NISSAN PICK-UP 1998 Repair Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 851 of 1659

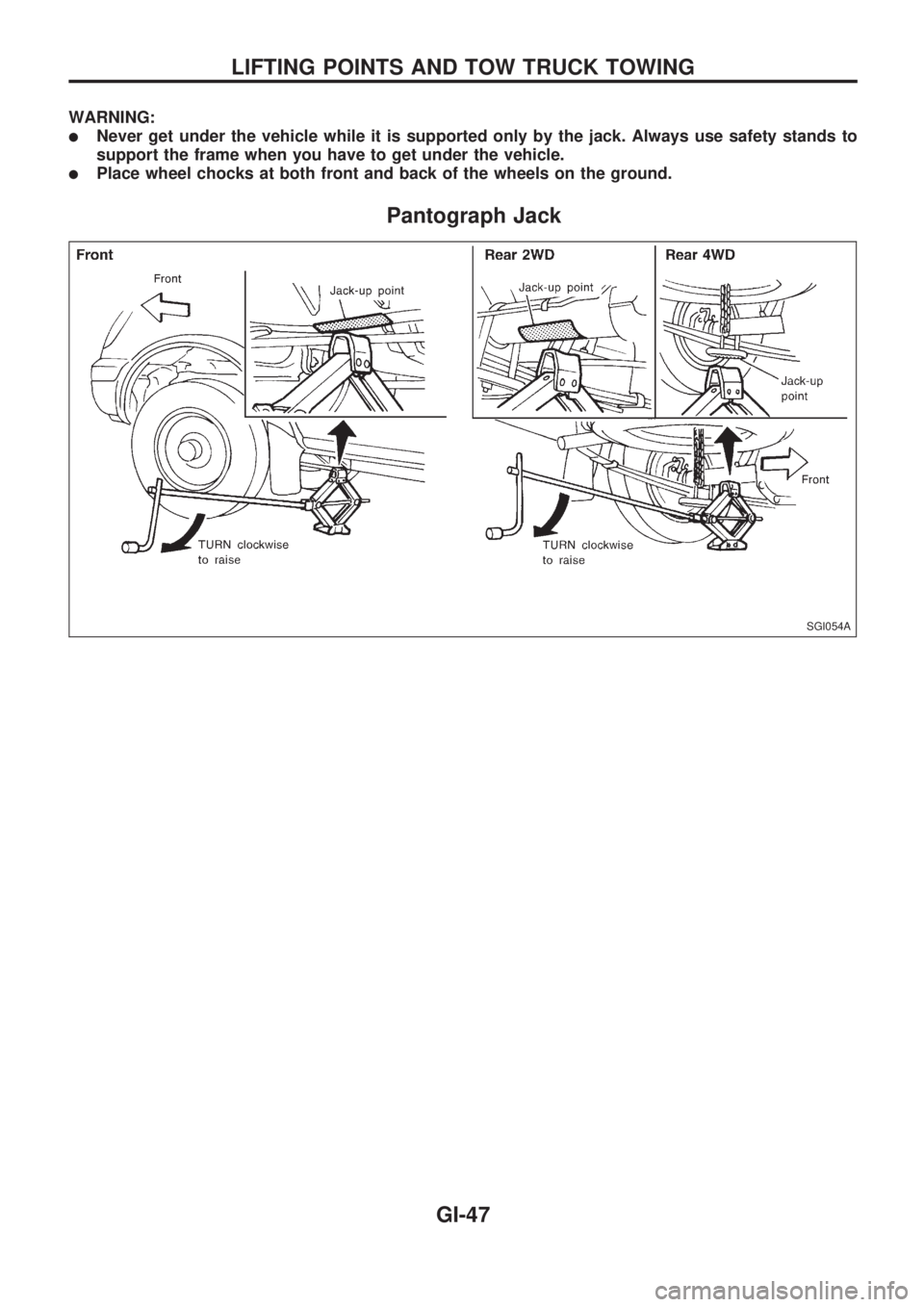

WARNING:

lNever get under the vehicle while it is supported only by the jack. Always use safety stands to

support the frame when you have to get under the vehicle.

lPlace wheel chocks at both front and back of the wheels on the ground.

Pantograph Jack

SGI054A

LIFTING POINTS AND TOW TRUCK TOWING

GI-47

Page 852 of 1659

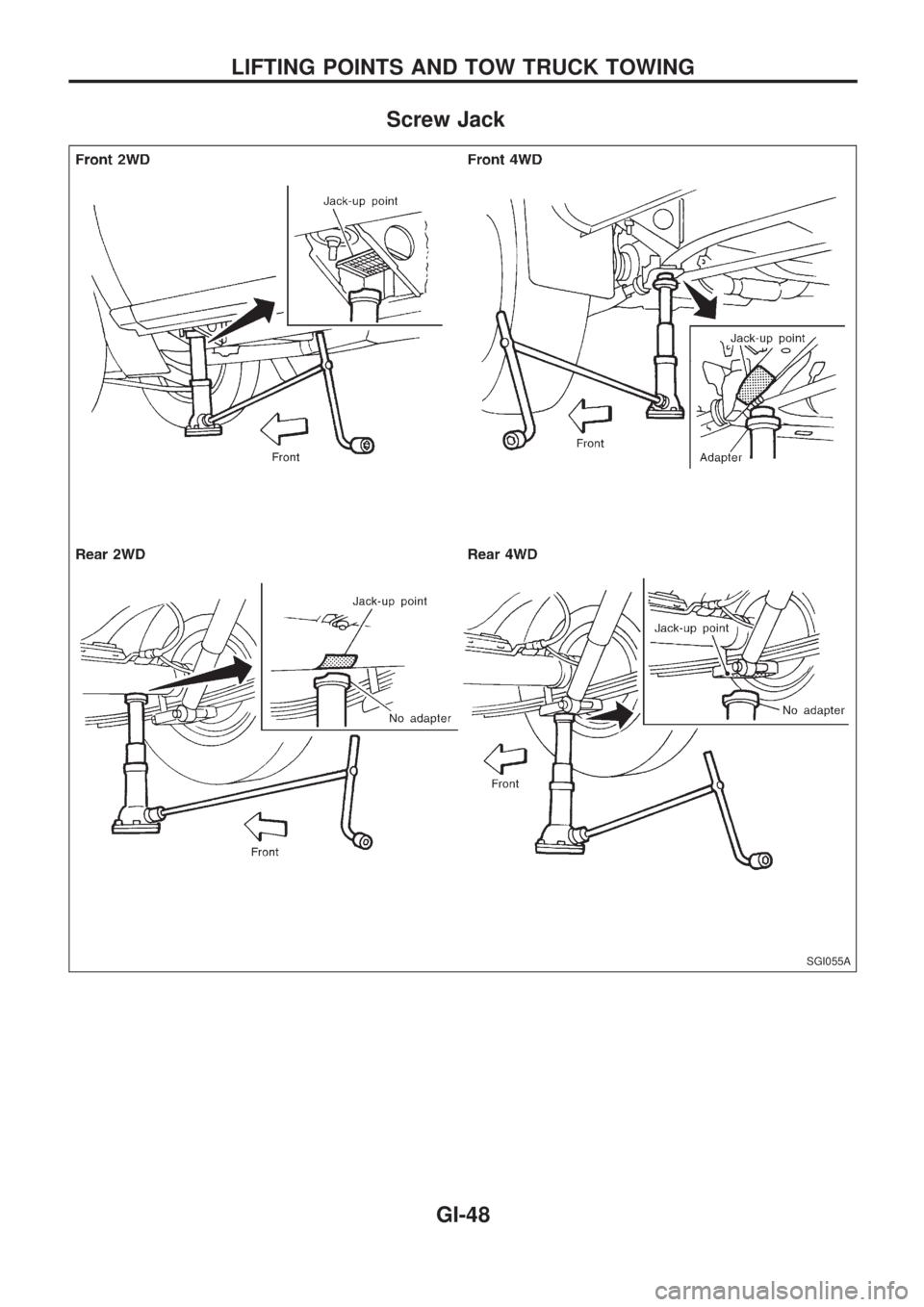

Screw Jack

SGI055A

LIFTING POINTS AND TOW TRUCK TOWING

GI-48

Page 853 of 1659

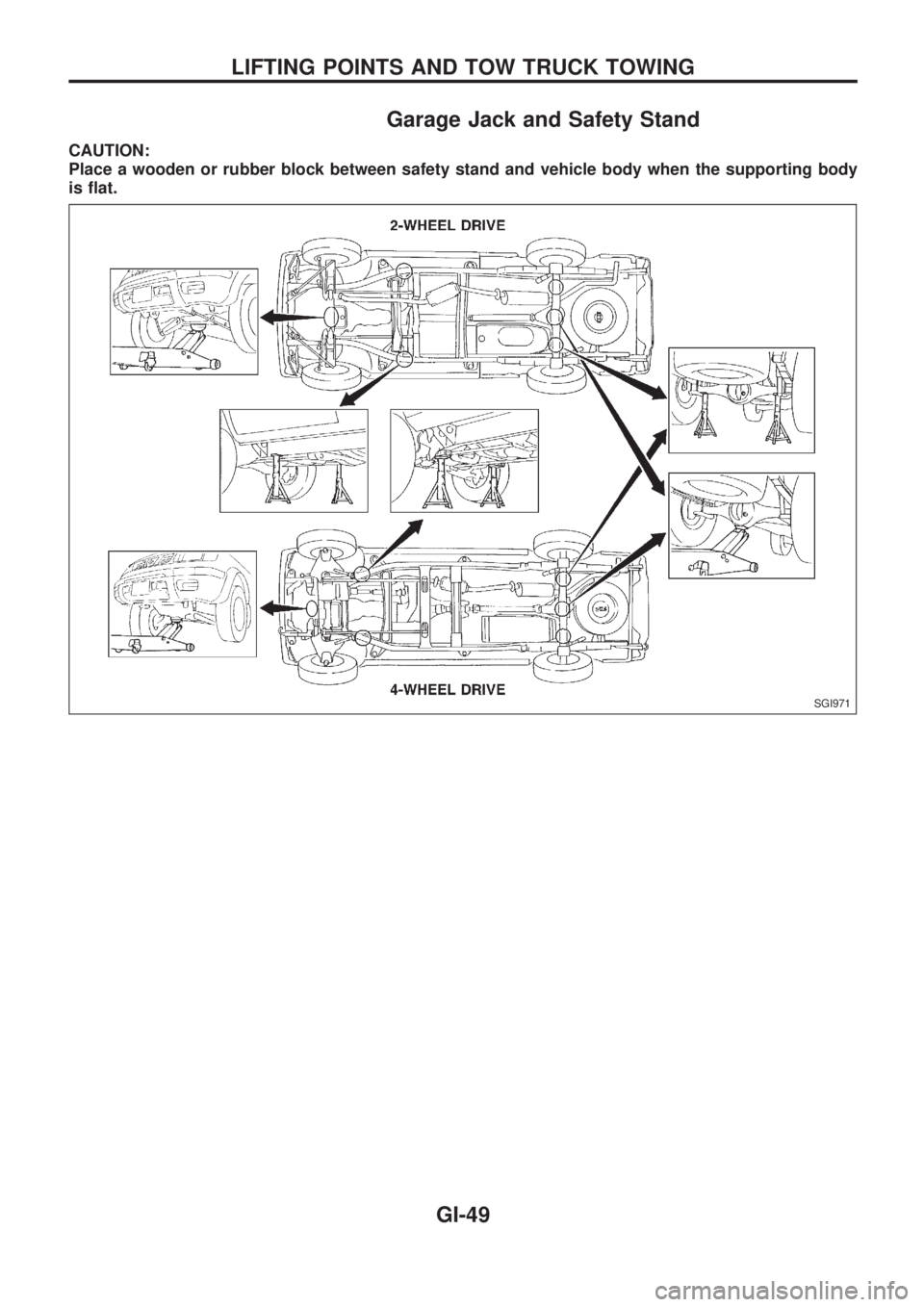

Garage Jack and Safety Stand

CAUTION:

Place a wooden or rubber block between safety stand and vehicle body when the supporting body

is flat.

SGI971

LIFTING POINTS AND TOW TRUCK TOWING

GI-49

Page 854 of 1659

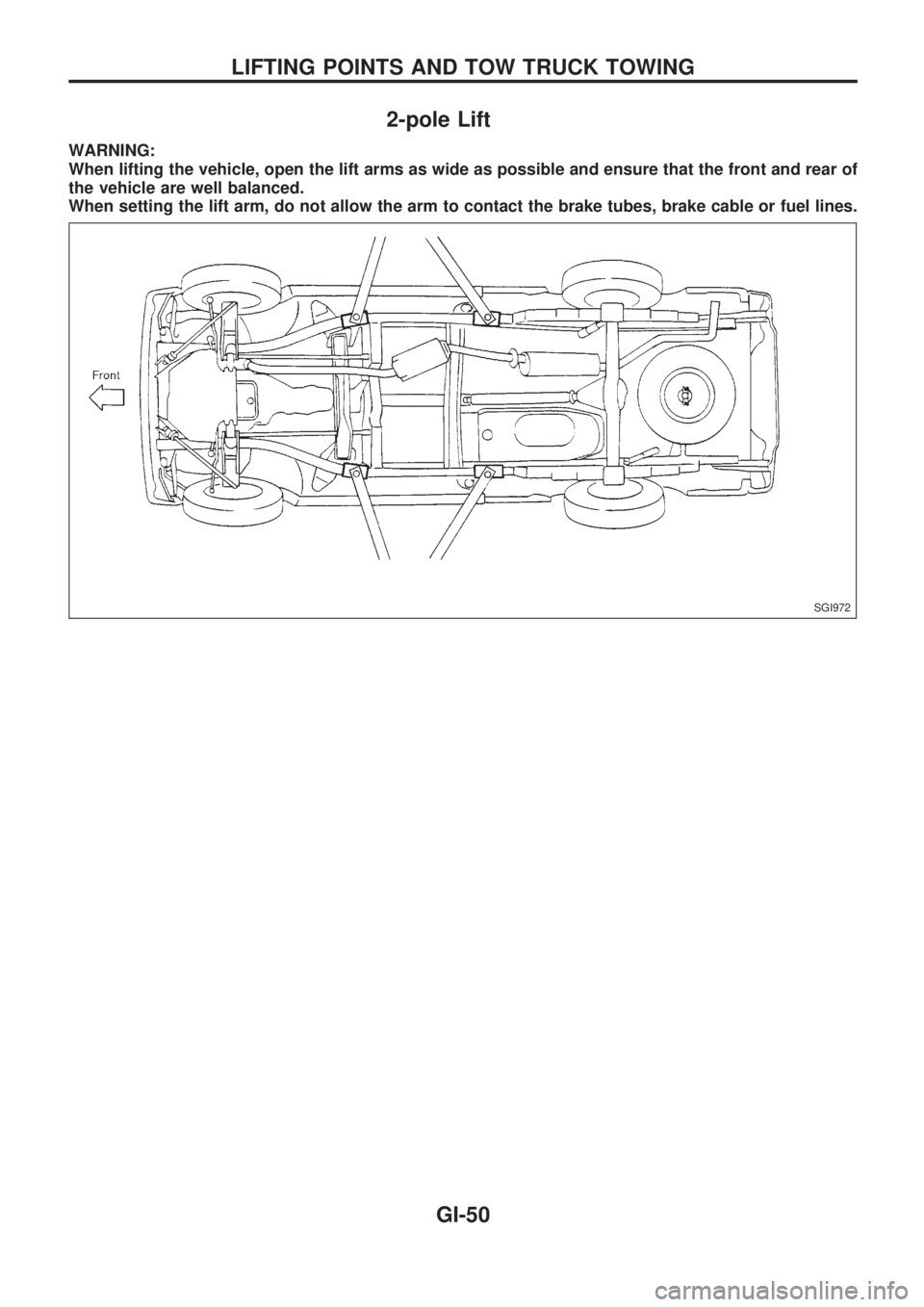

2-pole Lift

WARNING:

When lifting the vehicle, open the lift arms as wide as possible and ensure that the front and rear of

the vehicle are well balanced.

When setting the lift arm, do not allow the arm to contact the brake tubes, brake cable or fuel lines.

SGI972

LIFTING POINTS AND TOW TRUCK TOWING

GI-50

Page 855 of 1659

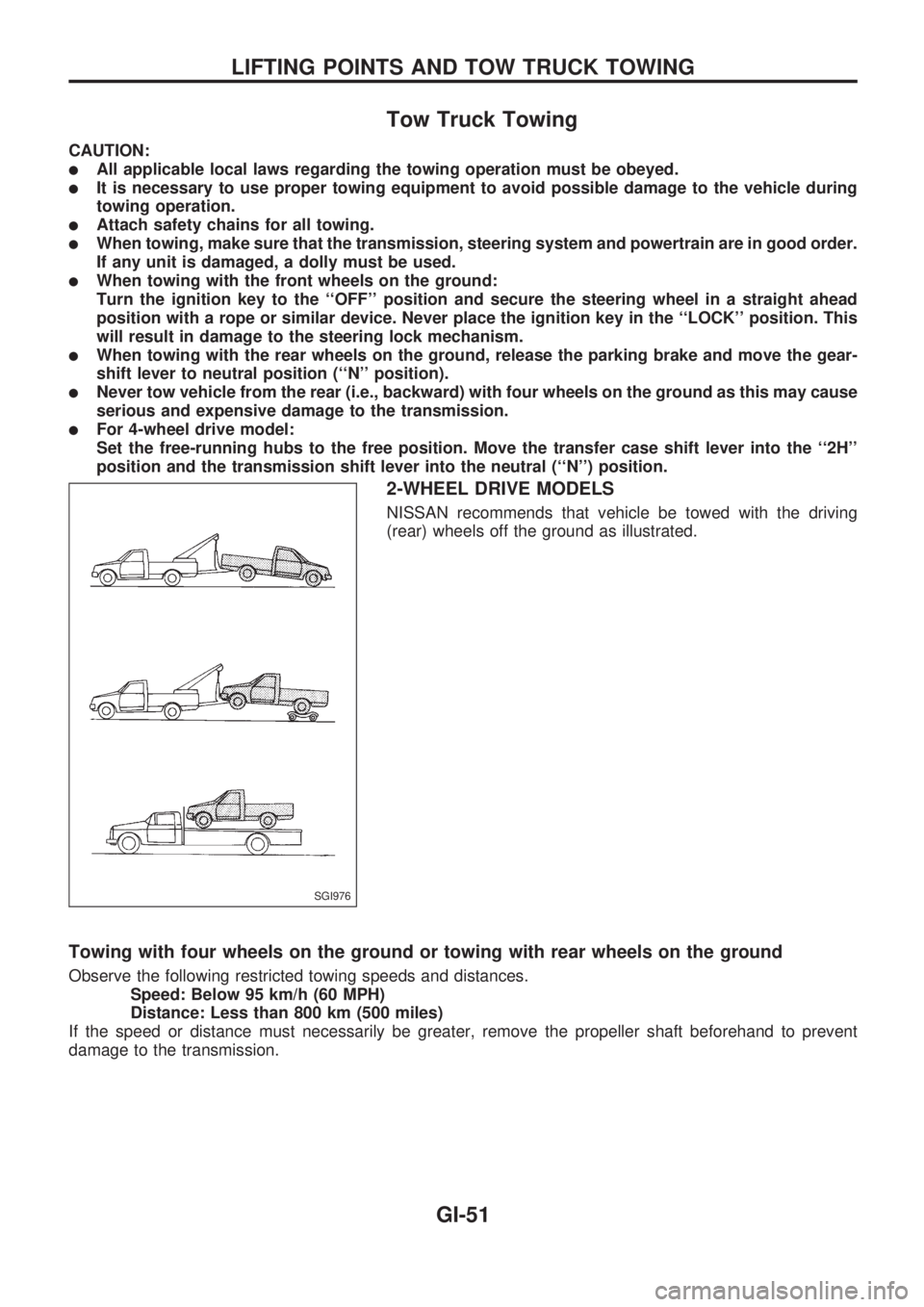

Tow Truck Towing

CAUTION:

lAll applicable local laws regarding the towing operation must be obeyed.

lIt is necessary to use proper towing equipment to avoid possible damage to the vehicle during

towing operation.

lAttach safety chains for all towing.

lWhen towing, make sure that the transmission, steering system and powertrain are in good order.

If any unit is damaged, a dolly must be used.

lWhen towing with the front wheels on the ground:

Turn the ignition key to the ``OFF'' position and secure the steering wheel in a straight ahead

position with a rope or similar device. Never place the ignition key in the ``LOCK'' position. This

will result in damage to the steering lock mechanism.

lWhen towing with the rear wheels on the ground, release the parking brake and move the gear-

shift lever to neutral position (``N'' position).

lNever tow vehicle from the rear (i.e., backward) with four wheels on the ground as this may cause

serious and expensive damage to the transmission.

lFor 4-wheel drive model:

Set the free-running hubs to the free position. Move the transfer case shift lever into the ``2H''

position and the transmission shift lever into the neutral (``N'') position.

2-WHEEL DRIVE MODELS

NISSAN recommends that vehicle be towed with the driving

(rear) wheels off the ground as illustrated.

Towing with four wheels on the ground or towing with rear wheels on the ground

Observe the following restricted towing speeds and distances.

Speed: Below 95 km/h (60 MPH)

Distance: Less than 800 km (500 miles)

If the speed or distance must necessarily be greater, remove the propeller shaft beforehand to prevent

damage to the transmission.

SGI976

LIFTING POINTS AND TOW TRUCK TOWING

GI-51

Page 856 of 1659

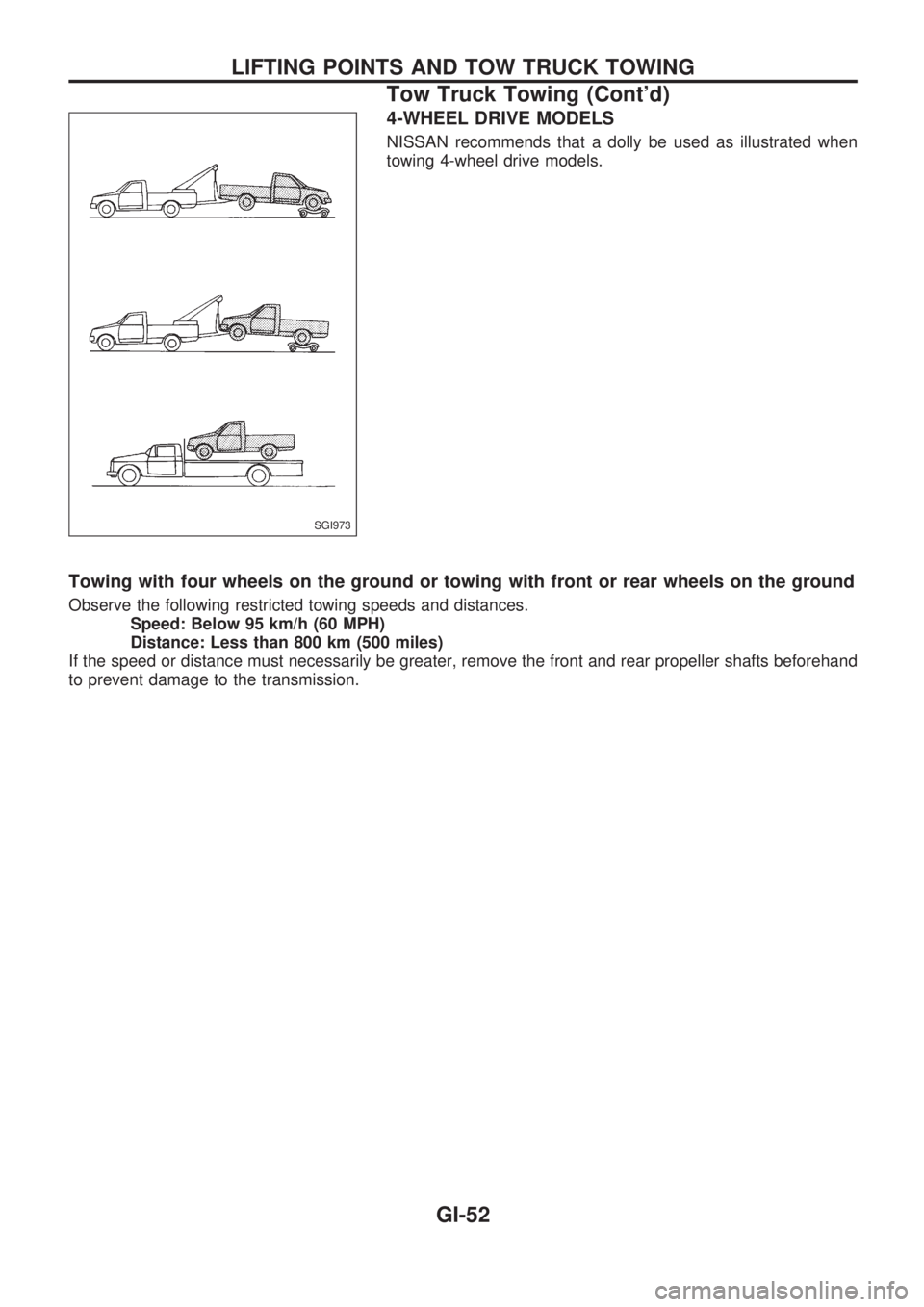

4-WHEEL DRIVE MODELS

NISSAN recommends that a dolly be used as illustrated when

towing 4-wheel drive models.

Towing with four wheels on the ground or towing with front or rear wheels on the ground

Observe the following restricted towing speeds and distances.

Speed: Below 95 km/h (60 MPH)

Distance: Less than 800 km (500 miles)

If the speed or distance must necessarily be greater, remove the front and rear propeller shafts beforehand

to prevent damage to the transmission.

SGI973

LIFTING POINTS AND TOW TRUCK TOWING

Tow Truck Towing (Cont'd)

GI-52

Page 857 of 1659

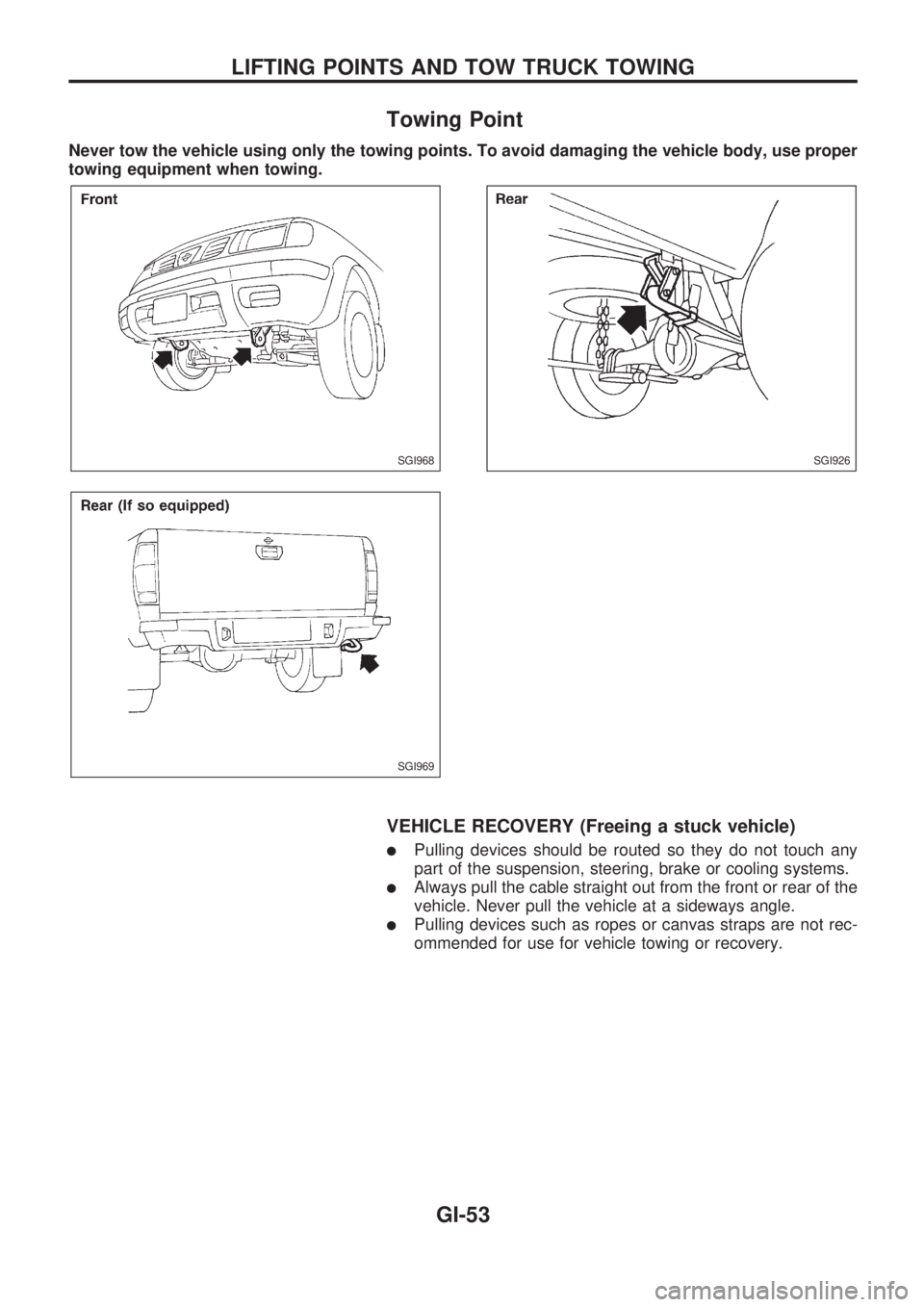

Towing Point

Never tow the vehicle using only the towing points. To avoid damaging the vehicle body, use proper

towing equipment when towing.

VEHICLE RECOVERY (Freeing a stuck vehicle)

lPulling devices should be routed so they do not touch any

part of the suspension, steering, brake or cooling systems.

lAlways pull the cable straight out from the front or rear of the

vehicle. Never pull the vehicle at a sideways angle.

lPulling devices such as ropes or canvas straps are not rec-

ommended for use for vehicle towing or recovery.

SGI968

SGI969

SGI926

LIFTING POINTS AND TOW TRUCK TOWING

GI-53

Page 858 of 1659

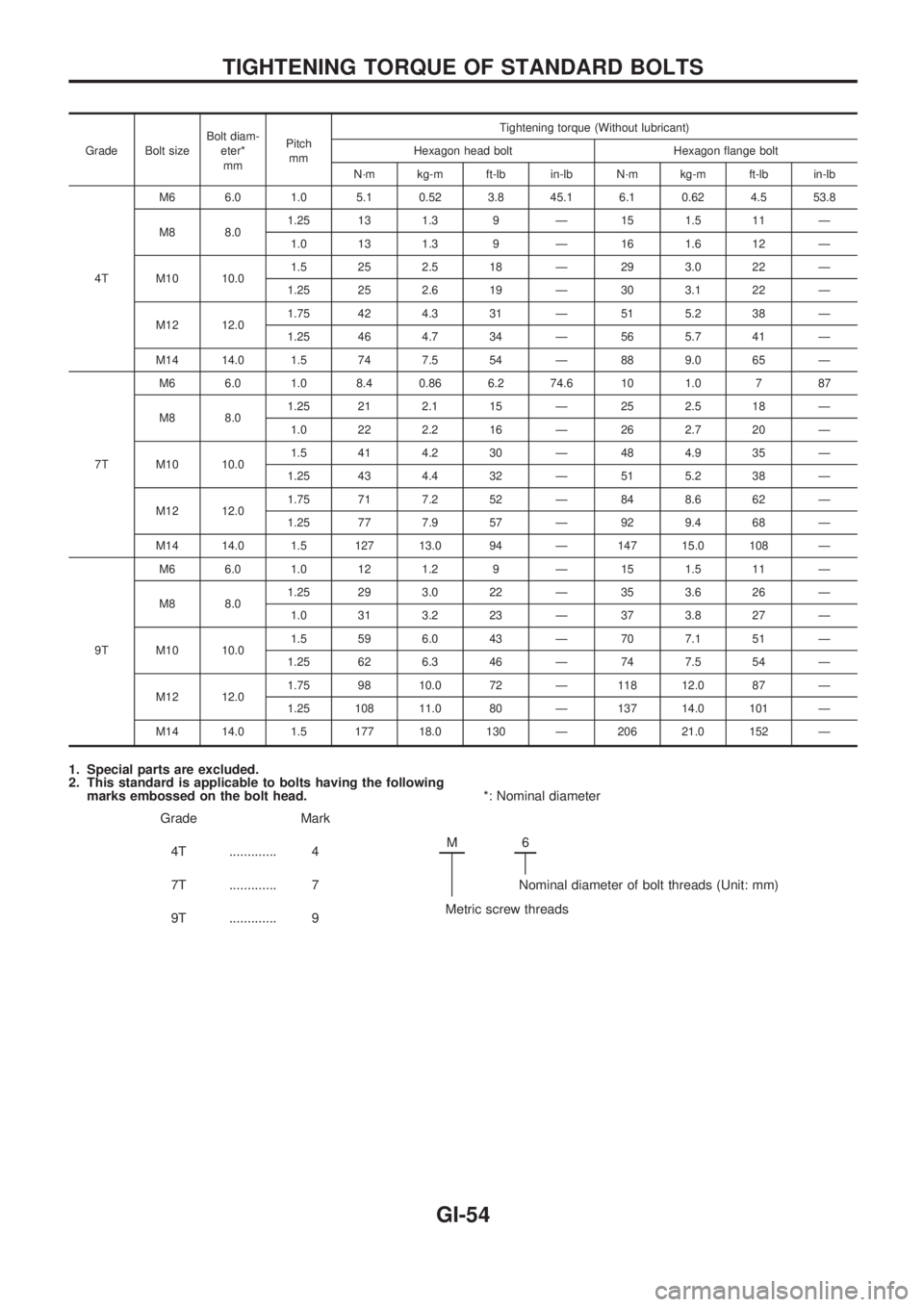

Grade Bolt sizeBolt diam-

eter*

mmPitch

mmTightening torque (Without lubricant)

Hexagon head bolt Hexagon flange bolt

N´m kg-m ft-lb in-lb N´m kg-m ft-lb in-lb

4TM6 6.0 1.0 5.1 0.52 3.8 45.1 6.1 0.62 4.5 53.8

M8 8.01.25 13 1.3 9 Ð 15 1.5 11 Ð

1.0 13 1.3 9 Ð 16 1.6 12 Ð

M10 10.01.5 25 2.5 18 Ð 29 3.0 22 Ð

1.25 25 2.6 19 Ð 30 3.1 22 Ð

M12 12.01.75 42 4.3 31 Ð 51 5.2 38 Ð

1.25 46 4.7 34 Ð 56 5.7 41 Ð

M14 14.0 1.5 74 7.5 54 Ð 88 9.0 65 Ð

7TM6 6.0 1.0 8.4 0.86 6.2 74.6 10 1.0 7 87

M8 8.01.25 21 2.1 15 Ð 25 2.5 18 Ð

1.0 22 2.2 16 Ð 26 2.7 20 Ð

M10 10.01.5 41 4.2 30 Ð 48 4.9 35 Ð

1.25 43 4.4 32 Ð 51 5.2 38 Ð

M12 12.01.75 71 7.2 52 Ð 84 8.6 62 Ð

1.25 77 7.9 57 Ð 92 9.4 68 Ð

M14 14.0 1.5 127 13.0 94 Ð 147 15.0 108 Ð

9TM6 6.0 1.0 12 1.2 9 Ð 15 1.5 11 Ð

M8 8.01.25 29 3.0 22 Ð 35 3.6 26 Ð

1.0 31 3.2 23 Ð 37 3.8 27 Ð

M10 10.01.5 59 6.0 43 Ð 70 7.1 51 Ð

1.25 62 6.3 46 Ð 74 7.5 54 Ð

M12 12.01.75 98 10.0 72 Ð 118 12.0 87 Ð

1.25 108 11.0 80 Ð 137 14.0 101 Ð

M14 14.0 1.5 177 18.0 130 Ð 206 21.0 152 Ð

1. Special parts are excluded.

2. This standard is applicable to bolts having the following

marks embossed on the bolt head.*: Nominal diameter

Grade Mark

4T ............. 4M

6

7T ............. 7 Nominal diameter of bolt threads (Unit: mm)

9T ............. 9Metric screw threads

TIGHTENING TORQUE OF STANDARD BOLTS

GI-54

Page 859 of 1659

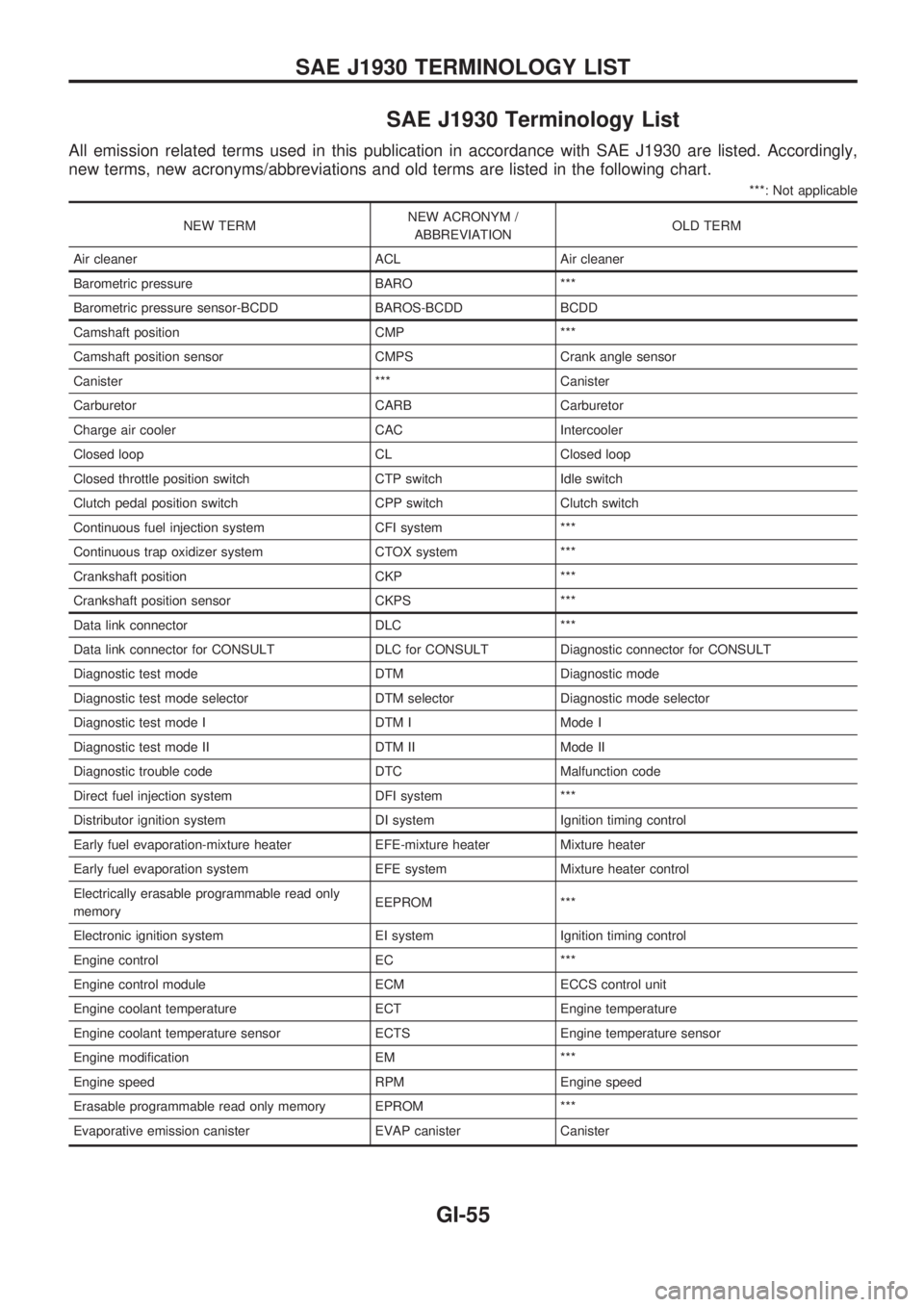

SAE J1930 Terminology List

All emission related terms used in this publication in accordance with SAE J1930 are listed. Accordingly,

new terms, new acronyms/abbreviations and old terms are listed in the following chart.

***: Not applicable

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Air cleaner ACL Air cleaner

Barometric pressure BARO ***

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPS Crank angle sensor

Canister *** Canister

Carburetor CARB Carburetor

Charge air cooler CAC Intercooler

Closed loop CL Closed loop

Closed throttle position switch CTP switch Idle switch

Clutch pedal position switch CPP switch Clutch switch

Continuous fuel injection system CFI system ***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP ***

Crankshaft position sensor CKPS ***

Data link connector DLC ***

Data link connector for CONSULT DLC for CONSULT Diagnostic connector for CONSULT

Diagnostic test mode DTM Diagnostic mode

Diagnostic test mode selector DTM selector Diagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM II Mode II

Diagnostic trouble code DTC Malfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programmable read only

memoryEEPROM ***

Electronic ignition system EI system Ignition timing control

Engine control EC ***

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPM Engine speed

Erasable programmable read only memory EPROM ***

Evaporative emission canister EVAP canister Canister

SAE J1930 TERMINOLOGY LIST

GI-55

Page 860 of 1659

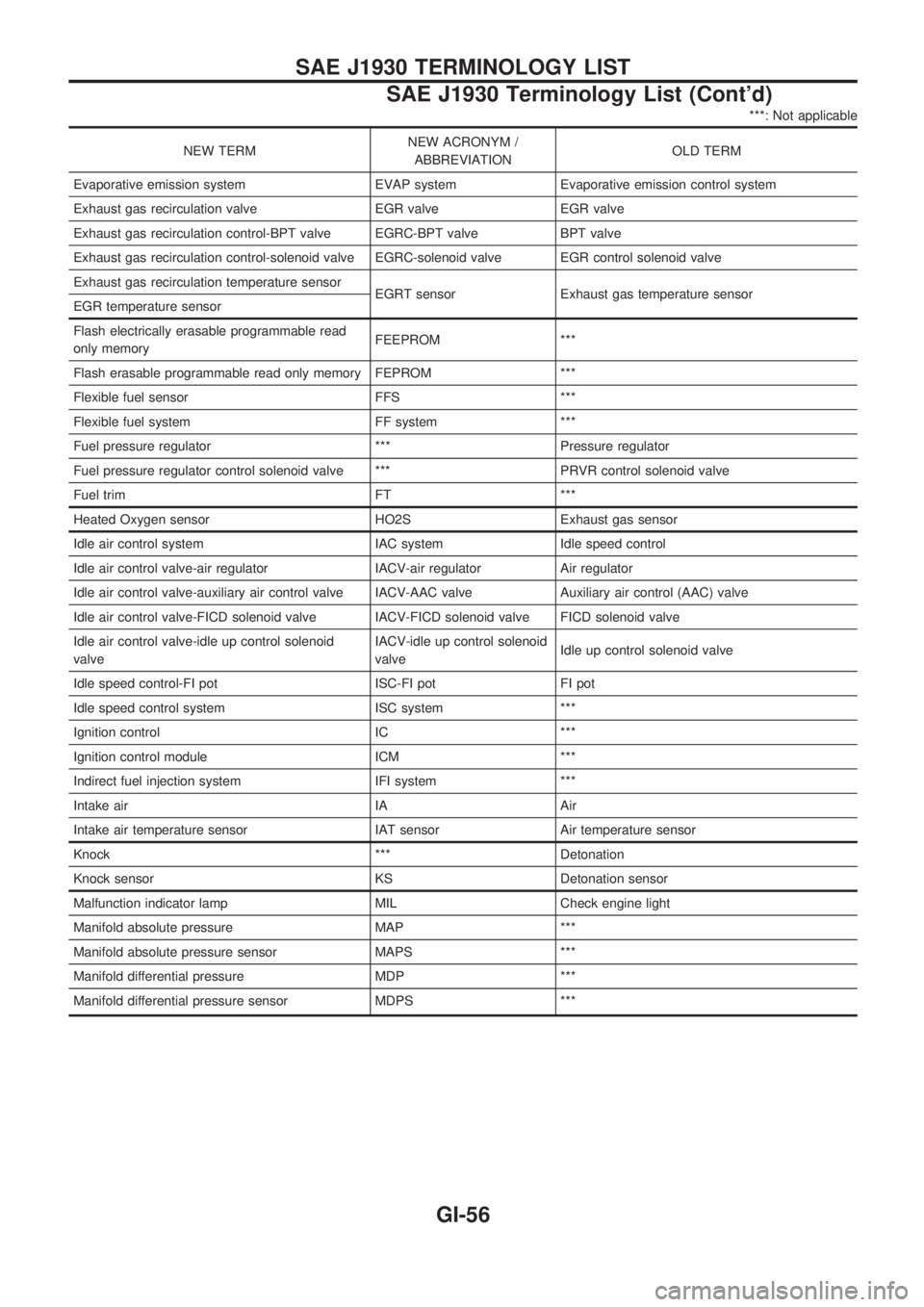

***: Not applicable

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Evaporative emission system EVAP system Evaporative emission control system

Exhaust gas recirculation valve EGR valve EGR valve

Exhaust gas recirculation control-BPT valve EGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid valve EGRC-solenoid valve EGR control solenoid valve

Exhaust gas recirculation temperature sensor

EGRT sensor Exhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable read

only memoryFEEPROM ***

Flash erasable programmable read only memory FEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel pressure regulator *** Pressure regulator

Fuel pressure regulator control solenoid valve *** PRVR control solenoid valve

Fuel trim FT ***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulator IACV-air regulator Air regulator

Idle air control valve-auxiliary air control valve IACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control solenoid

valveIACV-idle up control solenoid

valveIdle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control IC ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator lamp MIL Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

SAE J1930 TERMINOLOGY LIST

SAE J1930 Terminology List (Cont'd)

GI-56