NISSAN X-TRAIL 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2591 of 3066

INPUT SHAFT AND GEARS

MT-55

D

E

F

G

H

I

J

K

L

MA

B

MT

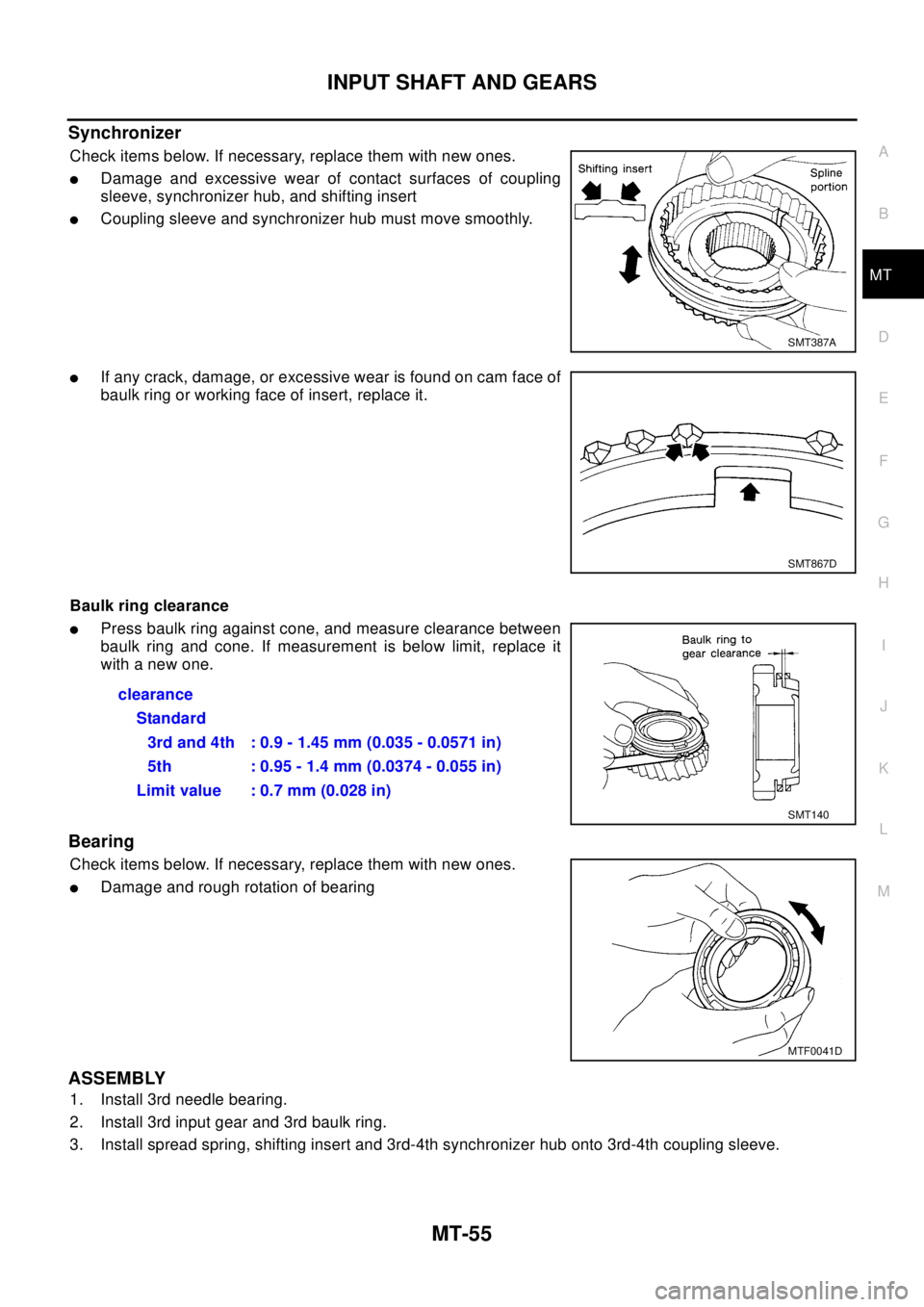

Synchronizer

Check items below. If necessary, replace them with new ones.

lDamage and excessive wear of contact surfaces of coupling

sleeve, synchronizer hub, and shifting insert

lCoupling sleeve and synchronizer hub must move smoothly.

lIf any crack, damage, or excessive wear is found on cam face of

baulk ring or working face of insert, replace it.

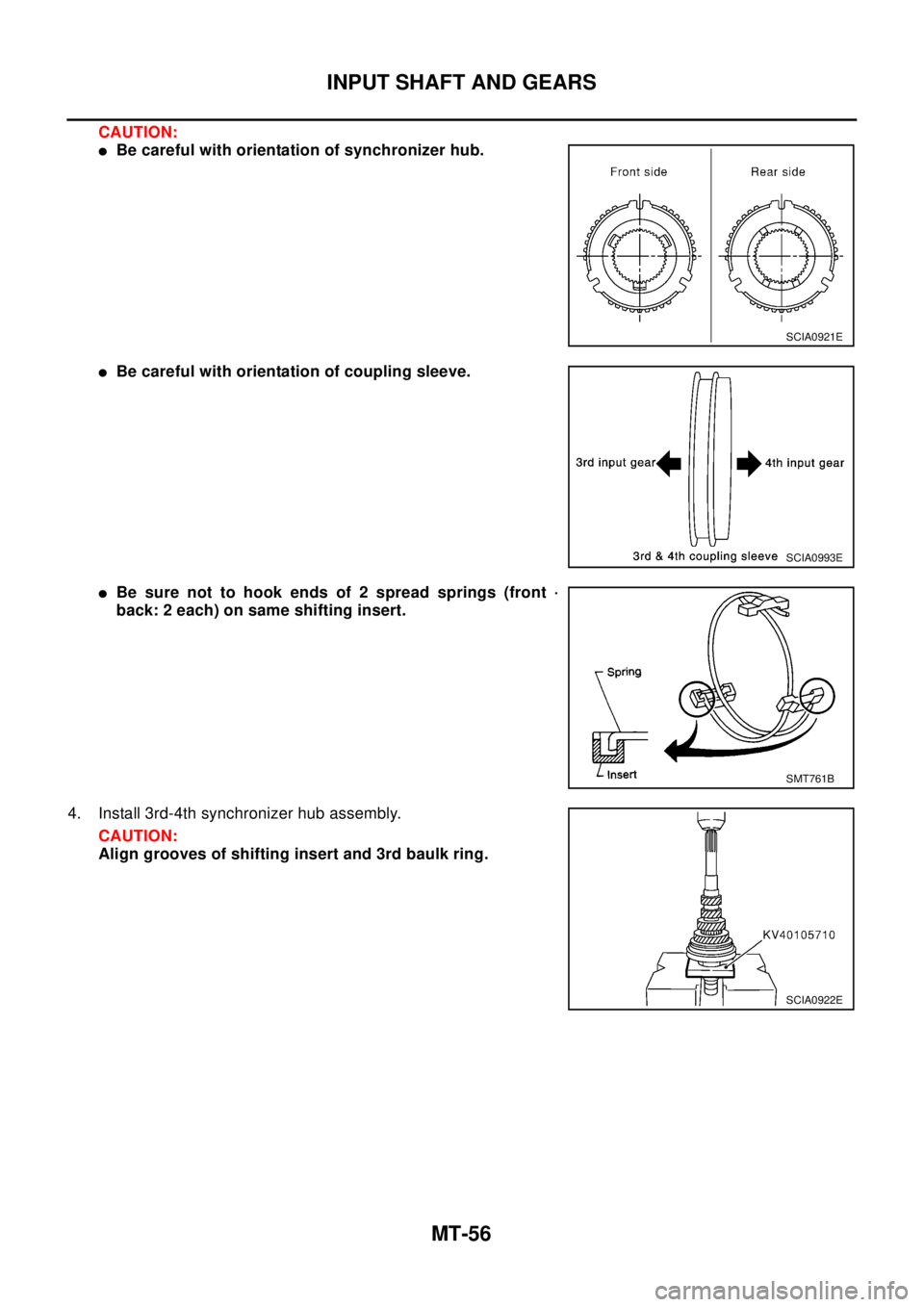

Baulk ring clearance

lPress baulk ring against cone, and measure clearance between

baulk ring and cone. If measurement is below limit, replace it

with a new one.

Bearing

Check items below. If necessary, replace them with new ones.

lDamage and rough rotation of bearing

ASSEMBLY

1. Install 3rd needle bearing.

2. Install 3rd input gear and 3rd baulk ring.

3. Install spread spring, shifting insert and 3rd-4th synchronizer hub onto 3rd-4th coupling sleeve.

SMT387A

SMT867D

clearance

Standard

3rd and 4th : 0.9 - 1.45 mm (0.035 - 0.0571 in)

5th : 0.95 - 1.4 mm (0.0374 - 0.055 in)

Limit value : 0.7 mm (0.028 in)

SMT140

MTF0041D

Page 2592 of 3066

MT-56

INPUT SHAFT AND GEARS

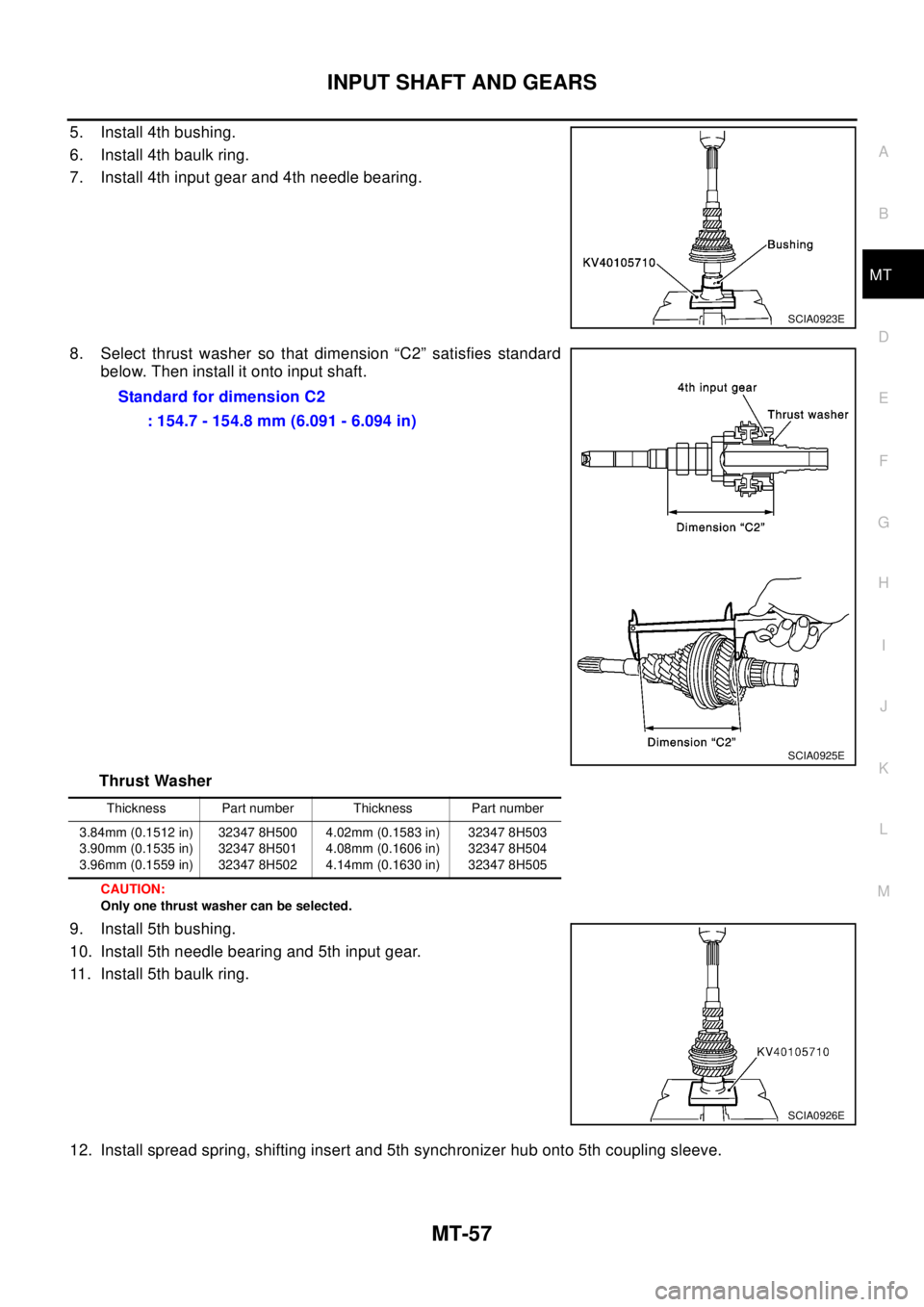

CAUTION:

lBe careful with orientation of synchronizer hub.

lBe careful with orientation of coupling sleeve.

lBe sure not to hook ends of 2 spread springs (front ·

back: 2 each) on same shifting insert.

4. Install 3rd-4th synchronizer hub assembly.

CAUTION:

Align grooves of shifting insert and 3rd baulk ring.

SCIA0921E

SCIA0993E

SMT761B

SCIA0922E

Page 2593 of 3066

INPUT SHAFT AND GEARS

MT-57

D

E

F

G

H

I

J

K

L

MA

B

MT

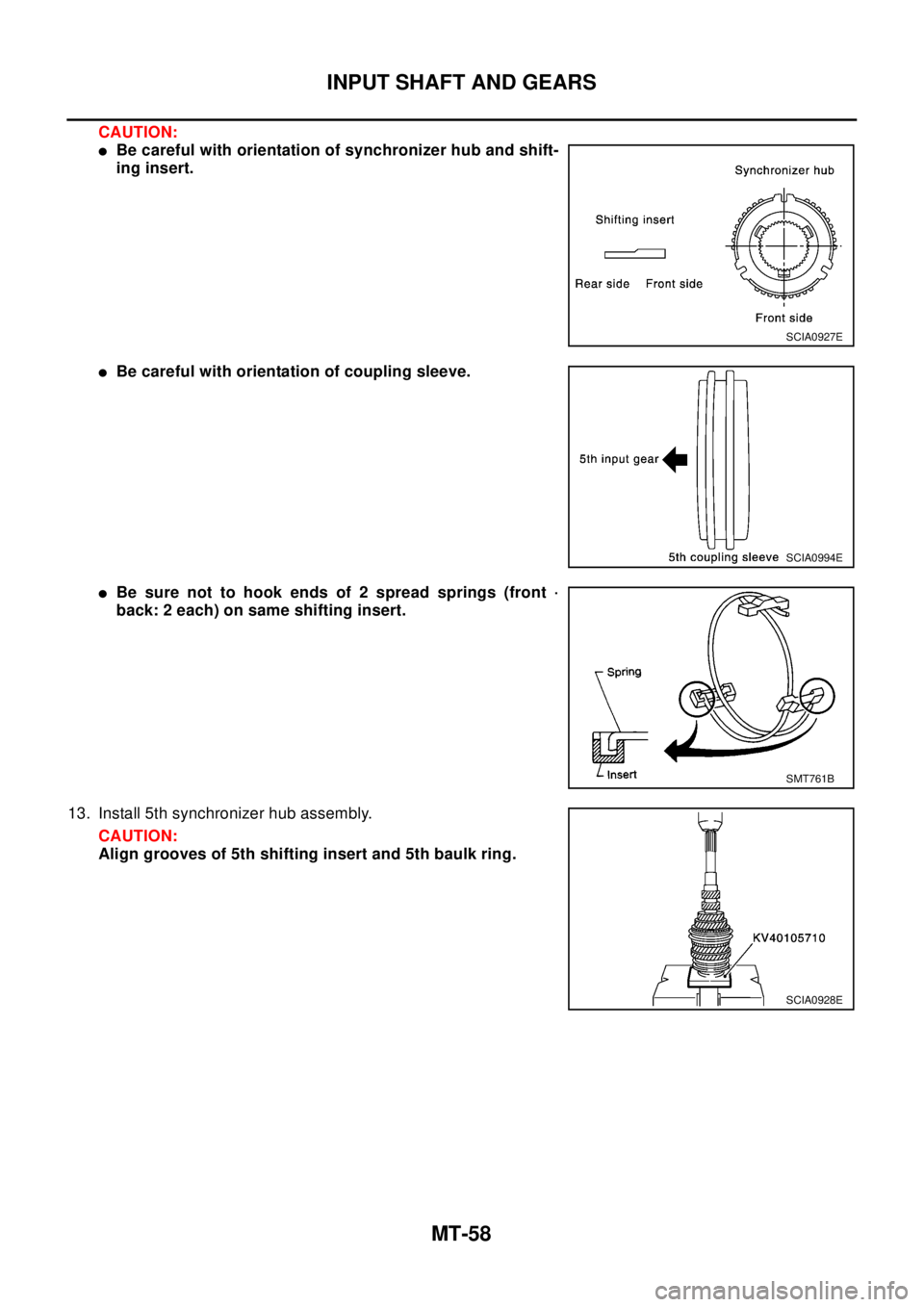

5. Install 4th bushing.

6. Install 4th baulk ring.

7. Install 4th input gear and 4th needle bearing.

8. Select thrust washer so that dimension “C2” satisfies standard

below. Then install it onto input shaft.

Thrust Washer

CAUTION:

Only one thrust washer can be selected.

9. Install 5th bushing.

10. Install 5th needle bearing and 5th input gear.

11. Install 5th baulk ring.

12. Install spread spring, shifting insert and 5th synchronizer hub onto 5th coupling sleeve.

SCIA0923E

Standard for dimension C2

: 154.7 - 154.8 mm (6.091 - 6.094 in)

SCIA0925E

Thickness Part number Thickness Part number

3.84mm (0.1512 in)

3.90mm (0.1535 in)

3.96mm (0.1559 in)32347 8H500

32347 8H501

32347 8H5024.02mm (0.1583 in)

4.08mm (0.1606 in)

4.14mm (0.1630 in)32347 8H503

32347 8H504

32347 8H505

SCIA0926E

Page 2594 of 3066

MT-58

INPUT SHAFT AND GEARS

CAUTION:

lBe careful with orientation of synchronizer hub and shift-

ing insert.

lBe careful with orientation of coupling sleeve.

lBe sure not to hook ends of 2 spread springs (front ·

back: 2 each) on same shifting insert.

13. Install 5th synchronizer hub assembly.

CAUTION:

Align grooves of 5th shifting insert and 5th baulk ring.

SCIA0927E

SCIA0994E

SMT761B

SCIA0928E

Page 2595 of 3066

INPUT SHAFT AND GEARS

MT-59

D

E

F

G

H

I

J

K

L

MA

B

MT

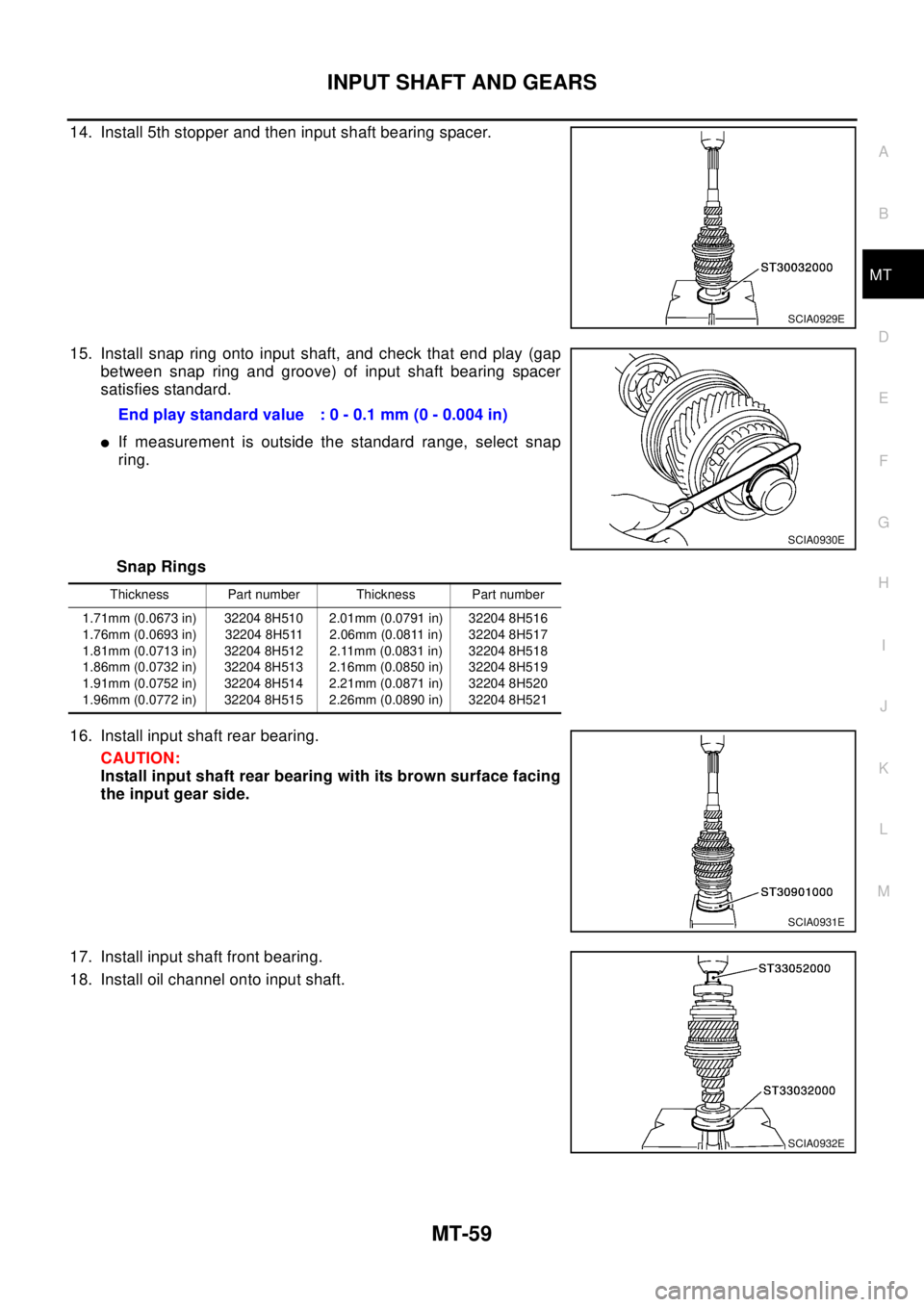

14. Install 5th stopper and then input shaft bearing spacer.

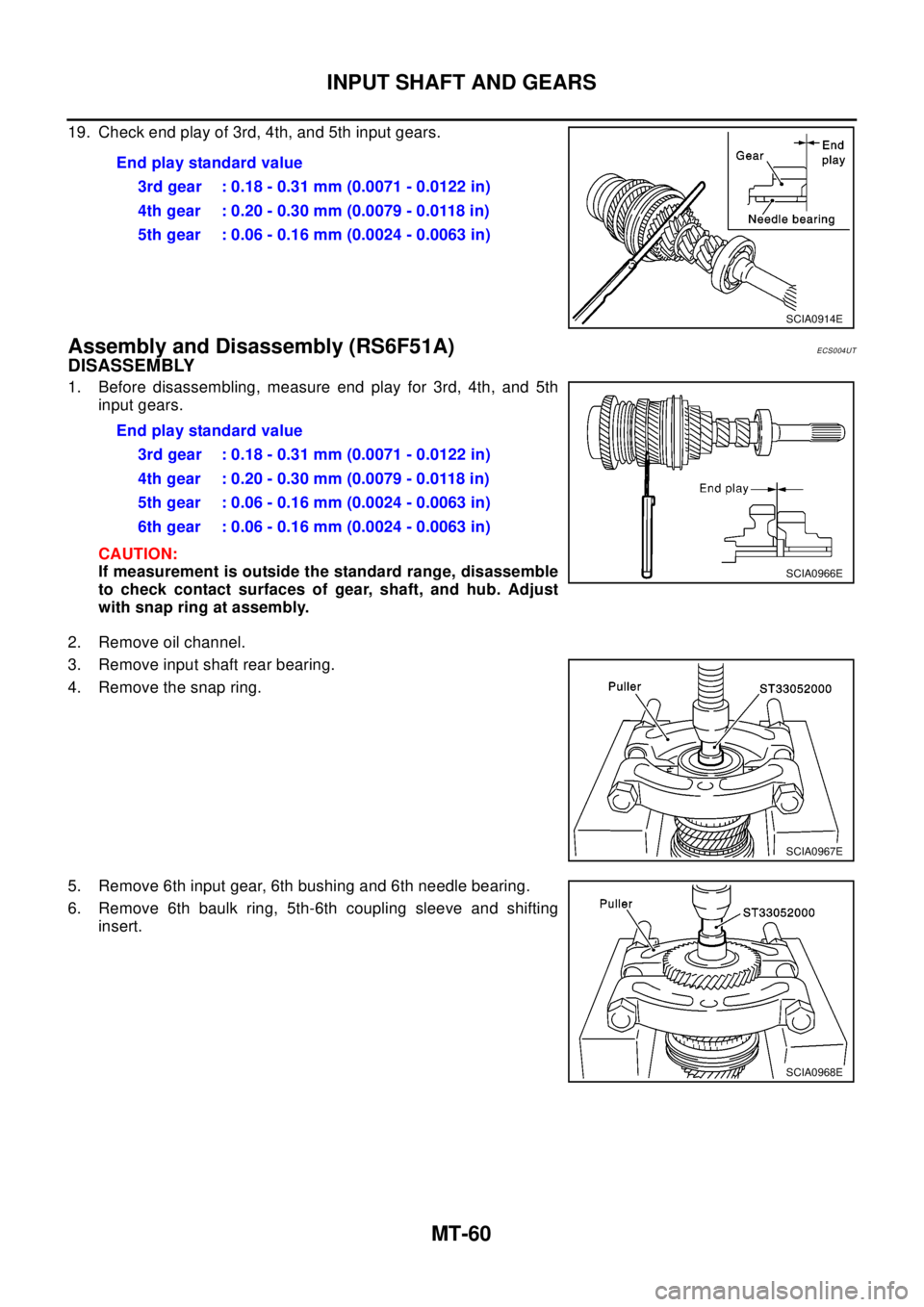

15. Install snap ring onto input shaft, and check that end play (gap

between snap ring and groove) of input shaft bearing spacer

satisfies standard.

lIf measurement is outside the standard range, select snap

ring.

Snap Rings

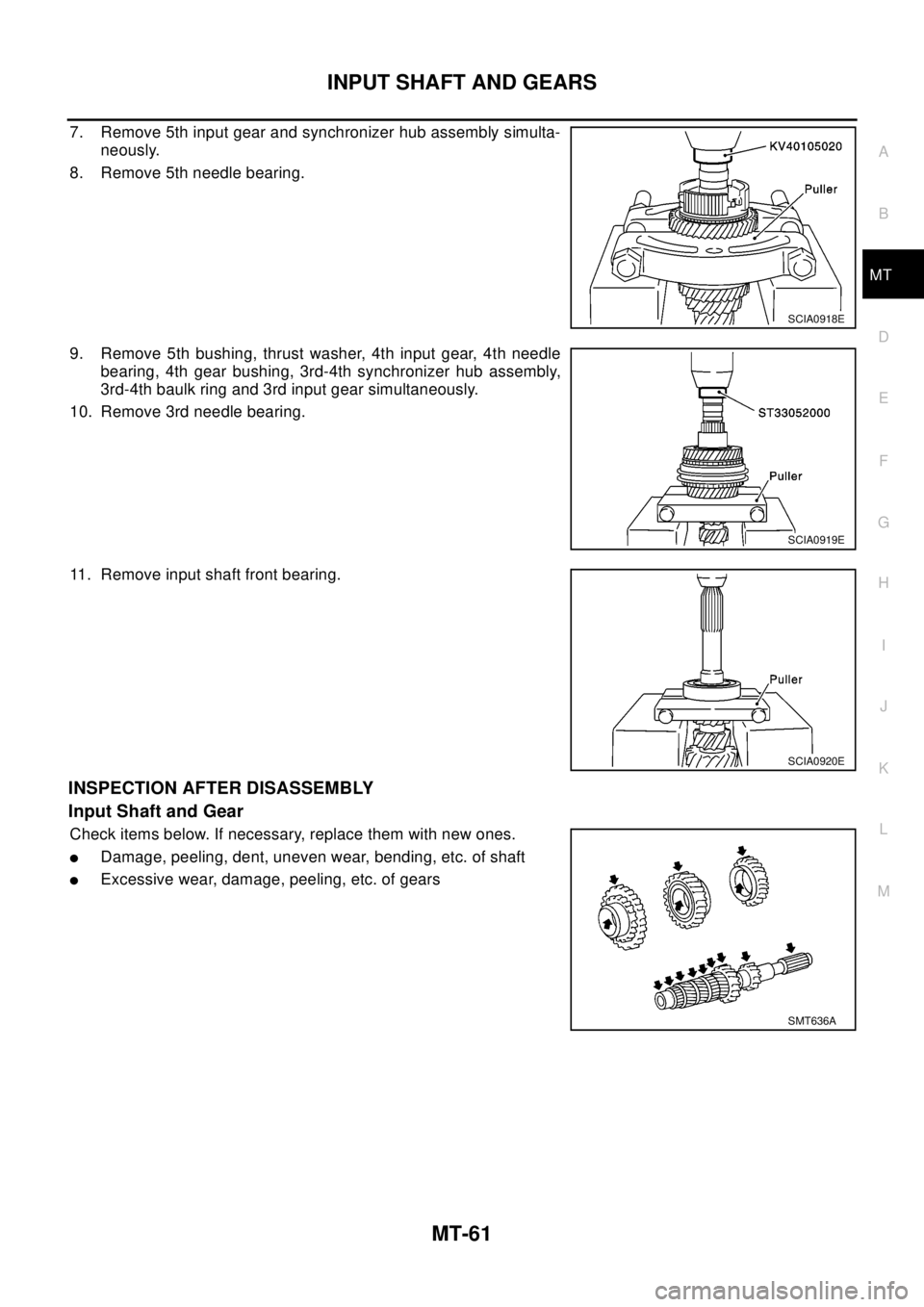

16. Install input shaft rear bearing.

CAUTION:

Install input shaft rear bearing with its brown surface facing

the input gear side.

17. Install input shaft front bearing.

18. Install oil channel onto input shaft.

SCIA0929E

Endplaystandardvalue :0-0.1mm(0-0.004in)

SCIA0930E

Thickness Part number Thickness Part number

1.71mm (0.0673 in)

1.76mm (0.0693 in)

1.81mm (0.0713 in)

1.86mm (0.0732 in)

1.91mm (0.0752 in)

1.96mm (0.0772 in)32204 8H510

32204 8H511

32204 8H512

32204 8H513

32204 8H514

32204 8H5152.01mm (0.0791 in)

2.06mm (0.0811 in)

2.11mm (0.0831 in)

2.16mm (0.0850 in)

2.21mm (0.0871 in)

2.26mm (0.0890 in)32204 8H516

32204 8H517

32204 8H518

32204 8H519

32204 8H520

32204 8H521

SCIA0931E

SCIA0932E

Page 2596 of 3066

MT-60

INPUT SHAFT AND GEARS

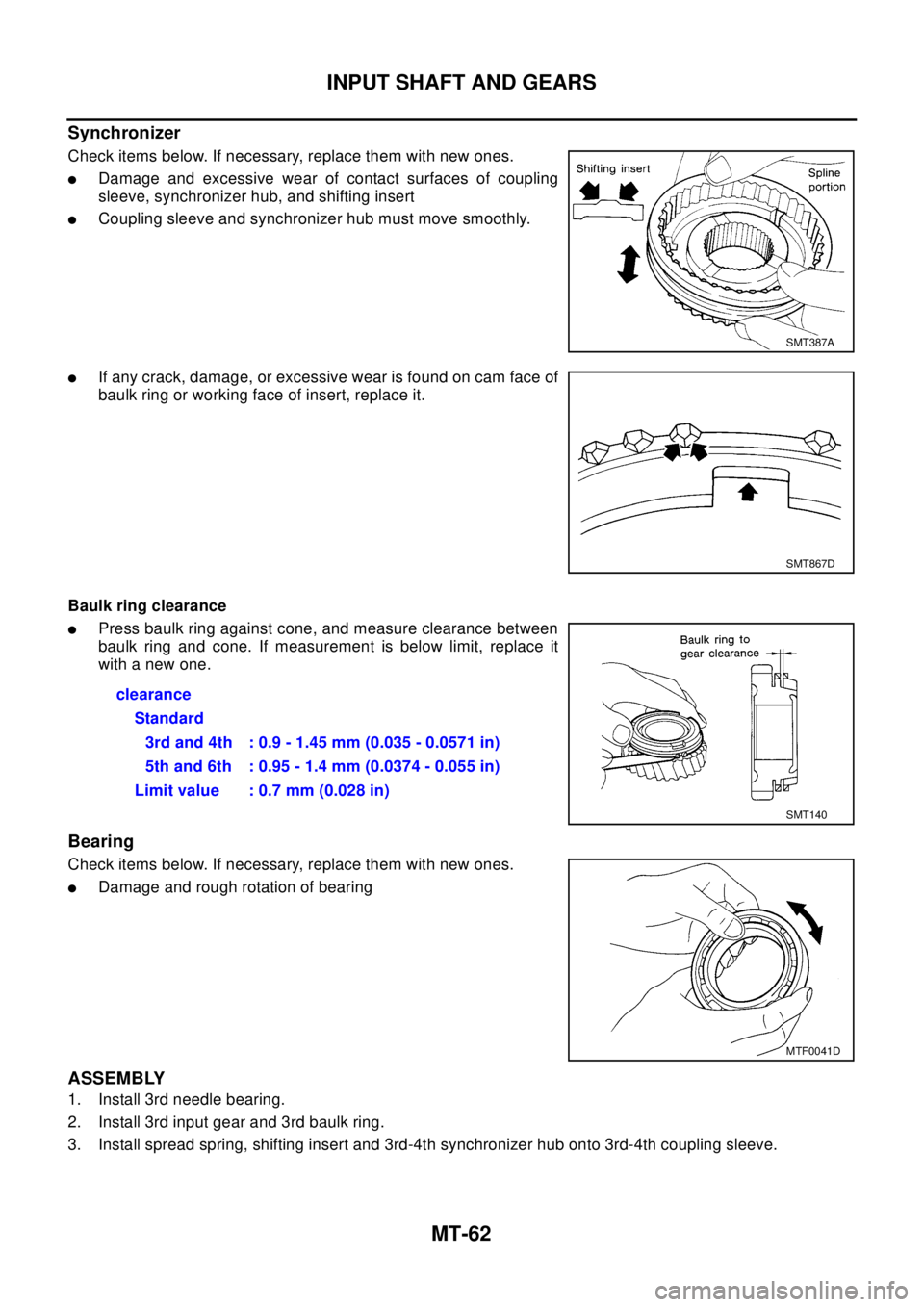

19. Check end play of 3rd, 4th, and 5th input gears.

Assembly and Disassembly (RS6F51A)ECS004UT

DISASSEMBLY

1. Before disassembling, measure end play for 3rd, 4th, and 5th

input gears.

CAUTION:

If measurement is outside the standard range, disassemble

to check contact surfaces of gear, shaft, and hub. Adjust

with snap ring at assembly.

2. Remove oil channel.

3. Remove input shaft rear bearing.

4. Remove the snap ring.

5. Remove 6th input gear, 6th bushing and 6th needle bearing.

6. Remove 6th baulk ring, 5th-6th coupling sleeve and shifting

insert.Endplaystandardvalue

3rd gear : 0.18 - 0.31 mm (0.0071 - 0.0122 in)

4th gear : 0.20 - 0.30 mm (0.0079 - 0.0118 in)

5th gear : 0.06 - 0.16 mm (0.0024 - 0.0063 in)

SCIA0914E

Endplaystandardvalue

3rd gear : 0.18 - 0.31 mm (0.0071 - 0.0122 in)

4th gear : 0.20 - 0.30 mm (0.0079 - 0.0118 in)

5th gear : 0.06 - 0.16 mm (0.0024 - 0.0063 in)

6th gear : 0.06 - 0.16 mm (0.0024 - 0.0063 in)

SCIA0966E

SCIA0967E

SCIA0968E

Page 2597 of 3066

INPUT SHAFT AND GEARS

MT-61

D

E

F

G

H

I

J

K

L

MA

B

MT

7. Remove 5th input gear and synchronizer hub assembly simulta-

neously.

8. Remove 5th needle bearing.

9. Remove 5th bushing, thrust washer, 4th input gear, 4th needle

bearing, 4th gear bushing, 3rd-4th synchronizer hub assembly,

3rd-4th baulk ring and 3rd input gear simultaneously.

10. Remove 3rd needle bearing.

11. Remove input shaft front bearing.

INSPECTION AFTER DISASSEMBLY

Input Shaft and Gear

Check items below. If necessary, replace them with new ones.

lDamage, peeling, dent, uneven wear, bending, etc. of shaft

lExcessive wear, damage, peeling, etc. of gears

SCIA0918E

SCIA0919E

SCIA0920E

SMT636A

Page 2598 of 3066

MT-62

INPUT SHAFT AND GEARS

Synchronizer

Check items below. If necessary, replace them with new ones.

lDamage and excessive wear of contact surfaces of coupling

sleeve, synchronizer hub, and shifting insert

lCoupling sleeve and synchronizer hub must move smoothly.

lIf any crack, damage, or excessive wear is found on cam face of

baulk ring or working face of insert, replace it.

Baulk ring clearance

lPress baulk ring against cone, and measure clearance between

baulk ring and cone. If measurement is below limit, replace it

with a new one.

Bearing

Check items below. If necessary, replace them with new ones.

lDamage and rough rotation of bearing

ASSEMBLY

1. Install 3rd needle bearing.

2. Install 3rd input gear and 3rd baulk ring.

3. Install spread spring, shifting insert and 3rd-4th synchronizer hub onto 3rd-4th coupling sleeve.

SMT387A

SMT867D

clearance

Standard

3rd and 4th : 0.9 - 1.45 mm (0.035 - 0.0571 in)

5th and 6th : 0.95 - 1.4 mm (0.0374 - 0.055 in)

Limit value : 0.7 mm (0.028 in)

SMT140

MTF0041D

Page 2599 of 3066

INPUT SHAFT AND GEARS

MT-63

D

E

F

G

H

I

J

K

L

MA

B

MT

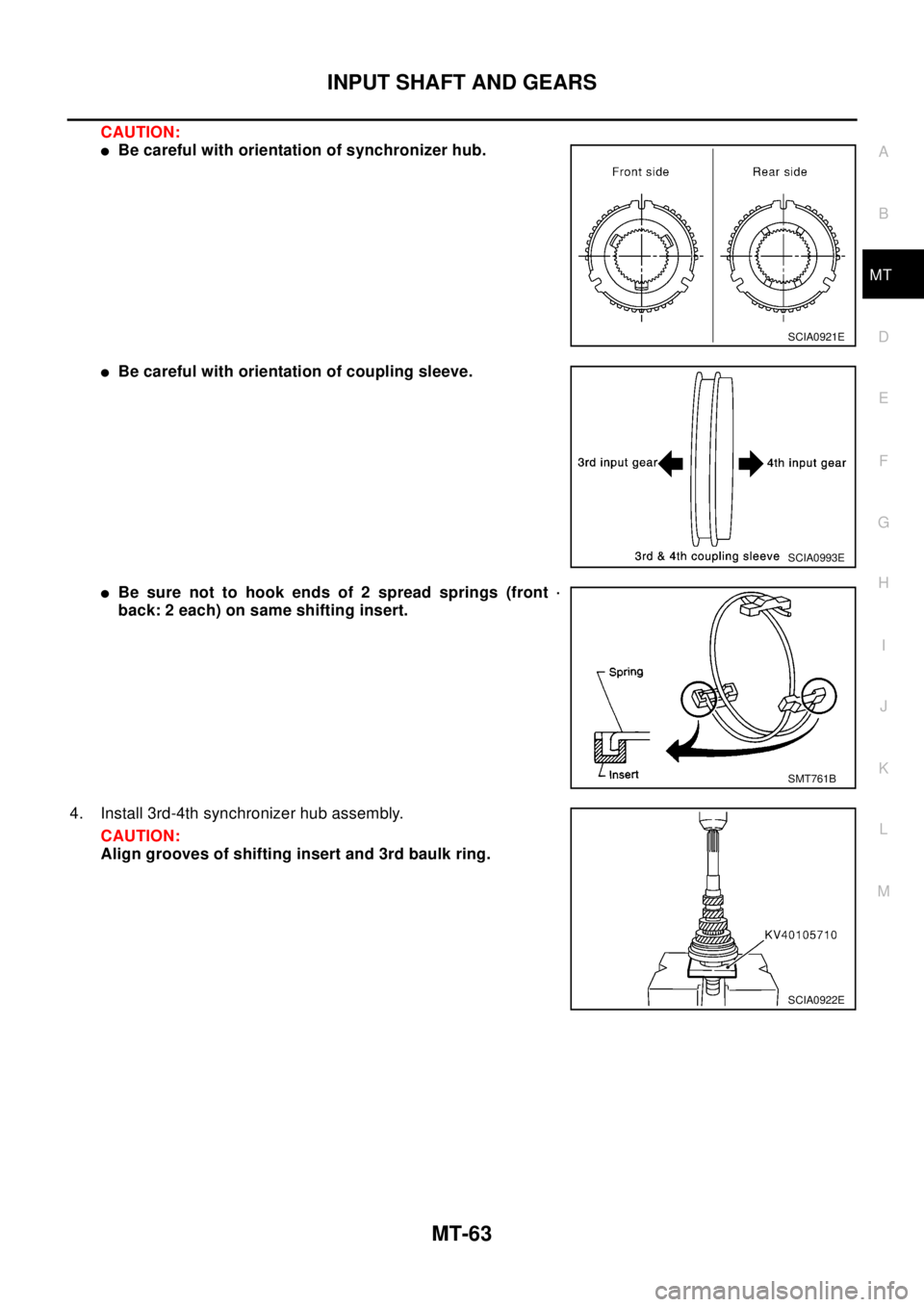

CAUTION:

lBe careful with orientation of synchronizer hub.

lBe careful with orientation of coupling sleeve.

lBe sure not to hook ends of 2 spread springs (front ·

back: 2 each) on same shifting insert.

4. Install 3rd-4th synchronizer hub assembly.

CAUTION:

Align grooves of shifting insert and 3rd baulk ring.

SCIA0921E

SCIA0993E

SMT761B

SCIA0922E

Page 2600 of 3066

MT-64

INPUT SHAFT AND GEARS

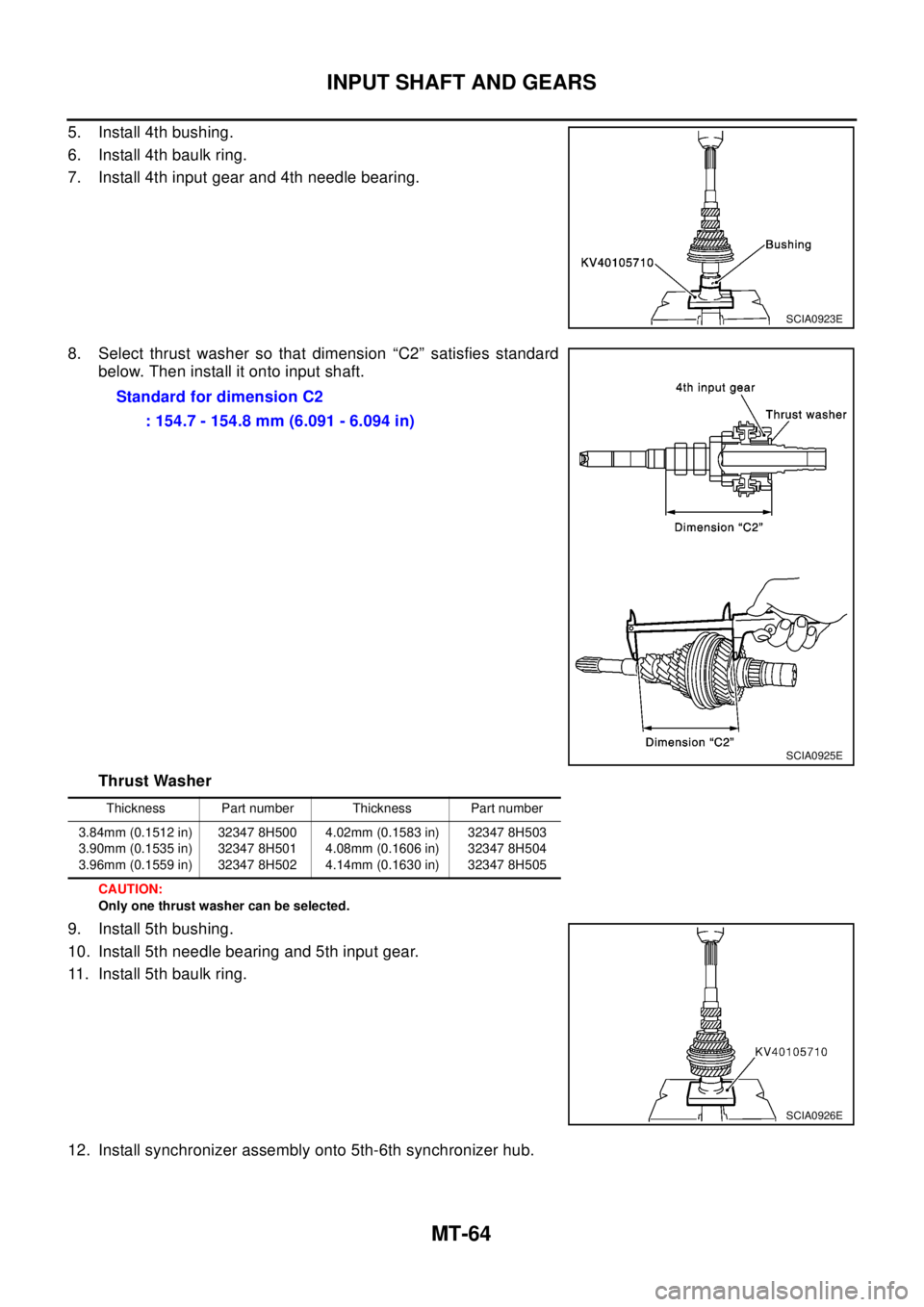

5. Install 4th bushing.

6. Install 4th baulk ring.

7. Install 4th input gear and 4th needle bearing.

8. Select thrust washer so that dimension “C2” satisfies standard

below. Then install it onto input shaft.

Thrust Washer

CAUTION:

Only one thrust washer can be selected.

9. Install 5th bushing.

10. Install 5th needle bearing and 5th input gear.

11. Install 5th baulk ring.

12. Install synchronizer assembly onto 5th-6th synchronizer hub.

SCIA0923E

Standard for dimension C2

: 154.7 - 154.8 mm (6.091 - 6.094 in)

SCIA0925E

Thickness Part number Thickness Part number

3.84mm (0.1512 in)

3.90mm (0.1535 in)

3.96mm (0.1559 in)32347 8H500

32347 8H501

32347 8H5024.02mm (0.1583 in)

4.08mm (0.1606 in)

4.14mm (0.1630 in)32347 8H503

32347 8H504

32347 8H505

SCIA0926E