NISSAN X-TRAIL 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2611 of 3066

MAINSHAFT AND GEARS

MT-75

D

E

F

G

H

I

J

K

L

MA

B

MT

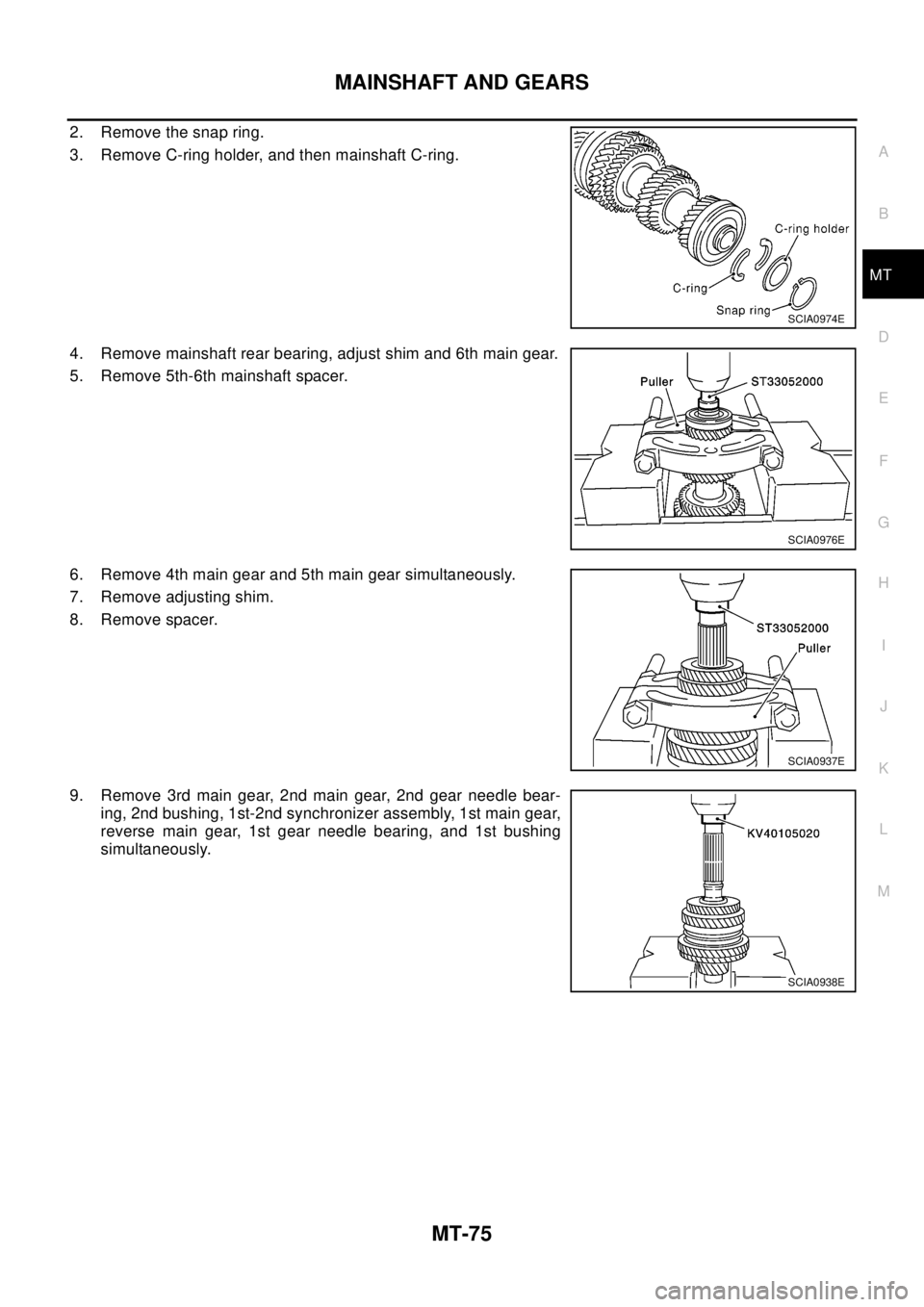

2. Removethesnapring.

3. Remove C-ring holder, and then mainshaft C-ring.

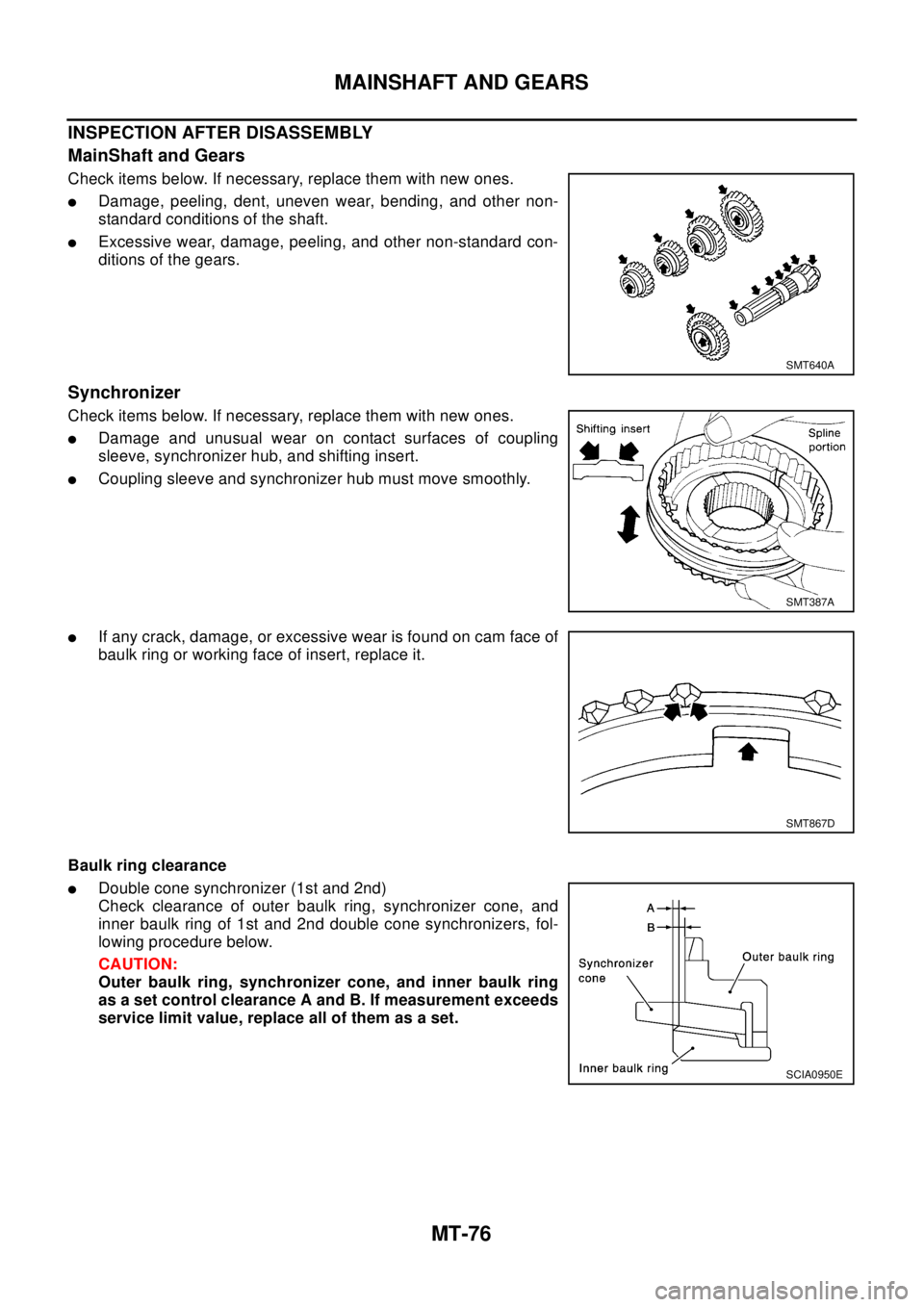

4. Remove mainshaft rear bearing, adjust shim and 6th main gear.

5. Remove 5th-6th mainshaft spacer.

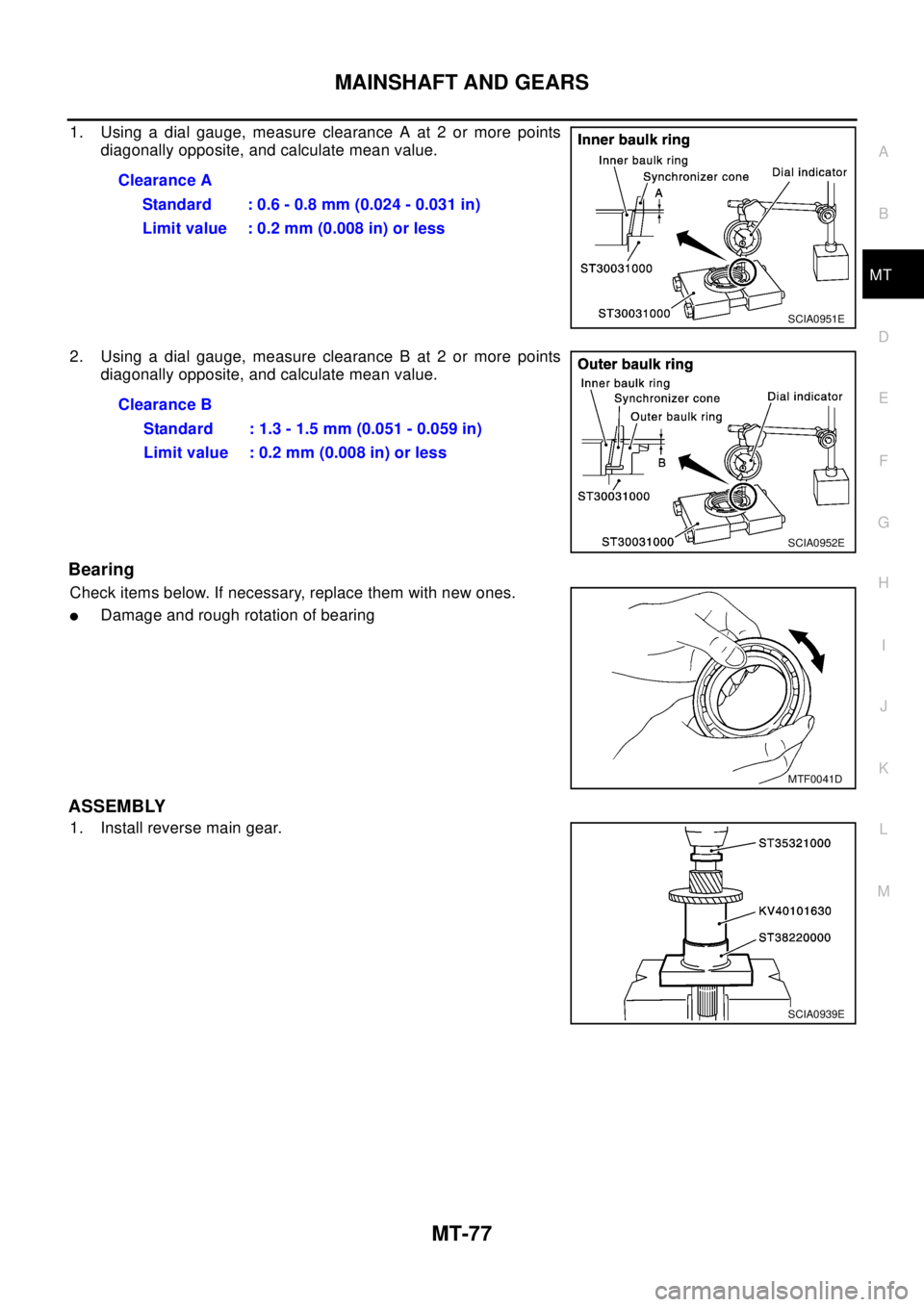

6. Remove 4th main gear and 5th main gear simultaneously.

7. Remove adjusting shim.

8. Remove spacer.

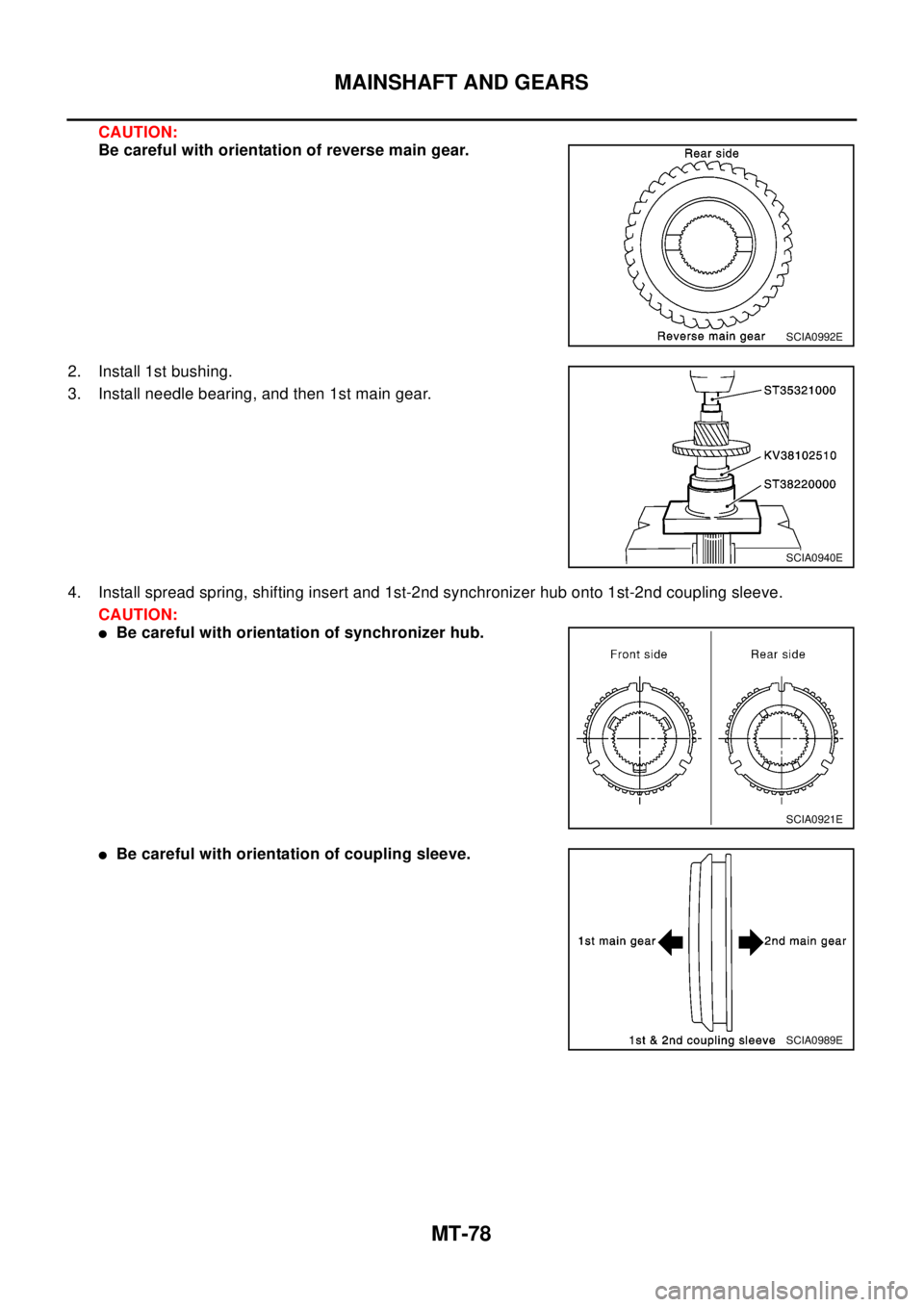

9. Remove 3rd main gear, 2nd main gear, 2nd gear needle bear-

ing, 2nd bushing, 1st-2nd synchronizer assembly, 1st main gear,

reverse main gear, 1st gear needle bearing, and 1st bushing

simultaneously.

SCIA0974E

SCIA0976E

SCIA0937E

SCIA0938E

Page 2612 of 3066

MT-76

MAINSHAFT AND GEARS

INSPECTION AFTER DISASSEMBLY

MainShaft and Gears

Check items below. If necessary, replace them with new ones.

lDamage, peeling, dent, uneven wear, bending, and other non-

standard conditions of the shaft.

lExcessive wear, damage, peeling, and other non-standard con-

ditions of the gears.

Synchronizer

Check items below. If necessary, replace them with new ones.

lDamage and unusual wear on contact surfaces of coupling

sleeve, synchronizer hub, and shifting insert.

lCoupling sleeve and synchronizer hub must move smoothly.

lIf any crack, damage, or excessive wear is found on cam face of

baulk ring or working face of insert, replace it.

Baulk ring clearance

lDouble cone synchronizer (1st and 2nd)

Check clearance of outer baulk ring, synchronizer cone, and

inner baulk ring of 1st and 2nd double cone synchronizers, fol-

lowing procedure below.

CAUTION:

Outer baulk ring, synchronizer cone, and inner baulk ring

as a set control clearance A and B. If measurement exceeds

service limit value, replace all of them as a set.

SMT640A

SMT387A

SMT867D

SCIA0950E

Page 2613 of 3066

MAINSHAFT AND GEARS

MT-77

D

E

F

G

H

I

J

K

L

MA

B

MT

1. Using a dial gauge, measure clearance A at 2 or more points

diagonally opposite, and calculate mean value.

2. Using a dial gauge, measure clearance B at 2 or more points

diagonally opposite, and calculate mean value.

Bearing

Check items below. If necessary, replace them with new ones.

lDamage and rough rotation of bearing

ASSEMBLY

1. Install reverse main gear.Clearance A

Standard : 0.6 - 0.8 mm (0.024 - 0.031 in)

Limit value : 0.2 mm (0.008 in) or less

SCIA0951E

Clearance B

Standard : 1.3 - 1.5 mm (0.051 - 0.059 in)

Limit value : 0.2 mm (0.008 in) or less

SCIA0952E

MTF0041D

SCIA0939E

Page 2614 of 3066

MT-78

MAINSHAFT AND GEARS

CAUTION:

Be careful with orientation of reverse main gear.

2. Install 1st bushing.

3. Install needle bearing, and then 1st main gear.

4. Install spread spring, shifting insert and 1st-2nd synchronizer hub onto 1st-2nd coupling sleeve.

CAUTION:

lBe careful with orientation of synchronizer hub.

lBe careful with orientation of coupling sleeve.

SCIA0992E

SCIA0940E

SCIA0921E

SCIA0989E

Page 2615 of 3066

MAINSHAFT AND GEARS

MT-79

D

E

F

G

H

I

J

K

L

MA

B

MT

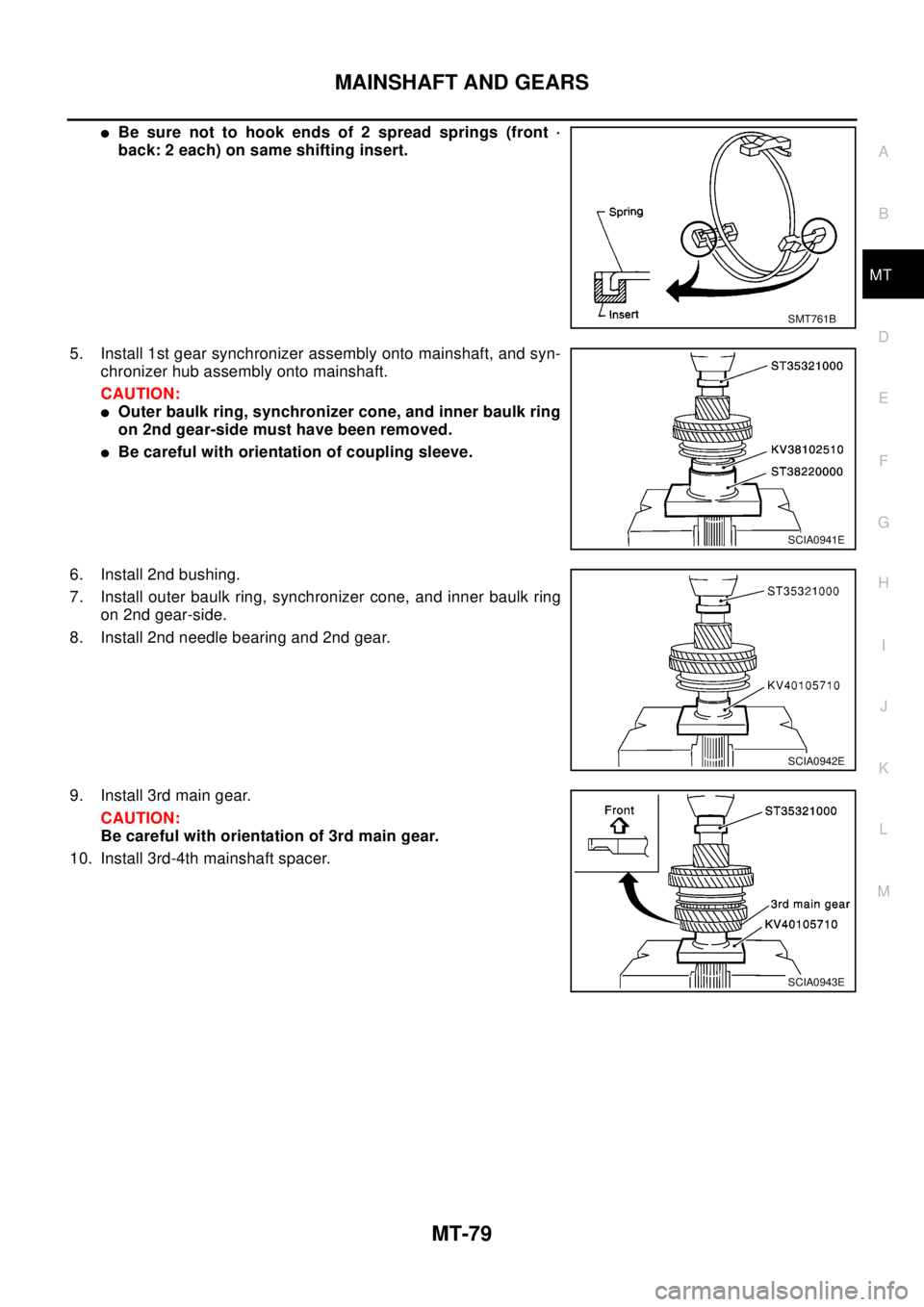

lBe sure not to hook ends of 2 spread springs (front ·

back: 2 each) on same shifting insert.

5. Install 1st gear synchronizer assembly onto mainshaft, and syn-

chronizer hub assembly onto mainshaft.

CAUTION:

lOuter baulk ring, synchronizer cone, and inner baulk ring

on 2nd gear-side must have been removed.

lBe careful with orientation of coupling sleeve.

6. Install 2nd bushing.

7. Install outer baulk ring, synchronizer cone, and inner baulk ring

on 2nd gear-side.

8. Install 2nd needle bearing and 2nd gear.

9. Install 3rd main gear.

CAUTION:

Be careful with orientation of 3rd main gear.

10. Install 3rd-4th mainshaft spacer.

SMT761B

SCIA0941E

SCIA0942E

SCIA0943E

Page 2616 of 3066

MT-80

MAINSHAFT AND GEARS

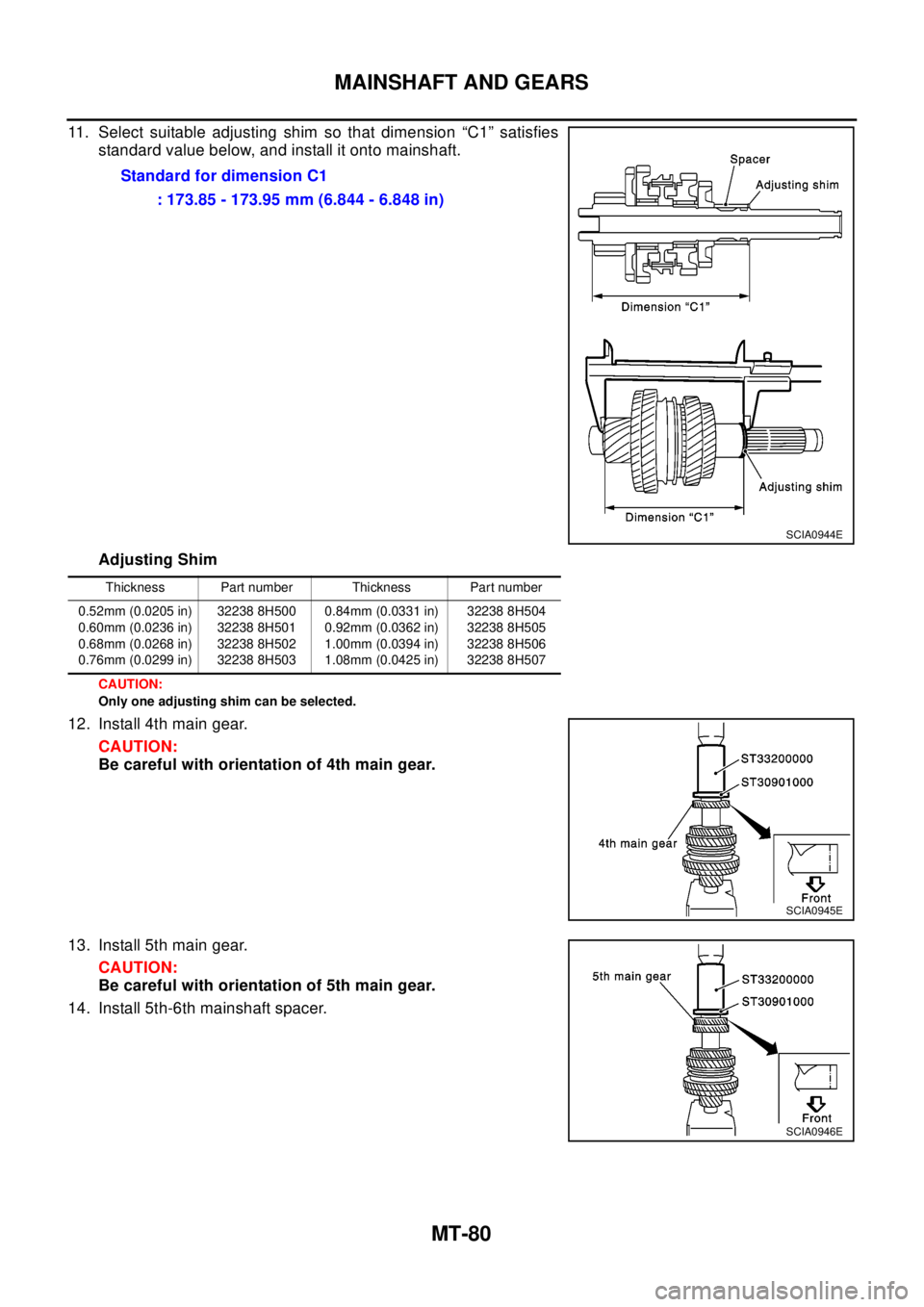

11. Select suitable adjusting shim so that dimension “C1” satisfies

standard value below, and install it onto mainshaft.

Adjusting Shim

CAUTION:

Only one adjusting shim can be selected.

12. Install 4th main gear.

CAUTION:

Be careful with orientation of 4th main gear.

13. Install 5th main gear.

CAUTION:

Be careful with orientation of 5th main gear.

14. Install 5th-6th mainshaft spacer.Standard for dimension C1

: 173.85 - 173.95 mm (6.844 - 6.848 in)

SCIA0944E

Thickness Part number Thickness Part number

0.52mm (0.0205 in)

0.60mm (0.0236 in)

0.68mm (0.0268 in)

0.76mm (0.0299 in)32238 8H500

32238 8H501

32238 8H502

32238 8H5030.84mm (0.0331 in)

0.92mm (0.0362 in)

1.00mm (0.0394 in)

1.08mm (0.0425 in)32238 8H504

32238 8H505

32238 8H506

32238 8H507

SCIA0945E

SCIA0946E

Page 2617 of 3066

MAINSHAFT AND GEARS

MT-81

D

E

F

G

H

I

J

K

L

MA

B

MT

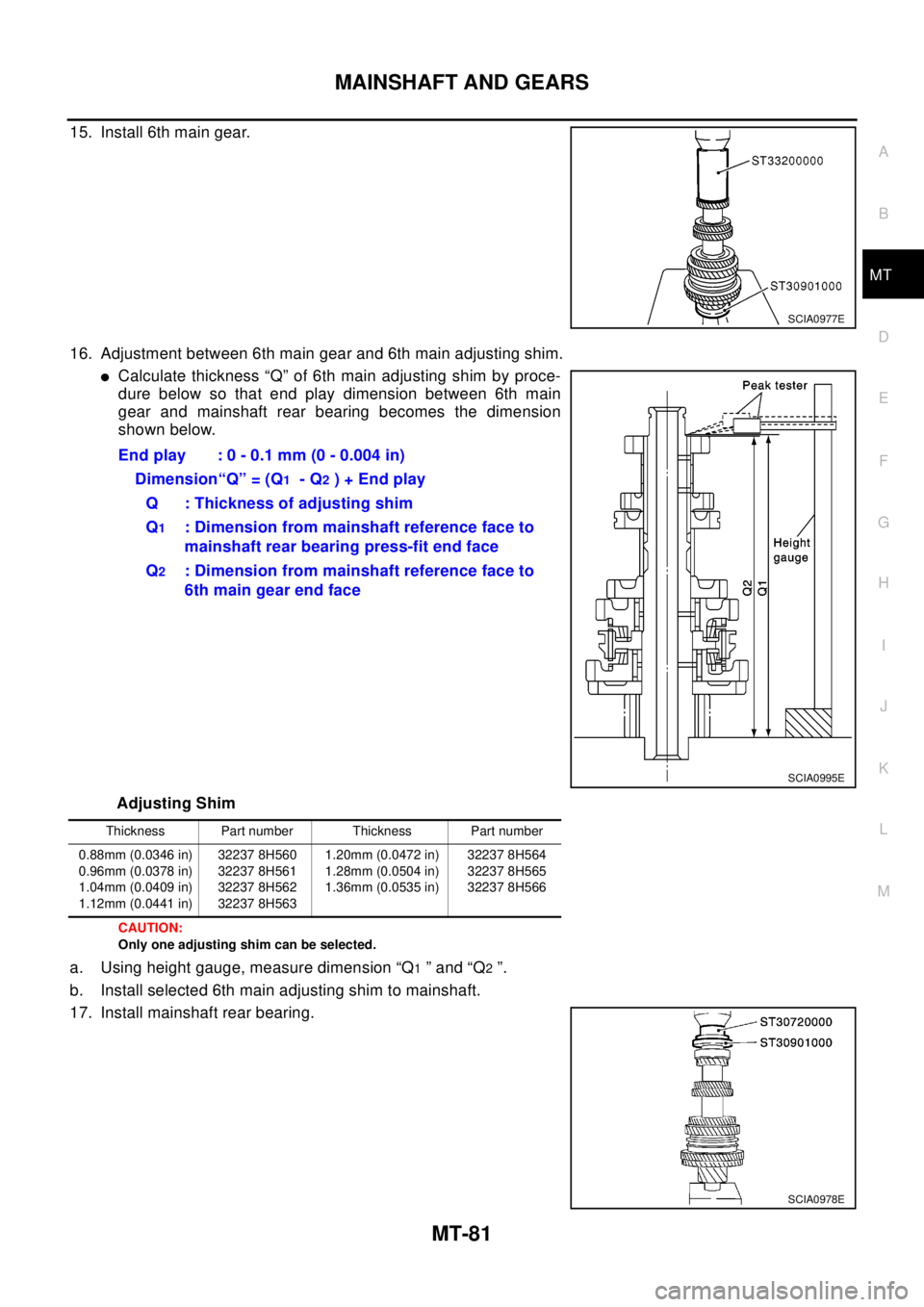

15. Install 6th main gear.

16. Adjustment between 6th main gear and 6th main adjusting shim.

lCalculate thickness “Q” of 6th main adjusting shim by proce-

dure below so that end play dimension between 6th main

gear and mainshaft rear bearing becomes the dimension

shown below.

Adjusting Shim

CAUTION:

Only one adjusting shim can be selected.

a. Using height gauge, measure dimension “Q1”and“Q2”.

b. Install selected 6th main adjusting shim to mainshaft.

17. Install mainshaft rear bearing.

SCIA0977E

Endplay :0-0.1mm(0-0.004in)

Dimension“Q” = (Q

1-Q2)+Endplay

Q : Thickness of adjusting shim

Q

1: Dimension from mainshaft reference face to

mainshaft rear bearing press-fit end face

Q

2: Dimension from mainshaft reference face to

6th main gear end face

SCIA0995E

Thickness Part number Thickness Part number

0.88mm (0.0346 in)

0.96mm (0.0378 in)

1.04mm (0.0409 in)

1.12mm (0.0441 in)32237 8H560

32237 8H561

32237 8H562

32237 8H5631.20mm (0.0472 in)

1.28mm (0.0504 in)

1.36mm (0.0535 in)32237 8H564

32237 8H565

32237 8H566

SCIA0978E

Page 2618 of 3066

MT-82

MAINSHAFT AND GEARS

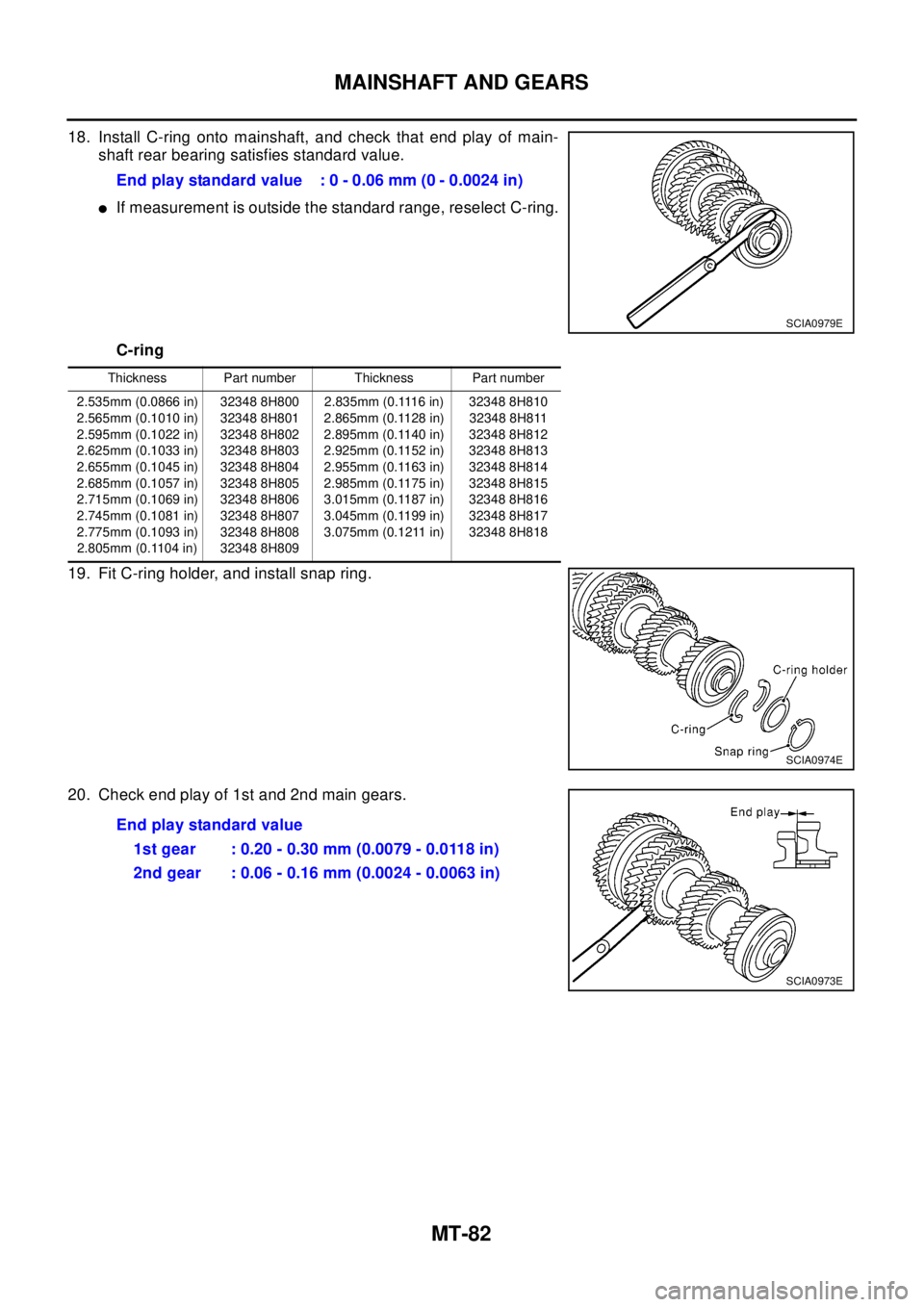

18. Install C-ring onto mainshaft, and check that end play of main-

shaft rear bearing satisfies standard value.

lIf measurement is outside the standard range, reselect C-ring.

C-ring

19. Fit C-ring holder, and install snap ring.

20. Check end play of 1st and 2nd main gears.End play standard value : 0 - 0.06 mm (0 - 0.0024 in)

SCIA0979E

Thickness Part number Thickness Part number

2.535mm (0.0866 in)

2.565mm (0.1010 in)

2.595mm (0.1022 in)

2.625mm (0.1033 in)

2.655mm (0.1045 in)

2.685mm (0.1057 in)

2.715mm (0.1069 in)

2.745mm (0.1081 in)

2.775mm (0.1093 in)

2.805mm (0.1104 in)32348 8H800

32348 8H801

32348 8H802

32348 8H803

32348 8H804

32348 8H805

32348 8H806

32348 8H807

32348 8H808

32348 8H8092.835mm (0.1116 in)

2.865mm (0.1128 in)

2.895mm (0.1140 in)

2.925mm (0.1152 in)

2.955mm (0.1163 in)

2.985mm (0.1175 in)

3.015mm (0.1187 in)

3.045mm (0.1199 in)

3.075mm (0.1211 in)32348 8H810

32348 8H811

32348 8H812

32348 8H813

32348 8H814

32348 8H815

32348 8H816

32348 8H817

32348 8H818

SCIA0974E

Endplaystandardvalue

1st gear : 0.20 - 0.30 mm (0.0079 - 0.0118 in)

2nd gear : 0.06 - 0.16 mm (0.0024 - 0.0063 in)

SCIA0973E

Page 2619 of 3066

REVERSE IDLER SHAFT AND GEARS

MT-83

D

E

F

G

H

I

J

K

L

MA

B

MT

REVERSE IDLER SHAFT AND GEARSPFP:32281

Assembly and Disassembly (RS5F51A)ECS004UQ

DISASSEMBLY

1. Remove reverse idler gear adjusting shim.

2. Remove reverse idler gear (rear), reverse coupling sleeve and insert spring simultaneously.

3. Remove reverse idler gear needle bearing.

4. Remove thrust needle bearing.

5. Remove reverse baulk ring.

6. Remove reverse idler gear (front).

7. Remove reverse idler gear needle bearing.

8. Remove thrust needle bearing.

9. Pull off locking pin from reverse idler shaft.

INSPECTION AFTER DISASSEMBLY

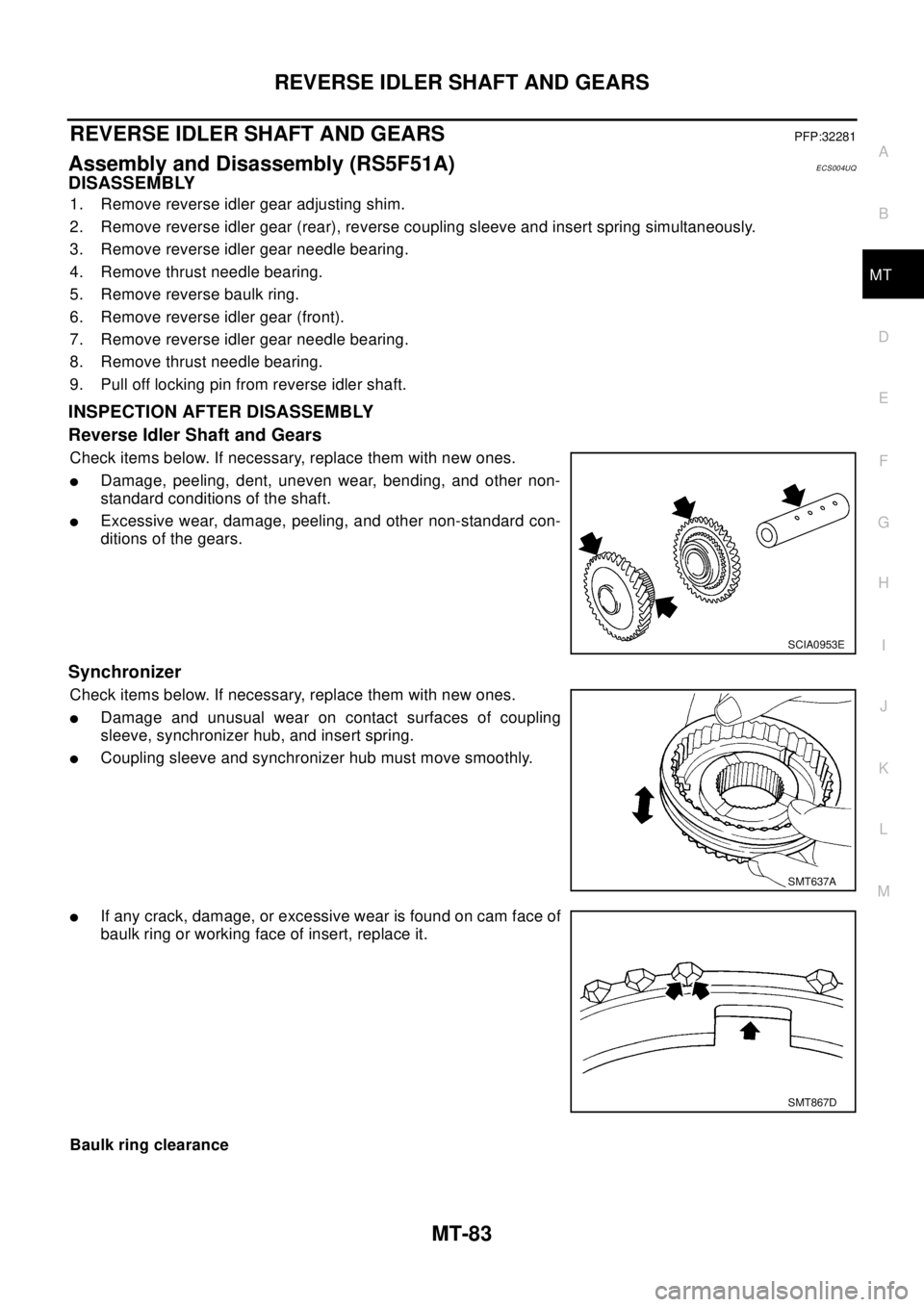

Reverse Idler Shaft and Gears

Check items below. If necessary, replace them with new ones.

lDamage, peeling, dent, uneven wear, bending, and other non-

standard conditions of the shaft.

lExcessive wear, damage, peeling, and other non-standard con-

ditions of the gears.

Synchronizer

Check items below. If necessary, replace them with new ones.

lDamage and unusual wear on contact surfaces of coupling

sleeve, synchronizer hub, and insert spring.

lCoupling sleeve and synchronizer hub must move smoothly.

lIf any crack, damage, or excessive wear is found on cam face of

baulk ring or working face of insert, replace it.

Baulk ring clearance

SCIA0953E

SMT637A

SMT867D

Page 2620 of 3066

MT-84

REVERSE IDLER SHAFT AND GEARS

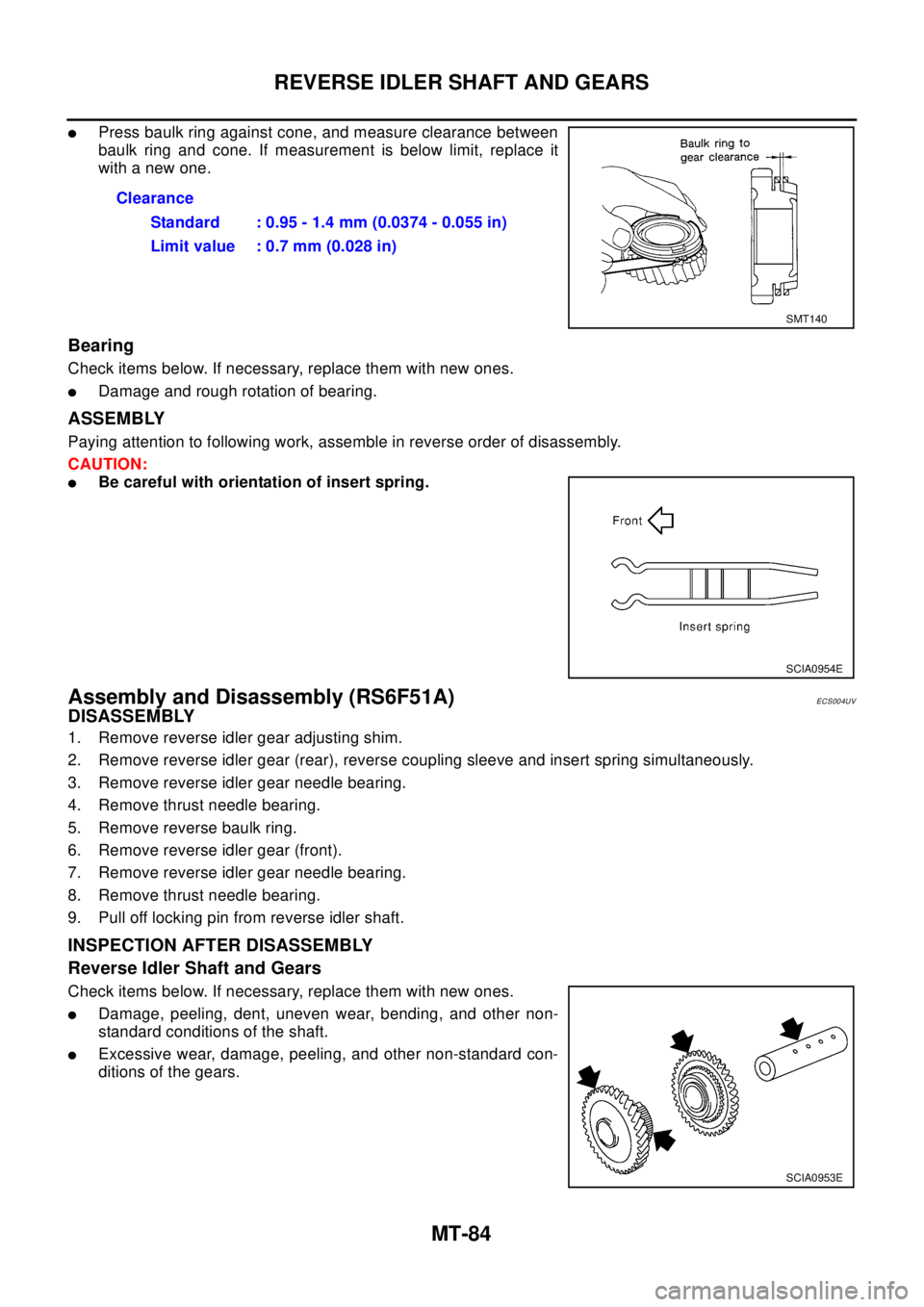

lPress baulk ring against cone, and measure clearance between

baulk ring and cone. If measurement is below limit, replace it

with a new one.

Bearing

Check items below. If necessary, replace them with new ones.

lDamage and rough rotation of bearing.

ASSEMBLY

Paying attention to following work, assemble in reverse order of disassembly.

CAUTION:

lBe careful with orientation of insert spring.

Assembly and Disassembly (RS6F51A)ECS004UV

DISASSEMBLY

1. Remove reverse idler gear adjusting shim.

2. Remove reverse idler gear (rear), reverse coupling sleeve and insert spring simultaneously.

3. Remove reverse idler gear needle bearing.

4. Remove thrust needle bearing.

5. Remove reverse baulk ring.

6. Remove reverse idler gear (front).

7. Remove reverse idler gear needle bearing.

8. Remove thrust needle bearing.

9. Pull off locking pin from reverse idler shaft.

INSPECTION AFTER DISASSEMBLY

Reverse Idler Shaft and Gears

Check items below. If necessary, replace them with new ones.

lDamage, peeling, dent, uneven wear, bending, and other non-

standard conditions of the shaft.

lExcessive wear, damage, peeling, and other non-standard con-

ditions of the gears.Clearance

Standard : 0.95 - 1.4 mm (0.0374 - 0.055 in)

Limit value : 0.7 mm (0.028 in)

SMT140

SCIA0954E

SCIA0953E