PONTIAC FIERO 1988 Service Repair Manual

FIERO 1988

PONTIAC

PONTIAC

https://www.carmanualsonline.info/img/50/57415/w960_57415-0.png

PONTIAC FIERO 1988 Service Repair Manual

Trending: wheel bolt torque, oil, height, wiper size, suspension, gas tank size, octane

Page 1631 of 1825

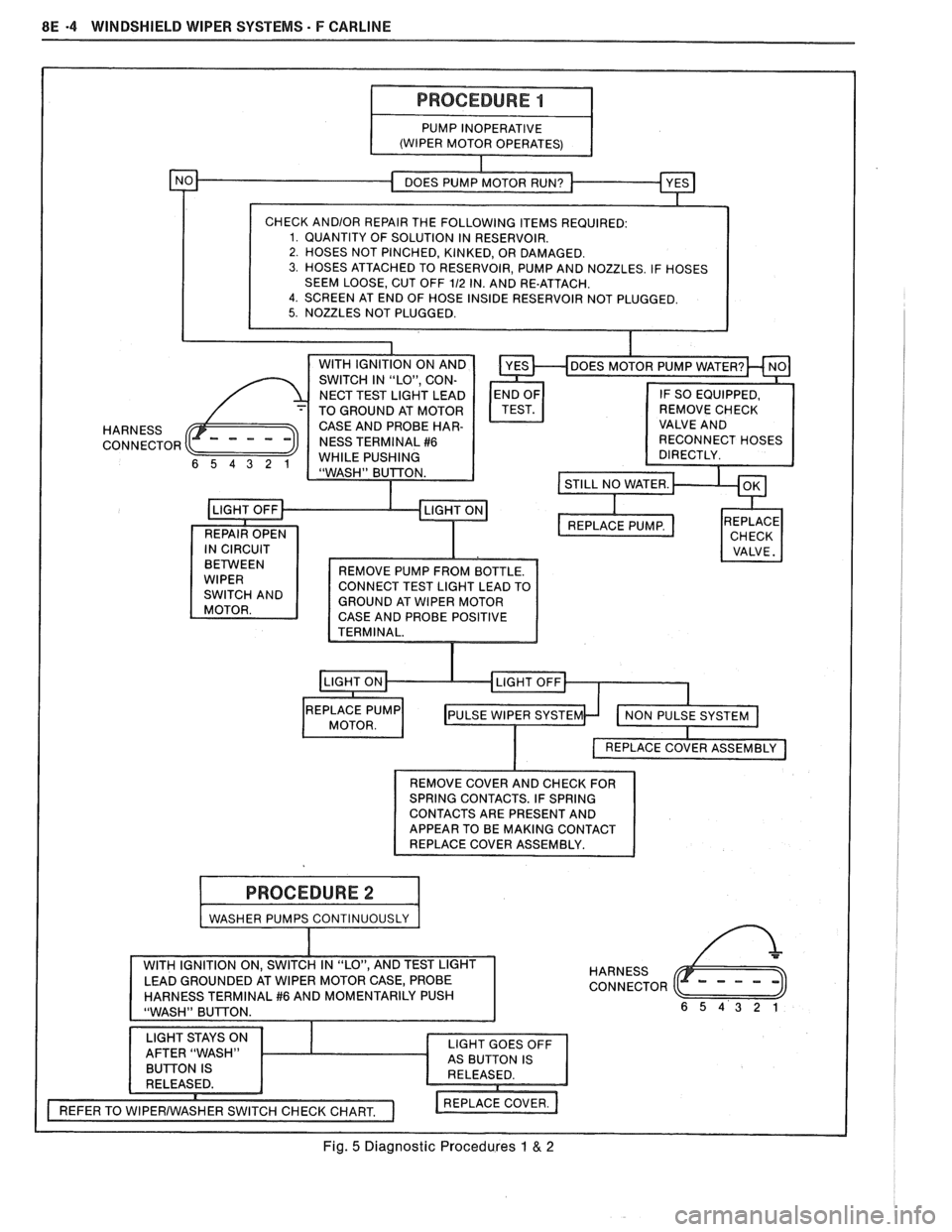

8E -4 WINDSHIELD WIPER SYSTEMS - F CARLINE

SEEM LOOSE, CUT OFF 112 IN. AND RE-ATTACH. 4. SCREEN AT END OF HOSE INSIDE RESERVOIR NOT PLUGGED.

HARNESS

CONNECTOR

CONNECT TEST LIGHT LEAD TO

GROUND AT WIPER MOTOR

CASE AND PROBE POSITIVE

I VALVE. I

t

REMOVE COVER AND CHECK FOR

SPRING CONTACTS. IF SPRING

CONTACTS ARE PRESENT AND

APPEAR TO BE MAKING CONTACT

REPLACE COVER ASSEMBLY.

I WASHER PUMPS CONTINUOUSLY I

HARNESS

CONNECTOR

Fig. 5 Diagnostic Procedures 1 & 2

Page 1632 of 1825

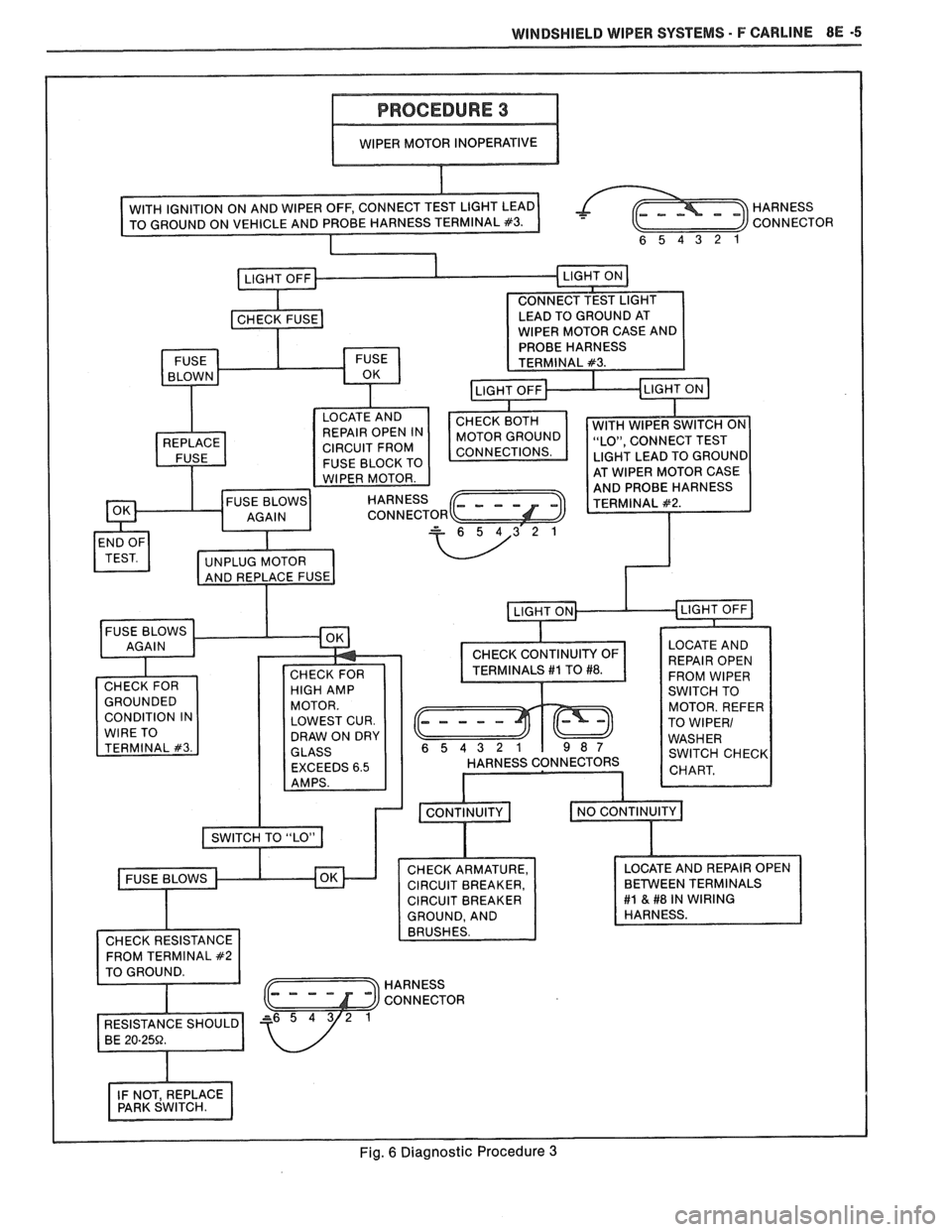

WINDSHIELD WIPER SYSTEMS - F CARLINE 8E -5

--

I WIPER MOTOR INOPERATIVE I

HARNESS

CONNECTOR

MOTOR GROUND

CIRCUIT FROM

FUSE BLOCK TO

TERMINALS

#I TO #8.

WITCH CHECK

EXCEEDS 6.5

CIRCUIT BREAKER

HARNESS

CONNECTOR

Fig. 6 Diagnostic Procedure 3

Page 1633 of 1825

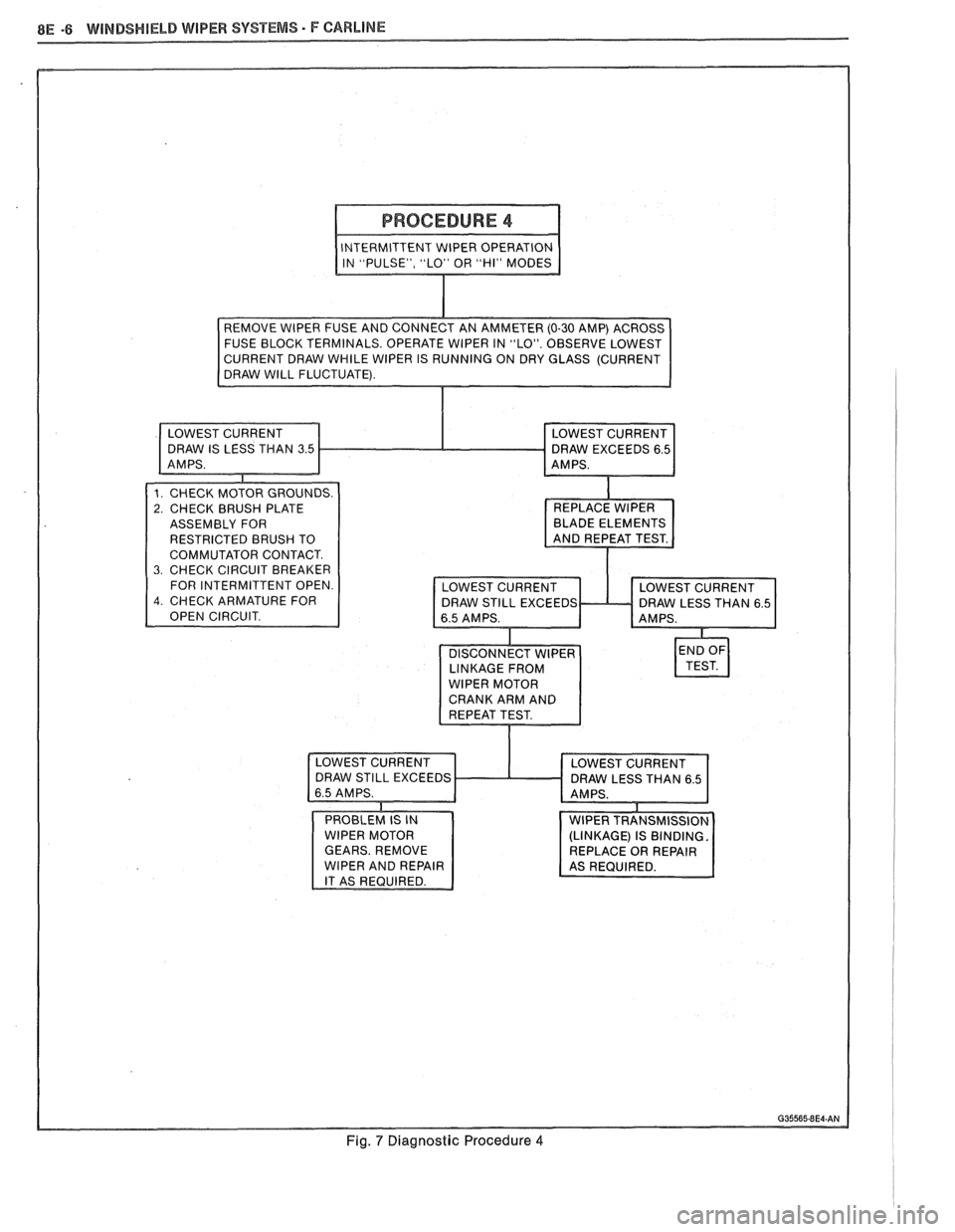

8E -8 WINDSHIELD WIPER SYSTEMS - F CAWLINE

FOR INTERMITTENT OPEN

ILL

EXCEEDS

Fig. 7 Diagnostic Procedure 4

Page 1634 of 1825

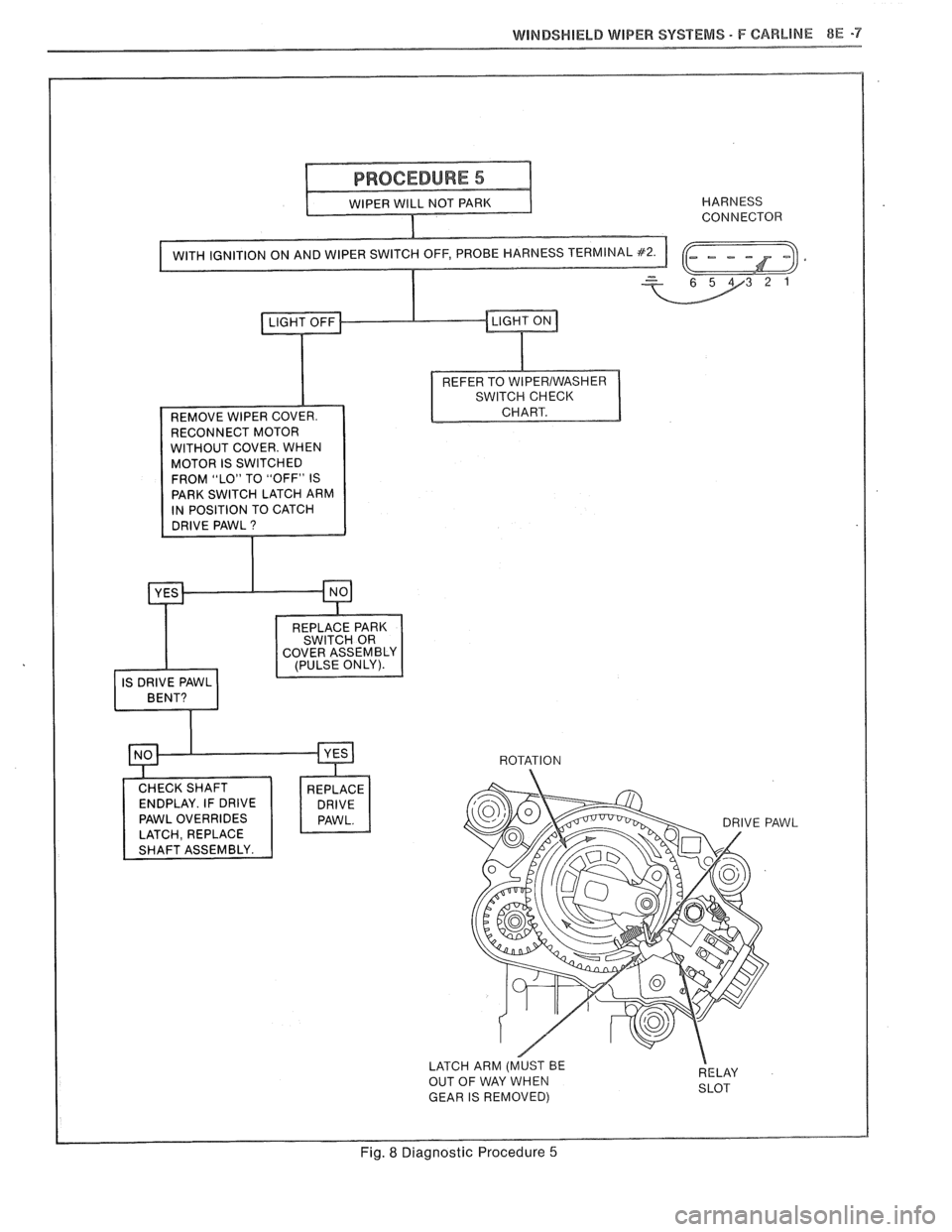

WINDSHIELD WIPER SYSTEMS - F CARLllNE 8E -7

HARNESS

CONNECTOR

RECONNECT MOTOR

WITHOUT COVER. WHEN

MOTOR IS SWITCHED

FROM "LO" TO "OFF" IS

PARK SWITCH LATCH ARM

IN POSITION TO CATCH

REPLACE PARK

SWITCH OR

COVER ASSEMBLY

I (PULSEONLY). I

DRIVE

PAWL.

LATCH. REPLACE ROTATION

DRIVE PAWL

LATCH ARM (MUST BE

OUT OF WAY WHEN

GEAR IS REMOVED) RELAY

SLOT

Fig. 8 Diagnostic Procedure 5

Page 1635 of 1825

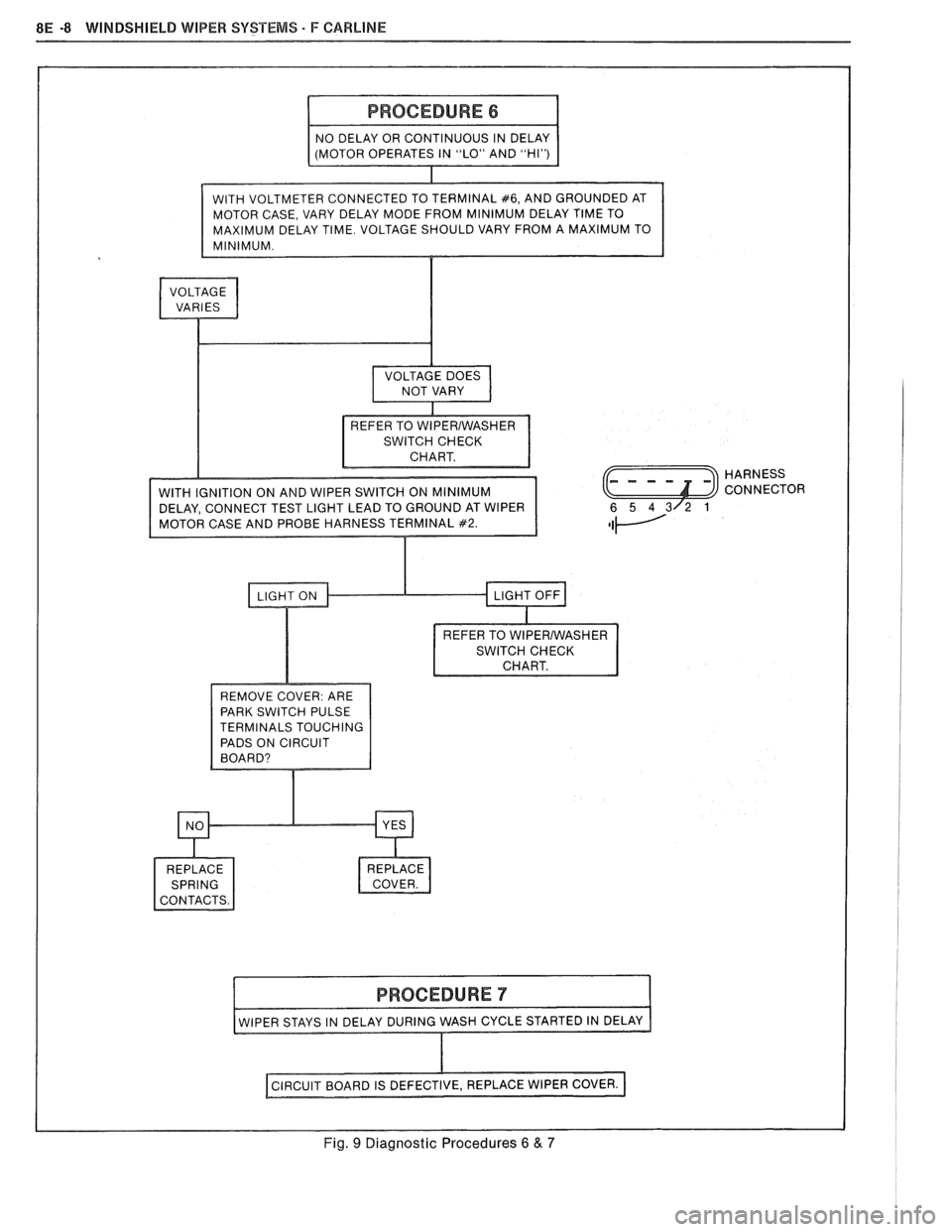

8E -8 WINDSHIELD WIPER SYSTEMS - F CARLINE

MOTOR CASE, VARY DELAY MODE FROM MINIMUM DELAY TlME TO

MAXIMUM DELAY TlME VOLTAGE SHOULD VARY FROM A MAXIMUM TO

IGNITION ON AND WIPER SWITCH ON MINIMUM

REMOVE COVER ARE

PARK SWITCH PULSE

TERMINALS TOUCHING

Fig. 9 Diagnostic Procedures 6 & 7

Page 1636 of 1825

WINDSHIELD WIPER SYSTEMS - F CARLINE 8E -9

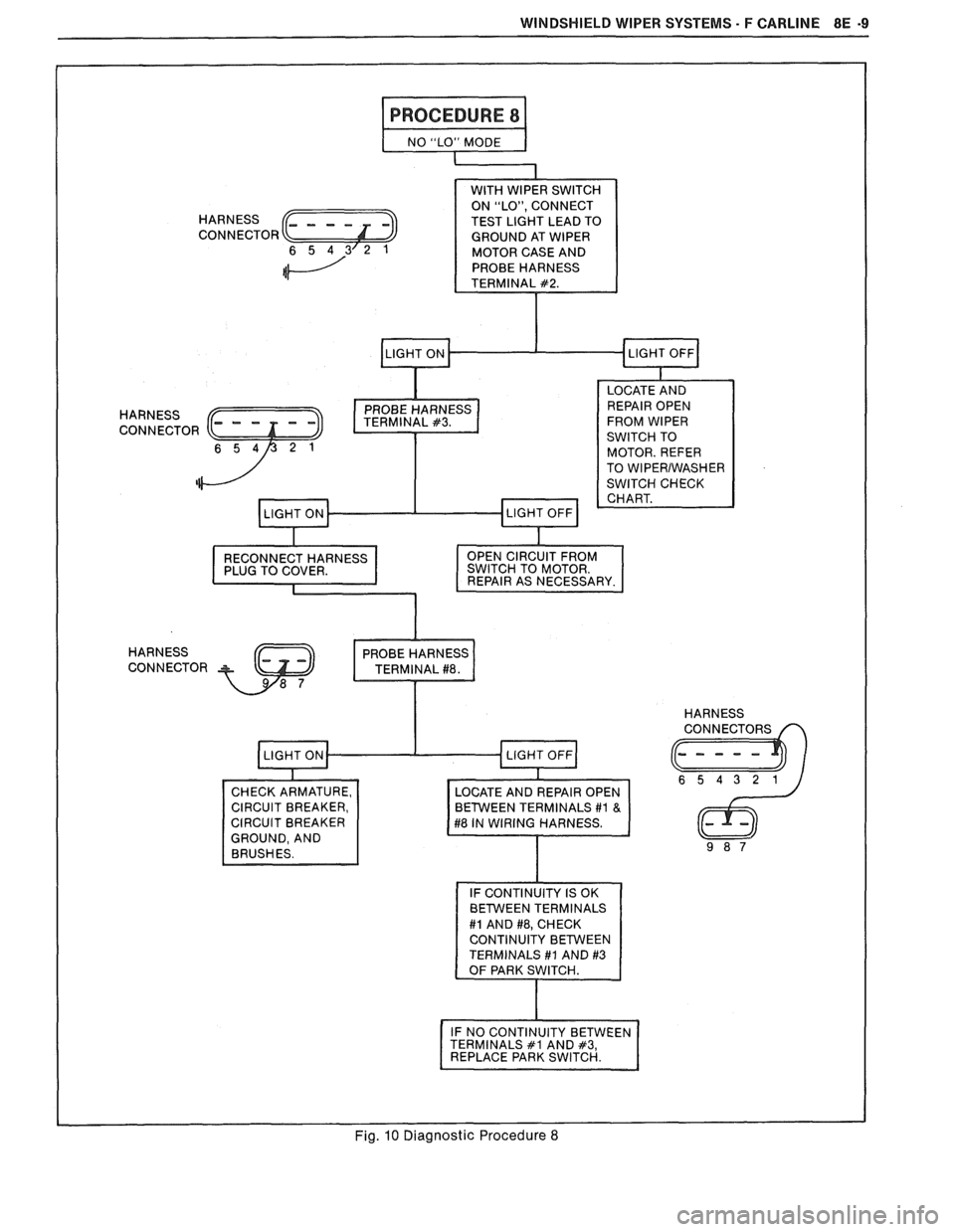

I PROCEDURE 8 I

NO "LO.' MODE I

WITH WIPER SWITCH

ON "LO", CONNECT

TEST LIGHT LEAD TO

GROUND AT WIPER

MOTOR CASE AND

PROBE HARNESS

TERMINAL

#2.

I PROBE C

I LOCATE AND

REPAIR OPEN

FROM WIPER

SWITCH TO

MOTOR. REFER

TO

WlPERlWASHER

SWITCH CHECK CHART.

RECONNECT HARNESS

PLUG TO COVER.

I

HARNESS

CONNECTOR OPEN CIRCUIT FROM

SWITCH TO MOTOR.

REPAIR AS NECESSARY.

2

PROBE HARNES

CHECK ARMATURE,

CIRCUIT BREAKER,

CIRCUIT BREAKER

GROUND, AND BRUSHES.

TERMINALS

#1 AND #3

I

IF NO CONTINUITY BETWEEN

TERMINALS #1 AND #3, REPLACE PARK SWITCH. I

HARNESS

I I Fig. 10 Diagnostic Procedure 8

Page 1637 of 1825

BE -10 WINDSHIELD WIPER SYSTEMS - F CARLINE

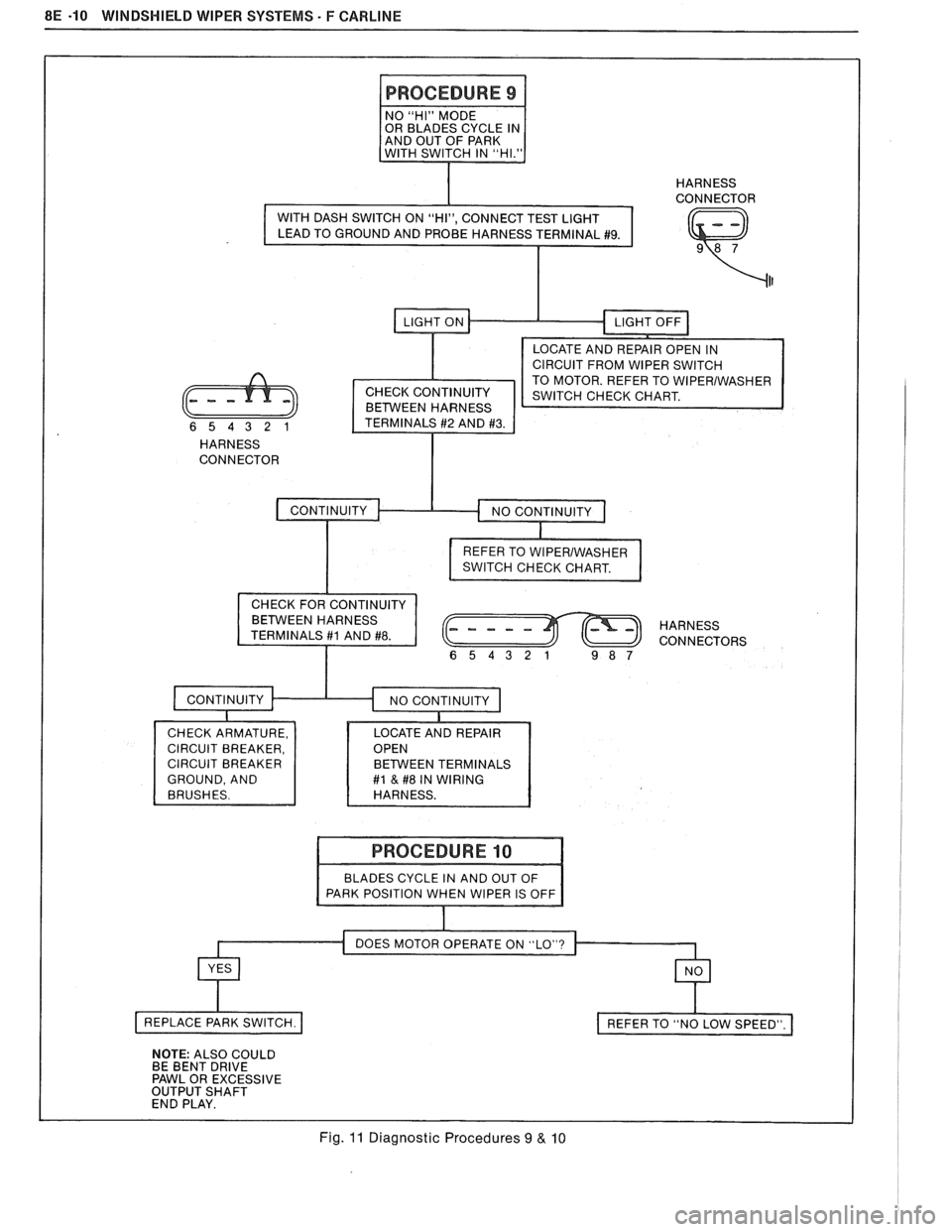

I PROCEDURE 9 1

I I HARNESS I CONNECTOR

(Q)

CIRCUIT FROM WIPER SWITCH

TO MOTOR. REFER TO

WlPERlWASHER CHECK CONTINUITY

BETWEEN HARNESS

HARNESS

CONNECTOR

I

REFER TO WlPERlWASHER

SWITCH CHECK CHART. I

HARNESS

CONNECTORS

654321 9 8 7

GROUND, AND EEN TERMINALS #l & #8 IN WIRING

BLADES

CYCLE IN AND OUT OF

DOES MOTOR OPERATE ON "LO"?

Fig. 11 Diagnostic Procedures 9 & 10

Page 1638 of 1825

WINDSHIELD WIPER SYSTEMS - F CARLINE BE -11

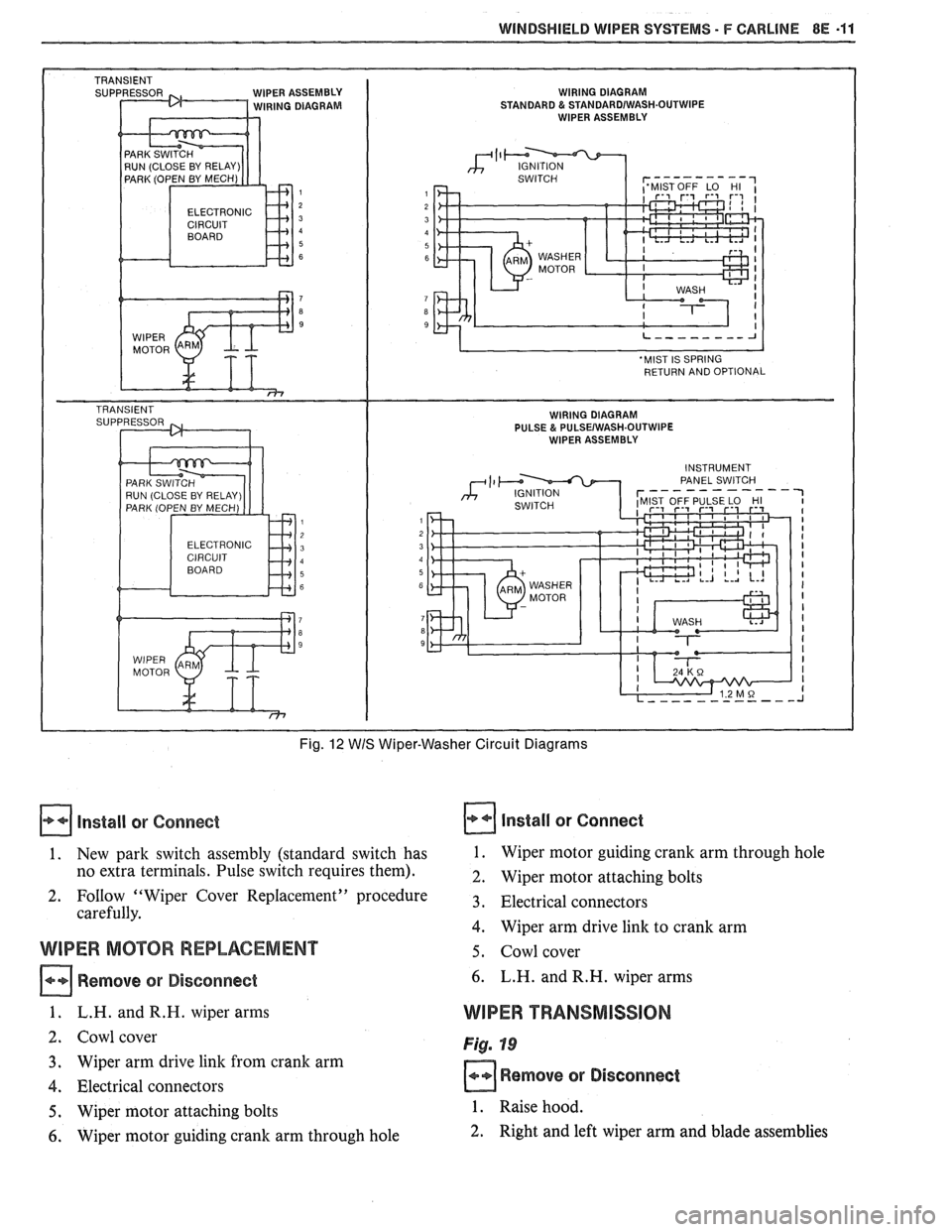

IPER ASSEMBLY WIRING DIAGRAM IRING DIAGRAM STANDARD & STANDARDIWASH.OUTWIPE WIPER ASSEMBLY

ELECTRONIC

Fig. 12 WIS Wiper-Washer Circuit Diagrams

Install or Connect

1. New park switch assembly (standard switch has

no extra terminals. Pulse switch requires them).

2. FoIlow "Wiper Cover Replacement" procedure

carefully.

WIPER MOTOR REPLACEMENT

Remove or Disconnect

1. L.H. andR.H. wiper arms

2. Cowl cover

3. Wiper arm drive link from crank arm

4. Electrical connectors

5. Wiper motor attaching bolts

6. Wiper motor guiding crank arm through hole

Install or Connect

1. Wiper motor guiding crank arm through hole

2. Wiper motor attaching bolts

3. Electrical connectors

4. Wiper arm drive link to crank arm

5. Cowl cover

6. L.H. and R.H. wiper arms

WIPER TRANSMISSION

Fig. 19

Remove or Disconnect

1. Raise hood.

2. Right and left wiper arm and blade assemblies

Page 1639 of 1825

8E -12 WINDSHIELD WIPER SYSTEMS. F CAWLINE

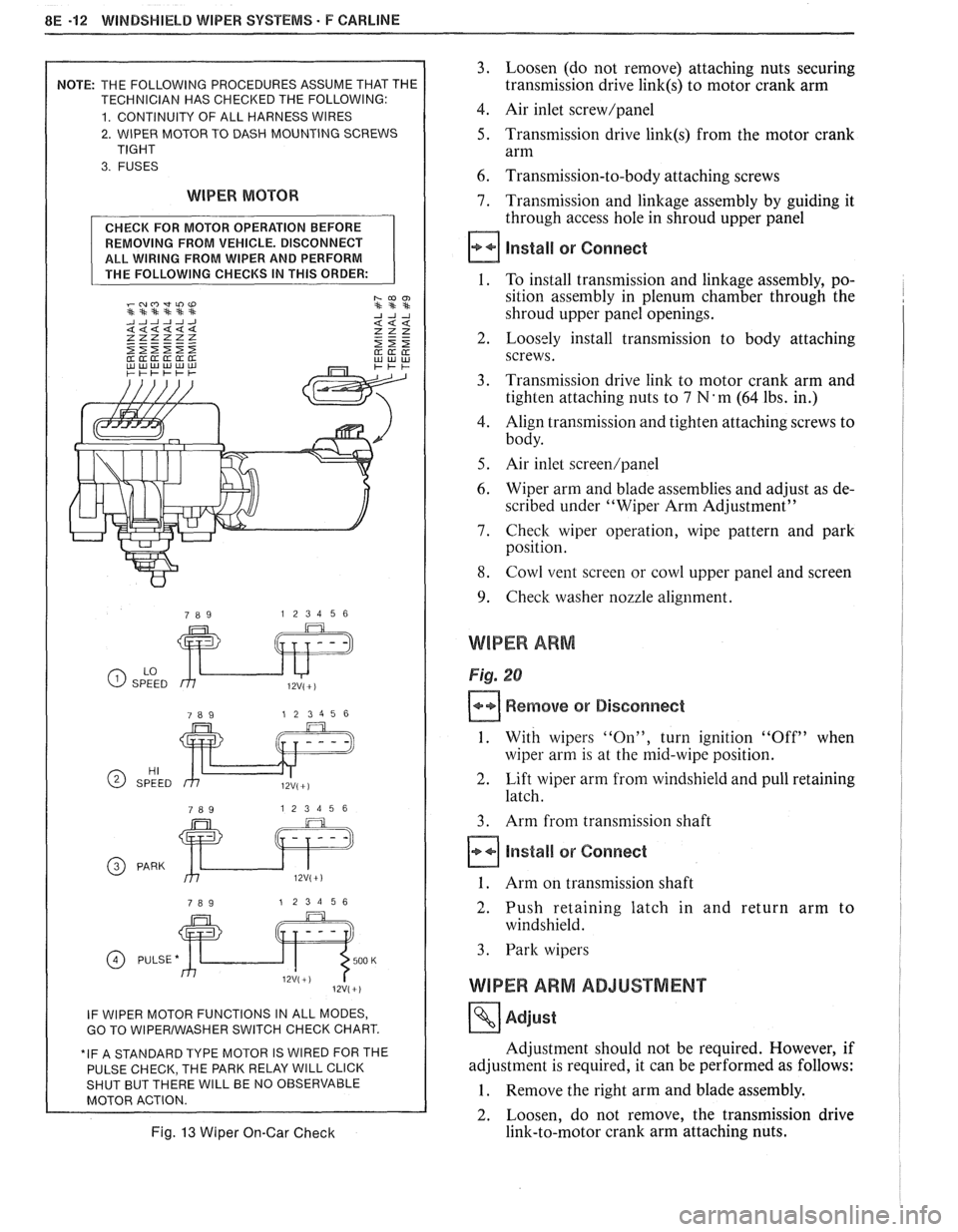

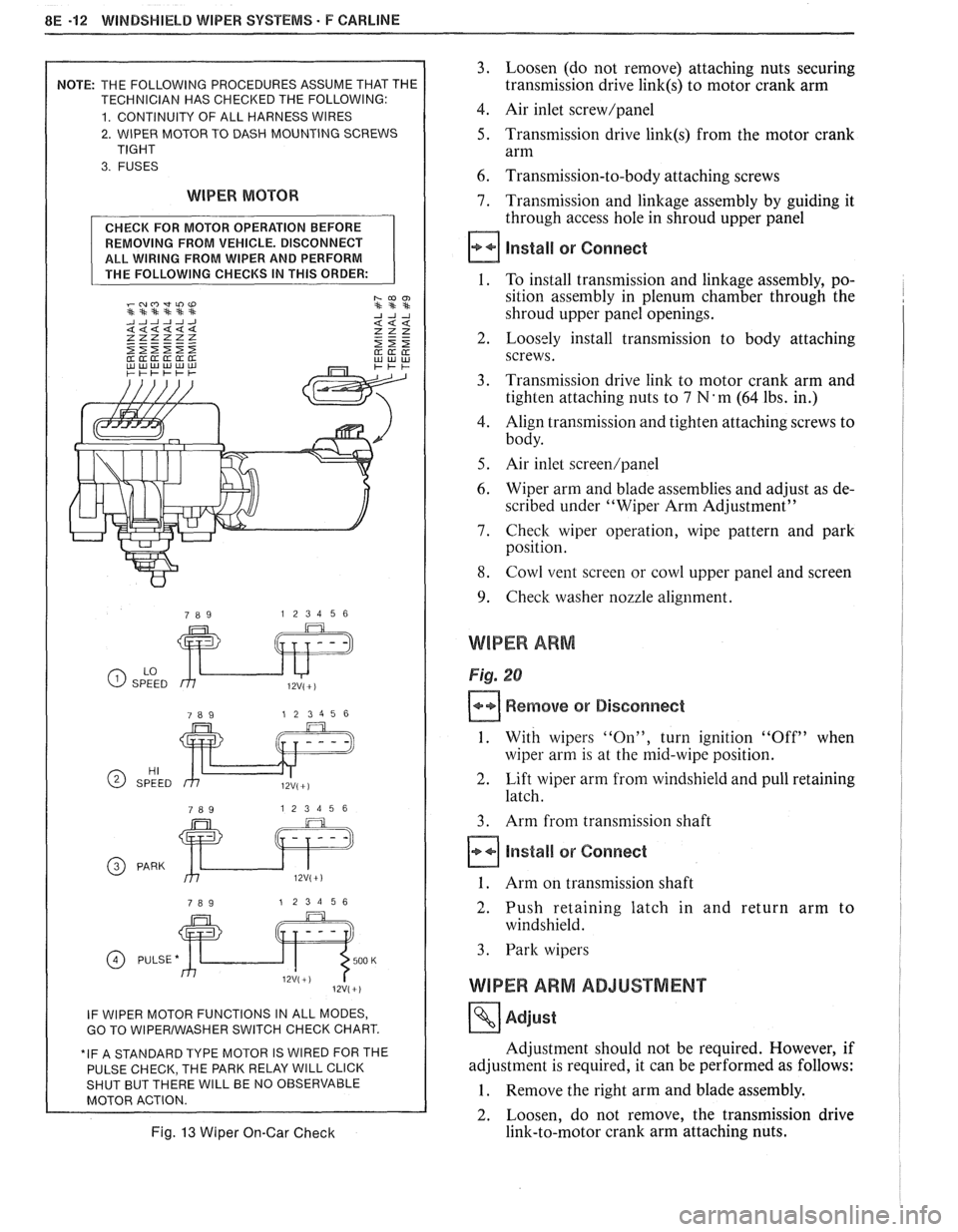

2. WIPER MOTOR TO DASH MOUNTING SCREWS

WIPER MOTOR

REMOVING FROM VEHICLE. DISCONNECT

ALL WIRING FROM WIPER AND PERFORM

GO TO WlPERlWASHER SWITCH CHECK CHART.

E PARK RELAY

WlLL CLICK WlLL BE NO OBSERVABLE

Fig. 13 Wiper On-Gar Check

3. Loosen (do not remove) attaching nuts securing

transmission drive

link(s) to motor crank arm

4. Air inlet screw/panel

5. Transmission drive link(s) from the motor crank

arm

6. Transmission-to-body attaching screws

7. Transmission and linkage assembly by guiding it

through access hole in shroud upper panel

install or Connect

1. To install transmission and linkage assembly, po-

sition assembly in plenum chamber through the

shroud upper panel openings.

2. Loosely install transmission to body attaching

screws.

3. Transmission drive link to motor crank arm and

tighten attaching nuts to

7 N'm (64 lbs. in.)

4. Align transmission and tighten attaching screws to

body.

5. Air inlet screen/panel

6. Wiper arm and blade assemblies and adjust as de-

scribed under "Wiper Arm Adjustment"

7. Check wiper operation, wipe pattern and park

position.

8. Cowl vent screen or cowl upper panel and screen

9. Check washer nozzle alignment.

WIPER ARM

Fig. 20

Remove or Disconnect

1. With wipers "On", turn ignition "Off" when

wiper arm is at the mid-wipe position.

2. Lift wiper arm from windshield and pull retaining

latch.

3. Arm from transmission shaft

Install or Connect

1. Arm on transmission shaft

2. Push retaining latch in and return arm to

windshield.

3. Park wipers

WIPER ARM ADJUSTMENT

Adjust

Adjustment should not be required. However, if

adjustment is required, it can be performed as follows:

1. Remove the right arm and blade assembly.

2. Loosen, do not remove, the transmission drive

link-to-motor crank arm attaching nuts.

Page 1640 of 1825

WINDSHIELD WIPER SYSTEMS - F CARLINE 8E -13

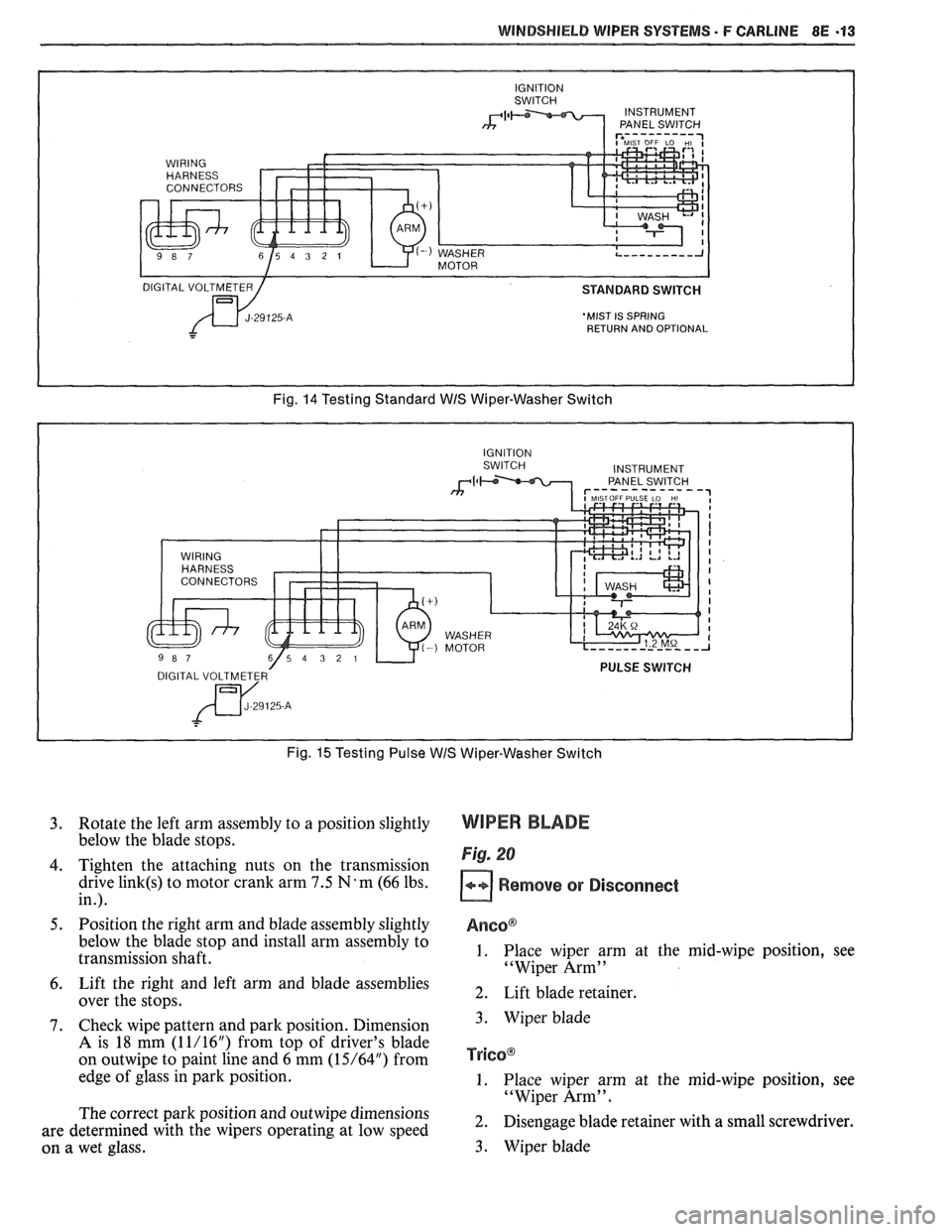

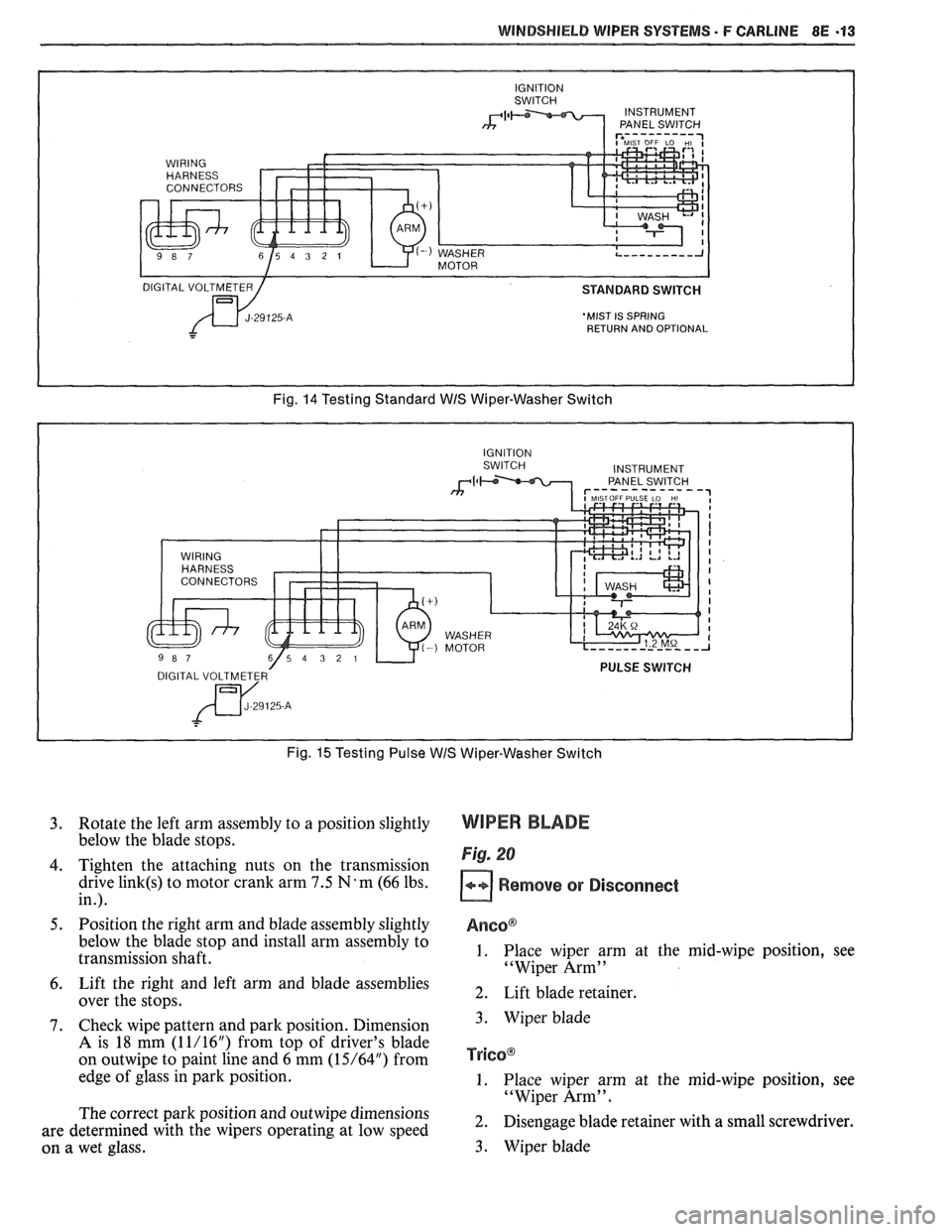

'MIST IS SPRING

RETURN AND OPTIONAL

Fig. 14 Testing Standard WIS Wiper-Washer Switch

Fig.

15 Testing Pulse WIS Wiper-Washer Switch

3. Rotate the left arm assembly to a position slightly

below the blade stops.

4. Tighten the attaching nuts on the transmission

drive

link(s) to motor crank arm 7.5 N'm (66 lbs.

in.).

5. Position the right arm and blade assembly slightly

below the blade stop and install arm assembly to

transmission shaft.

6. Lift the right and left arm and blade assemblies

over the stops.

7. Check wipe pattern and park position. Dimension

A is 18 mm (1 1/16") from top of driver's blade

on

outwipe to paint line and 6 mm (15/64") from

edge of glass in park position.

The correct park position and

outwipe dimensions

are determined with the wipers operating at low speed

on a wet glass.

WIPER BLADE

Fig. 20

Remove or Disconnect

Anso@

1. Place wiper arm at the mid-wipe position, see

"Wiper Arm"

2. Lift blade retainer.

3. Wiper blade

TY~GO@

1. Place wiper arm at the mid-wipe position, see

"Wiper Arm".

2. Disengage blade retainer with a small screwdriver.

3. Wiper blade

Trending: boot, radio antenna, turn signal, fuse box location, AUX, fuse box, fuse diagram