NISSAN X-TRAIL 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2461 of 3066

INTERIOR ROOM LAMP

LT-63

C

D

E

F

G

H

I

J

L

MA

B

LT

4.CHECK FRONT DOOR UNLOCK SENSOR INPUT SIGNAL

Check voltage between time control unit harness connector.

OK or NG

OK >> GO TO 6

NG >> GO TO 5

5.CHECK FRONT DOOR UNLOCK SENSOR

1. Disconnect front door unlock sensor harness connector.

2. Check continuity between door unlock sensor terminals 2and 5.

OK or NG

OK >> Check the following.

lDoor unlock sensor ground circuit

lHarness for open or short between time control unit

and door unlock sensor

NG >> Replace door unlock sensor.

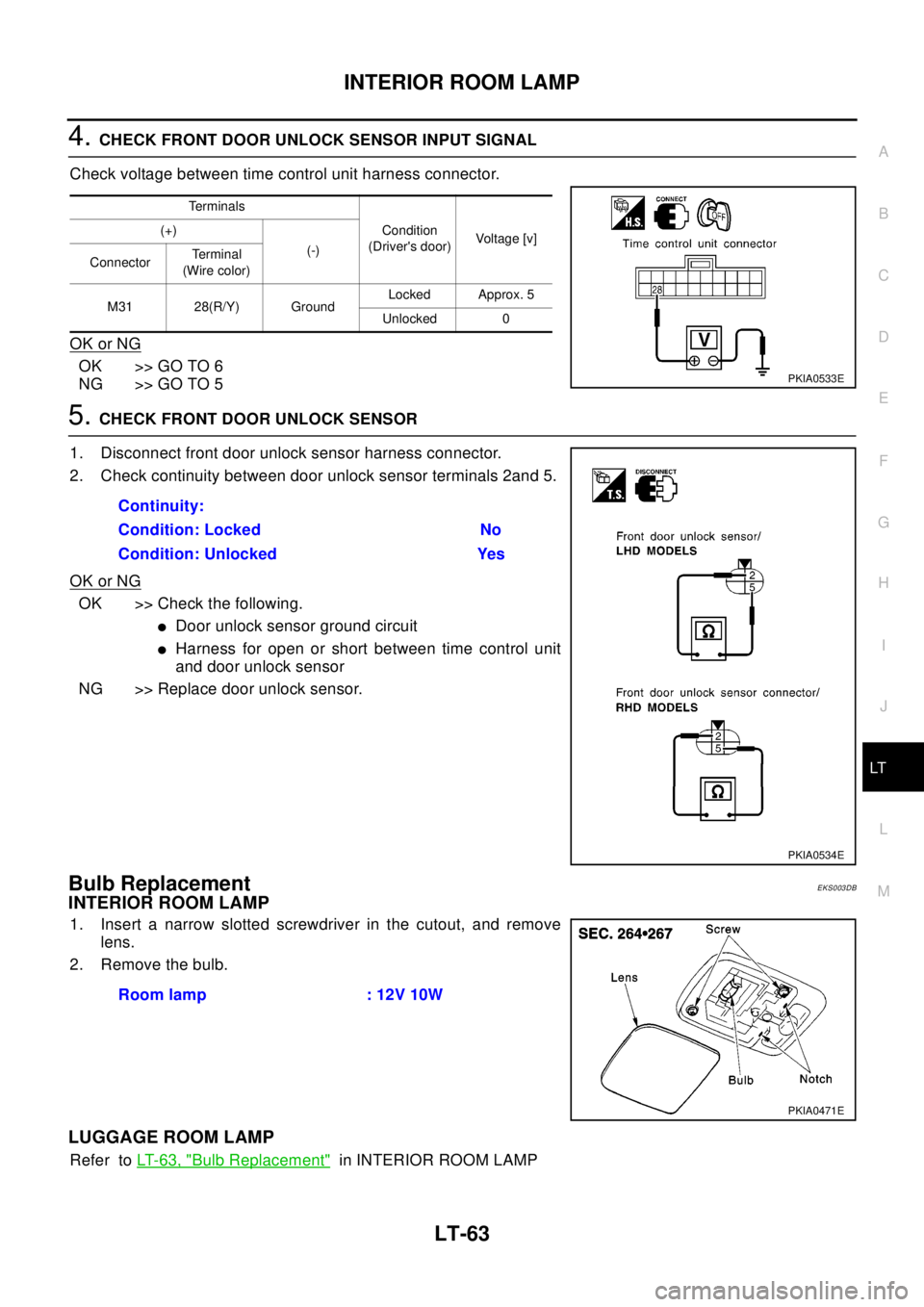

Bulb ReplacementEKS003DB

INTERIOR ROOM LAMP

1. Insert a narrow slotted screwdriver in the cutout, and remove

lens.

2. Remove the bulb.

LUGGAGE ROOM LAMP

Refer toLT-63, "Bulb Replacement"in INTERIOR ROOM LAMP

Terminals

Condition

(Driver's door)Voltag e [v ] (+)

(-)

ConnectorTerminal

(Wire color)

M31 28(R/Y) GroundLocked Approx. 5

Unlocked 0

PKIA0533E

Continuity:

Condition: Locked No

Condition: Unlocked Yes

PKIA0534E

Room lamp : 12V 10W

PKIA0471E

Page 2462 of 3066

LT-64

INTERIOR ROOM LAMP

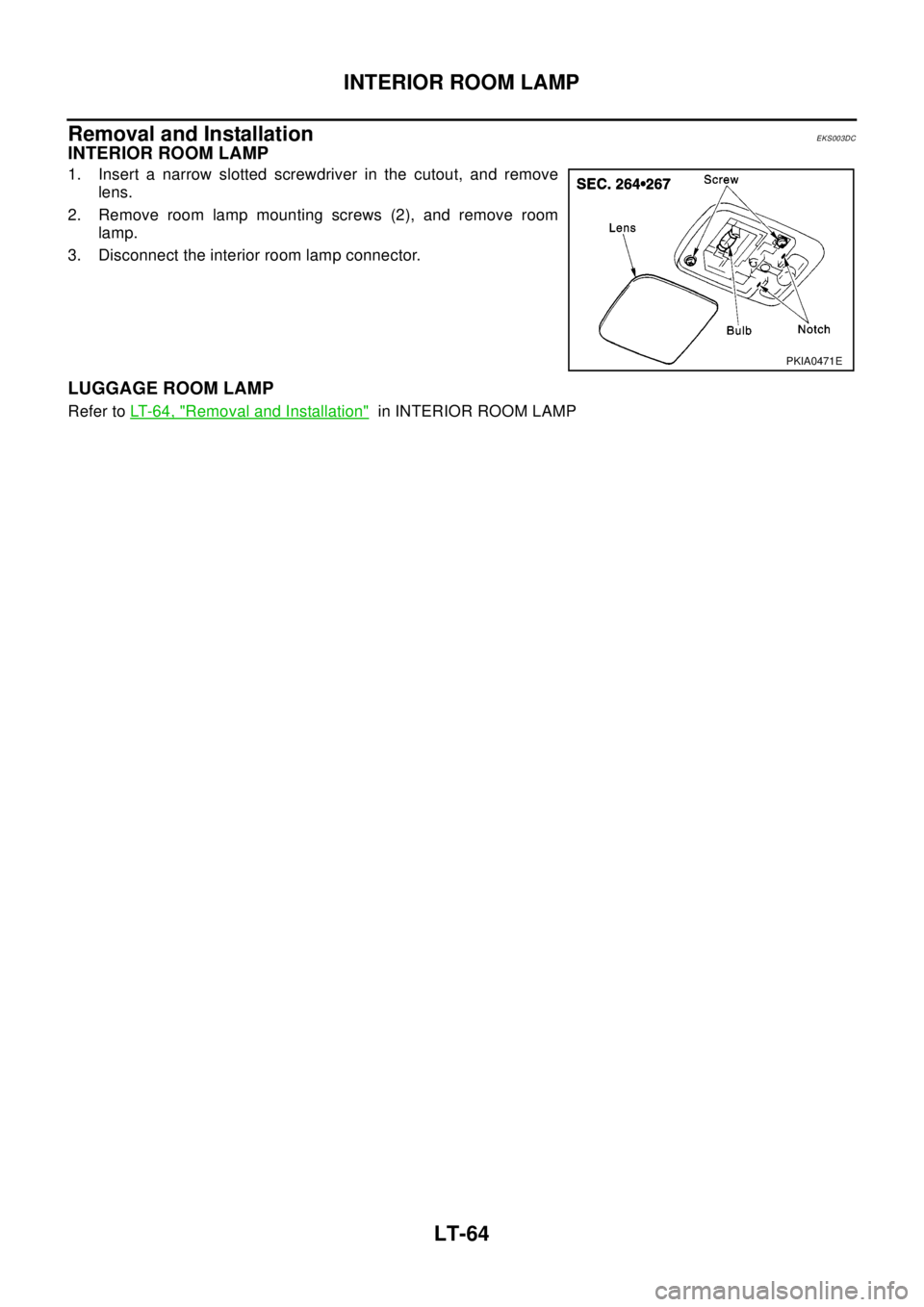

Removal and Installation

EKS003DC

INTERIOR ROOM LAMP

1. Insert a narrow slotted screwdriver in the cutout, and remove

lens.

2. Remove room lamp mounting screws (2), and remove room

lamp.

3. Disconnect the interior room lamp connector.

LUGGAGE ROOM LAMP

Refer toLT- 6 4 , "Removal and Installation"in INTERIOR ROOM LAMP

PKIA0471E

Page 2463 of 3066

SPOT LAMPS

LT-65

C

D

E

F

G

H

I

J

L

MA

B

LT

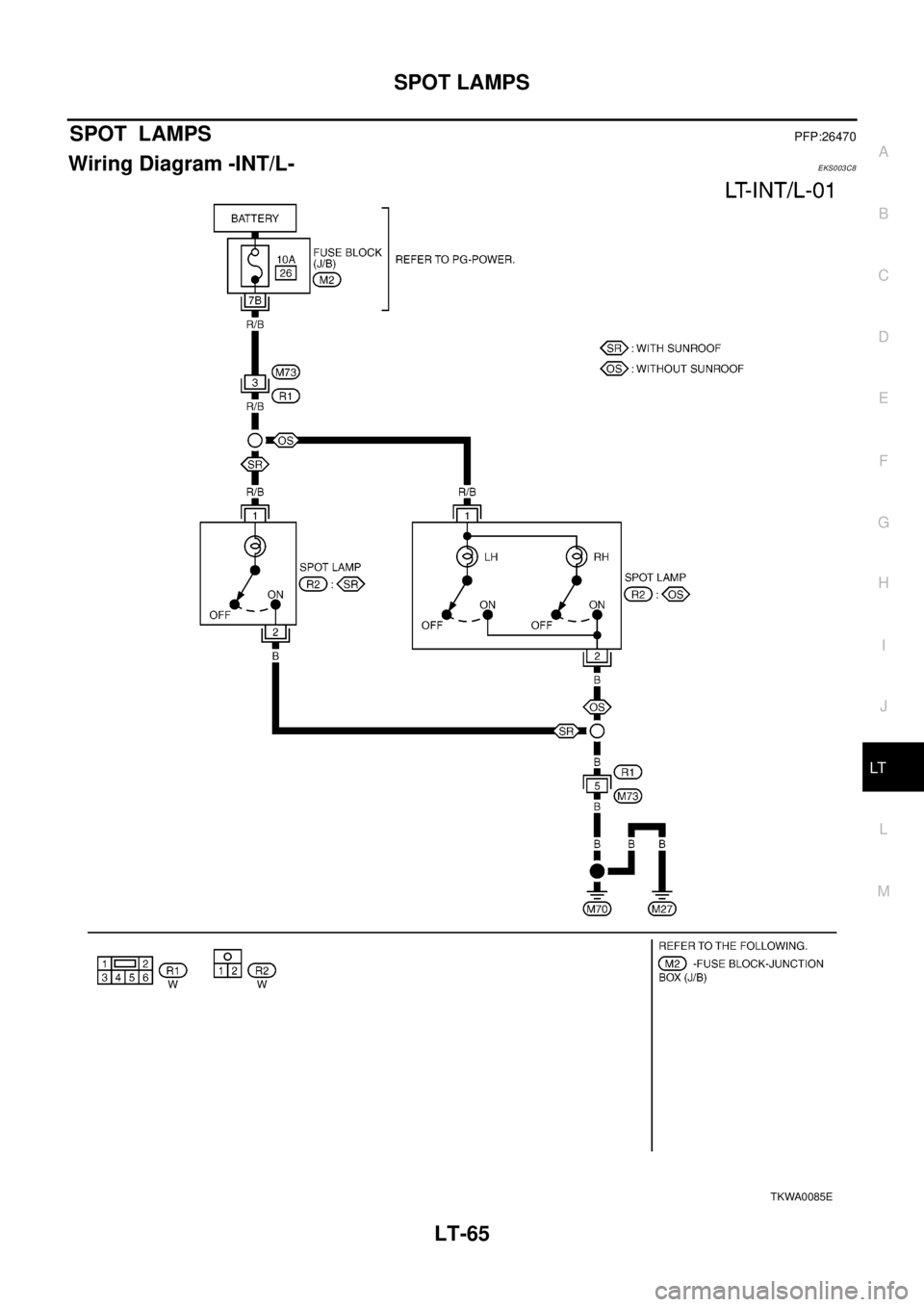

SPOT LAMPSPFP:26470

Wiring Diagram -INT/L-EKS003C8

TKWA0085E

Page 2464 of 3066

LT-66

SPOT LAMPS

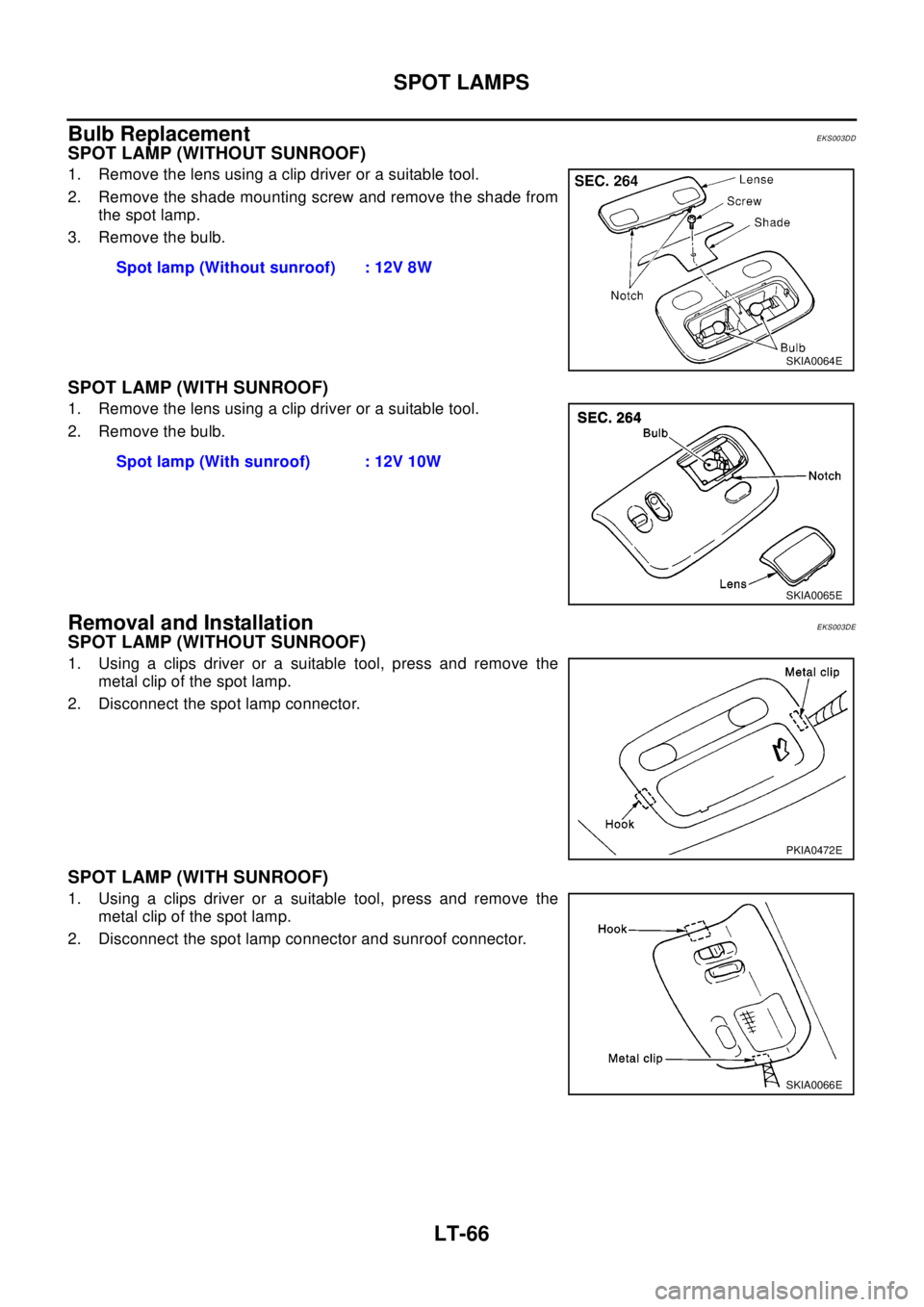

Bulb Replacement

EKS003DD

SPOT LAMP (WITHOUT SUNROOF)

1. Remove the lens using a clip driver or a suitable tool.

2. Remove the shade mounting screw and remove the shade from

the spot lamp.

3. Remove the bulb.

SPOT LAMP (WITH SUNROOF)

1. Remove the lens using a clip driver or a suitable tool.

2. Remove the bulb.

Removal and InstallationEKS003DE

SPOT LAMP (WITHOUT SUNROOF)

1. Using a clips driver or a suitable tool, press and remove the

metal clip of the spot lamp.

2. Disconnect the spot lamp connector.

SPOT LAMP (WITH SUNROOF)

1. Using a clips driver or a suitable tool, press and remove the

metal clip of the spot lamp.

2. Disconnect the spot lamp connector and sunroof connector.Spot lamp (Without sunroof) : 12V 8W

SKIA0064E

Spot lamp (With sunroof) : 12V 10W

SKIA0065E

PKIA0472E

SKIA0066E

Page 2465 of 3066

BULB SPECIFICATIONS

LT-67

C

D

E

F

G

H

I

J

L

MA

B

LT

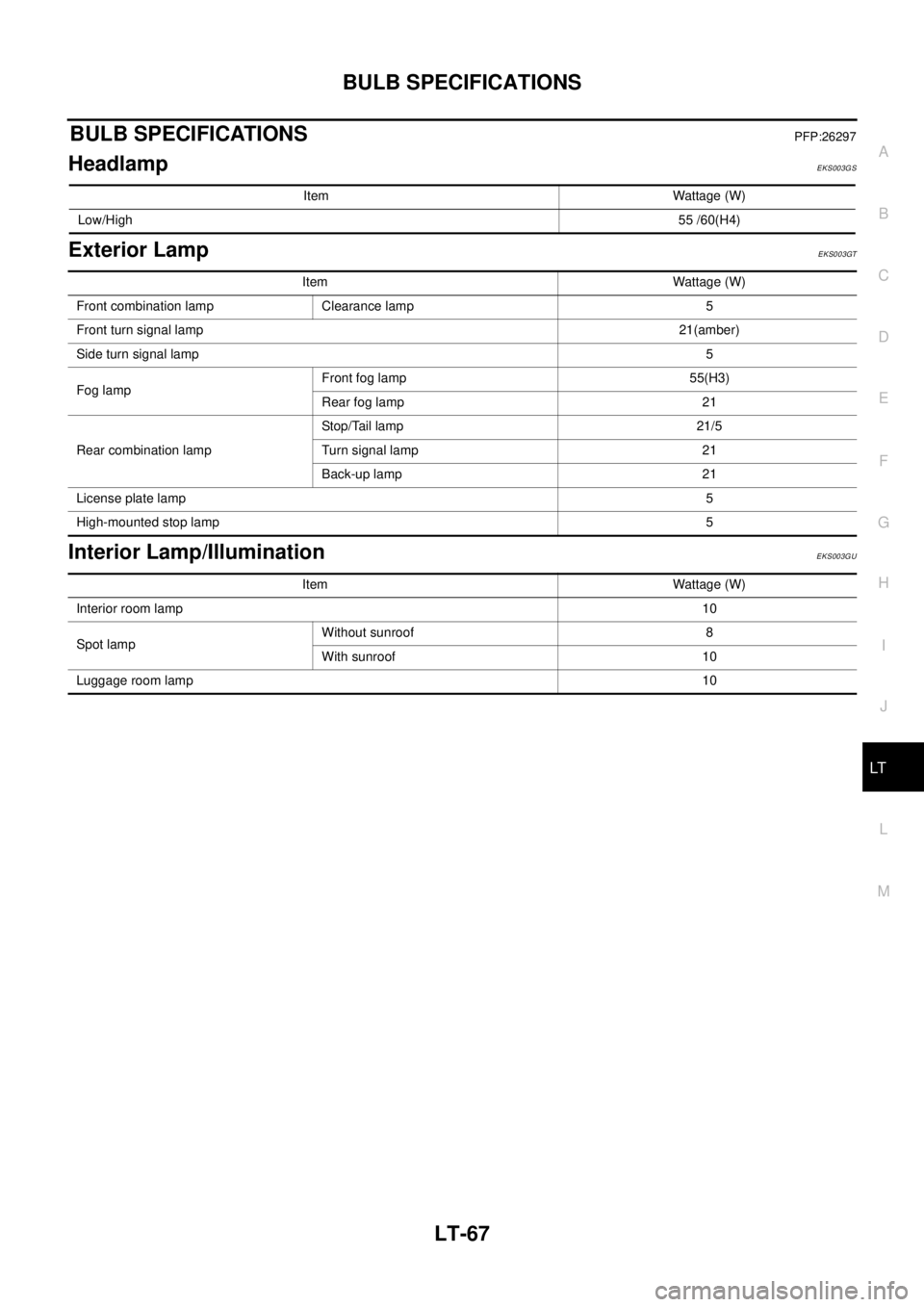

BULB SPECIFICATIONSPFP:26297

HeadlampEKS003GS

Exterior LampEKS003GT

Interior Lamp/IlluminationEKS003GU

Item Wattage (W)

Low/High55 /60(H4)

Item Wattage (W)

Front combination lamp Clearance lamp 5

Front turn signal lamp21(amber)

Side turn signal lamp5

Fog lampFront fog lamp 55(H3)

Rear fog lamp 21

Rear combination lampStop/Tail lamp 21/5

Turn signal lamp 21

Back-up lamp 21

License plate lamp5

High-mounted stop lamp5

Item Wattage (W)

Interior room lamp10

Spot lampWithout sunroof 8

With sunroof 10

Luggage room lamp10

Page 2466 of 3066

LT-68

BULB SPECIFICATIONS

Page 2467 of 3066

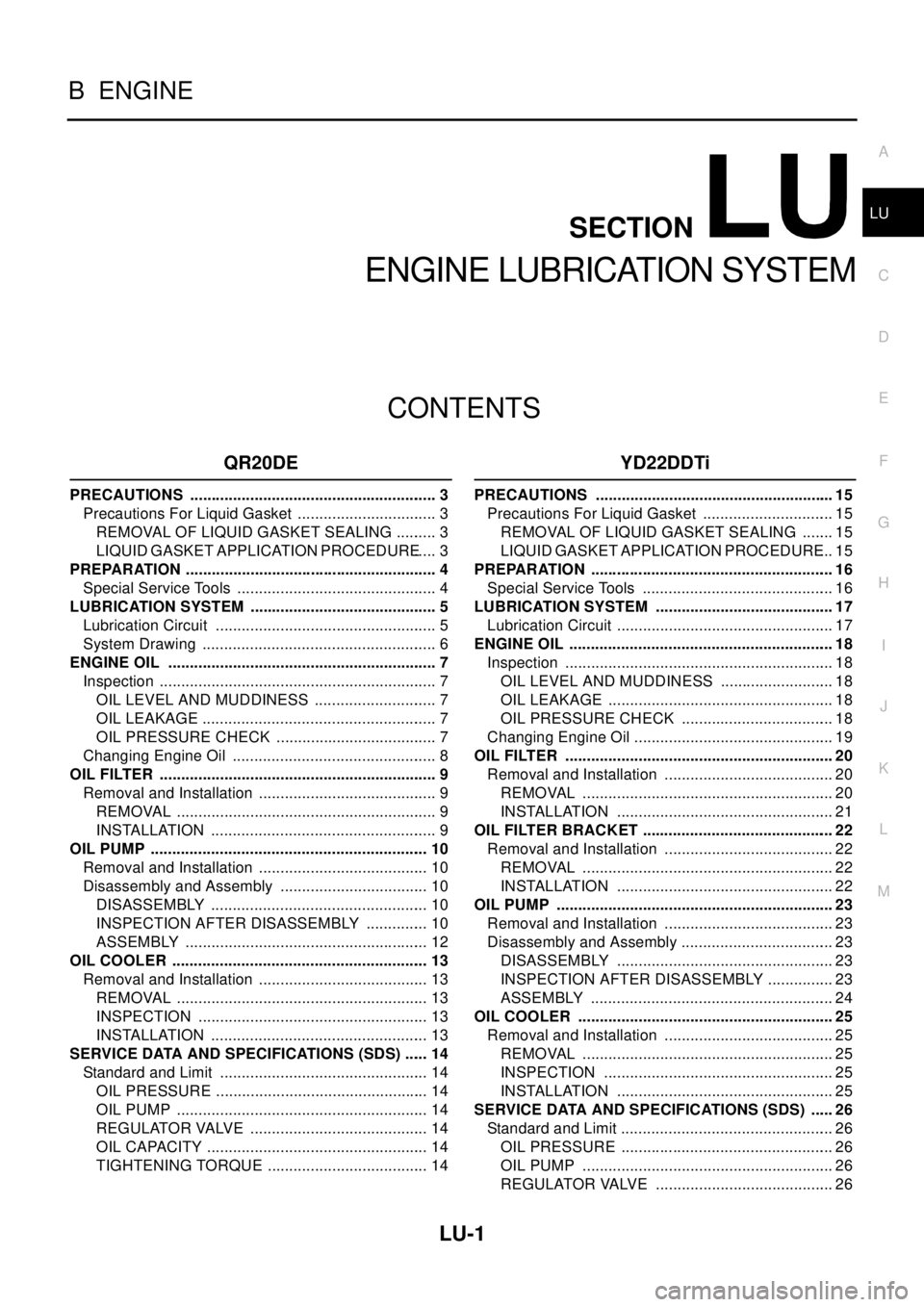

LU-1

ENGINE LUBRICATION SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

LU

ENGINE LUBRICATION SYSTEM

QR20DE

PRECAUTIONS .......................................................... 3

Precautions For Liquid Gasket ................................. 3

REMOVAL OF LIQUID GASKET SEALING .......... 3

LIQUID GASKET APPLICATION PROCEDURE..... 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

LUBRICATION SYSTEM ............................................ 5

Lubrication Circuit .................................................... 5

System Drawing ....................................................... 6

ENGINE OIL ............................................................... 7

Inspection ................................................................. 7

OIL LEVEL AND MUDDINESS ............................. 7

OIL LEAKAGE ....................................................... 7

OIL PRESSURE CHECK ...................................... 7

Changing Engine Oil ................................................ 8

OIL FILTER ................................................................. 9

Removal and Installation .......................................... 9

REMOVAL ............................................................. 9

INSTALLATION ..................................................... 9

OIL PUMP ................................................................. 10

Removal and Installation ........................................ 10

Disassembly and Assembly ................................... 10

DISASSEMBLY ................................................... 10

INSPECTION AFTER DISASSEMBLY ............... 10

ASSEMBLY ......................................................... 12

OIL COOLER ............................................................ 13

Removal and Installation ........................................ 13

REMOVAL ........................................................... 13

INSPECTION ...................................................... 13

INSTALLATION ................................................... 13

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 14

Standard and Limit ................................................. 14

OIL PRESSURE .................................................. 14

OIL PUMP ........................................................... 14

REGULATOR VALVE .......................................... 14

OIL CAPACITY .................................................... 14

TIGHTENING TORQUE ...................................... 14

YD22DDTi

PRECAUTIONS ........................................................ 15

Precautions For Liquid Gasket ............................... 15

REMOVAL OF LIQUID GASKET SEALING ........ 15

LIQUID GASKET APPLICATION PROCEDURE... 15

PREPARATION ......................................................... 16

Special Service Tools ............................................. 16

LUBRICATION SYSTEM .......................................... 17

Lubrication Circuit ................................................... 17

ENGINE OIL .............................................................. 18

Inspection ............................................................... 18

OIL LEVEL AND MUDDINESS ........................... 18

OIL LEAKAGE ..................................................... 18

OIL PRESSURE CHECK .................................... 18

Changing Engine Oil ............................................... 19

OIL FILTER ............................................................... 20

Removal and Installation ........................................ 20

REMOVAL ........................................................... 20

INSTALLATION ................................................... 21

OIL FILTER BRACKET ............................................. 22

Removal and Installation ........................................ 22

REMOVAL ........................................................... 22

INSTALLATION ................................................... 22

OIL PUMP ................................................................. 23

Removal and Installation ........................................ 23

Disassembly and Assembly .................................... 23

DISASSEMBLY ................................................... 23

INSPECTION AFTER DISASSEMBLY ................ 23

ASSEMBLY ......................................................... 24

OIL COOLER ............................................................ 25

Removal and Installation ........................................ 25

REMOVAL ........................................................... 25

INSPECTION ...................................................... 25

INSTALLATION ................................................... 25

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 26

Standard and Limit .................................................. 26

OIL PRESSURE .................................................. 26

OIL PUMP ........................................................... 26

REGULATOR VALVE .......................................... 26

Page 2468 of 3066

LU-2

OIL CAPACITY .................................................... 26

Tightening Torque ................................................... 26

Page 2469 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual PRECAUTIONS

LU-3

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

[QR20DE]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS009SQ

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, dis NISSAN X-TRAIL 2003 Electronic Repair Manual PRECAUTIONS

LU-3

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

[QR20DE]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS009SQ

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, dis](/img/5/57402/w960_57402-2468.png)

PRECAUTIONS

LU-3

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

LU

[QR20DE]PRECAUTIONSPFP:00001

Precautions For Liquid GasketEBS009SQ

REMOVAL OF LIQUID GASKET SEALING

lAfter removing the mounting bolts and nuts, disconnect and

remove the liquid gasket sealing using a seal cutter.

CAUTION:

Be careful not to damage the mating surfaces.

lIn areas where the cutter is difficult to use, use a plastic hammer

to lightly tap the areas where the liquid gasket is applied.

CAUTION:

If for some unavoidable reason a tool such as a flat-bladed

screwdriver is used, be careful not to damage the mating sur-

faces.

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper, remove the old liquid gasket adhering to the

gasket application surface and the mating surface.

lRemove the liquid gasket completely from the groove of the gas-

ket application surface, mounting bolts, and bolt holes.

2. Wipe the gasket application surface and the mating surface with

white gasoline (lighting and heating use) to remove adhering

moisture, grease and foreign materials.

3. Attach the liquid gasket to the tube presser.

Use Genuine Liquid Gasket or equivalent.

4. Apply the gasket without breaks to the specified location with the

specified dimensions.

lIf there is a groove for the liquid gasket application, apply the

gasket to the groove.

lAs for the bolt holes, normally apply the gasket inside the holes.

Occasionally, it should be applied outside the holes. Make sure

to read the text of service manual.

lWithin five minutes of gasket application, install the mating com-

ponent.

lIf the liquid gasket protrudes, wipe it off immediately.

lDo not retighten after the installation.

lAfter 30 minutes or more have passed from the installation, fill

the engine oil and coolant.

CAUTION:

If there are specific instructions in the service manual, observe

them.

PBIC0275E

PBIC0003E

EMA0622D

SEM164F

Page 2470 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual LU-4

[QR20DE]

PREPARATION

PREPARATION

PFP:00002

Special Service ToolsEBS009SR

Tool number

Tool nameDescription

ST25051001

Oil pressure gaugeMeasuring oil pressure

Maximum measuring range:

2,452 kPa (2 NISSAN X-TRAIL 2003 Electronic Repair Manual LU-4

[QR20DE]

PREPARATION

PREPARATION

PFP:00002

Special Service ToolsEBS009SR

Tool number

Tool nameDescription

ST25051001

Oil pressure gaugeMeasuring oil pressure

Maximum measuring range:

2,452 kPa (2](/img/5/57402/w960_57402-2469.png)

LU-4

[QR20DE]

PREPARATION

PREPARATION

PFP:00002

Special Service ToolsEBS009SR

Tool number

Tool nameDescription

ST25051001

Oil pressure gaugeMeasuring oil pressure

Maximum measuring range:

2,452 kPa (25 kg/cm2, 356 psi)

ST25052000

HoseAdapting oil pressure gauge to cylinder block

KV10115801

Oil filter wrenchRemoving oil filter

WS39930000

Tube presserPressing the tube of liquid gasket

S-NT050

S-NT559

S-NT772

S-NT052