engine NISSAN TIIDA 2007 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 449 of 5883

![NISSAN TIIDA 2007 Service Manual PDF CHG-28

< SYMPTOM DIAGNOSIS >[MR18DE]

CHARGING SYSTEM

SYMPTOM DIAGNOSIS

CHARGING SYSTEM

Symptom TableINFOID:0000000001724533

Symptom Reference

Battery discharged

Refer to CHG-19, "

Work Flow". The char NISSAN TIIDA 2007 Service Manual PDF CHG-28

< SYMPTOM DIAGNOSIS >[MR18DE]

CHARGING SYSTEM

SYMPTOM DIAGNOSIS

CHARGING SYSTEM

Symptom TableINFOID:0000000001724533

Symptom Reference

Battery discharged

Refer to CHG-19, "

Work Flow". The char](/img/5/57395/w960_57395-448.png)

CHG-28

< SYMPTOM DIAGNOSIS >[MR18DE]

CHARGING SYSTEM

SYMPTOM DIAGNOSIS

CHARGING SYSTEM

Symptom TableINFOID:0000000001724533

Symptom Reference

Battery discharged

Refer to CHG-19, "

Work Flow". The charge warning lamp does not illuminate when the ignition

switch is set to ON.

The charge warning lamp does not turn OFF after the engine

starts.

The charging warning lamp turns ON when increasing the engine

speed.

Page 455 of 5883

![NISSAN TIIDA 2007 Service Manual PDF CHG-34

< BASIC INSPECTION >[K9K]

DIAGNOSIS AND REPAIR WORKFLOW

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be done

as a set from start to f NISSAN TIIDA 2007 Service Manual PDF CHG-34

< BASIC INSPECTION >[K9K]

DIAGNOSIS AND REPAIR WORKFLOW

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be done

as a set from start to f](/img/5/57395/w960_57395-454.png)

CHG-34

< BASIC INSPECTION >[K9K]

DIAGNOSIS AND REPAIR WORKFLOW

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be done

as a set from start to finish.

1.PRELIMINARY INSPECTION

Perform the preliminary inspection. Refer to CHG-37, "

Inspection Procedure".

>> GO TO 2

2.DISABLE THE POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

Disable the power generation voltage variable control with either of the following procedures.

After selecting “ENGINE” on the “SELECT SYSTEM” screen of CONSULT-III, set the “ALTERNATOR DUTY”

value to 0 % by selecting “ALTERNATOR DUTY” with “Active Test”. Continue “Active Test” until the end of

inspection. (When the DUTY value is 0 or 100 %, the normal power generation is performed according to the

characteristic of the IC regulator of the generator.)

Turn the ignition switch OFF, disconnect the battery current sensor connector and leave it disconnected dur-

ing the course of the test.

NOTE:

Running the engine with the battery current sensor disconnected will cause DTC's (P1550-P1554) to set.

After finishing the inspection, connect the battery current sensor connector and erase the self-diagnostic

results history of the engine using CONSULT-III.

>> GO TO 3

3.DIAGNOSIS WITH STARTING/CHARGING SYSTEM TESTER

Perform the charging system test using Starting/Charging System Tester (J-44373). For details and operating

instructions, refer to Technical Service Bulletin.

Te s t r e s u l t

CHARGING SYSTEM NOMAL>>Charging system is normal and will also show “DIODE RIPPLE” test result.

NO CHARGING VOLTAGE>>GO TO 4

LOW CHARGING VOLTAGE>>GO TO 12

HIGH CHARGING VOLTAGE>>GO TO 14

DIODE RIPPLE NORMAL>>Diode ripple is OK and will also show “CHARGING VOLTAGE” test result.

EXCESS RIPPLE DETECTED>>Replace the generator. Perform “DIODE RIPPLE” test again using Starting/

Charging System Tester (J-44373) to confirm repair.

DIODE RIPPLE NOT DETECTED>>GO TO 4

4.INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS ON)

Turn the ignition switch ON.

Does the charge warning lamp illuminate?

YES >> GO TO 6

NO >> GO TO 5

5.TERMINAL“2” (OPEN) CIRCUIT INSPECTION

Check terminal “2” circuit for open circuits. Refer to CHG-39, "

Diagnosis Procedure".

Is the terminal

“2” circuit normal?

YES >> Replace generator.

NO >> Repair as needed.

6.INSPECTION WITH CHARGE WARNING LAMP (IDLING)

Start the engine and run it at idle.

Does the charge warning lamp turn OFF?

YES >> GO TO 9

NO >> GO TO 7

7.TERMINAL “2”(SHORT) CIRCUIT INSPECTION

Check terminal “2” circuit for short to ground. Refer to CHG-39, "

Diagnosis Procedure".

Is the terminal

“2” circuit normal?

Page 456 of 5883

![NISSAN TIIDA 2007 Service Manual PDF CHG

DIAGNOSIS AND REPAIR WORKFLOW

CHG-35

< BASIC INSPECTION >[K9K]

C

D

E

F

G

H

I

J

K

L B A

O

P N

YES >> GO TO 8

NO >> Repair as needed.

8.TERMINAL“3” CIRCUIT INSPECTION

Check terminal “3” circ NISSAN TIIDA 2007 Service Manual PDF CHG

DIAGNOSIS AND REPAIR WORKFLOW

CHG-35

< BASIC INSPECTION >[K9K]

C

D

E

F

G

H

I

J

K

L B A

O

P N

YES >> GO TO 8

NO >> Repair as needed.

8.TERMINAL“3” CIRCUIT INSPECTION

Check terminal “3” circ](/img/5/57395/w960_57395-455.png)

CHG

DIAGNOSIS AND REPAIR WORKFLOW

CHG-35

< BASIC INSPECTION >[K9K]

C

D

E

F

G

H

I

J

K

L B A

O

P N

YES >> GO TO 8

NO >> Repair as needed.

8.TERMINAL“3” CIRCUIT INSPECTION

Check terminal “3” circuit. Refer to CHG-40, "

Diagnosis Procedure".

Is the terminal

“3” circuit normal?

YES >> GO TO 10

NO >> Repair as needed.

9.INSPECTION WITH CHARGE WARNING LAMP (ENGINE AT 3,000 RPM)

Increase and maintain the engine speed at 3,000 rpm.

Does the charge warning lamp remain off?

YES >> GO TO 11

NO >> GO TO 10

10.INSPECTION OF GENERATOR PULLEY

Check generator pulley.

Is generator pulley normal?

YES >> Replace generator. Refer to XX-XX, "*****".

NO >> Repair as needed.

11 .TERMINAL “1” CIRCUIT INSPECTION

Check terminal “1””circuit. Refer to CHG-38, "

Diagnosis Procedure".

Is terminal

“1” circuit normal?

YES >> Replace generator. Refer to XX-XX, "*****".

NO >> Repair as needed.

12.TERMINAL “1” CIRCUIT INSPECTION

Check terminal “1” circuit. Refer to CHG-38, "

Diagnosis Procedure".

Is terminal

“1” circuit normal?

YES >> GO TO 13

NO >> Repair as needed.

13.INSPECTION OF GENERATOR PULLEY

Check generator pulley.

Is generator pulley normal?

YES >> Replace generator. Refer to XX-XX, "*****".

NO >> Repair as needed.

14.TERMINAL “3” CIRCUIT INSPECTION

Check terminal“3” circuit. Refer to CHG-40, "

Diagnosis Procedure".

Is the terminal

“3” circuit normal?

YES >> Replace generator. Refer to XX-XX, "*****".

NO >> Repair as needed.

Page 459 of 5883

![NISSAN TIIDA 2007 Service Manual PDF CHG-38

< COMPONENT DIAGNOSIS >[K9K]

B TERMINAL CIRCUIT

B TERMINAL CIRCUIT

DescriptionINFOID:0000000001724509

The terminal “1” (B) circuit supplies power to charge the battery and operate the vehic NISSAN TIIDA 2007 Service Manual PDF CHG-38

< COMPONENT DIAGNOSIS >[K9K]

B TERMINAL CIRCUIT

B TERMINAL CIRCUIT

DescriptionINFOID:0000000001724509

The terminal “1” (B) circuit supplies power to charge the battery and operate the vehic](/img/5/57395/w960_57395-458.png)

CHG-38

< COMPONENT DIAGNOSIS >[K9K]

B TERMINAL CIRCUIT

B TERMINAL CIRCUIT

DescriptionINFOID:0000000001724509

The terminal “1” (B) circuit supplies power to charge the battery and operate the vehicles electrical system.

Diagnosis ProcedureINFOID:0000000001724510

1.CHECK TERMINAL “1” CONNECTION

1. Turn ignition switch OFF.

2. Verify terminal “1” is clean and tight.

Is the inspection result normal?

YES >> GO TO 2

NO >> Repair terminal “1” connection. Confirm repair by performing complete Starting/Charging system

test. Refer to Technical Service Bulletin.

2.CHECK TERMINAL “1” CIRCUIT

Check voltage between generator connector F2 terminal 1 and

ground.

Is voltage reading as specified?

YES >> GO TO 3.

NO >> Check harness for open between generator and fusible

link.

3.CHECK TERMINAL “1” CONNECTION (VOLTAGE DROP TEST)

1. Start engine, then engine running at idle and warm.

2. Check voltage between battery positive terminal and generator

connector F2 terminal 1.

Is the voltage reading as specified?

YES >> Terminal “1” circuit is normal. Refer to CHG-33, "Work

Flow".

NO >> Check harness between battery and generator for high resistance.

(+)

(-) Voltage

Connector Terminal

F2 1 Ground Battery voltage

ALMIA0197ZZ

(+)

(-) Voltage

Connector Terminal

F2 1 Battery positive terminal Less than 0.2V

ALMIA0198ZZ

Page 460 of 5883

![NISSAN TIIDA 2007 Service Manual PDF CHG

L TERMINAL CIRCUIT

CHG-39

< COMPONENT DIAGNOSIS >[K9K]

C

D

E

F

G

H

I

J

K

L B A

O

P N

L TERMINAL CIRCUIT

DescriptionINFOID:0000000001724511

The terminal “2” (L) circuit controls the charge warn NISSAN TIIDA 2007 Service Manual PDF CHG

L TERMINAL CIRCUIT

CHG-39

< COMPONENT DIAGNOSIS >[K9K]

C

D

E

F

G

H

I

J

K

L B A

O

P N

L TERMINAL CIRCUIT

DescriptionINFOID:0000000001724511

The terminal “2” (L) circuit controls the charge warn](/img/5/57395/w960_57395-459.png)

CHG

L TERMINAL CIRCUIT

CHG-39

< COMPONENT DIAGNOSIS >[K9K]

C

D

E

F

G

H

I

J

K

L B A

O

P N

L TERMINAL CIRCUIT

DescriptionINFOID:0000000001724511

The terminal “2” (L) circuit controls the charge warning lamp. The charge warning lamp illuminates when the

ignition switch is set to ON or START. When the generator is providing sufficient voltage with the engine run-

ning, the charge warning lamp will go off. If the charge warning lamp illuminates with the engine running, a

malfunction is indicated.

Diagnosis ProcedureINFOID:0000000001724512

1.CHECK CHARGE WARNING LAMP CIRCUIT CONNECTION

Verify generator connector F1 terminal 2 is clean and tight.

Is the connection secure?

YES >> GO TO 2

NO >> Repair the connection. Confirm repair by performing complete Starting/Charging system test.

Refer to Technical Service Bulletin.

2.CHECK CHARGE WARNING LAMP CIRCUIT

1. Disconnect generator connector F1.

2. Apply ground to generator harness connector F1 terminal 2 with

the ignition switch in the ON position.

Does the charge lamp illuminate?

YES >> Check generator function. Refer to CHG-33, "Work

Flow".

NO >> GO TO 3

3.CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect the generator connector F1 and combination meter

connector M24.

3. Check continuity between generator harness connector F1 ter-

minal 2 and combination meter harness connector M24 terminal

38.

4. Check continuity between generator harness connector F1 ter-

minal 2 and ground.

Are the continuity results as specified?

YES >> Replace the combination meter. Refer to XX-XX, "*****".

NO >> Repair the harness or connector.Charge lamp should illuminate

ALMIA0328GB

Terminal Terminal

Continuity

Connector Terminal Connector Terminal

F1 2 M24 38 Yes

Te r , m i n a l

—

Continuity

Connector Terminal

F1 2 Ground No

ALMIA0329GB

Page 463 of 5883

![NISSAN TIIDA 2007 Service Manual PDF CHG-42

< SYMPTOM DIAGNOSIS >[K9K]

CHARGING SYSTEM

SYMPTOM DIAGNOSIS

CHARGING SYSTEM

Symptom TableINFOID:0000000001724516

Symptom Reference

Battery discharged

Refer to CHG-33, "

Work Flow". The charge NISSAN TIIDA 2007 Service Manual PDF CHG-42

< SYMPTOM DIAGNOSIS >[K9K]

CHARGING SYSTEM

SYMPTOM DIAGNOSIS

CHARGING SYSTEM

Symptom TableINFOID:0000000001724516

Symptom Reference

Battery discharged

Refer to CHG-33, "

Work Flow". The charge](/img/5/57395/w960_57395-462.png)

CHG-42

< SYMPTOM DIAGNOSIS >[K9K]

CHARGING SYSTEM

SYMPTOM DIAGNOSIS

CHARGING SYSTEM

Symptom TableINFOID:0000000001724516

Symptom Reference

Battery discharged

Refer to CHG-33, "

Work Flow". The charge warning lamp does not illuminate when the ignition

switch is set to ON.

The charge warning lamp does not turn OFF after the engine

starts.

The charging warning lamp turns ON when increasing the engine

speed.

Page 469 of 5883

CL-4

< SERVICE INFORMATION >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

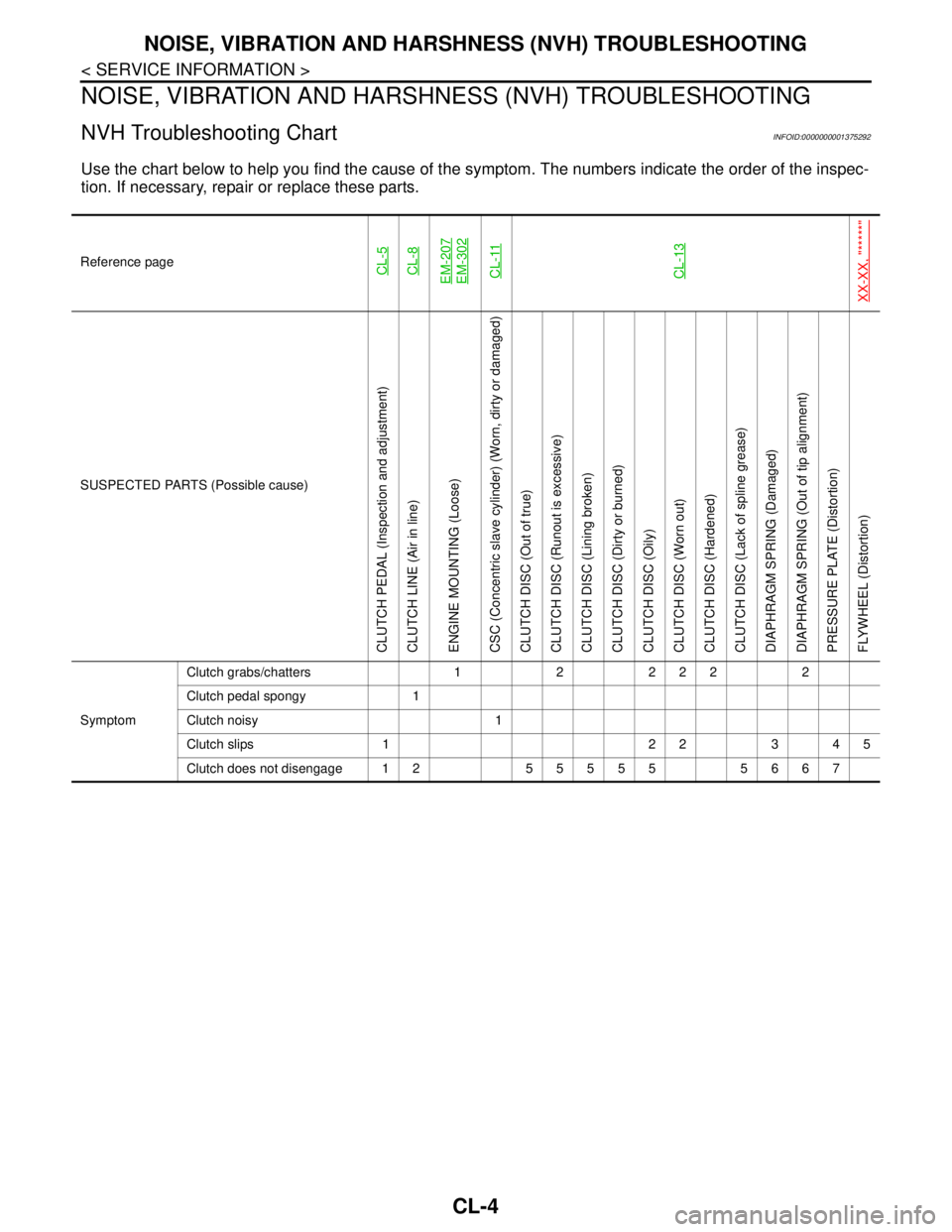

NVH Troubleshooting ChartINFOID:0000000001375292

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

Reference pageCL-5CL-8EM-207EM-302CL-11CL-13

XX-XX, "*****"

SUSPECTED PARTS (Possible cause)

CLUTCH PEDAL (Inspection and adjustment)

CLUTCH LINE (Air in line)

ENGINE MOUNTING (Loose)

CSC (Concentric slave cylinder) (Worn, dirty or damaged)

CLUTCH DISC (Out of true)

CLUTCH DISC (Runout is excessive)

CLUTCH DISC (Lining broken)

CLUTCH DISC (Dirty or burned)

CLUTCH DISC (Oily)

CLUTCH DISC (Worn out)

CLUTCH DISC (Hardened)

CLUTCH DISC (Lack of spline grease)

DIAPHRAGM SPRING (Damaged)

DIAPHRAGM SPRING (Out of tip alignment)

PRESSURE PLATE (Distortion)

FLYWHEEL (Distortion)

SymptomClutch grabs/chatters 1 2 2 2 2 2

Clutch pedal spongy 1

Clutch noisy 1

Clutch slips 1 2 2 3 4 5

Clutch does not disengage 12 55555 5667

Page 482 of 5883

CO-1

ENGINE

C

D

E

F

G

H

I

J

K

L

M

SECTION CO

A

CO

N

O

P

CONTENTS

ENGINE COOLING SYSTEM

HR16DE

FUNCTION DIAGNOSIS ...............................

4

DESCRIPTION ....................................................4

Engine Cooling System .............................................4

Engine Cooling System Schematic ...........................5

SYMPTOM DIAGNOSIS ...............................6

OVERHEATING CAUSE ANALYSIS ..................6

Troubleshooting Chart ...............................................6

PRECAUTION ...............................................8

PRECAUTIONS ...................................................8

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

8

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .....................................

8

Precaution for Liquid Gasket .....................................8

PREPARATION ...........................................10

PREPARATION ..................................................10

Special Service Tool ...............................................10

Commercial Service Tool ........................................10

ON-VEHICLE MAINTENANCE ....................11

ENGINE COOLANT ...........................................11

Inspection ................................................................11

Changing Engine Coolant .......................................11

RADIATOR .........................................................14

Checking Radiator Cap ...........................................14

Checking Radiator ...................................................14

ON-VEHICLE REPAIR .................................16

RADIATOR .........................................................16

Component ..............................................................16

Removal and Installation .........................................16

COOLING FAN ..................................................18

Component (Models with A/C) .................................18

Component (Models without A/C) ............................18

Removal and Installation .........................................19

WATER PUMP ..................................................20

Exploded View .........................................................20

Removal and Installation .........................................20

Inspection ................................................................21

THERMOSTAT ..................................................22

Exploded View .........................................................22

Removal and Installation .........................................22

Inspection ................................................................23

WATER OUTLET ..............................................24

Exploded View .........................................................24

Removal and Installation .........................................24

Inspection ................................................................25

DISASSEMBLY AND ASSEMBLY ..............26

COOLING FAN ..................................................26

DISASSEMBLY AND ASSEMBLY ..........................26

SERVICE DATA AND SPECIFICATIONS

(SDS) ............................................................

27

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

27

Periodical Maintenance Specification ......................27

Radiator ...................................................................27

Thermostat ..............................................................27

MR18DE

FUNCTION DIAGNOSIS ..............................

28

COOLING SYSTEM ..........................................28

Cooling Circuit .........................................................28

Page 483 of 5883

CO-2

SYMPTOM DIAGNOSIS .............................30

OVERHEATING CAUSE ANALYSIS ................30

Troubleshooting Chart ............................................30

PRECAUTION .............................................32

PRECAUTIONS .................................................32

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

32

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ..................................

32

Precaution for Liquid Gasket ..................................32

PREPARATION ...........................................34

PREPARATION .................................................34

Special Service Tool ...............................................34

Commercial Service Tool .......................................34

ON-VEHICLE MAINTENANCE ...................35

ENGINE COOLANT ...........................................35

Inspection ...............................................................35

Changing Engine Coolant .......................................35

RADIATOR ........................................................38

Checking Radiator Cap ..........................................38

Checking Radiator ..................................................38

ON-VEHICLE REPAIR ................................40

RADIATOR ........................................................40

Component .............................................................40

Removal and Installation ........................................40

COOLING FAN ..................................................42

Component (Models with A/C) ................................42

Component (Models without A/C) ...........................42

Removal and Installation ........................................43

WATER PUMP ...................................................44

Component .............................................................44

Removal and Installation ........................................44

THERMOSTAT ..................................................45

Component .............................................................45

Removal and Installation ........................................45

WATER OUTLET AND WATER CONTROL

VALVE ...............................................................

47

Component .............................................................47

Removal and Installation ........................................47

DISASSEMBLY AND ASSEMBLY .............50

COOLING FAN ..................................................50

DISASSEMBLY AND ASSEMBLY .........................50

SERVICE DATA AND SPECIFICATIONS

(SDS) ...........................................................

51

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

51

Standard and Limit ..................................................51

K9K

FUNCTION DIAGNOSIS ............................

52

DESCRIPTION ...................................................52

Engine Cooling System .........................................52

SYMPTOM DIAGNOSIS ............................53

OVERHEATING CAUSE ANALYSIS ................53

Troubleshooting Chart ............................................53

PRECAUTION ............................................55

PRECAUTIONS .................................................55

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

55

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ..................................

55

Precaution for Liquid Gasket ...................................55

PREPARATION ..........................................57

PREPARATION .................................................57

Special Service Tools .............................................57

Commercial Service Tools ......................................57

ON-VEHICLE MAINTENANCE ..................58

ENGINE COOLANT ...........................................58

Inspection ................................................................58

Draining ...................................................................58

Refilling ...................................................................58

Flushing ..................................................................59

RADIATOR ........................................................60

Checking Radiator Cap ...........................................60

Checking Radiator ..................................................60

ON-VEHICLE REPAIR ...............................62

RADIATOR ........................................................62

Exploded View ........................................................62

Removal and Installation .........................................62

Inspection ................................................................63

COOLING FAN ..................................................64

Exploded View ........................................................64

Removal and Installation .........................................64

Disassembly and Assembly ....................................65

Inspection ................................................................65

WATER PUMP ...................................................66

Exploded View ........................................................66

Removal and Installation .........................................66

Inspection ................................................................66

Page 485 of 5883

![NISSAN TIIDA 2007 Service Manual PDF CO-4

< FUNCTION DIAGNOSIS >[HR16DE]

DESCRIPTION

FUNCTION DIAGNOSIS

DESCRIPTION

Engine Cooling SystemINFOID:0000000001381550

AWBIA0155ZZ

1. Cylinder head 2. Cylinder block 3. Water pump

4. Thermostat 5 NISSAN TIIDA 2007 Service Manual PDF CO-4

< FUNCTION DIAGNOSIS >[HR16DE]

DESCRIPTION

FUNCTION DIAGNOSIS

DESCRIPTION

Engine Cooling SystemINFOID:0000000001381550

AWBIA0155ZZ

1. Cylinder head 2. Cylinder block 3. Water pump

4. Thermostat 5](/img/5/57395/w960_57395-484.png)

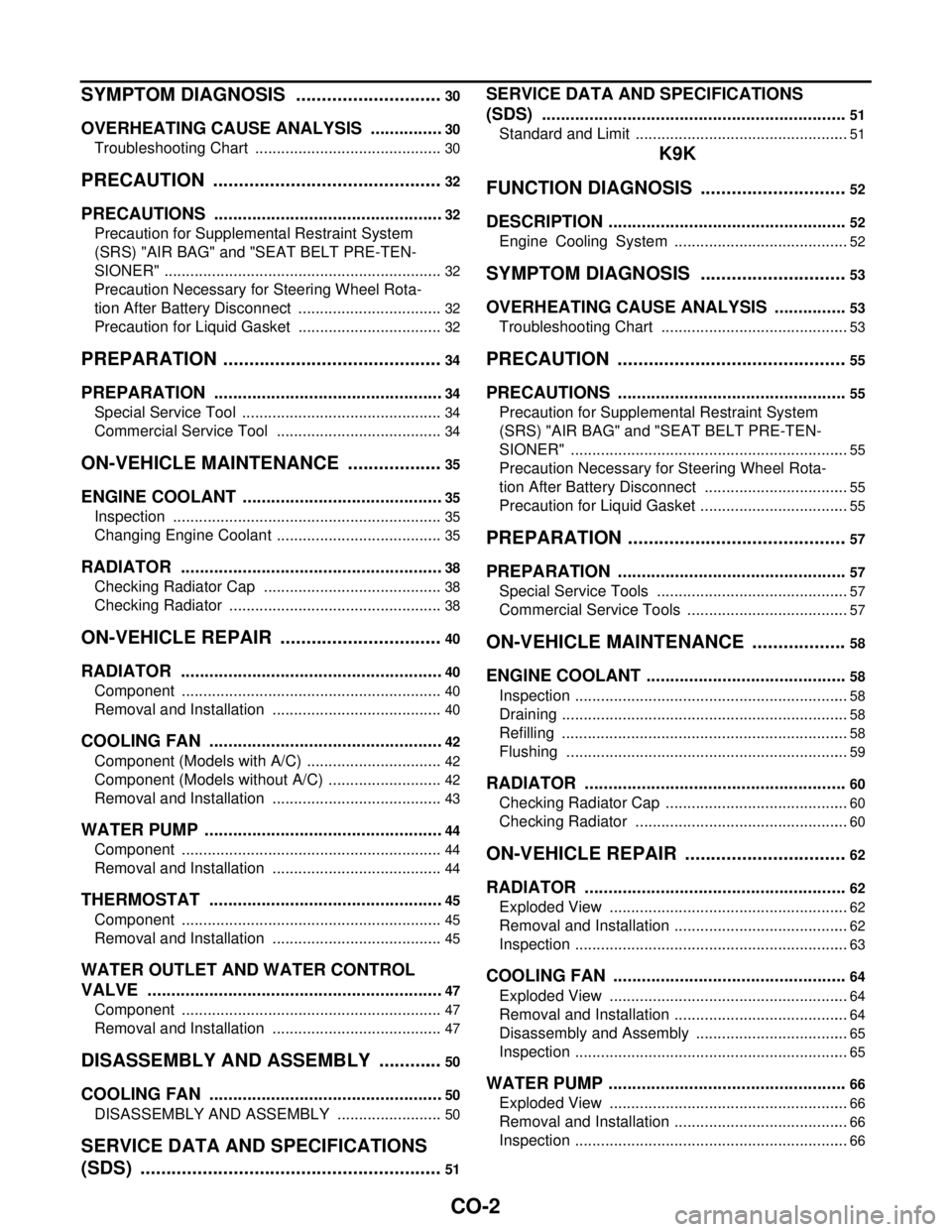

CO-4

< FUNCTION DIAGNOSIS >[HR16DE]

DESCRIPTION

FUNCTION DIAGNOSIS

DESCRIPTION

Engine Cooling SystemINFOID:0000000001381550

AWBIA0155ZZ

1. Cylinder head 2. Cylinder block 3. Water pump

4. Thermostat 5. Water inlet 6. Water bypass

7. Water outlet A. From radiator B. To radiator

C. From electronic throttle control actu-

ator (Northern European models)D. From heater E. To heater

F. To electronic throttle control actuator

(Northern European models)