full hot.

b. Check for hot air at discharge air outlets.

6. Check A/C switch

Move fan control lever to the desired position (1 to 4) and press

air conditioner switch to turn ON air conditioner.

Indicator light will come on when air conditioner is ON.

RHA349G

RHA350G

RHA351G

TROUBLE DIAGNOSES

Operational Check (Cont'd)

HA-19