transmission oil NISSAN TIIDA 2007 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 2741 of 5883

![NISSAN TIIDA 2007 Service User Guide EM-94

< DISASSEMBLY AND ASSEMBLY >[HR16DE]

ENGINE STAND SETTING

DISASSEMBLY AND ASSEMBLY

ENGINE STAND SETTING

SettingINFOID:0000000001381427

NOTE:

Explained here is how to disassemble with engine stan NISSAN TIIDA 2007 Service User Guide EM-94

< DISASSEMBLY AND ASSEMBLY >[HR16DE]

ENGINE STAND SETTING

DISASSEMBLY AND ASSEMBLY

ENGINE STAND SETTING

SettingINFOID:0000000001381427

NOTE:

Explained here is how to disassemble with engine stan](/img/5/57395/w960_57395-2740.png)

EM-94

< DISASSEMBLY AND ASSEMBLY >[HR16DE]

ENGINE STAND SETTING

DISASSEMBLY AND ASSEMBLY

ENGINE STAND SETTING

SettingINFOID:0000000001381427

NOTE:

Explained here is how to disassemble with engine stand supporting transmission surface. When using differ-

ent type of engine stand, note with difference in steps and etc.

1. Remove the engine and the transaxle assembly from the vehicle, and separate the transaxle from the

engine. Refer to EM-89, "

Exploded View".

2. Remove clutch cover and clutch disc. Refer to CL-13, "

Removal and Installation".

3. Remove flywheel.

Secure flywheel with a stopper plate [SST: KV11105210], and remove mounting bolts.

CAUTION:

Never disassemble flywheel.

Never place flywheel with signal plate facing down.

When handling signal plate, take care not to damage or scratch it.

Handle signal plate in a manner that prevents it from becoming magnetized.

4. Lift the engine with a hoist to install it onto widely use engine stand.

CAUTION:

Use the engine stand that has a load capacity [approximately 135 kg (298 lb) or more] large

enough for supporting the engine weight.

If the load capacity of stand is not adequate, remove the following parts beforehand to reduce the poten-

tial risk of overturning stand.

- Intake manifold: Refer to EM-29, "

Exploded View".

- Exhaust manifold: Refer to EM-32, "

Exploded View".

- Rocker cover: Refer to EM-47, "

Exploded View".

NOTE:

The figure shows an example of widely use engine stand that

can support mating surface of transaxle with flywheel removed.

CAUTION:

Before removing the hanging chains, make sure the engine

stand is stable and there is no risk of overturning.

5. Drain engine oil. Refer to LU-7, "

Draining".

6. Drain engine coolant by removing water drain plug (1) from

inside of the engine.

Use Genuine Liquid Gasket or equivalent.

PBIC0085E

: Engine front

PBIC3742E

Page 2824 of 5883

![NISSAN TIIDA 2007 Service User Guide TIMING CHAIN

EM-177

< ON-VEHICLE REPAIR >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P ORemoval and InstallationINFOID:0000000001337796

CAUTION:

The rotating direction indicated in the text indicates all dir NISSAN TIIDA 2007 Service User Guide TIMING CHAIN

EM-177

< ON-VEHICLE REPAIR >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P ORemoval and InstallationINFOID:0000000001337796

CAUTION:

The rotating direction indicated in the text indicates all dir](/img/5/57395/w960_57395-2823.png)

TIMING CHAIN

EM-177

< ON-VEHICLE REPAIR >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P ORemoval and InstallationINFOID:0000000001337796

CAUTION:

The rotating direction indicated in the text indicates all directions seen from the engine front.

REMOVAL

1. Remove front RH wheel. Refer to WT-6, "Rotation".

2. Remove front fender protector (RH). Refer to EXT-22, "

Removal and Installation".

3. Drain engine oil. Refer to LU-16, "

Changing Engine Oil".

NOTE:

Perform this step when engine is cold.

4. Remove the following parts.

Rocker cover: Refer to EM-173, "

Removal and Installation".

Drive belt: Refer to EM-142, "

Component".

Water pump pulley: Refer to CO-44, "

Component".

Ground cable (between engine bracket (RH) and radiator core support)

5. Support the bottom surface of engine using a transmission jack, and then remove the engine bracket and

insulator (RH). Refer to EM-207

.

6. Set No. 1 cylinder at TDC on its compression stroke with the following procedure:

a. Rotate crankshaft pulley (1) clockwise and align TDC mark (no paint) (B) to timing indicator (A) on front

cover.

b. At the same time, make sure that the cam noses of the No.1 cyl-

inder are located ( ) as shown.

If not, rotate crankshaft pulley one revolution (360 degrees)

and align as shown.

16. Oil pump drive chain 17. Camshaft sprocket (INT) 18. Timing chain tension guide

19. O-ring 20. Chain tensioner (for oil pump)

A. Refer to EM-177

B. Refer to EM-186

C : White paint mark (Not use for service)

PBIC3960E

1 : Camshaft (INT)

2 : Camshaft (EXH)

: Engine front

PBIC3359J

Page 2840 of 5883

![NISSAN TIIDA 2007 Service User Guide CAMSHAFT

EM-193

< ON-VEHICLE REPAIR >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

10. Install camshaft sprocket (EXH) (2).

NOTE:

Secure the hexagonal part (A) of camshaft (EXH) using wrench

to tighten bol NISSAN TIIDA 2007 Service User Guide CAMSHAFT

EM-193

< ON-VEHICLE REPAIR >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

10. Install camshaft sprocket (EXH) (2).

NOTE:

Secure the hexagonal part (A) of camshaft (EXH) using wrench

to tighten bol](/img/5/57395/w960_57395-2839.png)

CAMSHAFT

EM-193

< ON-VEHICLE REPAIR >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

10. Install camshaft sprocket (EXH) (2).

NOTE:

Secure the hexagonal part (A) of camshaft (EXH) using wrench

to tighten bolt.

11. Install timing chain and related parts. Refer to EM-176

.

12. Inspect and adjust valve clearance. Refer to EM-148, "

Valve Clearance".

13. Installation of the remaining components is in the reverse order of removal.

INSPECTION AFTER INSTALLATION

The following are procedures for checking fluids leak, lubricates leak.

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to GI-27, "

Recommended Chemical Products and Sealants".

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal/installation, slack in the guide may

generate a pounding noise during and just after engine start. However, this is normal. Noise will stop after

hydraulic pressure rises.

Warm up engine thoroughly to make sure there is no leakage of fuel, or any oil/fluids including engine oil and

engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

* Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

Inspection of Camshaft Sprocket (INT) Oil Groove

CAUTION:

Perform this inspection only when DTC P0011 is detected in self-diagnostic results of CONSULT-III

and it is directed according to inspection procedure of EC section. Refer to EC-796, "

Diagnosis Pro-

cedure".

Check when engine is cold so as to prevent burns from the splashing engine oil.

1. Check engine oil level. Refer to LU-15, "

Inspection".

2. Perform the following procedure so as to prevent the engine from being unintentionally started while

checking.

a. Remove intake manifold. Refer to EM-156, "

Component".

b. Disconnect ignition coil and injector harness connectors.

3. Remove intake valve timing control solenoid valve. Refer to EM-176, "

Component".

1 : Camshaft sprocket (INT)

Camshaft sprocket

bolt (EXH): 88.2 N·m (9.0 kg-m, 65 ft-lb)

PBIC3454J

Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 2855 of 5883

![NISSAN TIIDA 2007 Service User Guide EM-208

< REMOVAL AND INSTALLATION >[MR18DE]

ENGINE ASSEMBLY

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type lift as best you can. If board-on type NISSAN TIIDA 2007 Service User Guide EM-208

< REMOVAL AND INSTALLATION >[MR18DE]

ENGINE ASSEMBLY

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type lift as best you can. If board-on type](/img/5/57395/w960_57395-2854.png)

EM-208

< REMOVAL AND INSTALLATION >[MR18DE]

ENGINE ASSEMBLY

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type lift as best you can. If board-on type is used for unavoid-

able reasons, support at the rear axle jacking point with a transmission jack or similar tool before

starting work, in preparation for the backward shift of center of gravity.

For supporting points for lifting and jacking point at rear axle, refer to GI-48, "

Garage Jack and

Safety Stand and 2-Pole Lift".

REMOVAL

Remove the engine and the transaxle assembly from the vehicle downward. Separate the engine and the tran-

saxle.

1. Remove engine undercover

2. Drain engine coolant from radiator. Refer to CO-35, "

Changing Engine Coolant".

CAUTION:

Perform this step when the engine is cold.

Do not spill engine coolant on drive belt.

3. Remove front fender protector (RH and LH); Refer to EXT-22, "

Removal and Installation".

4. Remove exhaust front tube; Refer to EX-10, "

Component".

5. Remove drive shafts (LH and RH) from steering knuckle. Refer to FA X - 7 , "

Removal and Installation".

6. Remove transaxle joint bolts which pierce at oil pan (upper) lower rear side. Refer to EM-207, "

Compo-

nent".

7. Remove rear torque rod (1).

8. Remove hood assembly. Refer to DLK-214, "

Removal and Installation".

9. Remove cowl top cover and cowl top extension assembly. Refer to EXT-20, "

Removal and Installation".

10. Release fuel pressure. Refer to EC-1035, "

Inspection".

11. Remove battery and battery tray; Refer to PG-6, "

Removal and Installation".

12. Remove drive belt; Refer to EM-142, "

Component".

13. Remove air duct and air cleaner case assembly; Refer to EM-154

.

14. Remove cooling fan assembly.

15. Remove radiator hose (upper and lower). Refer to CO-40, "

Component".

16. Disconnect all connections of engine harness around the engine mounting insulator (LH), and then tem-

porarily secure the engine harness into the engine side.

CAUTION:

Protect connectors using a resin bag to protect against foreign materials during the operation.

17. Disconnect fuel feed hose at engine side. Refer to EM-162, "

Component".

18. Disconnect heater hoses, and install plugs them to prevent engine coolant from draining. Refer to CO-47,

"Component".

19. Disconnect control cable from transaxle. Refer to TM-674, "

Exploded View".

20. Remove ground cable at transaxle side.

21. Remove ground cable between front cover and vehicle.

22. Remove generator. Refer to CHG-29, "

Removal and Installation".

23. Remove A/C compressor with piping connected from the engine. Temporarily secure it on the vehicle side

with a rope to avoid putting load on it. Refer to HA-32, "

Removal and Installation of Compressor -

MR18DE".

LBIA0460E

Page 2856 of 5883

![NISSAN TIIDA 2007 Service User Guide ENGINE ASSEMBLY

EM-209

< REMOVAL AND INSTALLATION >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

24. Remove the intake manifold to prevent the hanging chain from interfering. Refer to EM-156, "Removal

and NISSAN TIIDA 2007 Service User Guide ENGINE ASSEMBLY

EM-209

< REMOVAL AND INSTALLATION >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

24. Remove the intake manifold to prevent the hanging chain from interfering. Refer to EM-156, "Removal

and](/img/5/57395/w960_57395-2855.png)

ENGINE ASSEMBLY

EM-209

< REMOVAL AND INSTALLATION >[MR18DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

24. Remove the intake manifold to prevent the hanging chain from interfering. Refer to EM-156, "Removal

and Installation".

25. Install engine slinger to cylinder head front left side (A) and rear

right side (B) and support the engine position with a hoist.

26. Support engine and transaxle assembly with a hoist and secure the engine in appropriate position.

27. Use a manual lift table caddy (A) or equivalently rigid tool such

as a transmission jack. Securely support bottom of the engine

and the transaxle, and simultaneously adjust hoist tension.

CAUTION:

Put a piece of wood or something similar as the supporting

surface, secure a completely stable condition.

28. Remove torque rod (RH) (1), engine insulator (RH) (2) and

engine bracket (RH) (3).

29. Remove engine through bolt-securing nut (C).

30. Remove the engine and the transaxle assembly from the vehicle downward by carefully operating sup-

porting tools.

CAUTION:

During the operation, make sure that no part interferes with the vehicle side.

Before and during this lifting, always check if any harnesses are left connected.

During the removal operation, always be careful to prevent the vehicle from falling off the lift due

to changes in the center of gravity.

If necessary, support the vehicle by setting jack or suitable tool at the rear.

During operation, securely support the engine by placing a piece of wood under the engine oil

pan and transaxle oil pan. Securely support the engine slingers with a hoist.

31. When the engine hoisting is not performed simultaneously, install engine slinger to cylinder head front left

side and rear right side. Refer to EM-207, "

Component".

32. Remove starter motor. Refer to STR-24, "

Removal and Installation".

33. Lift with a hoist and position above engine.

34. Separate the engine and the transaxle. Refer to EM-207, "

Component" .

INSTALLATION

Note the following, and install in the reverse order of removal.

Do not allow engine oil to get on engine mounting insulator. Be careful not to damage engine mounting insu-

lator.

: Engine front

Slinger bolts : 25.5 N·m (2.6 kg-m, 19 ft-lb)

LBIA0461E

PBIC3223J

4 : Engine insulator (LH)

A : Engine front side

B : Transaxle side

WBIA0784E

Page 2857 of 5883

![NISSAN TIIDA 2007 Service User Guide EM-210

< REMOVAL AND INSTALLATION >[MR18DE]

ENGINE ASSEMBLY

When installation directions are specified, install parts according to the directions. Refer to EM-207, "Com-

ponent".

Prior to installi NISSAN TIIDA 2007 Service User Guide EM-210

< REMOVAL AND INSTALLATION >[MR18DE]

ENGINE ASSEMBLY

When installation directions are specified, install parts according to the directions. Refer to EM-207, "Com-

ponent".

Prior to installi](/img/5/57395/w960_57395-2856.png)

EM-210

< REMOVAL AND INSTALLATION >[MR18DE]

ENGINE ASSEMBLY

When installation directions are specified, install parts according to the directions. Refer to EM-207, "Com-

ponent".

Prior to installing the upper torque rod, apply a light coat of silicone

lubricant (A) to the washer facing side of the bushing inner tube as

shown.

NOTE:

Apply silicone lubricant (A) by dabbing the outward facing tube

surface with a sponge or suitable tool.

Do not apply excess lubricant.

Make sure that each mounting insulator is seated properly, and tighten nuts and bolts.

Tighten engine mounting insulator (RH) bolts in the numerical

order shown.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak and exhaust gases leak.

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to LU-15, "

Inspection", CO-35, "Inspection".

Use procedure below to check for fuel leakage.

- Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids includ-

ing engine oil and engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

* Transmission/transaxle fluid, power steering fluid, brake fluid, etc.: Vehicle front

LBIA0470E

: Vehicle front

WBIA0785E

Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluid* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 2932 of 5883

![NISSAN TIIDA 2007 Service User Guide OIL PAN

EM-285

< ON-VEHICLE REPAIR >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

10. Remove oil pan and transaxle joint bolts.

11. Support the engine bottom of the oil pan with a transmission jack

etc.

12. R NISSAN TIIDA 2007 Service User Guide OIL PAN

EM-285

< ON-VEHICLE REPAIR >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

10. Remove oil pan and transaxle joint bolts.

11. Support the engine bottom of the oil pan with a transmission jack

etc.

12. R](/img/5/57395/w960_57395-2931.png)

OIL PAN

EM-285

< ON-VEHICLE REPAIR >[K9K]

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

10. Remove oil pan and transaxle joint bolts.

11. Support the engine bottom of the oil pan with a transmission jack

etc.

12. Remove oil pan bolts in reverse order as shown.

13. Insert seal cutter [SST: KV10111100 (—)] between upper oil pan

and cylinder block. Slide tool by tapping on the side of the tool

with a hammer.

CAUTION:

Exercise care not to damage mating surface.

14. Remove oil pan.

INSTALLATION

Installation is in the reverse order of removal.

MBIB1039E

MBIB0575E

MBIB1257E

SEM365EA

Page 3238 of 5883

GI-44

< PRECAUTION >

PRECAUTIONS

General Precaution

INFOID:0000000001606118

Do not operate the engine for an extended period of time without

proper exhaust ventilation.

Keep the work area well ventilated and free of any flammable

materials. Special care should be taken when handling any flam-

mable or poisonous materials, such as gasoline, refrigerant gas,

etc. When working in a pit or other enclosed area, be sure to prop-

erly ventilate the area before working with hazardous materials.

Do not smoke while working on the vehicle.

Before jacking up the vehicle, apply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving. After jack-

ing up the vehicle, support the vehicle weight with safety stands at

the points designated for proper lifting before working on the vehi-

cle.

These operations should be done on a level surface.

When removing a heavy component such as the engine or tran-

saxle/transmission, be careful not to lose your balance and drop

them. Also, do not allow them to strike adjacent parts, especially

the brake tubes and master cylinder.

Before starting repairs which do not require battery power:

Turn off ignition switch.

Disconnect the negative battery terminal.

If the battery terminals are disconnected, recorded memory of

radio and each control unit is erased.

Battery posts, terminals and related accessories contain lead and

lead compounds. Wash hands after handling.

To prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

Dispose of or recycle drained oil or the solvent used for cleaning

parts in an appropriate manner.

Do not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel spray

and possibly a fire.

Clean all disassembled parts in the designated liquid or solvent

prior to inspection or assembly.

Replace oil seals, gaskets, packings, O-rings, locking washers,

cotter pins, self-locking nuts, etc. with new ones.

Replace inner and outer races of tapered roller bearings and needle bearings as a set.

Arrange the disassembled parts in accordance with their assembled locations and sequence.

Do not touch the terminals of electrical components which use microcomputers (such as ECM).

Static electricity may damage internal electronic components.

After disconnecting vacuum or air hoses, attach a tag to indicate the proper connection.

Use only the fluids and lubricants specified in this manual.

Use approved bonding agent, sealants or their equivalents when required.

SGI285

SGI231

SEF289H

SGI233

Page 3239 of 5883

PRECAUTIONS

GI-45

< PRECAUTION >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

P

Use hand tools, power tools (disassembly only) and recommended

special tools where specified for safe and efficient service repairs.

When repairing the fuel, oil, water, vacuum or exhaust systems,

check all affected lines for leaks.

Before servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate covers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do not carelessly disconnect the harness

connectors which are related to the engine control system and TCM (transmission control module)

system. The connectors should be disconnected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

Precaution for Three Way CatalystINFOID:0000000001606119

If a large amount of unburned fuel flows into the catalyst, the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

Use unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

When checking for ignition spark or measuring engine compression, make tests quickly and only when nec-

essary.

Do not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to the

catalyst.

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

Precaution for Fuel (Unleaded Regular Gasoline Recommended)INFOID:0000000001606120

Use unleaded regular gasoline with an octane rating of at least 87 AKI (Anti-Knock Index) number (Research

octane number 91).

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will damage the three way catalyst. Do not use E-85

fuel (85% fuel ethanol, 15% unleaded gasoline) unless the vehicle is specifically designed for E-85 fuel

(i.e. Flexible Fuel Vehicle - FFV models). Using a fuel other than that specified could adversely affect

the emission control devices and systems, and could also affect the warranty coverage validity.

PBIC0190E

SGI234

Page 3242 of 5883

GI-48

< PRECAUTION >

LIFTING POINT

LIFTING POINT

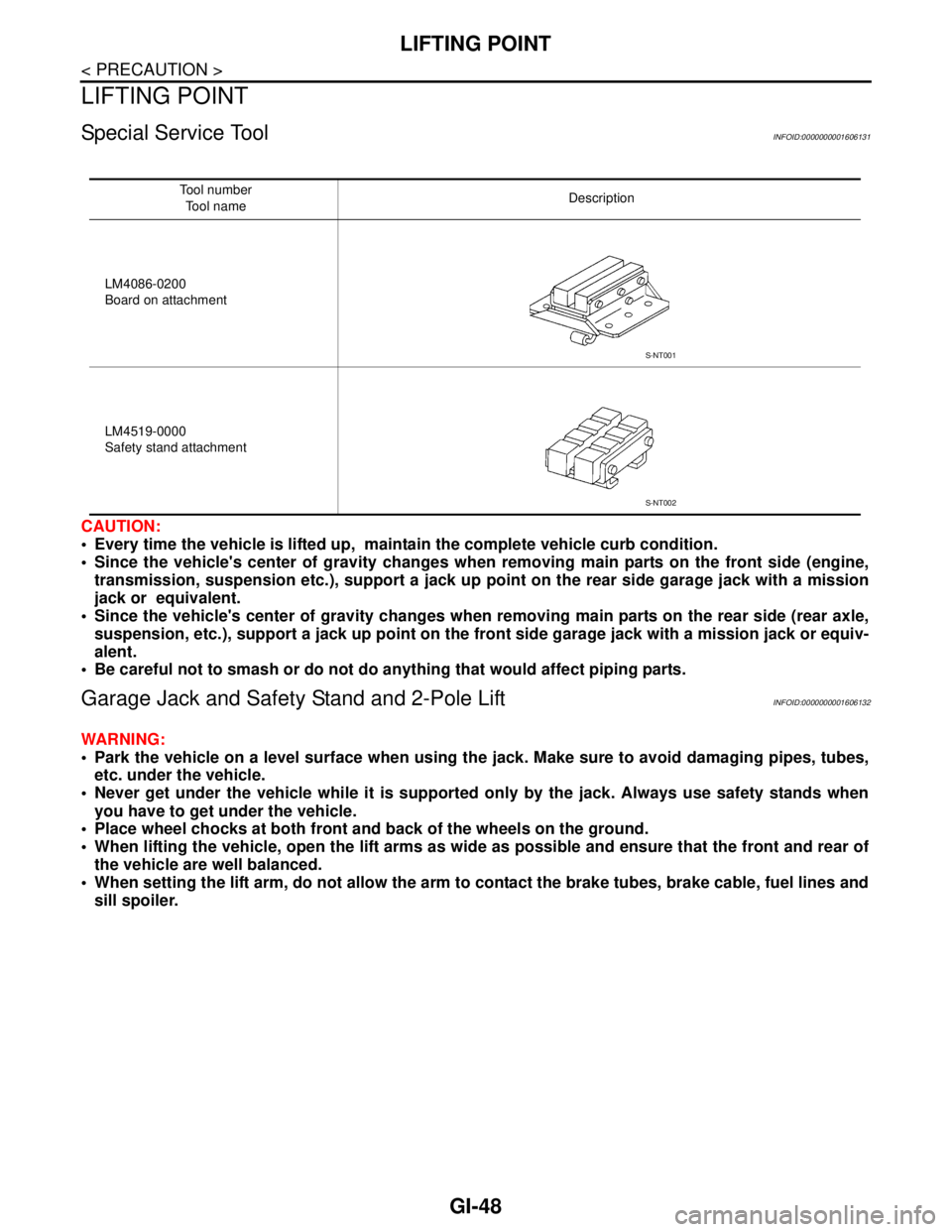

Special Service ToolINFOID:0000000001606131

CAUTION:

Every time the vehicle is lifted up, maintain the complete vehicle curb condition.

Since the vehicle's center of gravity changes when removing main parts on the front side (engine,

transmission, suspension etc.), support a jack up point on the rear side garage jack with a mission

jack or equivalent.

Since the vehicle's center of gravity changes when removing main parts on the rear side (rear axle,

suspension, etc.), support a jack up point on the front side garage jack with a mission jack or equiv-

alent.

Be careful not to smash or do not do anything that would affect piping parts.

Garage Jack and Safety Stand and 2-Pole LiftINFOID:0000000001606132

WARNING:

Park the vehicle on a level surface when using the jack. Make sure to avoid damaging pipes, tubes,

etc. under the vehicle.

Never get under the vehicle while it is supported only by the jack. Always use safety stands when

you have to get under the vehicle.

Place wheel chocks at both front and back of the wheels on the ground.

When lifting the vehicle, open the lift arms as wide as possible and ensure that the front and rear of

the vehicle are well balanced.

When setting the lift arm, do not allow the arm to contact the brake tubes, brake cable, fuel lines and

sill spoiler.

Tool number

Tool nameDescription

LM4086-0200

Board on attachment

LM4519-0000

Safety stand attachment

S-NT001

S-NT002