NISSAN PICK-UP 1998 Manual Online

Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 81 of 1659

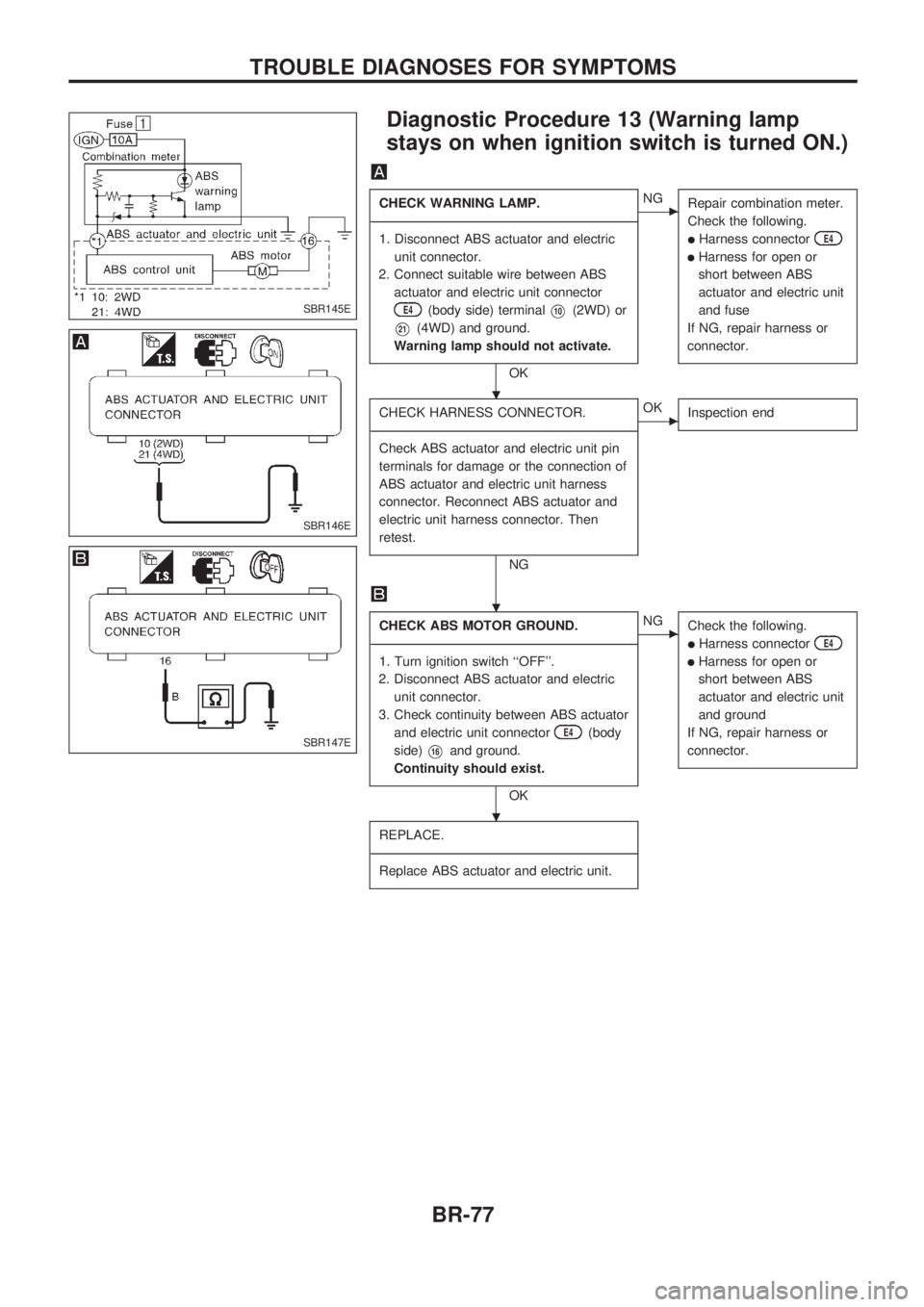

Diagnostic Procedure 13 (Warning lamp

stays on when ignition switch is turned ON.)

CHECK WARNING LAMP.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Disconnect ABS actuator and electric

unit connector.

2. Connect suitable wire between ABS

actuator and electric unit connector

E4(body side) terminalV10(2WD) or

V21(4WD) and ground.

Warning lamp should not activate.

OK

cNG

Repair combination meter.

Check the following.

lHarness connectorE4

lHarness for open or

short between ABS

actuator and electric unit

and fuse

If NG, repair harness or

connector.

CHECK HARNESS CONNECTOR.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector. Reconnect ABS actuator and

electric unit harness connector. Then

retest.

NG

cOK

Inspection end

CHECK ABS MOTOR GROUND.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch ``OFF''.

2. Disconnect ABS actuator and electric

unit connector.

3. Check continuity between ABS actuator

and electric unit connector

E4(body

side)

V16and ground.

Continuity should exist.

OK

cNG

Check the following.

lHarness connectorE4

lHarness for open or

short between ABS

actuator and electric unit

and ground

If NG, repair harness or

connector.

REPLACE.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Replace ABS actuator and electric unit.

SBR145E

SBR146E

SBR147E

.

.

.

TROUBLE DIAGNOSES FOR SYMPTOMS

BR-77

Page 82 of 1659

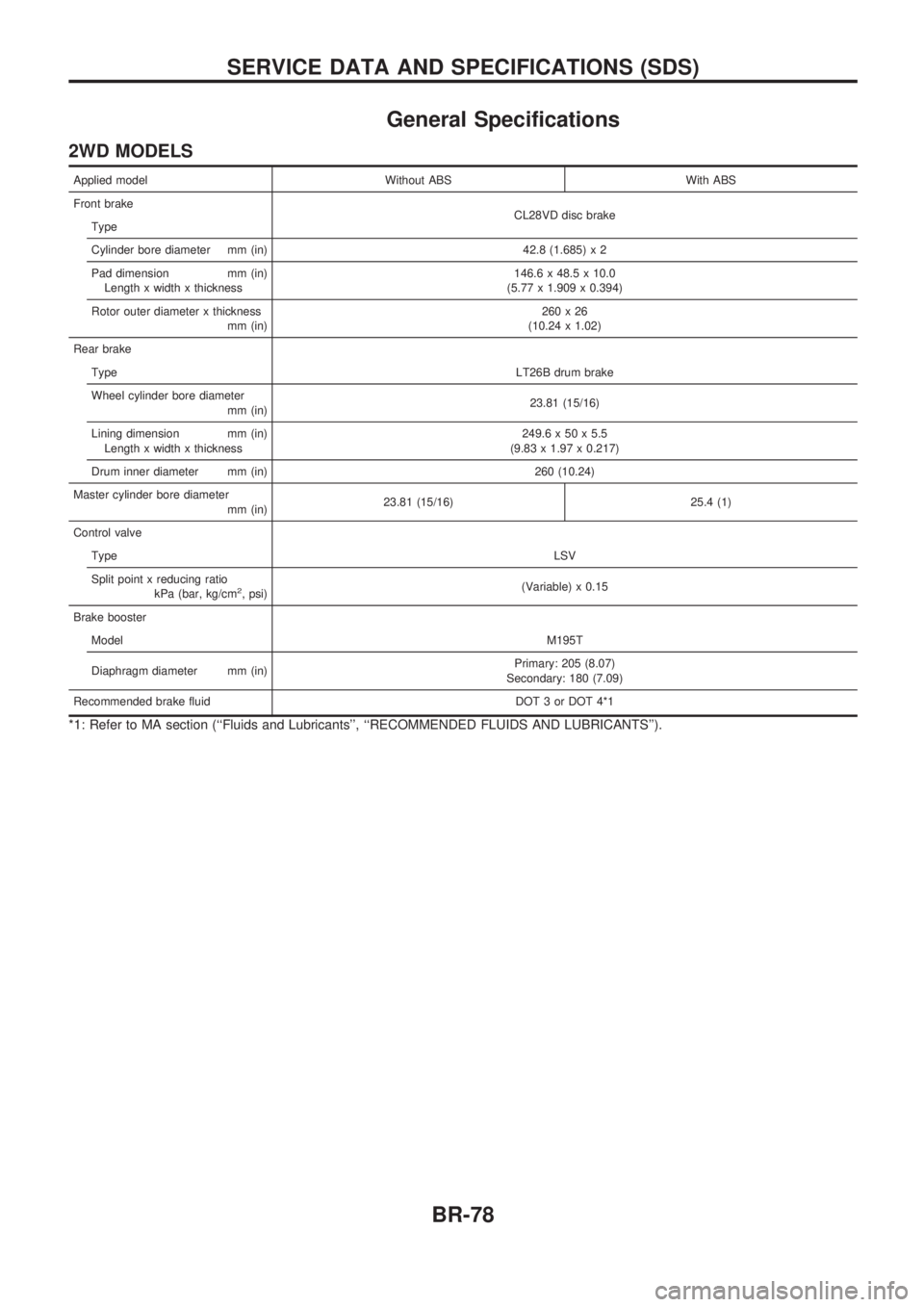

General Specifications

2WD MODELS

Applied model Without ABS With ABS

Front brake

CL28VD disc brake

Type

Cylinder bore diameter mm (in) 42.8 (1.685) x 2

Pad dimension mm (in)

Length x width x thickness146.6 x 48.5 x 10.0

(5.77 x 1.909 x 0.394)

Rotor outer diameter x thickness

mm (in)260x26

(10.24 x 1.02)

Rear brake

TypeLT26B drum brake

Wheel cylinder bore diameter

mm (in)23.81 (15/16)

Lining dimension mm (in)

Length x width x thickness249.6 x 50 x 5.5

(9.83 x 1.97 x 0.217)

Drum inner diameter mm (in) 260 (10.24)

Master cylinder bore diameter

mm (in)23.81 (15/16) 25.4 (1)

Control valve

TypeLSV

Split point x reducing ratio

kPa (bar, kg/cm

2, psi)(Variable) x 0.15

Brake booster

ModelM195T

Diaphragm diameter mm (in)Primary: 205 (8.07)

Secondary: 180 (7.09)

Recommended brake fluid DOT 3 or DOT 4*1

*1: Refer to MA section (``Fluids and Lubricants'', ``RECOMMENDED FLUIDS AND LUBRICANTS'').

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-78

Page 83 of 1659

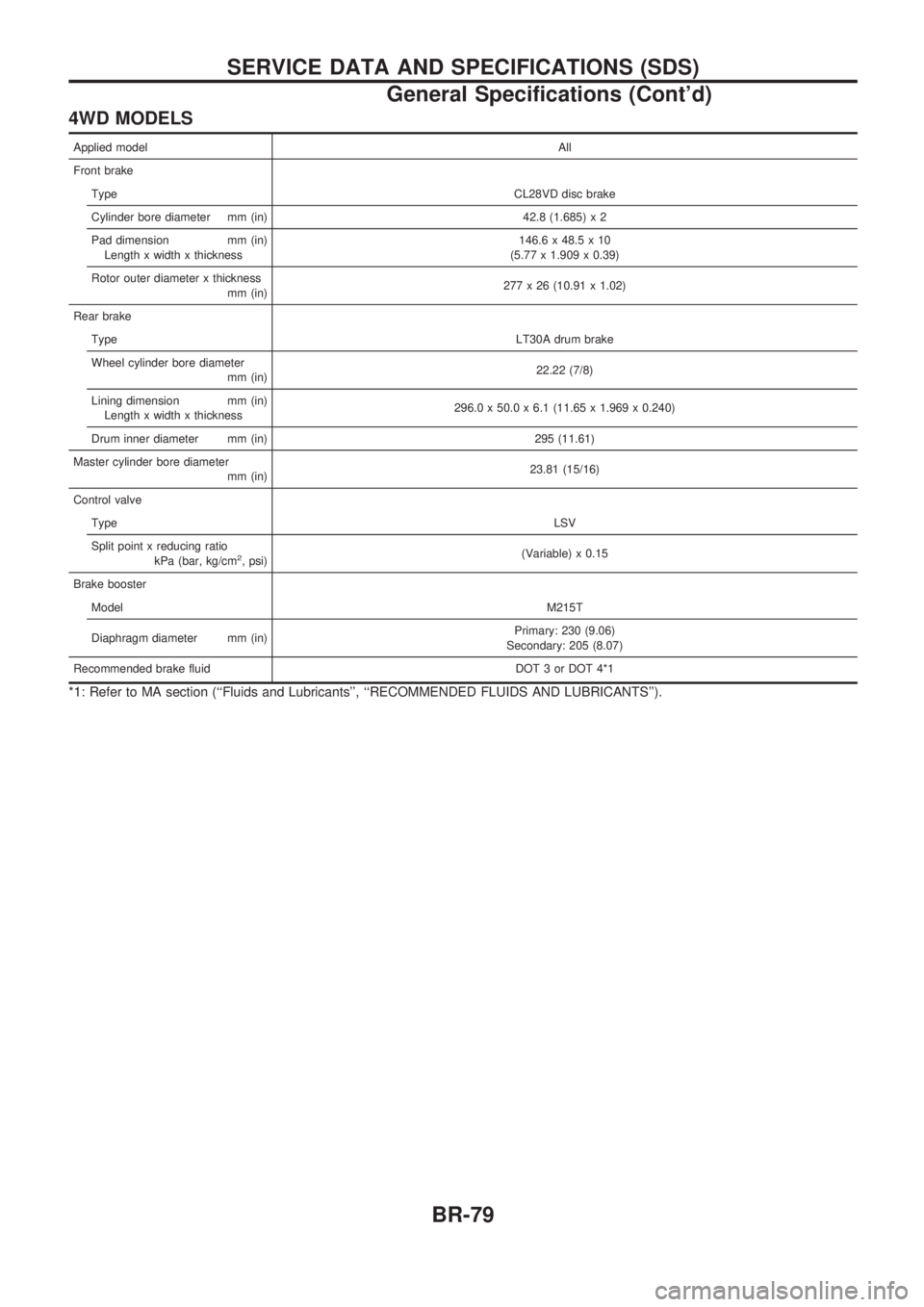

4WD MODELS

Applied modelAll

Front brake

TypeCL28VD disc brake

Cylinder bore diameter mm (in) 42.8 (1.685) x 2

Pad dimension mm (in)

Length x width x thickness146.6 x 48.5 x 10

(5.77 x 1.909 x 0.39)

Rotor outer diameter x thickness

mm (in)277 x 26 (10.91 x 1.02)

Rear brake

TypeLT30A drum brake

Wheel cylinder bore diameter

mm (in)22.22 (7/8)

Lining dimension mm (in)

Length x width x thickness296.0 x 50.0 x 6.1 (11.65 x 1.969 x 0.240)

Drum inner diameter mm (in) 295 (11.61)

Master cylinder bore diameter

mm (in)23.81 (15/16)

Control valve

TypeLSV

Split point x reducing ratio

kPa (bar, kg/cm

2, psi)(Variable) x 0.15

Brake booster

ModelM215T

Diaphragm diameter mm (in)Primary: 230 (9.06)

Secondary: 205 (8.07)

Recommended brake fluid DOT 3 or DOT 4*1

*1: Refer to MA section (``Fluids and Lubricants'', ``RECOMMENDED FLUIDS AND LUBRICANTS'').

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specifications (Cont'd)

BR-79

Page 84 of 1659

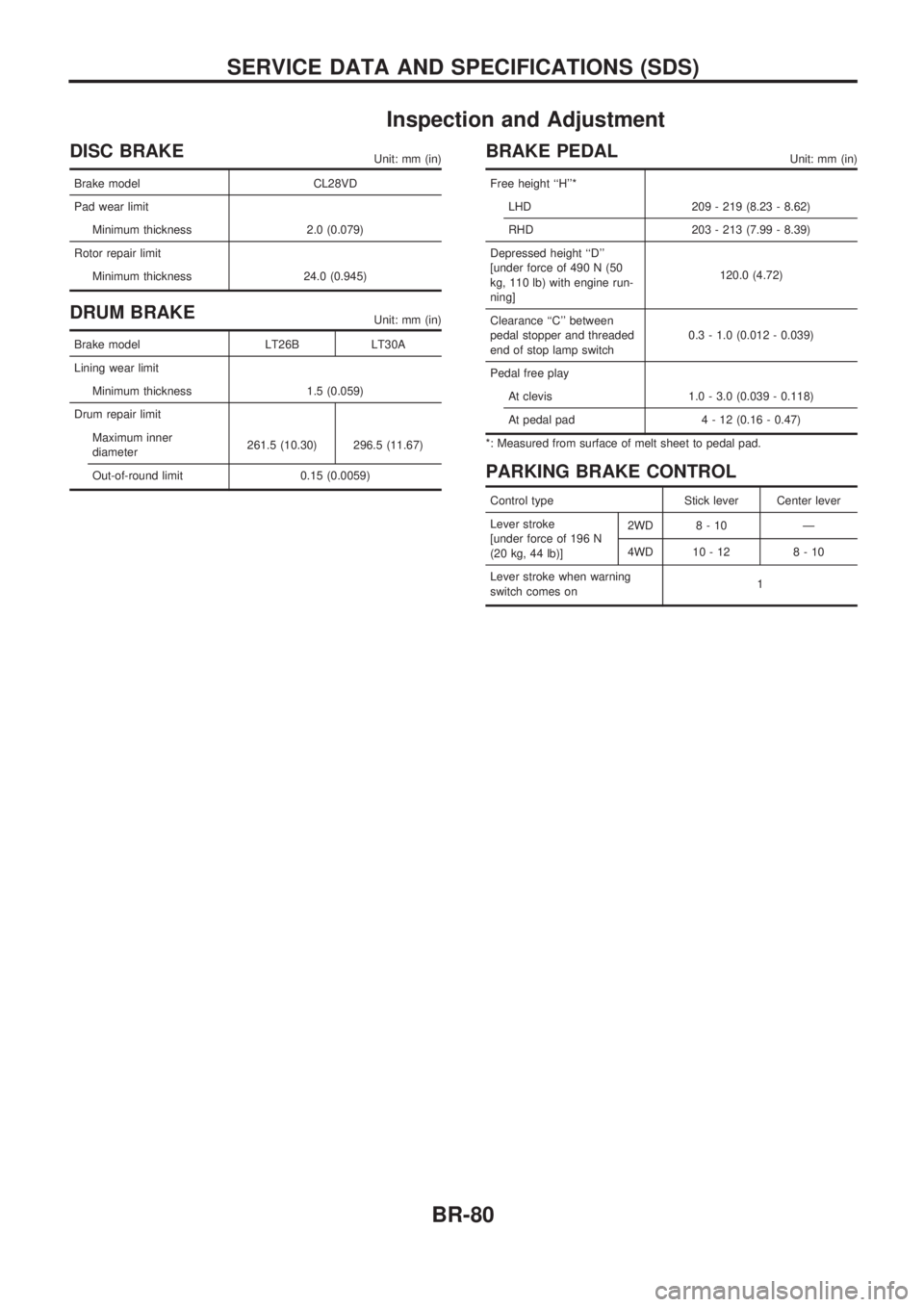

Inspection and Adjustment

DISC BRAKEUnit: mm (in)

Brake model CL28VD

Pad wear limit

Minimum thickness 2.0 (0.079)

Rotor repair limit

Minimum thickness 24.0 (0.945)

DRUM BRAKEUnit: mm (in)

Brake model LT26B LT30A

Lining wear limit

Minimum thickness 1.5 (0.059)

Drum repair limit

Maximum inner

diameter261.5 (10.30) 296.5 (11.67)

Out-of-round limit 0.15 (0.0059)

BRAKE PEDALUnit: mm (in)

Free height ``H''*

LHD 209 - 219 (8.23 - 8.62)

RHD 203 - 213 (7.99 - 8.39)

Depressed height ``D''

[under force of 490 N (50

kg, 110 lb) with engine run-

ning]120.0 (4.72)

Clearance ``C'' between

pedal stopper and threaded

end of stop lamp switch0.3 - 1.0 (0.012 - 0.039)

Pedal free play

At clevis 1.0 - 3.0 (0.039 - 0.118)

At pedal pad 4 - 12 (0.16 - 0.47)

*: Measured from surface of melt sheet to pedal pad.

PARKING BRAKE CONTROL

Control type Stick lever Center lever

Lever stroke

[under force of 196 N

(20 kg, 44 lb)]2WD 8 - 10 Ð

4WD 10-12 8-10

Lever stroke when warning

switch comes on1

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-80

Page 85 of 1659

CLUTCH

SECTIONCL

CONTENTS

PRECAUTIONS AND PREPARATION..................... 1

Precautions ............................................................ 1

Special Service Tools ............................................ 1

Commercial Service Tools ..................................... 2

CLUTCH SYSTEM..................................................... 3

Clutch Pedal........................................................... 4

INSPECTION AND ADJUSTMENT........................... 5

Adjusting Clutch Pedal........................................... 5

Air Bleeding Procedure .......................................... 5

HYDRAULIC CLUTCH CONTROL........................... 6Clutch Master Cylinder .......................................... 6

Operating Cylinder ................................................. 8

CLUTCH RELEASE MECHANISM........................... 9

CLUTCH DISC AND CLUTCH COVER.................. 12

Clutch Disc and Flywheel .................................... 12

Clutch Cover ........................................................ 13

SERVICE DATA AND SPECIFICATIONS (SDS)... 14

General Specifications ......................................... 14

Inspection and Adjustment .................................. 14

CL

Page 86 of 1659

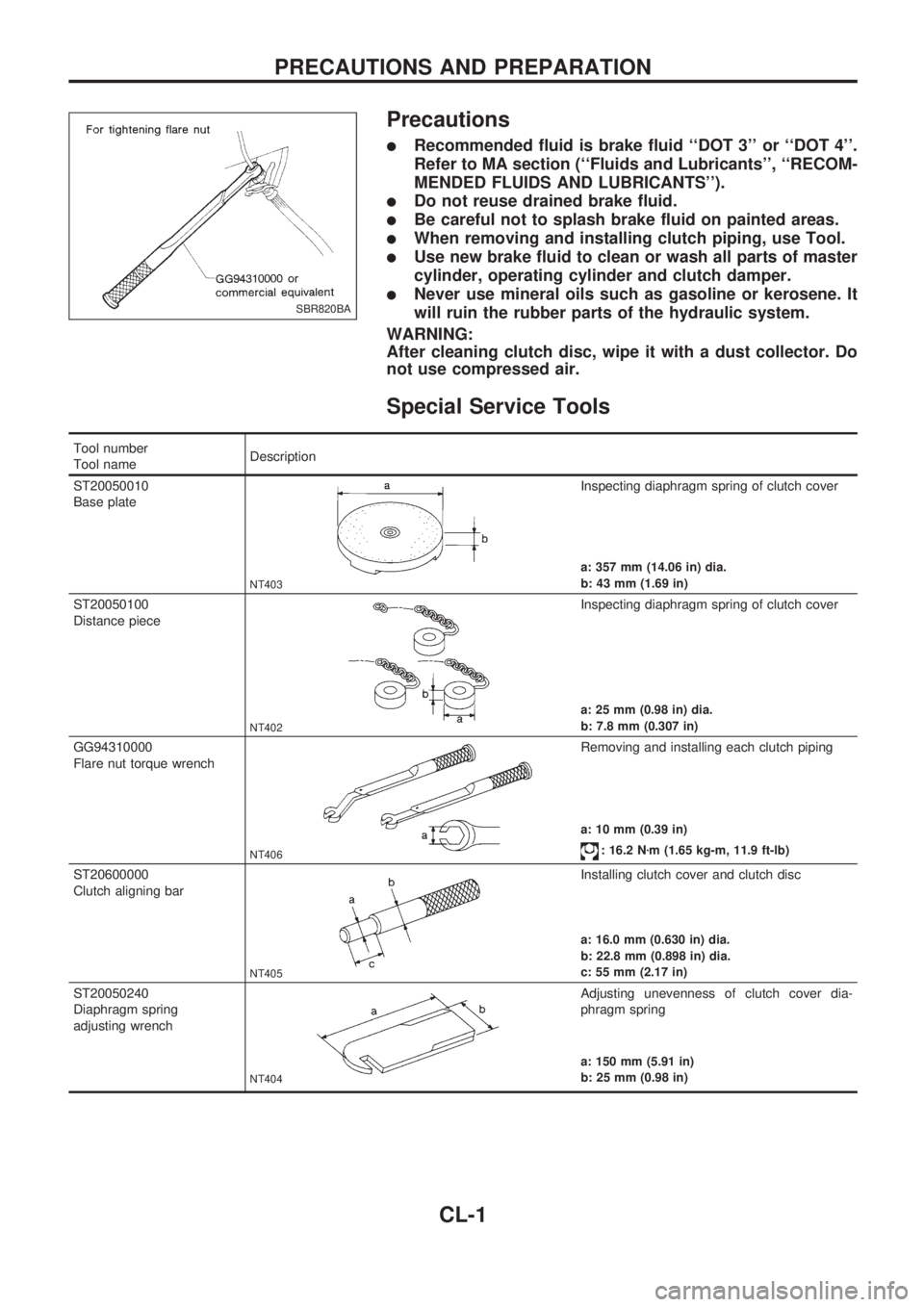

Precautions

lRecommended fluid is brake fluid ``DOT 3'' or ``DOT 4''.

Refer to MA section (``Fluids and Lubricants'', ``RECOM-

MENDED FLUIDS AND LUBRICANTS'').

lDo not reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas.

lWhen removing and installing clutch piping, use Tool.

lUse new brake fluid to clean or wash all parts of master

cylinder, operating cylinder and clutch damper.

lNever use mineral oils such as gasoline or kerosene. It

will ruin the rubber parts of the hydraulic system.

WARNING:

After cleaning clutch disc, wipe it with a dust collector. Do

not use compressed air.

Special Service Tools

Tool number

Tool nameDescription

ST20050010

Base plate

NT403

Inspecting diaphragm spring of clutch cover

a: 357 mm (14.06 in) dia.

b: 43 mm (1.69 in)

ST20050100

Distance piece

NT402

Inspecting diaphragm spring of clutch cover

a: 25 mm (0.98 in) dia.

b: 7.8 mm (0.307 in)

GG94310000

Flare nut torque wrench

NT406

Removing and installing each clutch piping

a: 10 mm (0.39 in)

: 16.2 Nzm (1.65 kg-m, 11.9 ft-lb)

ST20600000

Clutch aligning bar

NT405

Installing clutch cover and clutch disc

a: 16.0 mm (0.630 in) dia.

b: 22.8 mm (0.898 in) dia.

c: 55 mm (2.17 in)

ST20050240

Diaphragm spring

adjusting wrench

NT404

Adjusting unevenness of clutch cover dia-

phragm spring

a: 150 mm (5.91 in)

b: 25 mm (0.98 in)

SBR820BA

PRECAUTIONS AND PREPARATION

CL-1

Page 87 of 1659

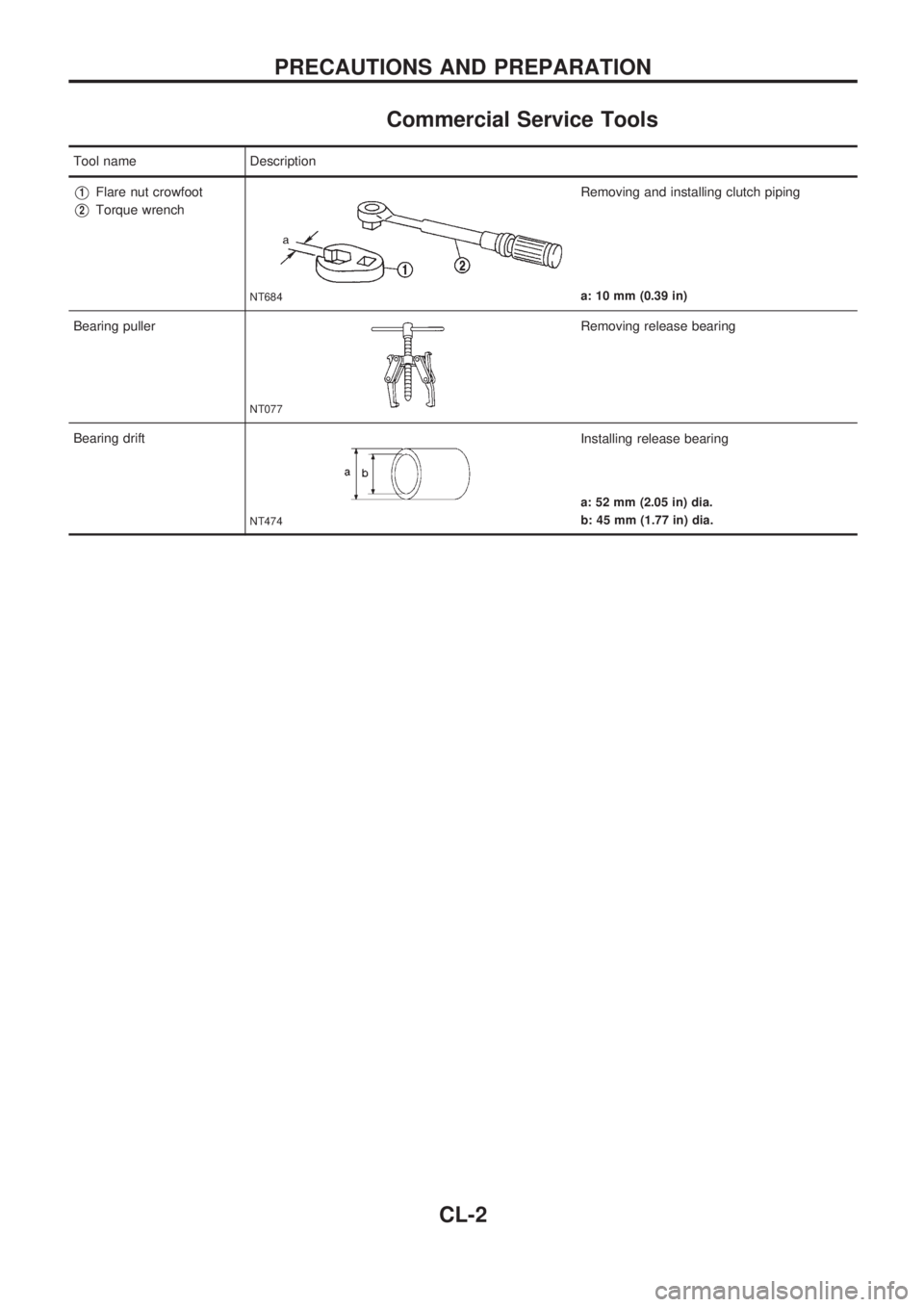

Commercial Service Tools

Tool name Description

V1Flare nut crowfoot

V2Torque wrench

NT684

Removing and installing clutch piping

a: 10 mm (0.39 in)

Bearing puller

NT077

Removing release bearing

Bearing drift

NT474

Installing release bearing

a: 52 mm (2.05 in) dia.

b: 45 mm (1.77 in) dia.

PRECAUTIONS AND PREPARATION

CL-2

Page 88 of 1659

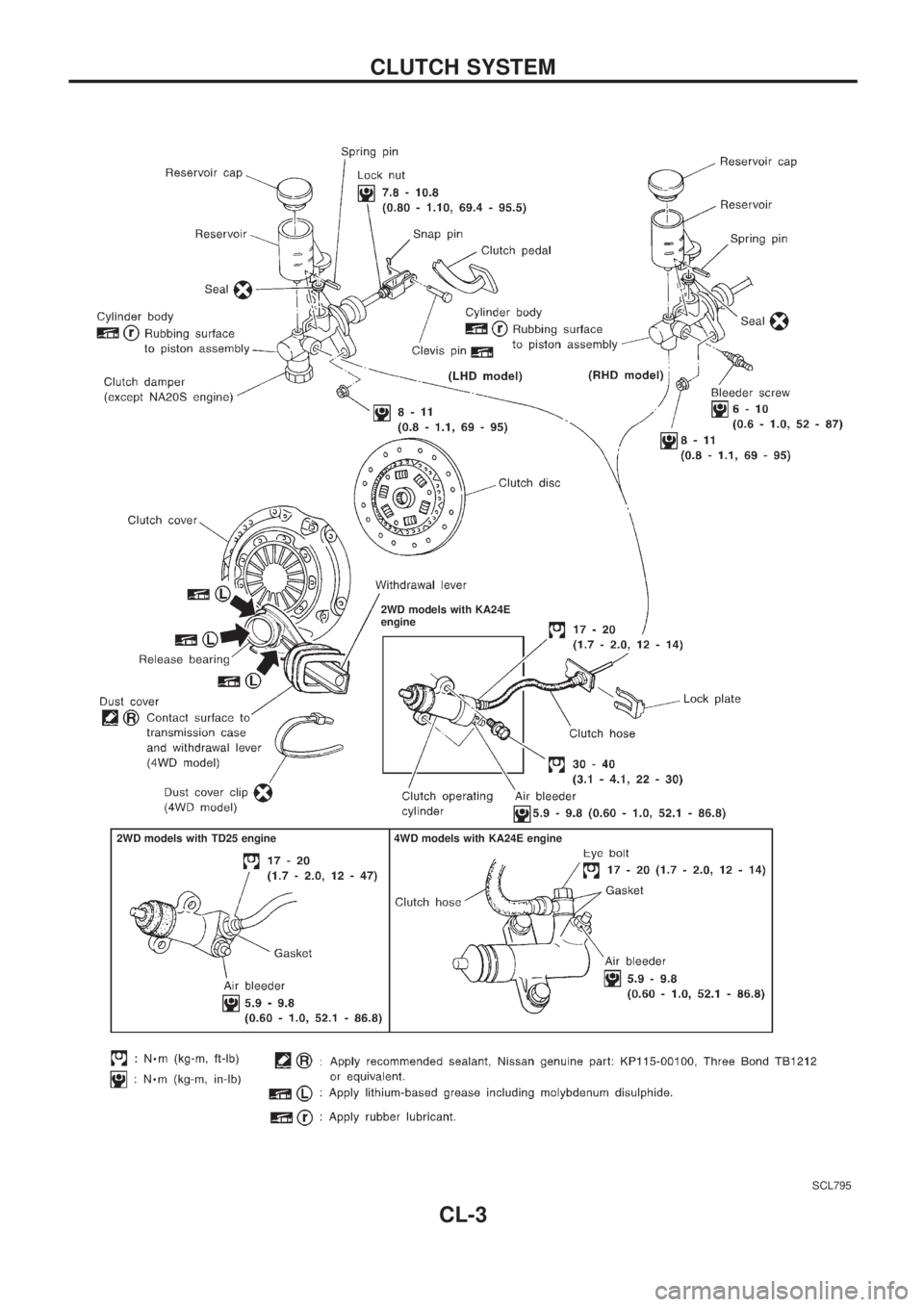

SCL795

.2WD models with KA24E

engine

.2WD models with TD25 engine.4WD models with KA24E engine

CLUTCH SYSTEM

CL-3

Page 89 of 1659

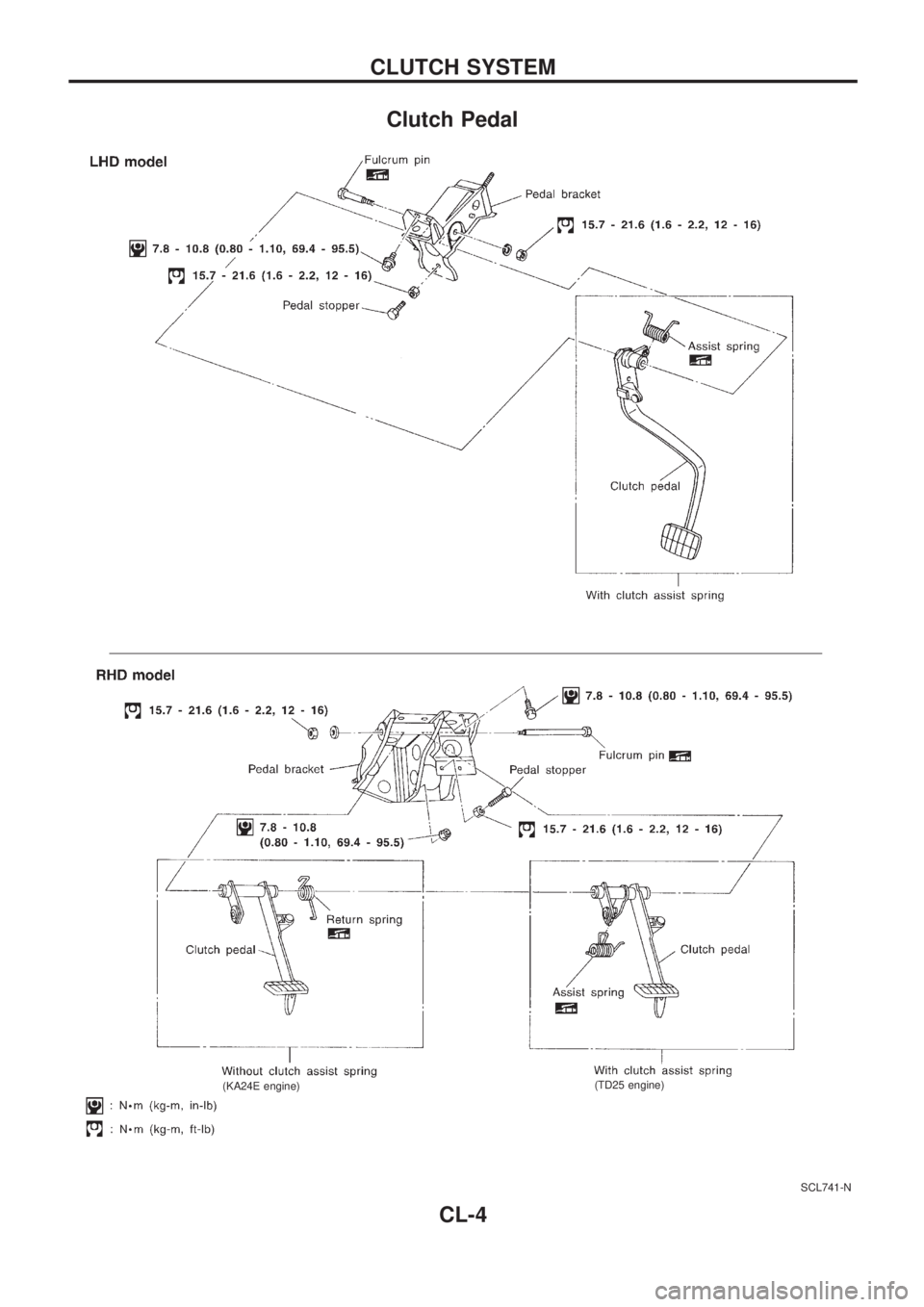

Clutch Pedal

SCL741-N

.(KA24E engine).(TD25 engine)

CLUTCH SYSTEM

CL-4

Page 90 of 1659

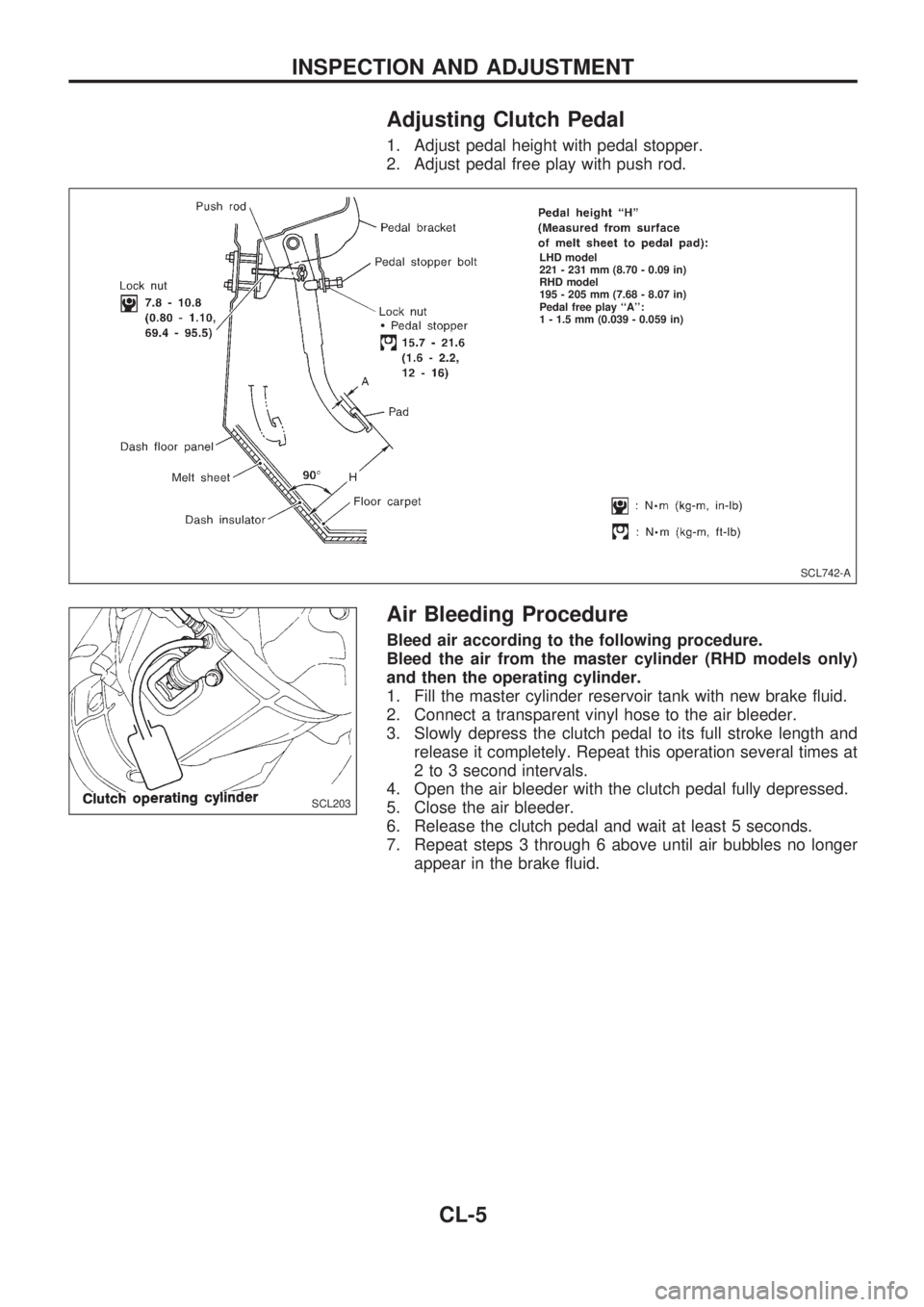

Adjusting Clutch Pedal

1. Adjust pedal height with pedal stopper.

2. Adjust pedal free play with push rod.

Air Bleeding Procedure

Bleed air according to the following procedure.

Bleed the air from the master cylinder (RHD models only)

and then the operating cylinder.

1. Fill the master cylinder reservoir tank with new brake fluid.

2. Connect a transparent vinyl hose to the air bleeder.

3. Slowly depress the clutch pedal to its full stroke length and

release it completely. Repeat this operation several times at

2 to 3 second intervals.

4. Open the air bleeder with the clutch pedal fully depressed.

5. Close the air bleeder.

6. Release the clutch pedal and wait at least 5 seconds.

7. Repeat steps 3 through 6 above until air bubbles no longer

appear in the brake fluid.

SCL742-A

.LHD model

221 - 231 mm (8.70 - 0.09 in)

RHD model

195 - 205 mm (7.68 - 8.07 in)

Pedal free play ``A'':

1 - 1.5 mm (0.039 - 0.059 in)

SCL203

INSPECTION AND ADJUSTMENT

CL-5