NISSAN TEANA 2014 Service Manual

Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 4721 of 4801

WT-46

< DTC/CIRCUIT DIAGNOSIS >

C1735 IGNITION SIGNAL

C1735 IGNITION SIGNAL

DTC LogicINFOID:0000000009464512

NOTE:

The Signal Tech II Tool (J-50190) can be used to perform the following functions. Refer to the Signal Tech II

User Guide for additional information.

• Activate and display TPMS transmitter IDs

• Display tire pressure reported by the TPMS transmitter

• Read TPMS DTCs

• Register TPMS transmitter IDs

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF DIAGNOSTIC RESULT

With CONSULT

Perform Self Diagnostic Result.

Is DTC C1735 detected?

YES >> Proceed to WT-46, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009464513

NOTE:

The Signal Tech II Tool (J-50190) can be used to perform the following functions. Refer to the Signal Tech II

User Guide for additional information.

• Activate and display TPMS transmitter IDs

• Display tire pressure reported by the TPMS transmitter

• Read TPMS DTCs

• Register TPMS transmitter IDs

1.CHECK CAN IGNITION SIGNAL

With CONSULT

1. Select Data Monitor from INTELLIGENT KEY of BCM.

2. Check IGN RLY1-F/B value.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Check CAN system. Refer to LAN-18, "Trouble Diagnosis Flow Chart"

.

2.CHECK BCM POWER SUPPLY AND GROUND

Check BCM power supply and ground. Refer to BCS-74, "Diagnosis Procedure"

.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness or connectors.

3.DRIVE VEHICLE

Clear DTC and test drive vehicle to check for low tire pressure warning lamp.

Does the vehicle operate without any low tire pressure warning lamp?

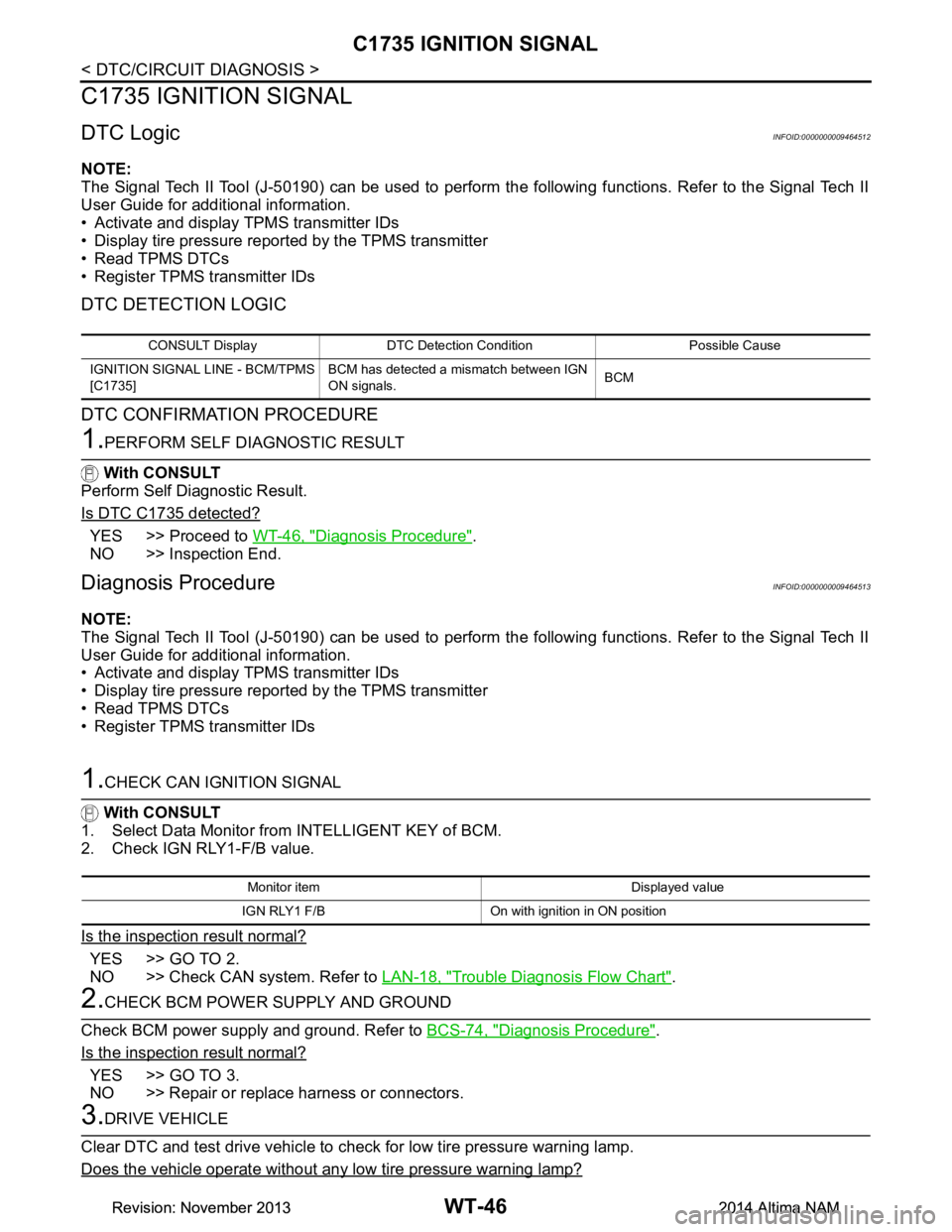

CONSULT Display DTC Detectio n Condition Possible Cause

IGNITION SIGNAL LINE - BCM/TPMS

[C1735] BCM has detected a mismatch between IGN

ON signals. BCM

Monitor item Displayed value

IGN RLY1 F/B On with ignition in ON position

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4722 of 4801

C1735 IGNITION SIGNALWT-47

< DTC/CIRCUIT DIAGNOSIS >

C

D

F

G H

I

J

K L

M A

B

WT

N

O P

YES >> Inspection End.

NO >> Replace BCM. Refer to BCS-80, "Removal and Installation"

.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4723 of 4801

WT-48

< SYMPTOM DIAGNOSIS >

TPMS

SYMPTOM DIAGNOSIS

TPMS

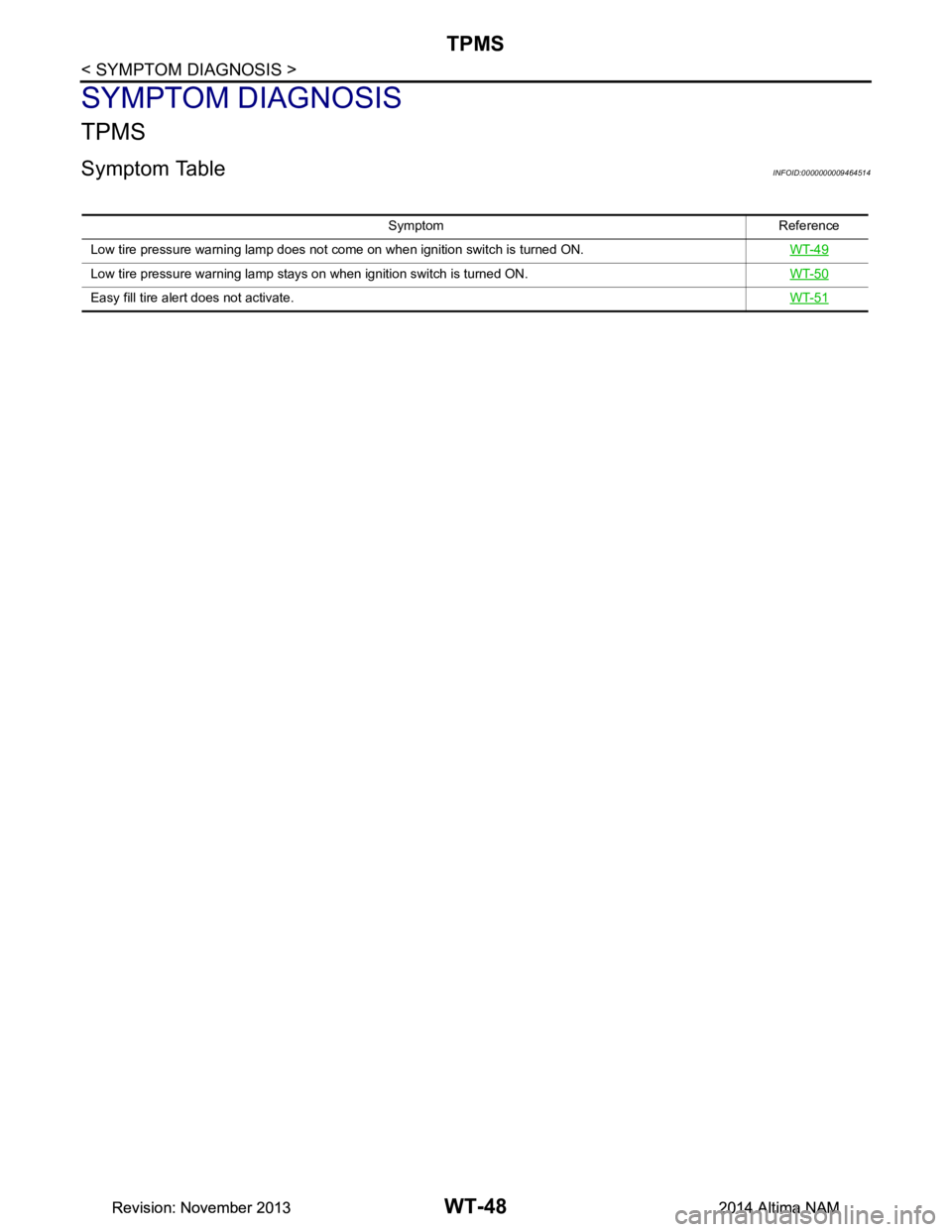

Symptom TableINFOID:0000000009464514

Symptom Reference

Low tire pressure warning lamp does not come on when ignition switch is turned ON. WT-49

Low tire pressure warning lamp stays on when ignition switch is turned ON.WT-50

Easy fill tire alert does not activate.WT-51

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4724 of 4801

LOW TIRE PRESSURE WARNING LAMP DOES NOT TURN ON

WT-49

< SYMPTOM DIAGNOSIS >

C

D

F

G H

I

J

K L

M A

B

WT

N

O P

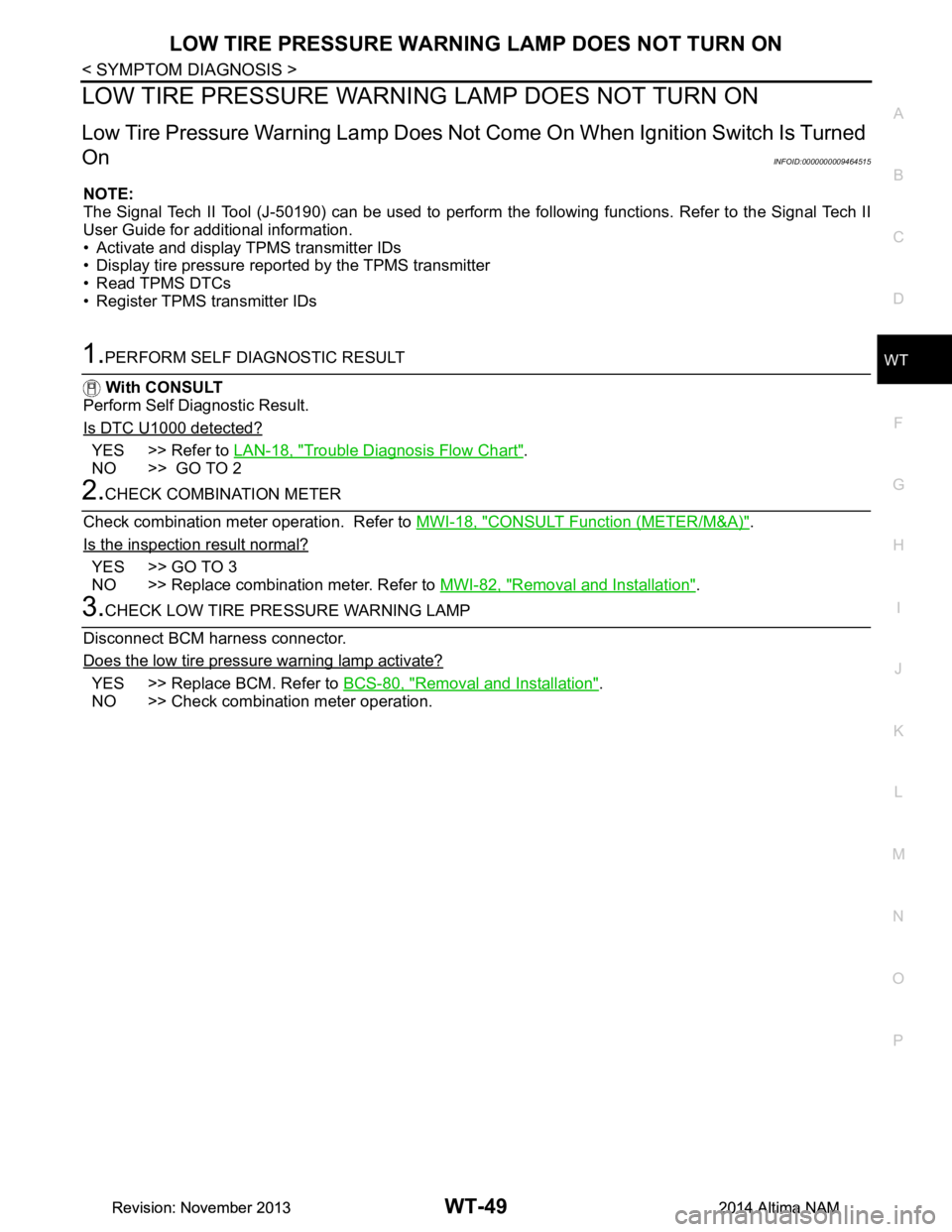

LOW TIRE PRESSURE WARNIN G LAMP DOES NOT TURN ON

Low Tire Pressure Warning Lamp Does Not Come On When Ignition Switch Is Turned

On

INFOID:0000000009464515

NOTE:

The Signal Tech II Tool (J-50190) can be used to perform the following functions. Refer to the Signal Tech II

User Guide for additional information.

• Activate and display TPMS transmitter IDs

• Display tire pressure repor ted by the TPMS transmitter

• Read TPMS DTCs

• Register TPMS transmitter IDs

1.PERFORM SELF DIAGNOSTIC RESULT

With CONSULT

Perform Self Diagnostic Result.

Is DTC U1000 detected?

YES >> Refer to LAN-18, "Trouble Diagnosis Flow Chart".

NO >> GO TO 2

2.CHECK COMBINATION METER

Check combination meter operation. Refer to MWI-18, "CONSULT Function (METER/M&A)"

.

Is the inspection result normal?

YES >> GO TO 3

NO >> Replace combination meter. Refer to MWI-82, "Removal and Installation"

.

3.CHECK LOW TIRE PRESSURE WARNING LAMP

Disconnect BCM harness connector.

Does the low tire pressure warning lamp activate?

YES >> Replace BCM. Refer to BCS-80, "Removal and Installation".

NO >> Check combination meter operation.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4725 of 4801

WT-50

< SYMPTOM DIAGNOSIS >

LOW TIRE PRESSURE WARNING LAMP STAYS ON

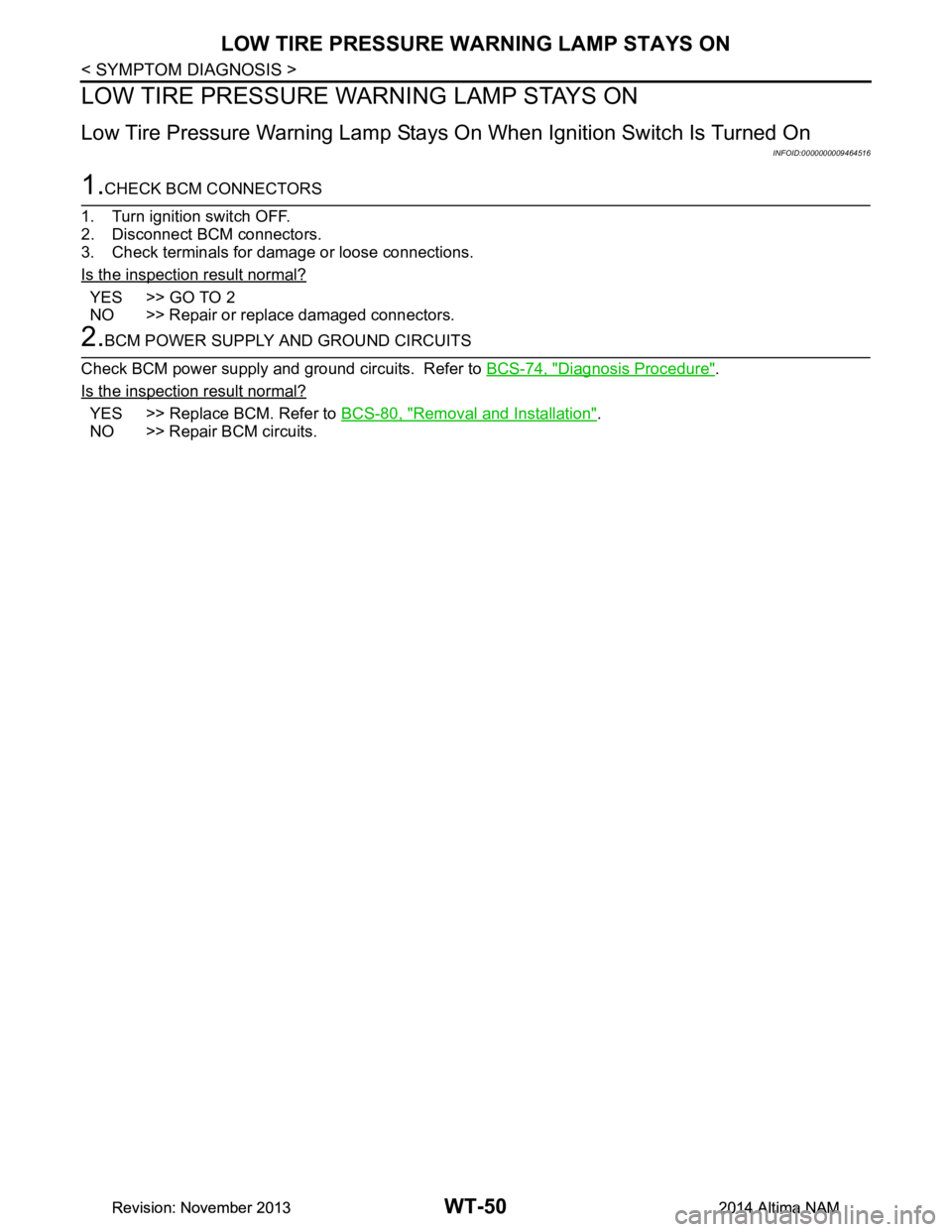

LOW TIRE PRESSURE WARNING LAMP STAYS ON

Low Tire Pressure Warning Lamp Stays On When Ignition Switch Is Turned On

INFOID:0000000009464516

1.CHECK BCM CONNECTORS

1. Turn ignition switch OFF.

2. Disconnect BCM connectors.

3. Check terminals for damage or loose connections.

Is the inspection result normal?

YES >> GO TO 2

NO >> Repair or replace damaged connectors.

2.BCM POWER SUPPLY AND GROUND CIRCUITS

Check BCM power supply and ground circuits. Refer to BCS-74, "Diagnosis Procedure"

.

Is the inspection result normal?

YES >> Replace BCM. Refer to BCS-80, "Removal and Installation".

NO >> Repair BCM circuits.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4726 of 4801

EASY FILL TIRE ALERT DOES NOT ACTIVATEWT-51

< SYMPTOM DIAGNOSIS >

C

D

F

G H

I

J

K L

M A

B

WT

N

O P

EASY FILL TIRE ALERT DOES NOT ACTIVATE

DescriptionINFOID:0000000009464517

The Easy Fill tire alert does not function while inflating a tire when the select lever position is in P-range with

the ignition switch ON. Refer to WT-9, "Easy Fill Tire Alert Function"

.

Diagnosis ProcedureINFOID:0000000009464518

1. LOCATION CHANGE

Move the vehicle to another area and repeat the procedure of the Easy Fill tire alert function. Refer to WT-9,

"Easy Fill Tire Alert Function".

Is the function normal?

YES >> Inspection End.

NO >> GO TO 2.

2.PERFORM SELF DIAGNOSTIC RESULT

With CONSULT

Perform Self Diagnostic Result.

Are any DTCs detected?

YES >> Refer to BCS-52, "DTC Index".

NO >> GO TO 3.

3.CHECK HAZARD WARNING LAMP OPERATION

Check hazard warning lamp operation with hazard switch.

Do the hazard warning lamps operate?

YES >> GO TO 4.

NO >> Refer to EXL-106, "Diagnosis Procedure"

.

4.PERFORM SELF DIAGNOSTIC RESULT FOR TCM

With CONSULT

Perform Self Diagnostic Result for TRANSMISSION.

Are any DTCs detected?

YES >> Refer to TM-43, "CONSULT Function" (with RE0F10D) or TM-245, "CONSULT Function" (with

RE0F10E).

NO >> GO TO 5.

5.CHECK HORN OPERATION

Check horn operation.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair or replace malfunctioning components.

6.PERFORM SELF DIAGNOSTIC RESULT

With CONSULT

1. Drive at a speed of 40 km/h (25 MPH) or more fo r 3 minutes, and then drive the vehicle at any speed for

10 minutes.

2. Perform Self Diagnostic Result.

Are any DTCs detected?

YES >> Refer to BCS-52, "DTC Index".

NO >> Replace BCM. Refer to BCS-80, "Removal and Installation"

.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4727 of 4801

WT-52

< SYMPTOM DIAGNOSIS >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

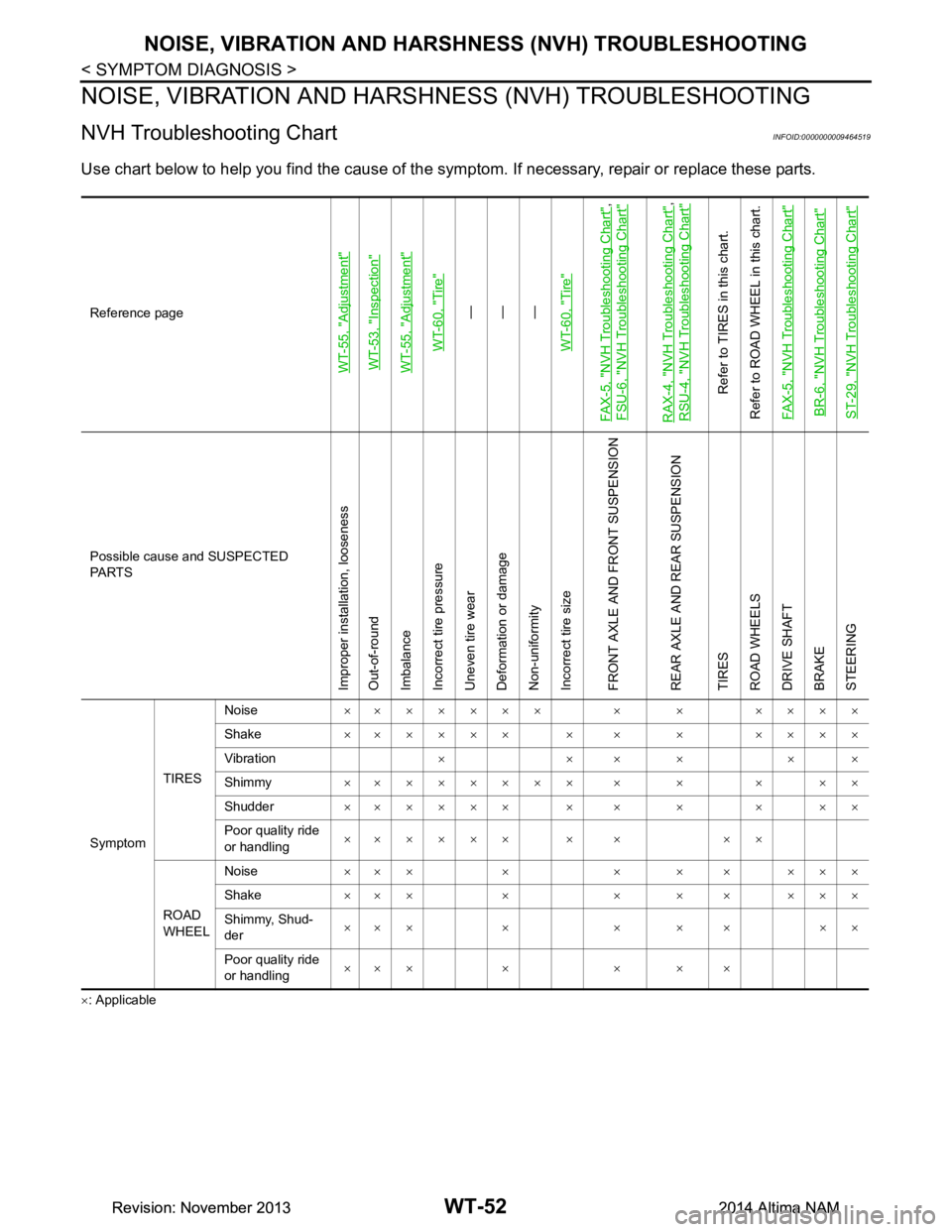

NVH Troubleshooting ChartINFOID:0000000009464519

Use chart below to help you find the cause of the symp tom. If necessary, repair or replace these parts.

×: ApplicableReference page

WT-55, "Adjustment"WT-53, "Inspection"WT-55, "Adjustment"

WT-60, "Tire"

—

—

—

WT-60, "Tire"

FAX-5, "NVH Troubleshooting Chart"

,

FSU-6, "NVH Troubleshooting Chart"

RAX-4, "NVH Troubleshooting Chart"

,

RSU-4, "NVH Troubleshooting Chart"

Refer to TIRES in this chart.

Refer to ROAD WHEEL in this chart.

FAX-5, "NVH Troubleshooting Chart"

BR-6, "NVH Troubleshooting Chart"ST-29, "NVH Troubleshooting Chart"

Possible cause and SUSPECTED

PA R T S

Improper installation, looseness

Out-of-round

Imbalance

Incorrect tire pressure

Uneven tire wear

Deformation or damage

Non-uniformity

Incorrect tire size

FRONT AXLE AND FRONT SUSPENSION

REAR AXLE AND REAR SUSPENSION

TIRES

ROAD WHEELS

DRIVE SHAFT

BRAKE

STEERING

Symptom TIRESNoise

××××××× × × ××××

Shake ×××××× × × × ××××

Vibration ××××××

Shimmy ×××××××× × × × ××

Shudder ×××××× × × × × ××

Poor quality ride

or handling ×××××× × × ××

ROAD

WHEEL Noise

×× × × × × × × × ×

Shake ×× × × × × × × × ×

Shimmy, Shud-

der ×××× ×××××

Poor quality ride

or handling ×× × × × × ×

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4728 of 4801

ROAD WHEELWT-53

< PERIODIC MAINTENANCE >

C

D

F

G H

I

J

K L

M A

B

WT

N

O P

PERIODIC MAINTENANCE

ROAD WHEEL

InspectionINFOID:0000000009464520

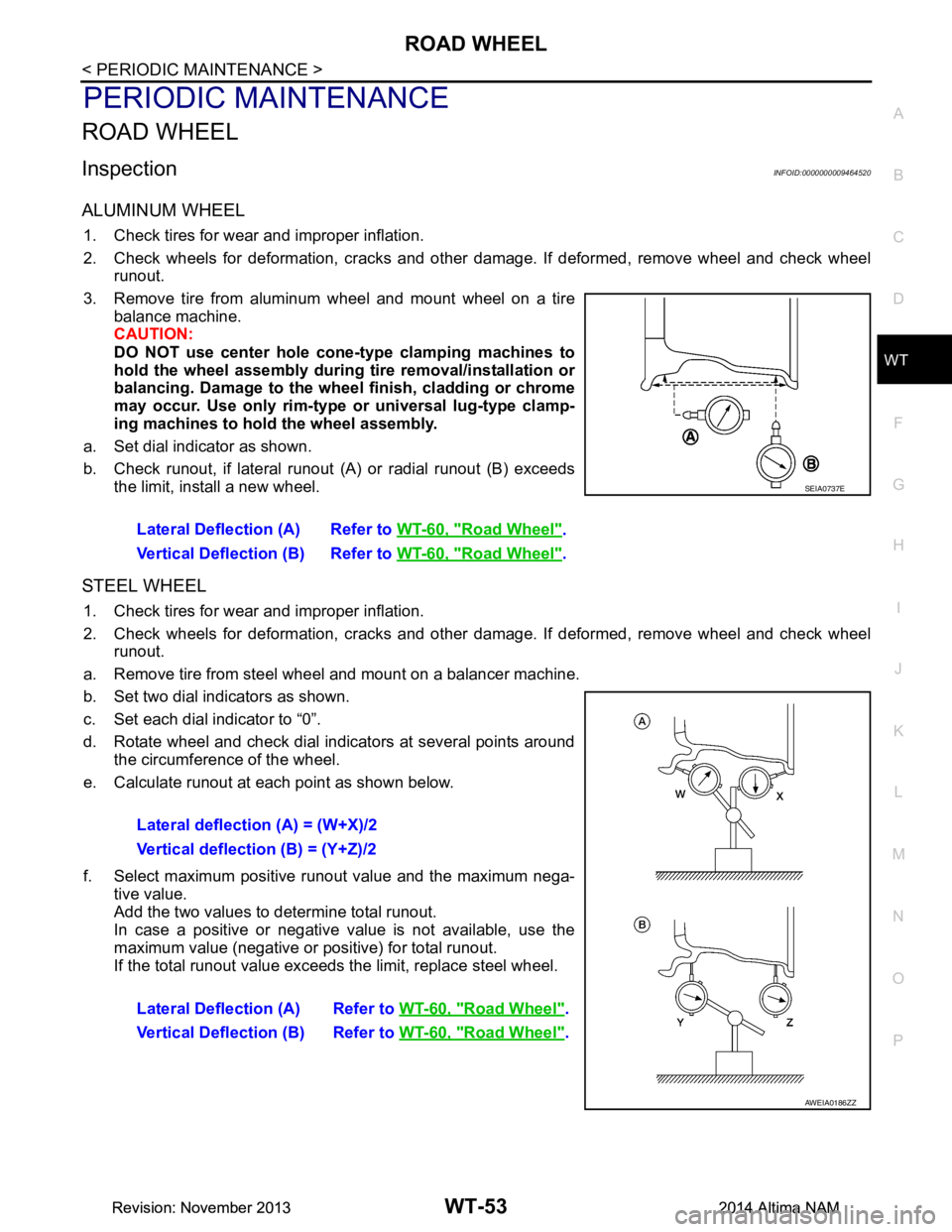

ALUMINUM WHEEL

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If deformed, remove wheel and check wheel

runout.

3. Remove tire from aluminum wheel and mount wheel on a tire balance machine.

CAUTION:

DO NOT use center hole cone-type clamping machines to

hold the wheel assembly during tire removal/installation or

balancing. Damage to the wheel finish, cladding or chrome

may occur. Use only rim-type or universal lug-type clamp-

ing machines to hold the wheel assembly.

a. Set dial indicator as shown.

b. Check runout, if lateral runout (A) or radial runout (B) exceeds

the limit, install a new wheel.

STEEL WHEEL

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If deformed, remove wheel and check wheel

runout.

a. Remove tire from steel wheel and mount on a balancer machine.

b. Set two dial indicators as shown.

c. Set each dial indicator to “0”.

d. Rotate wheel and check dial indicators at several points around the circumference of the wheel.

e. Calculate runout at each point as shown below.

f. Select maximum positive runout value and the maximum nega- tive value.

Add the two values to determine total runout.

In case a positive or negative value is not available, use the

maximum value (negative or positive) for total runout.

If the total runout value exceeds the limit, replace steel wheel.

Lateral Deflection (A) Refer to

WT-60, "Road Wheel"

.

Vertical Deflection (B) Refer to WT-60, "Road Wheel"

.

SEIA0737E

Lateral deflection (A) = (W+X)/2

Vertical deflection (B) = (Y+Z)/2

Lateral Deflection (A) Refer to WT-60, "Road Wheel"

.

Vertical Deflection (B) Refer to WT-60, "Road Wheel"

.

AWEIA0186ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4729 of 4801

WT-54

< REMOVAL AND INSTALLATION >

REMOTE KEYLESS ENTRY RECEIVER

REMOVAL AND INSTALLATION

REMOTE KEYLESS ENTRY RECEIVER

Removal and InstallationINFOID:0000000009464521

The Tire Pressure Receiver is an integral part of the Remote Keyless Entry Receiver. Refer to DLK-224,

"Removal and Installation".

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4730 of 4801

ROAD WHEEL TIRE ASSEMBLYWT-55

< REMOVAL AND INSTALLATION >

C

D

F

G H

I

J

K L

M A

B

WT

N

O P

ROAD WHEEL TIRE ASSEMBLY

AdjustmentINFOID:0000000009464522

BALANCING WHEELS (ADH ESIVE WEIGHT TYPE)

Preparation Before Adjustment

Remove inner and outer balance weights from the r oad wheel. Using releasing agent, remove double-faced

adhesive tape from the road wheel.

CAUTION:

• Be careful not scratch the road wheel during removal.

• After removing double-faced adhesive tape, wipe clean traces of releasing agent from the road

wheel.

Wheel Balance Adjustment

• If a balancer machine has an adhesive weight mode setting, select the adhesive weight mode setting and skip Step 2. below. If a balancer machine only has the clip-on (rim flange) weight mode setting, follow Step 2.

to calculate the correct size adhesive weight.

1. Set road wheel on balancer machine using the cent er hole as a guide. Start the balancer machine.

2. For balancer machines that only have a clip-on (rim fl ange) weight mode setting, follow this step to calcu-

late the correct size adhesive weight to use. W hen inner and outer imbalance values are shown on the

balancer machine indicator, multiply outer imbalance value by 5/3 (1.67) to determine balance weight that

should be used. Select the outer balance weight with a value closest to the calculated value above and

install in to the designated outer position of, or at the designated angle in relation to the road wheel.

a. Indicated imbalance value × 5/3 (1.67) = balance weight to be

installed

Calculation example:

23 g (0.81 oz) × 5/3 (1.67) = 38.33 g (1.35 oz) ⇒ 40 g (1.41 oz)

balance weight (closer to calculated balance weight value)

NOTE:

Note that balance weight value must be closer to the calculated

balance weight value.

Example:

37.4 ⇒ 35 g (1.23 oz)

37.5 ⇒ 40 g (1.41 oz)

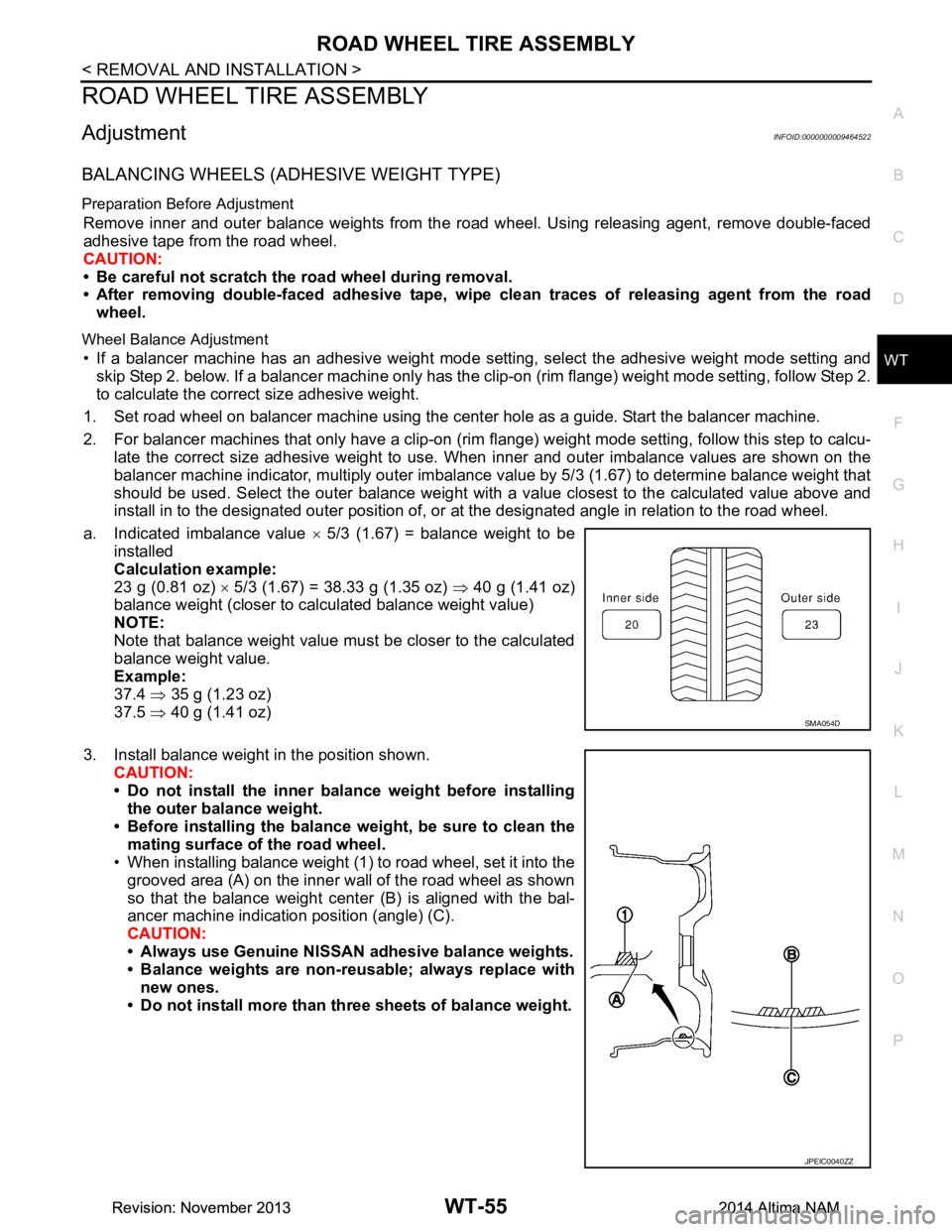

3. Install balance weight in the position shown. CAUTION:

• Do not install the inner bala nce weight before installing

the outer balance weight.

• Before installing the balance weight, be sure to clean the mating surface of the road wheel.

• When installing balance weight (1) to road wheel, set it into the

grooved area (A) on the inner wall of the road wheel as shown

so that the balance weight cent er (B) is aligned with the bal-

ancer machine indication position (angle) (C).

CAUTION:

• Always use Genuine NISSAN adhesive balance weights.

• Balance weights are non-re usable; always replace with

new ones.

• Do not install more than th ree sheets of balance weight.

SMA054D

JPEIC0040ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM