OPEL FRONTERA 1998 Workshop Manual

FRONTERA 1998

OPEL

OPEL

https://www.carmanualsonline.info/img/37/57409/w960_57409-0.png

OPEL FRONTERA 1998 Workshop Manual

Trending: catalytic converter, height adjustment, length, fuse box, spare wheel, pairing phone, fuse chart

Page 5761 of 6000

7A–72

AUTOMATIC TRANSMISSION (4L30–E)

3–4 Accumulator Piston

Disassembled View

244RS005

Legend

(1) Snap Ring

(2) Cover(3) Spring

(4) Piston Assembly

Disassembly

1. Install the 5–8840–2277–1 (J–38559–A) cover

compressor on adapter case.

Compress piston cover then remove snap ring.

242RW009

2. Install the 5–8840–2403–0 (J–41096) cover remover

and 5–8840–2266–0 (J–38584) adapter to center

hole of cover.

Use the 5–8840–0019–0 and 5–8840–2000–0

(J–23907) slide hammer to remove cover.

3. Remove spring and piston assembly.

242RW010

Page 5762 of 6000

7A–73 AUTOMATIC TRANSMISSION (4L30–E)

Inspection And Repair

Visual Check:

If any damage, deformation or wear is found, replace the

damaged part.

Reassembly

1. Place the 5–8840–2264–0 (J–38553) piston fitter into

adaptor case and push the piston into position, using

suitable diameter tube.

Remove the piston fitter.

244RW005

2. Install spring and cover.

3. Install snap ring, using the 5–8840–2277–1

(J–38559–A) compressor tool.

Install snap ring in groove.

Remove the compressor tool.

244RW006

Page 5763 of 6000

7A–74

AUTOMATIC TRANSMISSION (4L30–E)

Reverse Clutch Piston And Center Support

Disassembled View

242RS006

Legend

(1) Retaining Ring

(2) Spring Seat

(3) Springs

(4) Piston Assembly

(5) Center Support

(6) Gasket(7) Transfer Plate

(8) Gasket

(9) Restrictor

(10) Retainer Plate

(11) Plug

(12) Spring

(13) Overrun Lock Out Valve

Page 5764 of 6000

7A–75 AUTOMATIC TRANSMISSION (4L30–E)

Disassembly

1. Install the 5–8840–0195–0 (J–23327) compressor

tool on spring seat, then compress the spring seat.

Remove retaining ring (1).

NOTE: Do not over–stress the springs and seat, as this

will cause damage to the spring seat.

Remove the compressor tool.

247RW006

2. Remove spring seat (2) and springs (3).

3. Remove piston assembly (4).

4. Remove 8 bolts from center support (5), then remove

center support (5) from adapter case.

5. Remove gasket transfer plate/outer support (6),

center support transfer plate (7), and gasket transfer

plate/adapter case (8).

6. Remove restrictor (9) from adapter case housing.

7. Remove retainer plate (10), plug (11), spring (12), and

overrun lock out valve (13) from center support (5).

Inspection And Repair

Visual Check:

If any damage, deformation or wear is found, replace the

damaged part.

Reassembly

1. Install overrun lock out valve (13) and spring (12) to

center support.

NOTE: Ensure correct assembly of valve. The spring

should be located over the long small diameter end.

2. Install plug (11) and retainer plate (10).

3. Place restrictor (9) in the lube overdrive channel in the

adapter case housing.

242RS005

4. Install gasket transfer plate/adapter case (8), center

support transfer plate (7), and gasket transfer

plate/center support (6).

5. Install center support (5) with 8 bolts.

Torque : 25 N

m (2.5 kgꞏm/18 lb ft)

6. Install piston assembly (4) into center support (5).

7. Install twenty four springs (3), spring seat (2), and

retaining ring (1).

Install the 5–8840–0195–0 (J–23327) compressor

and compress spring seat (2) and springs (3), then

seat snap ring (1) in groove.

Remove the tool.

Page 5765 of 6000

7A–76

AUTOMATIC TRANSMISSION (4L30–E)

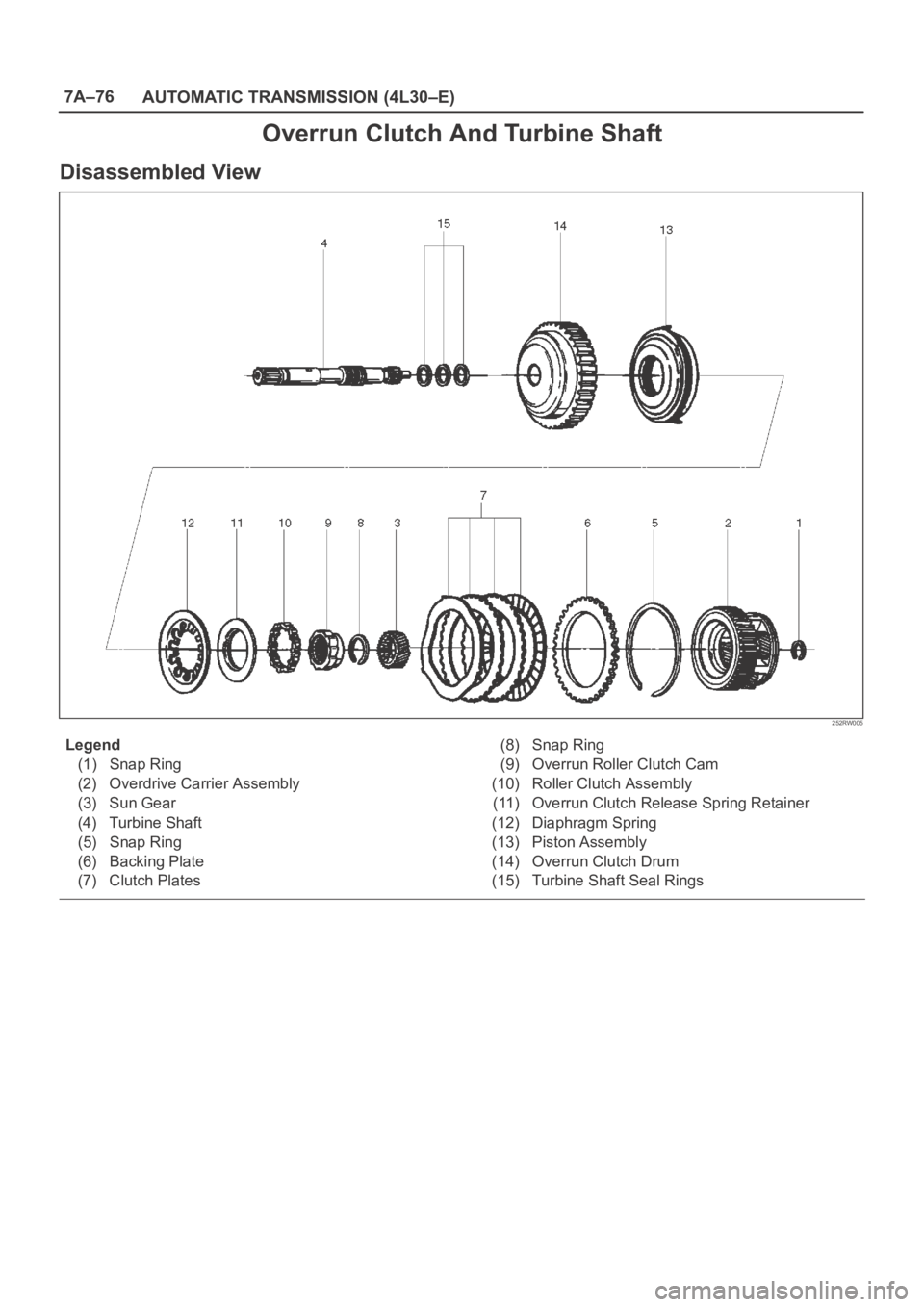

Overrun Clutch And Turbine Shaft

Disassembled View

252RW005

Legend

(1) Snap Ring

(2) Overdrive Carrier Assembly

(3) Sun Gear

(4) Turbine Shaft

(5) Snap Ring

(6) Backing Plate

(7) Clutch Plates(8) Snap Ring

(9) Overrun Roller Clutch Cam

(10) Roller Clutch Assembly

(11) Overrun Clutch Release Spring Retainer

(12) Diaphragm Spring

(13) Piston Assembly

(14) Overrun Clutch Drum

(15) Turbine Shaft Seal Rings

Page 5766 of 6000

7A–77 AUTOMATIC TRANSMISSION (4L30–E)

Disassembly

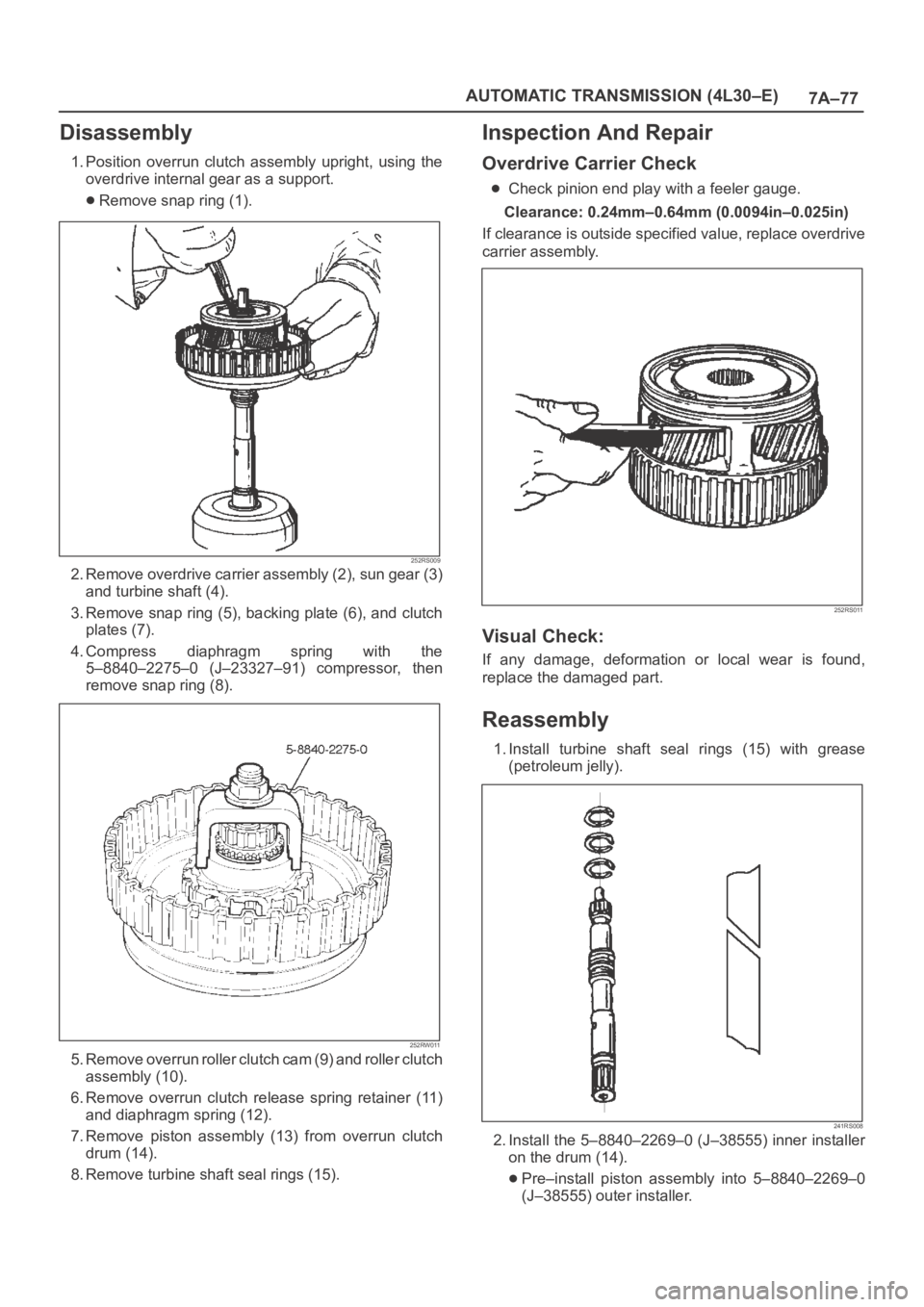

1. Position overrun clutch assembly upright, using the

overdrive internal gear as a support.

Remove snap ring (1).

252RS009

2. Remove overdrive carrier assembly (2), sun gear (3)

and turbine shaft (4).

3. Remove snap ring (5), backing plate (6), and clutch

plates (7).

4. Compress diaphragm spring with the

5–8840–2275–0 (J–23327–91) compressor, then

remove snap ring (8).

252RW011

5 . R e m o v e o v e r r u n r o l l e r c l u t c h c a m ( 9 ) a n d r o l l e r c l u t c h

assembly (10).

6. Remove overrun clutch release spring retainer (11)

and diaphragm spring (12).

7. Remove piston assembly (13) from overrun clutch

drum (14).

8. Remove turbine shaft seal rings (15).

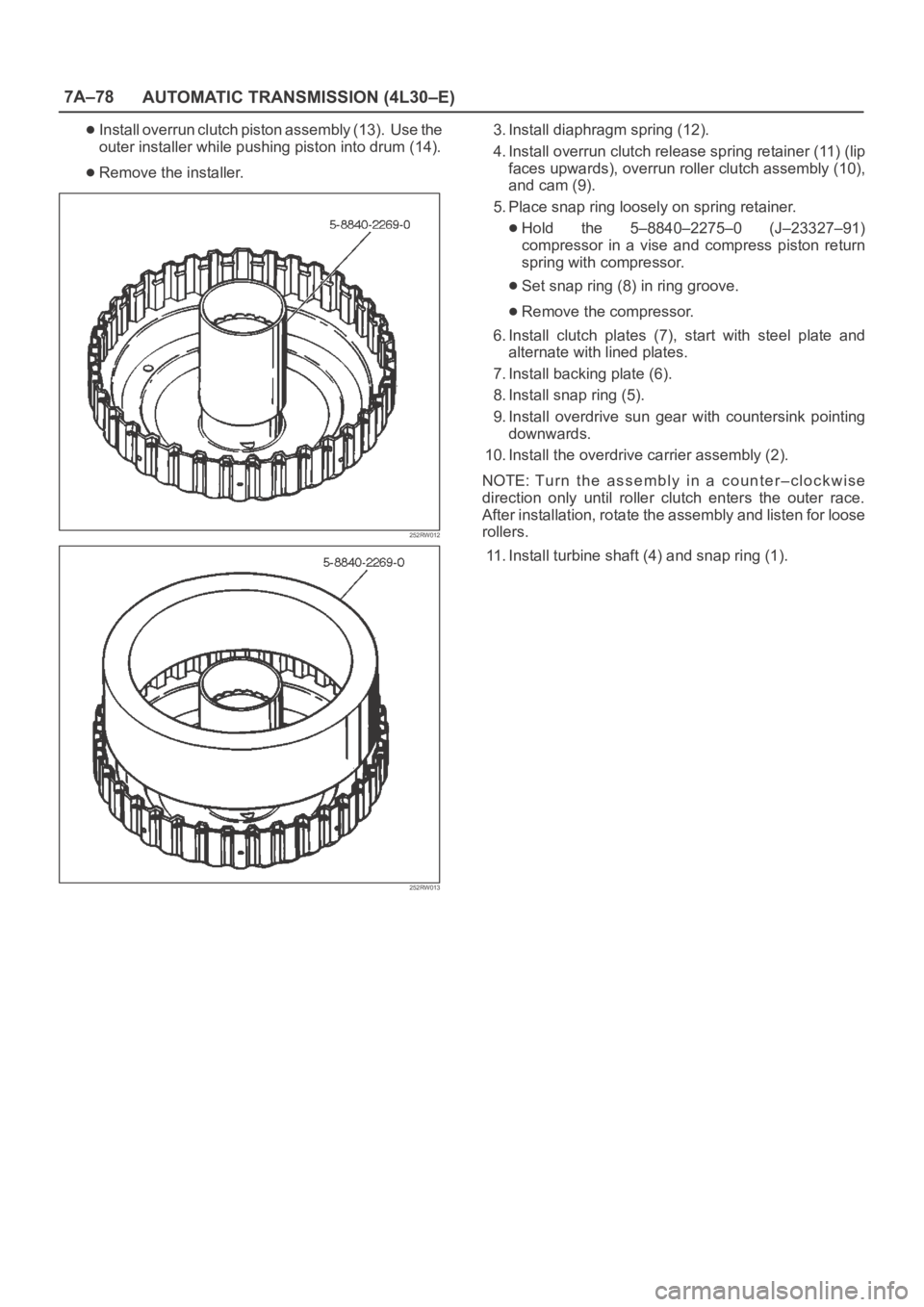

Inspection And Repair

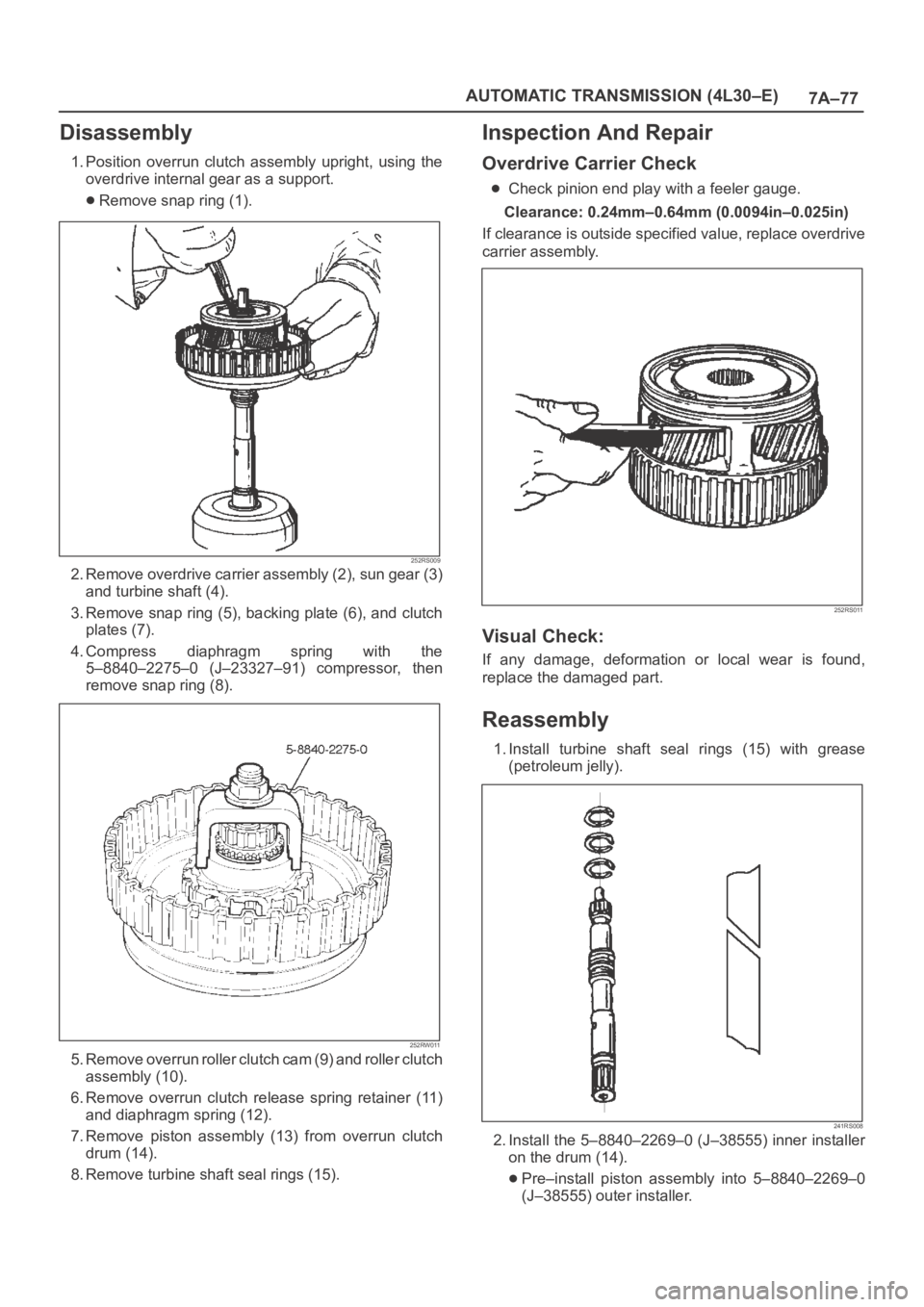

Overdrive Carrier Check

Check pinion end play with a feeler gauge.

Clearance: 0.24mm–0.64mm (0.0094in–0.025in)

If clearance is outside specified value, replace overdrive

carrier assembly.

252RS011

Visual Check:

If any damage, deformation or local wear is found,

replace the damaged part.

Reassembly

1. Install turbine shaft seal rings (15) with grease

(petroleum jelly).

241RS008

2. Install the 5–8840–2269–0 (J–38555) inner installer

on the drum (14).

Pre–install piston assembly into 5–8840–2269–0

(J–38555) outer installer.

Page 5767 of 6000

7A–78

AUTOMATIC TRANSMISSION (4L30–E)

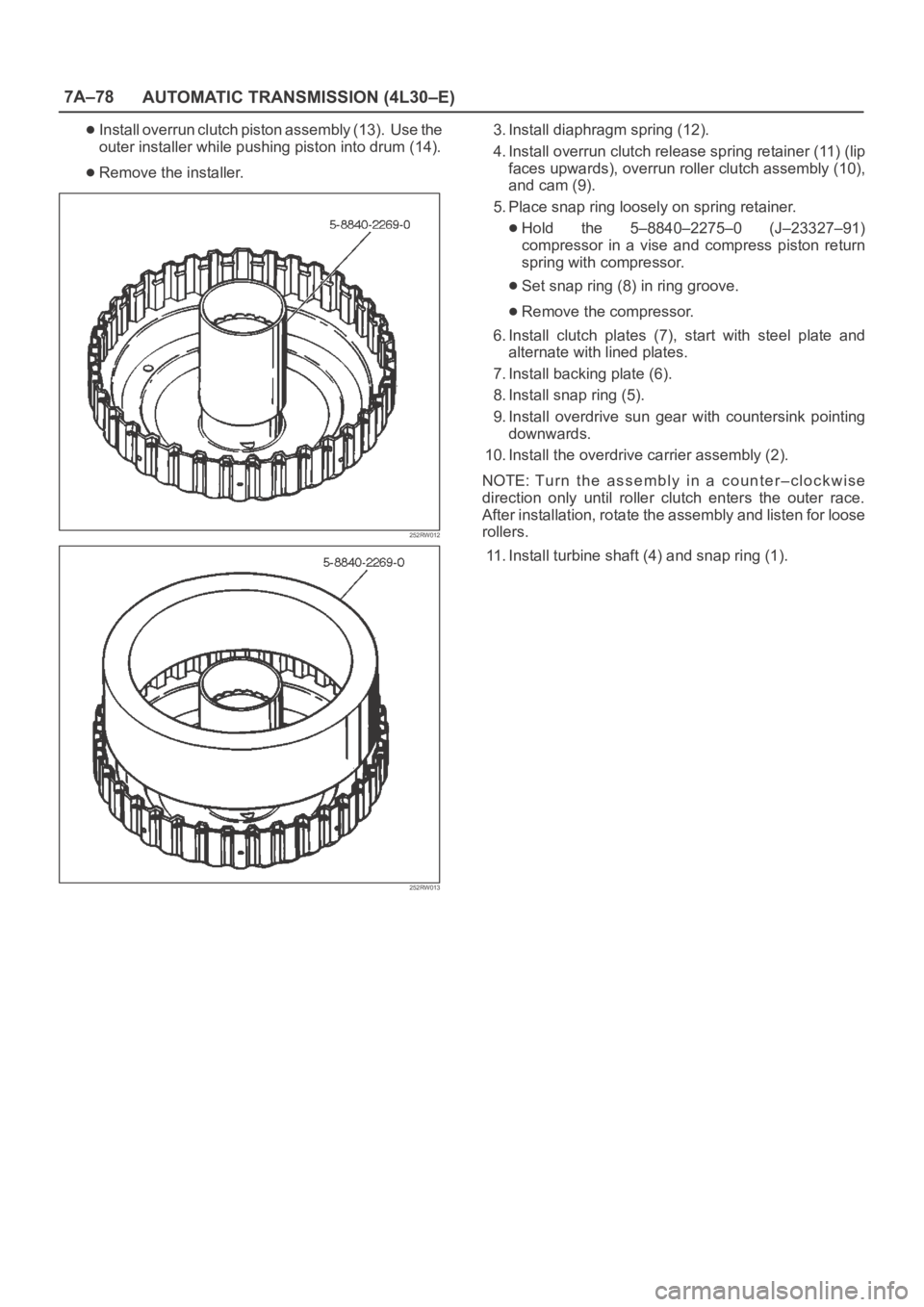

Install overrun clutch piston assembly (13). Use the

outer installer while pushing piston into drum (14).

Remove the installer.

252RW012

252RW013

3. Install diaphragm spring (12).

4. Install overrun clutch release spring retainer (11) (lip

faces upwards), overrun roller clutch assembly (10),

and cam (9).

5. Place snap ring loosely on spring retainer.

Hold the 5–8840–2275–0 (J–23327–91)

compressor in a vise and compress piston return

spring with compressor.

Set snap ring (8) in ring groove.

Remove the compressor.

6. Install clutch plates (7), start with steel plate and

alternate with lined plates.

7. Install backing plate (6).

8. Install snap ring (5).

9. Install overdrive sun gear with countersink pointing

downwards.

10. Install the overdrive carrier assembly (2).

NOTE: Tu r n t h e a s s e m b l y i n a c o u n t e r – c l o c k w i s e

direction only until roller clutch enters the outer race.

After installation, rotate the assembly and listen for loose

rollers.

11. Install turbine shaft (4) and snap ring (1).

Page 5768 of 6000

7A–79 AUTOMATIC TRANSMISSION (4L30–E)

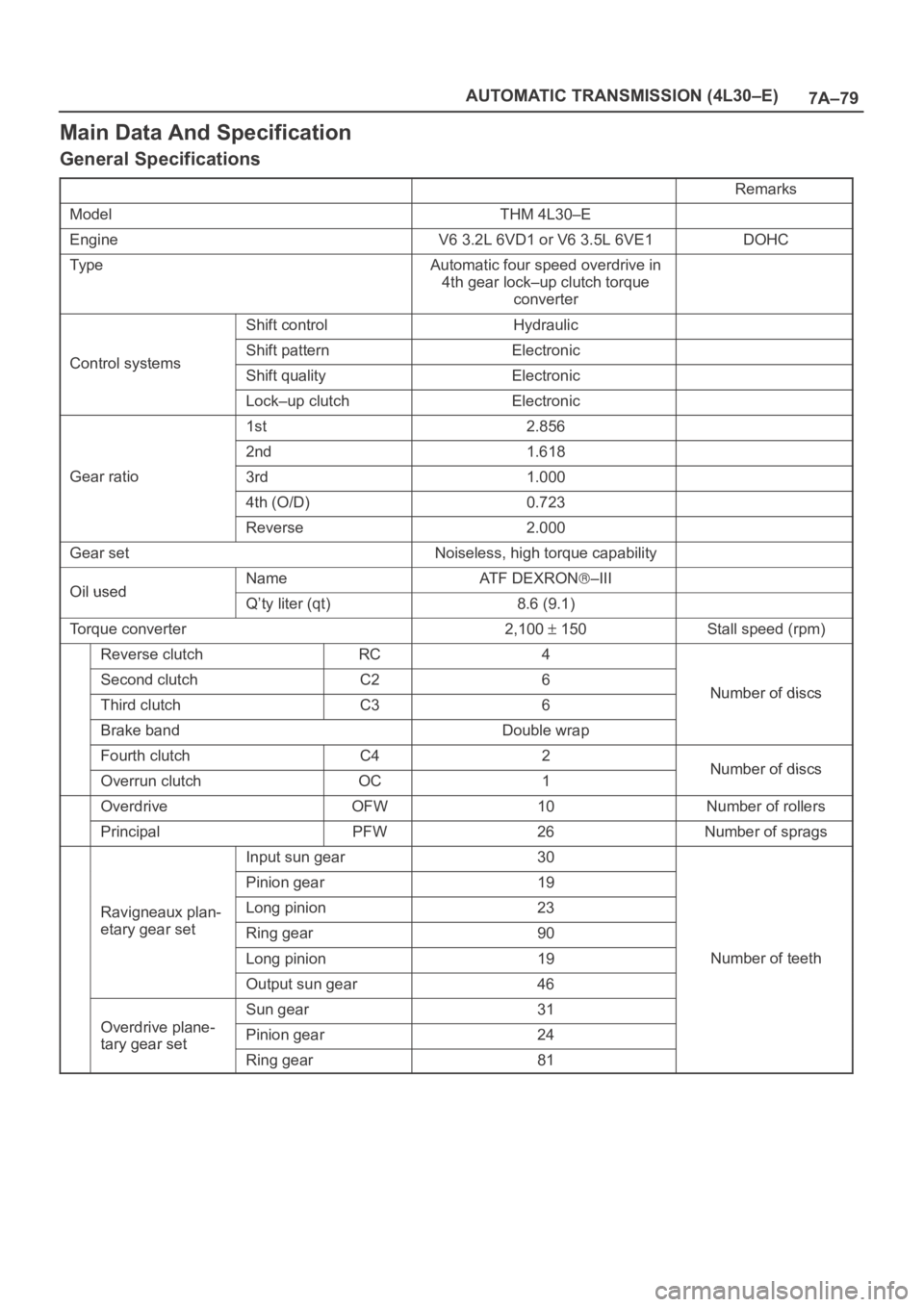

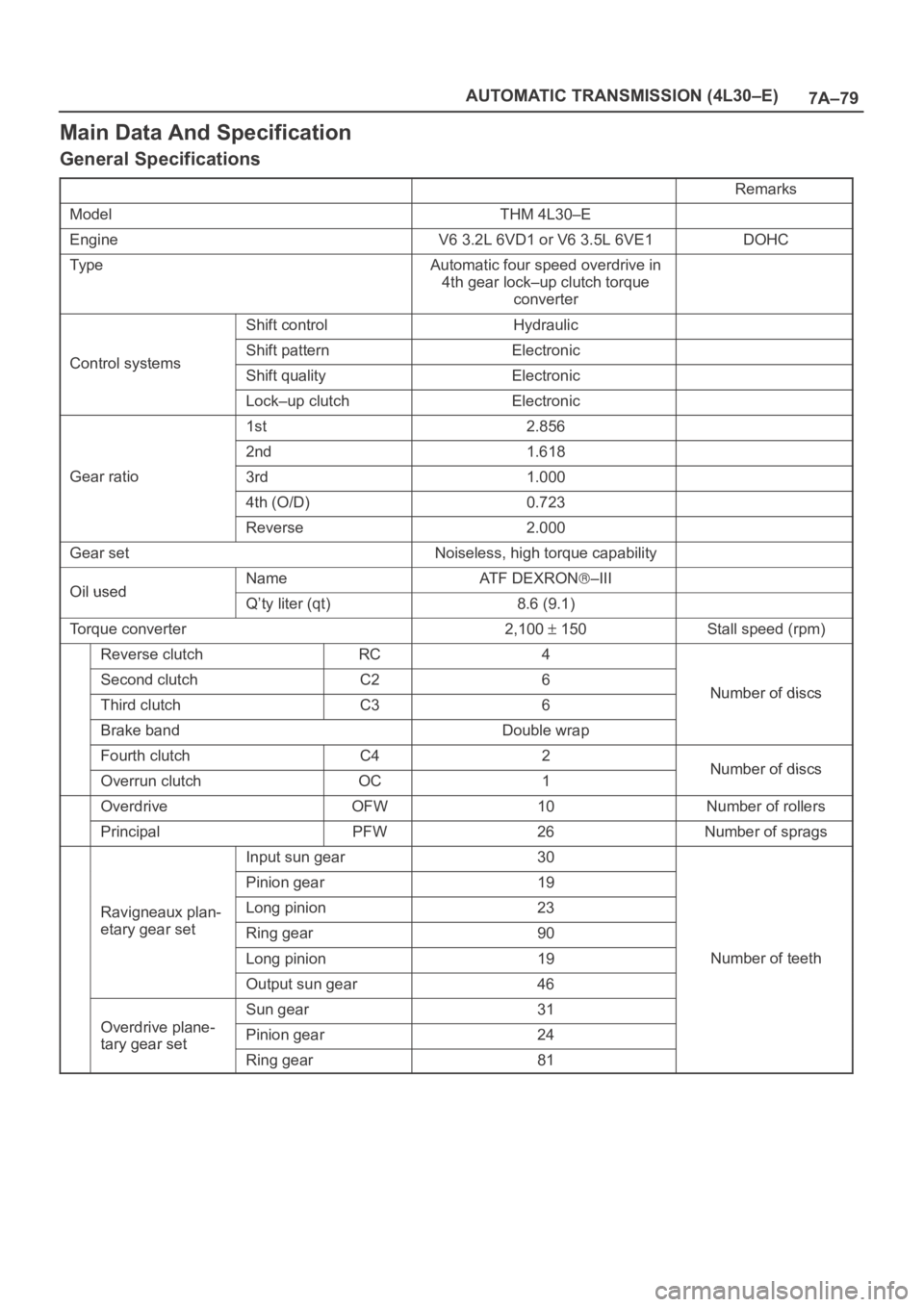

Main Data And Specification

General Specifications

Remarks

ModelTHM 4L30–E

EngineV6 3.2L 6VD1 or V6 3.5L 6VE1DOHC

Ty p eAutomatic four speed overdrive in

4th gear lock–up clutch torque

converter

Shift controlHydraulic

Control systemsShift patternElectronicControl systemsShift qualityElectronic

Lock–up clutchElectronic

1st2.856

2nd1.618

Gear ratio3rd1.000

4th (O/D)0.723

Reverse2.000

Gear setNoiseless, high torque capability

Oil usedNameAT F D E X R O N–IIIOil usedQ’ty liter (qt)8.6 (9.1)

Torque converter2,100 150Stall speed (rpm)

Reverse clutchRC4

Second clutchC26Number of discsThird clutchC36Number of discs

Brake bandDouble wrap

Fourth clutchC42Number of discsOverrun clutchOC1Number of discs

OverdriveOFW10Number of rollers

PrincipalPFW26Number of sprags

Input sun gear30

Pinion gear19

Ravigneaux plan-Long pinion23g

etary gear setRing gear90

Long pinion19Number of teeth

Output sun gear46

Odi l

Sun gear31

Overdrive plane-

tary gear setPinion gear24tary gear set

Ring gear81

Page 5769 of 6000

7A–80

AUTOMATIC TRANSMISSION (4L30–E)

Torque Specifications

E07RY00011

Page 5770 of 6000

7A–81 AUTOMATIC TRANSMISSION (4L30–E)

E07RW079

Trending: interior light, maintenance schedule, tire size, horn, service interval, oil dipstick, fuel pump