OPEL FRONTERA 1998 Workshop Manual

Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5781 of 6000

7A–92

AUTOMATIC TRANSMISSION (4L30–E)

(646) Gear Assembly, Input Sun

(647) Race Assembly, Sprag

(648) Ring, Retaining/Sprag

(649) Ring, Retaining

(650) Cage Assembly, Sprag

(651) Bearing, Output Shaft/Input Sun

(652) Washer, Output Shaft/Input Sun

(653) Carrier Assembly, Planetary(658) Gear, Reaction Sun

(659) Drum, Reaction Sun

(664) Band Assembly, Brake

(667) Seal, Ring/Wheel Parking Lock

(668) Wheel, Parking Lock

(672) Wheel, Speed

(673) Ring, Retaining

(675) Bearing, Thrust Assembly

Center Support Assembly

241RS010

Legend

(701) Center Support

(702) Retainer Plate(703) Plug, Lockout

(704) Spring, Overrun Lockout

(705) Valve, Overrun Lockout

Page 5782 of 6000

AUTOMATIC TRANSMISSION (AW30-40LE) 7A–1

SECTION 7A

CONTENTS

AUTOMATIC TRANSMISSION (AW30-40LE)

GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–3

CONSTRUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–3

ELECTRONIC CONTROL COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–4

TRANSMISSION CONTROL MODULE (TCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–5

CONTROL SYSTEM DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–6

CONTROL AND FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–7

MAJOR INPUT/OUTPUT COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–9

LOCATION OF CLUTCH, BRAKE ONE-WAY CLUTCH AND SOLENOID . . . . . . . . . . . . . . . . . . . . . . . 7A–10

OPERATION OF CLUTCH, BRAKE AND ONE-WAY CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–11

SPEED CHANGE AND LOCK-UP PATTERN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–11

OVERDRIVE AND LOCK-UP OPERATING CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–12

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–13

BASIC TROUBLESHOOTING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–13

SELF-DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–14

DIAGNOSIS WITH TECH2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–17

TECH2 CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–18

TECH2 OPERATING FLOW CHART (START UP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–19

TRANSMISSION DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–21

TCC DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–22

INTERMITTENT CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–23

IDENTIFICATION OF TRANSMISSION CONTROL MODULE (TCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–24

DIAGNOSTIC TROUBLE CODES (DTC) CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–25

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–52

CONNECTOR LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–54

TROUBLESHOOTING CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–56

MANUAL SHIFTING TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–62

STALL TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–63

TIME LAG TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–64

HYDRAULIC TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–65

ROAD TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–66

SHIFT POINT CHART AND LOCK-UP POINT CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–69

TCM VOLTAGE CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–71

TCM STANDARD VOLTAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–72

ON-VEHICLE SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–75

TRANSIMISSION FLUID LEVEL AND CONDITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–75

ATF REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–75

NEUTRAL START SWITCH INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–76

BRAKE SIGNAL INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–77

VEHICLE SPEED SENSOR INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–77

INPUT AND OUTPUT REVOLUTION SENSOR INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–77

PATTERN SELECT SWITCH INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–78

OVERDRIVE OFF SWITCH INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–78

SOLENOID INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–78

THROTTLE POSITION SENSOR INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–79

ATF TEMPERATURE SENSOR INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–79

SELECTOR LEVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–80

TRANSMISSION CONTROL MODULE (TCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–81

SHIFT SOLENOID AND LOCK-UP SOLENOID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–83

Page 5783 of 6000

7A–2 AUTOMATIC TRANSMISSION (AW30-40LE)

VALVE BODY ASSEMBLY AND PRESSERE CONTOROL SOLENOID . . . . . . . . . . . . . . . . . . . . . . . . 7A–84

TRANSMISSION REMOVAL AND INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–86

UNIT REPAIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–91

DISASSEMBLY OF MAJOR COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–91

DISASSEMBLY, INSPECTION AND REASSEMBLY OF MINOR COMPONENTS. . . . . . . . . . . . . . . . . 7A–107

OIL PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–108

OD PLANETARY GEAR AND OD DIRECT CLUTCH ASSEMBLY (C-0) . . . . . . . . . . . . . . . . . . . . . . . . 7A–114

OD SUPPORT ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–126

DIRECT CLUTCH ASSEMBLY (C-2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–133

FORWARD CLUTCH ASSEMBLY (C-1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–141

FRONT PLANETARY GEAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–150

PLANETARY SUN GEAR AND NO.1 ONE–WAY CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–153

SECOND BRAKE ASSEMBLY (B–2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–158

REAR PLANETARY GEAR ASSEMBLY AND OUTPUT SHAFT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–163

FIRST AND REVERSE BRAKE (B–3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–171

TRANSMISSION CASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–177

TORQUE CONVERTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–181

REASSEMBLY OF MAJOR COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–182

MAIN DATA AND SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–207

GENERAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–207

TORQUE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–208

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7A–211

CAUTION: When fasteners are removed, always

reinstall them at a the same location from which

they were removed. If a fastener needs to be

replaced, use the correct part number fastener for

that application. If the correct part number fastener

is not available, a fastener of equal size and

strength (or stronger) may be used. Fasteners that

are not reused, and those requiring thread locking

compound, will be called out. The correct torque

values must be used when installing fasteners that

require torque. If the above conditions are not

followed, parts or system damage could result.

Page 5784 of 6000

AUTOMATIC TRANSMISSION (AW30-40LE) 7A–3

GENERAL DESCRIPTION

CONSTRUCTION

A07RY00001

Page 5785 of 6000

7A–4 AUTOMATIC TRANSMISSION (AW30-40LE)

ELECTRONIC CONTROL COMPONENTS

C07RY00072

Page 5786 of 6000

AUTOMATIC TRANSMISSION (AW30-40LE) 7A–5

TRANSMISSION CONTROL MODULE (TCM)

C07RY00027

Page 5787 of 6000

7A–6 AUTOMATIC TRANSMISSION (AW30-40LE)

CONTROL SYSTEM DIAGRAM

C07RY00071

Page 5788 of 6000

AUTOMATIC TRANSMISSION (AW30-40LE) 7A–7

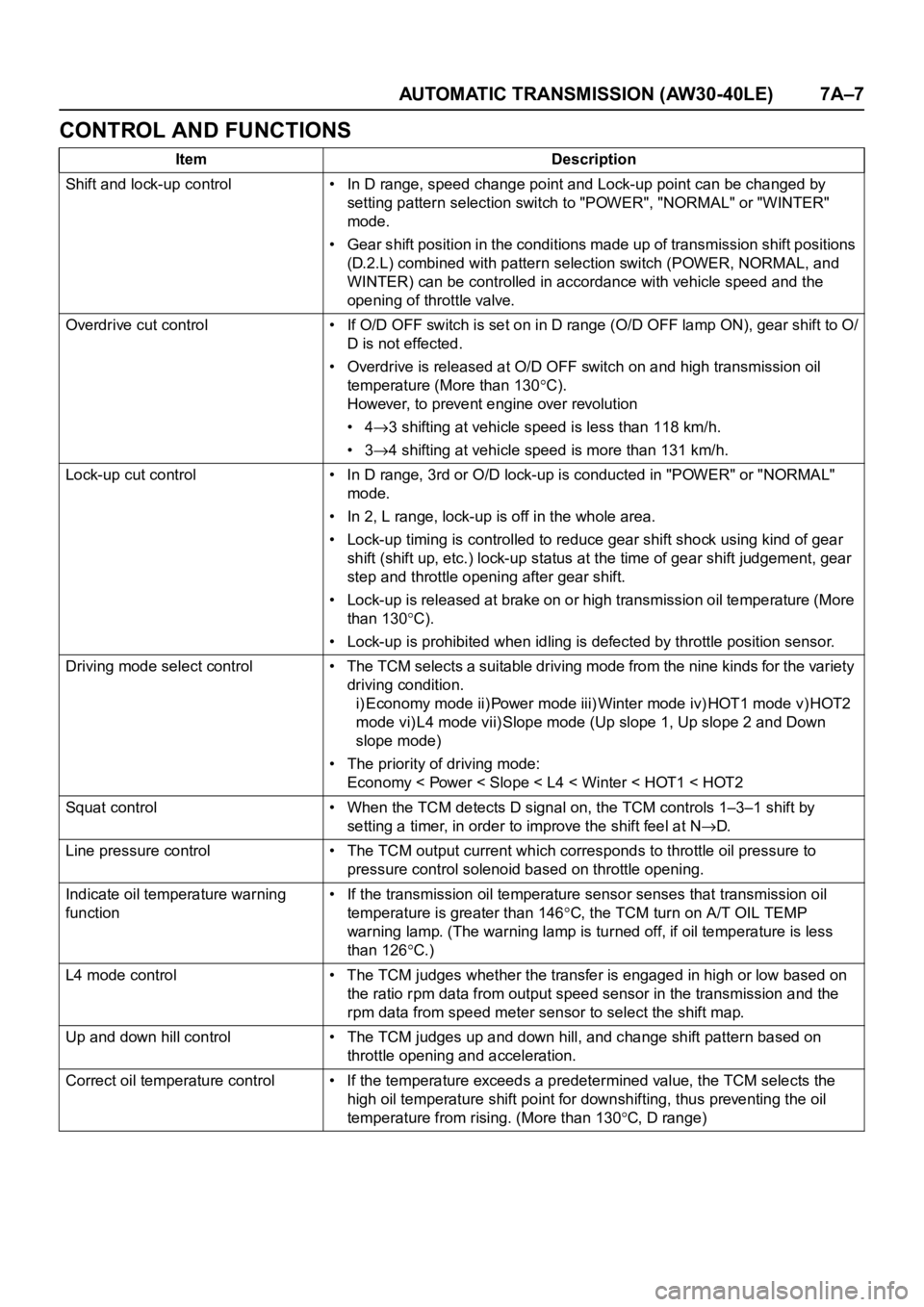

CONTROL AND FUNCTIONS

Item Description

Shift and lock-up control • In D range, speed change point and Lock-up point can be changed by

setting pattern selection switch to "POWER", "NORMAL" or "WINTER"

mode.

• Gear shift position in the conditions made up of transmission shift positions

(D.2.L) combined with pattern selection switch (POWER, NORMAL, and

WINTER) can be controlled in accordance with vehicle speed and the

opening of throttle valve.

Overdrive cut control • If O/D OFF switch is set on in D range (O/D OFF lamp ON), gear shift to O/

D is not effected.

• Overdrive is released at O/D OFF switch on and high transmission oil

temperature (More than 130

C).

However, to prevent engine over revolution

•4

3 shifting at vehicle speed is less than 118 km/h.

•3

4 shifting at vehicle speed is more than 131 km/h.

Lock-up cut control • In D range, 3rd or O/D lock-up is conducted in "POWER" or "NORMAL"

mode.

• In 2, L range, lock-up is off in the whole area.

• Lock-up timing is controlled to reduce gear shift shock using kind of gear

shift (shift up, etc.) lock-up status at the time of gear shift judgement, gear

step and throttle opening after gear shift.

• Lock-up is released at brake on or high transmission oil temperature (More

than 130

C).

• Lock-up is prohibited when idling is defected by throttle position sensor.

Driving mode select control • The TCM selects a suitable driving mode from the nine kinds for the variety

driving condition.

i) Economy mode ii) Power mode iii) Winter mode iv) HOT1 mode v) HOT2

mode vi) L4 mode vii) Slope mode (Up slope 1, Up slope 2 and Down

slope mode)

• The priority of driving mode:

Economy < Power < Slope < L4 < Winter < HOT1 < HOT2

Squat control • When the TCM detects D signal on, the TCM controls 1–3–1 shift by

setting a timer, in order to improve the shift feel at N

D.

Line pressure control • The TCM output current which corresponds to throttle oil pressure to

pressure control solenoid based on throttle opening.

Indicate oil temperature warning

function• If the transmission oil temperature sensor senses that transmission oil

temperature is greater than 146

C, the TCM turn on A/T OIL TEMP

warning lamp. (The warning lamp is turned off, if oil temperature is less

than 126

C.)

L4 mode control • The TCM judges whether the transfer is engaged in high or low based on

the ratio rpm data from output speed sensor in the transmission and the

rpm data from speed meter sensor to select the shift map.

Up and down hill control • The TCM judges up and down hill, and change shift pattern based on

throttle opening and acceleration.

Correct oil temperature control • If the temperature exceeds a predetermined value, the TCM selects the

high oil temperature shift point for downshifting, thus preventing the oil

temperature from rising. (More than 130

C, D range)

Page 5789 of 6000

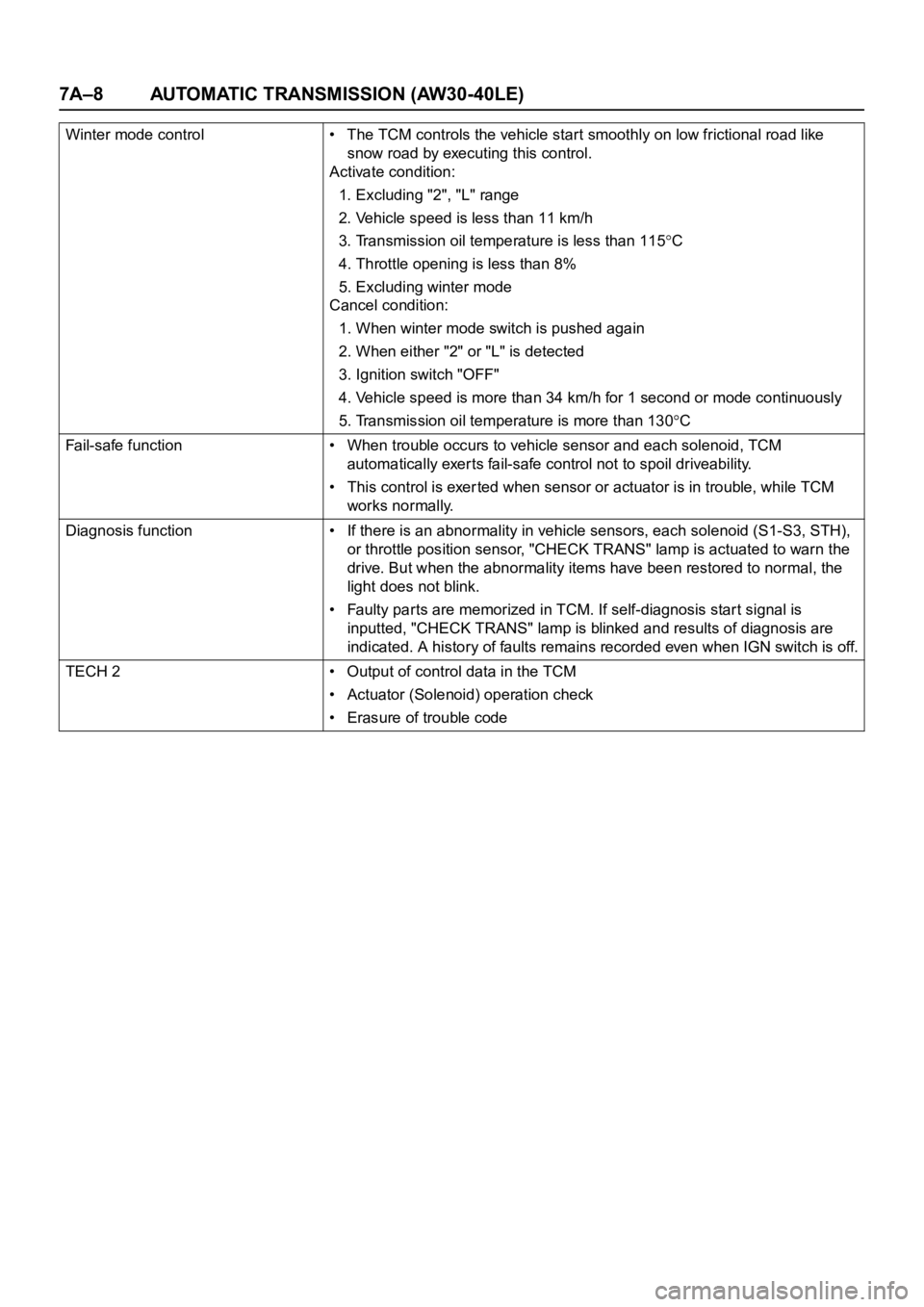

7A–8 AUTOMATIC TRANSMISSION (AW30-40LE)

Winter mode control • The TCM controls the vehicle start smoothly on low frictional road like

snow road by executing this control.

Activate condition:

1. Excluding "2", "L" range

2. Vehicle speed is less than 11 km/h

3. Transmission oil temperature is less than 115

C

4. Throttle opening is less than 8%

5. Excluding winter mode

Cancel condition:

1. When winter mode switch is pushed again

2. When either "2" or "L" is detected

3. Ignition switch "OFF"

4. Vehicle speed is more than 34 km/h for 1 second or mode continuously

5. Transmission oil temperature is more than 130

C

Fail-safe function • When trouble occurs to vehicle sensor and each solenoid, TCM

automatically exer ts fail-safe control not to spoil driveability.

• This control is exer ted when sensor or actuator is in trouble, while TCM

works normally.

Diagnosis function • If there is an abnormality in vehicle sensors, each solenoid (S1-S3, STH),

or throttle position sensor, "CHECK TRANS" lamp is actuated to warn the

drive. But when the abnormality items have been restored to normal, the

light does not blink.

• Faulty parts are memorized in TCM. If self-diagnosis star t signal is

inputted, "CHECK TRANS" lamp is blinked and results of diagnosis are

indicated. A history of faults remains recorded even when IGN switch is off.

TECH 2 • Output of control data in the TCM

• Actuator (Solenoid) operation check

• Erasure of trouble code

Page 5790 of 6000

AUTOMATIC TRANSMISSION (AW30-40LE) 7A–9

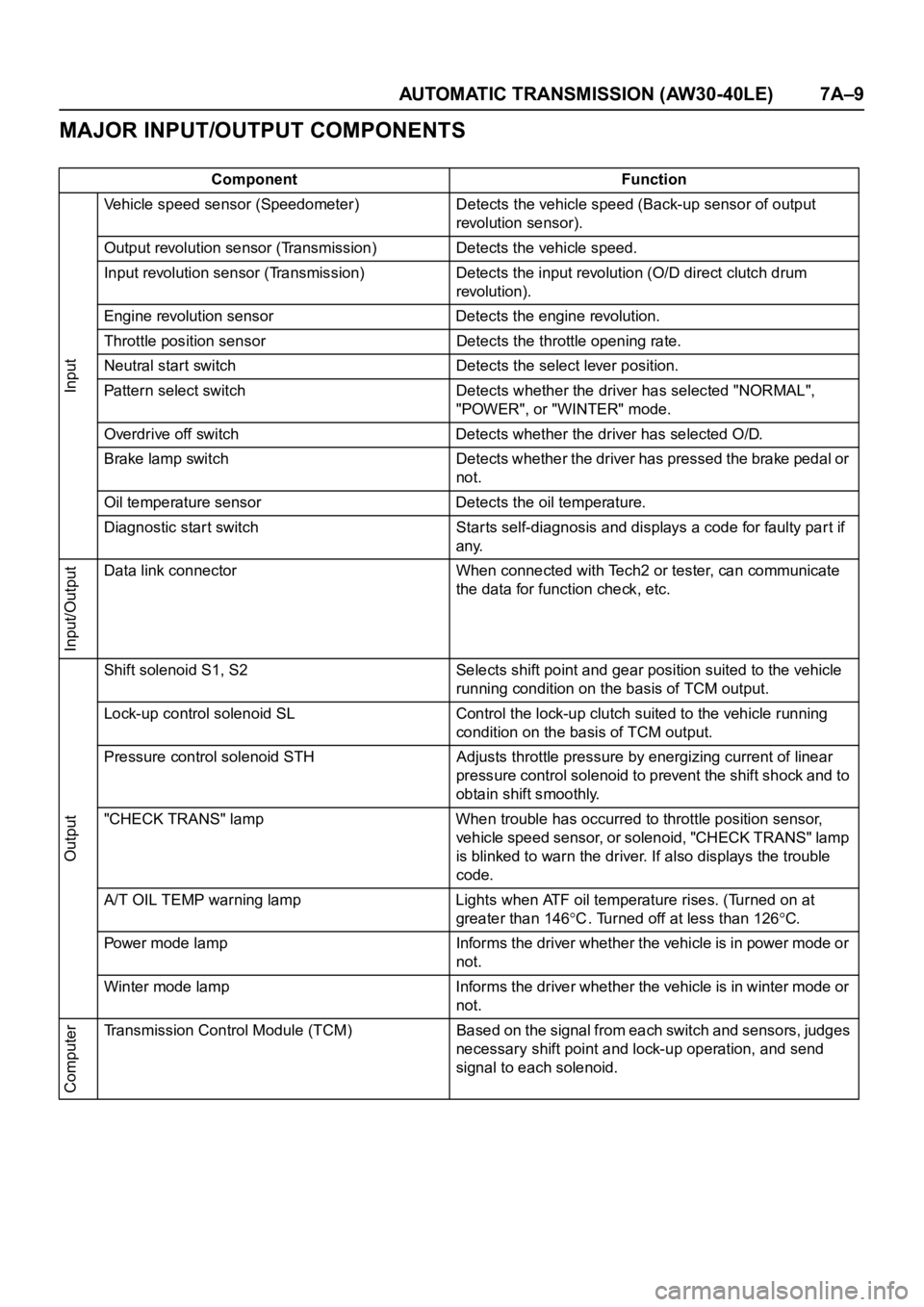

MAJOR INPUT/OUTPUT COMPONENTS

Component Function

Input

Vehicle speed sensor (Speedometer) Detects the vehicle speed (Back-up sensor of output

revolution sensor).

Output revolution sensor (Transmission) Detects the vehicle speed.

Input revolution sensor (Transmission) Detects the input revolution (O/D direct clutch drum

revolution).

Engine revolution sensor Detects the engine revolution.

Throttle position sensor Detects the throttle opening rate.

Neutral start switch Detects the select lever position.

Pattern select switch Detects whether the driver has selected "NORMAL",

"POWER", or "WINTER" mode.

Overdrive off switch Detects whether the driver has selected O/D.

Brake lamp switch Detects whether the driver has pressed the brake pedal or

not.

Oil temperature sensor Detects the oil temperature.

Diagnostic star t switch Star ts self-diagnosis and displays a code for faulty part if

any.

Input/Output

Data link connector When connected with Tech2 or tester, can communicate

the data for function check, etc.

Output

Shift solenoid S1, S2 Selects shift point and gear position suited to the vehicle

running condition on the basis of TCM output.

Lock-up control solenoid SL Control the lock-up clutch suited to the vehicle running

condition on the basis of TCM output.

Pressure control solenoid STH Adjusts throttle pressure by energizing current of linear

pressure control solenoid to prevent the shift shock and to

obtain shift smoothly.

"CHECK TRANS" lamp When trouble has occurred to throttle position sensor,

vehicle speed sensor, or solenoid, "CHECK TRANS" lamp

is blinked to warn the driver. If also displays the trouble

code.

A/T OIL TEMP warning lamp Lights when ATF oil temperature rises. (Turned on at

greater than 146

C . Turned off at less than 126C.

Power mode lamp Informs the driver whether the vehicle is in power mode or

not.

Winter mode lamp Informs the driver whether the vehicle is in winter mode or

not.

Computer

Transmission Control Module (TCM) Based on the signal from each switch and sensors, judges

necessary shift point and lock-up operation, and send

signal to each solenoid.