PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

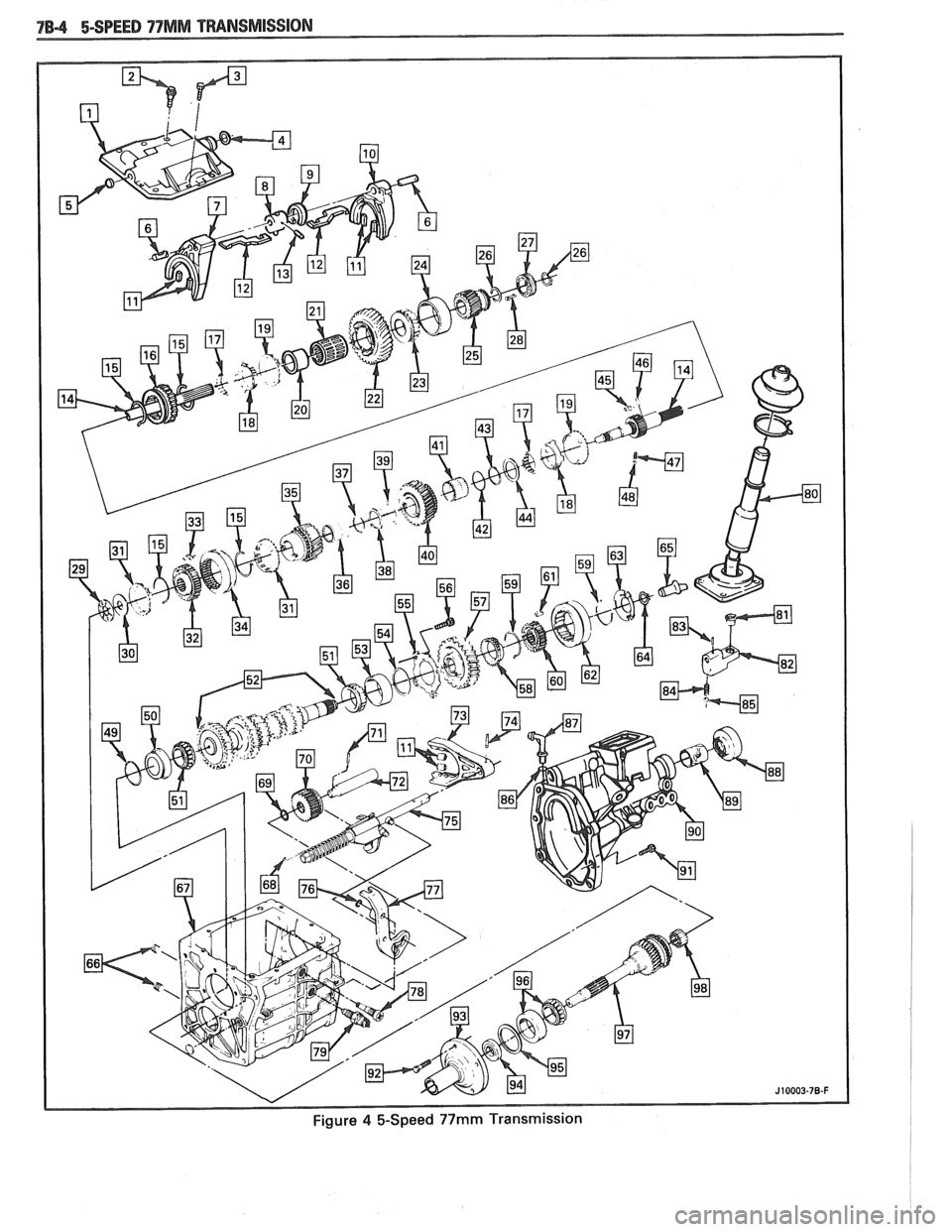

Page 1141 of 1825

Page 1142 of 1825

5-SPEED 97MM TRANSMISSION 7B-5

1. COVER, TRANSMISSION

50. RACE, FRONT COUNTERSHAFT BEARING

2. BOLT, ALIGNMENT DOWEL

51. BEARING, COUNTERSHAFT

52. GEAR CLUSTER, COUNTERSHAFT

4. SEAL, O-RING

53. RACE, REAR COUNTERSHAFT

5. PLUG, SHIFT

RAIL 54. SHIM, COUNTERSHAFT BEARING ADJUSTMENT

6. RAIL, SHIFT

55. RETAINER, COUNTERSHAFT

7. FORK, 3RD AND 4TH SHIFT

56. BOLT, COUNTERSHAFT RETAINER

8. ARM, SELECTOR

57. GEAR, 5TH SPEED DRIVE

9. PLATE, GEAR SELECT INTERLOCK

58. RING, BLOCKER

- 5TH SYNCHRONIZER

10. FORK,

1ST AND 2ND SHIFT

59. SPRING, 5TH SYNCHRONIZER

11. INSERT, SHIFT FORK

60. HUB, 5TH SYNCHRONIZER

12. PLATE, SHIFT FORK

61. KEY, 5TH SYNCHRONIZER

13. PIN, ROLL

- SELECTOR ARM

62. SLEEVE, 5TH SYNCHRONIZER

14. SHAFT,

MAIN WITH 1ST AND 2ND

63. RETAINER, 5TH SYNCHRONIZER

SYNCHRONIZER HUB

64. RING, SNAP

- 5TH

15. SPRING, SYNCHRONIZER SYNCHRONIZER RETAINER

16. GEAR, REVERSE SLIDING

65. FUNNEL, TRANSMISSION OILING

17. CONE, INNER

- 1ST AND 2ND SYNCHRONIZER

66. PLUG, FILL AND DRAIN

18. CONE, OUTER - 1ST AND 2ND SYNCHRONIZER

67. CASE, TRANSMISSION

19. RING, BLOCKER

- 1ST AND 2ND SYNCHRONIZER

68. SPRING, REVERSE LOCK

20. SLEEVE,

1ST GEAR BEARING

69. O-RING, REVERSE IDLER

21. BEARING,

1ST GEAR

70. GEAR, REVERSE IDLER

22. GEAR,

1ST SPEED 71. PIN, ROLL - REVERSE IDLER

23. BEARING, MAINSHAFT REAR

72. SHAFT, REVERSE IDLER

24. RACE,

MAINSHAFT REAR BEARING

73. FORK, 5TH SHIFT

25. GEAR, 5TH SPEED DRIVEN

74. PIN, ROLL - SHIFT FORK

26. RING, SNAP

75. RAIL, 5TH AND REVERSE SHIFT

27. GEAR, SPEEDOMETER DRIVE

76. RETAINER, SPRING CLIP - 5TH AND

28. CLIP, SPEEDOMETER DRIVE GEAR REVERSE LEVER

29. BEARING,

MAIN DRIVE GEAR THRUST 77.

LEVER, 5TH AND REVERSE SHIFT

30. RACE,

MAIN DRIVE GEAR THRUST BEARING 78. BOLT, 5TH

AND REVERSE

31. RING, BLOCKER

- 3RD AND 4TH SHIFT

LEVER PIVOT

SYNCHRONIZER 79. SWITCH, REVERSE LAMP

32. HUB, 3RD AND 4TH SYNCHRONIZER 80.

CONTROL, TRANSMISSION SHIFT LEVER AND HOUSING

33. KEY, SYNCHRONIZER 81.

SLEEVE, SHIFT LEVER DAMPER

34. SLEEVE, 3RD AND 4TH SYNCHRONIZER 82.

LEVER, OFFSET SHIFT

35. GEAR, 3RD SPEED 83. PIN, ROLL

- OFFSET

LEVER

36. BEARING, 3RD GEAR 84.

SPRING, DETENT

37. SPACER, 3RD GEAR BEARING 85.

BALL, DETENT

38. RING, SNAP 2ND GEAR THRUST WASHER 86.

O-RING, EXTENSION HOUSING VENT

39. WASHER, THRUST

- 2ND GEAR 87. VENT, EXTENSION HOUSING

40. GEAR, 2ND SPEED 88. SEAL, EXTENSION HOUSING REAR OIL

41. BEARING, 2ND GEAR 89. BUSHING, EXTENSION HOUSING

42. SPACER,

2ND GEAR BEARING 90.

HOUSING, EXTENSION

43. RING, SPIRAL RETAINING

- 2ND SYNCHRONIZER 91. BOLT, EXTENSION HOUSING

44. WASHER, THRUST - 2ND SYNCHRONIZER 92.

BOLT, DRIVE GEAR BEARING RETAINER

45. KEY, 1ST-2ND SYNCHRONIZER 93.

RETAINER, DRIVE GEAR BEARING

46. PIN, LOCATING

- 1ST SPEED 94. SEAL, DRIVE GEAR BEARING RETAINER OIL

BEARING SLEEVE

95. SHIM,

MAINSHAFT BEARING ADJUSTMENT

47. SPRING, ANTI-RAlTLE 96. BEARING, FRONT MAIN DRIVE GEAR 48. BALL, ANTI-RATTLE

97. GEAR, MAIN DRIVE

49. O-RING, BEARING RACE

98. ROLLERS, BEARING

- MAIN DRIVE GEAR PILOT

Figure 5 &Speed 99mm Transmission

Page 1143 of 1825

Install or Conned

1. New seal using Tool J 21426.

2. Propeller shaft. (See Section 4A)

3. Lower vehicle.

4. Check transmission fluid level.

SPEEDOMETER DRIVEN GEAR

Remove or Disconnect

1. Raise vehicle.

2. Speedometer cable.

3. Lock plate and retaining bolt.

4. Pry gear fitting and shaft from housing.

5. O-ring from fitting.

Install or Connecl

1. Coat driven gear shaft and new O-ring with

transmission lubricant.

2. New O-ring.

3. Insert shaft.

4. Position fitting into extension housing.

5. Lock plate and retaining bolt.

6. Speedometer cable.

7. Lower vehicle.

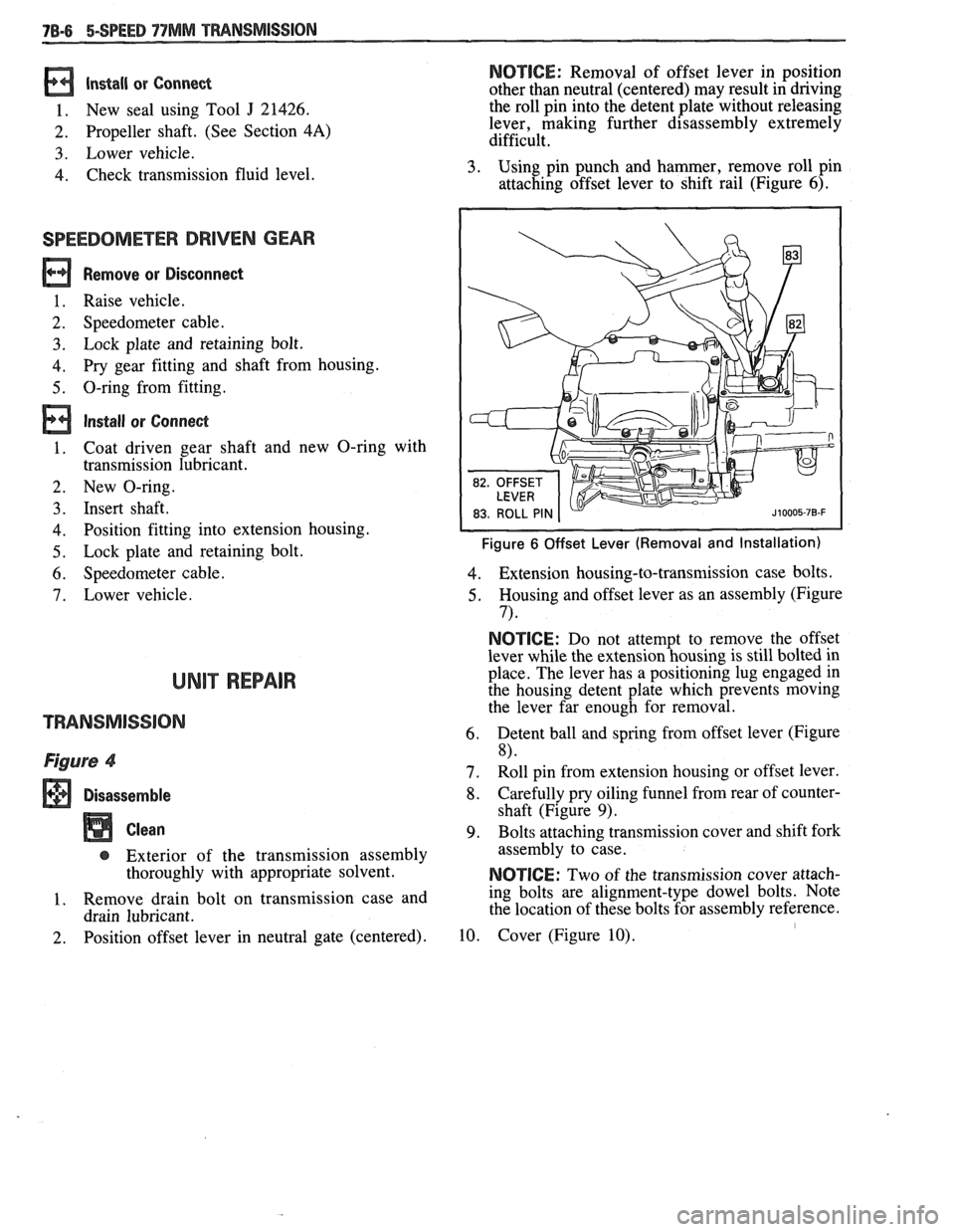

TRANSMISSION

Figure 4

Disassemble

@ Exterior of the transmission assembly

thoroughly with appropriate solvent.

1. Remove drain bolt on transmission case and

drain lubricant.

2. Position offset lever in neutral gate (centered).

NO"6CE: Removal of offset lever in position

other than neutral (centered) may result in driving

the roll pin into the detent plate without releasing

lever, making further disassembly extremely

difficult.

3. Using pin punch and hammer, remove roll pin

attaching offset lever to shift rail (Figure

6).

Figure 6 Offset Lever (Removal and Installation)

4. Extension housing-to-transmission case bolts.

5. Housing and offset lever as an assembly (Figure

7) *

NOTICE: Do not attempt to remove the offset

lever while the extension housing is still bolted in

place. The lever has a positioning lug engaged in

the housing detent plate which prevents moving

the lever far enough for removal.

6. Detent ball and spring from offset lever (Figure

8)

7. Roll pin from extension housing or offset lever.

8. Carefully pry oiling funnel from rear of counter-

shaft (Figure

9).

9. Bolts attaching transmission cover and shift fork

assembly to case.

NOTICE: Two of the transmission cover attach-

ing bolts are alignment-type dowel bolts. Note

the location of these bolts for assembly reference.

10. Cover (Figure 10). I

Page 1144 of 1825

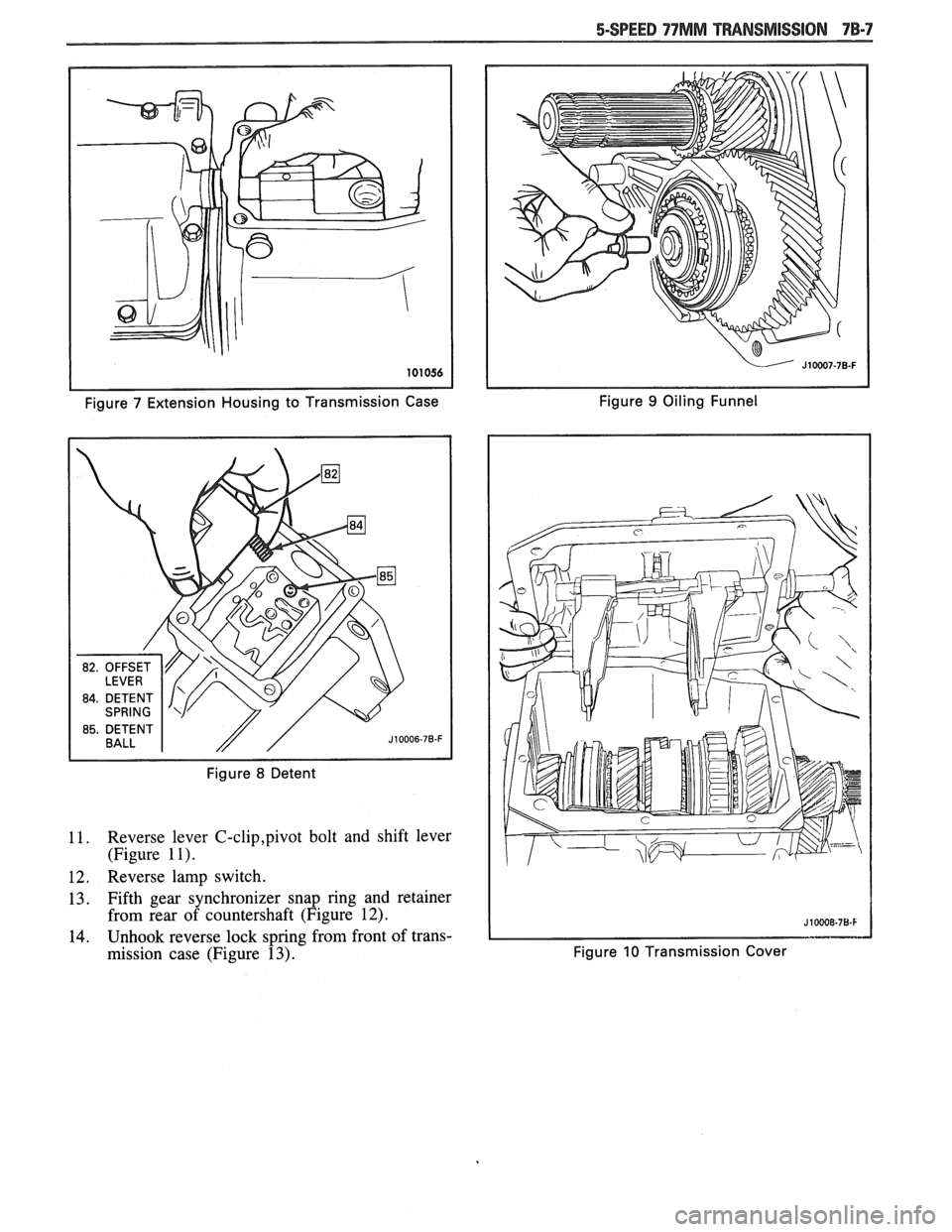

Figure 7 Extension Housing to Transmission Case Figure 9 Oiling

Funnel

Figure

8 Detent

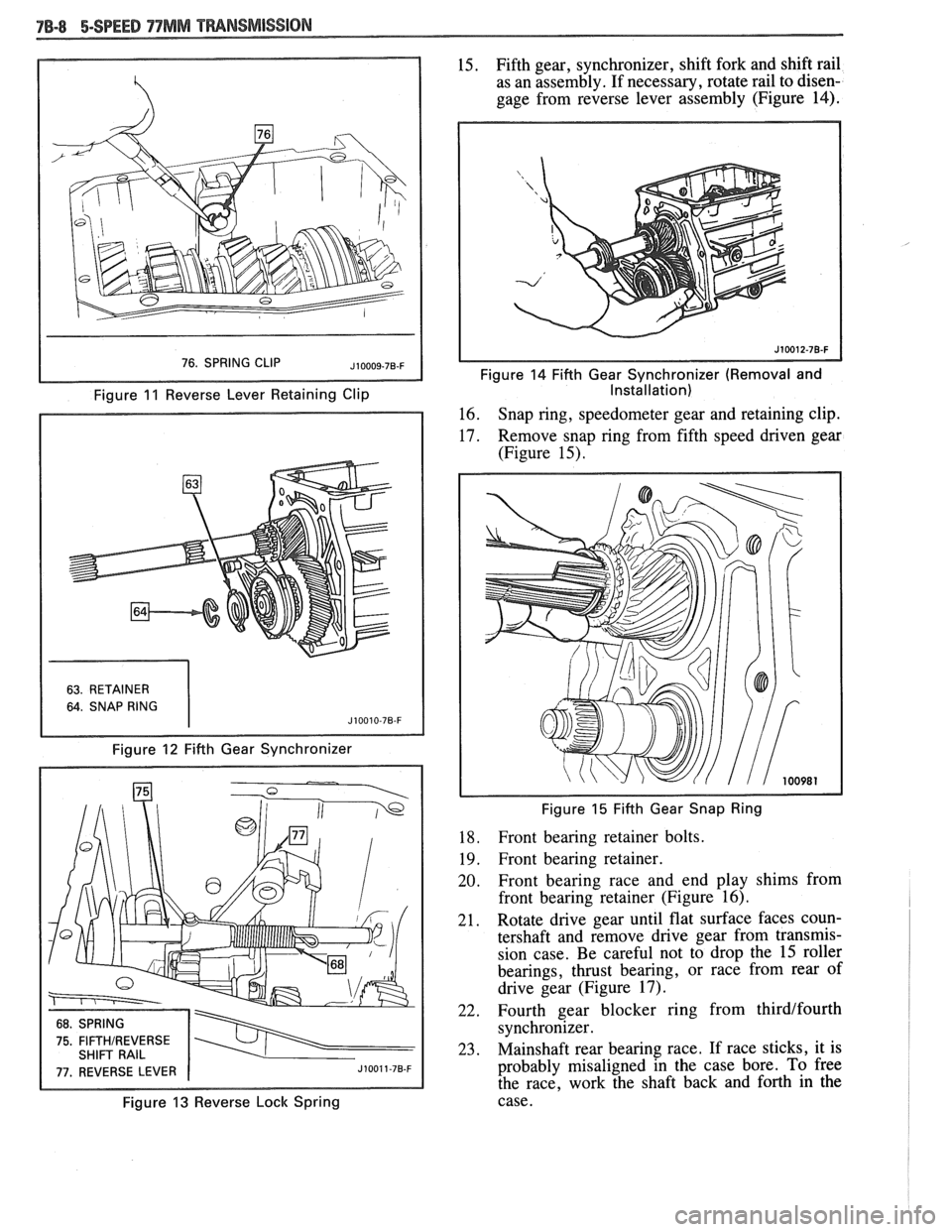

11. Reverse lever C-clip,pivot bolt and shift lever

(Figure

1 I).

12. Reverse lamp switch.

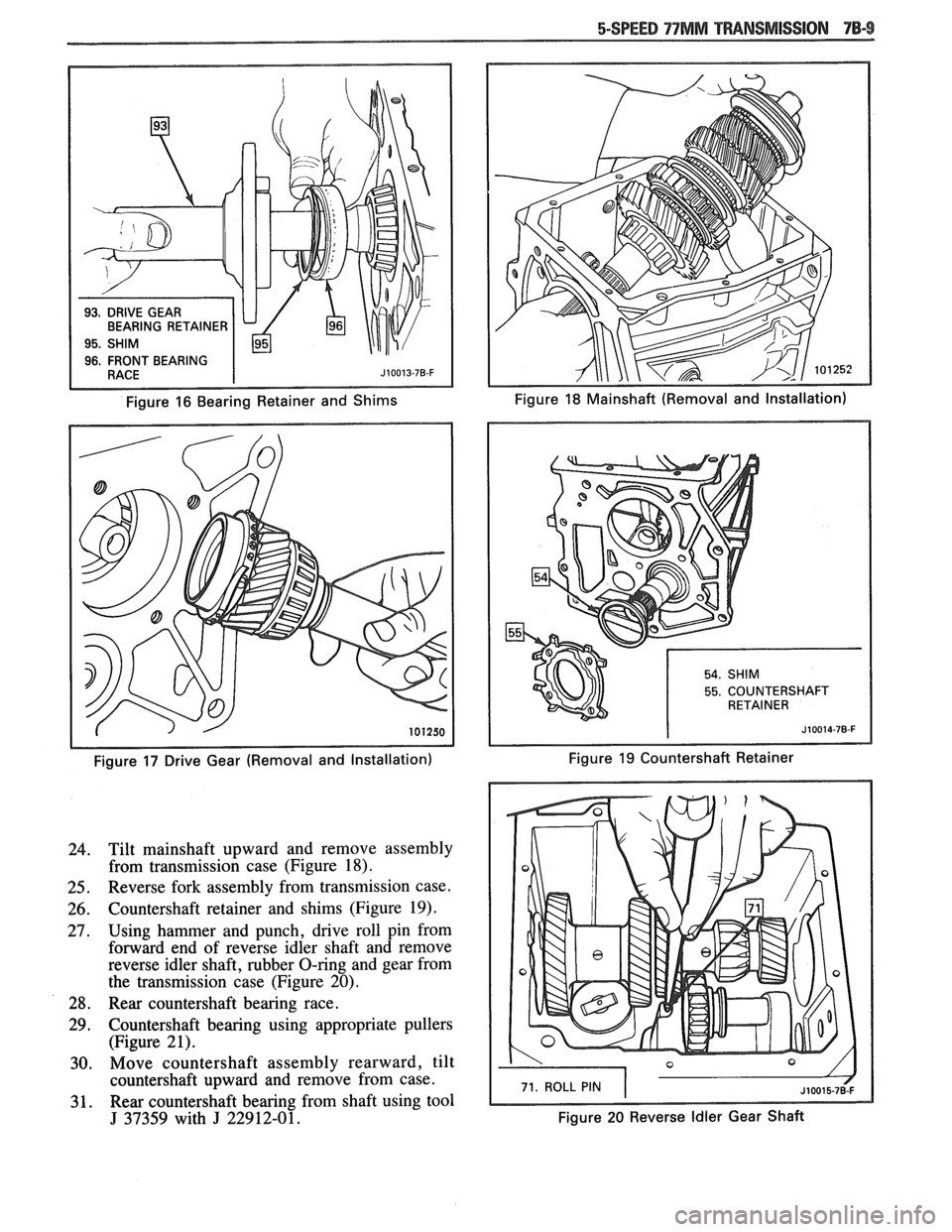

13. Fifth gear synchronizer snap ring and retainer

from rear of countershaft (Figure

12).

14. Unhook reverse lock spring from front of trans-

mission case (Figure

13). Figure 10 Transmission Cover

Page 1145 of 1825

76. SPRING CLIP JIOOO~-7~-F

Figure 11 Reverse Lever Retaining Clip

63. RETAINER

64. SNAP RING

Figure 12 Fifth Gear Synchronizer

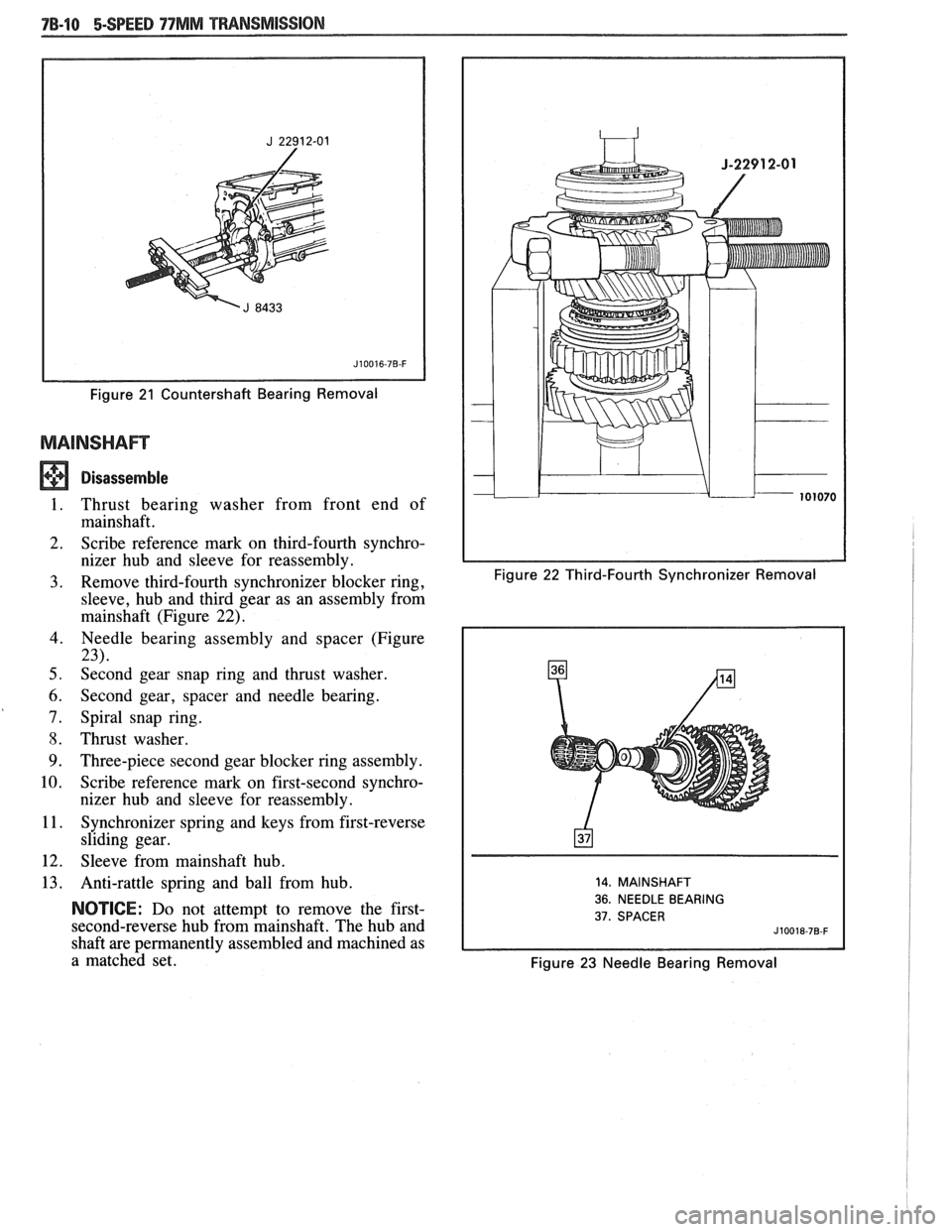

15. Fifth

gear, synchronizer, shift fork and shift rail

as an assembly. If necessary, rotate rail to disen-

gage from reverse lever assembly (Figure 14).

Figure 14 Fifth Gear Synchronizer (Removal and

Installation)

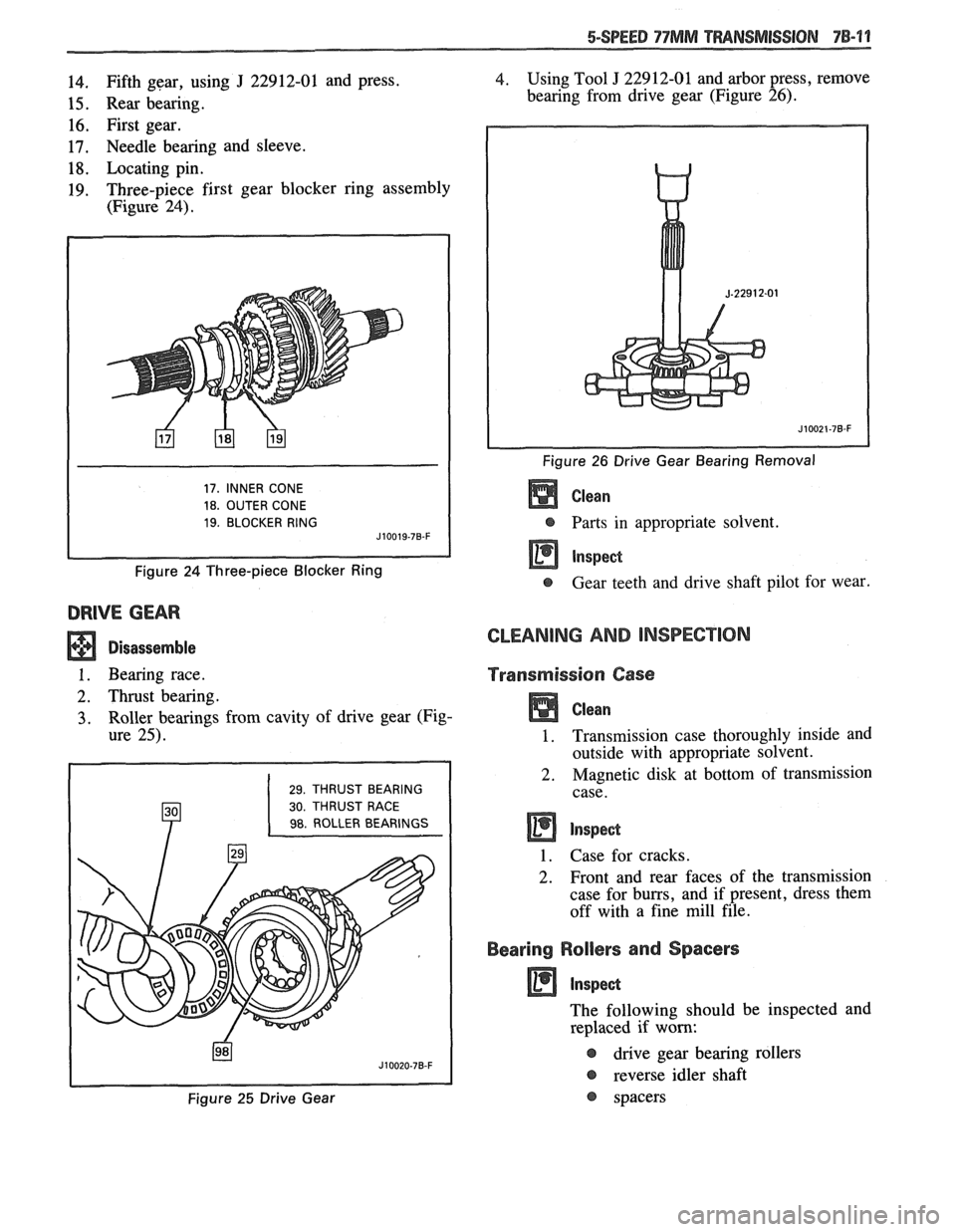

16. Snap ring, speedometer gear and retaining clip.

17. Remove

snap ring from fifth speed driven gear

(Figure 15).

Figure 15 Fifth Gear Snap Ring

18. Front bearing retainer bolts.

19. Front bearing retainer.

20. Front bearing race and end play shims from

front bearing retainer (Figure 16).

21. Rotate drive gear until

flat surface faces

coun-

tershaft and remove drive gear from transmis-

sion case. Be careful not to drop the 15 roller

bearings, thrust bearing, or race from rear of

drive gear (Figure 17).

22. Fourth

gear blocker ring from

thirdlfourth

synchronizer.

23. Mainshaft rear bearing race. If race sticks, it is

probably misaligned in the case bore. To free

the race, work the shaft back and forth in the

Figure 13 Reverse Lock Spring case.

Page 1146 of 1825

BEARING RETAINER

Figure 16 Bearing Retainer and Shims Figure 18 Mainshaft

(Removal and Installation)

Figure

17 Drive Gear (Removal and Installation)

Tilt mainshaft upward and remove assembly

from transmission case (Figure 18).

Reverse fork assembly from transmission case.

Countershaft retainer and shims (Figure 19).

Using hammer and punch, drive roll pin from

forward end of reverse idler shaft and remove

reverse idler shaft, rubber O-ring and gear from

the transmission case (Figure 20).

Rear countershaft bearing race.

Countershaft bearing using appropriate pullers (Figure 21).

Move countershaft assembly rearward, tilt

countershaft upward and remove from case.

Rear countershaft bearing from shaft using tool

J 37359 with J 22912-01.

55. COUNTERSHAFT

Figure 19 Countershaft Retainer

71. ROLL PIN

Figure 20 Reverse Idler Gear Shaft

Page 1147 of 1825

Figure 21 Countershaft Bearing Removal

Disassemble

I. Thrust bearing washer from front end of

mainshaft.

2. Scribe reference

mark on third-fourth synchro-

nizer hub and sleeve for reassembly.

3. Remove third-fourth synchronizer blocker ring, Figure 22 Third-Fourth Synchronizer Removal

sleeve, hub and third gear as an assembly from

mainshaft (Figure

22).

4. Needle bearing assembly and spacer (Figure

23).

5. Second gear snap ring and thrust washer.

6. Second gear, spacer and needle bearing.

7. Spiral snap ring.

8. Thrust washer.

9. Three-piece second gear blocker ring assembly.

10. Scribe reference mark on first-second synchro-

nizer hub and sleeve for reassembly.

1 I. Synchronizer spring and keys from first-reverse

sliding gear.

12. Sleeve from mainshaft hub.

13. Anti-rattle spring and ball from hub.

NOTICE: Do not attempt to remove the first-

second-reverse hub from mainshaft. The hub and

shaft are permanently assembled and machined as

a matched set.

14. MAINSHAFT

36. NEEDLE BEARING

37. SPACER

Figure 23 Needle Bearing Removal

Page 1148 of 1825

5-SPEED 77MM TRANSMISSION 78-9 1

14. Fifth gear, using J 22912-01 and press.

15. Rear bearing.

16. First gear.

17. Needle bearing and sleeve.

18. Locating pin.

19. Three-piece first gear blocker ring assembly

(Figure

24).

17, INNER CONE

18. OUTER CONE

19. BLOCKER RING J10019-78-F

Figure 24 Three-piece Blocker Ring

DRIVE GEAR

Disassemble

1. Bearing race.

2. Thrust bearing.

3. Roller bearings from cavity of drive gear (Fig-

ure

25).

29. THRUST BEARING

30. THRUST RACE

98. ROLLER BEARINGS

J10020-78-F

4. Using Tool J 229 12-01 and arbor press, remove

bearing from drive gear (Figure

26).

-

Figure 26 Drive Gear Bearing Removal

Clean

@ Parts in appropriate solvent.

Gear teeth and drive shaft pilot for wear.

GLEANING AND INSPECnION

Transmission Case

Clean

1. Transmission case thoroughly inside and

outside with appropriate solvent.

2. Magnetic disk at bottom of transmission

case.

1. Case for cracks.

2. Front and rear faces of the transmission

case for burrs, and if present, dress them

off with a fine mill file.

Bearing Rollers and Spacers

The following should be inspected and

replaced if worn:

@ dkve gear bearing rollers

@ reverse idler shaft

@ spacers Figure 25 Drive Gear

Page 1149 of 1825

Gears .

t, Drive gear bearing rollers for chips,

cracks, or excessive wear and replace if

necessary.

@ Clutch sleeves to insure that they slide

freely on their hubs.

Front and Rear Bearings

Clean

t, Front and rear bearings thoroughly with

appropriate solvent.

1. Blow out bearings with compressed air.

NOTICE: Do not allow the bearings to spin.

Turn them slowly by hana. Spinning bearings

may damage the race and rollers.

2. Lubricate bearings with transmission lubricant.

@ Bearings for roughness by slowly turning

race by hand.

Synchronizer Blocking Rings

Firsthecond and thirdlfourth blocker rings are

lined with friction material and cannot be checked

visually for wear. Replacement is necessary when gap

between blocker teeth and adjacent clutch teeth is sig-

nificantly less than specified. Fifth gear blocker ring

is brass and can be checked visually for wear or

damage.

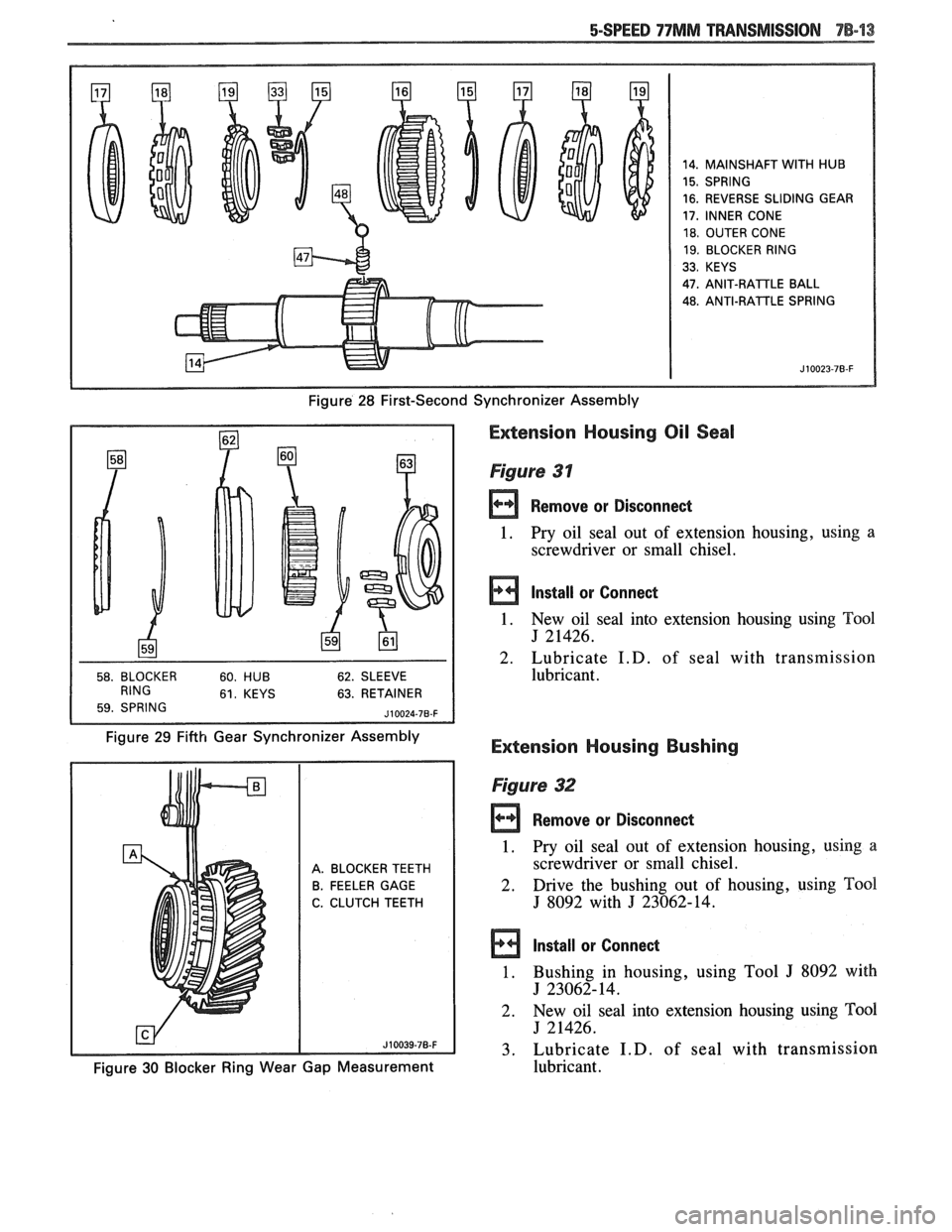

ThirdIFouHh Blocker Rings

Assemble

1. Third gear blocker ring to third gear with twist-

ing motion to fully seat.

2. Fourth gear blocker ring to main drive gear with

twisting motion to fully seat.

Measure

Gap between vertical faces of blocker teeth and

clutch teeth. Nominal gap is

.035 -.059 inches

(.88 - 1.5mm) for new blocker rings (Figure

30).

FirsvSecond Blocker Rings

Assemble

1. Three-piece first gear blocker ring assembly

with twisting motion to fully seat. 2.

Three-piece first gear

blocker ring assembly,

with needle bearing and bearing sleeve, to first

gear.

3. Three-piece second gear blocker ring assembly with twisting motion to fully seat.

4. Three-piece second gear blocker ring assembly,

with thrust washer, to second gear.

Measure

Gap between vertical faces of blocker teeth and

clutch teeth. Nominal gap is ,032

-.056 inches

(.81 -1.4mm) for new blocker ring assemblies

(Figure 30).

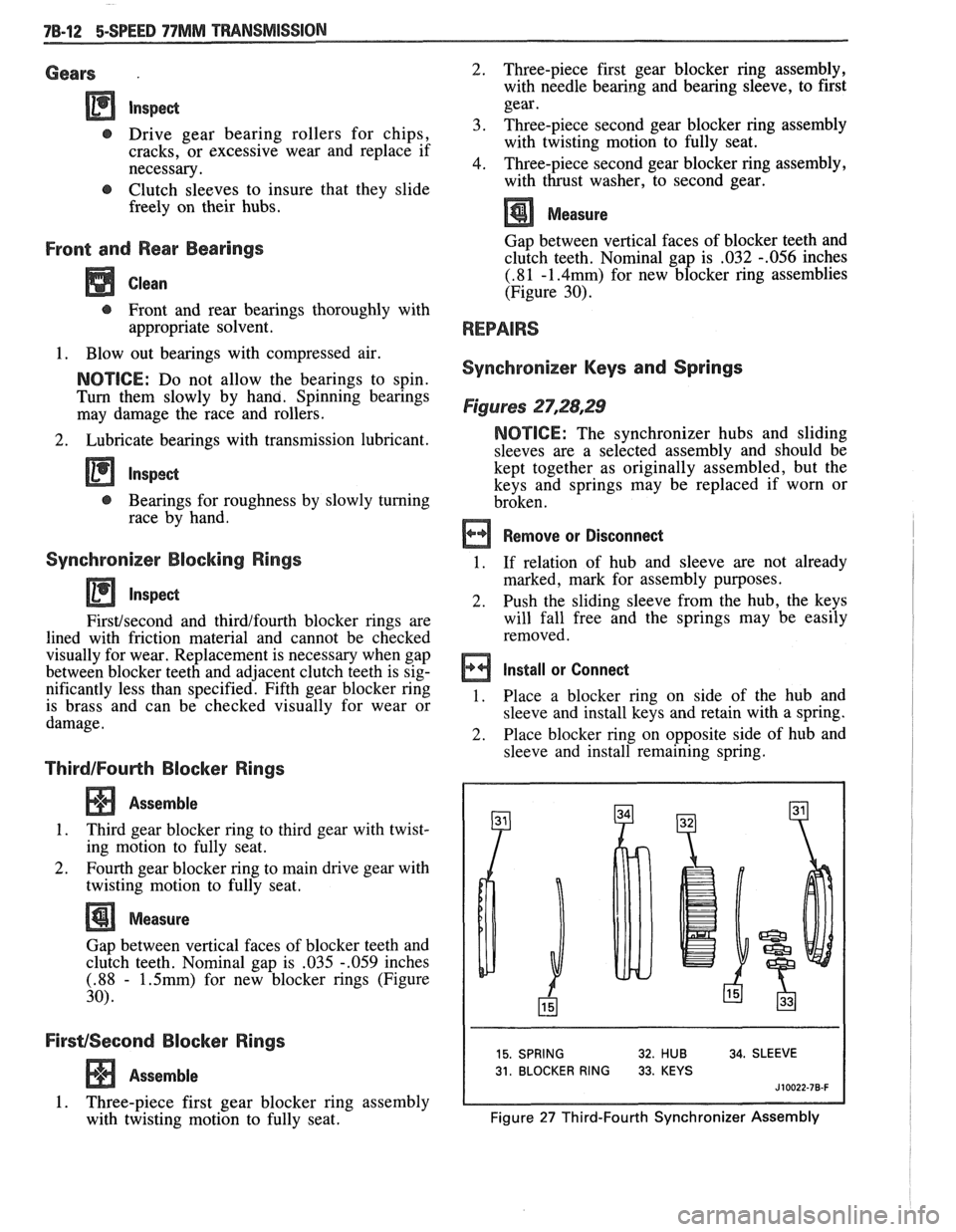

Synchronizer Keys and Springs

Figures 27,28,29

NOTICE: The synchronizer hubs and sliding

sleeves are a selected assembly and should be

kept together as originally assembled, but the

keys and springs may be replaced if worn or

broken.

Remove or Disconnect

1. If

relation of hub and sleeve are not already

marked, mark for assembly purposes.

2.

Push the sliding sleeve from the hub, the keys

will fall free and the springs may be easily

removed.

Install or Connect

1. Place a blocker ring on side of the hub and

sleeve and install keys and retain with a spring.

2. Place blocker ring on opposite side of hub and

sleeve and install remaining spring.

15. SPRING 32. HUB 34. SLEEVE

31. BLOCKER RING 33. KEYS

J 10022-78-F

Figure 27 Third-Fourth Synchronizer Assembly

Page 1150 of 1825

14. MAINSHAFT WITH HUB

15. SPRING

16. REVERSE SLIDING GEAR

17, INNER CONE

18. OUTER CONE

19. BLOCKER RING

33. KEYS

47.

ANIT-RAlTLE BALL

48. ANTI-RATTLE SPRING

Figure 28 First-Second Synchronizer Assembly

63. RETAINER

Figure 29 Fifth Gear Synchronizer Assembly

Extension Housing Oil Seal

Figure 31

Remove or Disconnect

1. Pry oil seal

out of extension housing, using a

screwdriver or small chisel.

Install or Connect

1. New oil seal into extension housing using Tool

J 21426.

2. Lubricate

I.D. of seal with transmission

lubricant.

Extension Housing Bushing

A. BLOCKER TEETH

B. FEELER GAGE

C. CLUTCH TEETH

Figure 32

rn Remove or Disconned

1. Pry oil seal out of extension housing, using a

screwdriver or small chisel.

2. Drive the bushing

out of housing, using Tool

J 8092 with J 23062-14.

Install or Connect

1. Bushing in housing, using Tool J 8092 with

J 23062-14.

2. New

oil seal into extension housing using

Tm1

J 21426.

3. Lubricate

I.D. of seal with transmission

Figure 30 Blocker Ring Wear Gap Measurement lubricant.