NISSAN TERRANO 2004 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 701 of 1833

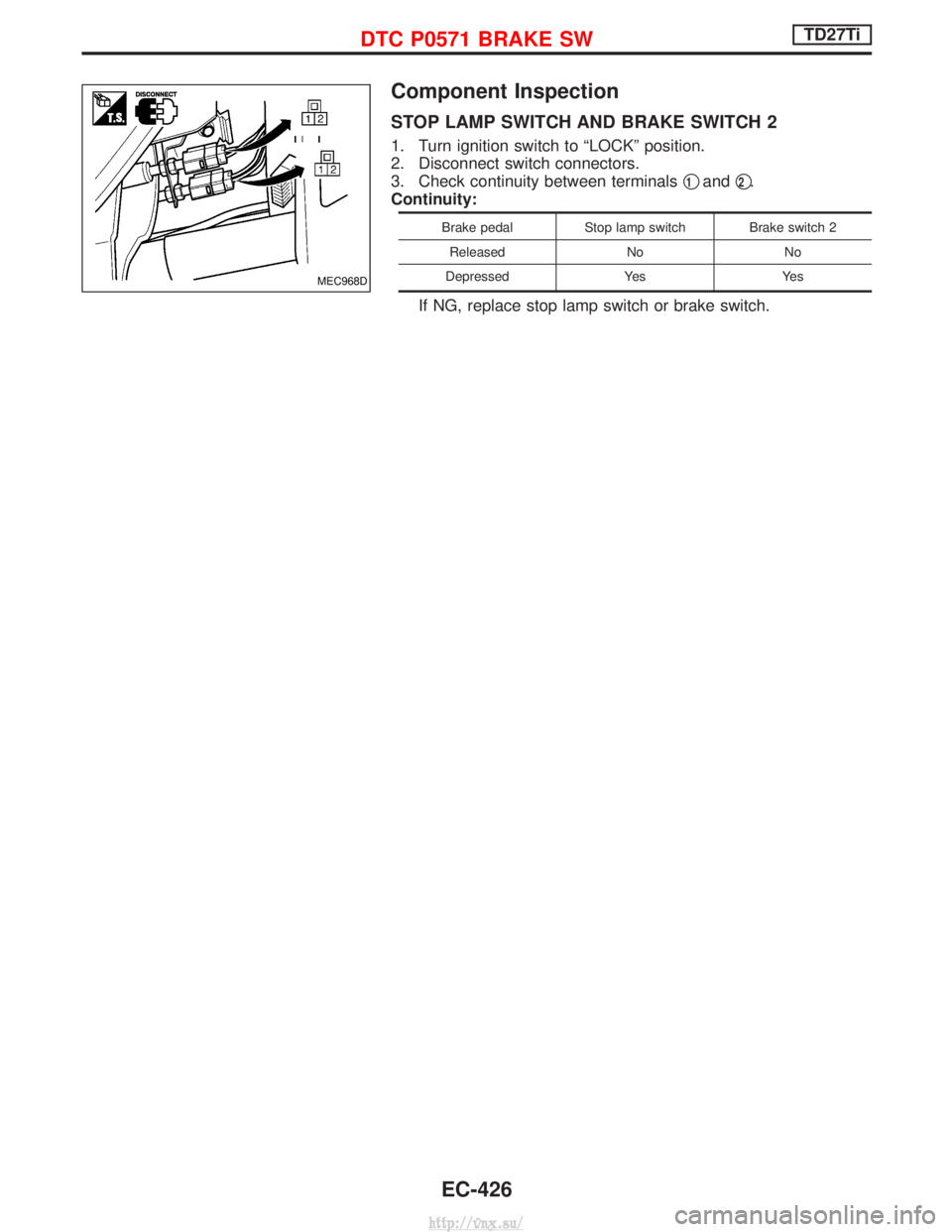

Component Inspection

STOP LAMP SWITCH AND BRAKE SWITCH 2

1. Turn ignition switch to ªLOCKº position.

2. Disconnect switch connectors.

3. Check continuity between terminalsq

1andq2.

Continuity:

Brake pedal Stop lamp switch Brake switch 2

Released NoNo

Depressed YesYes

If NG, replace stop lamp switch or brake switch.

MEC968D

DTC P0571 BRAKE SWTD27Ti

EC-426

http://vnx.su/

Page 702 of 1833

Component Description

Malfunction Indicator (MI) is located on the instrument panel. When the ignition switch is turned ON without

engine running, MI will light up. This is a bulb check. When the engine is started, MI should go off. If MI remains

on, the on board diagnostic system has detected an engine system malfunction.

On Board Diagnosis Logic

DTC No.Trouble diagnosis name DTC detecting condition Possible cause

P0650

0907 Malfunction indicator (MI) control cir-

cuit I

An excessively high voltage is sent

to ECM through the MI circuit

under the condition that calls for MI

light up.

I An excessively low voltage is sent

to ECM through the MI circuit

under the condition that calls for MI

not to light up. I

Harness or connectors

(MI circuit is open or shorted.)

I MI

DTC Confirmation Procedure

NOTE:

If ªDTC Confirmation Procedureº has been previously

conducted, always turn ignition switch ªOFFº and wait at least

10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªDATA MONITORº mode with CONSULT-II.

3. Start engine and let it idle for 2 second.

WITHOUT CONSULT-II

1. Turn ignition switch ªONº.

2. Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

3. Start engine and let it idle for 2 second.

4. Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

SEF817Y

DTC P0650 MITD27Ti

EC-427

http://vnx.su/

Page 703 of 1833

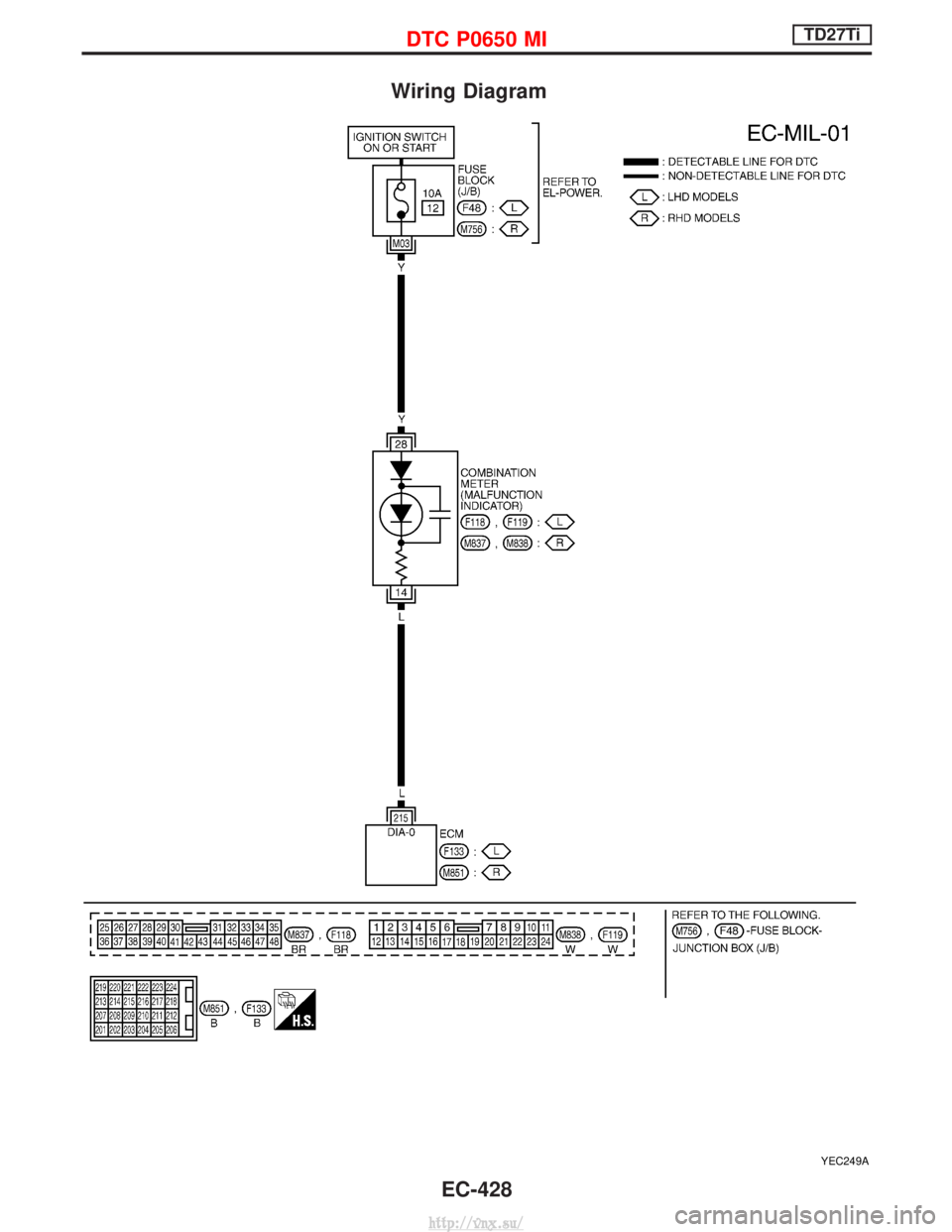

Wiring Diagram

YEC249A

DTC P0650 MITD27Ti

EC-428

http://vnx.su/

Page 704 of 1833

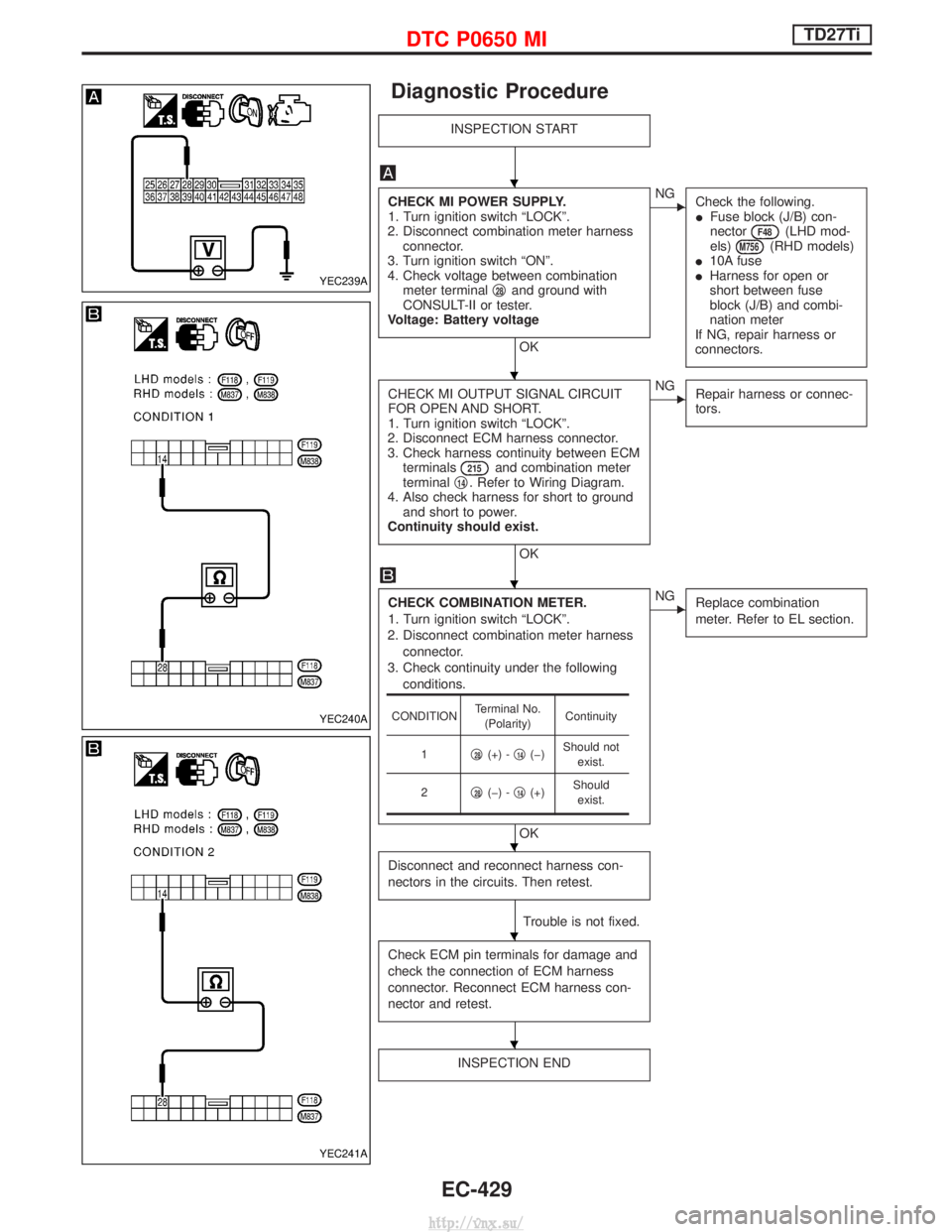

Diagnostic Procedure

INSPECTION START

CHECK MI POWER SUPPLY.

1. Turn ignition switch ªLOCKº.

2. Disconnect combination meter harness connector.

3. Turn ignition switch ªONº.

4. Check voltage between combination meter terminal q

28and ground with

CONSULT-II or tester.

Voltage: Battery voltage

OK

ENG Check the following.

IFuse block (J/B) con-

nector

F48(LHD mod-

els)M756(RHD models)

I 10A fuse

I Harness for open or

short between fuse

block (J/B) and combi-

nation meter

If NG, repair harness or

connectors.

CHECK MI OUTPUT SIGNAL CIRCUIT

FOR OPEN AND SHORT.

1. Turn ignition switch ªLOCKº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals

215and combination meter

terminal q14. Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

Continuity should exist.

OK

ENG Repair harness or connec-

tors.

CHECK COMBINATION METER.

1. Turn ignition switch ªLOCKº.

2. Disconnect combination meter harness connector.

3. Check continuity under the following conditions.

OK

ENG Replace combination

meter. Refer to EL section.

Disconnect and reconnect harness con-

nectors in the circuits. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

CONDITION Terminal No.

(Polarity) Continuity

1 q

28(+) -q14(þ) Should not

exist.

2 q

28(þ) -q14(+) Should

exist.

YEC239A

YEC240A

YEC241A

H

H

H

H

H

H

DTC P0650 MITD27Ti

EC-429

http://vnx.su/

Page 705 of 1833

Description

The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the engine.

On Board Diagnosis Logic

DTCMalfunction is detected when ... Check Items (Possible Cause)

P1107

0802 I

An excessively high or low voltage from

the absolute pressure sensor (built-into

ECM) is sent to ECM. I

ECM

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait at least 2 seconds.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Start engine and wait at least 2 seconds.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then turn

ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with ECM.

SEC220B

SEF817Y

DTC P1107 ECM 10TD27Ti

EC-430

http://vnx.su/

Page 706 of 1833

Diagnostic Procedure

INSPECTION START

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªSELF DIAG RESULTSº mode with CONSULT-II.

3. Touch ªERASEº.

4. Perform ªDTC Confirmation Procedureº, EC-430 again.

5. Is the DTC P1107 displayed again?

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Erase the Diagnostic Test Mode II (Self- diagnostic results) memory.

3. Perform ªDTC Confirmation Procedureº, EC-430 again.

4. Perform ªDiagnostic Test Mode II (Self- diagnostic results)º.

5. Is the DTC 0802 displayed again?

No

EYe s Replace ECM.

INSPECTION END

H

H

DTC P1107 ECM 10TD27Ti

EC-431

http://vnx.su/

Page 707 of 1833

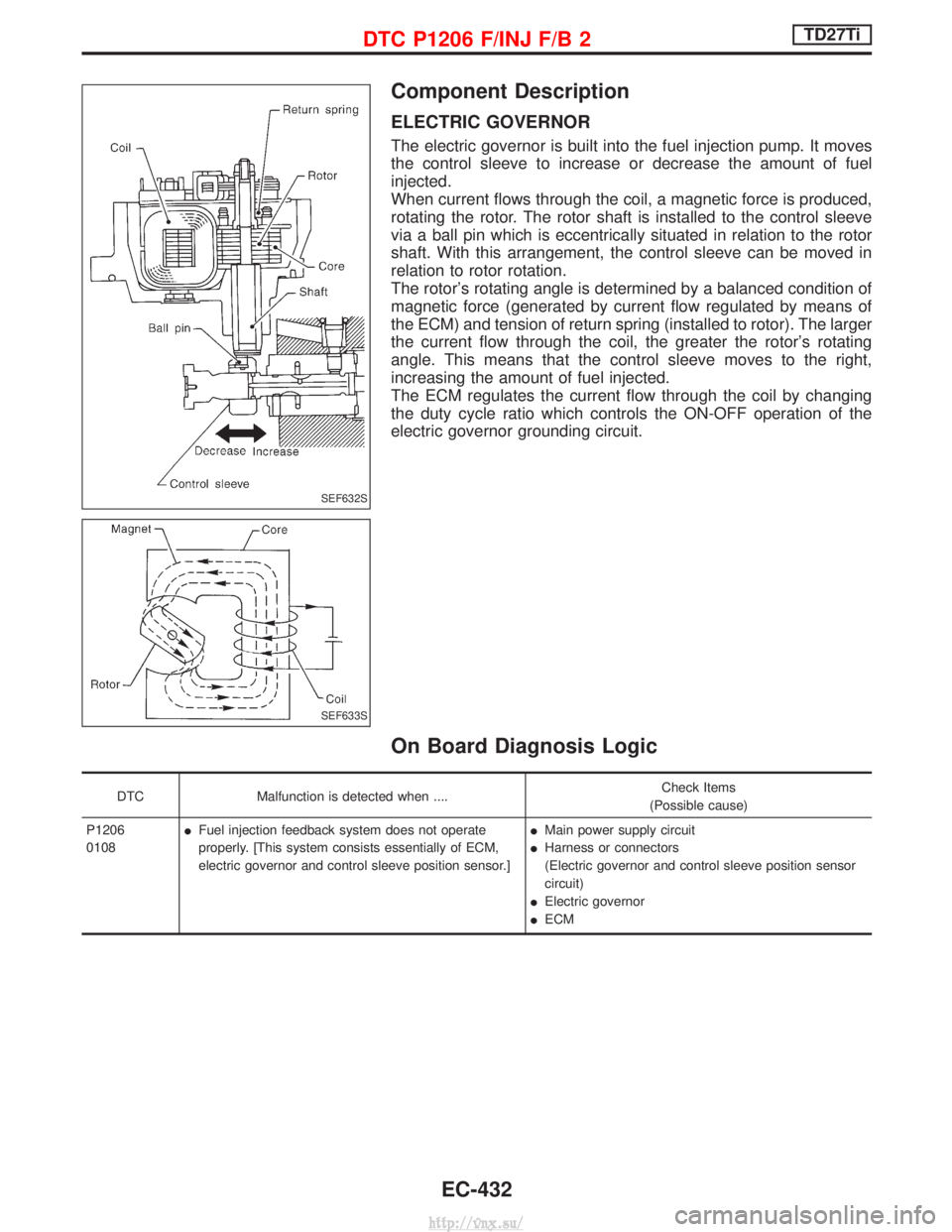

Component Description

ELECTRIC GOVERNOR

The electric governor is built into the fuel injection pump. It moves

the control sleeve to increase or decrease the amount of fuel

injected.

When current flows through the coil, a magnetic force is produced,

rotating the rotor. The rotor shaft is installed to the control sleeve

via a ball pin which is eccentrically situated in relation to the rotor

shaft. With this arrangement, the control sleeve can be moved in

relation to rotor rotation.

The rotor's rotating angle is determined by a balanced condition of

magnetic force (generated by current flow regulated by means of

the ECM) and tension of return spring (installed to rotor). The larger

the current flow through the coil, the greater the rotor's rotating

angle. This means that the control sleeve moves to the right,

increasing the amount of fuel injected.

The ECM regulates the current flow through the coil by changing

the duty cycle ratio which controls the ON-OFF operation of the

electric governor grounding circuit.

On Board Diagnosis Logic

DTCMalfunction is detected when .... Check Items

(Possible cause)

P1206

0108 I

Fuel injection feedback system does not operate

properly. [This system consists essentially of ECM,

electric governor and control sleeve position sensor.] I

Main power supply circuit

I Harness or connectors

(Electric governor and control sleeve position sensor

circuit)

I Electric governor

I ECM

SEF632S

SEF633S

DTC P1206 F/INJ F/B 2TD27Ti

EC-432

http://vnx.su/

Page 708 of 1833

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch to ªONº position and select ªDATA MONI-TORº mode with CONSULT-II.

2) Start engine above 1,200 rpm.

3) Run it for 2 seconds above 1,200 rpm. Return engine speed to idle.

WITHOUT CONSULT-II

1) Start engine above 1,200 rpm.

2) Run engine for 2 seconds above 1,200 rpm. Return enginespeed to idle.

3) Turn ignition switch to ªLOCKº position, wait at least 5 seconds and then turn to ªONº position.

4) Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

NOTE:

If malfunction occurs intermittently, conduct suitable driving

pattern for 10 minutes. This makes it possible to determine

DTC.

DTC P1206 F/INJ F/B 2TD27Ti

EC-433

http://vnx.su/

Page 709 of 1833

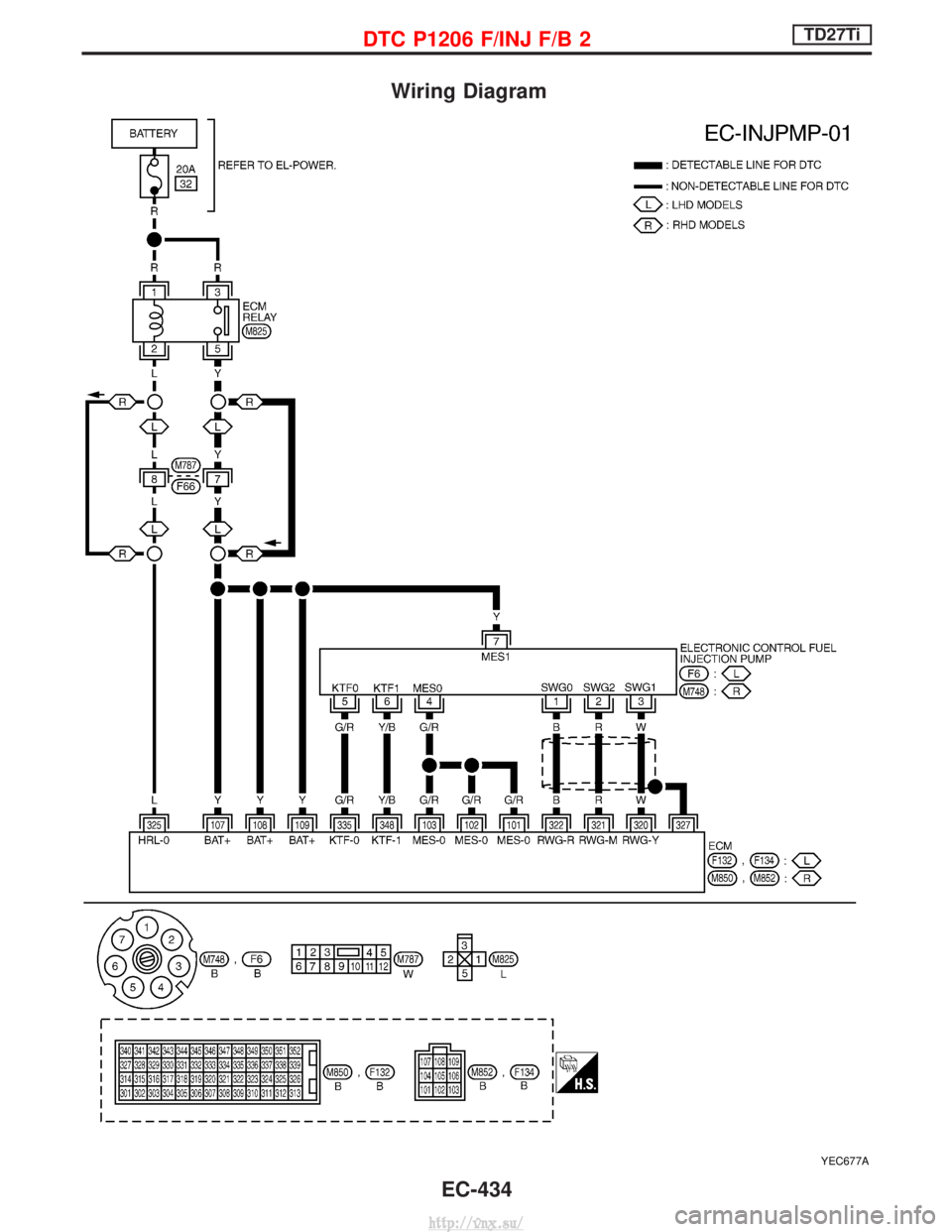

Wiring Diagram

YEC677A

DTC P1206 F/INJ F/B 2TD27Ti

EC-434

http://vnx.su/

Page 710 of 1833

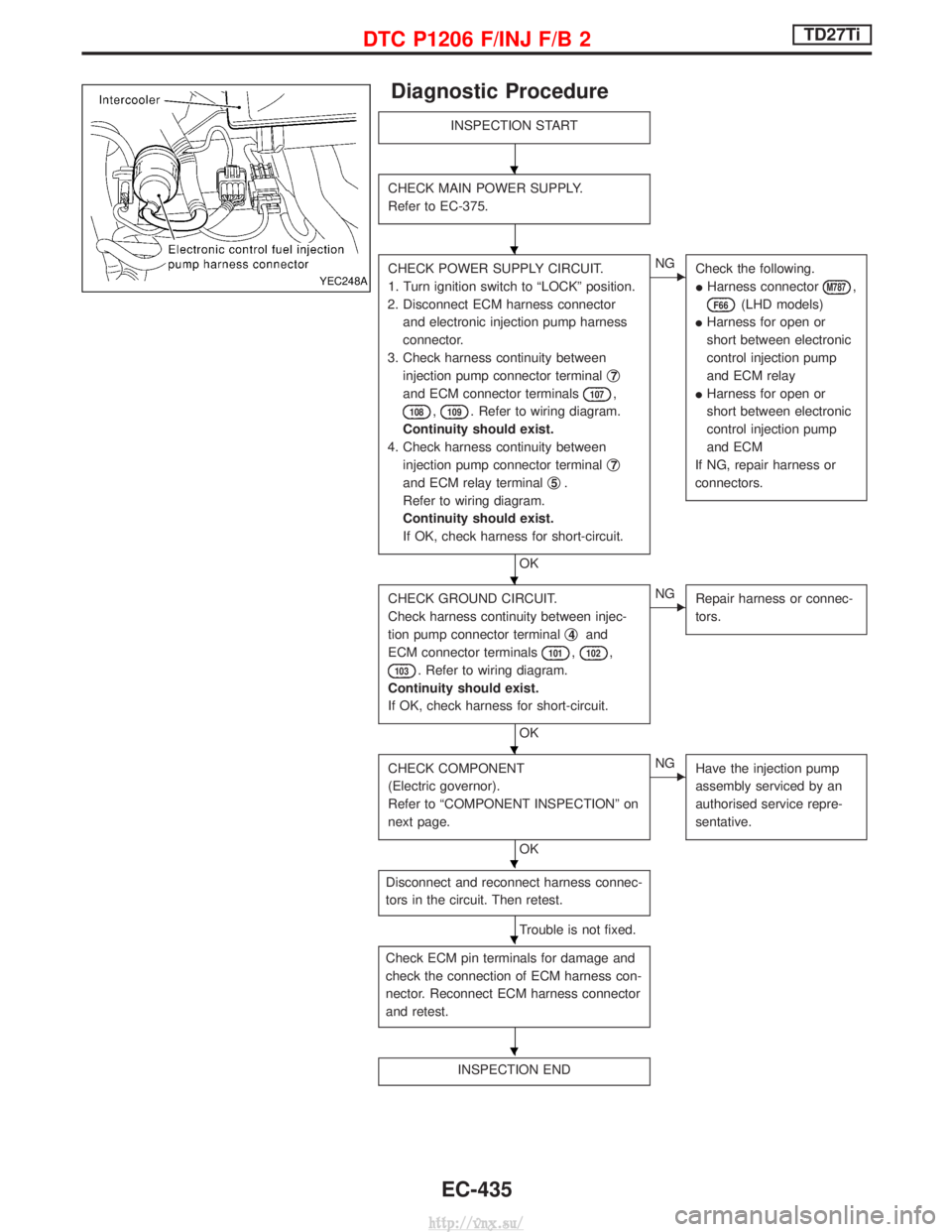

Diagnostic Procedure

INSPECTION START

CHECK MAIN POWER SUPPLY.

Refer to EC-375.

CHECK POWER SUPPLY CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector and electronic injection pump harness

connector.

3. Check harness continuity between injection pump connector terminal q

7

and ECM connector terminals107,

108,109. Refer to wiring diagram.

Continuity should exist.

4. Check harness continuity between injection pump connector terminal q

7

and ECM relay terminalq5.

Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Check the following.

IHarness connector

M787,

F66(LHD models)

I Harness for open or

short between electronic

control injection pump

and ECM relay

I Harness for open or

short between electronic

control injection pump

and ECM

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

Check harness continuity between injec-

tion pump connector terminal q

4and

ECM connector terminals

101,102,

103. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG Repair harness or connec-

tors.

CHECK COMPONENT

(Electric governor).

Refer to ªCOMPONENT INSPECTIONº on

next page.

OK

ENGHave the injection pump

assembly serviced by an

authorised service repre-

sentative.

Disconnect and reconnect harness connec-

tors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness con-

nector. Reconnect ECM harness connector

and retest.

INSPECTION END

YEC248A

H

H

H

H

H

H

H

DTC P1206 F/INJ F/B 2TD27Ti

EC-435

http://vnx.su/