PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 1621 of 1825

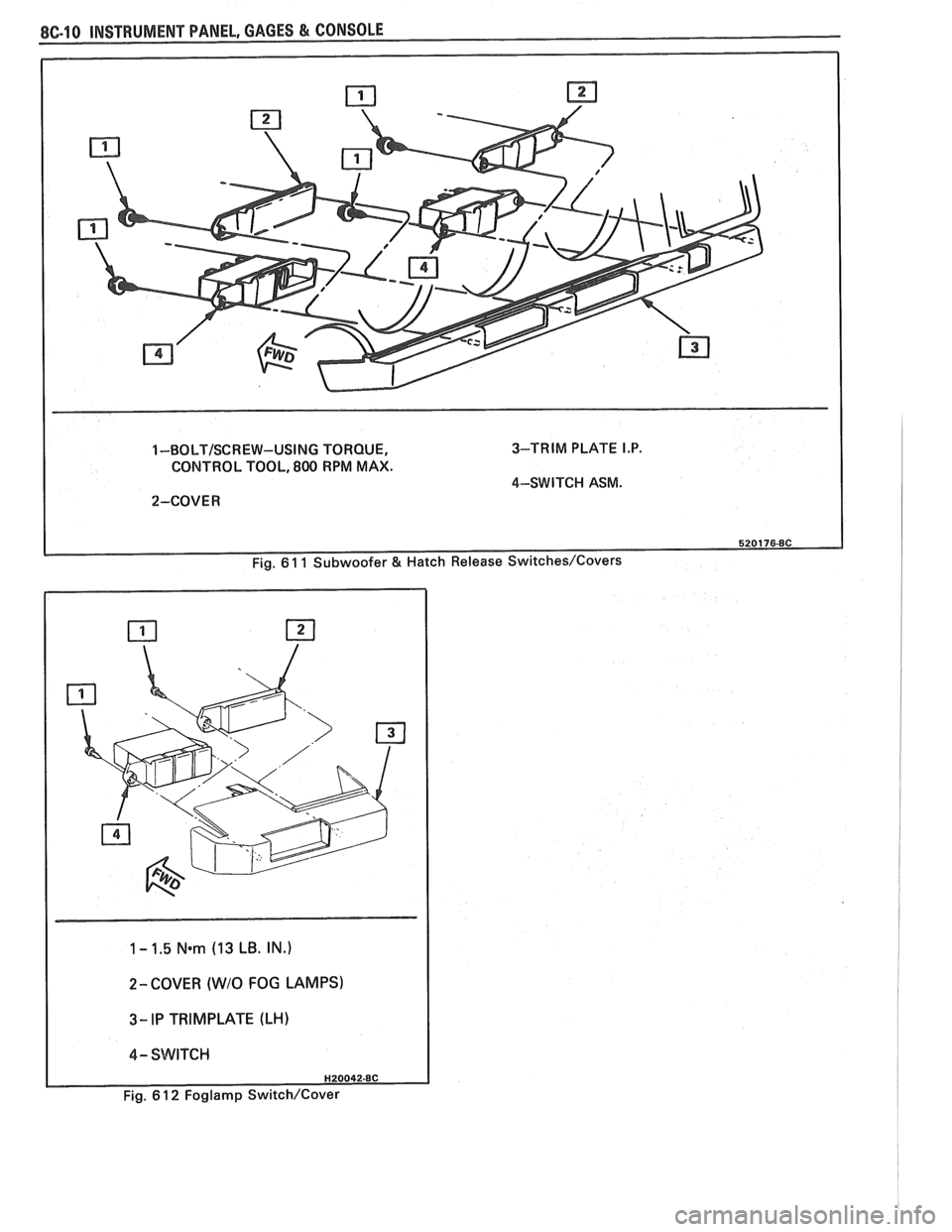

1 -BOLT/SCREW-USING TORQUE, 3-TRIM

PLATE I.P.

CONTROL TOOL, 800 RPM MAX.

4-SWITCI-I ASM.

2-COVER

1 - 1.5 N*m (13 LB. IN.)

I

2- COVER (WIO FOG LAMPS)

I 4- SWITCH I

Fig. 6 1 2 Foglamp Switch/Cover

Page 1622 of 1825

INSTRUMENT PANEL. GAGES & CONSOLE 8C-11

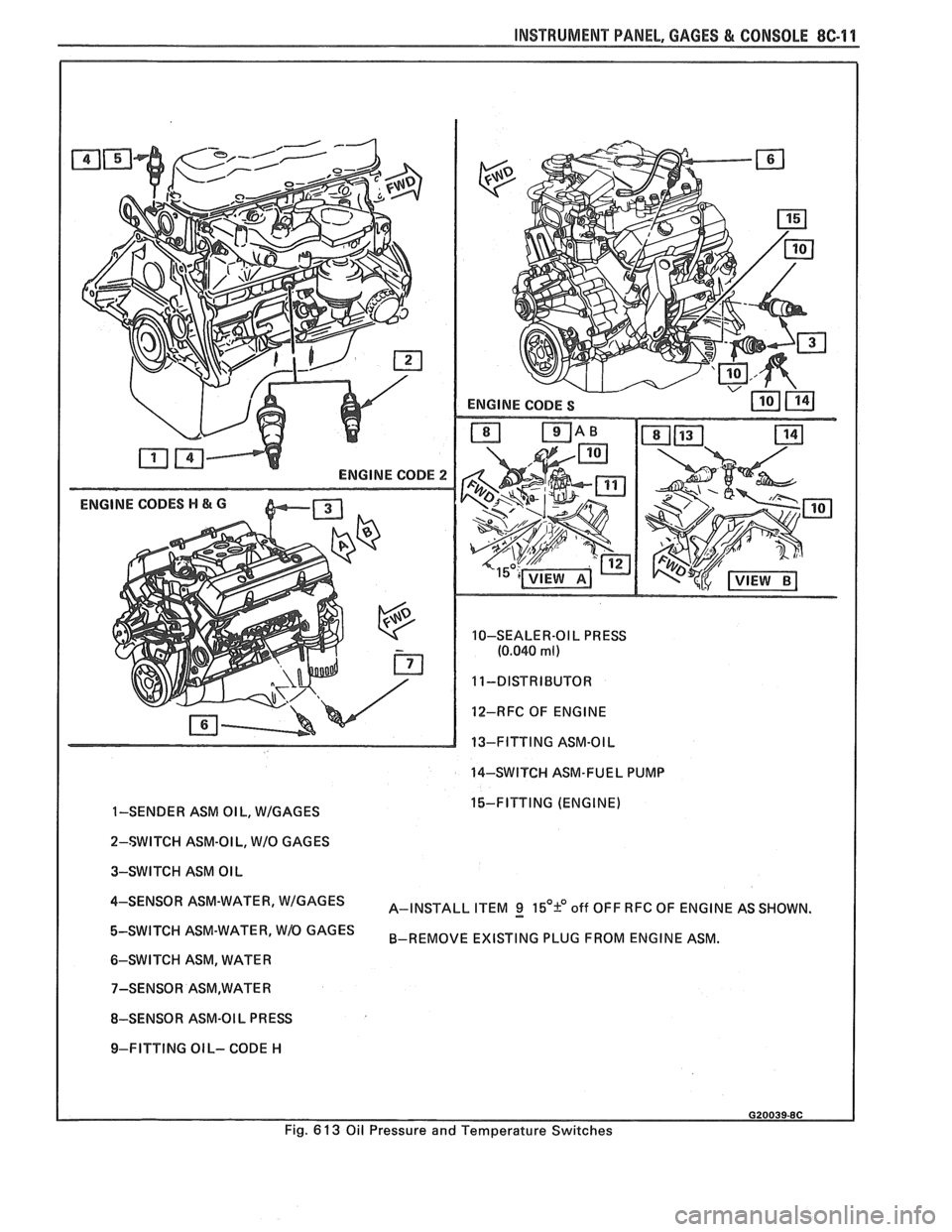

ENGINE CODE 2

ENGINE CODES H & G

10-SEALER-OI L PRESS

(0.040 ml)

12-RFC OF ENGINE

13-FITTING ASM-OIL

14-SWITCH ASM-FUEL PUMP

I

1-SENDER ASM OIL, WIGAGES 15-FITTING (ENGINE)

I

2-SWITCH ASM-OI L, WIO GAGES

3-SWITCH ASM OIL

4-SENS0R ASM-WATER' A-INSTALL ITEM g 15'9 off OFF RFC OF ENGINE AS SHOWN.

ASM-WATER' W1O GAGES B-REMOVE EXISTING PLUG FROM ENGINE ASM.

6-SWITCH ASM, WATER

8-SENSOR ASM-OI L

PR ESS

I 9-FITTING OIL- CODE H

Fig.

6 13 Oil Pressure and Temperature Switches

Page 1623 of 1825

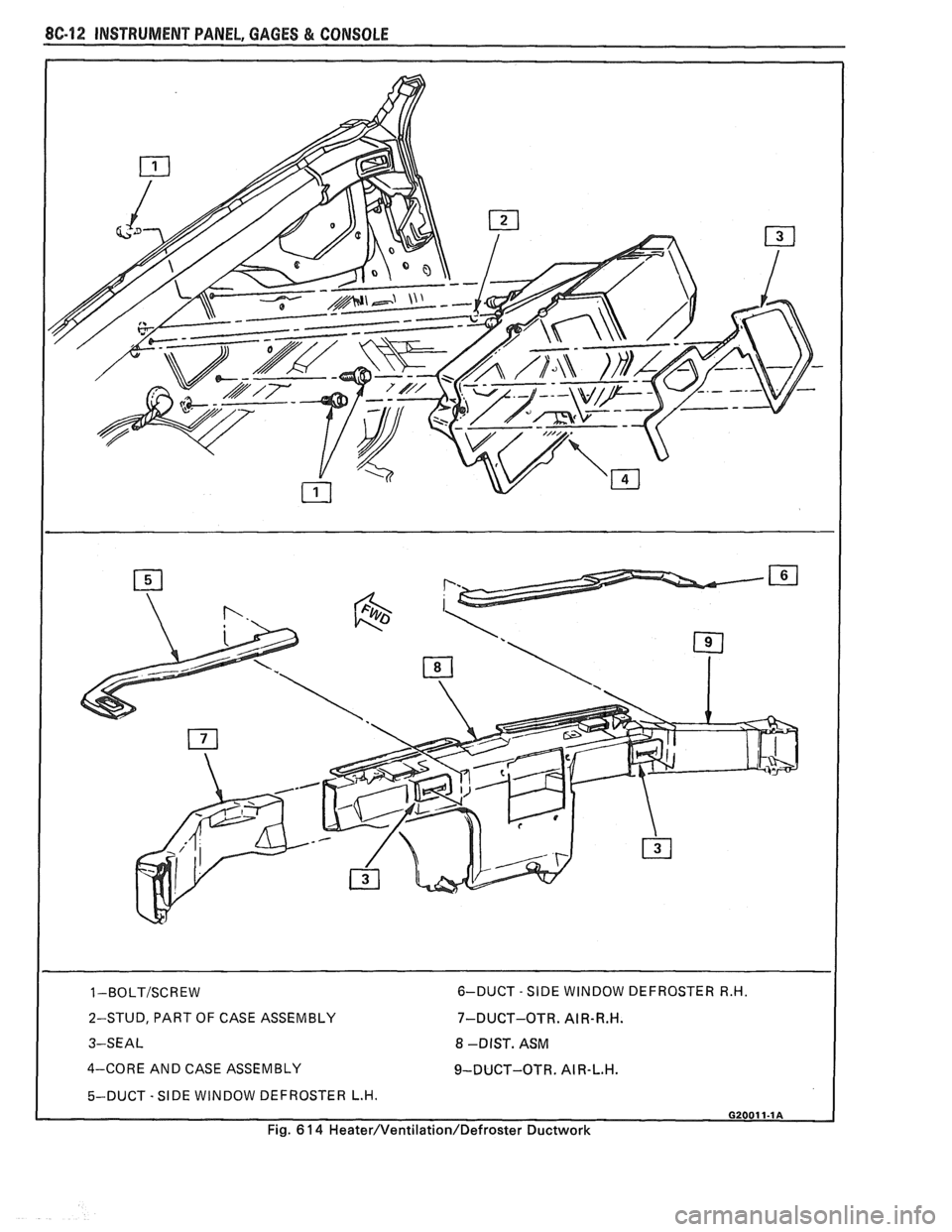

2-STUD, PART OF CASE ASSEMBLY

3-SEAL 7-DUCT-OTR.

AIR-R.H.

8 -DIST. ASM

4-CORE AND CASE ASSEMBLY

9-DUCT-OTR. AI R-L.H.

5-DUCT - SIDE WINDOW DEFROSTER L.H. I

Fig. 6 14 Heater/Ventilation/Defroster Ductwork

Page 1624 of 1825

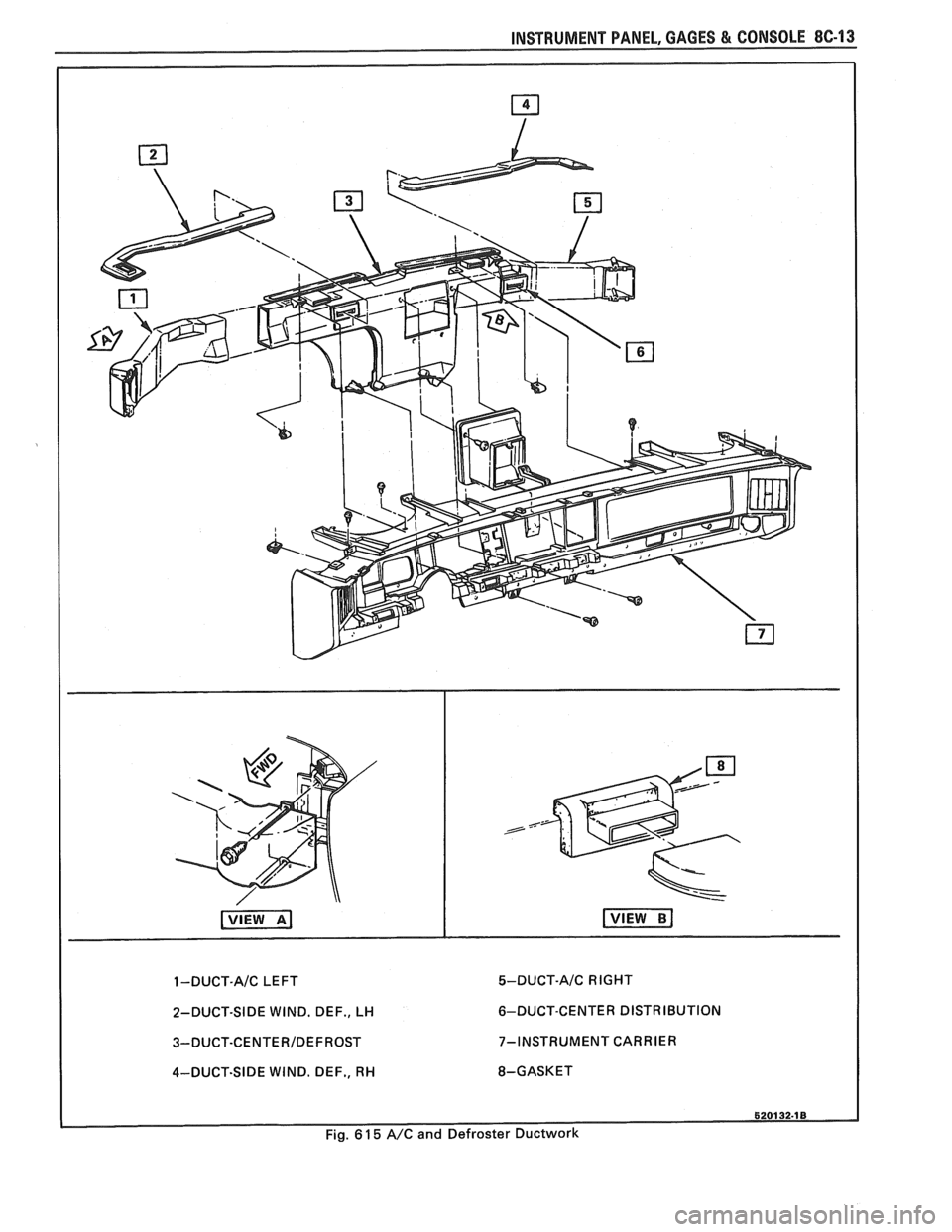

INSTRUMENT PANEL, GAGES & CONSOLE 8C-13

1 -DUCT-A/C LEFT

2-DUCT-SIDE WIND. DEF., LH

3-DUCT-CENTERIDEF ROST

4-DUCT-SIDE WIND. DEF., RH

5-DUCT-A/C RIGHT

6-DUCT-CENTER DISTRIBUTION

7-INSTRUMENT CARRIER

8-GASKET

Page 1625 of 1825

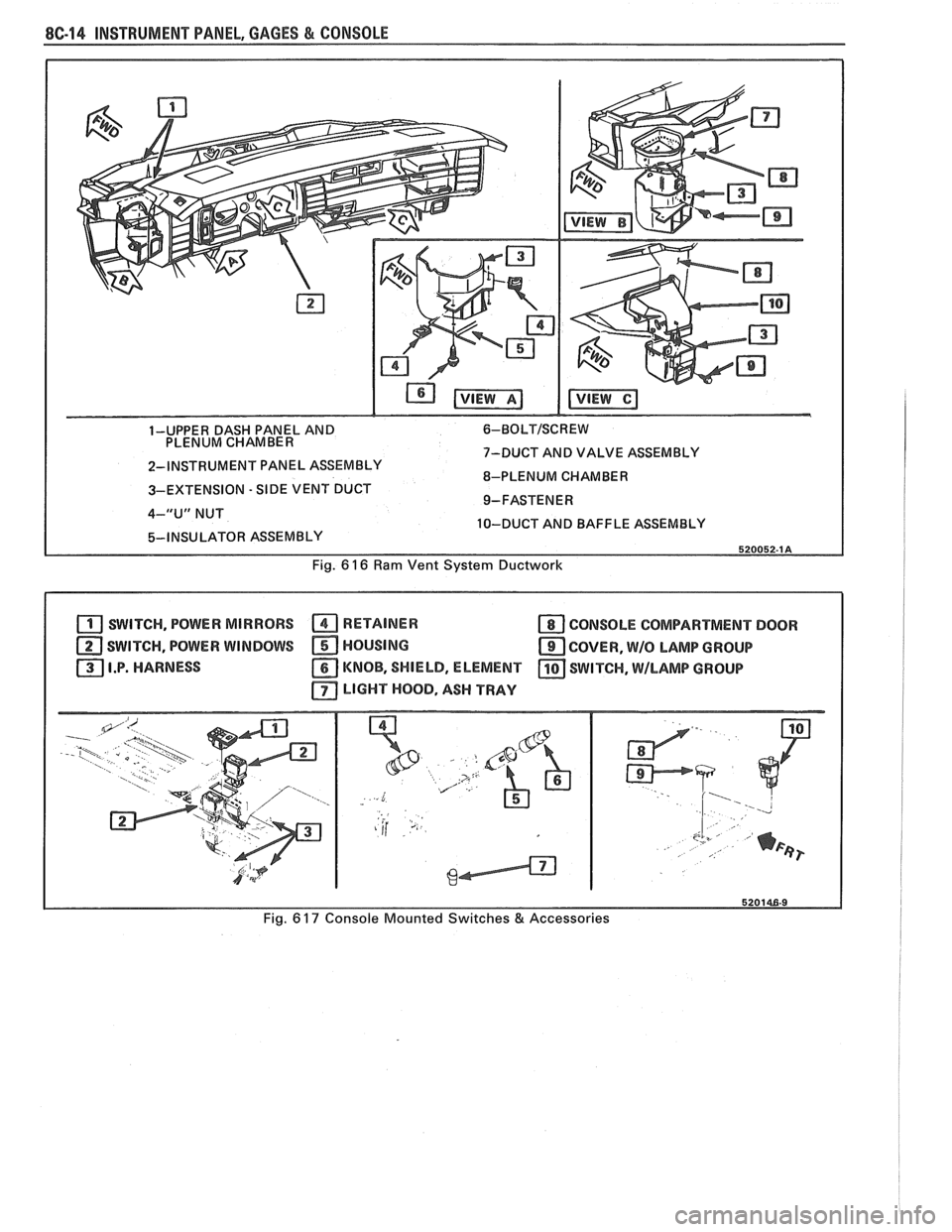

8C14 INSTRUMENT PANEL, GAGES & CONSOLE

1-UPPER DASH PANEL AND 6-BOLTISCREW

PLENUM CHAMBER

7-DUCT AND VALVE ASSEMBLY

2-INSTRUMENT PANEL ASSEMBLY

8-PLENUM CHAMBER

3-EXTENSION

- SIDE VENT DUCT

4-"U" NUT

10-DUCT AND BAFFLE ASSEMBLY

Fig.

6 16 Ram Vent System Ductwork

SWITCH, POWER MIRRORS RETAINER a CONSOLE COMPARTMENT DOOR

SWITCH, POWER WINDOWS HOUSING

COVER, W/O LAMP GROUP

I.P. HARNESS

KNOB, SHIELD, ELEMENT SWITCH, \MILAMP GROUP

LIGHT HOOD, ASH TRAY

Fig. 6 17 Console Mounted Switches & Accessories

Page 1626 of 1825

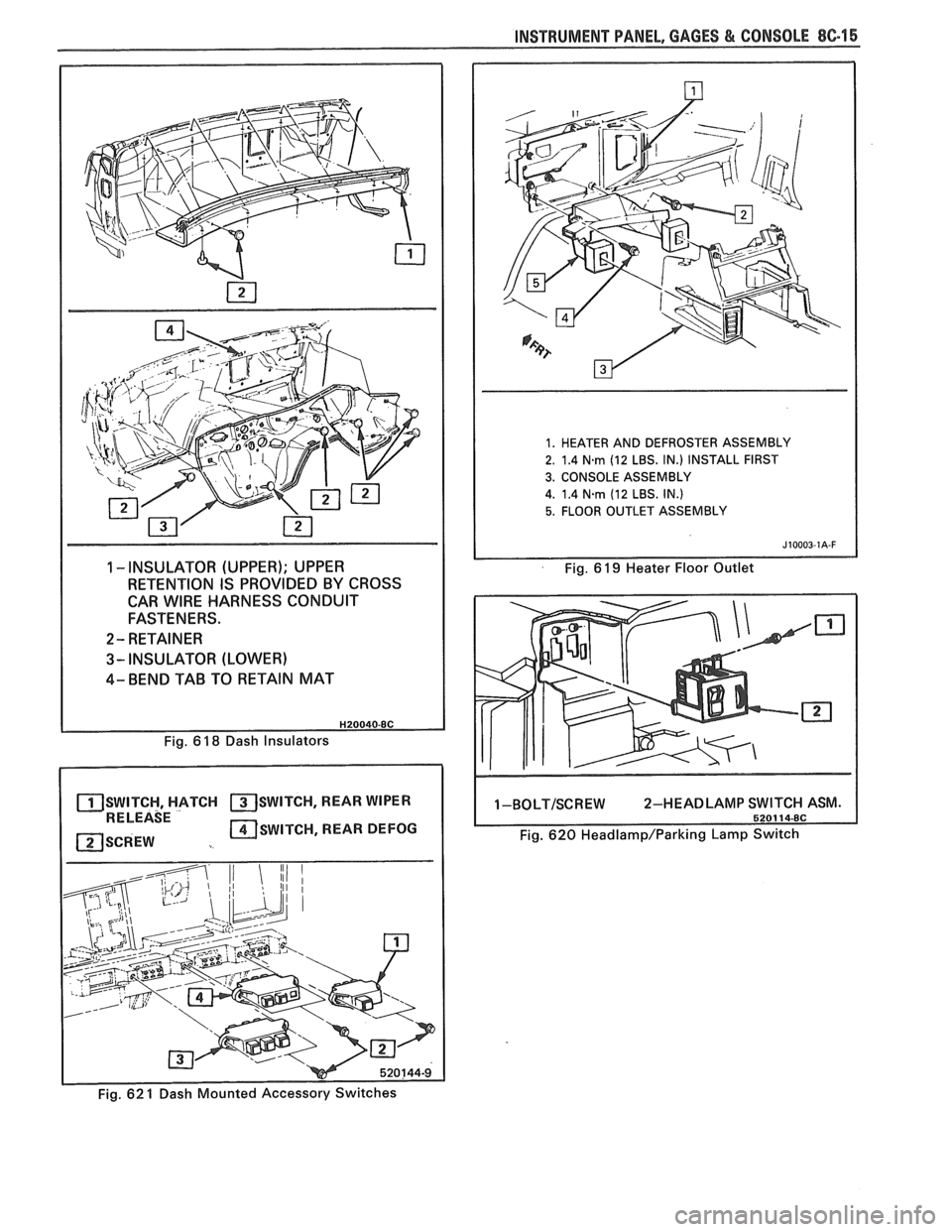

INSTRUMENT PANEL, GAGES & CONSOLE 8C-15

1 -INSULATOR (UPPER); UPPER

RETENTION IS PROVIDED BY CROSS

CAR

WIRE HARNESS CONDUIT

FASTENERS.

2- RETAINER

3- INSULATOR (LOWER)

4- BEND TAB TO RETAIN MAT

1. HEATER AND DEFROSTER ASSEMBLY

2. 1.4

N-rn (12 LBS. IN.) INSTALL FIRST

3. CONSOLE ASSEMBLY

4. 1.4

Narn (12 LBS. IN.)

5. FLOOR OUTLET ASSEMBLY

Fig. 6 19 Heater Floor Outlet

Fig. 6

18 Dash Insulators

SWITCH, HATCH SWITCH, REAR WIPER RELEASE

SCREW SWITCH, REAR DEFOG

1-BOLT/SCREW 2-HEADLAMP

Fig. 620 Headlamp/Parking Lamp Switch

- Fig. 62 1 Dash Mounted Accessory Switches

Page 1627 of 1825

Page 1628 of 1825

WINDSI4IELD WIPER SYSTEMS - F CARLINE 8E -1

SECTION 8E

F CARL

ELD W PER-WASHER SYSTEM

PULSE & STANDARD

CONTENTS

General Description ....................... 8E -1 Park Switch Replacement ............... .8E -3

Wiper and Washer Operation

............ 8E -1

Wiper Motor Replacement .............. 8E -1 1

Pulse Windshield Wiper System

........... 8E -1

Wiper Transmission .................... 8E -1 1

Diagnosis Wiper Arm

........................... 8E -12

Diagnostic Procedures

................... 8E -2 Wiper Blade ........................... 8E -13

Wiper Motor

........................... 8E -2 Wiper Blade Insert ..................... 8E -14

Washer Pump

.......................... 8E -2 Windshield Washer ..................... 8E -15

........................ Diagnostic Chart 8E -3 Unit Repair

On-Car Service Gear Replacement

..................... 8E - 15

Washer Pump Replacement .............. 8E -3 Wiper-Washer Nozzle and Container

Wiper Cover Replacement

............... 8E -3 Mounting ........................... 8E -1 8

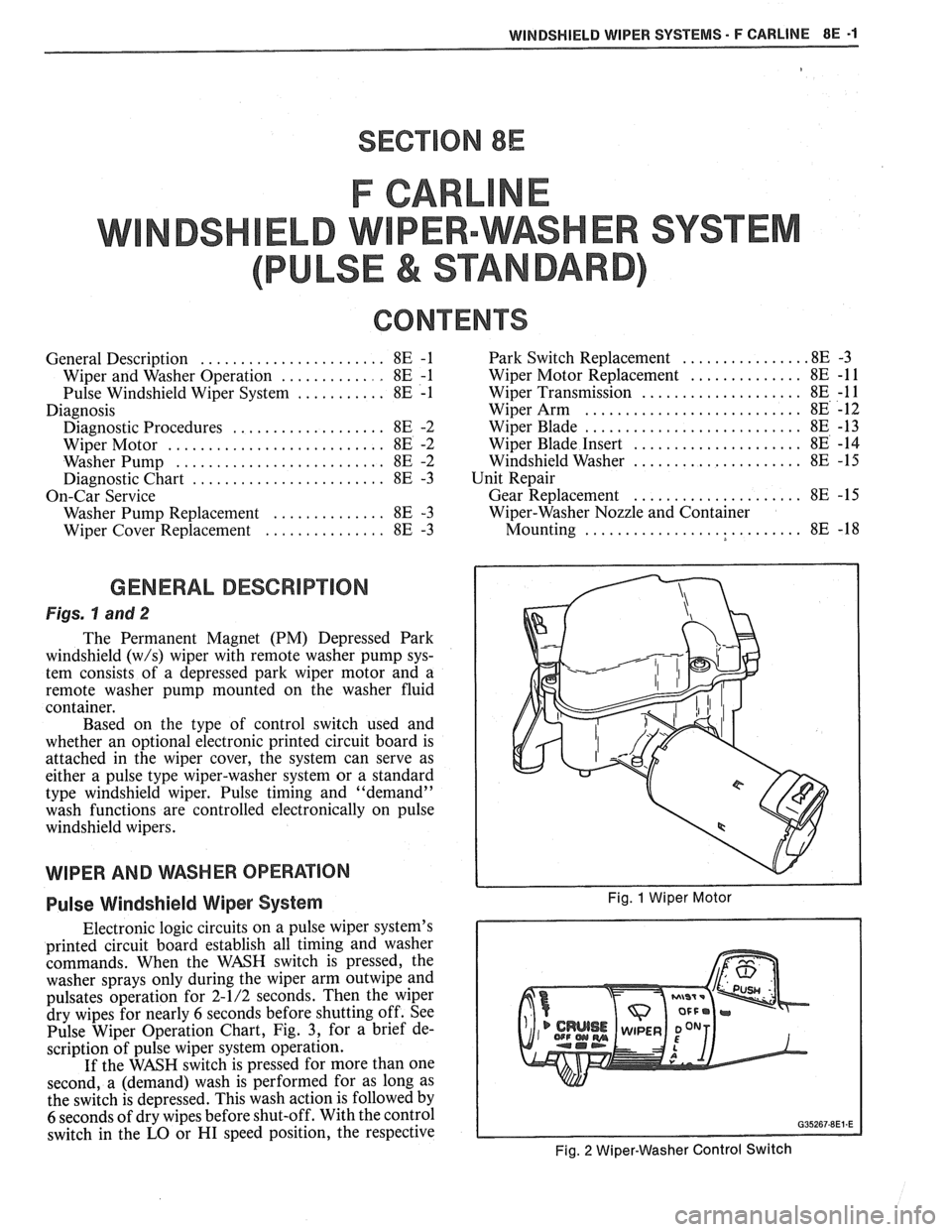

GENERAL DESCRIPTION

Figs. hand 2

The Permanent Magnet (PM) Depressed Park

windshield

(w/s) wiper with remote washer pump sys-

tem consists of a depressed park wiper motor and a

remote washer pump mounted on the washer fluid

container.

Based on the type of control switch used and

whether an optional electronic printed circuit board is

attached in the wiper cover, the system can serve as

either a pulse type wiper-washer system or a standard

type windshield wiper. Pulse timing and "demand"

wash functions are controlled electronically on pulse

windshield wipers.

WIPER AND WSHER OPERAflON

Pulse Windshield Wiper System Fig. 1 Wiper Motor

Electronic logic circuits on a pulse wiper system's

printed circuit board establish all timing and washer

commands. When the WASH switch is pressed, the

washer sprays only during the wiper arm

outwipe and

pulsates operation for 2-1/2 seconds. Then the wiper

dry wipes for nearly

6 seconds before shutting off. See

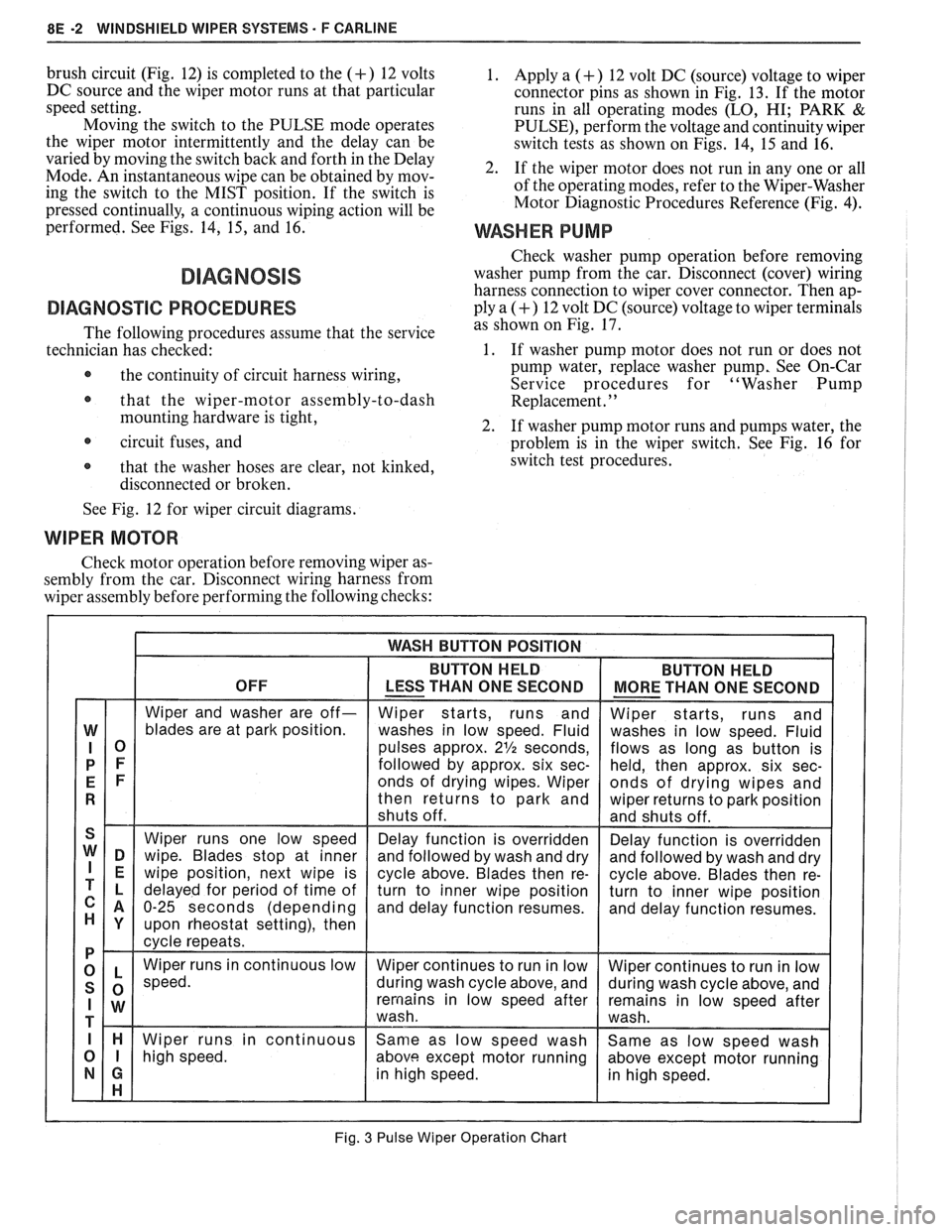

Pulse Wiper Operation Chart, Fig.

3, for a brief de-

scription of pulse wiper system operation.

If the WASH switch is pressed for more than one

second, a (demand) wash is performed for as long as

the switch is depressed. This wash action is followed by

6 seconds of dry wipes before shut-off. With the control

switch in the

LO or HI speed position, the respective

Fig. 2 Wiper-Washer Control Switch

Page 1629 of 1825

8E -2 WINDSHIELD WIPER SYSTEMS F CARLINE

brush circuit (Fig. 12) is completed to the (+) 12 volts

DC source and the wiper motor runs at that particular

speed setting.

Moving the switch to the PULSE mode operates

the wiper motor intermittently and the delay can be

varied by moving the switch back and forth in the Delay

Mode. An instantaneous wipe can be obtained by mov-

ing the switch to the MIST position. If the switch is

pressed continually, a continuous wiping action will be

performed. See Figs. 14,

15, and 16.

DIAGNOSVC PROCEDURES

The following procedures assume that the service

technician has checked:

@ the continuity of circuit harness wiring,

@ that the wiper-motor assembly-to-dash

mounting hardware is tight,

circuit fuses, and

@ that the washer hoses are clear, not kinked,

disconnected or broken.

1. Apply a (+) 12 volt DC (source) voltage to wiper

connector pins as shown in Fig. 13. If the motor

runs in all operating modes

(LO, HI; PARK &

PULSE), perform the voltage and continuity wiper

switch tests as shown on Figs. 14, 15 and 16.

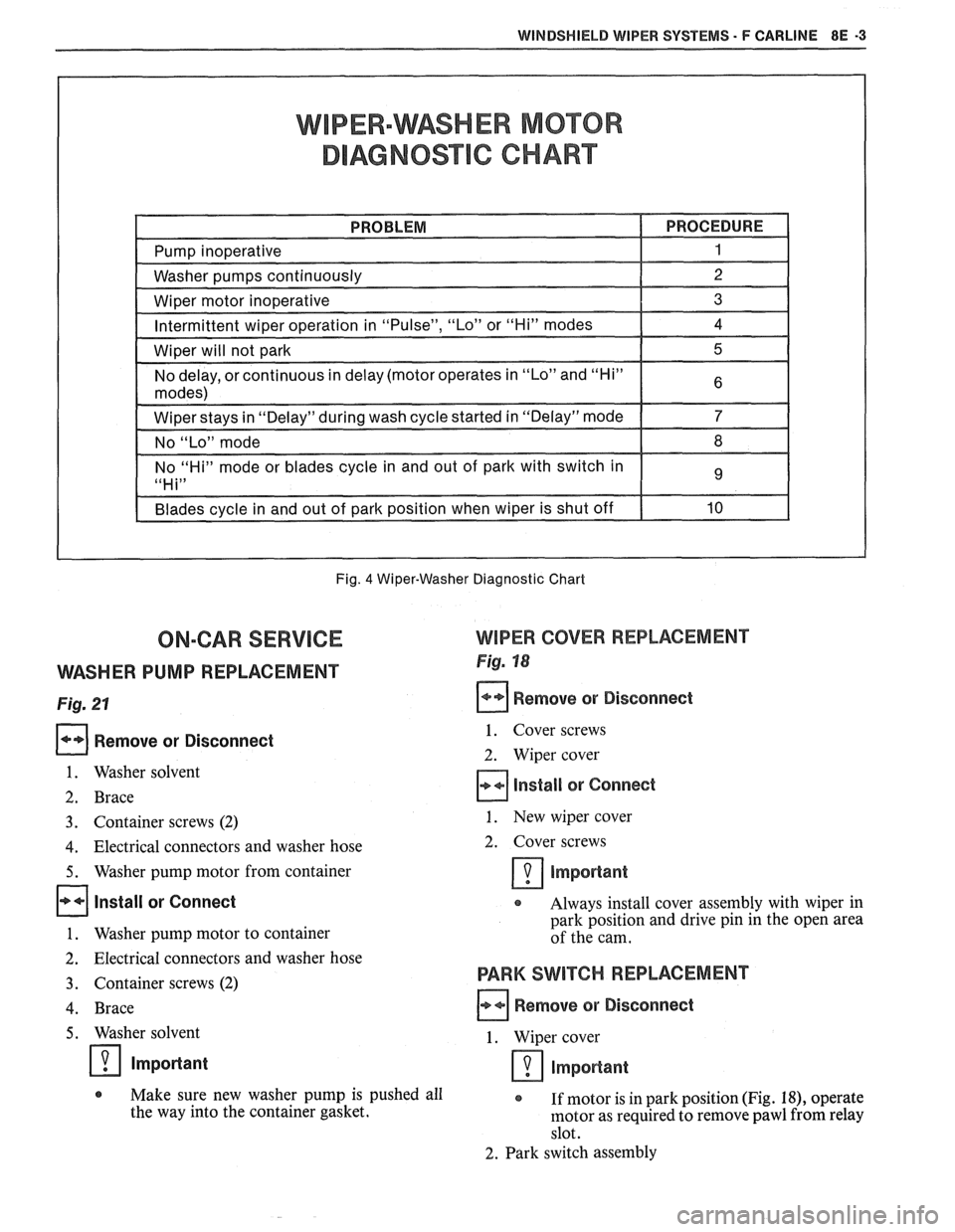

2. If the wiper motor does not run in any one or all

of the operating modes, refer to the Wiper-Washer

Motor Diagnostic Procedures Reference (Fig.

4).

WASHER PUMP

Check washer pump operation before removing

washer pump from the car. Disconnect (cover) wiring

harness connection to wiper cover connector. Then ap-

ply a

(+) 12 volt DC (source) voltage to wiper terminals

as shown on Fig. 17.

1. If washer pump motor does not run or does not

pump water, replace washer pump, See On-Car

Service procedures for "Washer Pump

Replacement.

' '

2. If washer pump motor runs and pumps water, the

problem is in the wiper switch. See Fig. 16 for

switch test procedures.

See Fig. 12 for wiper circuit diagrams.

WIPER MOTOR

Check motor operation before removing wiper as-

sembly from the car. Disconnect wiring harness from

wiper assembly before performing the following checks:

Fig. 3 Pulse Wiper Operation Chart

Page 1630 of 1825

WINDSHIELD WIPER SYSTEMS - F CARLINE 8E -3

WIPER-WASHER MOTOR

DIAGNOSTIC CHART

Fig. 4 Wiper-Washer Diagnostic Chart

ON-CAR SERVICE WIPER COVER REPLACEMENT

VVASHER PUMP REPLACEMENT Fig. 18

Fig. 21 Remove or Disconnect

Remove or Disconnect

1. Washer solvent

2. Brace

1. Cover screws

2. Wiper cover

Install sr Connect

3. Container screws (2) 1. New wiper cover

4. Electrical connectors and washer hose 2.

Cover screws

5. Washer pump motor from container Important

Install or Connect Always install cover assembly with wiper in

park position and drive pin in the open area

1. Washer pump motor to container of the cam.

2. Electrical connectors and washer hose

3. Container screws (2)

4. Brace

PARK SWITCH REPLACEMENT

Remove or Disconnect

Washer solvent 1. Wiper cover

Impo~ant important

@ Make sure new washer pump is pushed all

If motor is in park position (Fig. 18), operate

the way into the container gasket.

rnotor as required to remove pawl from relay

slot.

2. Park switch assembly