NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 701 of 2267

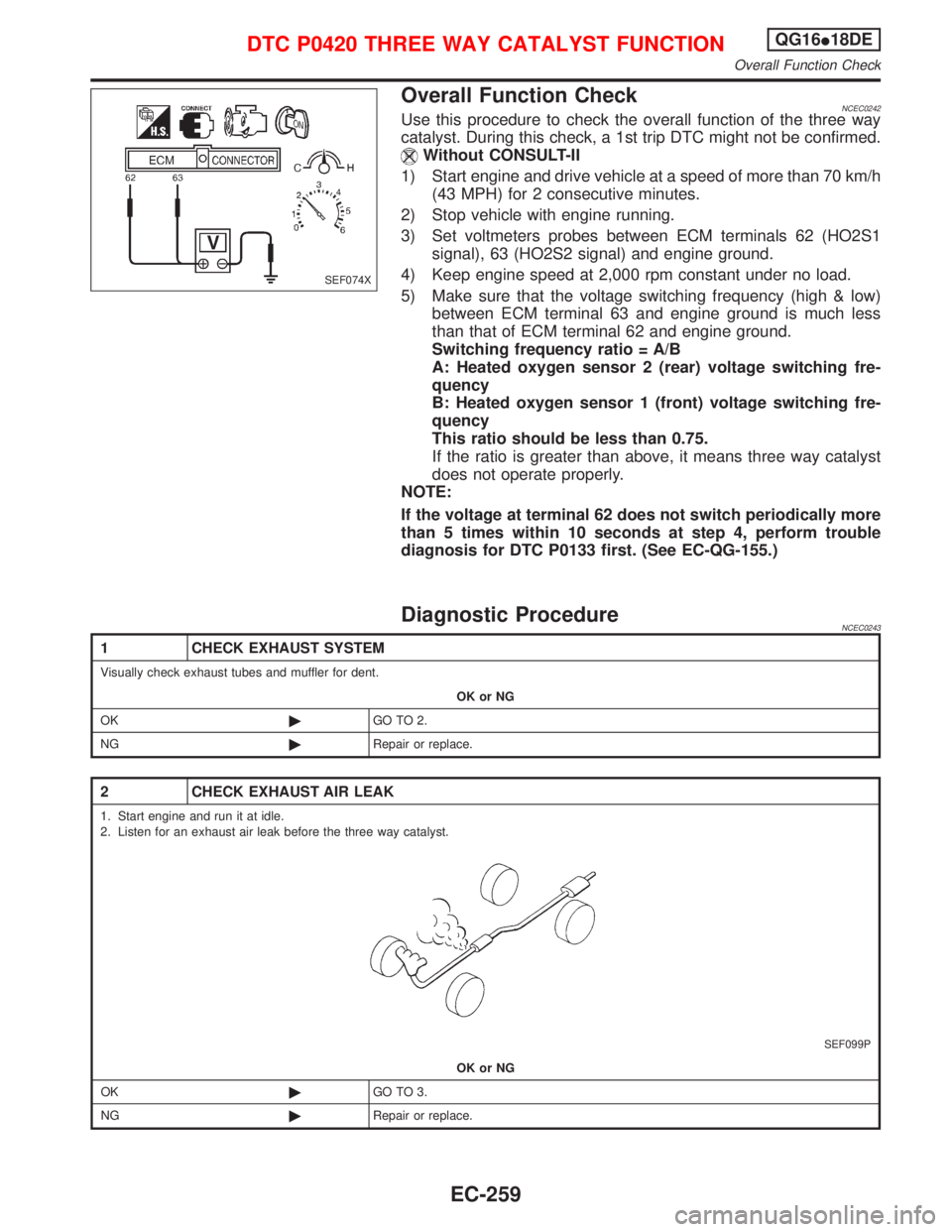

Overall Function CheckNCEC0242Use this procedure to check the overall function of the three way

catalyst. During this check, a 1st trip DTC might not be confirmed.

Without CONSULT-II

1) Start engine and drive vehicle at a speed of more than 70 km/h

(43 MPH) for 2 consecutive minutes.

2) Stop vehicle with engine running.

3) Set voltmeters probes between ECM terminals 62 (HO2S1

signal), 63 (HO2S2 signal) and engine ground.

4) Keep engine speed at 2,000 rpm constant under no load.

5) Make sure that the voltage switching frequency (high & low)

between ECM terminal 63 and engine ground is much less

than that of ECM terminal 62 and engine ground.

Switching frequency ratio = A/B

A: Heated oxygen sensor 2 (rear) voltage switching fre-

quency

B: Heated oxygen sensor 1 (front) voltage switching fre-

quency

This ratio should be less than 0.75.

If the ratio is greater than above, it means three way catalyst

does not operate properly.

NOTE:

If the voltage at terminal 62 does not switch periodically more

than 5 times within 10 seconds at step 4, perform trouble

diagnosis for DTC P0133 first. (See EC-QG-155.)

Diagnostic ProcedureNCEC0243

1 CHECK EXHAUST SYSTEM

Visually check exhaust tubes and muffler for dent.

OK or NG

OK©GO TO 2.

NG©Repair or replace.

2 CHECK EXHAUST AIR LEAK

1. Start engine and run it at idle.

2. Listen for an exhaust air leak before the three way catalyst.

SEF099P

OK or NG

OK©GO TO 3.

NG©Repair or replace.

SEF074X

DTC P0420 THREE WAY CATALYST FUNCTIONQG16I18DE

Overall Function Check

EC-259

Page 702 of 2267

3 CHECK INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK©GO TO 4.

NG©Repair or replace.

4 CHECK IGNITION TIMING

Check for ignition timing.

Refer to TROUBLE DIAGNOSIS Ð ªBASIC INSPECTIONº, EC-QG-72.

OK or NG

OK©GO TO 5.

NG©Check camshaft position sensor (PHASE) (EC-QG-238) and crankshaft position sensor

(POS) (EC-QG-232).

5 CHECK INJECTORS

1. Refer to Wiring Diagram for Injectors, EC-QG-319.

2. Stop engine and then turn ignition switch ªONº.

3. Check voltage between ECM terminals 101, 103, 105 and 107 and ground with CONSULT-II or tester.

SEF075XBattery voltage should exist.

OK or NG

OK©GO TO 6.

NG©Perform ªDiagnostic Procedureº INJECTOR, EC-QG-320.

DTC P0420 THREE WAY CATALYST FUNCTIONQG16I18DE

Diagnostic Procedure (Cont'd)

EC-260

Page 703 of 2267

6 CHECK IGNITION SPARK

1. Disconnect ignition coil assembly from rocker cover.

2. Connect a known good spark plug to the ignition coil assembly.

3. Place end of spark plug against a suitable ground and crank engine.

4. Check for spark.

SEF575Q

OK or NG

OK©GO TO 7.

NG©Check ignition coil, power transistor and their circuits. Refer to EC-QG-323.

7 CHECK INJECTOR

1. Turn ignition switch ªOFFº.

2. Remove injector assembly. Refer to EC-QG-30.

Keep fuel hose and all injectors connected to injector gallery.

3. Disconnect camshaft position sensor harness connector.

4. Turn ignition switch ªONº.

Make sure fuel does not drip from injector.

OK or NG

OK (Does not drip)©GO TO 8.

NG (Drips)©Replace the injector(s) from which fuel is dripping.

8 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-QG-102.

Trouble is fixed©INSPECTION END

Trouble is not fixed©Replace three way catalyst.

DTC P0420 THREE WAY CATALYST FUNCTIONQG16I18DE

Diagnostic Procedure (Cont'd)

EC-261

Page 704 of 2267

DescriptionNCEC0248SYSTEM DESCRIPTIONNCEC0248S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed

EVAP can-

ister purge

controlEVAP canister purge volume

control solenoid valve Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Battery Battery voltage

Ignition switch Start signal

Throttle position sensor Throttle position

Heated oxygen 1 sensorDensity of oxygen in exhaust gas

(Mixture ratio feedback signal)

Vehicle speed sensor or ABS actuator and

electric unit (control unit)Vehicle speed

This system controls flow rate of fuel vapor from the EVAP canis-

ter. The opening of the vapor by-pass passage in the EVAP canis-

ter purge volume control solenoid valve changes to control the flow

rate. The EVAP canister purge volume control solenoid valve

repeats ON/OFF operation according to the signal sent from the

ECM. The opening of the valve varies for optimum engine control.

The optimum value stored in the ECM is determined by consider-

ing various engine conditions. When the engine is operating, the

flow rate of fuel vapor from the EVAP canister is regulated as the

air flow changes.

COMPONENT DESCRIPTIONNCEC0248S02The EVAP canister purge volume control solenoid valve uses a

ON/OFF duty to control the flow rate of fuel vapor from the EVAP

canister. The EVAP canister purge volume control solenoid valve

is moved by ON/OFF pulses from the ECM. The longer the ON

pulse, the greater the amount of fuel vapor that will flow through the

valve.

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0249

MONITOR ITEM CONDITION SPECIFICATION

PURG VOL C/VIEngine: After warming up

INo-load

ILift up drive wheels and shift to

1st gear position.

IAir conditioner switch ªOFFºIdle 0%

More than 2,000 rpm Ð

SEF337U

DTC P0443 EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE (CIRCUIT)QG16I18DE

Description

EC-262

Page 705 of 2267

ECM Terminals and Reference ValueNCEC0250Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

14 P/BEVAP canister purge vol-

ume control solenoid valve[Engine is running]

IWarm-up condition

IIdle speedBATTERY VOLTAGE

(11 - 14V)

[Vehicle is running]

IWarm-up condition

I2,000 rpm5 - 12V

On Board Diagnosis LogicNCEC0251

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0443

0443IAn improper voltage signal is sent to ECM through the

valve.IHarness or connectors

(The valve circuit is open or shorted.)

IEVAP canister purge volume control solenoid

valve

DTC Confirmation ProcedureNCEC0252NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm battery

voltage is more than 11V.

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and let it idle for at least 5 seconds.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

QG-265.

With GST

Follow the procedure ªWith CONSULT-IIº above.

NEF068A

DTC P0443 EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE (CIRCUIT)QG16I18DE

ECM Terminals and Reference Value

EC-263

Page 706 of 2267

Wiring DiagramNCEC0253

YEC783

: Detectable line for DTC

: Non-detectable line for DTC

ECM EVAP CANISTER

PURGE VOLUME

CONTROL SOLENOID

VA LV EFUSE

BLOCK

(J/B)Refer to EL-POWER. IGNITION SWITCH

ON or START

Refer to last page (Foldout page)

DTC P0443 EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE (CIRCUIT)QG16I18DE

Wiring Diagram

EC-264

Page 707 of 2267

Diagnostic ProcedureNCEC0254

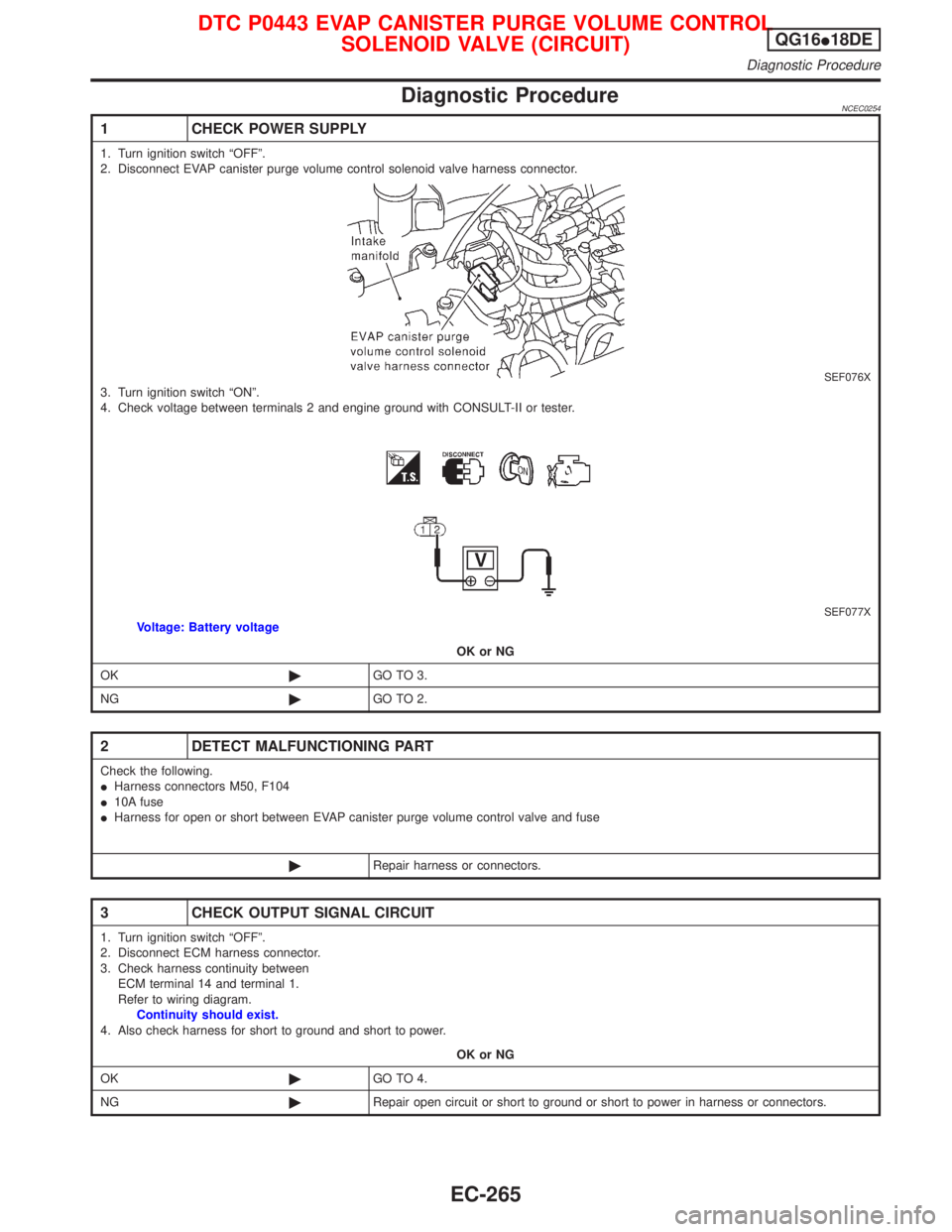

1 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect EVAP canister purge volume control solenoid valve harness connector.

SEF076X3. Turn ignition switch ªONº.

4. Check voltage between terminals 2 and engine ground with CONSULT-II or tester.

SEF077XVoltage: Battery voltage

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M50, F104

I10A fuse

IHarness for open or short between EVAP canister purge volume control valve and fuse

©Repair harness or connectors.

3 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between

ECM terminal 14 and terminal 1.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P0443 EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE (CIRCUIT)QG16I18DE

Diagnostic Procedure

EC-265

Page 708 of 2267

4 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

Refer to ªComponent Inspectionº EC-QG-266.

OK or NG

OK©GO TO 5.

NG©Replace EVAP canister purge volume control solenoid valve.

5 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-QG-102.

©INSPECTION END

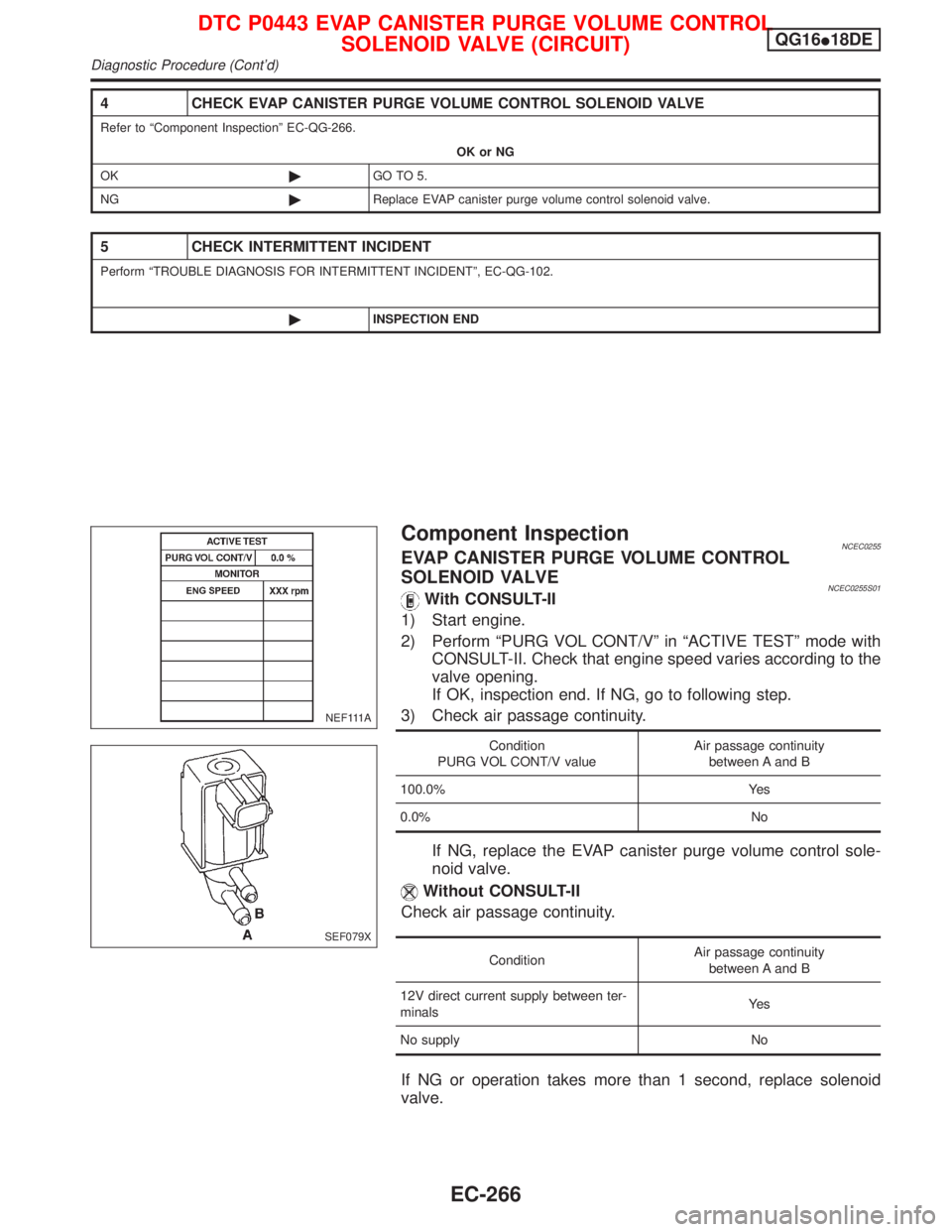

Component InspectionNCEC0255EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE

NCEC0255S01With CONSULT-II

1) Start engine.

2) Perform ªPURG VOL CONT/Vº in ªACTIVE TESTº mode with

CONSULT-II. Check that engine speed varies according to the

valve opening.

If OK, inspection end. If NG, go to following step.

3) Check air passage continuity.

Condition

PURG VOL CONT/V valueAir passage continuity

between A and B

100.0% Yes

0.0% No

If NG, replace the EVAP canister purge volume control sole-

noid valve.

Without CONSULT-II

Check air passage continuity.

ConditionAir passage continuity

between A and B

12V direct current supply between ter-

minalsYe s

No supply No

If NG or operation takes more than 1 second, replace solenoid

valve.

NEF111A

SEF079X

DTC P0443 EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE (CIRCUIT)QG16I18DE

Diagnostic Procedure (Cont'd)

EC-266

Page 709 of 2267

Component DescriptionNCEC0272MODELS WITH VEHICLE SPEED SENSOR

The vehicle speed sensor is installed in the transaxle. It contains a

pulse generator which provides a vehicle speed signal to the

speedometer. The speedometer then sends a signal to the ECM.

MODELS WITHOUT VEHICLE SPEED SENSOR

The ABS actuator and electric unit (control unit) provides a vehicle

speed signal to the speedometer. The speedometer then sends a

signal to the ECM.

ECM Terminals and Reference ValueNCEC0273Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

86 OR/WVehicle speed sensor or

ABS actuator and elec-

tric unit (control unit)[Engine is running]

ILift up the vehicle

IIn 2nd gear position

IVehicle speed is 40 km/h (25 MPH)2.0 - 3.0 V

SEF976W

On Board Diagnosis LogicNCEC0274

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0500

0500IThe almost 0 km/h (0 MPH) signal from vehicle speed

sensor or ABS actuator and electric unit (control unit) is

sent to ECM even when vehicle is being driven.Models with vehicle speed sensor

IHarness or connector

(The vehicle speed sensor circuit is open or

shorted.)

IVehicle speed sensor

Models without vehicle speed sensor

IHarness or connector (The ABS actuator and

electric unit (control unit) is open or shorted.)

IABS actuator and electric unit (control unit)

DTC Confirmation ProcedureNCEC0275CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

TESTING CONDITION:

This procedure may be conducted with the drive wheels lifted

in the shop or by driving the vehicle. If a road test is expected

to be easier, it is unnecessary to lift the vehicle.

SEF080X

DTC P0500 VEHICLE SPEED SENSOR (VSS)QG16I18DE

Component Description

EC-267

Page 710 of 2267

With CONSULT-II

1) Start engine

2) Read vehicle speed sensor signal in ªDATA MONITORº mode

with CONSULT-II. The vehicle speed on CONSULT-II should

exceed 10 km/h (6 MPH) when rotating wheels with suitable

gear position.

3) If NG, go to ªDiagnostic Procedureº, EC-QG-271.

If OK, go to following step.

4) Select ªDATA MONITORº mode with CONSULT-II.

5) Warm engine up to normal operating temperature.

6) Maintain the following conditions for at least 10 consecutive

seconds.

ENG SPEED 2,600 - 4,000 rpm

COOLAN TEMP/S More than 70ÉC (158ÉF)

B/FUEL SCHDL 6.0 - 11.7 msec

Selector lever Suitable position

PW/ST SIGNAL OFF

7) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

QG-271.

With GST

Follow the procedure ªWith CONSULT-IIº above.

NEF112A

DTC P0500 VEHICLE SPEED SENSOR (VSS)QG16I18DE

DTC Confirmation Procedure (Cont'd)

EC-268