NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 2171 of 2267

Precautions

lWhen installing each rubber part, final tightening must

be carried out under unladen condition* with tires on

ground.

*: Fuel, radiator coolant and engine oil full. Spare tire,

jack, hand tools and mats in designated positions.

lUse flare nut wrench when removing or installing brake

tubes.

lAfter installing removed suspension parts, check wheel

alignment.

lDo not jack up at the trailing arm and lateral link.

lAlways torque brake lines when installing.

Special Service Tools

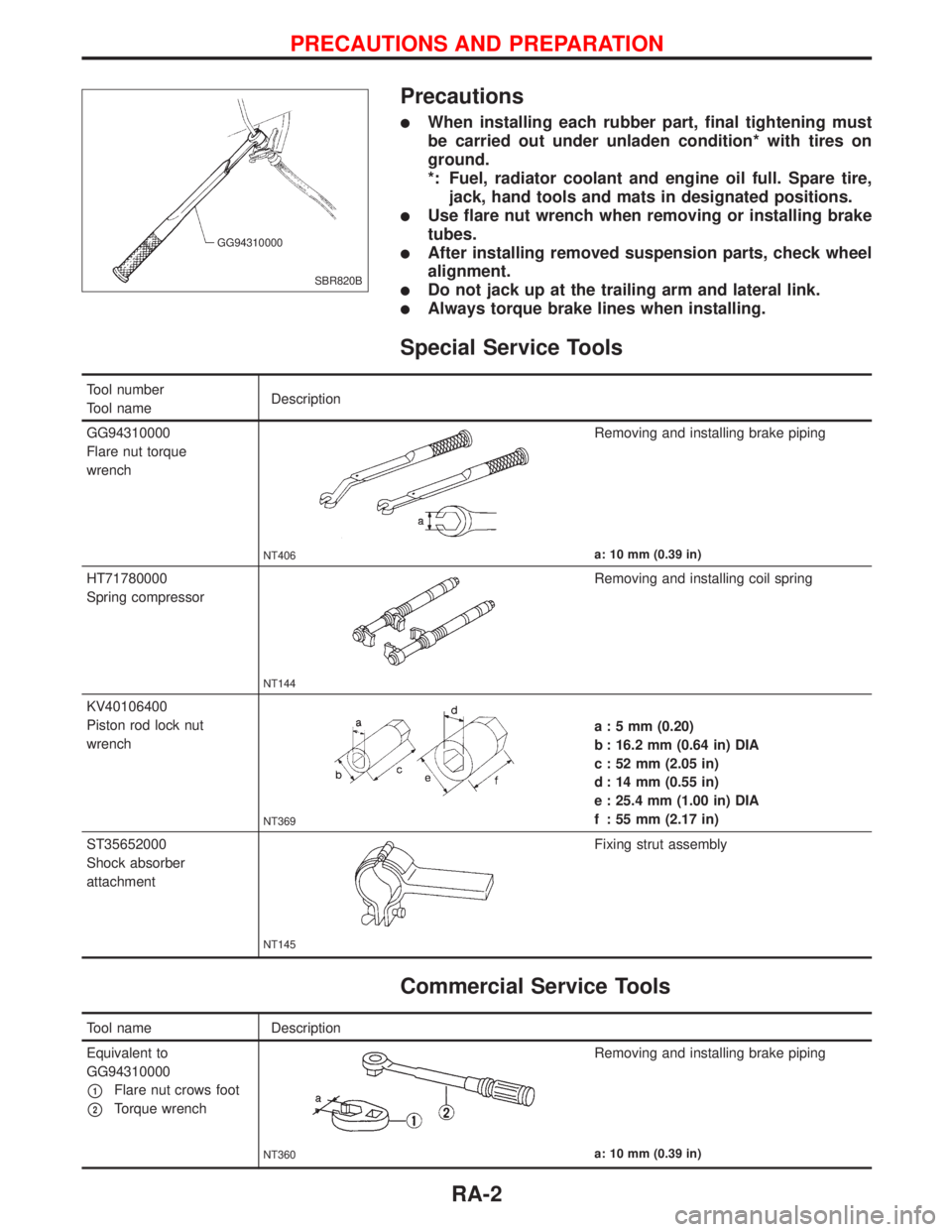

Tool number

Tool nameDescription

GG94310000

Flare nut torque

wrench

NT406

Removing and installing brake piping

a: 10 mm (0.39 in)

HT71780000

Spring compressor

NT144

Removing and installing coil spring

KV40106400

Piston rod lock nut

wrench

NT369

a : 5 mm (0.20)

b : 16.2 mm (0.64 in) DIA

c : 52 mm (2.05 in)

d : 14 mm (0.55 in)

e : 25.4 mm (1.00 in) DIA

f : 55 mm (2.17 in)

ST35652000

Shock absorber

attachment

NT145

Fixing strut assembly

Commercial Service Tools

Tool name Description

Equivalent to

GG94310000

p1Flare nut crows foot

p2Torque wrench

NT360

Removing and installing brake piping

a: 10 mm (0.39 in)

SBR820B GG94310000

PRECAUTIONS AND PREPARATION

RA-2

Page 2172 of 2267

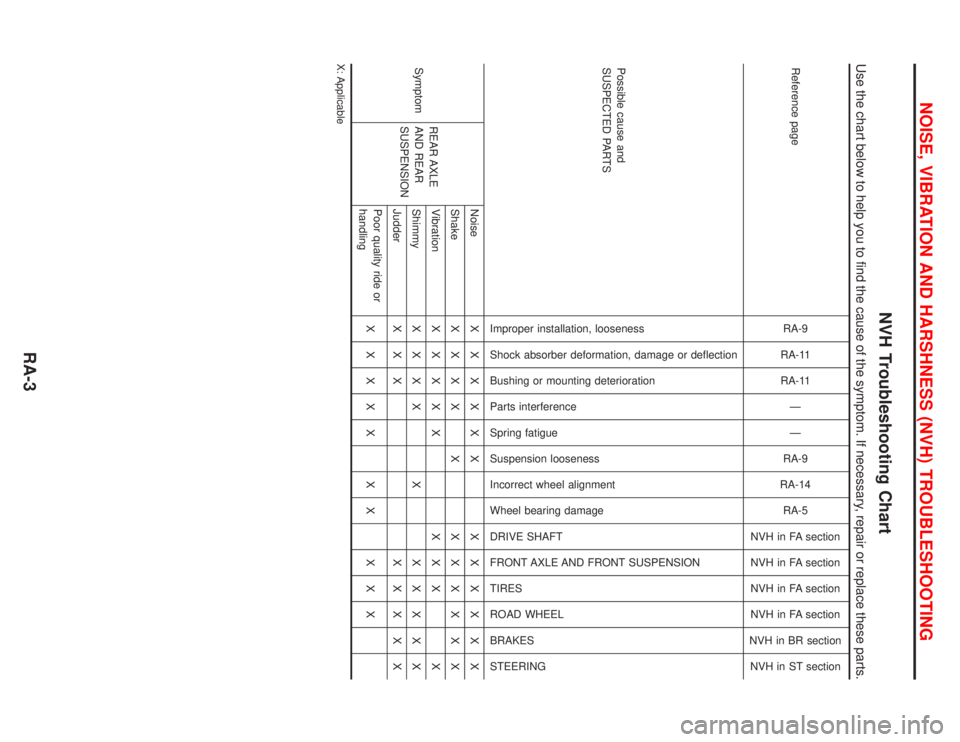

NVH Troubleshooting Chart

Use the chart below to help you to find the cause of the symptom. If necessary, repair or replace these parts.

Reference pageRA-9

RA-11

RA-11

Ð

Ð

RA-9

RA-14

RA-5

NVH in FA section

NVH in FA section

NVH in FA section

NVH in FA section

NVH in BR section

NVH in ST section

Possible cause and

SUSPECTED PARTS

Improper installation, looseness

Shock absorber deformation, damage or deflection

Bushing or mounting deterioration

Parts interference

Spring fatigue

Suspension looseness

Incorrect wheel alignment

Wheel bearing damage

DRIVE SHAFT

FRONT AXLE AND FRONT SUSPENSION

TIRES

ROAD WHEEL

BRAKES

STEERING

SymptomREAR AXLE

AND REAR

SUSPENSIONNoiseXXXXXX XXXXXX

ShakeXXXX X XXXXXX

VibrationXXXXX XXX X

ShimmyXXXX X XXXXX

Judder X X XXXXXX

Poor quality ride or

handlingXXXXX XX XXX

X: Applicable

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

RA-3

Page 2173 of 2267

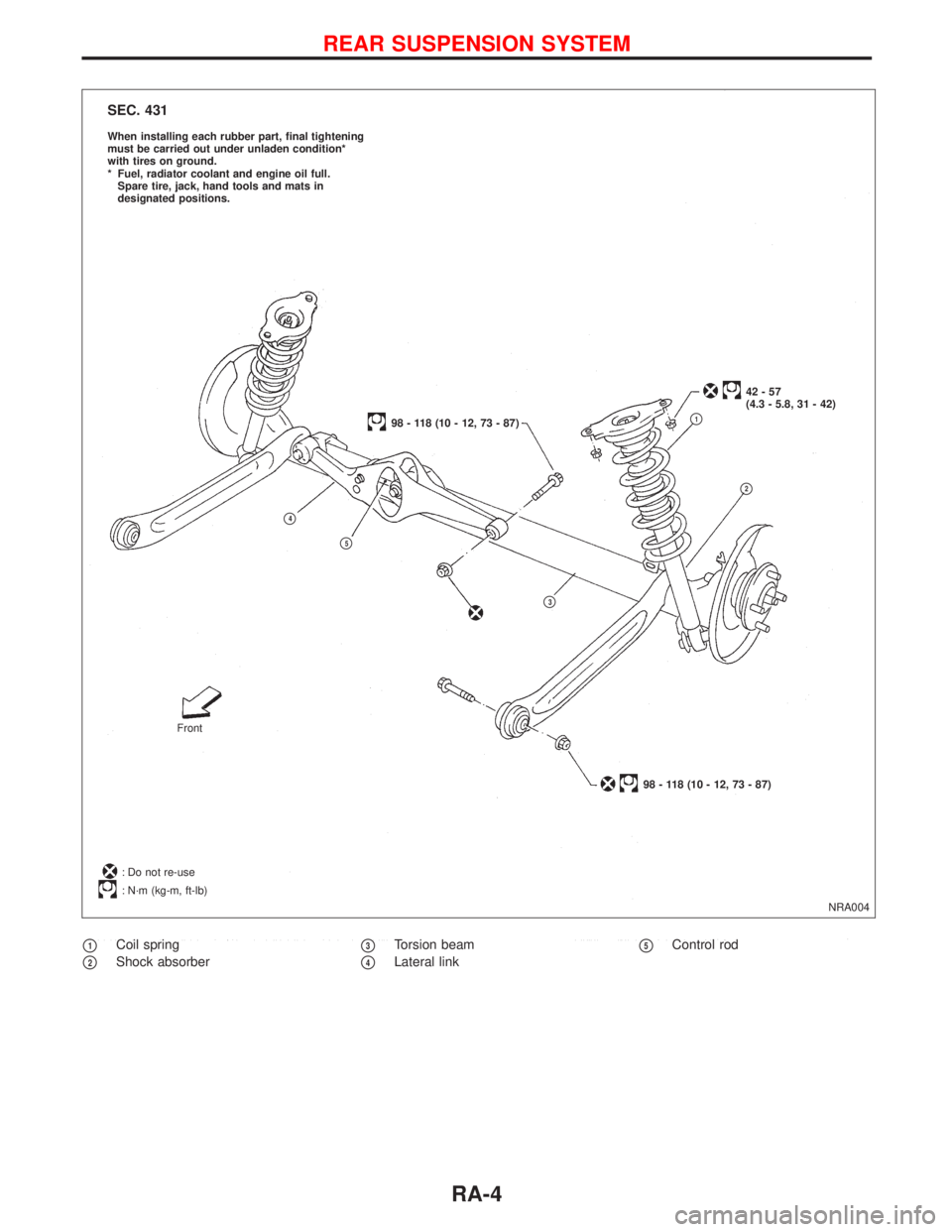

p1Coil spring

p2Shock absorberp3Torsion beam

p4Lateral linkp5Control rod

NRA004

98 - 118 (10 - 12, 73 - 87)

42-57

(4.3 - 5.8, 31 - 42)

p1

p2

p3

p4

p5

98 - 118 (10 - 12, 73 - 87) Front

: Do not re-use

: N´m (kg-m, ft-lb)

SEC. 431

When installing each rubber part, final tightening

must be carried out under unladen condition*

with tires on ground.

* Fuel, radiator coolant and engine oil full.

Spare tire, jack, hand tools and mats in

designated positions.

REAR SUSPENSION SYSTEM

RA-4

Page 2174 of 2267

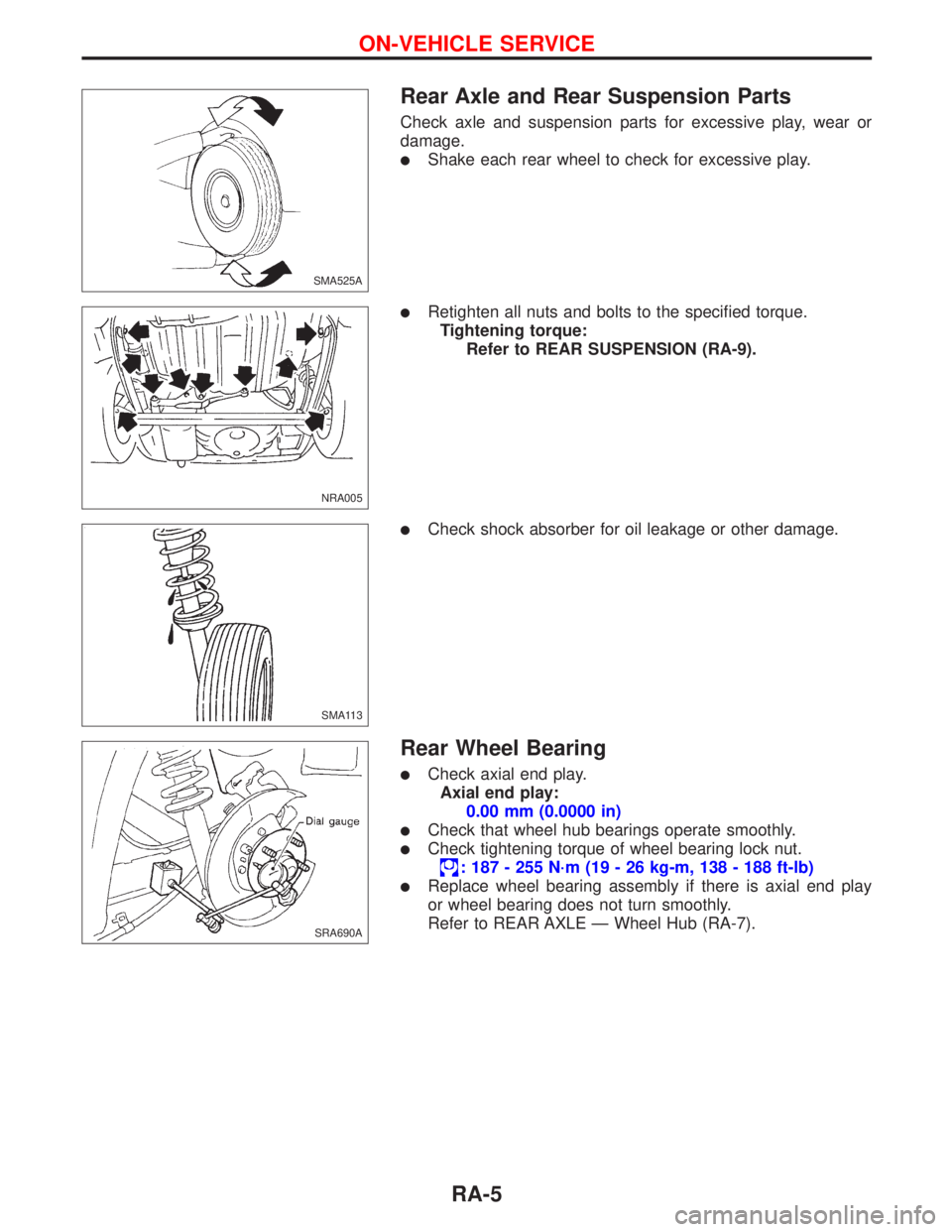

Rear Axle and Rear Suspension Parts

Check axle and suspension parts for excessive play, wear or

damage.

lShake each rear wheel to check for excessive play.

lRetighten all nuts and bolts to the specified torque.

Tightening torque:

Refer to REAR SUSPENSION (RA-9).

lCheck shock absorber for oil leakage or other damage.

Rear Wheel Bearing

lCheck axial end play.

Axial end play:

0.00 mm (0.0000 in)

lCheck that wheel hub bearings operate smoothly.

lCheck tightening torque of wheel bearing lock nut.

: 187 - 255 N´m (19 - 26 kg-m, 138 - 188 ft-lb)

lReplace wheel bearing assembly if there is axial end play

or wheel bearing does not turn smoothly.

Refer to REAR AXLE Ð Wheel Hub (RA-7).

SMA525A

NRA005

SMA113

SRA690A

ON-VEHICLE SERVICE

RA-5

Page 2175 of 2267

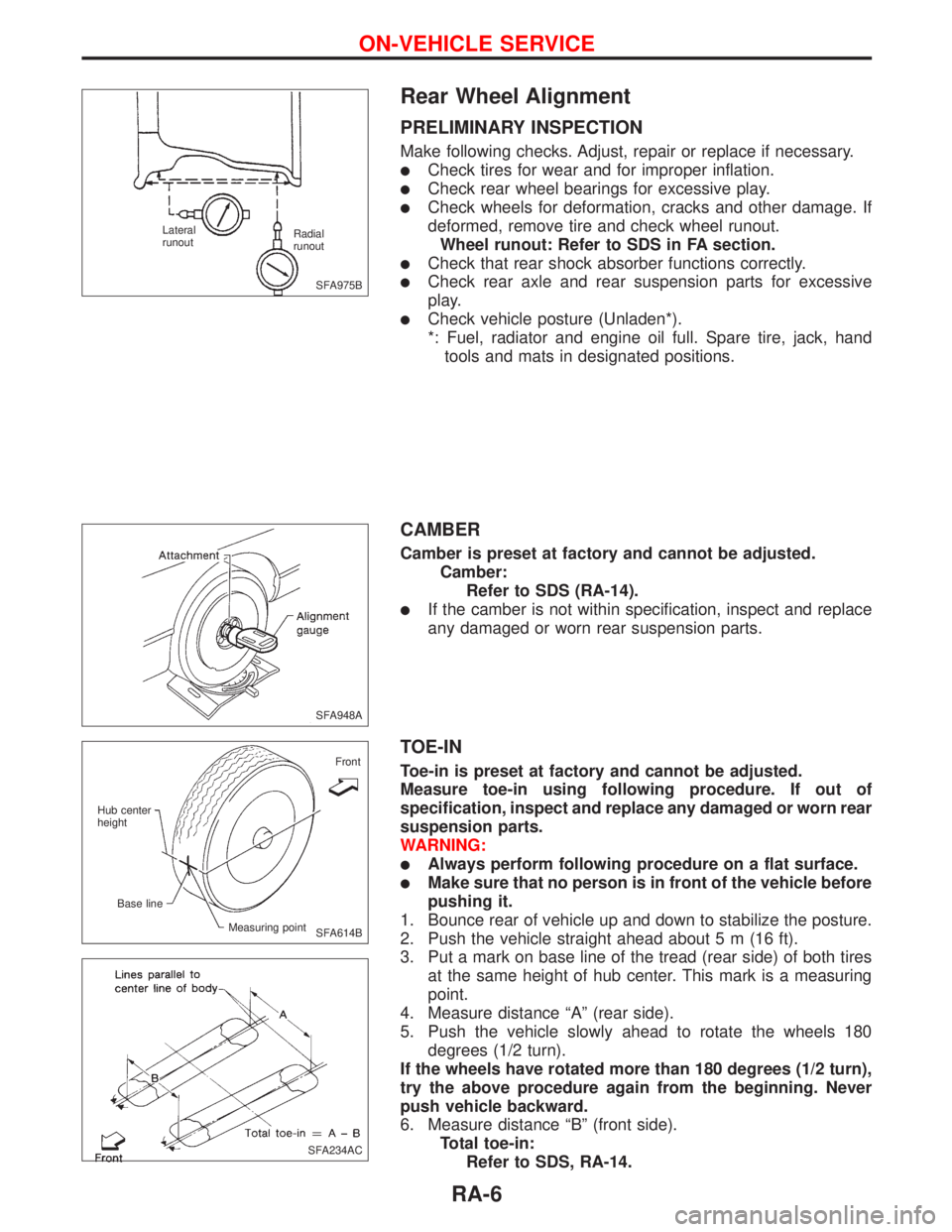

Rear Wheel Alignment

PRELIMINARY INSPECTION

Make following checks. Adjust, repair or replace if necessary.

lCheck tires for wear and for improper inflation.

lCheck rear wheel bearings for excessive play.

lCheck wheels for deformation, cracks and other damage. If

deformed, remove tire and check wheel runout.

Wheel runout: Refer to SDS in FA section.

lCheck that rear shock absorber functions correctly.

lCheck rear axle and rear suspension parts for excessive

play.

lCheck vehicle posture (Unladen*).

*: Fuel, radiator and engine oil full. Spare tire, jack, hand

tools and mats in designated positions.

CAMBER

Camber is preset at factory and cannot be adjusted.

Camber:

Refer to SDS (RA-14).

lIf the camber is not within specification, inspect and replace

any damaged or worn rear suspension parts.

TOE-IN

Toe-in is preset at factory and cannot be adjusted.

Measure toe-in using following procedure. If out of

specification, inspect and replace any damaged or worn rear

suspension parts.

WARNING:

lAlways perform following procedure on a flat surface.

lMake sure that no person is in front of the vehicle before

pushing it.

1. Bounce rear of vehicle up and down to stabilize the posture.

2. Push the vehicle straight ahead about 5 m (16 ft).

3. Put a mark on base line of the tread (rear side) of both tires

at the same height of hub center. This mark is a measuring

point.

4. Measure distance ªAº (rear side).

5. Push the vehicle slowly ahead to rotate the wheels 180

degrees (1/2 turn).

If the wheels have rotated more than 180 degrees (1/2 turn),

try the above procedure again from the beginning. Never

push vehicle backward.

6. Measure distance ªBº (front side).

Total toe-in:

Refer to SDS, RA-14.

SFA975B Radial

runout Lateral

runout

SFA948A

SFA614BFront

Hub center

height

Base line

Measuring point

SFA234AC

ON-VEHICLE SERVICE

RA-6

Page 2176 of 2267

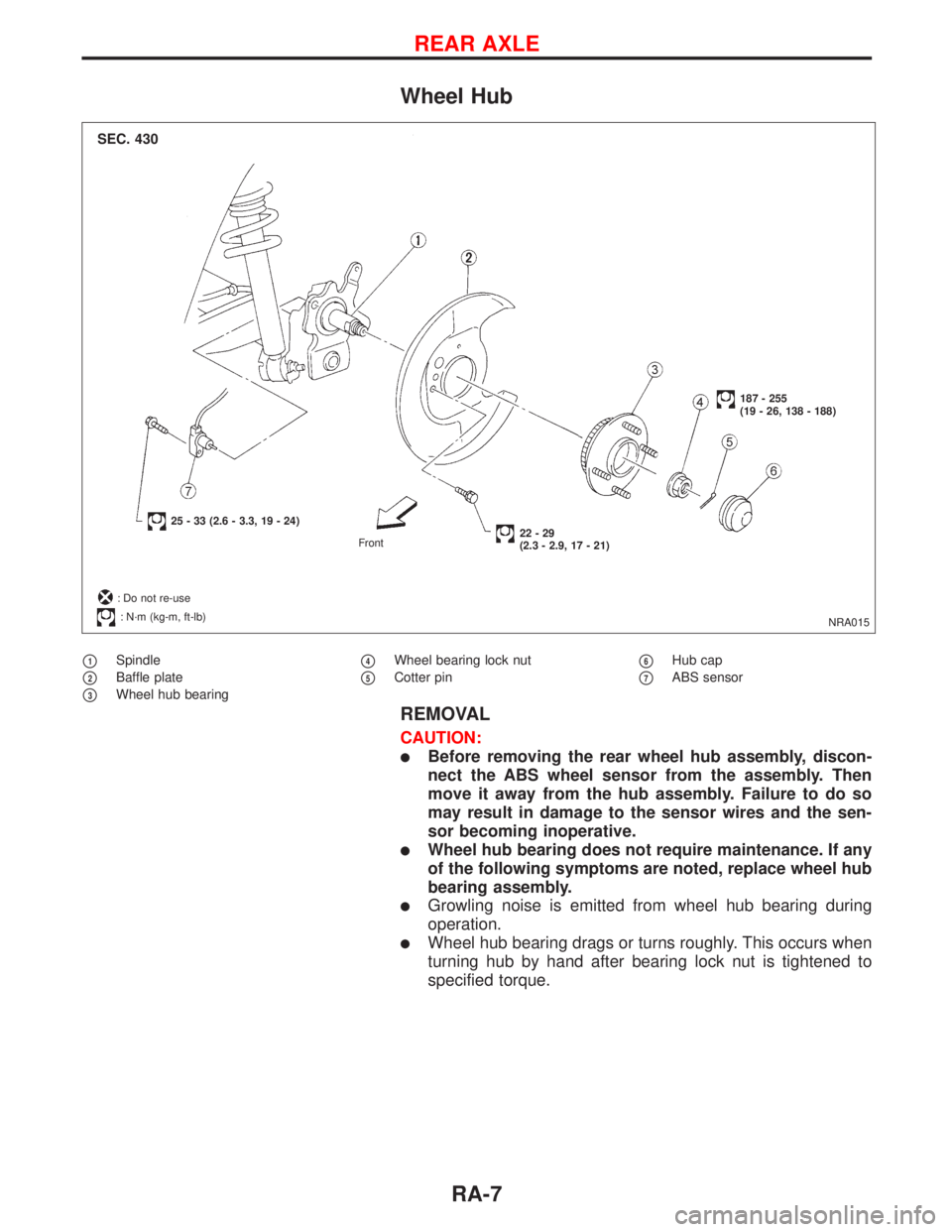

Wheel Hub

p1Spindle

p2Baffle plate

p3Wheel hub bearing

p4Wheel bearing lock nut

p5Cotter pinp6Hub cap

p7ABS sensor

REMOVAL

CAUTION:

lBefore removing the rear wheel hub assembly, discon-

nect the ABS wheel sensor from the assembly. Then

move it away from the hub assembly. Failure to do so

may result in damage to the sensor wires and the sen-

sor becoming inoperative.

lWheel hub bearing does not require maintenance. If any

of the following symptoms are noted, replace wheel hub

bearing assembly.

lGrowling noise is emitted from wheel hub bearing during

operation.

lWheel hub bearing drags or turns roughly. This occurs when

turning hub by hand after bearing lock nut is tightened to

specified torque.

NRA015

SEC. 430

Front

187 - 255

(19 - 26, 138 - 188)

22-29

(2.3 - 2.9, 17 - 21)25 - 33 (2.6 - 3.3, 19 - 24)

: Do not re-use

: N´m (kg-m, ft-lb)

REAR AXLE

RA-7

Page 2177 of 2267

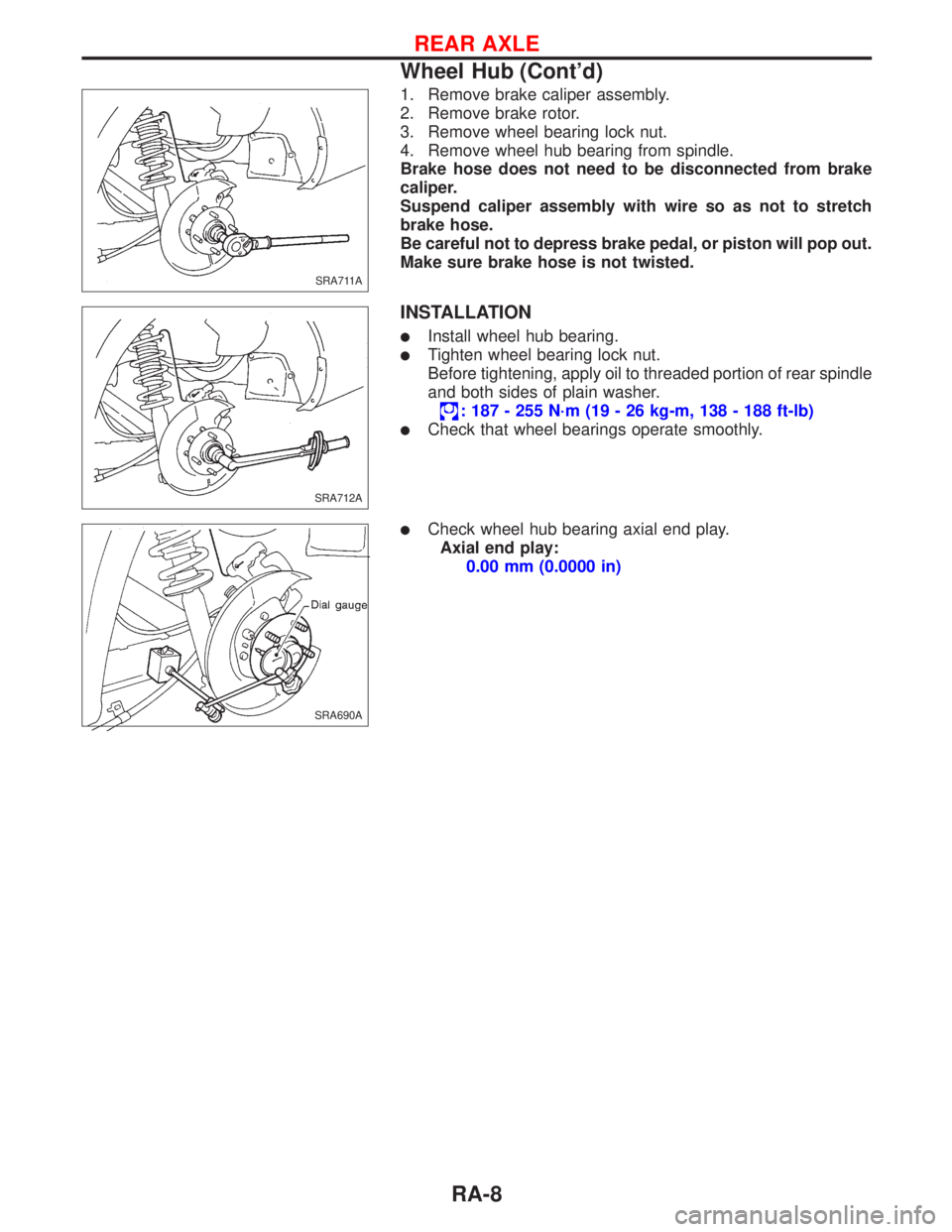

1. Remove brake caliper assembly.

2. Remove brake rotor.

3. Remove wheel bearing lock nut.

4. Remove wheel hub bearing from spindle.

Brake hose does not need to be disconnected from brake

caliper.

Suspend caliper assembly with wire so as not to stretch

brake hose.

Be careful not to depress brake pedal, or piston will pop out.

Make sure brake hose is not twisted.

INSTALLATION

lInstall wheel hub bearing.

lTighten wheel bearing lock nut.

Before tightening, apply oil to threaded portion of rear spindle

and both sides of plain washer.

: 187 - 255 N´m (19 - 26 kg-m, 138 - 188 ft-lb)

lCheck that wheel bearings operate smoothly.

lCheck wheel hub bearing axial end play.

Axial end play:

0.00 mm (0.0000 in)

SRA711A

SRA712A

SRA690A

REAR AXLE

Wheel Hub (Cont'd)

RA-8

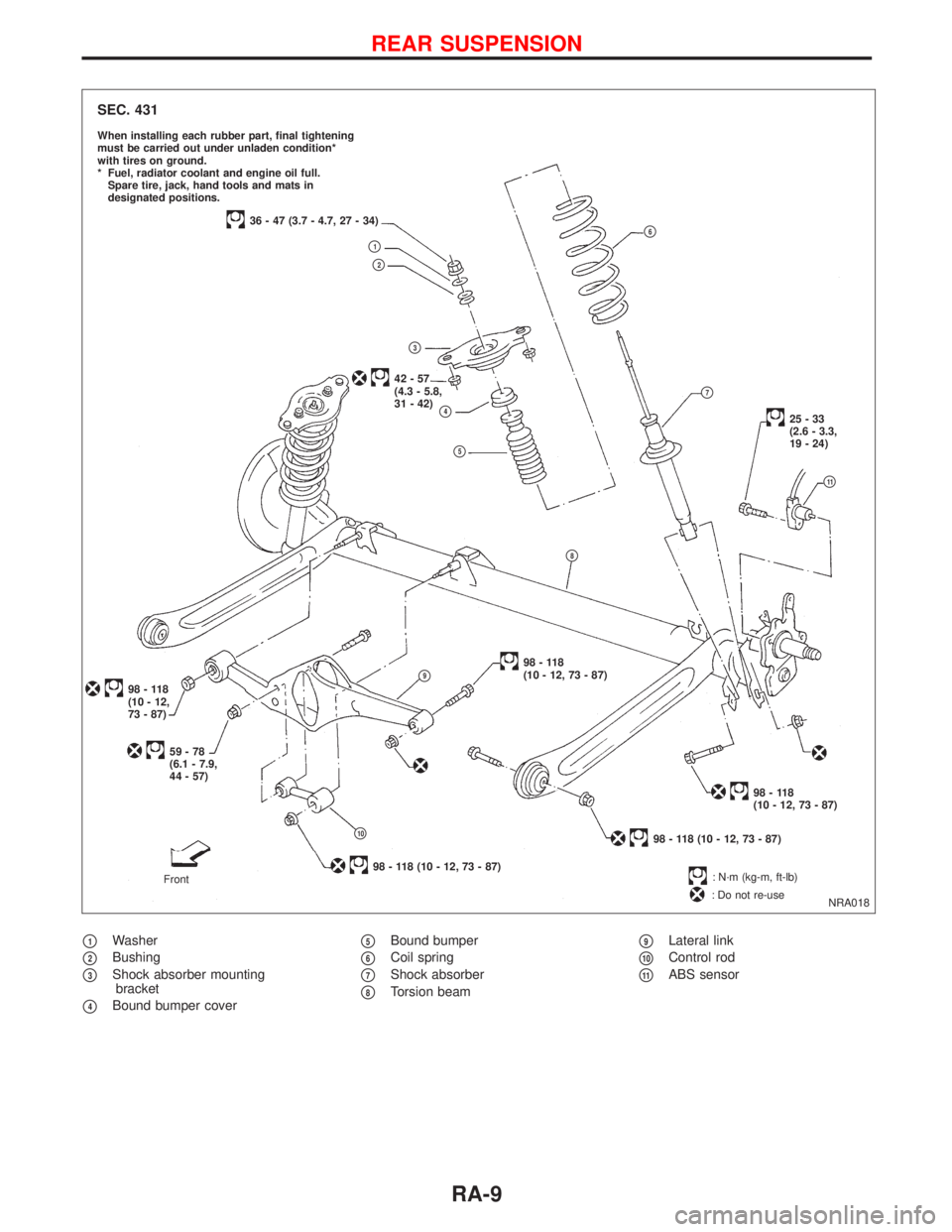

Page 2178 of 2267

p1Washer

p2Bushing

p3Shock absorber mounting

bracket

p4Bound bumper cover

p5Bound bumper

p6Coil spring

p7Shock absorber

p8Torsion beam

p9Lateral link

p10Control rod

p11ABS sensor

NRA018

SEC. 431

When installing each rubber part, final tightening

must be carried out under unladen condition*

with tires on ground.

* Fuel, radiator coolant and engine oil full.

Spare tire, jack, hand tools and mats in

designated positions.

36 - 47 (3.7 - 4.7, 27 - 34)

p1

p2

p3

42-57

(4.3 - 5.8,

31 - 42)

p4

p5

p6

p7

25-33

(2.6 - 3.3,

19 - 24)

p8

98-118

(10 - 12, 73 - 87)p9

p10

98-118

(10 - 12,

73 - 87)

59-78

(6.1 - 7.9,

44 - 57)

Front

98 - 118 (10 - 12, 73 - 87)

p11

98-118

(10 - 12, 73 - 87)

: N´m (kg-m, ft-lb)

: Do not re-use

98 - 118 (10 - 12, 73 - 87)

REAR SUSPENSION

RA-9

Page 2179 of 2267

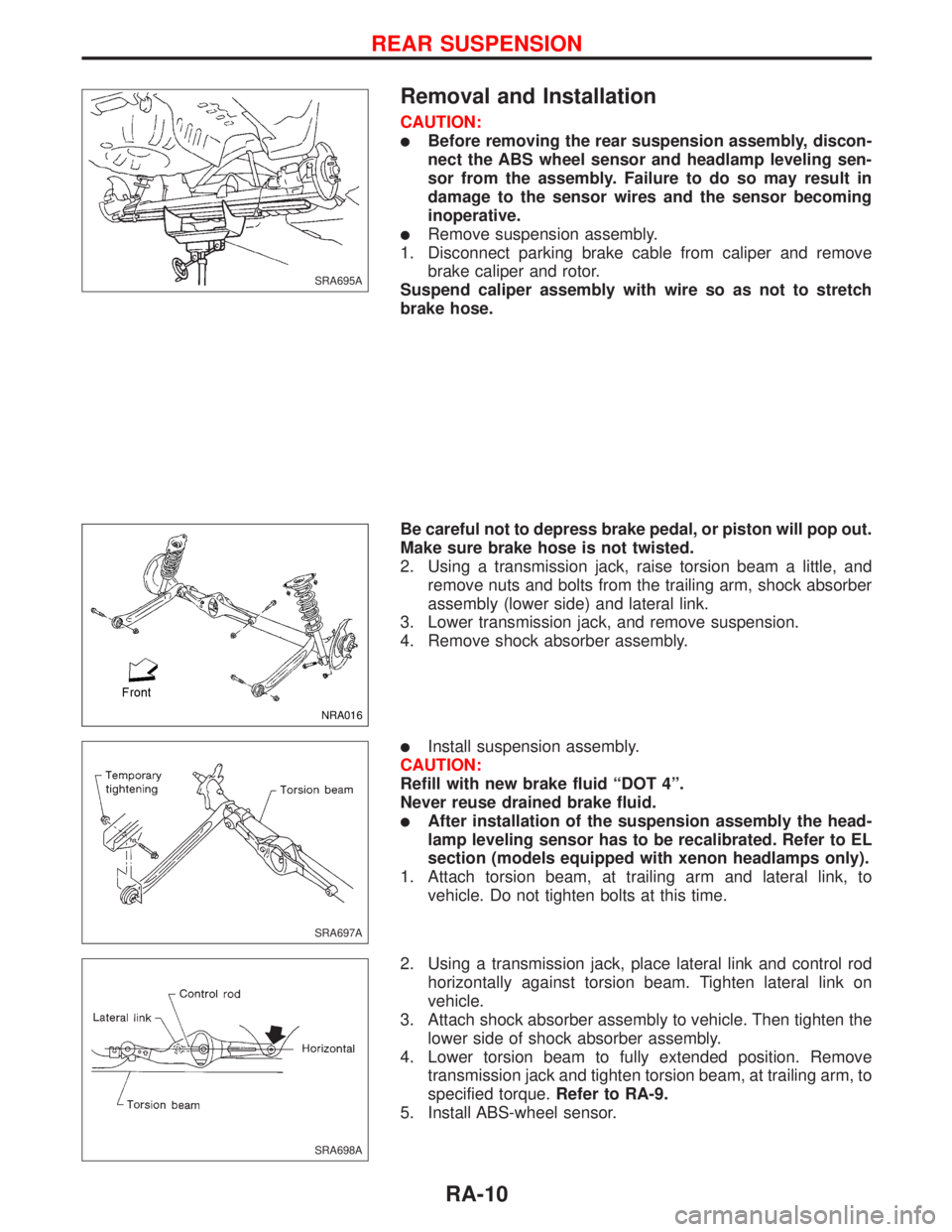

Removal and Installation

CAUTION:

lBefore removing the rear suspension assembly, discon-

nect the ABS wheel sensor and headlamp leveling sen-

sor from the assembly. Failure to do so may result in

damage to the sensor wires and the sensor becoming

inoperative.

lRemove suspension assembly.

1. Disconnect parking brake cable from caliper and remove

brake caliper and rotor.

Suspend caliper assembly with wire so as not to stretch

brake hose.

Be careful not to depress brake pedal, or piston will pop out.

Make sure brake hose is not twisted.

2. Using a transmission jack, raise torsion beam a little, and

remove nuts and bolts from the trailing arm, shock absorber

assembly (lower side) and lateral link.

3. Lower transmission jack, and remove suspension.

4. Remove shock absorber assembly.

lInstall suspension assembly.

CAUTION:

Refill with new brake fluid ªDOT 4º.

Never reuse drained brake fluid.

lAfter installation of the suspension assembly the head-

lamp leveling sensor has to be recalibrated. Refer to EL

section (models equipped with xenon headlamps only).

1. Attach torsion beam, at trailing arm and lateral link, to

vehicle. Do not tighten bolts at this time.

2. Using a transmission jack, place lateral link and control rod

horizontally against torsion beam. Tighten lateral link on

vehicle.

3. Attach shock absorber assembly to vehicle. Then tighten the

lower side of shock absorber assembly.

4. Lower torsion beam to fully extended position. Remove

transmission jack and tighten torsion beam, at trailing arm, to

specified torque.Refer to RA-9.

5. Install ABS-wheel sensor.

SRA695A

NRA016

SRA697A

SRA698A

REAR SUSPENSION

RA-10

Page 2180 of 2267

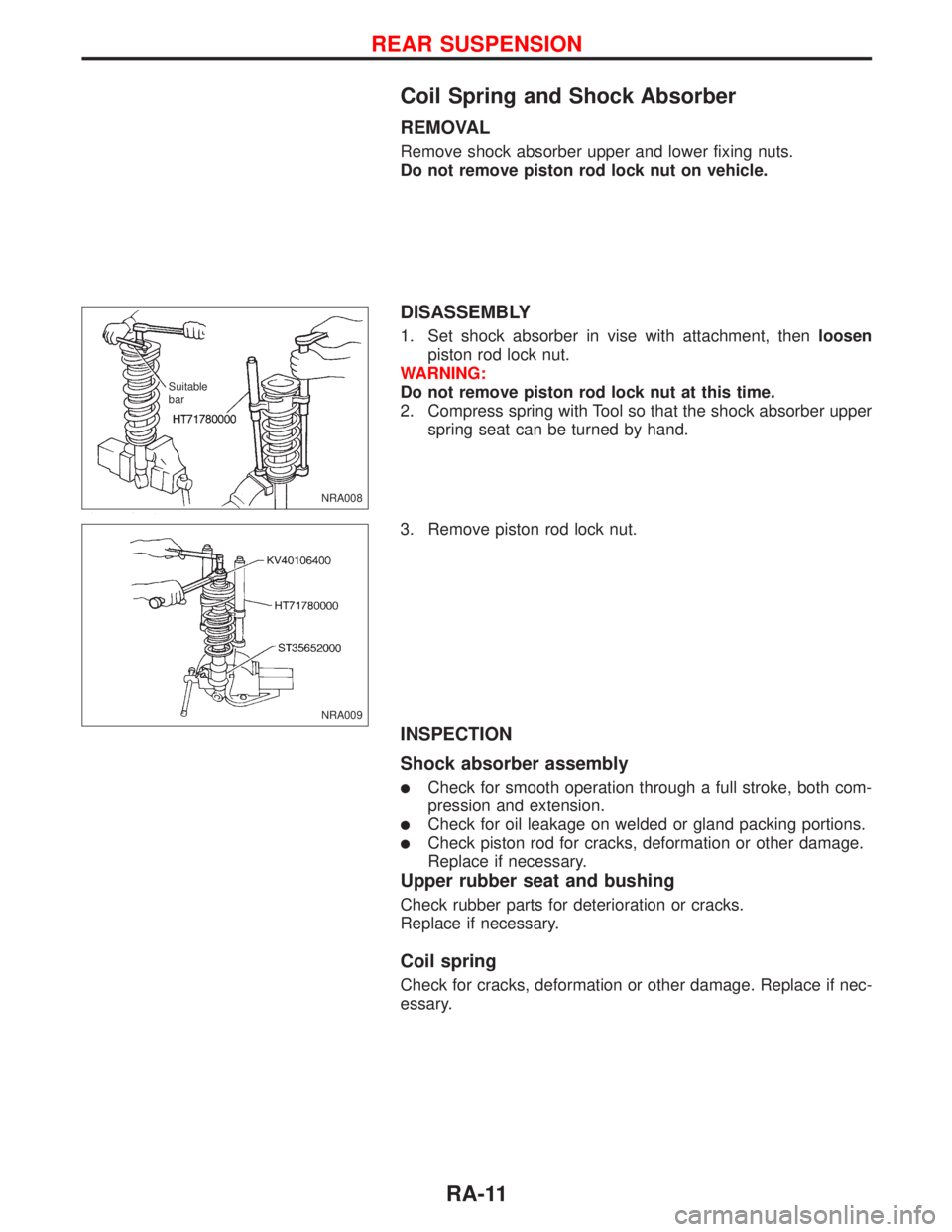

Coil Spring and Shock Absorber

REMOVAL

Remove shock absorber upper and lower fixing nuts.

Do not remove piston rod lock nut on vehicle.

DISASSEMBLY

1. Set shock absorber in vise with attachment, thenloosen

piston rod lock nut.

WARNING:

Do not remove piston rod lock nut at this time.

2. Compress spring with Tool so that the shock absorber upper

spring seat can be turned by hand.

3. Remove piston rod lock nut.

INSPECTION

Shock absorber assembly

lCheck for smooth operation through a full stroke, both com-

pression and extension.

lCheck for oil leakage on welded or gland packing portions.

lCheck piston rod for cracks, deformation or other damage.

Replace if necessary.

Upper rubber seat and bushing

Check rubber parts for deterioration or cracks.

Replace if necessary.

Coil spring

Check for cracks, deformation or other damage. Replace if nec-

essary.

NRA008 Suitable

bar

NRA009

REAR SUSPENSION

RA-11