PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 891 of 1825

6E3-CZ-4 5.OL (VIN F) & 5.7L(VIN 8) DRIVEABILITY AND EMISSIONS

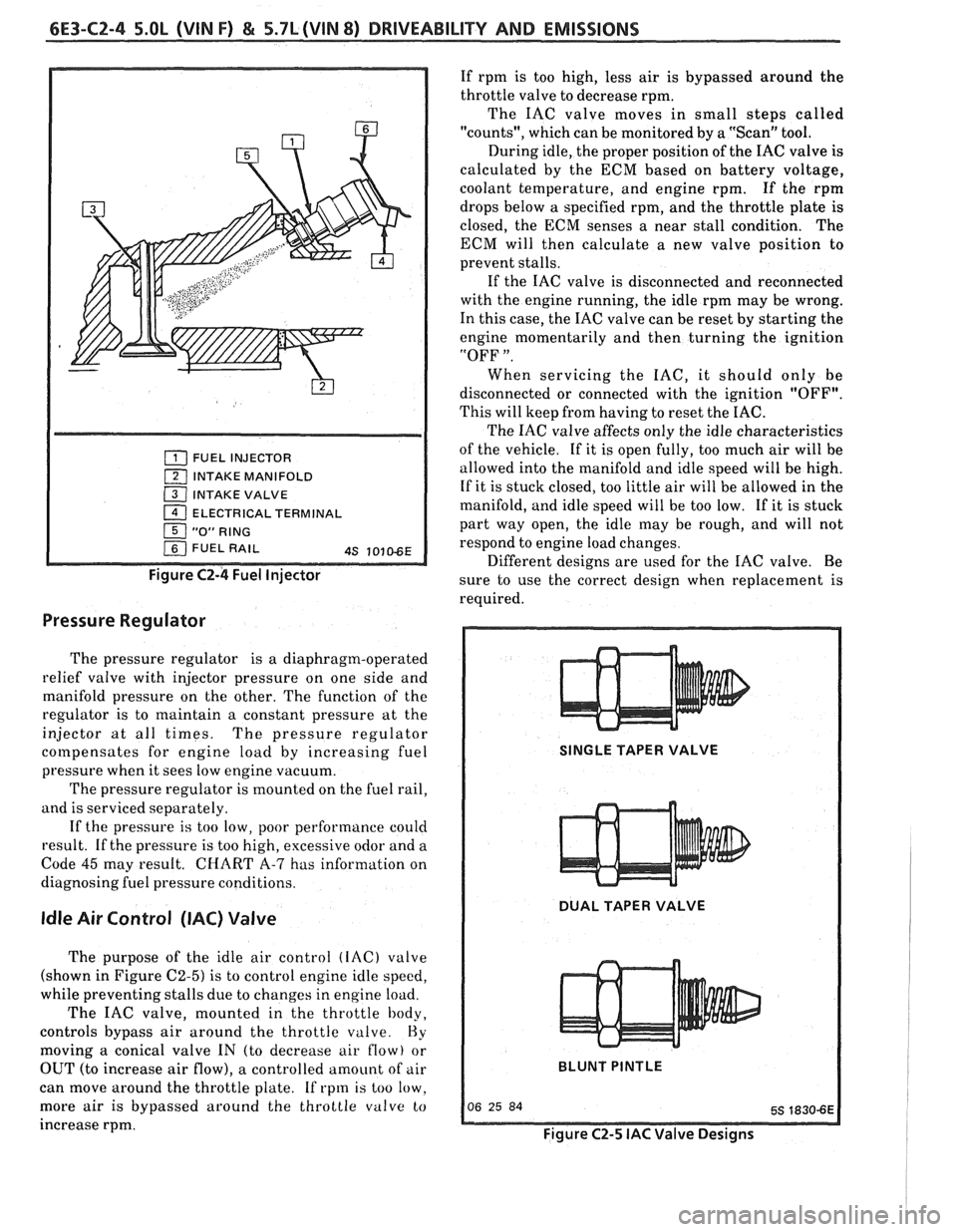

FUEL INJECTOR

1 INTAKE MANIFOLD

( INTAKE VALVE

1 ELECTRICAL TERMINAL

Figure C2-4 Fuel Injector

Pressure Regulator

The pressure regulator is a diaphragm-operated

relief valve with injector pressure on one side and

manifold pressure on the other. The function of the

regulator is to maintain a constant pressure at the

injector at all times. The pressure regulator

cotnpensates for engine load by increasing fuel

pressure when it sees low engine vacuum.

The pressure regulator is mounted on the fuel rail,

and is serviced separately.

If the pressure

is too low, poor performance could

result. If the pressure is too high, excessive odor and a

Code

45 may result. CHART A-7 has information on

diagnosing fuel pressure conditions.

Idle Air Control (IAC) Valve

The purpose of the idle air control (IAC) valve

(shown in Figure

C2-5) is to control engine idle speed,

while preventing stalls due to changes in engine load.

The IAC valve, mounted in the throttle body,

controls bypass air around the throttle

valve. Hy

moving a conical valve IN (to decrease air flow) or

OUT (to increase air flow), a controlled amount of air

can move around the throttle plate. If rpm is too low.

more air

is bypassed around the throttle valve to

increase rpm. If

rpm is too high, less air is bypassed around the

throttle valve to decrease rpm.

The IAC valve moves in small steps called

"counts", which can be monitored by a "Scan" tool.

During idle, the proper position of the IAC valve is

calculated by the ECM based on battery voltage,

coolant temperature, and engine rpm. If the rpm

drops below

a specified rpm, and the throttle plate is

closed, the ECM senses a near stall condition. The

ECM will then calculate a new valve position to

prevent stalls.

If the IAC valve is disconnected and reconnected

with the engine running, the idle rpm may be wrong.

In this case, the IAC valve can be reset by starting the

engine momentarily and then turning the ignition

"OFF

".

When servicing the IAC, it should only be

disconnected or connected with the ignition "OFF".

This will keep from having to reset the IAC.

The IAC valve affects only the idle characteristics

of the vehicle. If it is open fully, too much air will be

allowed into the manifold and idle speed will be high.

If it is stuck closed, too little air will be allowed in the

manifold, and idle speed will be too low. If it is stuck

part way open, the idle may be rough, and will not

respond to engine load changes.

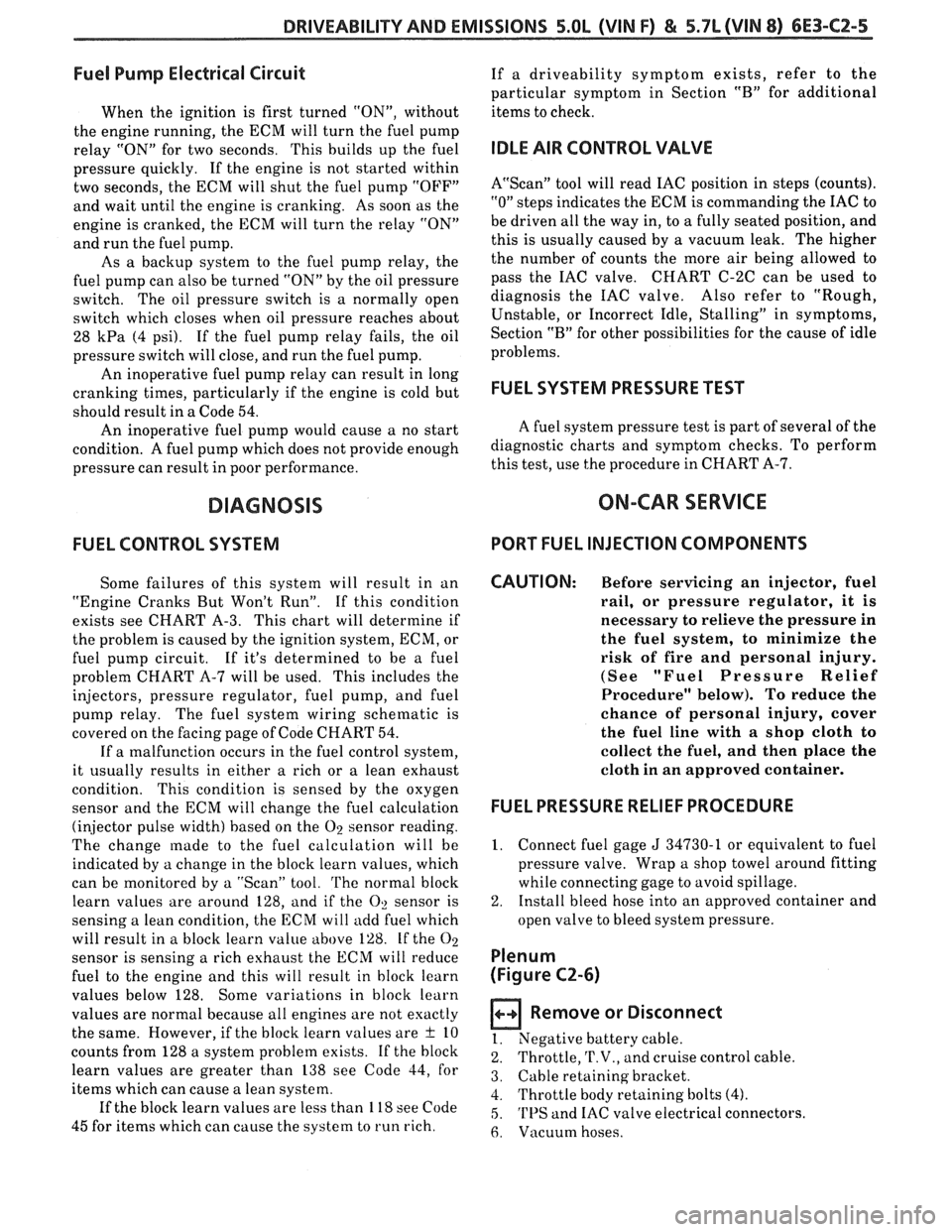

Different designs are used for the IAC valve. Be

sure to use the correct design when replacement is

required.

SINGLE TAPER VALVE

DUAL TAPER VALVE

BLUNT

PINTLE

Figure C2-5 IAC Valve Designs

Page 892 of 1825

DRIVEABILITY AND EMISSIONS 5.OL (VIN F) & 5.7L (VIN 8) 6E3-C2-5

Fuel Pump Electrical Circuit

When the ignition is first turned "ON", without

the engine running, the ECM will turn the fuel pump

relay "ON" for two seconds.

This builds up the fuel

pressure quickly. If the engine is not started within

two seconds, the ECM will shut the fuel pump "OFF"

and wait until the engine is cranking. As soon as the

engine is cranked, the ECM will turn the relay "ON"

and run the fuel pump.

As

a backup system to the fuel pump relay, the

fuel pump can also be turned "ON" by the oil pressure

switch. The oil pressure switch is a normally open

switch which closes when oil pressure reaches about

28

kPa (4 psi). If the fuel pump relay fails, the oil

pressure switch will close, and run the fuel pump.

An inoperative fuel pump relay can result in long

cranking times, particularly if the engine is cold but

should result in

a Code 54.

An inoperative fuel pump would cause a no start

condition. A fuel pump which does not provide enough

pressure can result in poor performance.

DIAGNOSIS

FUEL CONTROL SYSTEM

Some failures of this system will result in an

"Engine Cranks But Won't Run". If

this condition

exists see CHART A-3. This chart will determine if

the problem is caused by the ignition system, ECM, or

fuel pump circuit. If

it's determined to be a fuel

problem CHART A-7 will be used. This includes the

injectors, pressure regulator, fuel pump, and fuel

pump relay. The fuel system wiring schematic is

covered on the facing page of Code CHART 54.

If a malfunction occurs in the fuel control system,

it usually results in either a rich or

a lean exhaust

condition. This condition is sensed by the oxygen

sensor and the ECM will change the fuel calculation

(injector pulse width) based on the

O2 sensor reading.

The change

made to the fuel calculation will be

indicated by a change in the block learn values, which

can be monitored by a "Scan" tool.

The normal block

learn values are around 128, and if the

O2 sensor is

sensing a lean condition, the EC

M will add fuel which

will result in a block learn value above 128.

If the O2

sensor is sensing a rich exhaust the ECM will reduce

fuel to the engine and this will result in block learn

values below 128. Some variations in block

learn

values are normal because all engines are not exactly

the same. However, if the block learn values are

+ 10

counts from 128 a system problem exists. If the block

learn values are greater than 138 see Code 44, for

items which can cause a lean system.

If the block learn values are less than 118 see Code

45 for items which can cause the system to run rich. If

a driveability symptom exists, refer to the

particular symptom in Section

"B" for additional

items to check.

IDLE AIR CONTROL VALVE

AUScan" tool will read IAC position in steps (counts).

"0" steps indicates the ECM is commanding the IAC to

be driven all the way in, to a fully seated position, and

this is usually caused by a vacuum leak. The higher

the number of counts the more air being allowed to

pass the IAC valve. CHART C-2C can be used to

diagnosis the IAC valve. Also refer to "Rough,

Unstable, or Incorrect Idle, Stalling" in symptoms,

Section "B" for other possibilities for the cause

of idle

problems.

FUEL SYSTEM PRESSURE TEST

A fuel system pressure test is part of several of the

diagnostic charts and symptom checks. To perform

this test, use the procedure in CHART A-7.

ON-CAR SERVICE

PORT FUEL INJECTION COMPONENTS

CAUTION:

Before servicing an injector, fuel

rail, or pressure regulator,

it is

necessary to relieve the pressure in

the fuel system, to minimize the

risk of fire and personal injury.

(See "Fuel Pressure Relief

Procedure" below). To reduce the

chance of personal injury, cover

the fuel line with

a shop cloth to

collect the fuel, and then place the

cloth in an approved container.

FUEL PRESSURE RELIEF PROCEDURE

1. Connect fuel gage J 34730-1 or equivalent to fuel

pressure valve. Wrap a shop towel around fitting

while connecting gage to avoid spillage.

2. Install bleed hose into an approved container and

open valve to bleed system pressure.

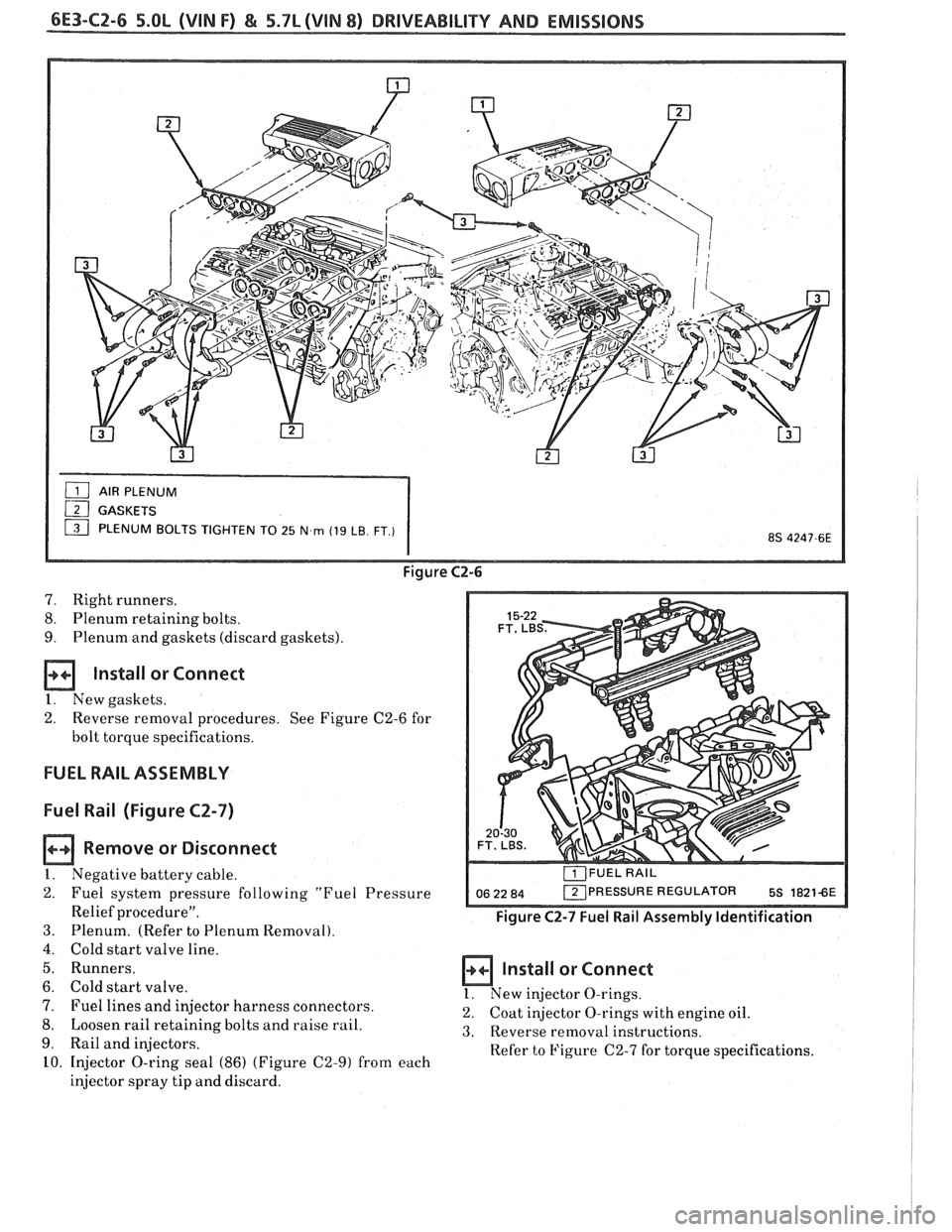

Plenum

(Figure

C2-6)

Remove or Disconnect

1. Negative battery cable.

2. Throttle, 'F.V., and cruise control cable.

3. Cable retaining bracket.

4.

'I'hrottle body retaining bolts (4).

5. 'L'l'S and IAC valve electrical connectors.

6. Vacuum hoses.

Page 893 of 1825

6E3-C2-6 5.OL (VIN F) & 5.7L(VIN 8) DRIVEABILITY AND EMISSIONS

PLENUM BOLTS TIGHTEN TO 25 N m (19 LB. FT.)

Figure C2-6

7. Right runners.

8. Plenum retaining bolts.

9. Plenum and gaskets (discard gaskets).

Install or Connect

1. New gaskets.

2. Reverse removal procedures. See Figure C2-6 for

bolt torque specifications.

FUEL RAIL ASSEMBLY

Fuel Rail (Figure C2-7)

n Remove or Disconnect

1. Negative battery cable

2. Fuel system pressure following "Fuel Pressure

Relief procedure".

3. Plenum. (Refer to Plenum Removal).

4. Cold start valve line.

5. Runners.

6. Cold start valve.

7. Fuel lines and injector harness connectors.

8. Loosen rail retaining bolts and raise rail.

9. Rail and injectors.

10. Injector O-ring seal (86) (Figure C2-9) from each

injector spray tip and discard.

) 06 22 84 PRESSURE REGULATOR 5s 1821SE I

Figure C2-7 Fuel Rail Assembly Identification

Install or Connect

1. New injector O-rings.

2. Coat injector O-rings with engine oil.

3. Reverse removal instructions.

Refer to Figure C2-7 for torque specifications.

Page 894 of 1825

DRIVEABILITY AND EMISSIONS 5.OL (VIN F) & 5.7L (VIN 8) 6E3-C2-7

Figure C2-8 Fuel Rail Pressure Regulator

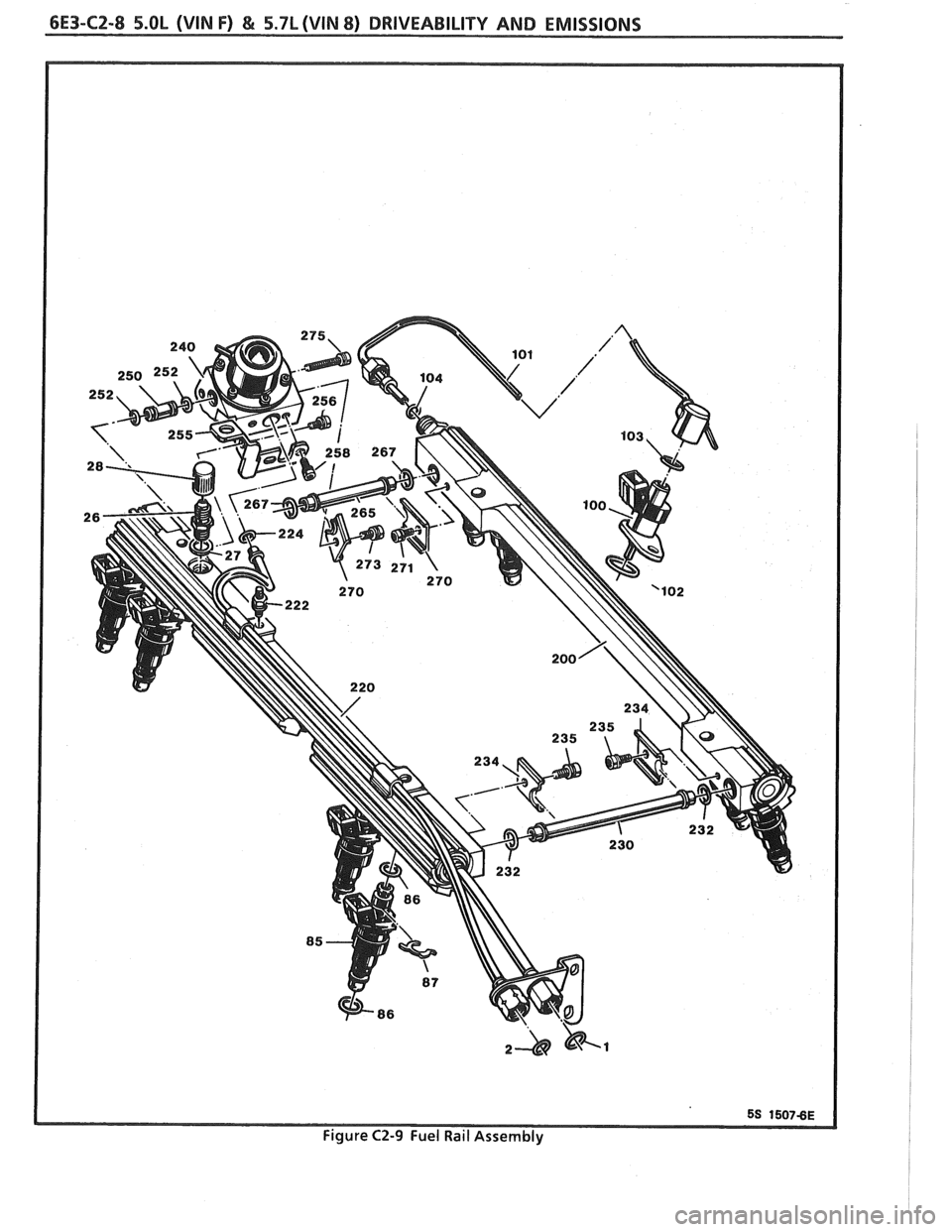

FUEL RAIL SERVICE

IDENTIFICATION

An eight digit identification number is stamped

on the fuel rail assembly, as shown in Figure C2-8.

Refer to this model identification number if servicing

or part replacement is required.

Names of component parts will be found on the

numbered list that accompanies the dis-assembled

view, (Figure C2-9). Numbers used to identify parts

there will be used to identify the same parts in other

illustrations of this section of the manual.

UNIT SERVICE PROCEDURES

lrnportant

When servicing the fuel rail assembly,

precautions must be taken to prevent dirt and

other contaminants from entering the fuel

passages. It is recommended that fittings be

capped, and holes

be plugged during servicing.

Important

At any time the fuel system is opened for service,

the

O-ring seals ised with the related

component(s) should be replaced.

Cleaning and Inspection

Before disassembly, the fuel rail assenlbly may be

cleaned with a spray type engine cleaner, such as

AC

Delco X-30A or equivalent, following

package

instructions. The fuel rail should not be immersed in

liquid solvent.

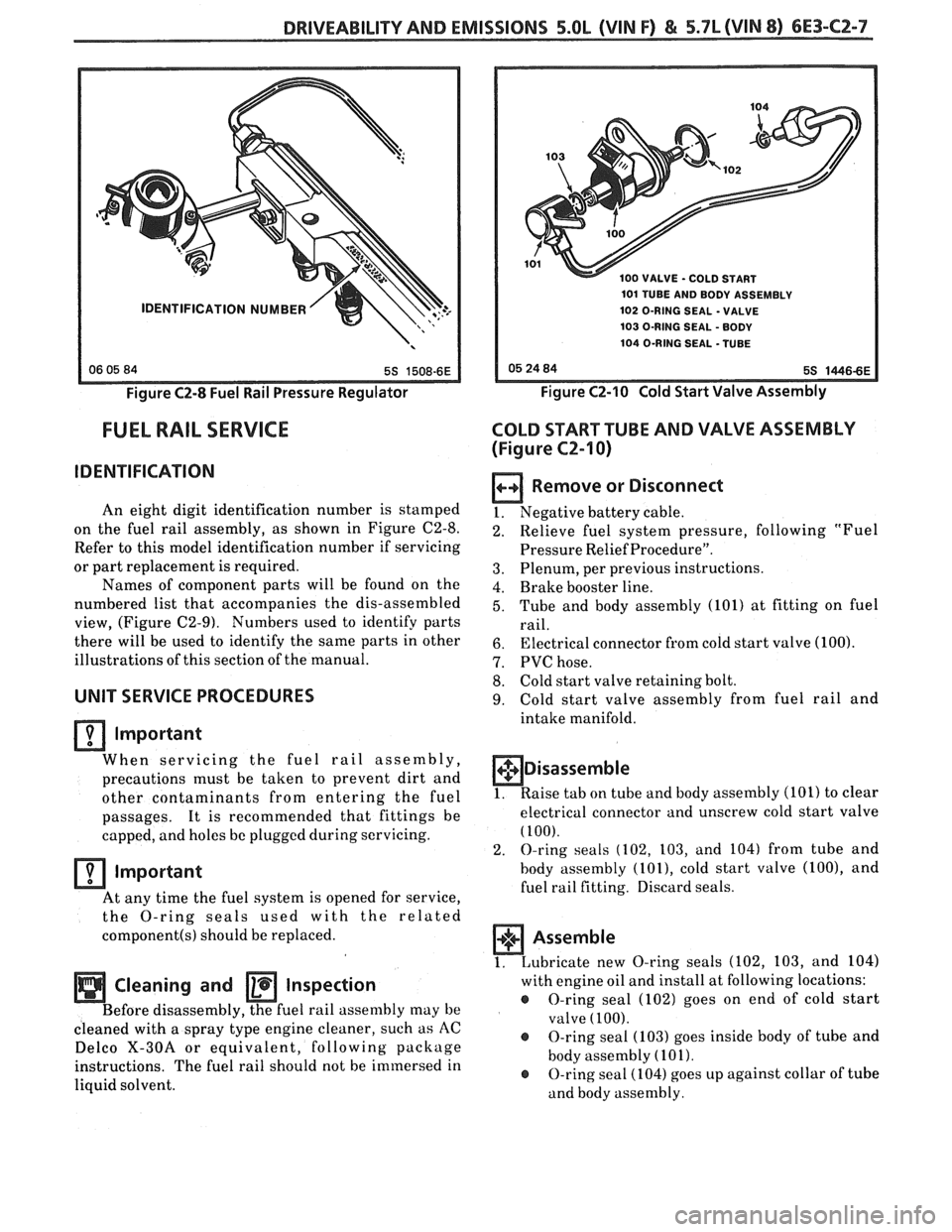

0 VALVE - COLD START

101 TUBE AND BODY ASSEMBLY

102 O-RING SEAL

- VALVE

103 O-RING SEAL

- BODY

104 O-RING SEAL -TUBE

Figure CZ-10 Cold Start Valve Assembly

COLD START TUBE AND VALVE ASSEMBLY

(Figure

CZ-I 0)

Remove or Disconnect

1. Negative battery cable. -

Relieve fuel system pressure, following "Fuel

Pressure Relief Procedure".

Plenum, per previous instructions.

Brake booster line.

Tube and body assembly (101) at fitting on fuel

rail.

Electrical connector from cold start valve (100).

PVC hose.

Cold start valve retaining bolt.

Cold start valve assembly from fuel rail and

intake manifold.

+$ Disassemble

1. Raise tab on tube and body assembly (101) to clear

electrical connector and unscrew cold start valve

(100).

2. O-ring seals (102, 103, and 104) from tube and

body assembly

(lOl), cold start valve (loo), and

fuel rail fitting. Discard seals.

1. Lubricate

new O-ring seals (102, 103, and 104)

with engine oil and install at following locations:

@ O-ring seal (102) goes on end of cold start

valve

(100).

@ O-ring seal (103) goes inside body of tube and

body assembly

(101).

@ O-ring seal (104) goes up against collar of tube

and body assembly.

Page 895 of 1825

6E3-CZ-8 5.OL (VIN F) & 5.7L(VIN 8) DRIVEABILITY AND EMISSIONS

F~gure C2-9 Fuel Rail Assembly

Page 896 of 1825

DRIVEABILITY AND EMISSIONS 5.OL (VIN F) & 5.7L (VIN 8) 6E3-CZ-9

Cold start valve (100) onto tube and body

assembly

.

Screw in until valve bottoms. then back off

until hole in mounting lug on valve will be

aligned properly with hole in fuel rail when

mounted

.

@ Bend tang over cold start valve to lock it in

position

.

Clean

@ Areas around valve and connection with AC

Delco X-30A or equivalent

.

Install or Connect

1 . Cold start (100) valve in intake manifold .

2 . Cold start valve retaining bolt .

Tighten

@ Retaining bolt to 27 Nwm (20 ft . lbs.). .

3 . PVC hose .

4 . Tube and body assembly (101) at fitting on fuel

rail

.

Tighten

@ Nut on fitting to 27 N-m (20 ft . lbs.).

6 . Brake booster line .

6 . Electrical connector on cold start valve (100)

7 . Negative battery cable .

Inspect

@ Energize fuel pump and inspect for leaks .

8 . Intake manifold plenum. per previous

instructions

.

FUEL RAIL SERVICE

FIGURE CZ-9

PARTS INFORMAION

PART NAME PART #

. .................. O-ring Fuel Inlet Line 1

. ................ O-ring Fuel Return Line 2

Assembly

. Fuel Pressure Connection ....... 26

Seal

. Fuel Pressure Connection ........... 27

Cap

. Fuel Pressure Connection ............ 28

Injector

. Port ......................... 85

. . .................. Seal 0-Ring Injector 86

. .................. Clip Injector Retainer 87

. ..................... Valve Cold Start 100

Assembly

. Tube & Body 101 Seal .

....................... O-ring Valve 102

. . .................... Seal 0-Ring Body 103

. . .................... Seal 0-Ring Tube 104

. .......... Assembly Fuel Rail & Plug (LH) 200

. .......... Assembly Fuel Rail & Plug (RH) 220

Stud Assembly

. Rear Bracket

......................... Attaching 222

Seal

. 0-Ring . Fuel Outlet Tube ........... 224

. ................. Tube Front Crossover 230

. . ........ Seal 0-Ring Fuel Crossover Tube 232

. .*............. Retainer Crossover Tube 234

...... . Screw Assembly Retainer Attaching 235

Assembly

. Pressure Regulator and

............................. Base 240

. ................ . Seal 0-Ring Connector 252

. ................. Connector Base to Rail 250

Bracket

. Pressure Regulator & Base

......................... Assembly 255

Screw Assembly

. Bracket to rail

......................... Attaching 256

Screw Assetnhly

. Bracket to Base

......................... Attaching 258

. .................. Tube Rear Crossover 265

. . ............ Seal 0-Ring Crossover Tube 267

........... . Retainer Rear Crossover Tube 270

....... . Screw Assembly Retainer to LH Rail 271

......... . Screw Assembly Retainer to Base 273

.......... . Screw Assembly Base to RH Rail 275

Page 897 of 1825

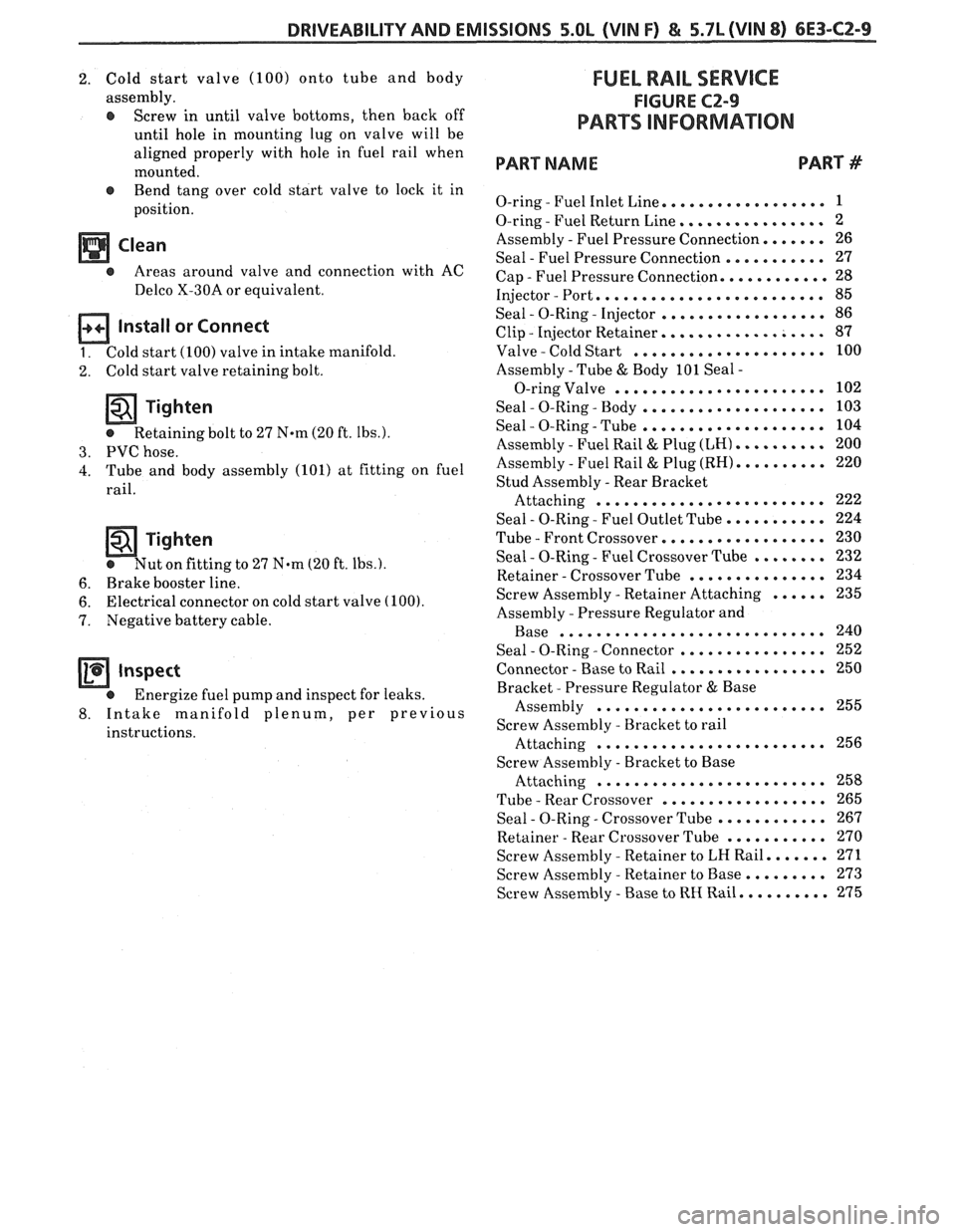

6E3-C2-"l s5.OL (VIN F) & 5.7b (VIN 8) DRIVEABILITY AND EMISSIONS

FUEL RAIL

26 FUEL PRESSURE CONNECTION ASSEMBLY

27 DEAL - FUEL PRESSURE CONNECTION ASSEMBLY

28 CAP -FUEL PRESSURE CONNECTION ASSEMBLY

06 85 84 5S 1509-6E

Figure

C2-'11 Fuel Pressure Connection Assembly

FUEL PRESSURE CONNECTION ASSEMBLY

(Figure

CZ-'I I)

Remove or Disconnect

1. Negative battery cable.

2. Relieve fuel system pressure following "Fuel

Pressure Relief' procedure.

a Clean

@ Area around valve and connection with AC

Delco X-30A or equivalent.

3. Fuel pressure connection assembly (26) and seal

(27). Discard seal

Install or Connect

I. New seal (27) on fuel pressure connection

assembly

(26).

2. Fuel pressure connection assembly (26)in fuel rail.

- @ Fuel pressure connection assembly to 10.0

Norn (88.0 in. Ibs.

3. Negative battery cable.

inspect

@ Energize fuel pump and check for leaks.

FUEL INJECTORS

(With Fuel Wail Removed)

Each port injector is located and held in position by

a retainer clip that must be rotated to release

and/or

lock the injector in place, as shown in Figure (22-12.

FUEL RAIL

I 85 INJECTOR - PORT I

Figure CZ-12 Port Injector with Injector Retainer Clip

a Remove or Disconnect

1. Rotate injector retaining clip(s) (87) to unlocked

position.

2. Injectors (85).

+$ Disassemble

1. Injector O-ring seals (86) from both ends of

injectors

(85) and discard.

Assemble

@ New O-ring seals (86) and install on injectors (85).

Install or Connect

1. Injectors

to fuel rail and pressure regulator

assembly

(1 1).

2. Rotate

injector retainer clips (87) to loclring

position (Figure C2-12).

PRESSURE REGULATOR

(With Fuel Rail Removed)

Important

The pressure regulator is factory adjusted and is

not serviceable. Do not attempt to remove regulator

cover.

Remove or Disconnect

1. Front crossover tube retainer attaching screw

assembly

(235) and crossover tube retainer (234)

on right hand rail side.

2. Retainer to base screw assembly (273)

and rear

crossover tube retainer

(270) at pressure regulator

and base assembly (240).

Page 898 of 1825

DRIVEABILITY AND EMISSIONS 5.OL (VIN F) & 5.7L (VIN 8) 6E3-C2-11

3. Separate left hand fuel rail and plug assembly

(200) from right hand fuel rail and plug assembly

(220).

4. Bracket-to-rail

attaching screw assembly (256),

two bracket-to-base attaching screw assemblies

(258) and pressure regulator and base assembly

bracket

(255).

5. Screw

assembly (235), which attaches fuel outlet

tube to right hand rail (220).

6. Base to right hand rail screw assembly (275).

7. Pressure regulator and base assembly (240) from

right hand rail assembly (220).

8. Rotate regulator and base assembly to remove

from fuel outlet tube.

9. Base to rail connector (250).

10. O-ring seals and discard:

@ Connector (252).

@ Fuel outlet tube (224).

@ Rear crossover tube (267).

@ Front crossover tube (232).

Important

When removing O-ring seals, note locations and

sizes, to assure correct replacement and re-

assembly.

Inspect

@ O-rings and sealing surfaces, for damage that

could prevent proper sealing.

- Replace any damaged O-ring seals.

n Install or Connect

1. Lubricate with engine oil, and install O-ring seals:

@ Connector (252).

@ Fuel outlet tube (224).

@ Rear crossover tube (267).

@ Front crossover tube (232).

Base-to-rail connector (250) in pressure regulator

and base assembly (240).

Regulator and base assembly on fuel outlet tube.

Rotate the regulator and base assembly to install

base to rail connector

(250) into right hand rail

assembly

(220).

Base to right hand rail screw assembly (275).

Pressure regulator and base assembly bracket

(2551, two brackets to base attaching screw

assembly (258) and bracket to rail attaching screw

assembly (256).

Rear bracket attaching screw assembly

(235).

Left hand rail and plug assembly (2001, with front

and rear crossover tubes (230) and

265), to right

hand rail and tube assembly

(220).

Rear crossover tube retainer (270) and retainer to

base screw assembly

(273).

240PRESSUREREGUbATORAND

BASE ASSEMBLY

Figure C2-13 Fuel Pressure Regulator

10. Front crossover tube retainer (234) and retainer

attaching screw assembly

(235).

Tighten

@ Above mentioned seven assemblies to 5 N-m

(44 in. lbs.).

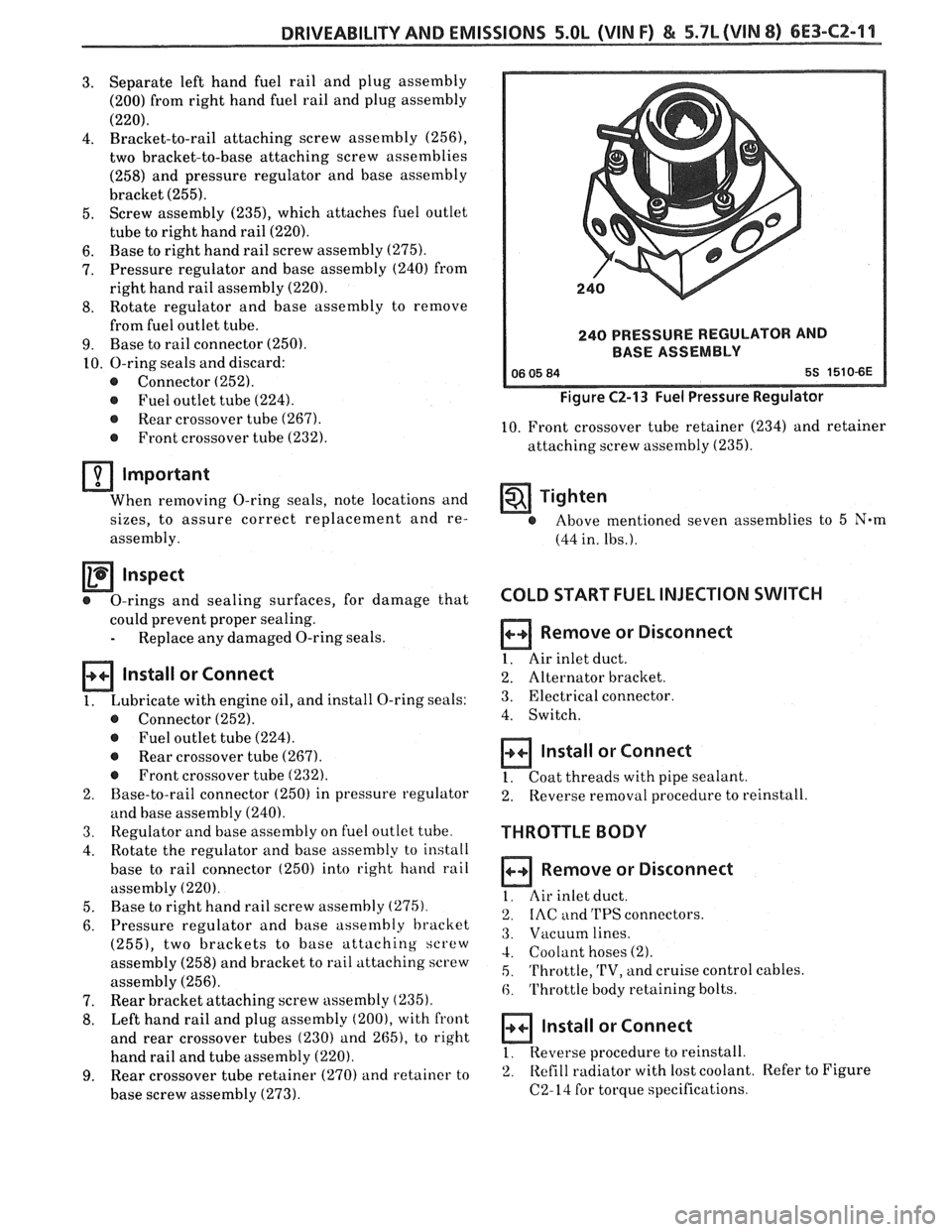

COLD START FUEL INJECTION SWITCH

Remove or Disconnect

1. Air inlet duct.

2. Alternator bracket.

3. Electrical connector

4. Switch.

Install or Connect

1. Coat threads with pipe sealant.

2. Reverse

removal procedure to reinstall.

THROTTLE BODY

Remove or Disconnect

I. Air inlet duct.

2. IAC and 'I'PS connectors.

3. Vacuum lines.

4. Coolant hoses (2).

5. 'I'hrottle, 'L'V, and cruise control cables.

6. Throttle body retaining bolts.

a Install or Connect

1, Reverse procedure to reinstall.

2. Refill

radiator with lost coolant. Refer to Figure

C2-14 for torque specifications.

Page 899 of 1825

6E3-C2-12 5.OL (VIN F) & 5.7L (VIN 8) DRIVEABILITY AND EMISSIONS

UNIT REPAIR PROCEDURES

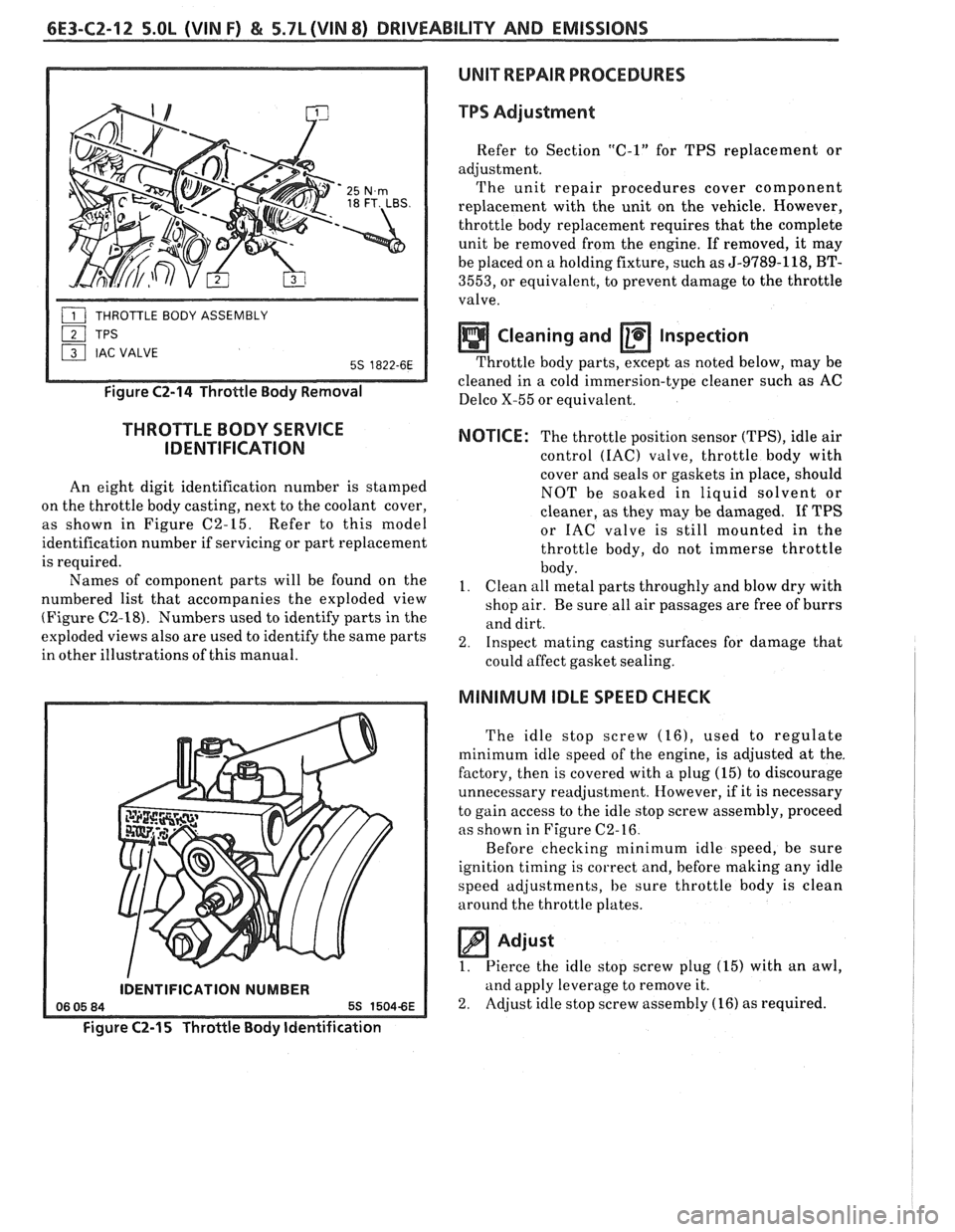

Figure C2-14 Throttle Body Removal

THROTTLE BODY SERVICE

IDENTIFICATION

An eight digit identification number is stamped

on the throttle body casting, next to the coolant cover,

as shown in Figure C2-15. Refer to this model

identification number if servicing or part replacement

is required.

Names of component parts will be found on the

numbered list that accompanies the exploded view

(Figure

C2-18). Numbers used to identify parts in the

exploded views also are used to identify the same parts

in other illustrations of this manual.

IDENTIFICATION NUMBER

Figure C2-15 Throttle Body Identification

TPS Adjustment

Refer to Section "C-1" for TPS replacement or

adjustment. The unit repair procedures cover component

replacement with the unit on the vehicle. However,

throttle body replacement requires that the complete

unit be removed from the engine. If removed, it may

be placed on a holding fixture, such as

5-9789-118, BT-

3553, or equivalent, to prevent damage to the throttle

valve.

Cleaning and a Inspection

Throttle body parts, except as noted below, may be

cleaned in a cold-immersion-type cleaner such

a; AC

Delco X-55 or equivalent.

NOTICE: The throttle position sensor (TPS), idle air

control

(IAC) valve, throttle body with

cover and seals or gaskets in place, should

NOT be soaked in liquid solvent or

cleaner, as they may be damaged. If TPS

or IAC valve is still mounted in the

throttle body, do not immerse throttle

body.

I. Clean all metal parts throughly and blow dry with

shop air. Be sure all air passages are free of burrs

and dirt.

2. Inspect mating casting surfaces for damage that

could affect gasket sealing.

MINIMUM IDLE SPEED CHECK

The idle stop screw (161, used to regulate

minimum idle speed of the engine, is adjusted at the.

factory, then is covered with a plug (15) to discourage

unnecessary readjustment. However, if it is necessary

to gain access to the idle stop screw assembly, proceed

as shown in Figure C2-16.

Before checking minimum idle speed, be sure

ignition timing is correct and, before making any idle

speed adjustments, be sure throttle body is clean

around the throttle plates.

Adjust

1. Pierce

the idle stop screw plug (15) with an awl,

and apply leverage to remove it.

2. Adjust idle stop screw assembly

(16) as required.

Page 900 of 1825

DRIVEABILITY AND EMISSIONS 5.OL (VIN F) & 5.7b (VIN 8) 6E3-CZ-13

IDLE STOP SCREW

ASSEMBLY

IDLE STOP

SCREW PLUG

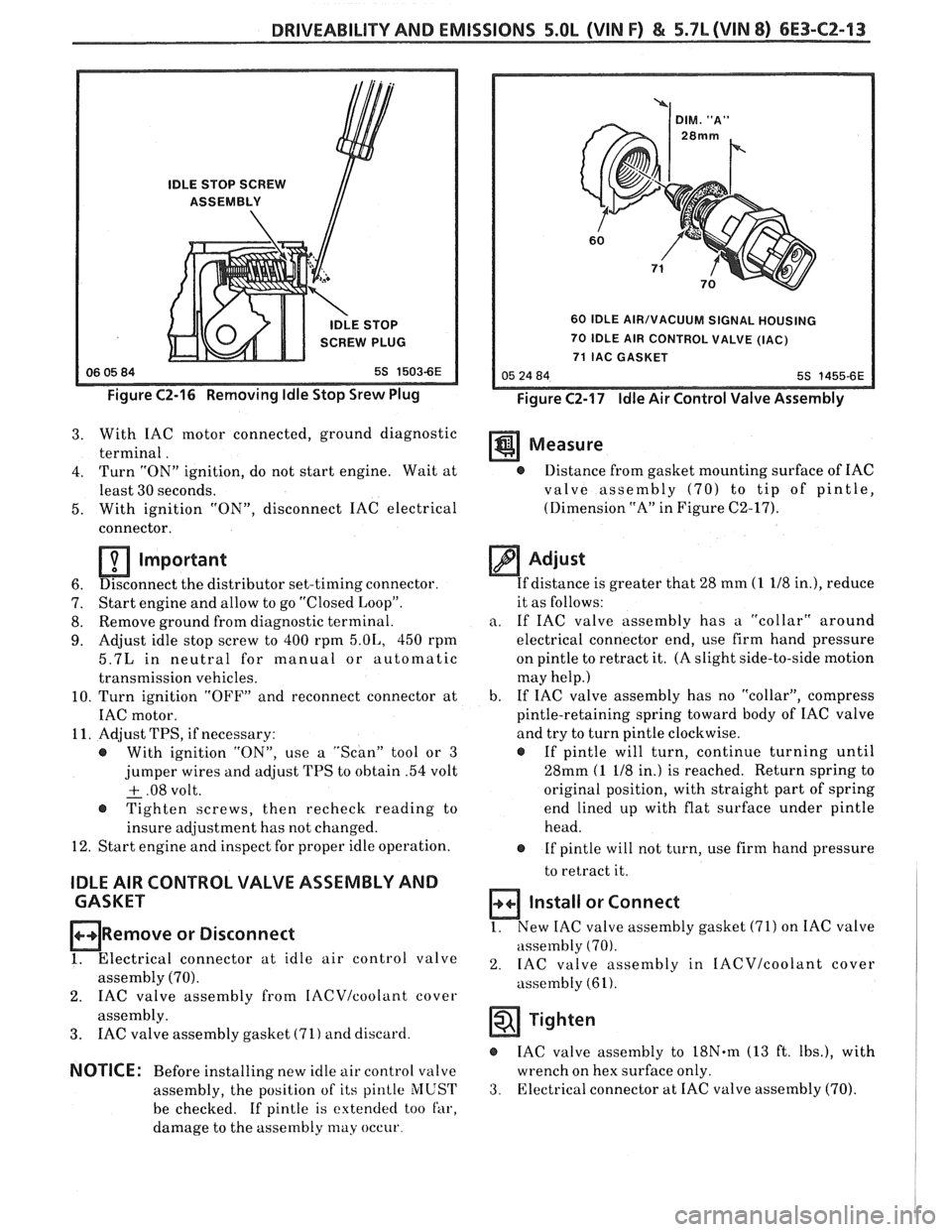

Figure C2-16 Removing Idle Stop Srew Plug

60 IDLE AIR/VACUUM SIGNAL HOUSING

70 IDLE AIR CONTROL VALVE (IAC)

71 IAC GASKET

Figure C2-17 Idle Air Control Valve Assembly

3. With IAC motor connected, ground diagnostic

terminal. Measure

4. Turn "ON" ignition, do not start engine. Wait at @ Distance from gasket mounting surface of IAC

least 30 seconds. valve assembly

(70) to tip of pintle,

5. With ignition

"ON", disconnect IAC electrical (Dimension

"A" in Figure C2-17).

connector.

Important

6. Disconnect

the distributor set-timing connector.

7. Start

engine and allow to go "Closed Loop".

8. Remove

ground from diagnostic terminal.

9. Adjust idle stop screw to 400 rpm 5.01,, 450 rpm

5.7L in neutral for manual or automatic

transmission vehicles.

10. Turn ignition "OFF" and reconnect connector at

IAC motor.

11. Adjust TPS, if necessary:

@ With ignition "ON", use a "Scan" tool or 3

jumper wires and adjust TPS to obtain .54 volt

+ .08 volt. - @ Tighten screws, then recheck reading to

insure adjustment has not changed.

12. Start engine and inspect for proper idle operation.

IDLE AIR CONTROL VALVE ASSEMBLY AND

CASKET

ORemove or Disconnect

1. Electrical connector at idle air control valve

assembly (70).

2. IAC valve assembly from IACVIcoolant cover

assembly.

3. IAC valve assembly gasket (71) and discard.

NOTICE: Before installing new idle air control valve

assembly, the position of its

pinlle MUST

be checked. If pintle is extended too far,

damage to the assembly

may occur

Adjust

If distance is greater that 28 mm (1 118 in.), reduce

it as follows:

a. If IAC valve assembly has a "collar" around

electrical connector end, use firm hand pressure

on pintle to retract it. (A slight side-to-side motion

may help.)

b. If

IAC valve assembly has no "collar", compress

pintle-retaining spring toward body of IAC valve

and try to turn pintle clockwise.

@ If pintle will turn, continue turning until

28mm

(1 118 in.) is reached. Return spring to

original position, with straight part of spring

end lined up with flat surface under pintle

head.

@ If pintle will not turn, use firm hand pressure

to retract it.

Install or Connect

1. New IAC valve assembly gasket (71) on IAC valve

assembly

(70).

2. IAC valve assembly in IACVIcoolant cover

assembly (61).

Tighten

IAC valve assembly to 18N.m (13 ft. Ibs.), with

wrench on hex surface only.

3. Electrical connector at IAC valve assembly (70).