PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 151 of 1825

3A-4 WHEEL ALIGNMENT

AXLE HOUSING ALIGNMENT 2. If a tram is used for checking toe out, it will still

be necessary to perform Steps

1 and 2 in order to If rear tire wear indicates that the axle housing

check camber.

may be bent, the alignment can be checked as follows:

The necessary straightening operations may be

1. Back the car squarely onto an alignment performed using frame straightening equipment

machine, ~h~ actual toe-out will be read on the without removing the axle housing from the car. This

scale as toe-in. However, if the toe-out is checked procedure will allow checks during the straightening

with a tram gage, disregard this notice. operation

to determine when the housing is within the

prescribed limits.

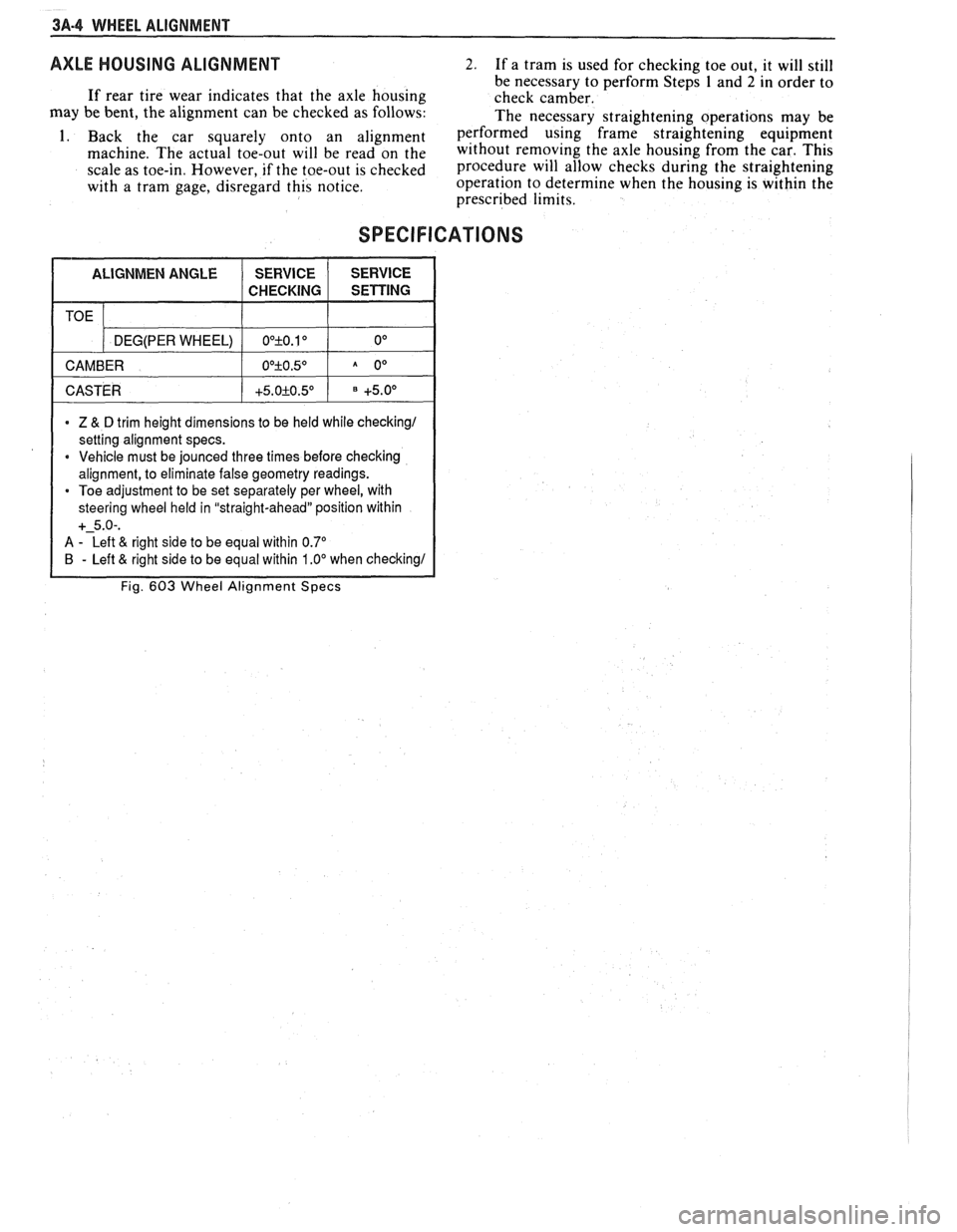

SPECIFICATIONS

1 CASTER 1 +5.0+0.5O 1 +5.0° 1

TOE

* Z & D trim height dimensions to be held while checking1

setting alignment specs.

* Vehicle must be jounced three times before checking

alignment, to eliminate false geometry readings.

Toe adjustment to be set separately per wheel, with

steering wheel held in "straight-ahead" position within

+-5.0-.

A - Left & right side to be equal within 0.7"

B - Left & right side to be equal within 1 .OO when checking1

Fig. 603 Wheel Alignment Specs

DEG(PER WHEEL)

CAMBER OO+O.10 0°

O0+O.5O A 0°

Page 152 of 1825

STEERING WHEELS AND COLUMNS 385.1

SECTION 3B5

STEER NG WHEELS AND COLUMNS

NOTICE: All steering wheel and column fasteners are important attaching parts in that they could affect

the performance of vital parts and systems, and/or could result in major repair expense. They

must be replaced

with one of the same part number or with an equivalent part if

replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. 'Torque values must be used as specified during reassembly

to assure proper retention of all parts. There is to be no welding as

it may result in extensive damage and weakening

of the metal.

For prevailing torque

nut(s) and bolts(s), refer to the "Reuse of Prevailing Torque Nut(<) and Bolt(s) " chart

in Section OA.

CONTENTS

..................... ................................................................... GENERAL DESCRIPTION .. 3B5-1 ............................................. ........................ MAINTENANCE AND ADJUSTMENTS .. 3B5-1 ON-CAR SERVICE ........................................................................................................ 3B5-2

Steering Column ............................................................................................................ 3B5-2 ......................................................................................................... Intermediateshaft 3B5-3

Park Lock Cable .................................................................... 3B54 ......................................................................................... Checking For Accident Damage 3B5-5 ............................................................................ Unit Repair Intermediate Shaft Assembly 3B5-6

..................................................................................... Standard Column @lanual Trans) 3B5-7 ......................................................... ....................... Standard Column (Auto Trans) .. 3B5-13 Tilt Column (Manual Trans) ............................................................................................. 3B5-19

Tilt Column (Auto Trans). ................................................................................................ 3B5-27

................ .................... TORQUE SPECIFICATIONS .. .. 3B5-35

SPECIAL TOOLS .......................................................................................................... 3B5-35

GENERAL DESCRIPTION

STEERING COLUMN

The function locking energy absorbing steering

column includes three important features in addition

to the steering function:

1. 'The column is energy absorbing, designed to

compress in a front-end collision to minimize the

possibility of an injury to the driver of the car.

2. The ignition switch and lock are mounted

conveniently on this column.

3. With the column mounted lock, the ignition and

steering operations can be locked to inhibit theft

of the car.

The turn signal lever provides for control of

headlight beams, windshield washer and wipers.

The column may be easily

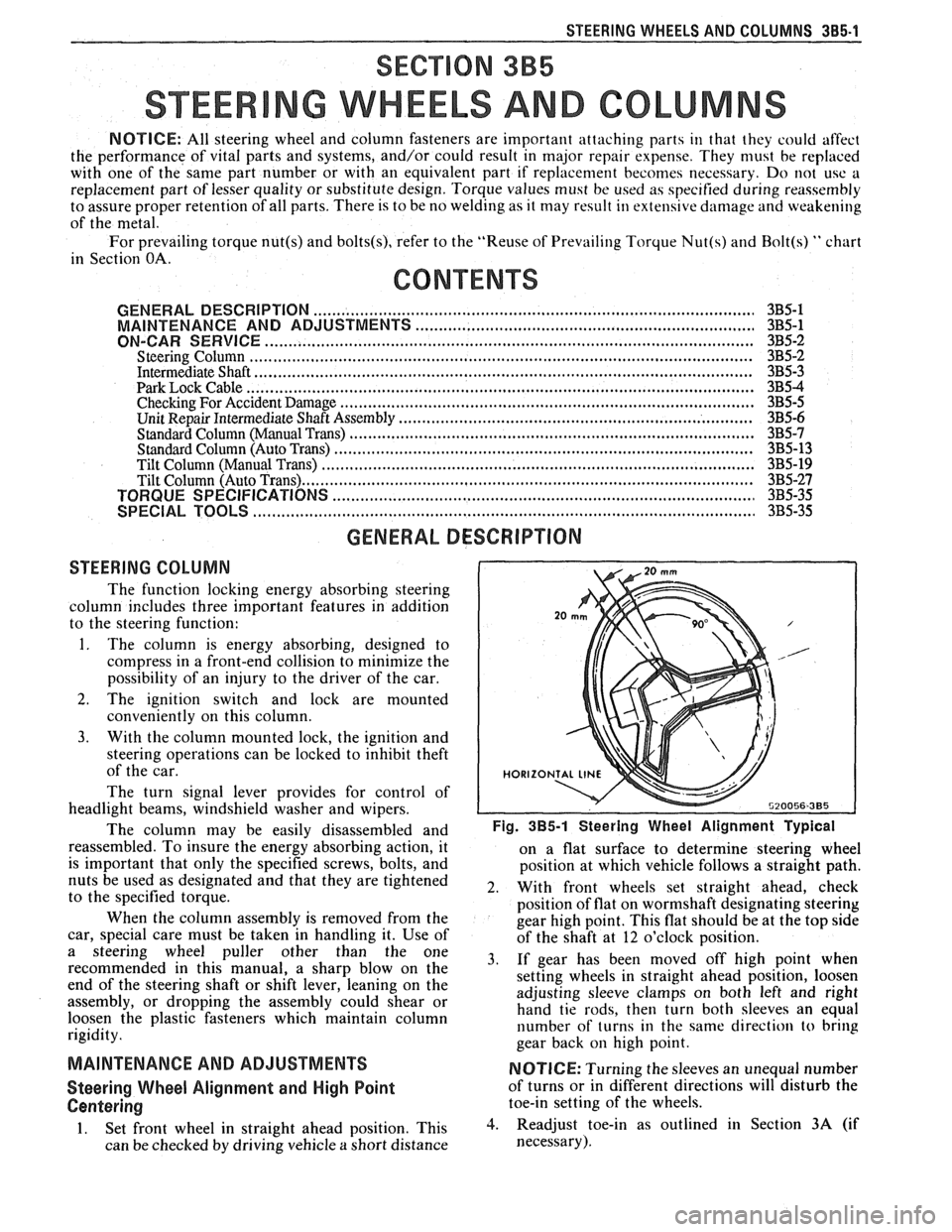

disassembled and Fig. 385-1 Steering Wheel Alignment ~ypical

reassembled. To insure the energy absorbing action, it

on a flat surface to determine steering wheel

is important that only the specified screws, bolts, and

position at which vehicle follows a straight path.

nuts be used as designated and that they are tightened

2. With front wheels set straight ahead, check to the specified torque.

position of flat on wormshaft designating steering

When the column assembly is removed from the

gear high point. This flat should be at the top side

car, special care must be taken in handling it. Use of

of the shaft at 12 o'clock position.

a steering puller other than the One 3, if gear has been moved off high when recommended in this manual, a sharp blow on the

setting wheels in straight ahead position, loosen

end of the steering shaft or shift lever, leaning on the

assembly, or dropping the assembly could shear or adjusting

sleeve clamps on both left and right

hand tie rods, then turn both sleeves an equal

loosen the plastic fasteners which maintain column

rigidity. number

of turns in the same direction

to bring

gear back

on high point.

MAINTENANCE AND ADJUSTMENTS NOTICE: Turning the sleeves an unequal number

Steering Wheel Alignment and High Point of turns or in different directions will disturb the

Centering toe-in setting of the wheels.

1. Set front wheel in straight ahead position, This 3. Readjust toe-in as outlined in Section 3A (if

can be checked by driving vehicle

a short distance necessary).

Page 153 of 1825

385-2 STEERING WHEELS AND COLUMNS

Fig. 385-2--The Flat on Worm Shaft

5. With wheels in a straight ahead position and the

steering gear on highpoint, check the steering

wheel alignment (Fig.

1). If the spokes are not

within the

limits specified, the wheel should be

removed

and centered. (See steering wheel

removal in this section).

NOTICE: The outer mast jacket shift tube,

steering shaft and instrument panel mounting

bracket are designed as energy absorbing units.

Because of the design of these components, it is

absolutely necessary to handle the column with

care when performing any service operation.

Avoid hammering, jarring, dropping or leaning on

any portion of the column.

NOTICE: When reassembling the column

components, use only the specified screws, nuts

and bolts and tighten to specified torque. Care

should be exercised in using over-length screws or

bolts as they may prevent a portion of the column

from compressing under impact.

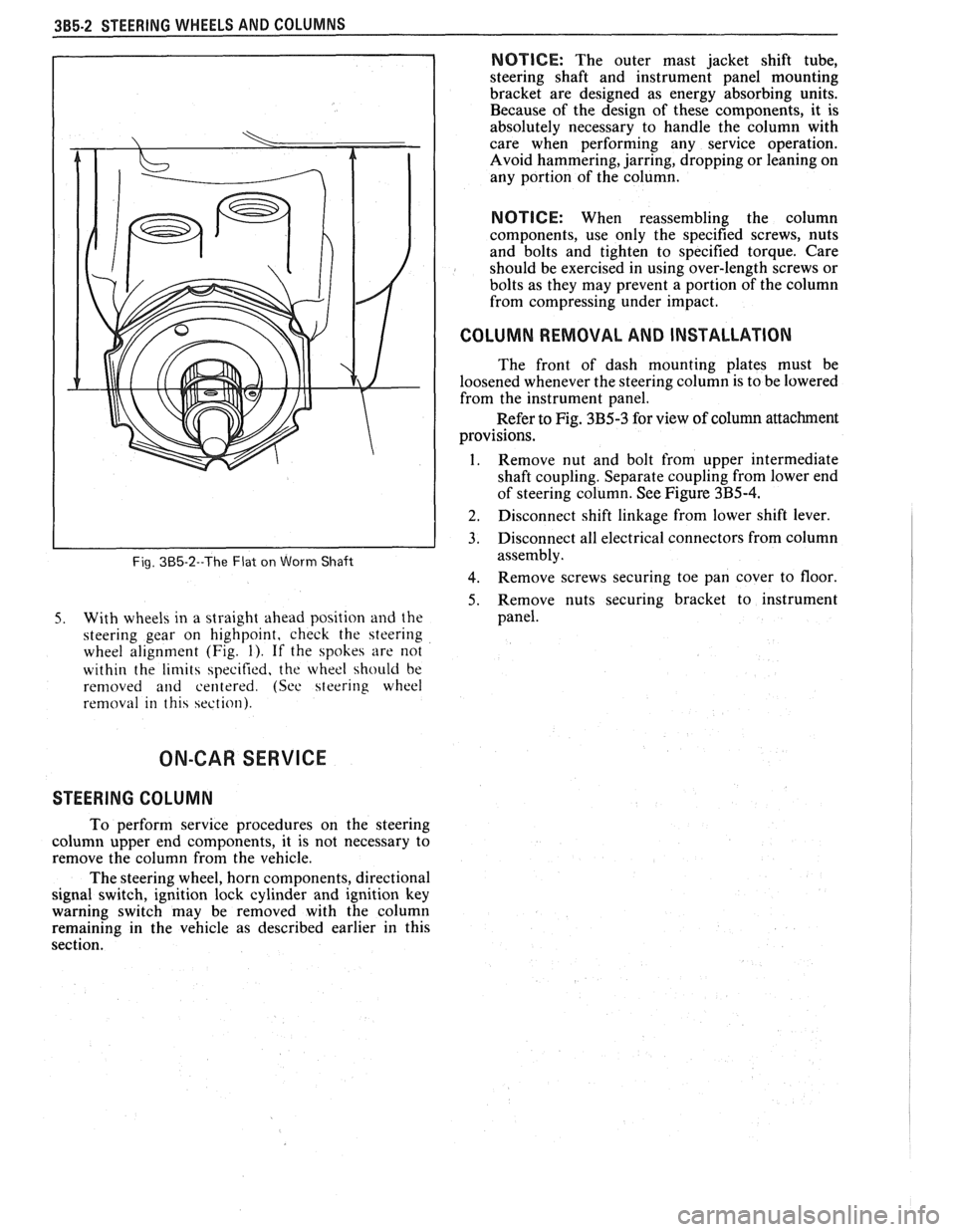

I COLUMN REMOVAL AND INSTALLATION

The front of dash mounting plates must be

loosened whenever the steering column is to be lowered

from the instrument panel.

Refer to Fig. 3B5-3 for view of column attachment

provisions.

1. Remove nut and bolt from upper intermediate

shaft coupling. Separate coupling from lower end

of steering column. See Figure

3B5-4.

] 2. Disconnect shift linkage from lower shift lever.

3. Disconnect all electrical connectors from column

assembly.

4. Remove screws securing toe pan cover to floor

5. Remove nuts securing bracket to instrument

panel.

ON-CAR SERVICE

STEERING COLUMN

To perform service procedures on the steering

column upper end components, it is not necessary to

remove the column from the vehicle.

The steering wheel, horn components, directional

signal switch, ignition lock cylinder and ignition key

warning switch may be removed with the column

remaining in the vehicle as described earlier in this

section.

Page 154 of 1825

STEERING WHEELS AND COLUMNS 385-3

ON-CAR SERVICE

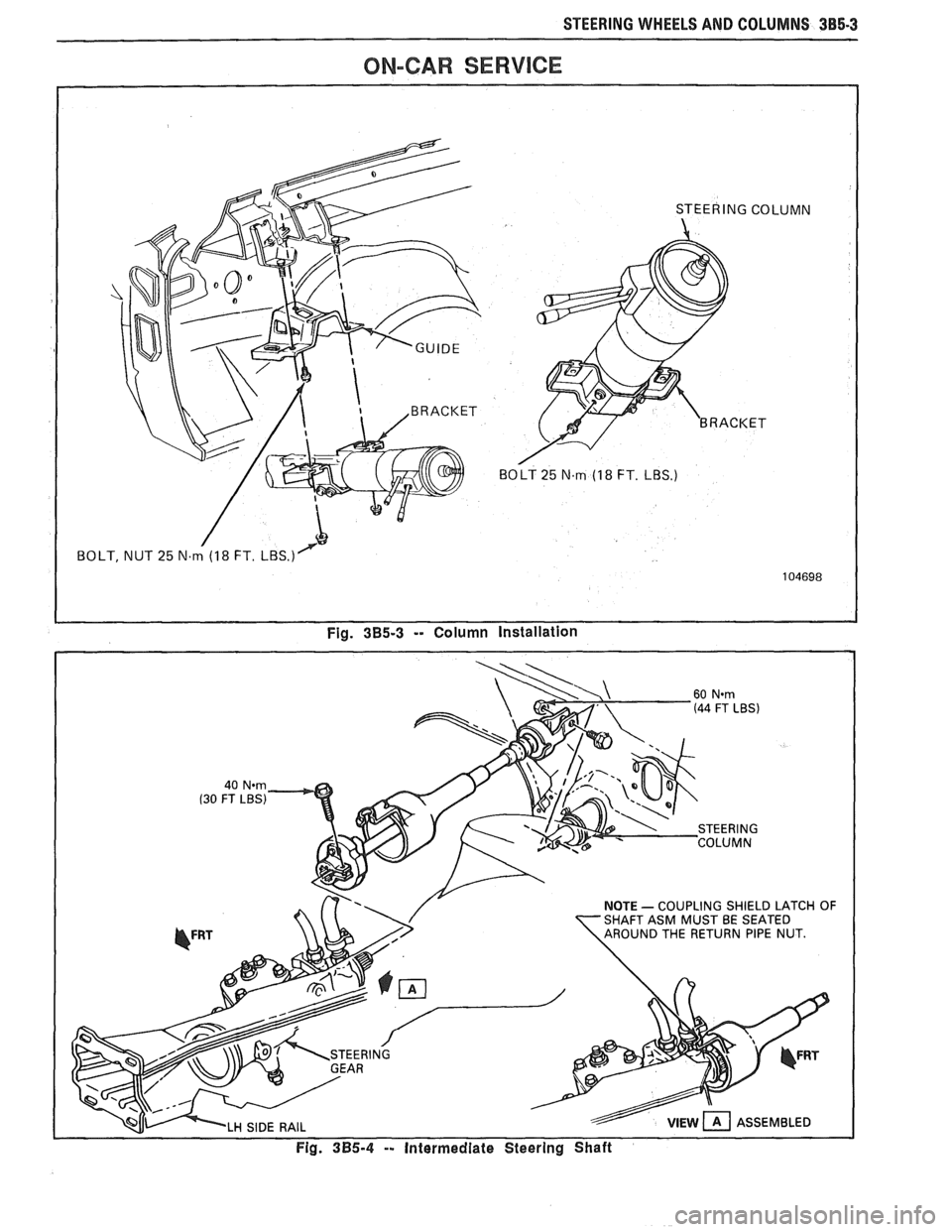

NOTE - COUPLING SHIELD LATCH OF

Fig. 3B5-4 -- Intermediate Steering Shaft

Page 155 of 1825

385-4 STEERING WHEELS AND COLUMNS

ON-CAR SERVICE

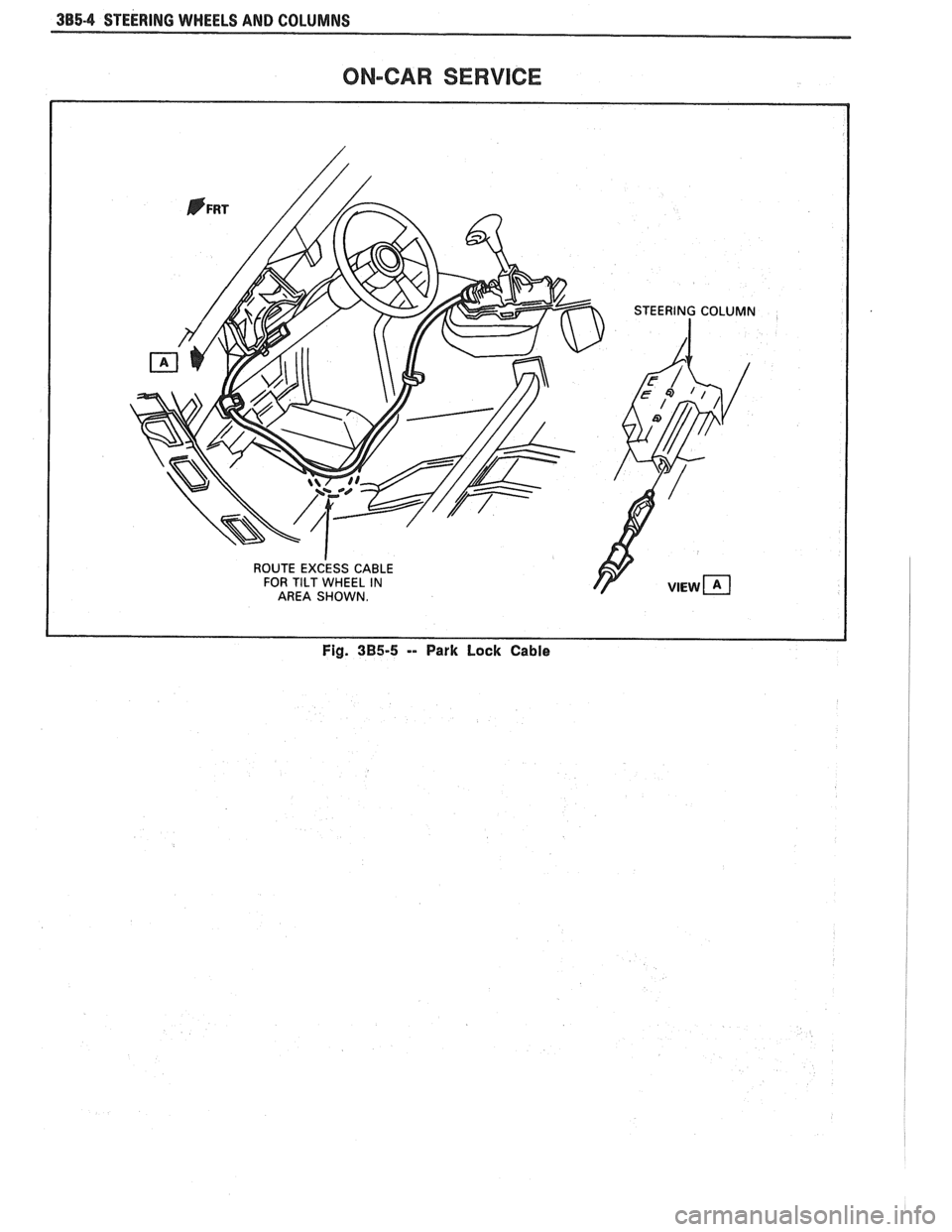

Fig. 3B5-5 -- Park Lock Cable

Page 156 of 1825

STEERING WHEELS AND COLUMNS 385-6

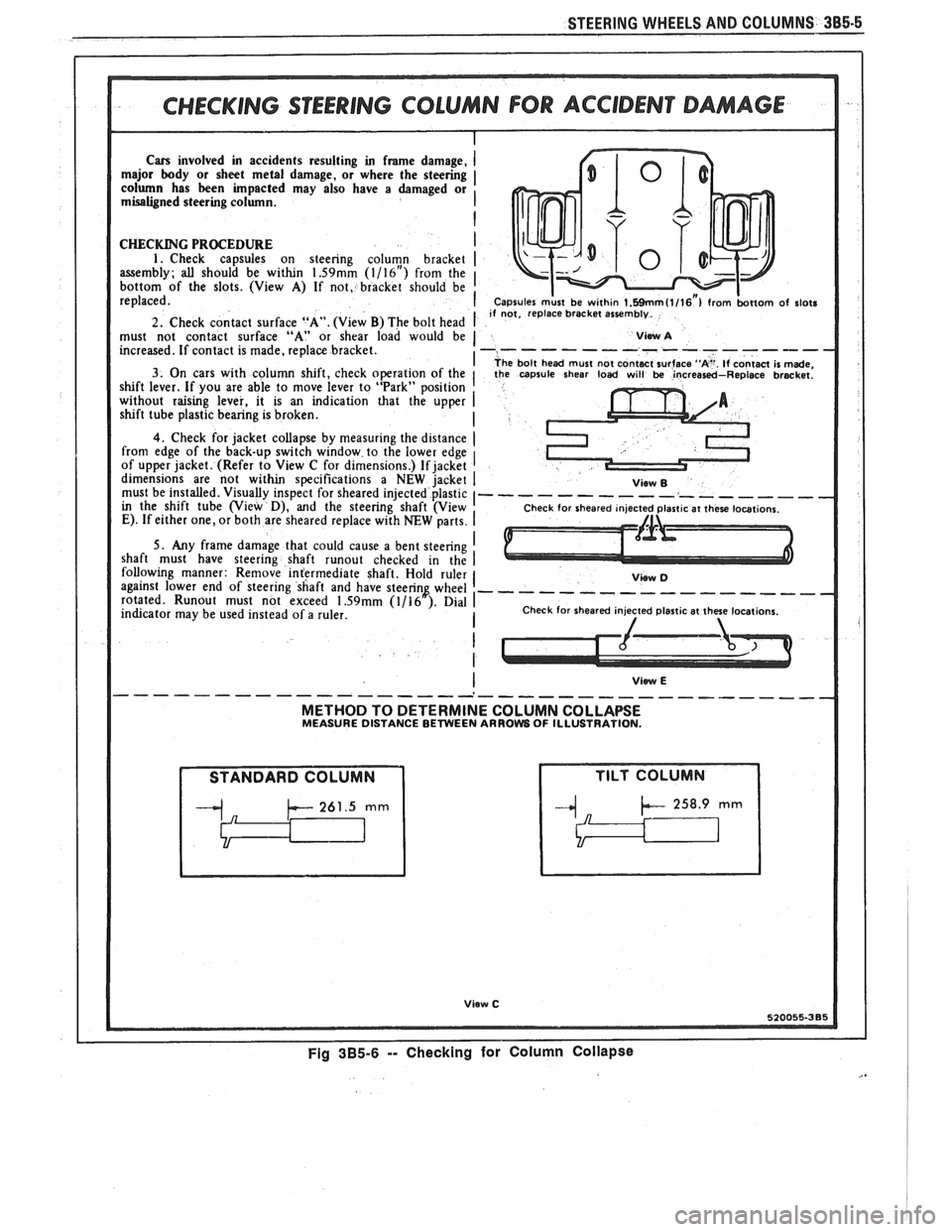

Cars involved in accidents resulting in frame damage,

major body or sheet metal damage, or where the steering

column has

been impacted may also have a damaged or

misaligned steering column.

2. Check contact surface "A". (View B) The bolt head I must not contact surface "A" or shear load would be 1 Visw A

increased. If contact is made, replace bracket. -----------------

I ;he bolt head must not contect surface "A". If contact is made, 3. On cars with column shift, check operation of the I the capsule sheer load w~ll be increased-Replace brecket. shift lever. If you are able to move lever to "Park" posltion without raising lever, it IS an indication that the upper I shift tube plastic bearing is broken.

4. Check for jacket collapse by measuring the dlstance ( from edge of the back-up switch wlndow to the lower edge

of upper jacket. (Refer to View C for dimenslons.) If jacket dimenslons are not within specificat~ons a NEW jacket I must be instatled. Visually inspect for sheared injected plastlc I------- in the shift tube (V~ew D), and the steering shaft (View E). If either one, or both are sheared replace w~th NEW parts. I

MEASURE DISTANCE BETWEEN ARROW OF ILLUSTRATION.

Viaw C

~ig 3~5-6 -- Checking for Column Collapse

Page 157 of 1825

385.8 STEERING WHEELS AND COLUMNS

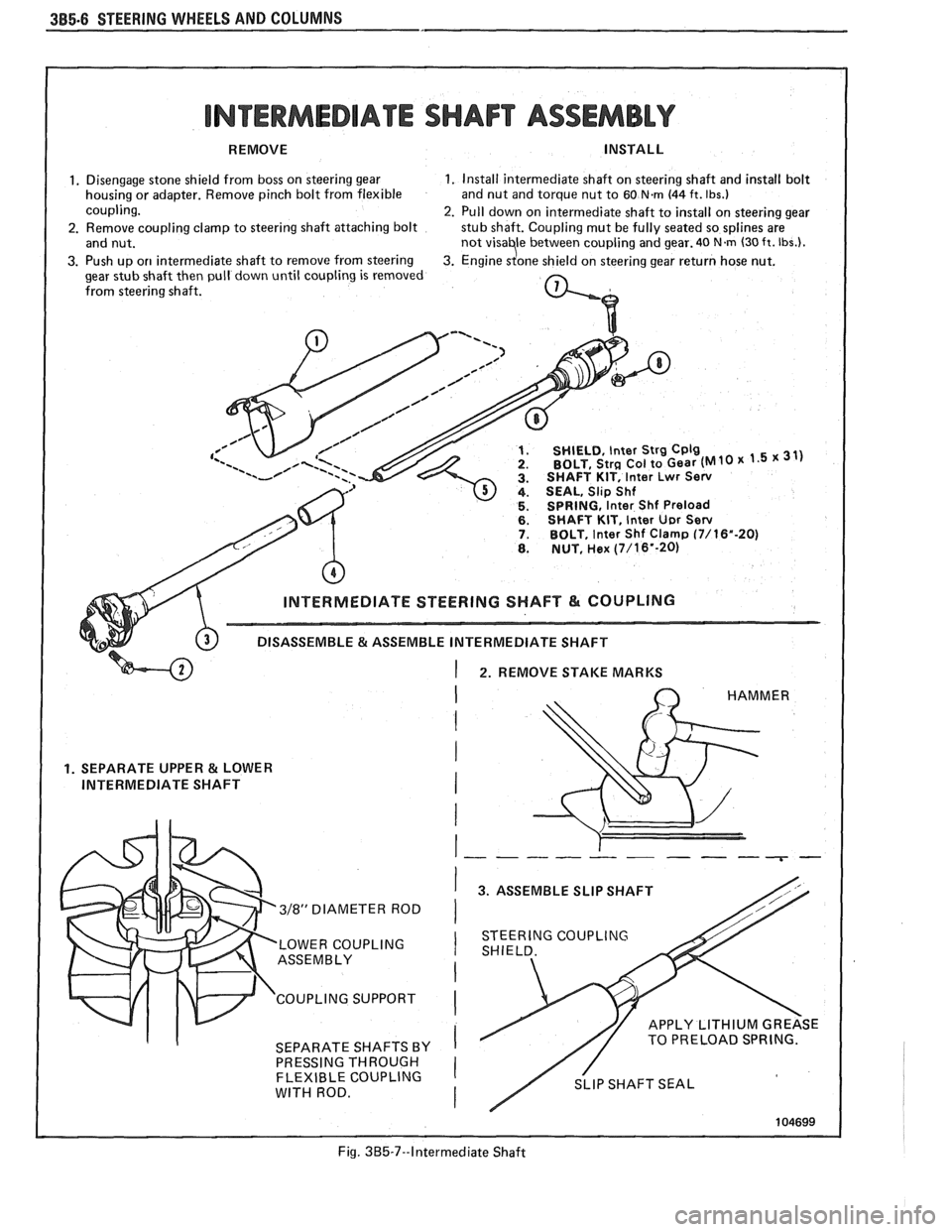

INTERMEDIATE SHAFT ASSEMBLY

REMOVE

1. Disengage stone shield from boss on steering gear

housing or adapter. Remove pinch bolt from flexible

coupling.

2. Remove coupling clamp to steering shaft attaching bolt

and nut.

3. Push up

on intermediate shaft to remove from steering

gear stub shaft then pull down until coupling is removed

from steering shaft. INSTALL

1. Install

intermediate shaft on steering shaft and install bolt

and nut and torque nut to 60 N.m (44 ft. Ibs.)

2. Pull down on intermediate shaft to install on steering gear

stub shaft. Coupling mut be fully seated so splines are

not visa

le between coupling and gear. 40 N.m (30ft. Ibs.).

3. Engine 4 one shield on steering gear return hose nut.

1. SHIELD, lnter Strg Cplg 2. BOLT, Str~ Col to Gear (MI0 31) 3. SHAFT KIT, lnter Lwr Sew 4. SEAL, Sl~p Shf 5. SPRING, lnter Shf Preload 6. SHAFT KIT, lnter UD~ Sew 7. BOLT, lnter Shf Clamp (7/16"-20) 8. NUT, Hex (7/16"-20)

1 2. REMOVE STAKE MARKS

1. SEPARATE UPPER & LOWER

INTERMEDIATE SHAFT

3/8" DIAMETER ROD

LOWER COUPLING

ASSEMBLY

COUPLING SUPPORT

SEPARATE SHAFTS BY

PRESSING THROUGH

FLEXIBLE COUPLING

WITH ROD. HAMMER

3. ASSEMBLE SLIP SHAFT /

STEERING COUPLING

SHIELD.

APPLY LITHIUM GREASE / // TO PRELOAD SPRING.

/ SLlP SHAFT SEAL

Fig. 385-7--Intermediate Shaft

Page 158 of 1825

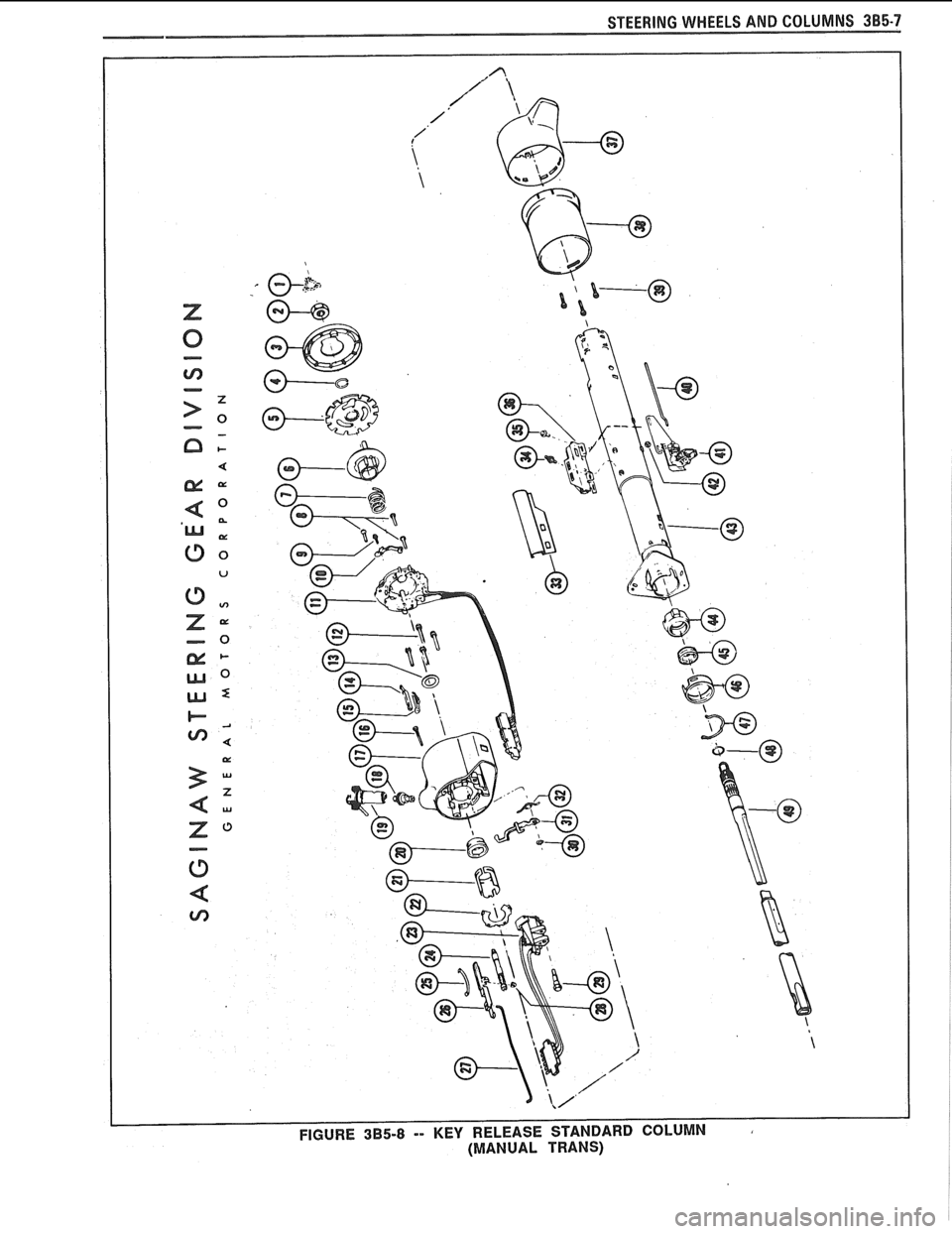

STEERING WHEELS AND COLUMNS 385-7

Page 159 of 1825

V)V) V,

5; E ;;I: -4-4 w my, 00 4 s- s zg By, " e, Om- B 4a 2 Oy, cs a gg o, ?gxcpB

0 -4:zz =A L ZR

5; "5 -4 Zi X(P, -4 50 -

oz

SNUUn183 QNV S133HM 9Nlt1331S %98€

Page 160 of 1825

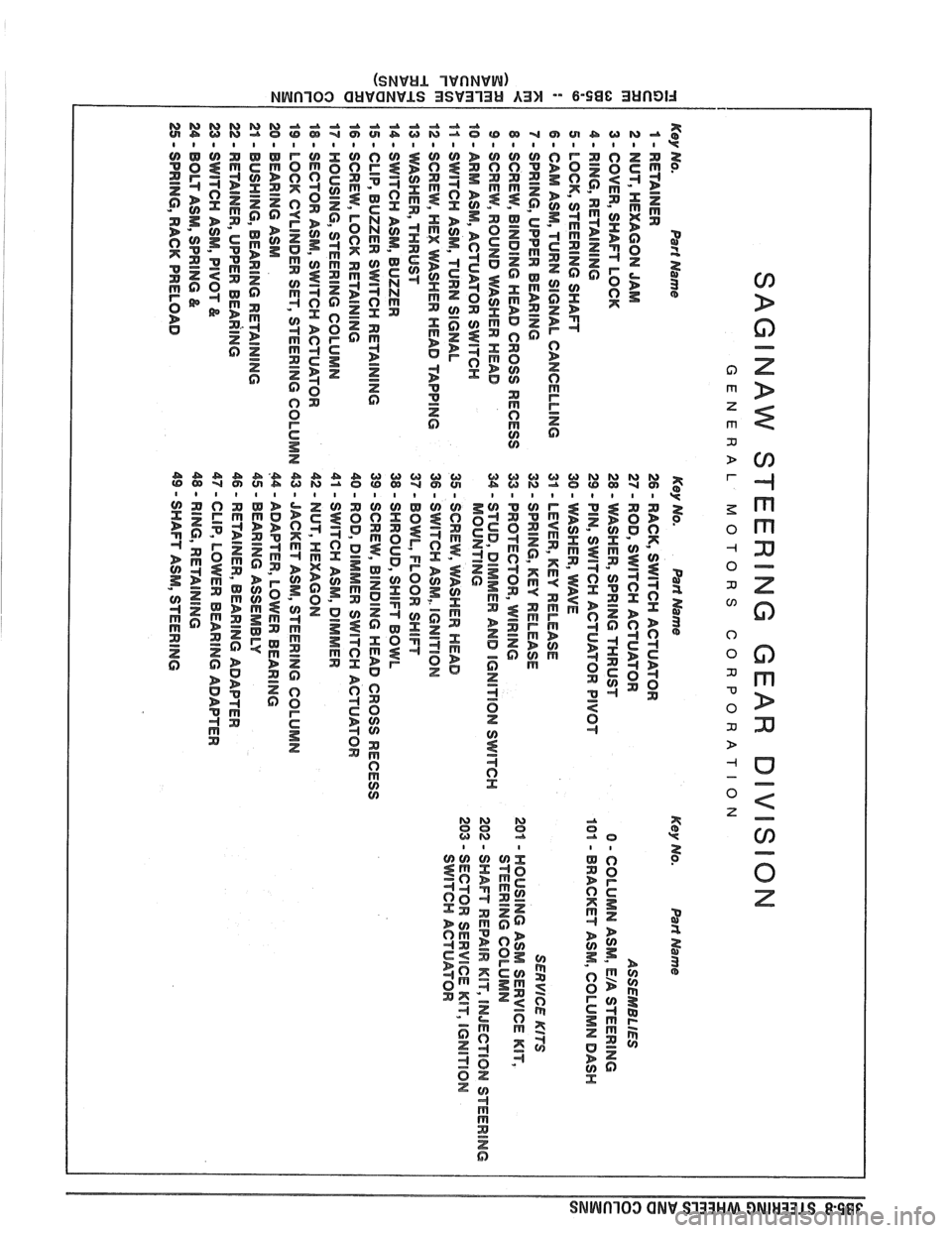

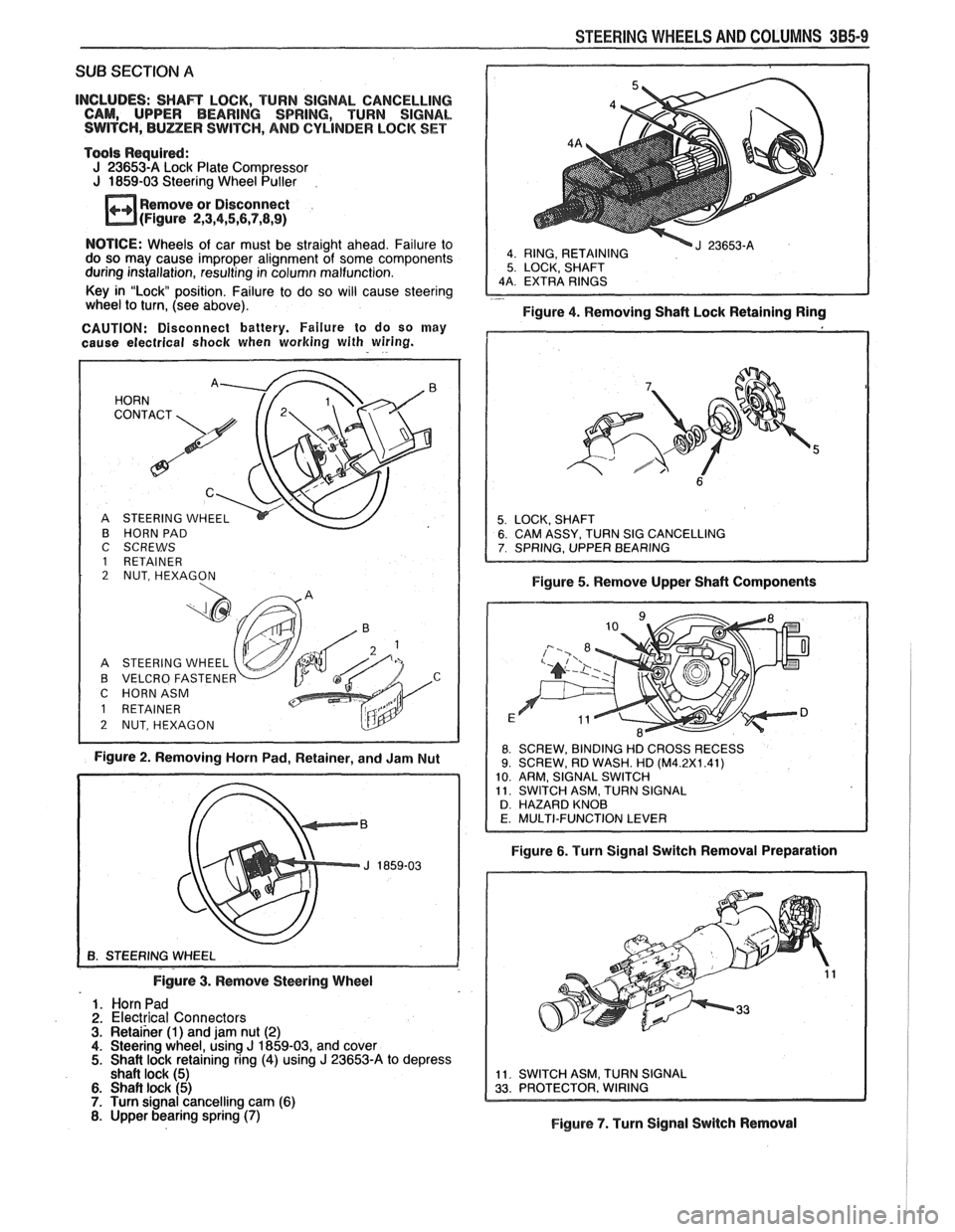

STEERING WHEELS AND COLUMNS 385-9

SUB SECTION A

INCLUDES: SHAR LOCK, TURN SIGNAL CANCELLING

CAM, UPPER BEARING SPRING, TURN SIGNAL

SWITCH,

BULZER SWITCH, AND CYLINDER LOCK SET

Tools Required:

J 23653-A Lock Plate Compressor

J 1859-03 Steering Wheel Puller

Remove or Disconnect

(Figure

2,3,4,5,6,7,8,9)

4 RING, RETAINING 5 LOCK, SHAFT

NOTICE: Wheels of car must be straight ahead. Failure to

do so may cause improper alignment of some components

during installation, resulting in column malfunction.

Key in "Lock position. Failure to do so will cause steering

- wheel to turn, (see above).

Figure 4. Removing Shaft Lock Retaining Ring

CAUTION: Disconnect battery. Failure to do so may

cause electrical

shock when working with wiring.

B HORN PAD

C SCREWS

1 RETAINER 2 NUT, HEXAGON

A STEERING WHEEL

B VELCRO FASTENE

C HORNASM

Figure 2. Removing Horn Pad, Retainer, and Jam Nut Figure

5. Remove Upper Shaft Components

8 SCREW,

BINDING HD CROSS RECESS 9. SCREW, RD WASH. HD (M4.2X1.41)

10 ARM, SIGNAL SWITCH

11 SWITCH ASM, TURN SIGNAL

D HAZARD KNOB

Figure 6. Turn Signal Switch Removal Preparation

Figure

3. Remove Steering Wheel

1. Horn Pad

2. Electrical Connectors 3. Retaiher (1) and jam nut (2) 4. Steering wheel, using J 1859-03, and cover 5. Shait lock retaining ring (4) using J 23653-A to depress

shaft lock (5)

6. Shaft lock (5) 7. Turn signal cancelling cam (6) 8. Upper bearing spring (7) Figure 7. Turn Signal Switch Removal