engine NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2159 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CYLINDER BLOCK

EM-189

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

DISASSEMBLY

1. Remove engine assembly from the vehicle, th NISSAN X-TRAIL 2003 Electronic Repair Manual CYLINDER BLOCK

EM-189

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

DISASSEMBLY

1. Remove engine assembly from the vehicle, th](/img/5/57402/w960_57402-2158.png)

CYLINDER BLOCK

EM-189

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

DISASSEMBLY

1. Remove engine assembly from the vehicle, then separate engine and transaxle. Refer toEM-184,

"ENGINE ASSEMBLY".

2. Remove clutch cover and disk. Refer toCL-15, "

CLUTCH DISC,

CLUTCH COVER AND FLYWHEEL".

3. If they need to be replaced, replace pilot bushing.

lUsing pilot bushing puller, remove the bushing from rear edge

of crankshaft.

4. Install engine to engine stand as follows.

a. Remove flywheel.

b. Secure ring gear with ring gear stopper, then loosen mounting

bolts with TORX bit (size: Q6T55 E9, Commercial Service Tools)

and remove them. As an alternative method hold the crankshaft

pulley with a pulley holder (SST) to remove the flywheel.

CAUTION:

Do not disassemble flywheel.

c. Install engine sub-attachment to the rear side of cylinder block.

lAlign knock pins on cylinder block with pin holes on attach-

ment to install.

NOTE:

Installation bolts are part of engine sub-attachment.

d. Install engine attachment.

NOTE:

Use commercially available M12 (0.47 in) mounting bolts and

nuts (4 sets) with strength grade of 9T (minimum).

1. Rear oil seal retainer 2. Oil pressure switch 3. Coppet washer

4. Oil jet relief valve 5. Cylinder block 6. Top ring

7. Second ring 8. Oil ring 9. Oil jet

10. Piston pin 11. Snap ring 12. Piston

13. Main bearing 14. Thrust bearing 15. Connecting rod

16. Key 17. Connecting rod bearing 18. Connecting rod cap

19. Connecting rod nut 20. Main bearing 21. Crankshaft

22. Main bearing cap 23. Pilot bush 24. Flywheel

25. Drain plug 26. Rear oil seal

SEM500G

SBIA0199E

JEM192G

Page 2160 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EM-190

[YD22DDTi]

CYLINDER BLOCK

e. Hoist engine and install it to the engine stand.

NOTE:

It is possible to set engine sub-attachment and engine attach-

ment to engine stand at first, then install en NISSAN X-TRAIL 2003 Electronic Repair Manual EM-190

[YD22DDTi]

CYLINDER BLOCK

e. Hoist engine and install it to the engine stand.

NOTE:

It is possible to set engine sub-attachment and engine attach-

ment to engine stand at first, then install en](/img/5/57402/w960_57402-2159.png)

EM-190

[YD22DDTi]

CYLINDER BLOCK

e. Hoist engine and install it to the engine stand.

NOTE:

It is possible to set engine sub-attachment and engine attach-

ment to engine stand at first, then install engine later.

lCommercial engine stand can be used.

NOTE:

The figure shows an example of general-purpose engine stand

that can hold mating surface of transmission with drive plate and

rear plate removed.

5. Drain engine oil and coolant from inside engine.

6. Remove the following parts and related parts. (Only major parts are listed.)

lIntake manifold collector and intake manifold (Refer toEM-115, "Removal and Installation".)

lExhaust manifold (Refer toEM-119, "Removal and Installation".)

lRocker cover (Refer toEM-147, "Removal and Installation").

lInjection tube and fuel injector (Refer toEM-135, "Removal and Installation".)

lOil pan and oil strainer (Refer toEM-125, "Removal and Installation".)

lWater pump (Refer toCO-40, "Removal and Installation".)

lThermostat and water piping (Refer toCO-42, "Removal and Installation".)

lVacuum pump and vacuum pipe (Refer toEM-131, "Removal and Installation".)

lSecondary timing chain (Refer toEM-158, "Removal and Installation")

lPrimary timing chain (Refer toEM-163, "Removal and Installation".)

lElectronic control fuel supply pump (Refer toEM-138, "Removal and Installation".)

lCamshaft (Refer toEM-149, "Removal and Installation".)

lCylinder head (Refer toEM-174, "Removal and Installation".)

lOil cooler (Refer toLU-25, "Removal and Installation".)

lAccessory, accessory bracket and mount brackets

7. Remove fuel supply pump bracket.

8. Remove rear oil seal retainer.

JEM193G

PBIC0085E

Page 2163 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CYLINDER BLOCK

EM-193

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

ASSEMBLY

1. Blow air sufficiently to inside coolant passage, oil passage,

crankcase and cylinder bore to remove foreign matter.

2. Install oi NISSAN X-TRAIL 2003 Electronic Repair Manual CYLINDER BLOCK

EM-193

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

ASSEMBLY

1. Blow air sufficiently to inside coolant passage, oil passage,

crankcase and cylinder bore to remove foreign matter.

2. Install oi](/img/5/57402/w960_57402-2162.png)

CYLINDER BLOCK

EM-193

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

ASSEMBLY

1. Blow air sufficiently to inside coolant passage, oil passage,

crankcase and cylinder bore to remove foreign matter.

2. Install oil jet relief valve.

3. Install oil jet.

lAlign knock pin on back of oil jet with hole on block when

installing oil jet.

4. Install main bearings and thrust bearings.

a. Remove contamination, dust and oil from bearing mounting

positions on cylinder block and main bearing caps.

b. Install thrust bearings on both sides of No. 3 housing on cylinder

block.

lInstall thrust bearings with oil groove facing to crankshaft arm

(outside).

c. Being careful with the direction, install main bearings.

lInstall main bearings with the oil holes and grooves onto the

cylinder block side, and those without oil holes and grooves

onto the main cap side.

lWhile installing bearings, apply engine oil to bearing surfaces

(inside). Do not apply oil to rear surfaces, but clean them

completely.

lAlign stopper notches on bearings to install them.

lCheck that the oil holes on the cylinder block body are mated

with the oil hole positions on the bearings.

5. Install crankshaft to cylinder block.

lMake sure crankshaft rotates smoothly by hand.

6. Install main bearing caps.

lIdentify main bearing caps by the punched mark. Install cor-

rectly matching the journal No. on the bearing cap and the

journal with the front mark facing forward.

lMain bearing caps are commonly processed with the cylinder

block. Therefore, caps and cylinder block should be replaced

as a set.

7. Check the main bearing cap bolts for deformation.

Refer toEM-207, "

MAIN BEARING CAP BOLT DEFORMA-

TION".

PBIC0389E

JEM224G

JEM213G

JEM225G

Page 2164 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EM-194

[YD22DDTi]

CYLINDER BLOCK

8. Tighten the main bearing cap bolts according to the following

procedure:

a. Apply engine oil to the threaded part and seat surface of each

bolt.

b. Tighten to 25 to NISSAN X-TRAIL 2003 Electronic Repair Manual EM-194

[YD22DDTi]

CYLINDER BLOCK

8. Tighten the main bearing cap bolts according to the following

procedure:

a. Apply engine oil to the threaded part and seat surface of each

bolt.

b. Tighten to 25 to](/img/5/57402/w960_57402-2163.png)

EM-194

[YD22DDTi]

CYLINDER BLOCK

8. Tighten the main bearing cap bolts according to the following

procedure:

a. Apply engine oil to the threaded part and seat surface of each

bolt.

b. Tighten to 25 to 30 N·m (2.5 to 3.1 kg-m, 18 to 22 ft-lb) in the

numerical order shown in the figure.

c. Put alignment marks (with paint) on each bolt and the main

bearing cap, all in the same direction. (When using a protractor)

d. Then, tighten 90°to 95°[target: 90°].

lAlways use either an angle wrench (SST) or protractor

during angular tightening. Avoid tightening based on

visual checks alone.

lAfter tightening bolts to specified torque, make sure that

crankshaft rotates smoothly.

lCheck crankshaft end side clearance. Refer toEM-200,

"CRANKSHAFT SIDE CLEARANCE".

9. Check the outer diameter of connecting rod bolts. Refer toEM-

207, "CONNECTING ROD BOLT DEFORMATION".

10. Install pistons to connecting rod.

a. Using long nose pliers, install snap rings to grooves on piston rear side.

lFit snap rings correctly into grooves.

b. Install pistons to connecting rods.

lUsing industrial dryer, heat pistons up to approx. 60 to 70°C(140to158°F) until piston pin can be

pressed down by finger touch. Then insert piston pins into piston and connecting rod from front side of

piston toward rear.

lAssemble piston and connecting rod with front mark of piston

crown and cylinder No. stamped on connecting rod being

positioned as shown in the figure.

c. Install snap rings to front side of pistons.

lRefertoabovestepaforprecautiononsnapringinstallation.

lAfter installation, check connecting rods for smooth move-

ment.

11. Use piston ring expander to install piston rings.

CAUTION:

When installing, prevent piston from being damaged.

lInstall top ring and second ring with stamped surfaces facing

upward.

lInstall rings so that three closed gap position 120°apart one

another.

lClosed gaps do not need to face in a specific directions, as long as each are positioned 120°apart.

JEM200G

JEM226G

JEM227G

Identification stamp:

To p r i n g : A E

Second ring : AE2

JEM228G

Page 2165 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CYLINDER BLOCK

EM-195

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

12. Install connecting rod bearings to connecting rods and caps.

lWhile installing connecting rod bearings, apply engine oil to

bearing surfa NISSAN X-TRAIL 2003 Electronic Repair Manual CYLINDER BLOCK

EM-195

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

12. Install connecting rod bearings to connecting rods and caps.

lWhile installing connecting rod bearings, apply engine oil to

bearing surfa](/img/5/57402/w960_57402-2164.png)

CYLINDER BLOCK

EM-195

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

12. Install connecting rod bearings to connecting rods and caps.

lWhile installing connecting rod bearings, apply engine oil to

bearing surfaces (inside). Do not apply oil to rear surfaces,

but clean them completely.

lAlign stoppers on connecting rod bearings with connecting

rod stopper notches to install connecting rod bearings.

13. Install piston and connecting rod assembly to crankshaft.

lMove crankshaft pin to be assembled to BDC.

lAlign cylinder position with cylinder No. on connecting rod to

install piston and connecting rod assembly.

lUsing piston ring compressor, install piston and connecting

rod assembly with front mark on piston crown facing toward

the front side of engine.

CAUTION:

When installing piston and connecting rod assembly, pre-

vent the big end of connecting rod from interfering with oil

jet.

14. Install connecting rod caps and mounting nuts.

lAlign cylinder No. stamped on connecting rod with that on cap

to install connecting rod cap.

lMake sure that the front mark on connecting rod cap faces

towards the front of the engine.

15. Tighten connecting rod nuts according to the following proce-

dure:

a. Apply engine oil on bolt threads and seat surface of nuts.

b. Tighten to 29 to 30 N·m (2.9 to 3.1 kg-m, 21 to 22 ft-lb).

c. Loosen completely to 0 N·m (0 kg-m, 0 in-lb).

d. Tighten to 19 to 20 N·m (1.9 to 2.1 kg-m, 14 to 15 ft-lb).

e. Tighten 120°to 125°[target: 120°]. (angular tightening)

lAlways use either an angle wrench (SST) or protractor

during angular tightening. Avoid tightening based on

visual checks alone.

lAfter tightening nuts, check that crankshaft rotates smoothly.

JEM229G

JEM230G

JEM227G

JEM231G

Page 2166 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EM-196

[YD22DDTi]

CYLINDER BLOCK

lCheck connecting rod side clearance. Refer toEM-200,

"CONNECTING ROD SIDE CLEARANCE".

16. Force fit rear oil seal into rear oil seal retainer.

lUsing a drift [105 mm NISSAN X-TRAIL 2003 Electronic Repair Manual EM-196

[YD22DDTi]

CYLINDER BLOCK

lCheck connecting rod side clearance. Refer toEM-200,

"CONNECTING ROD SIDE CLEARANCE".

16. Force fit rear oil seal into rear oil seal retainer.

lUsing a drift [105 mm](/img/5/57402/w960_57402-2165.png)

EM-196

[YD22DDTi]

CYLINDER BLOCK

lCheck connecting rod side clearance. Refer toEM-200,

"CONNECTING ROD SIDE CLEARANCE".

16. Force fit rear oil seal into rear oil seal retainer.

lUsing a drift [105 mm (4.13 in) dia.], force fit so that the

dimension is as specified in the figure.

lAvoid inclined fitting. Force fit perpendicularly.

17. Install rear oil seal and retainer assembly.

lApply a continuous bead of liquid gasket to rear oil seal and

retainer assembly as shown in the figure.

18. Press fit pilot bushing into flywheel.

lUsing drift with outer diameter of 19 mm (0.75 in), press fit

pilot bushing until it stops.

19. Install fuel supplypump bracket.

lAlign the bracket with the dowel pins on the block to install.

lThe two bolts used for dowel pins have a longer shanks than

the other two.

20. Install parts to the engine in the reverse order of disassembly.

21. Remove engine from engine stand in the reverse order of

assembly.

22. Install flywheel.

lHolding ring gear with ring stopper (SST), tighten securing

bolts with TORX bit (size: Q6T55 E9, Commercial Service

Tool).

lTighten bolts uniformly in a crisscross manner.

JEM232G

JEM233G

JEM234G

SBIA0200E

Page 2180 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EM-210

[YD22DDTi]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Standard and LimitEBS00BPO

GENERAL SPECIFICATIONS

INTAKE MANIFOLD AND EXHAUST MANIFOLD

Unit: mm NISSAN X-TRAIL 2003 Electronic Repair Manual EM-210

[YD22DDTi]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Standard and LimitEBS00BPO

GENERAL SPECIFICATIONS

INTAKE MANIFOLD AND EXHAUST MANIFOLD

Unit: mm](/img/5/57402/w960_57402-2179.png)

EM-210

[YD22DDTi]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Standard and LimitEBS00BPO

GENERAL SPECIFICATIONS

INTAKE MANIFOLD AND EXHAUST MANIFOLD

Unit: mm (in)

DRIVE BELTS

Belt Deflection:

Unit: mm (in)

*: When engine is cold.Cylinder arrangementIn-line 4

Displacement

Unit: cm

3(cu in)2,184 (133.27)

Bore and stroke Unit: mm (in) 86 x 94 (3.39 x 3.70)

Valve arrangementDOHC

Firing order1-3-4-2

Number of piston ringsCompression 2

Oil 1

Number of main bearings5

Compression ratio16.0

Compression pressure

Unit:kPa(bar,kg/cm

2,psi)/200rpmStandard 2,893 (28.9, 29.5, 419)

Minimum 2,452 (24.5, 25.0, 356)

Differential limit between cylinders 490 (4.9, 5.0, 71)

Valve timing

Unit: degree

abc de f

224 212 2 30 -2 46

EM120

Item Limit

Surface distortionIntake manifold 0.1 (0.004)

Exhaust manifold 0.3 (0.012)

Applied beltBelt deflection with 98 N (10 kg, 22 lb) force applied*

New Adjusted Limit for re-adjusting

Air conditioner compressor

belt4-5

(0.16 - 0.20)6-7

(0.24 - 0.28)8.5 (0.335)

Alternator & water pump

belt9.0 - 10.5

(0.354 - 0.413)11 . 0 - 1 2 . 5

(0.433 - 0.492)16.5 (0.650)

Page 2190 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EM-220

[YD22DDTi]

SERVICE DATA AND SPECIFICATIONS (SDS)

M8 bolt 16.0- 19.0 (1.6 - 1.9, 12 - 14)

Injection tube Nozzle side 21.6 - 24.5 (2.2 - 2.5, 16 - 18)

Pump side 26.5 - 29.4 (2.7 - 3.0, 20 - 21)

N NISSAN X-TRAIL 2003 Electronic Repair Manual EM-220

[YD22DDTi]

SERVICE DATA AND SPECIFICATIONS (SDS)

M8 bolt 16.0- 19.0 (1.6 - 1.9, 12 - 14)

Injection tube Nozzle side 21.6 - 24.5 (2.2 - 2.5, 16 - 18)

Pump side 26.5 - 29.4 (2.7 - 3.0, 20 - 21)

N](/img/5/57402/w960_57402-2189.png)

EM-220

[YD22DDTi]

SERVICE DATA AND SPECIFICATIONS (SDS)

M8 bolt 16.0- 19.0 (1.6 - 1.9, 12 - 14)

Injection tube Nozzle side 21.6 - 24.5 (2.2 - 2.5, 16 - 18)

Pump side 26.5 - 29.4 (2.7 - 3.0, 20 - 21)

Nozzle support25.1 - 28.0 (2.6 - 2.8, 19 - 20)

Spill tube Nozzle side 14.7 - 16.7 (1.5 - 1.7, 11 - 12)

Cylinder head side 16.7 - 20.6 (1.7 - 2.1, 13 - 15)

Common rail51.0 - 64.0 (5.2 - 6.5., 38 - 47)

Fuel supply pump46.0 - 56.0 (4.57 - 5.7, 37 - 41)

Fuel supply pump sprocket 37.0 - 41.0 (3.8 - 4.2, 28 - 30)

Fuel supply pump rear bracket 27.0 - 37.0 (2.8 - 3.8, 20 - 27)

Front chain case

6.9 - 8.8 ( 0.7 - 0.9, 61 - 78)*

2

Chain tensioner

8.5 - 10.7 (0.86 - 1.1, 75 - 95)*2

Tensior guide21.0 - 26.0 (2.1 - 2.7, 16 - 19)

Slack guide21.0 - 26.0 (2.1 - 2.7, 16 - 19)

Camshaft sprocket138- 147 (14.0 - 15.0, 102 - 108)

Fuel supply pump sprocket 38.0 -41.0 (3.8 - 4.2, 28 - 30)

Oil pump12 - 13 (1.3 - 1.4, 9 - 10)

Power steering pump51.0 - 56.0 (5.2 - 5.8, 38 - 41)

Rear chain case12.0 - 13.0 (1.2 - 1.4, 19 - 10)

Engine coolant temperature sensor 12.0- 15.0 (1.2 - 1.6, 9- 11)

*1 Cylinder head 1) 29 - 38 (2.9 - 3.9, 21 - 28)

2) 180°to185°

3) 0 (0, 0)

4) 35 to 44 (3.5 - 4.5, 26 - 32)

5) 90°to 95°(angle tightening)

6) 90°to 95°(angle tightening)

Water outlet21 - 28 (2.1 - 2.9, 16 - 20)

Glow plug18.0 - 2.0 (1.8 - 2.2, 13 - 15)

*1 Flywheel103 - 112 (10.5 - 115, 76 - 83)

Oil pressure switch13.0 - 17.0 (1.25 - 1.75, 9 - 12)

Oil jet6.1 - 10.7(0.62 - 1.1, 54 - 95)

Oil jet relief valve40 - 58 (4.0 - 6.0, 29 - 43)

Rear oil seal retainer12.0 - 13.0 (1.2 - 1.4, 9 - 10)

Page 2191 of 3066

EX-1

EXHAUST SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

EX

EXHAUST SYSTEM

EXHAUST SYSTEM ................................................... 2

Checking Exhaust System ....................................... 2

Removal and Installation .......................................... 2

QR20DE ................................................................ 2

YD22DDTI ............................................................. 3RREMOVAL ........................................................... 3

INSTALLATION ..................................................... 3

Inspection After Installation ...................................... 4

SERVICE DATA AND SPECIFICATIONS (SDS) ........ 5

Tightening Torque ..................................................... 5

Page 2192 of 3066

EX-2

EXHAUST SYSTEM

EXHAUST SYSTEM

PFP:20100

Checking Exhaust SystemEBS00AZ6

Check exhaust pipes, muffler and mounting for improper attachment,

leaks, cracks, damage or deterioration.

Removal and InstallationEBS003DN

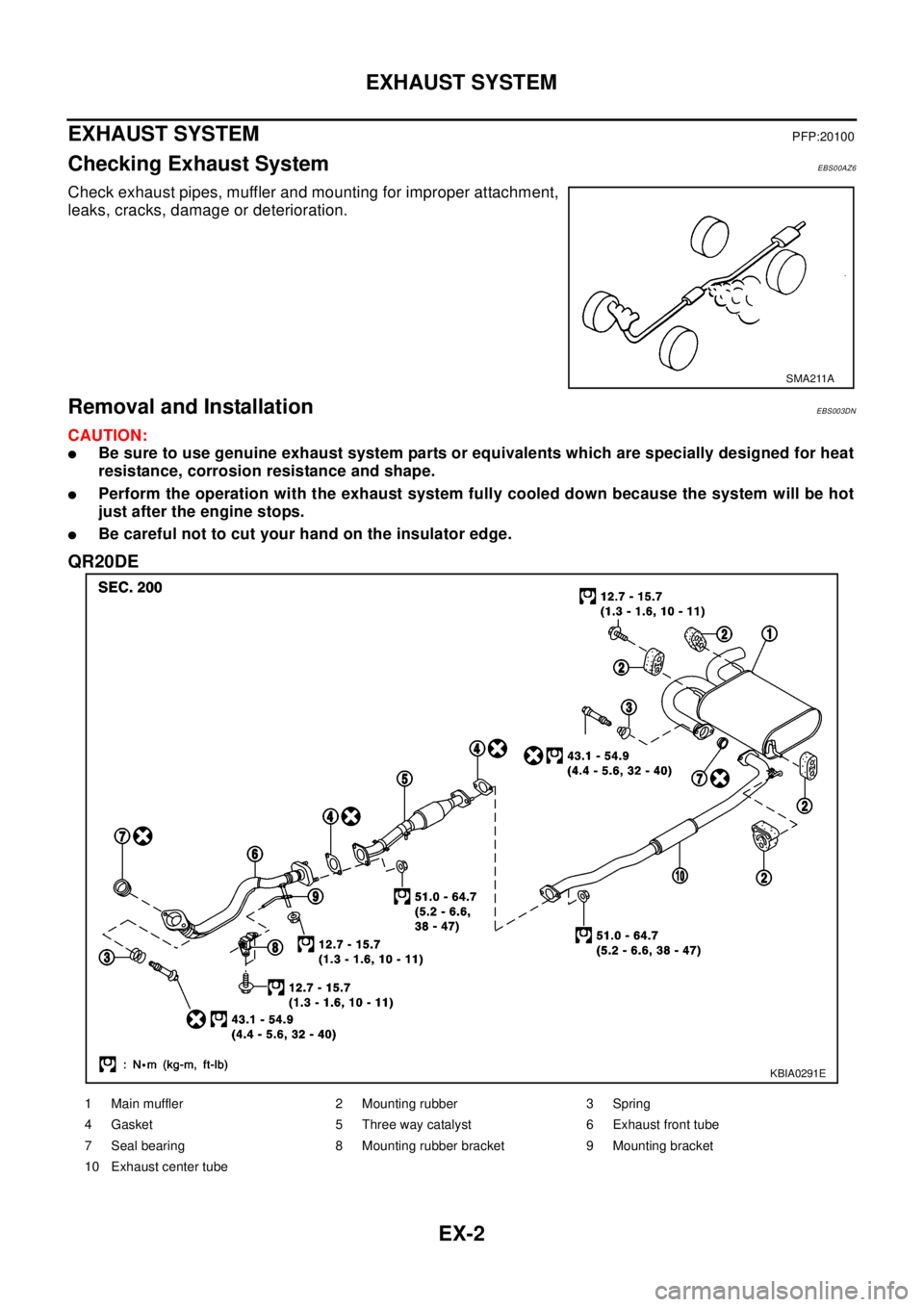

CAUTION:

lBe sure to use genuine exhaust system parts or equivalents which are specially designed for heat

resistance, corrosion resistance and shape.

lPerform the operation with the exhaust system fully cooled down because the system will be hot

just after the engine stops.

lBe careful not to cut your hand on the insulator edge.

QR20DE

SMA211A

KBIA0291E

1 Main muffler 2 Mounting rubber 3 Spring

4 Gasket 5 Three way catalyst 6 Exhaust front tube

7 Seal bearing 8 Mounting rubber bracket 9 Mounting bracket

10 Exhaust center tube