NISSAN TERRANO 2004 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 1411 of 1833

Precautions for Service Equipment

RECOVERY/RECYCLING/RECHARGING EQUIPMENT

Be certain to follow the manufacturers instructions for machine

operation and machine maintenance. Never introduce any refriger-

ant other than that specified into the machine.

ELECTRONIC LEAK DETECTOR

Be certain to follow the manufactures instructions for tester opera-

tion and tester maintenance.

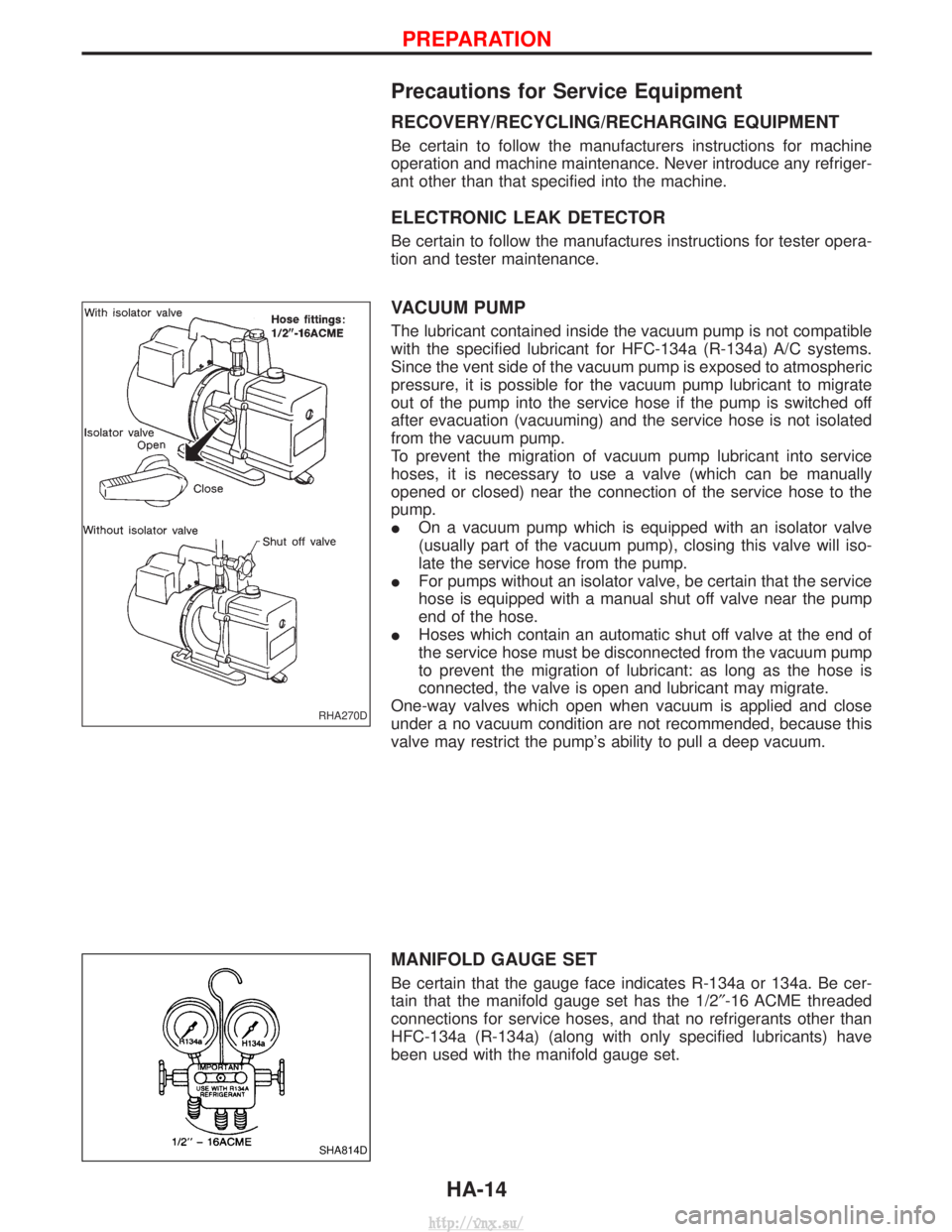

VACUUM PUMP

The lubricant contained inside the vacuum pump is not compatible

with the specified lubricant for HFC-134a (R-134a) A/C systems.

Since the vent side of the vacuum pump is exposed to atmospheric

pressure, it is possible for the vacuum pump lubricant to migrate

out of the pump into the service hose if the pump is switched off

after evacuation (vacuuming) and the service hose is not isolated

from the vacuum pump.

To prevent the migration of vacuum pump lubricant into service

hoses, it is necessary to use a valve (which can be manually

opened or closed) near the connection of the service hose to the

pump.

IOn a vacuum pump which is equipped with an isolator valve

(usually part of the vacuum pump), closing this valve will iso-

late the service hose from the pump.

I For pumps without an isolator valve, be certain that the service

hose is equipped with a manual shut off valve near the pump

end of the hose.

I Hoses which contain an automatic shut off valve at the end of

the service hose must be disconnected from the vacuum pump

to prevent the migration of lubricant: as long as the hose is

connected, the valve is open and lubricant may migrate.

One-way valves which open when vacuum is applied and close

under a no vacuum condition are not recommended, because this

valve may restrict the pump's ability to pull a deep vacuum.

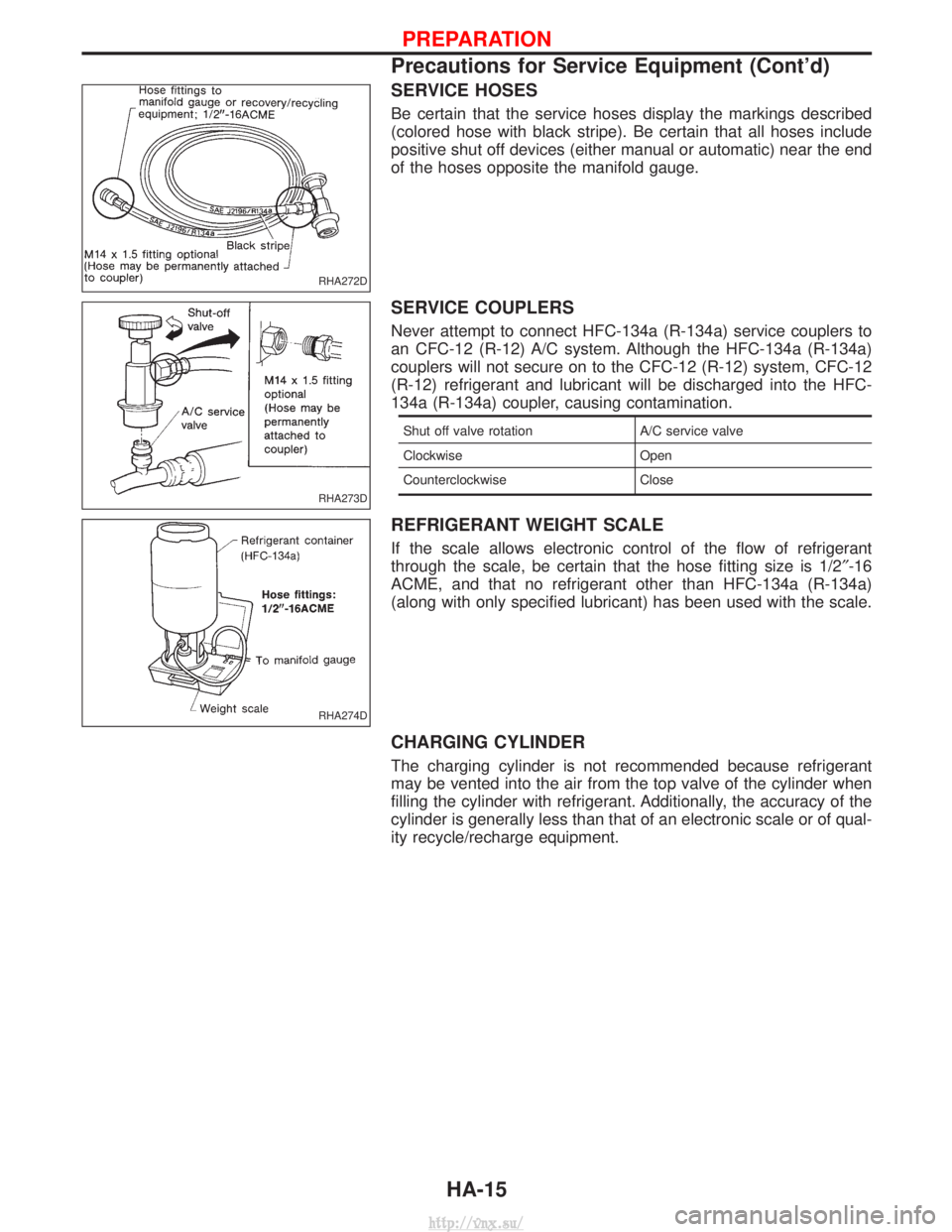

MANIFOLD GAUGE SET

Be certain that the gauge face indicates R-134a or 134a. Be cer-

tain that the manifold gauge set has the 1/2 ²-16 ACME threaded

connections for service hoses, and that no refrigerants other than

HFC-134a (R-134a) (along with only specified lubricants) have

been used with the manifold gauge set.

RHA270D

SHA814D

PREPARATION

HA-14

http://vnx.su/

Page 1412 of 1833

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe). Be certain that all hoses include

positive shut off devices (either manual or automatic) near the end

of the hoses opposite the manifold gauge.

SERVICE COUPLERS

Never attempt to connect HFC-134a (R-134a) service couplers to

an CFC-12 (R-12) A/C system. Although the HFC-134a (R-134a)

couplers will not secure on to the CFC-12 (R-12) system, CFC-12

(R-12) refrigerant and lubricant will be discharged into the HFC-

134a (R-134a) coupler, causing contamination.

Shut off valve rotationA/C service valve

Clockwise Open

Counterclockwise Close

REFRIGERANT WEIGHT SCALE

If the scale allows electronic control of the flow of refrigerant

through the scale, be certain that the hose fitting size is 1/2 ²-16

ACME, and that no refrigerant other than HFC-134a (R-134a)

(along with only specified lubricant) has been used with the scale.

CHARGING CYLINDER

The charging cylinder is not recommended because refrigerant

may be vented into the air from the top valve of the cylinder when

filling the cylinder with refrigerant. Additionally, the accuracy of the

cylinder is generally less than that of an electronic scale or of qual-

ity recycle/recharge equipment.

RHA272D

RHA273D

RHA274D

PREPARATION

Precautions for Service Equipment (Cont'd)

HA-15

http://vnx.su/

Page 1413 of 1833

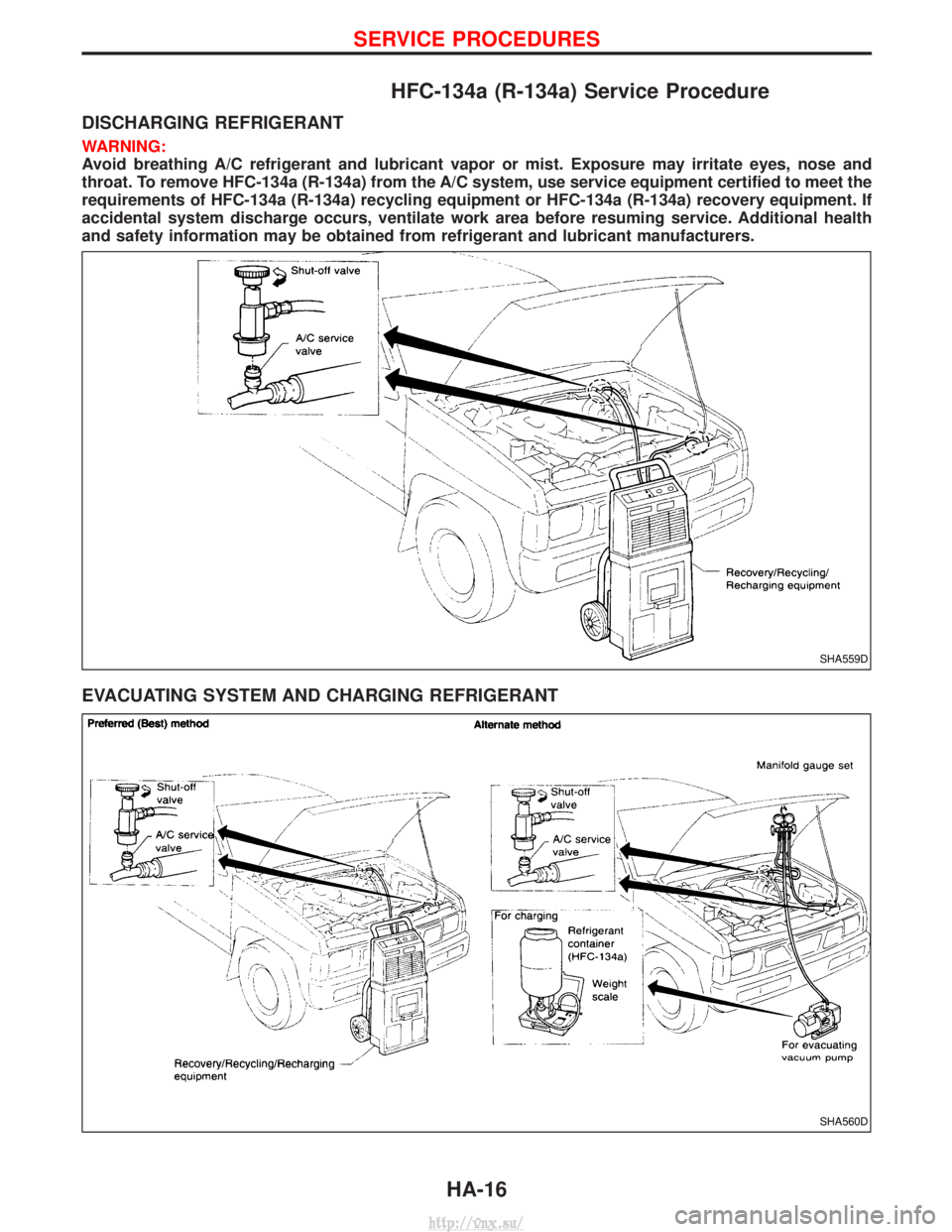

HFC-134a (R-134a) Service Procedure

DISCHARGING REFRIGERANT

WARNING:

Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose and

throat. To remove HFC-134a (R-134a) from the A/C system, use service equipment certified to meet the

requirements of HFC-134a (R-134a) recycling equipment or HFC-134a (R-134a) recovery equipment. If

accidental system discharge occurs, ventilate work area before resuming service. Additional health

and safety information may be obtained from refrigerant and lubricant manufacturers.

EVACUATING SYSTEM AND CHARGING REFRIGERANT

SHA559D

SHA560D

SERVICE PROCEDURES

HA-16

http://vnx.su/

Page 1414 of 1833

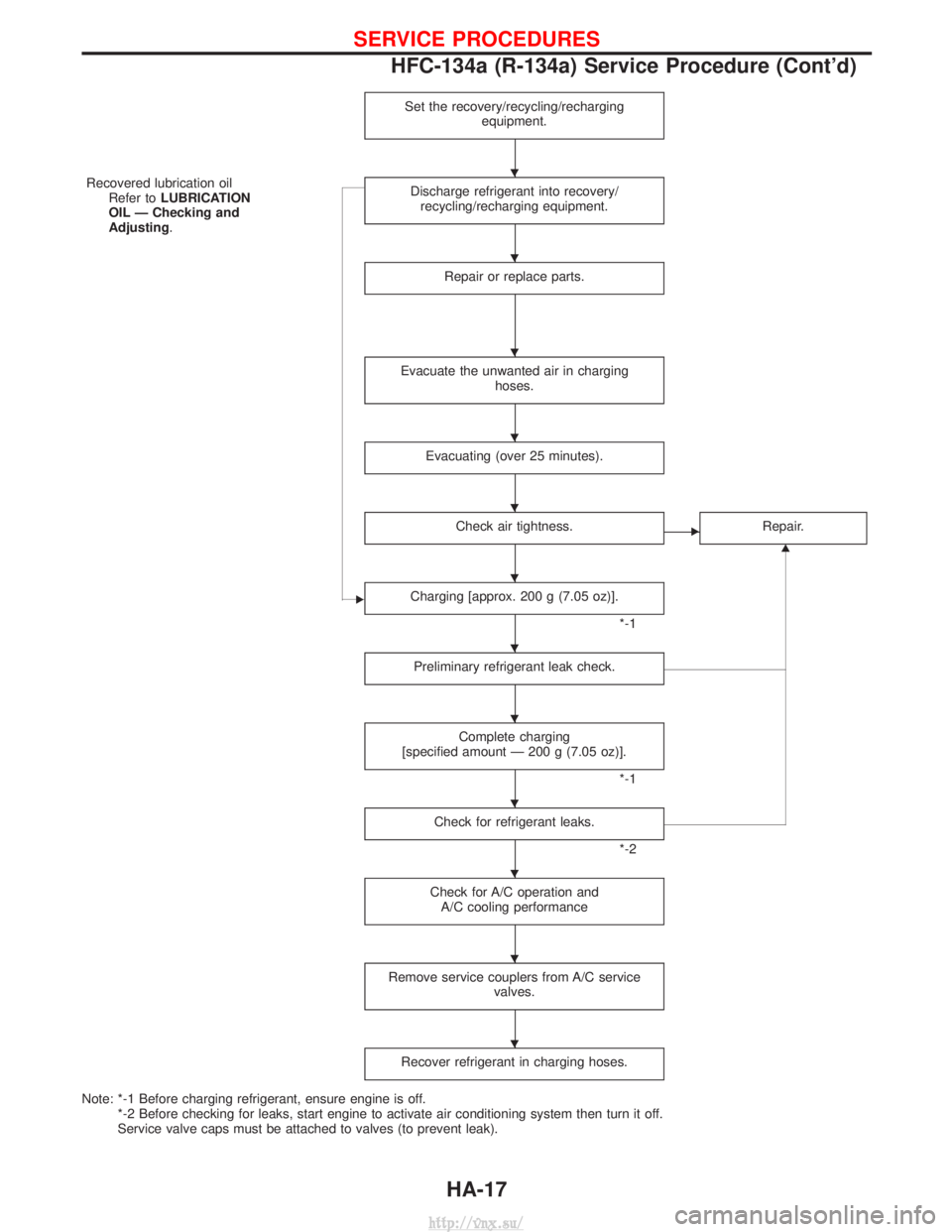

Set the recovery/recycling/rechargingequipment.

Recovered lubrication oilRefer to LUBRICATION

OIL Ð Checking and

Adjusting. Discharge refrigerant into recovery/

recycling/recharging equipment.

Repair or replace parts.

Evacuate the unwanted air in charging hoses.

Evacuating (over 25 minutes).

Check air tightness.ERepair.

G

ECharging [approx. 200 g (7.05 oz)].

*-1

Preliminary refrigerant leak check.

Complete charging

[specified amount Ð 200 g (7.05 oz)].

*-1

Check for refrigerant leaks.

*-2

Check for A/C operation and A/C cooling performance

Remove service couplers from A/C service valves.

Recover refrigerant in charging hoses.

Note: *-1 Before charging refrigerant, ensure engine is off.*-2 Before checking for leaks, start engine to activate air conditioning system then turn it off.

Service valve caps must be attached to valves (to prevent leak).

H

H

H

H

H

H

H

H

H

H

H

H

SERVICE PROCEDURES

HFC-134a (R-134a) Service Procedure (Cont'd)

HA-17

http://vnx.su/

Page 1415 of 1833

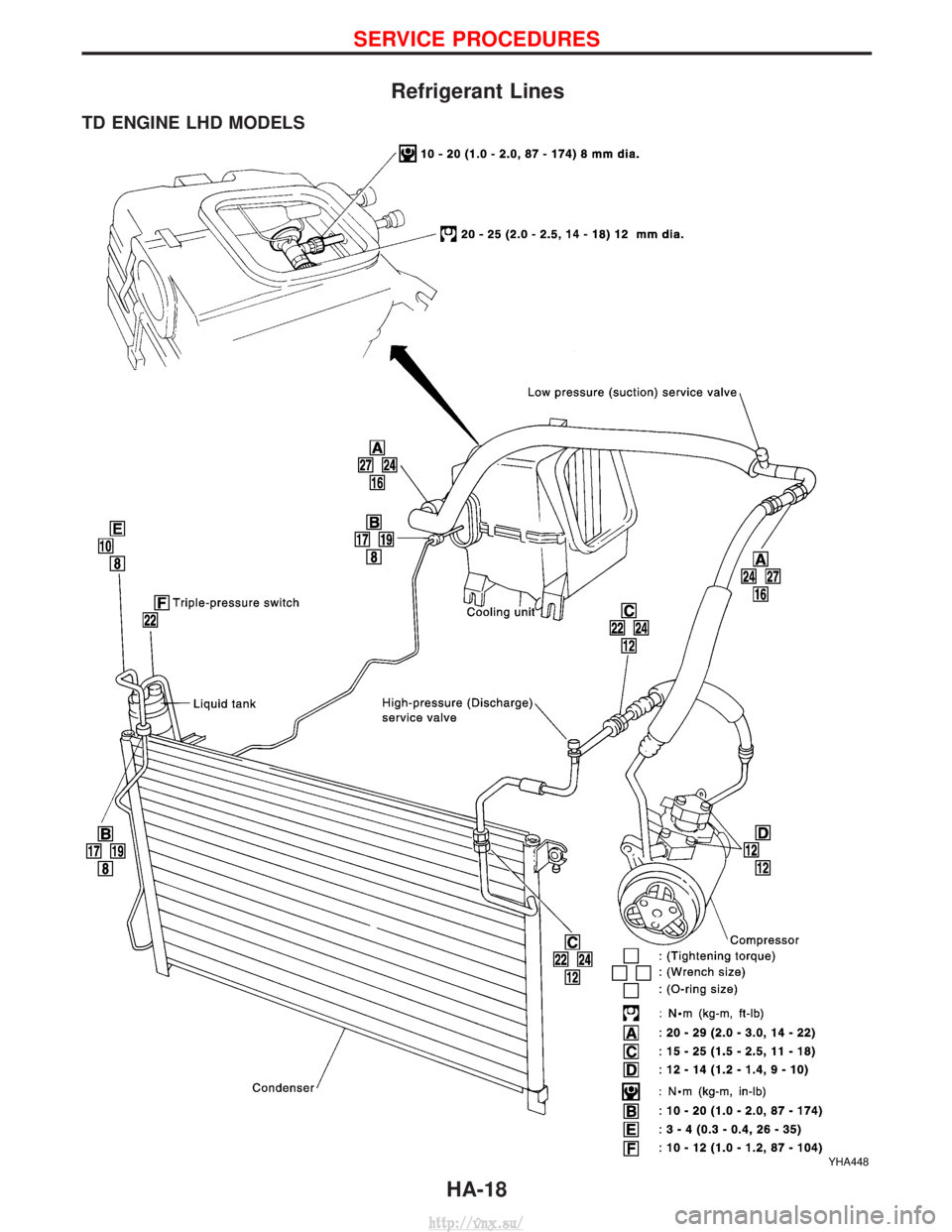

Refrigerant Lines

TD ENGINE LHD MODELS

YHA448

SERVICE PROCEDURES

HA-18

http://vnx.su/

Page 1416 of 1833

TD ENGINE RHD MODELS

YHA449

SERVICE PROCEDURES

Refrigerant Lines (Cont'd)HA-19

http://vnx.su/

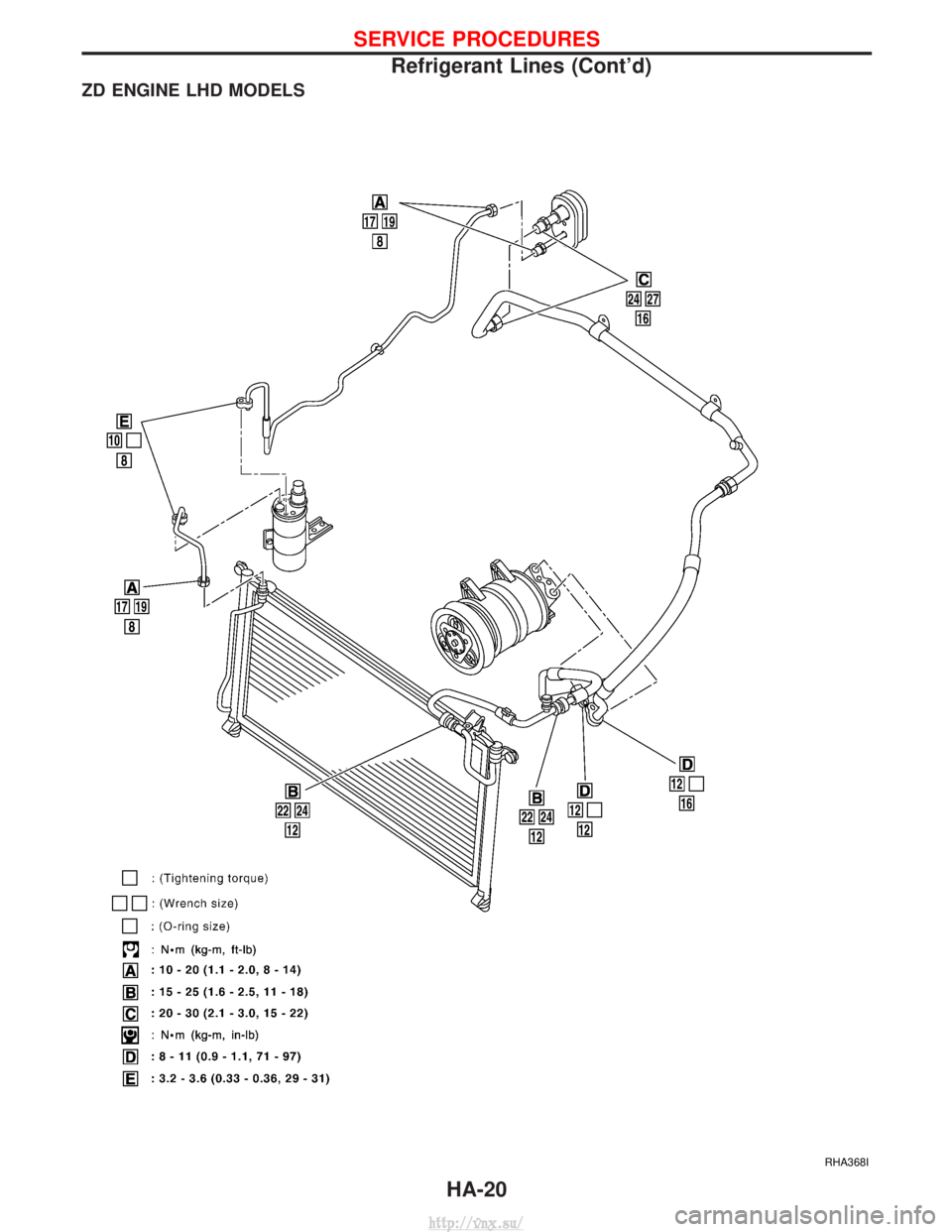

Page 1417 of 1833

ZD ENGINE LHD MODELS

RHA368I

SERVICE PROCEDURES

Refrigerant Lines (Cont'd)HA-20

http://vnx.su/

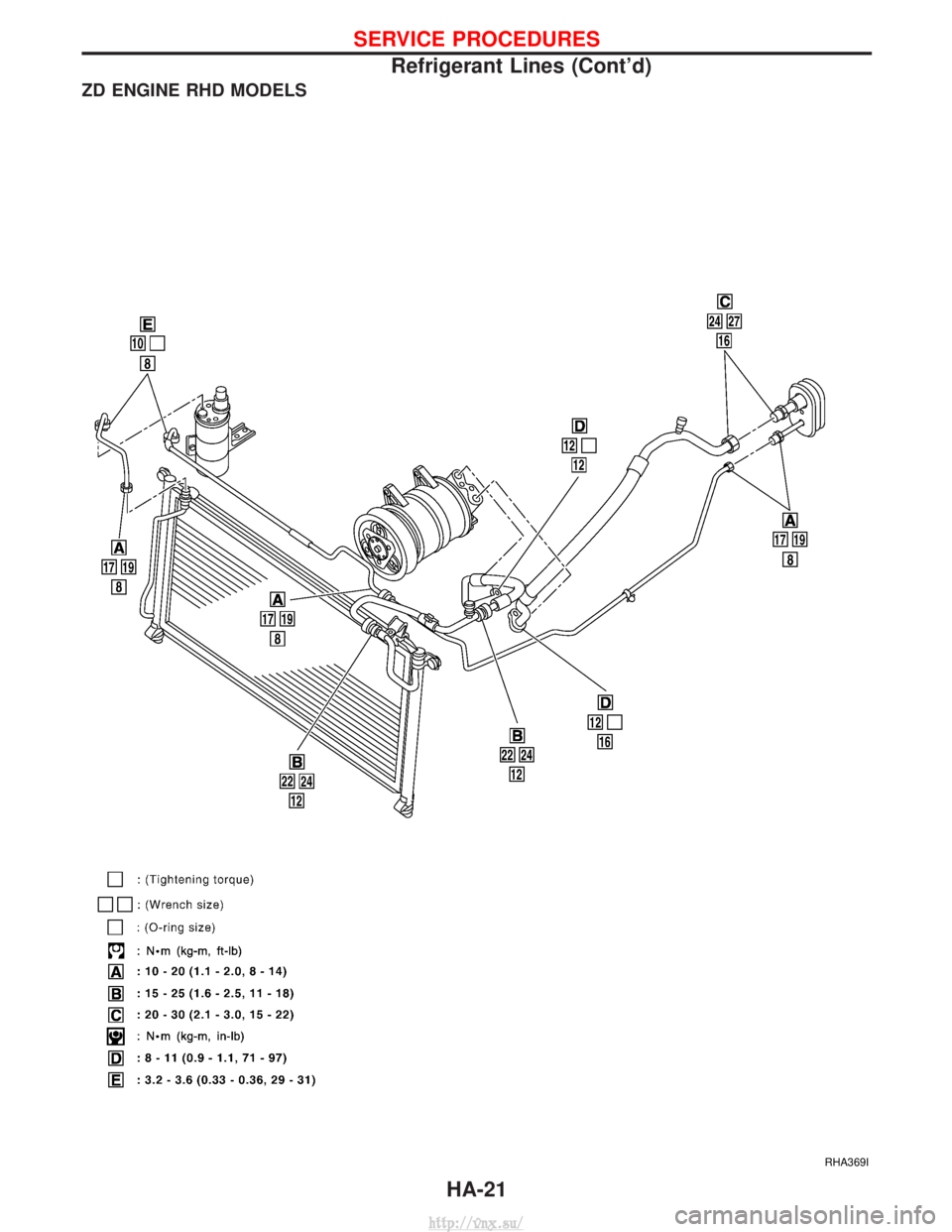

Page 1418 of 1833

ZD ENGINE RHD MODELS

RHA369I

SERVICE PROCEDURES

Refrigerant Lines (Cont'd)HA-21

http://vnx.su/

Page 1419 of 1833

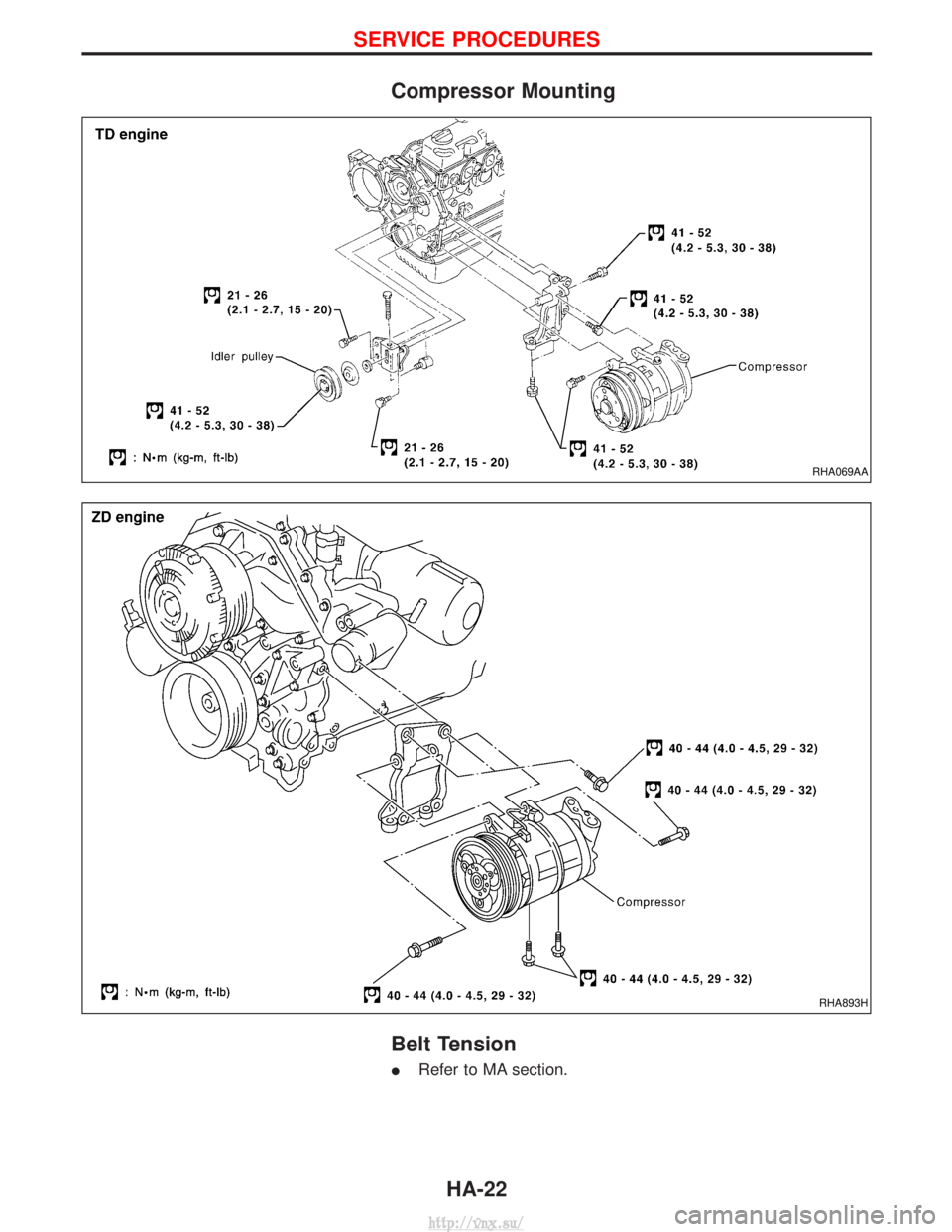

Compressor Mounting

Belt Tension

IRefer to MA section.

RHA069AA

RHA893H

SERVICE PROCEDURES

HA-22

http://vnx.su/

Page 1420 of 1833

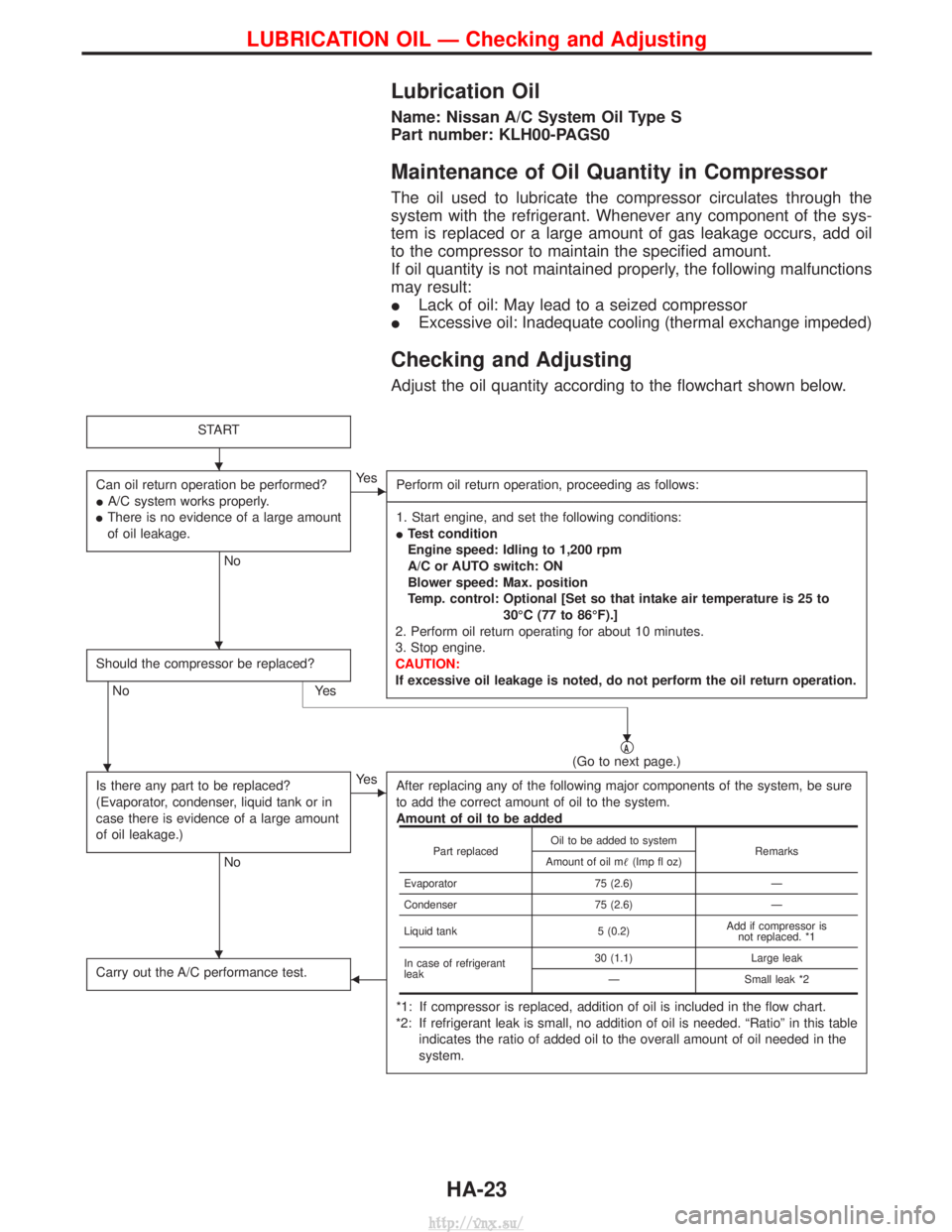

Lubrication Oil

Name: Nissan A/C System Oil Type S

Part number: KLH00-PAGS0

Maintenance of Oil Quantity in Compressor

The oil used to lubricate the compressor circulates through the

system with the refrigerant. Whenever any component of the sys-

tem is replaced or a large amount of gas leakage occurs, add oil

to the compressor to maintain the specified amount.

If oil quantity is not maintained properly, the following malfunctions

may result:

ILack of oil: May lead to a seized compressor

I Excessive oil: Inadequate cooling (thermal exchange impeded)

Checking and Adjusting

Adjust the oil quantity according to the flowchart shown below.

START

Can oil return operation be performed?

IA/C system works properly.

I There is no evidence of a large amount

of oil leakage.

No

EYe s

Perform oil return operation, proceeding as follows:

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- 1. Start engine, and set the following conditions:

I Test condition

Engine speed: Idling to 1,200 rpm

A/C or AUTO switch: ON

Blower speed: Max. position

Temp. control: Optional [Set so that intake air temperature is 25 to

30ÉC (77 to 86ÉF).]

2. Perform oil return operating for about 10 minutes.

3. Stop engine.

CAUTION:

If excessive oil leakage is noted, do not perform the oil return operation.

Should the compressor be replaced?

No Yes

qA(Go to next page.)

Is there any part to be replaced?

(Evaporator, condenser, liquid tank or in

case there is evidence of a large amount

of oil leakage.)

No

EYe s After replacing any of the following major components of the system, be sure

to add the correct amount of oil to the system.

Amount of oil to be added

*1: If compressor is replaced, addition of oil is included in the flow chart.

*2: If refrigerant leak is small, no addition of oil is needed. ªRatioº in this table indicates the ratio of added oil to the overall amount of oil needed in the

system.

Carry out the A/C performance test.F

Part replaced Oil to be added to system

Remarks

Amount of oil m (Imp fl oz)

Evaporator 75 (2.6)Ð

Condenser 75 (2.6)Ð

Liquid tank 5 (0.2)Add if compressor is

not replaced. *1

In case of refrigerant

leak 30 (1.1)

Large leak

Ð Small leak *2

H

H

H

H

H

LUBRICATION OIL Ð Checking and Adjusting

HA-23

http://vnx.su/