PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 1611 of 1825

Page 1612 of 1825

INSTRUMENT PANEL, GAGES & CONSOLE 8C-'I

SECTION 8C

NSTRUMENT PANEL, GAGES & CONSOLE

CONTENTS

General Description ................................... 8C-1

Instrument Panel and Gages ........................ 8C-1

Printed Circuit .......................................... 8C-1

Instruments ................................................... 8C- 1

Speed Sensors

............................ .. ............. 8C- 1

Pinion Gear

............................................. 8C-2

Photo Speed Sensor ................................ 8C-2

PM Generator ................... .. ...... ............... 8C-2

Speedometer ................................................ 8C-2

Mechanical ....................... .. .................... 8C-2

Quartz ........................ .. .......................... 8C-2

Digital .................... .. ...... ................. 8C-2

Fuel Gage .................................................... 8C-2

Temperature Warning Light ...................... 8C-3

Generator Warning Light ............................ 8C-3

Engine Oil Pressure Light ............................ 8C-3

"Service Engine Soon" Light ....................... 8C-3

Upshift Indicator Light .............................. 8C-3

Diagnosis .................... .. ........................... 8C-3

General Information .................................. 8C-3

Instrument Panel & Gages ...................... ..... 8C-3

On-Car Service ......................... .. ........... 8C-4

Instrument Panel Pad ................................... 8C-4

Instrument Panel Cluster ........................... 8C-4

Instrument Panel Carrier ............................. 8C-4

Headlight Switch .......................................... 8C-4

Console Mounted Switches and

Accessories

............................................... 8C-4

Console ......................................................... 8C-4

Speedometer .................................................. 8C-5

Illustra3ions ................................................. 8C-5

IP Pad ........................................................... 8C-5

IP Carrier ................................................... 8C-6

Instrument Cluster ....................................... 8C-6

Lower IP Covers ......................................... 8C-7

IP Trimplates ............................................... 8C-7

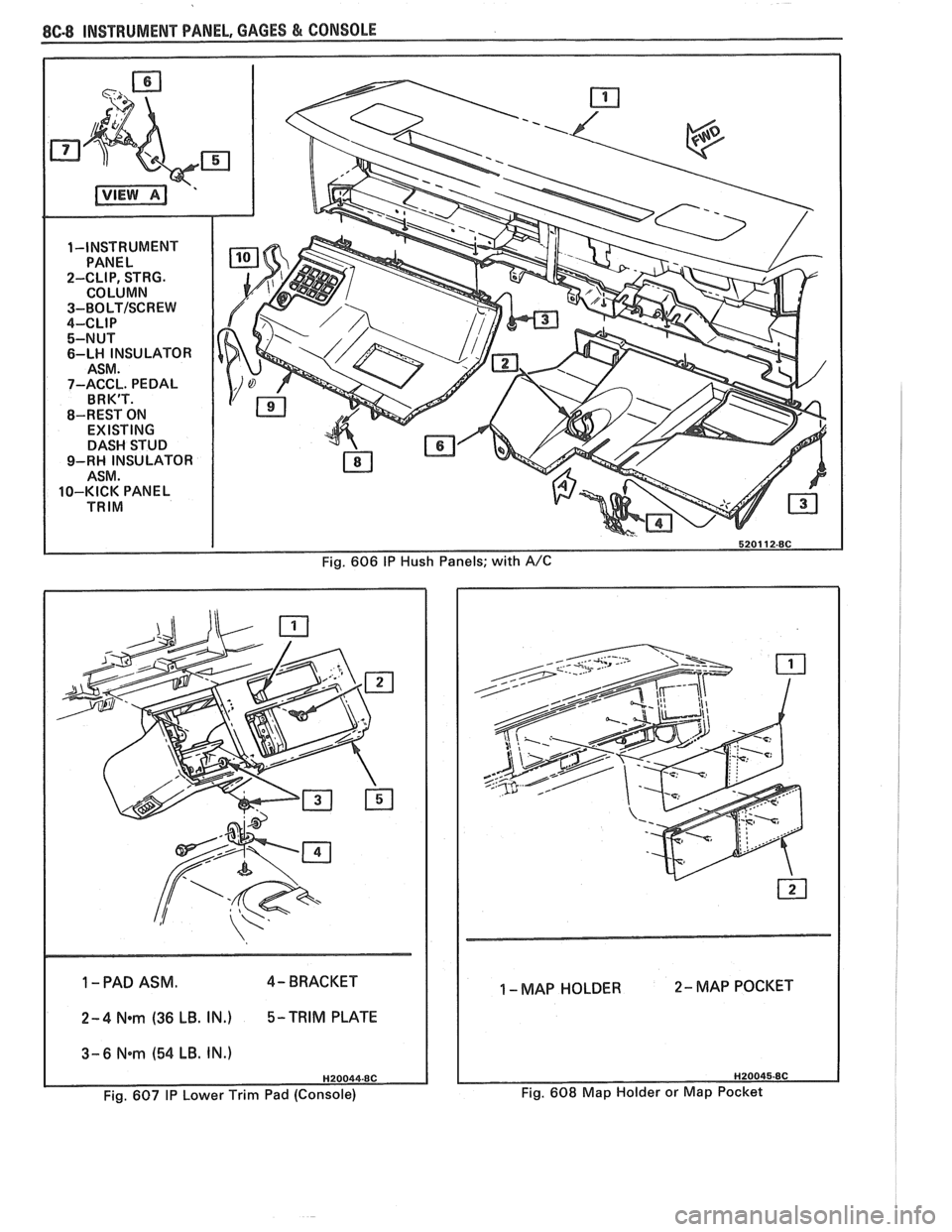

IP Hush Panels; with A/C .......................... 8C-8

..................... IP Lower Trim Pad (Console) 8C-8

Map Holder or Map Pocket ........................ 8C-8

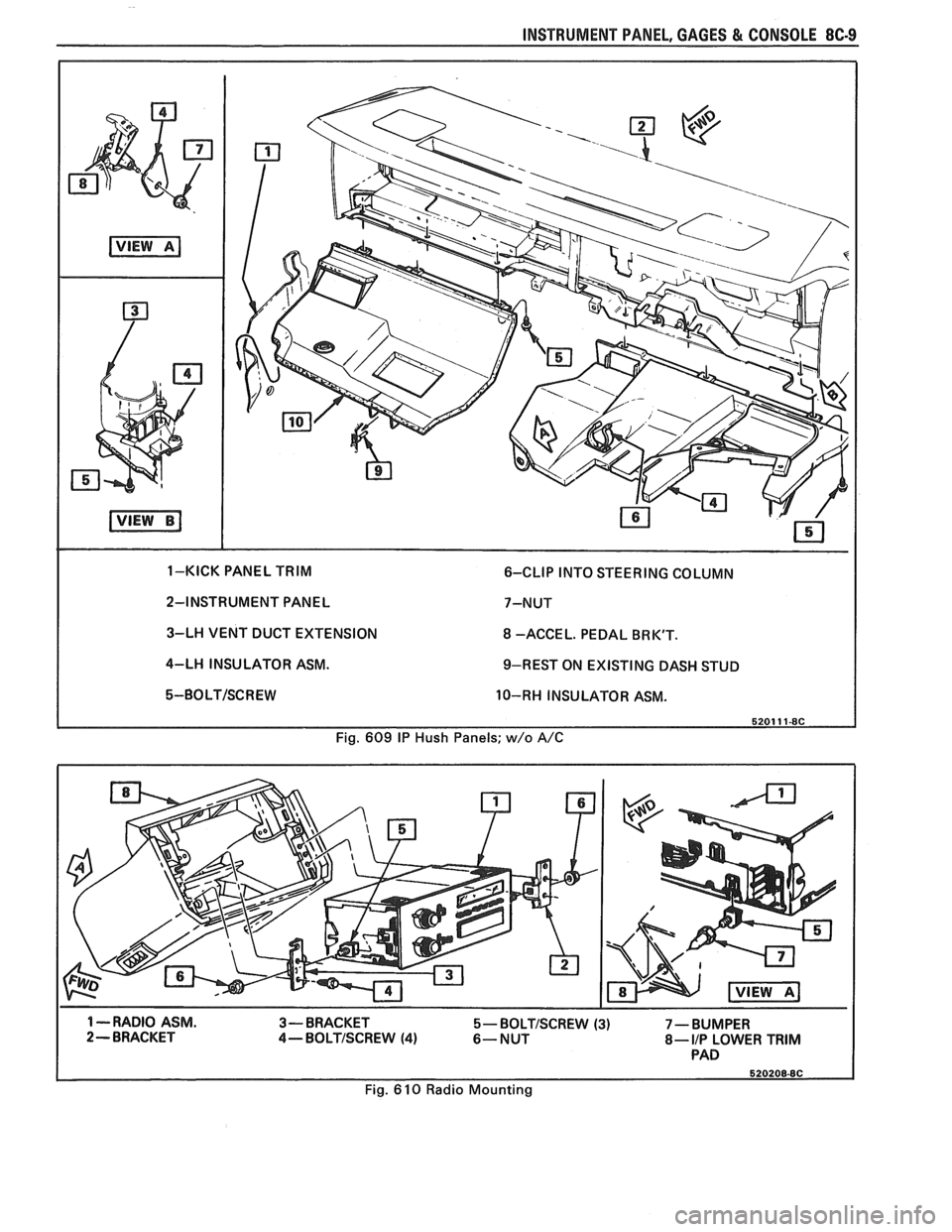

IP Hush Panels; without A/C ..................... 8C-9

Radio Mounting ........................................... 8C-9

Subwoofer & Hatch Release

Switches/Covers ........................................ 8C- 10

Foglamp Switch/Cover ................................ 8C- 10

Oil Pressure and Temperature

Switches

..................................................... 8C-11

Heater/Ventilation/Defroster

Ductwork .................................................. 8C- 12

A/C and Defroster Ductwork ..................... 8C-13

Ram Vent System Ductwork ....................... 8C-14

Console Mounted Switches

&

Accessories ................................................. 8C- 14

Dash Insulators

............................................ 8C- 15

Heater Floor Outlet

..................................... 8C-15

................ Headlamp/Parking Lamp Switch 8C- 15

............. Dash Mounted Accessory Switches 8C- 15

GENERAL DESCRIPTION

INSTRUMENT PANEL AND GAGES

INSTRUMENTS

Instruments consist of fuel gage, temperature

The instrument panel on most cars is a sing,e unit indicator light, generator light, oil pressure indicator

design and all parts attach to the main instrument light, and speedometer. See Section 9F for optional

panel with clips and screws. To service the instrument Gages and tachometer. Service on instruments

panel and components see on-car service information, can be obtained through authorized repair stations.

However, knowledge of instrument circuit checks will

PRINTED CIRCUIT

All models are equipped with printed circuits

which supply current to most instrument panel lights

and instruments. These circuits are made of copper foil

which is die cut and bonded to a polyester base film

(usually mylar). The printed circuit electrical power is

supplied by a connector containing several wires, as

shown in the instrument panel wiring harness

installation instructions. The connector also helps

retain the printed circuit to the speedo cluster. The rest

of the circuit is retained by additional connectors (if

used) and snap-in

bulbs/sockets. For individual

printed circuit diagrams, see Section

8A-80/8 1/82/83,

'Instrument Panel'. help

in determining if operating difficulties lie in the

instrument itself or its related circuit.

Instruments have been designed for easy removal

by elimination of separate wiring. With the wiring

provisions integrated with the instrument panel wiring,

the instruments can be removed after removing the

trim and lens.

SPEED SENSORS

There are three speed sensors currently in use:

1. PINION GEAR; used in mechanical systems

2. PHOTO SPEED SENSORS; used in mechanical

systems

3. PM GENERATOR; used in electronic systems

Page 1613 of 1825

842-2 INSTRUMENT PANEL. GAGES & CONSOLE

Pinion Gear

The PINION GEAR is attached to the

traaasmission/transaxle output shaft and rotates in

proportion to the speed of the car. This rotation is

transferred from the pinion gear to the speedometer

head by the speedometer cable.

Photo Speed Sensor

On vehicles that use a mechanical drag-cup

speedometer, the PHOTO SPEED SENSOR is

inserted into the frame of the mechanical speedometer

to provide an electrical feedback to the ECM that

represents vehicle speed. The ECM needs to know how

fast the car is traveling in order to control and operate

the cruise control, cooling fan, and transmission and

evaporative systems.

The photo speed sensor is made up of two special

electronic devices: a Eight-Emitting Diode (LED) and

a photo transistor (a light-sensitive amplifying device).

In the mechanical speedometer, there is a reflective

blade attached to the rotating magnet that is polished

to

reflect light from the LED back to the photo

transistor. Whenever the light strikes the photo

transistor, it conducts electricity. The rate that the

transistor conducts and does not conduct is

proportional to the speed of the magnet, which reflects

the speed of the vehicle. This voltage signal from the

photo transistor is sent to a buffer amplifier (part of the

speed sensor) to be conditioned to a signal the ECM

can understand and use.

PM Generator

The PM (Permanent Magnet) GENERATOR is

a small

AC generator used to sense vehicle speed. The

shaft of the generator fits into a pinion gear in the

transmission/transaxle output shaft (as does the cable

in

a mechanical system).

When the output shaft rotates, the magnet rotates

and generates a voltage. Except for the permanent

magnet, the

PM Generator is exactly like a miniature

alternator. The PM generator is constructed to provide

a voltage whose frequency is about

1.1 cycles per

second for every mile per hour of vehicle speed. This

signal is sent to a buffer amplifier, and then to the

speedometer and the

EGM.

SPEEDOMETER

The speedometer is a road speed indicator with

an odometer to record total mileage, and, on some cars,

a resettable trip odometer.

The major types of speedometers in use are

mechanical instruments and electronic instruments.

Mechanical speedometers use a dial needle to indicate

road speed. Electronic speedometers include

instruments that use a dial indicator and those using

bar-graph

LCD's (Liquid Crystal Displays) or VTF

(Vacuum Tube Fluorescent) displays.

Meehanice! Speedometers

A mechanical speedometer uses a cable driven

(through a pinion gear) by the transmission output

shaft. The cable connects to a magnetic drag-cup inside the

speedometer, which rotates the speedometer

needle. The end of the rotating cable causes a small bar

magnet to rotate within a metal cup. As the magnet

rotates within the cup, it magnetically attracts (drags)

the metal cup along behind it. Two things work to

prevent the cup from rotating as quickly as the magnet.

1. The distance of the magnet from the cup reduces

its effect on the cup.

2. A counterspring is wound around the shaft of the

cup in such a way as to oppose the normal

rotation of the cup. The counterspring loads the

drag-cup to give correct indication of the speed,

prevent needle overshoot, and also to return the

drag cup to a zero point.

Mechanical speedometers require a photo speed

sensor to provide road speed information for the ECM

and other systems, such as Cruise Control and the TCC

(Torque Converter Clutch).

The odometer on these instruments consists of

numbered wheels that are rotated by the speedometer

cable through worm gears.

Quartz Speedometer

The quartz speedometer is an electrically driven

instrument. The indicator needle is driven by a

precision DC motor, and is countersprung to provide

a mechanical load, prevent overshoot of the needle, and

return the indicator to zero when the road speed is

zero.

The source of speed information for a quartz

speedometer is the PM generator. From the PM

generator, speed information goes to the buffer

amplifier to be converted to digital voltage, and then

to the cluster circuitry, which interprets the speed of

the vehicle and produces small voltage to apply to the

speedometer motor.

The odometer on this instrument consists of

numbered wheels that are electrically driven by a

special precision DC motor called a stepper motor.

Digital Speedometer

Digital clusters utilize two types of displays: LCD

(Liquid Crystal Display) and VTF (Vacuum Tube

Fluorescent). They are used in digital speedometers

and bar-graph tachometers, fuel gages, etc.

Speed information entering the cluster from the

buffer amplifier is interpreted by a microcomputer

which controls the speed indication, the tachometer

display and the odometer reading.

The odometers associated with these instruments

utilize either numbered wheels driven by a small motor

or electronic displays. With an electronic display, the

mileage reading is stored in a computer chip (called a

non-volatile RAM chip; NVRAM) that does not

become 'erased' when the vehicle is turned off,

as the

display does not retain the information.

FUEL GAGE

An electrical fuel gage is used on all models,

consisting of an instrument panel gage and a fuel tank

pick-up. The fuel gage indicates the quantity of fuel in

Page 1614 of 1825

INSTRUMENT PANEL. GAGES & CONSOLE 8C-3

tank only when ignition switch is turned to "ON" or

"ACCESSORY" positions.

When ignition is turned to "OFF" or "START"

positions, the pointer may come to rest at any position.

The letters

"E" and "F" on the fuel gage are used to

point out direction of indicator travel only.

TEMPERATURE WARNING LIGHT

The engine temperature warning light is

controlled by a thermal switch which senses engine

coolant temperatures.

When the ignition switch is turned to "START"

position, a test circuit is closed and the light will come

on to indicate whether the light is functioning properly.

It is important to note that with low boiling-point

coolants (such as plain water) the temperature light

may not come on even though the coolant is boiling.

GENERATOR WARNING LIGHT

The generator warning light, located in the

instrument cluster, should come on when the ignition

switch is turned

"ON" and engine is not running. If

not, either the bulb is burned out or wiring to generator

has an open circuit.

When the generator voltage output becomes

greater than the battery voltage, the

"GEN" light

should go out. This does not, however, indicate

whether the battery is being charged or if the voltage

regulator is functioning properly.

Checks of the charging system are covered in

Section 6D, 'Engine Electrical'.

ENGINE OIL PRESSURE LIGHT

The engine oil pressure warning light is mounted

in the instrument cluster and controlled by a pressure

operated switch located on the engine block. When the ignition switch is

in the

"run" or "start9' position, the

oil pressure light should come on. If not, the bulb is

burned out, there is an open circuit between the bulb

and the oil pressure switch, or there is an open circuit

between the oil pressure switch and the choke heater.

After the engine is running, the oil pressure light

should go out when the oil pressure reaches the correct

specification. If not an oil pressure problem, a faulty oil

pressure switch or an open circuit from the choke

heater fuse to the oil pressure switch is indicated.

"SERVICE ENGINE SOON" LIGHT

All cars have a "SERVICE ENGINE SOON"

light mounted in the instrument cluster. The

"SERVICE ENGINE SOON9' light should come on

during engine starting. The light may stay on

a short

time after the engine starts.

If the light comes on while

driving, service to the emission control system may be

required. See Section

6E and Section 8A-80,

'Instrument Cluster', for complete diagnosis and

wiring diagrams of the

""P;RVICE ENGINE SOON"

light circuit.

UPSHIFT INDICATOR LIGHT

If your vehicle has a manual transmission, there

may be an

''Upshift" light on the instrument panel.

This light is illuminated to indicate optimum shift

points throughout the range from optimum fuel

economy to optimum performance. When this light is

on, shift your transmission to the next higher gear

range if conditions permit. For fuel economy,

accelerate slowly and shift when the light goes on. For

performance, accelerate as desired and shift when the

light goes on.

Safe operation of the vehicle may require shifting

differently than indicated by the "Upshift" light to

adapt to weather, road or traffic conditions.

Downshifting one or more gears may be required

to keep the engine running smoothly or to maintain

satisfactory performance.

DIAGNOSIS

Diagnostic information for all instrument panel

electrical systems is found in Section

8A-80,

'Instrument Panel'.

CAUTION: When removing or

installing any electrical units,

disconnect the negative battery cable

to prevent possible short circuits

which could lead to personal injury

and/or property damage. When

replacing a speedometer or

odometer assembly, the law requires the

odometer reading of the replacement unit to

be set to register the same mileage as the

prior odometer.

if the same mileage cannot be

set, the

law requires that the replacement

odometer be set to zero and a label be

installed on the driver's door frame to show

the previous odometer reading and the date

of replacement.

GENERAL BNFORMATlOM

INSTRUMENT PANEL AND GAGES

The instrument panel is a single unit design and

and screws. To service the instrument panel and

all parts attach to the main instrument panel with clips components see Figs. 601 through 610.

Page 1615 of 1825

8C.4 INSTRUMENT PANEL, GAGES & CONSOLE

ON-CAR SERVlCE

lNSTRUMEMT PANEL PAD

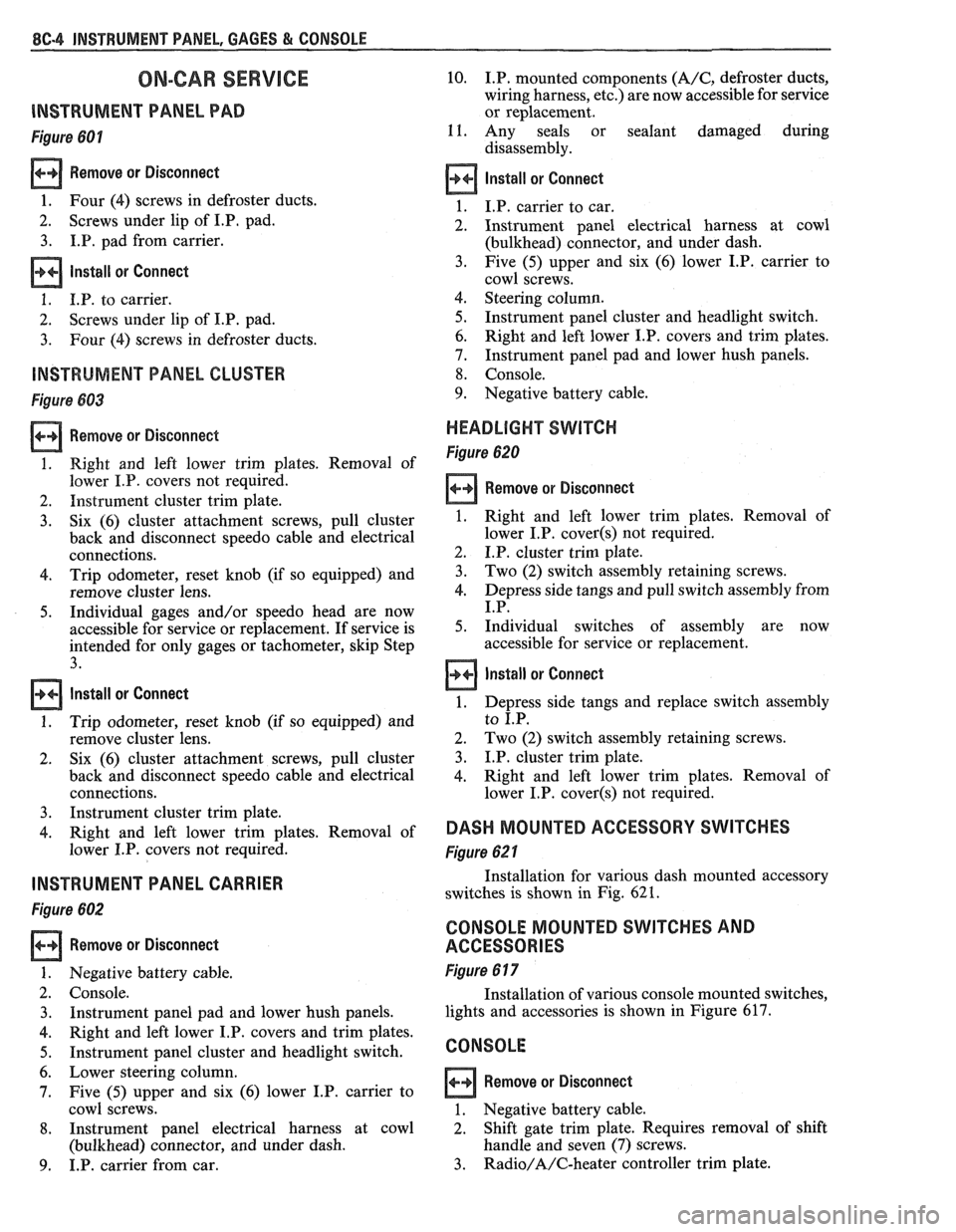

Figure 601

Remove or Disconnect

1. Four (4) screws in defroster ducts.

2. Screws

under lip of

I.P, pad.

3. I.P. pad from carrier.

lnstall or Connect

1. I.P. to carrier.

2. Screws

under lip of I.P. pad.

3. Four (4) screws in defroster ducts.

INSTRUMENT PANEL CLUSTER

Figure 683

Remove or Disconnect

1. Right and left lower trim plates. Removal of

lower I.P. covers not required.

2. Instrument cluster trim plate.

3. Six (6) cluster attachment screws, pull cluster

back and disconnect speedo cable and electrical

connections.

4. Trip odometer, reset knob (if so equipped) and

remove cluster lens.

5. Individual gages and/or speedo head are now

accessible for service or replacement. If service is

intended for only gages or tachometer, skip Step

3.

Install or Connect

1. Trip odometer, reset knob (if so equipped) and

remove cluster lens.

2. Six

(6) cluster attachment screws, pull cluster

back and disconnect speedo cable and electrical

connections.

3. Instrument cluster trim plate.

4. Right and left lower trim plates. Removal of

lower I.P. covers not required.

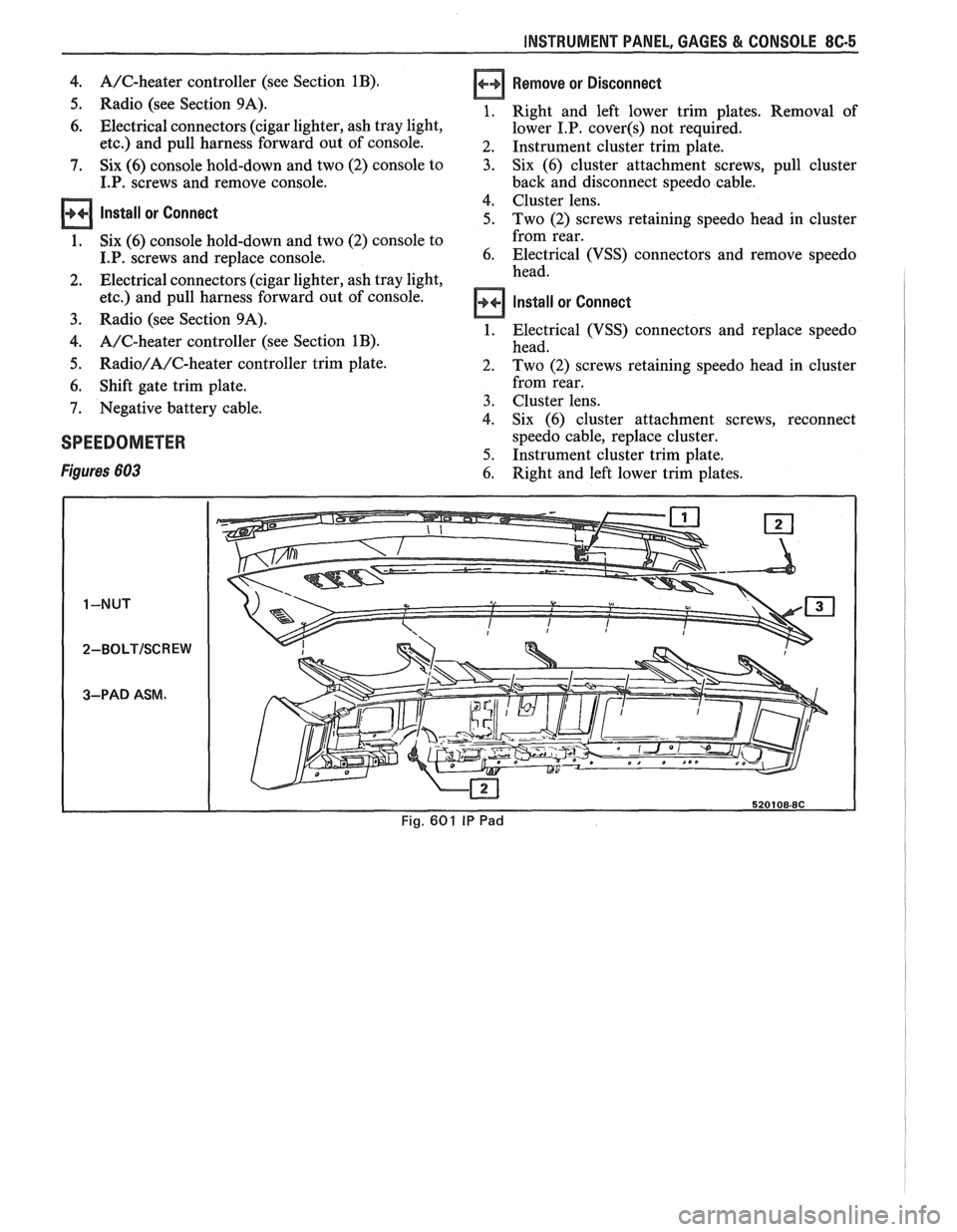

INSTRUMENT PANEL CARRIER

Figure 602

Remove or Disconnect

Negative battery cable.

Console. Instrument panel pad and lower hush panels.

Right and left lower I.P. covers and trim plates.

Instrument panel cluster and headlight switch.

Lower steering column.

Five (5) upper and six (6) lower I.P. carrier to

cowl screws.

Instrument panel electrical harness at cowl

(bulkhead) connector, and under dash.

I.P. carrier from car.

10. I.P. mounted components (A/C, defroster ducts,

wiring harness, etc.) are now accessible for service

or replacement.

11. Any seals or sealant damaged during

disassembly.

Install or Connect

I.P. carrier to car.

Instrument panel electrical harness at cowl

(bulkhead) connector, and under dash.

Five (5) upper and six (6) lower I.P. carrier to

cowl screws.

Steering column.

Instrument panel cluster and headlight switch.

Right and left lower I.P. covers and trim plates.

Instrument panel pad and lower hush panels.

Console.

Negative battery cable.

HEADLIGHT SWITCH

Figure 620

Remove or Disconnect

1. Right and left lower trim plates. Removal of

lower I.P.

cover(s) not required.

2. I.P. cluster trim plate.

3. Two (2) switch assembly retaining screws.

4. Depress side tangs and pull switch assembly from

I.P.

5. Individual switches of assembly are now

accessible for service or replacement.

Install or Connect

1. Depress side tangs and replace switch assembly

to I.P.

2. Two

(2) switch assembly retaining screws.

3. I.P. cluster trim plate.

4. Right and

left lower trim plates. Removal of

lower I.P.

cover(s) not required.

DASH MOUNTED ACCESSORY SWITCHES

Figure 62 1

Installation for various dash mounted accessory

switches is shown in Fig.

62 1.

CONSOLE MOUNTED SWITCHES AND

ACCESSORIES

Figure 6 17

Installation of various console mounted switches,

lights and accessories is shown in Figure 617.

CONSOLE

Remove or Disconnect

1. Negative battery cable.

2. Shift gate trim plate. Requires removal

of shift

handle and seven (7) screws.

3. Radio/A/C-heater controller trim plate.

Page 1616 of 1825

INSTRUMENT PANEL, GAGES & CONSOLE 8C-5

4. A/C-heater controller (see Section 1B).

5. Radio (see Section 9A).

6. Electrical connectors (cigar lighter, ash tray light,

etc.) and pull harness forward out of console.

7. Six (6) console hold-down and two (2) console to

I.P. screws and remove console.

Install or Connect

1. Six (6) console hold-down and two (2) console to

I.P. screws and replace console.

2. Electrical connectors (cigar lighter, ash tray light,

etc.) and pull harness forward out of console.

3. Radio (see Section 9A).

4. A/C-heater controller (see Section 1B).

5. Radio/A/C-heater controller trim plate.

6. Shift gate trim plate.

7. Negative battery cable.

SPEEDOMETER

Figures 603

Remove or Disconnect

Right and left lower trim plates. Removal of

lower

I.P. cover(s) not required.

Instrument cluster trim plate.

Six (6) cluster attachment screws, pull cluster

back and disconnect speedo cable.

Cluster lens.

Two (2) screws retaining speedo head in cluster

from rear.

Electrical (VSS) connectors and remove speedo

head.

Install or Connect

Electrical (VSS) connectors and replace speedo

head.

Two (2) screws retaining speedo head in cluster

from rear.

Cluster lens.

Six (6) cluster attachment screws, reconnect

speedo cable, replace cluster.

Instrument cluster trim plate.

Right and left lower trim plates.

Page 1617 of 1825

1 -SUPPORT

2-NUT

3-BOLTISCREW

4-PANE

L ASM.

Fig. 602 IP Carrler

Fig. 603 Instrument Cluster

Page 1618 of 1825

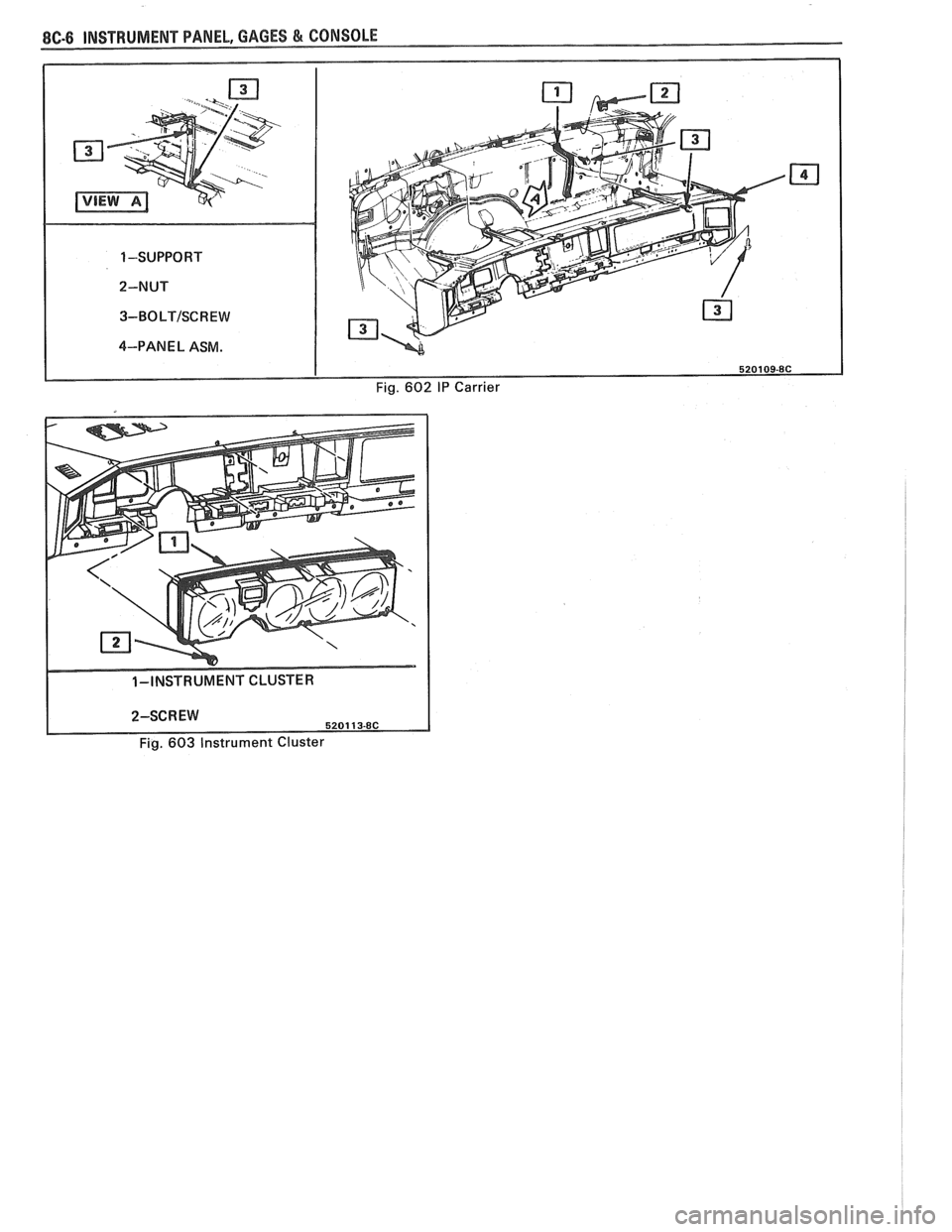

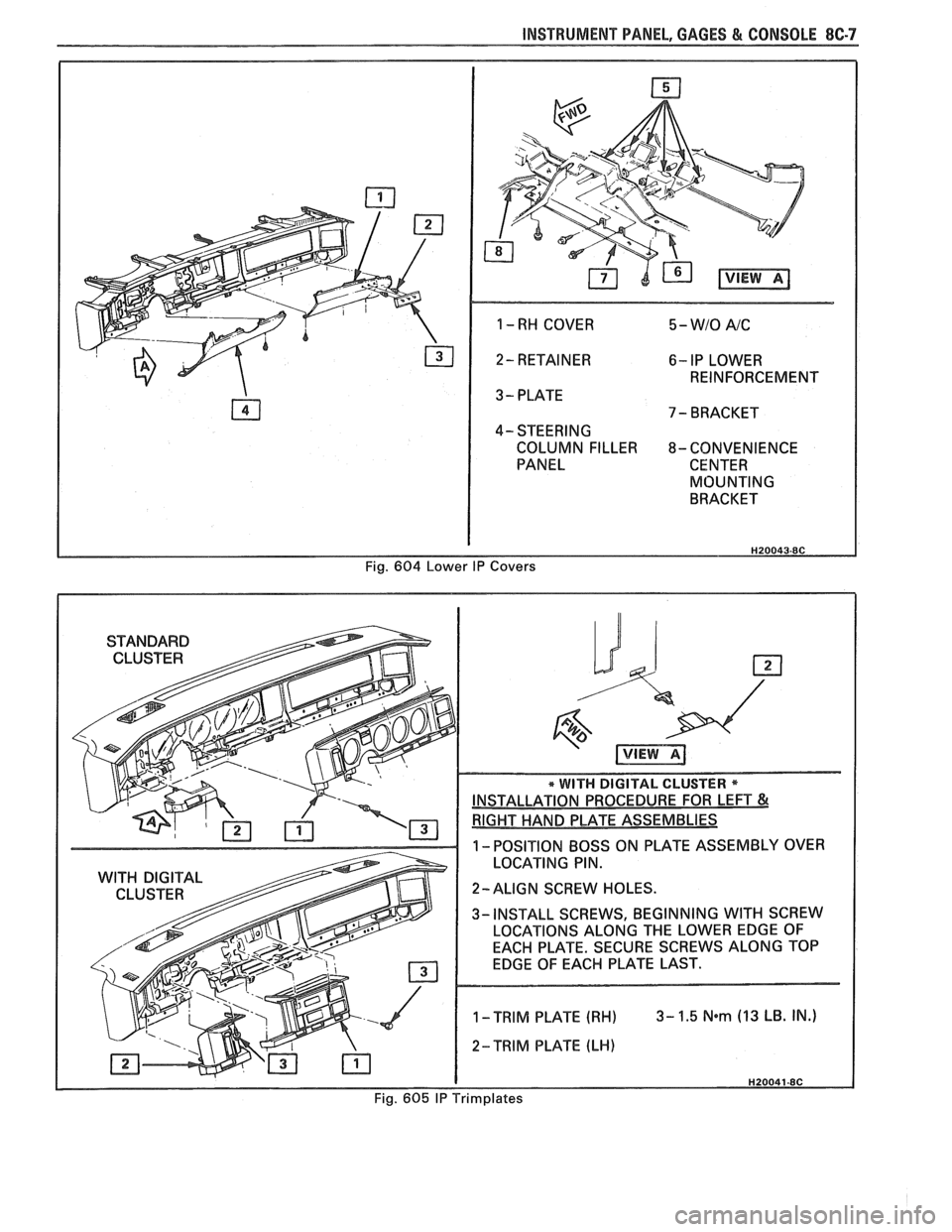

INSTRUMENT PANEL, GAGES & CONSOLE 86-7

1 - RH COVER 5 - WIO A/C

2- RETAINER 6- IP LOWER

REINFORCEMENT

3 - PLATE

7 - BRACKET

4- STEERING

COLUMN FILLER

8- CONVENIENCE

PANEL CENTER

MOUNTING

BRACKET

H20043-8C

Fig. 604 Lower IP Covers

Page 1619 of 1825

Fig. 606 I? Hush Panels; with A/C

1 -PAD ASM. 4- BRACKET

1 2-4 N*m (36 LB. IN.) 5-TRIM PLATE

1 3-6 Nem (54 LB. IN.)

Fig. 607 IP Lower Trim Pad (Console)

1 - MAP HOLDER 2- MAP POCKET

Fig. 608 Map Holder or Map Pocket

Page 1620 of 1825

INSTRUMENT PANEL, GAGES & CONSOLE 8C-9

2-INSTRUMENT PANEL 7-NUT

3-LH VENT DUCT EXTENSION

8 -ACCE L. PEDAL BR K'T.

4-LH INSULATOR ASM.

9-REST ON EXISTING DASH STUD

5-BOLT/SCREW 10-RH INSULATOR ASM.

Fig. 609

IP Hush Panels; w/o A/C

1 --RADIO ASM.

3-BRACKET 5- BOLTISCREW (3) 7 - BUMPER 2- BRACKET 4-BOLTISCREW (4) 6-NUT 8- I/P LOWER TRIM PAD

Fig. 610 Radio Mounting