OPEL FRONTERA 1998 Workshop Manual

Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5801 of 6000

7A–20 AUTOMATIC TRANSMISSION (AW30-40LE)

Once the test vehicle has been identified an “Application

(Power train) Menu" screen appears. Please select the

appropriate application.

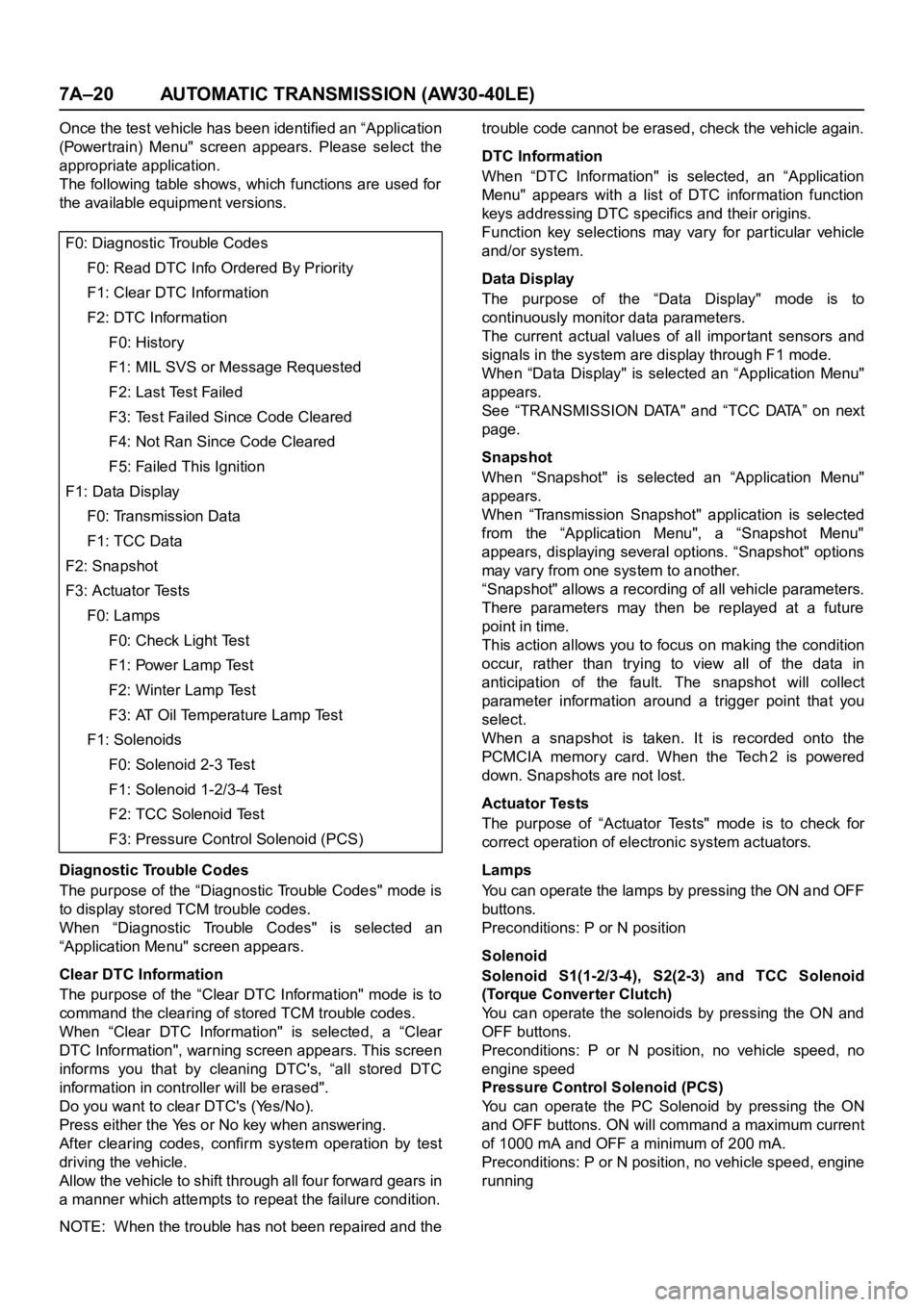

The following table shows, which functions are used for

the available equipment versions.

Diagnostic Trouble Codes

The purpose of the “Diagnostic Trouble Codes" mode is

to display stored TCM trouble codes.

When “Diagnostic Trouble Codes" is selected an

“Application Menu" screen appears.

Clear DTC Information

The purpose of the “Clear DTC Information" mode is to

command the clearing of stored TCM trouble codes.

When “Clear DTC Information" is selected, a “Clear

DTC Information", warning screen appears. This screen

informs you that by cleaning DTC's, “all stored DTC

information in controller will be erased".

Do you want to clear DTC's (Yes/No).

Press either the Yes or No key when answering.

After clearing codes, confirm system operation by test

driving the vehicle.

Allow the vehicle to shift through all four forward gears in

a manner which attempts to repeat the failure condition.

NOTE: When the trouble has not been repaired and thetrouble code cannot be erased, check the vehicle again.

DTC Information

When “DTC Information" is selected, an “Application

Menu" appears with a list of DTC information function

keys addressing DTC specifics and their origins.

Function key selections may vary for particular vehicle

and/or system.

Data Display

The purpose of the “Data Display" mode is to

continuously monitor data parameters.

The current actual values of all impor tant sensors and

signals in the system are display through F1 mode.

When “Data Display" is selected an “Application Menu"

appears.

See “TRANSMISSION DATA" and “TCC DATA” on next

page.

Snapshot

When “Snapshot" is selected an “Application Menu"

appears.

When “Transmission Snapshot" application is selected

from the “Application Menu", a “Snapshot Menu"

appears, displaying several options. “Snapshot" options

may vary from one system to another.

“Snapshot" allows a recording of all vehicle parameters.

There parameters may then be replayed at a future

point in time.

This action allows you to focus on making the condition

occur, rather than trying to view all of the data in

anticipation of the fault. The snapshot will collect

parameter information around a trigger point that you

select.

When a snapshot is taken. It is recorded onto the

PCMCIA memory card. When the Tech2 is powered

down. Snapshots are not lost.

Actuator Tests

The purpose of “Actuator Tests" mode is to check for

correct operation of electronic system actuators.

Lamps

You can operate the lamps by pressing the ON and OFF

buttons.

Preconditions: P or N position

Solenoid

Solenoid S1(1-2/3-4), S2(2-3) and TCC Solenoid

(Torque Converter Clutch)

You can operate the solenoids by pressing the ON and

OFF buttons.

Preconditions: P or N position, no vehicle speed, no

engine speed

Pressure Control Solenoid (PCS)

You can operate the PC Solenoid by pressing the ON

and OFF buttons. ON will command a maximum current

of 1000 mA and OFF a minimum of 200 mA.

Preconditions: P or N position, no vehicle speed, engine

running F0: Diagnostic Trouble Codes

F0: Read DTC Info Ordered By Priority

F1: Clear DTC Information

F2: DTC Information

F0: History

F1: MIL SVS or Message Requested

F2: Last Test Failed

F3: Test Failed Since Code Cleared

F4: Not Ran Since Code Cleared

F5: Failed This Ignition

F1: Data Display

F0: Transmission Data

F1: TCC Data

F2: Snapshot

F3: Actuator Tests

F0: Lamps

F0: Check Light Test

F1: Power Lamp Test

F2: Winter Lamp Test

F3: AT Oil Temperature Lamp Test

F1: Solenoids

F0: Solenoid 2-3 Test

F1: Solenoid 1-2/3-4 Test

F2: TCC Solenoid Test

F3: Pressure Control Solenoid (PCS)

Page 5802 of 6000

AUTOMATIC TRANSMISSION (AW30-40LE) 7A–21

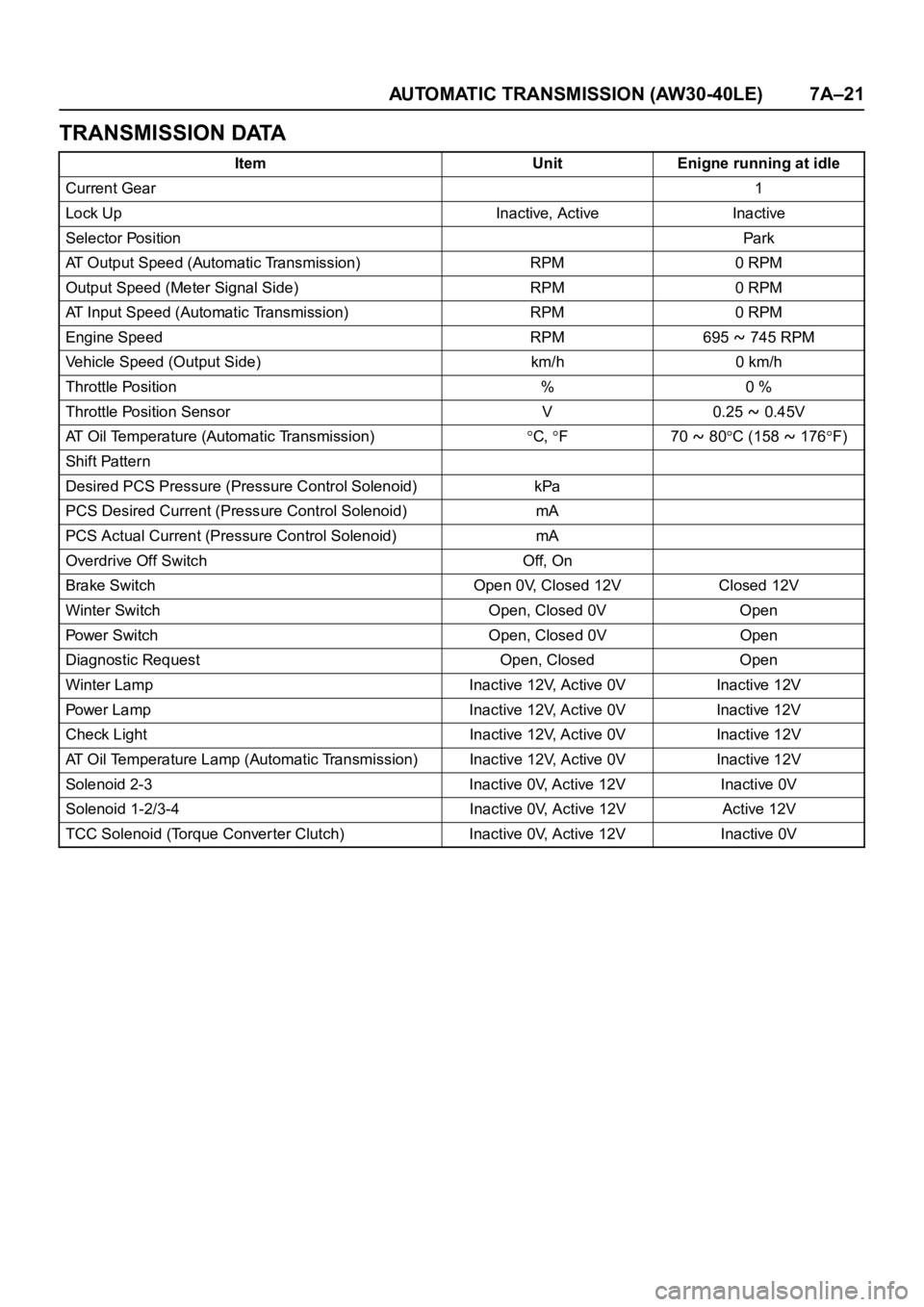

TRANSMISSION DATA

Item Unit Enigne running at idle

Current Gear1

Lock Up Inactive, Active Inactive

Selector PositionPar k

AT Output Speed (Automatic Transmission) RPM 0 RPM

Output Speed (Meter Signal Side) RPM 0 RPM

AT Input Speed (Automatic Transmission) RPM 0 RPM

Engine Speed RPM 695

745 RPM

Vehicle Speed (Output Side) km/h 0 km/h

Throttle Position % 0 %

Throttle Position Sensor V 0.25

0.45V

AT Oil Temperature (Automatic Transmission)

C, F70 80C (158 176F)

Shift Pattern

Desired PCS Pressure (Pressure Control Solenoid) kPa

PCS Desired Current (Pressure Control Solenoid) mA

PCS Actual Current (Pressure Control Solenoid) mA

Overdrive Off Switch Off, On

Brake Switch Open 0V, Closed 12V Closed 12V

Winter Switch Open, Closed 0V Open

Power Switch Open, Closed 0V Open

Diagnostic Request Open, Closed Open

Winter Lamp Inactive 12V, Active 0V Inactive 12V

Power Lamp Inactive 12V, Active 0V Inactive 12V

Check Light Inactive 12V, Active 0V Inactive 12V

AT Oil Temperature Lamp (Automatic Transmission) Inactive 12V, Active 0V Inactive 12V

Solenoid 2-3 Inactive 0V, Active 12V Inactive 0V

Solenoid 1-2/3-4 Inactive 0V, Active 12V Active 12V

TCC Solenoid (Torque Conver ter Clutch) Inactive 0V, Active 12V Inactive 0V

Page 5803 of 6000

7A–22 AUTOMATIC TRANSMISSION (AW30-40LE)

TCC DATA

Item Unit Enigne running at idle

Current Gear1

Lock Up Inactive, Active Inactive

AT Output Speed (Automatic Transmission) RPM 0 RPM

Output Speed (Meter Signal Side) RPM 0 RPM

AT Input Speed (Automatic Transmission) RPM 0 RPM

Engine Speed RPM 695

745 RPM

Vehicle Speed (Output Side) km/h 0 km/h

Throttle Position % 0 %

Gear Ratio :1 2.804

AT Oil Temperature (Automatic Transmission)

C, F 70 80C (158 176F)

TCC Slip Speed RPM 695

745 RPM

TCC Solenoid Pressure Desired kPa 0 kPa

Desired TCC Solenoid Current mA 0 mA

Actual TCC Solenoid Current mA 0 mA

Page 5804 of 6000

AUTOMATIC TRANSMISSION (AW30-40LE) 7A–23

INTERMITTENT CONDITIONS

If the Tech2 displays a code as intermittent, or if after a

test drive a code does not reappear, the problem is most

likely a faulty electrical connection or loose wiring.

Terminals should always be the prime suspect.

Intermittent rarely occur in sophisticated electronic

components such as the Transmission Control Module

(TCM).

When an intermittent problem is encountered, check

suspect circuits for:

• Poor terminal to wire connection.

• Terminals not fully seated in the connector body

(backed out).

• Improperly formed or damaged terminals.

• Loose, dirty, or corroded ground connections.

HINT: Any time you have an intermittent in more than

one circuit, check whether the circuits share a

common ground connection.

• Pinched or damaged wires.

• Electro-Magnetic Interference (EMI)

HINT: Check that all wires are properly routed away

from spark plug wires, distributor wires, coil,

and generator. Also check for improperly

installed electrical options, such as lights, 2-

way radios, etc.

Use the F2: SNAPSHOT mode of the Tech2 to help

isolate the cause of an intermittent fault. The snapshot

mode will record information before and after the

problem occurs. Set the snapshot to "trigger" on the

suspect code (or codes) or, if you notice the repor ted

symptom during test drive, trigger the snapshot

manually.

After the snapshot has been triggered, command the

Tech2 to play back the flow of data recorded from each

of the various sensors. Signs of an intermittent fault in a

sensor circuit are a sudden unexplainable jump in data

values out of the normal range.

Page 5805 of 6000

7A–24 AUTOMATIC TRANSMISSION (AW30-40LE)

826RY00004

IDENTIFICATION OF TRANSMISSION

CONTROL MODULE (TCM)

ISUZU Part No: 8-97230-821-0

Page 5806 of 6000

AUTOMATIC TRANSMISSION (AW30-40LE) 7A–25

DIAGNOSTIC TROUBLE CODES (DTC) CHECK

DTC

NUMBERFLASHING

CODEDESCRIPTION

P0120 21 ANALOG THROTTLE SIGNAL FAILURE (VTH)

P0502 24 SPEED METER SENSOR FAILURE (SP1)

P0705 17 GEAR SELECTOR FAILURE (PRND2L)

P0710 16 OIL TEMPERATURE SENSOR FAILURE (OT2)

P0717 14 INPUT REVOLUTION SENSOR FAILURE (NC0)

P0722 11 OUTPUT REVOLUTION SENSOR FAILURE (SP2)

P0727 13 ENGINE REVOLUTION SIGNAL FAILURE (NE)

P0743 33 TORQUE CONVERTER CLUTCH CONTROL LOCK-UP (ON/OFF) SOLENOID

FA I L U R E ( S L )

P0748 35 PRESSURE CONTROL SOLENOID FAILURE (STH)

P0753 31 SOLENOID 1 FAILURE (S1)

P0758 32 SOLENOID 2 FAILURE (S2)

P1121 23 ANALOG THROTTLE SIGNAL FAILURE (VREF, VGND)

Page 5807 of 6000

7A–26 AUTOMATIC TRANSMISSION (AW30-40LE)

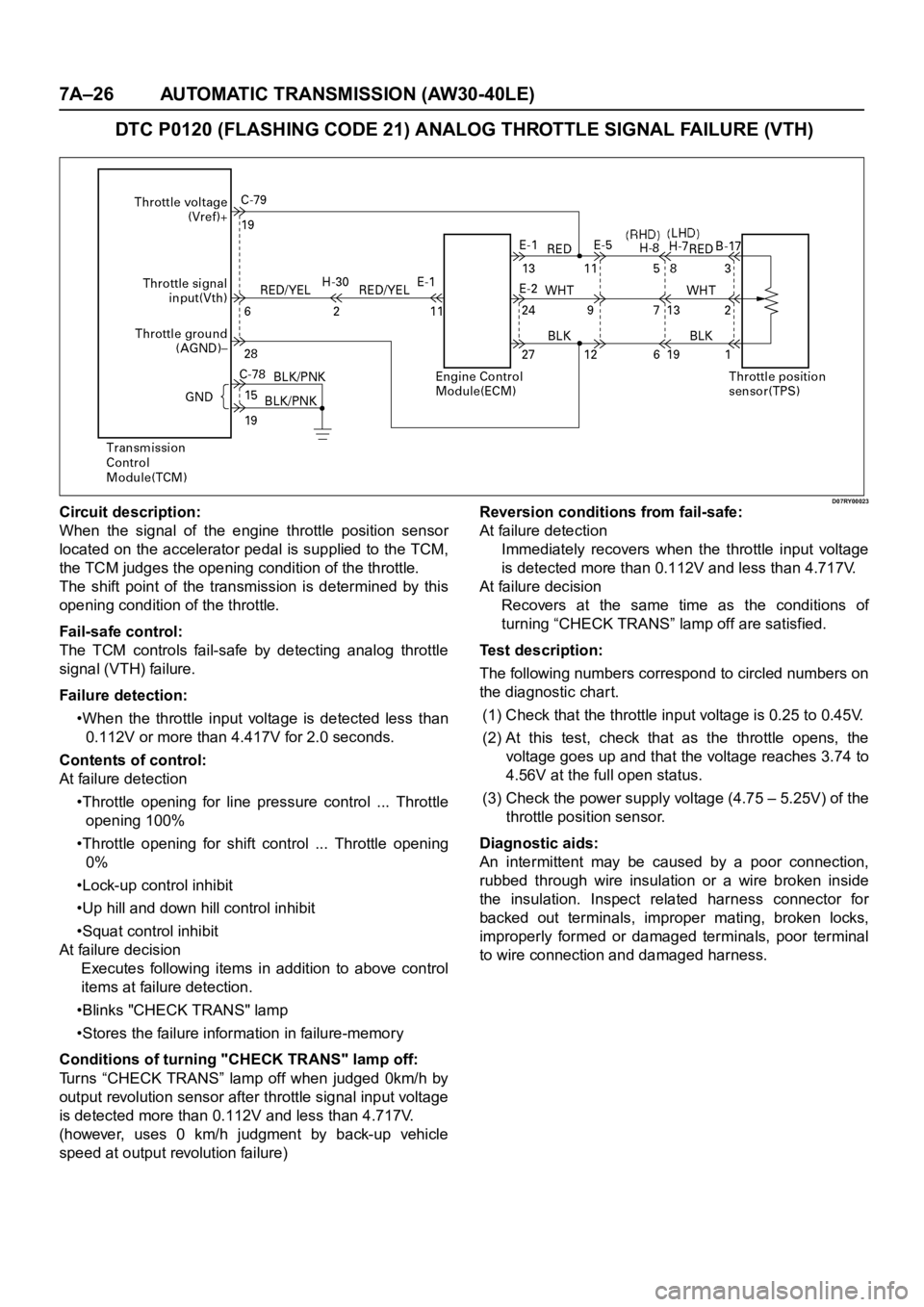

DTC P0120 (FLASHING CODE 21) ANALOG THROTTLE SIGNAL FAILURE (VTH)

D07RY00023Circuit description:

When the signal of the engine throttle position sensor

located on the accelerator pedal is supplied to the TCM,

the TCM judges the opening condition of the throttle.

The shift point of the transmission is determined by this

opening condition of the throttle.

Fail-safe control:

The TCM controls fail-safe by detecting analog throttle

signal (VTH) failure.

Failure detection:

•When the throttle input voltage is detected less than

0.112V or more than 4.417V for 2.0 seconds.

Contents of control:

At failure detection

•Throttle opening for line pressure control ... Throttle

opening 100%

•Throttle opening for shift control ... Throttle opening

0%

•Lock-up control inhibit

•Up hill and down hill control inhibit

•Squat control inhibit

At failure decision

Executes following items in addition to above control

items at failure detection.

•Blinks "CHECK TRANS" lamp

•Stores the failure information in failure-memory

Conditions of turning "CHECK TRANS" lamp off:

Turns “CHECK TRANS” lamp off when judged 0km/h by

output revolution sensor after throttle signal input voltage

is detected more than 0.112V and less than 4.717V.

(however, uses 0 km/h judgment by back-up vehicle

speed at output revolution failure)Reversion conditions from fail-safe:

At failure detection

Immediately recovers when the throttle input voltage

is detected more than 0.112V and less than 4.717V.

At failure decision

Recovers at the same time as the conditions of

turning “CHECK TRANS” lamp off are satisfied.

Test description:

The following numbers correspond to circled numbers on

the diagnostic char t.

(1) Check that the throttle input voltage is 0.25 to 0.45V.

(2)At this test, check that as the throttle opens, the

voltage goes up and that the voltage reaches 3.74 to

4.56V at the full open status.

(3) Check the power supply voltage (4.75 – 5.25V) of the

throttle position sensor.

Diagnostic aids:

An intermittent may be caused by a poor connection,

rubbed through wire insulation or a wire broken inside

the insulation. Inspect related harness connector for

backed out terminals, improper mating, broken locks,

improperly formed or damaged terminals, poor terminal

to wire connection and damaged harness.

Page 5808 of 6000

AUTOMATIC TRANSMISSION (AW30-40LE) 7A–27

DTC P0120 (FLASHING CODE 21) ANALOG THROTTLE SIGNAL FAILURE (VTH)

DTCP0120

Page 5809 of 6000

7A–28 AUTOMATIC TRANSMISSION (AW30-40LE)

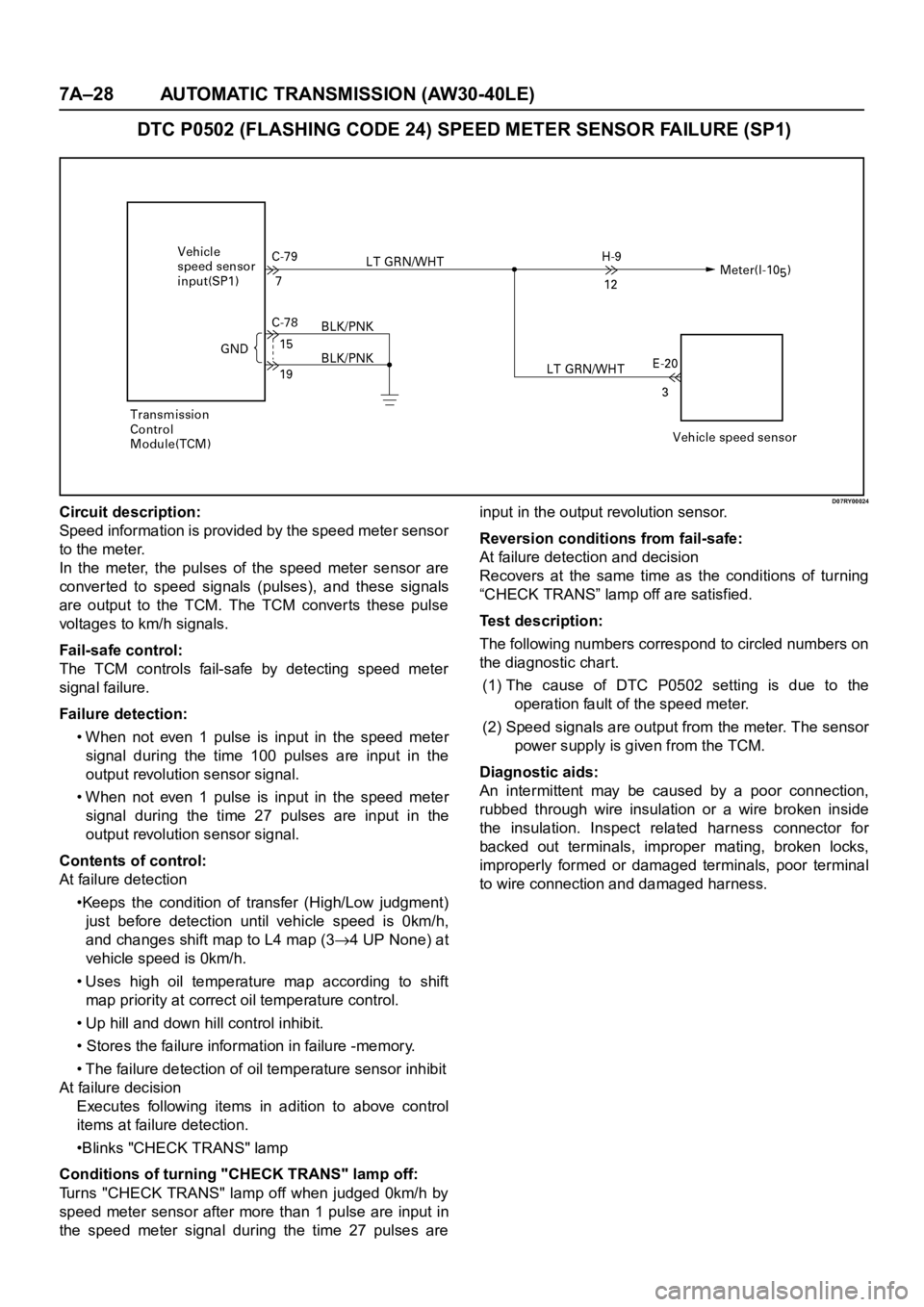

DTC P0502 (FLASHING CODE 24) SPEED METER SENSOR FAILURE (SP1)

D07RY00024Circuit description:

Speed information is provided by the speed meter sensor

to the meter.

In the meter, the pulses of the speed meter sensor are

converted to speed signals (pulses), and these signals

are output to the TCM. The TCM converts these pulse

voltages to km/h signals.

Fail-safe control:

The TCM controls fail-safe by detecting speed meter

signal failure.

Failure detection:

• When not even 1 pulse is input in the speed meter

signal during the time 100 pulses are input in the

output revolution sensor signal.

• When not even 1 pulse is input in the speed meter

signal during the time 27 pulses are input in the

output revolution sensor signal.

Contents of control:

At failure detection

•Keeps the condition of transfer (High/Low judgment)

just before detection until vehicle speed is 0km/h,

and changes shift map to L4 map (3

4 UP None) at

vehicle speed is 0km/h.

•Uses high oil temperature map according to shift

map priority at correct oil temperature control.

• Up hill and down hill control inhibit.

• Stores the failure information in failure -memory.

• The failure detection of oil temperature sensor inhibit

At failure decision

Executes following items in adition to above control

items at failure detection.

•Blinks "CHECK TRANS" lamp

Conditions of turning "CHECK TRANS" lamp off:

Turns "CHECK TRANS" lamp off when judged 0km/h by

speed meter sensor after more than 1 pulse are input in

the speed meter signal during the time 27 pulses areinput in the output revolution sensor.

Reversion conditions from fail-safe:

At failure detection and decision

Recovers at the same time as the conditions of turning

“CHECK TRANS” lamp off are satisfied.

Test description:

The following numbers correspond to circled numbers on

the diagnostic char t.

(1) The cause of DTC P0502 setting is due to the

operation fault of the speed meter.

(2) Speed signals are output from the meter. The sensor

power supply is given from the TCM.

Diagnostic aids:

An intermittent may be caused by a poor connection,

rubbed through wire insulation or a wire broken inside

the insulation. Inspect related harness connector for

backed out terminals, improper mating, broken locks,

improperly formed or damaged terminals, poor terminal

to wire connection and damaged harness.

Page 5810 of 6000

AUTOMATIC TRANSMISSION (AW30-40LE) 7A–29

DTC P0502 (FLASHING CODE 24) SPEED METER SENSOR FAILURE (SP1)

DTCP0502