PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 901 of 1825

Page 902 of 1825

DRIVEABILITY AND EMISSIONS 5.OL (WIN F) & 5.7L (WIN 8) 6E3-C2-15

Important

No physical adjustment is made to the IAC

assembly after installation. IAC

valve resetting

occurs after reinstallation on the vehicle, and is

reset after the engine is started and then the

ignition turned "OFF".

THROTTLE BODY

PARTS INFORMATION

FIGURE CZ-18

PART NAME PART #

. Gasket Flange ......................... 1

Throttle Body Assembly .................. 10

Plug . Idle Stop Screw .................... 15

Screw Assembly - Idle Stop. ................ 16

Spring

- Idle Stop Screw ................... 17

Sensor - Throttle Position (TPS) ............. 20

Screw Assembly

- TPS Attaching ............ 21

Retainer

- TPS Attaching Screw ............. 22

Cover-CleanAir........................ 41

Screw Assembly

- Clean Air Cover

Attaching...

.......................... 42

Gasket

- Clean Air Cover .................. 43

IACVICoolant Cover Assembly ............. 61

Screw Assembly

- IACV Cover

Assembly to Throttle Body

................ 62

Gasket

- IACVICoolant Cover to

Throttle Body..

........................ 63

Valve Assembly

- ldle Air Control

(IAC) ................................ 70

Gasket

- IAC Valve Assembly .............. 71

CLEAN AIR COVER AND GASKET

ORemove or Disconnect

1. Clean

air cover attaching screw assemblies (42)

2. Clean air cover (41).

3. Clean air cover gasket (43).

@ Cover mounting surface to ensure a good seal.

Install and Connect

1. New clean air cover gasket (43) on throttle body

assembly

(10).

2. Clean air cover (41).

3. Clean air cover attaching screw assemblies (42).

61 IACVICOOLANT COVER ASSV 62 SCREW ASSY . IACV COVER ASSY TO THROrRE BODV 63 GASKET. IACV COOLANT COVER TO THROTTLE BODY 70 VALVE ASSV -IDLE AIR CONTROL 71 GASKET - IDLE AIR COHTROLVALVE

Figure C2-19 ldle Air Control/Coolant Cover

Assembly

IDLE AIR CONTRBLICOOLANT COVER

ASSEMBLY (Figure

CZ-19)

(With Throttle Body Removed From Engine)

a Remove or Disconnect

1. Idle

air control (IAC) valve assembly (70) from

IACVIcoolant cover assembly. (See "Idle Air

Control Valve and Gasket" instructions.)

2. IACV

cover assembly to throttle body screw

assemblies

(62).

3. Cover assembly (61).

4. Cover

assembly to throttle body gasket (63) and

discard.

alnstall or Connect

Clean

e Throttle body gasket mounting surface to

ensure a good seal.

e Sealing surface for damage that could prevent

sealing properly or

cause coolant leak.

a Install and Connect

1. New IACVIcoolant cover

assembly to throttle body

gasket

(63).

2. IACV/coolant cover assembly (61).

3. IACV

cover assembly to throttle body screw

assemblies

(62).

Page 903 of 1825

6E3-CZ-16 5.OL (VIN F) & 5.7L(VIN 8) DRIVEABILITY AND EMISSIONS

Tighten

- @ Screw assemblies to 3.0 Nem (27.0 in. lbs.).

4. IAC valve assembly (70). (See "Idle Air Control

Valve and Gasket" instructions).

NOTICE: Before installing the IAC valve assembly,

the position of its pintle

MUST be checked.

If pintle is extended too far, damage to the

assembly may occur. (See

"Idle Air

Control Valve and Gasket" instructions.)

FUEL PUMP RELAY

The fuel pump relay is mounted in the engine

compartment (see Figure

C2-20). Other than

checking for loose connectors, the only service possible

is replacement.

BRAKE BOOSTER

Figure C2-20 Fuel Pump Relay

OIL PRESSURE SWITCH

The oil pressure switch is mounted as shown in

Figures C2-2

1.

Figure C2-21 Oil Pressure Switch

a Remove or Disconnect

I. Electrical connector.

2. Oil pressure switch.

Install or Connect

1. Make sure fittings (41) are properly aligned to

allow switch installation.

2. Oil pressure switch.

3. Electrical connector.

PARTS INFORMATION

PART NAME GROUP

Injector, fuel ......................... 3.300

Pump, Fuel (In-Tank)

.................. 3.900

Relay, Fuel Pump

..................... 3.900

Switch, Oil Pressure,

................... 1.800

Valve Asm, Idle Air Control: Part

Of Control Kit, Idle Air Valve. .......... 3.820

Regulator, Fuel Pressure

................ 3.164

Itail, Fuel Feed ....................... 3.330

Page 904 of 1825

DRIVEABILITY AND EMISSIONS 5.OL (VIN F) & 5.7L (VIN 8) 6E3-CZ-17

BLANK

Page 905 of 1825

6E3-CZ-18 5.OL (VIN F) & 5.7L(VIN 8) DRIVEABILITY AND EMISSIONS

CHART C-2A

INJECWR BALANCE TEST

The injector balance tester is a tool used to turn the injector on for a precise

amount of time, thus spraying

a measured amount of fuel into the manifold.

This causes a drop in fuel rail pressure that we can record and compare between

each injector. All injectors should have the same amount of pressure drop

( f 10

kPa). Any injector with a pressure drop that is 10 kPa (or more) greater or less

than the average drop of the other injectors should be considered faulty and

replaced.

STEP 1

Engine "cool down" period (10 minutes) is necessary to avoid irregular

readings due to "Hot Soak" fuel boiling. With ignition "OFF" connect fuel gauge

5347301 or equivalent to fuel pressure tap. Wrap a shop towel around fitting

while connecting gage to avoid fuel spillage.

Disconnect harness connectors at all injectors, and connect injector tester

J-

34730-3, or equivalent, to one injector. On turbo equipped engines, use adaptor

harness furnished with injector tester to energize injectors that are not

accessible. Follow manufacturers instructions for use of adaptor harness.

Ignition must be "OFF" at least 10 seconds to complete

ECM shutdown cycle.

Fuel pump should run about

2 seconds after ignition is turned "ON". At this

point, insert clear tubing attached to vent valve into a suitable container and

bleed air from gauge and hose to insure accurate gauge operation. Repeat this

step until all air is bled from gauge.

Turn ignition

"OFF" for 10 seconds and then "ON" again to get fuel pressure

to its maximum. Record this initial pressure reading. Energize tester one time

and note pressure drop at its lowest point (Disregard any slight pressure

increase after drop hits low point.). By subtracting this second pressure reading

from the initial pressure, we have

the actual amount of injector pressure drop.

STEP 3

Rcpcat stcp 2 on each injector and compare the amount of drop. Usually, good

injectors will have virtually the same drop. Retest any injector that has a

pressure difference of

LOkPa, either more or less than the average of the other

injectors on the engine. Replace any injector that also fails the retest.

If the

pressure drop of all injectors is within

lOkPa of this average, the injectors

appear to be flowing properly. Reconnect them and review symptoms, section

"B".

NOTE: The entire test should not be repeated more than once without

running the engine to prevent flooding. (This includes any retest on

faulty injectors).

Page 906 of 1825

DRIVEABILITY AND EMISSIONS 5.OL (VIN F) & 5.7L (VIN 8) 6E3-CZ-19

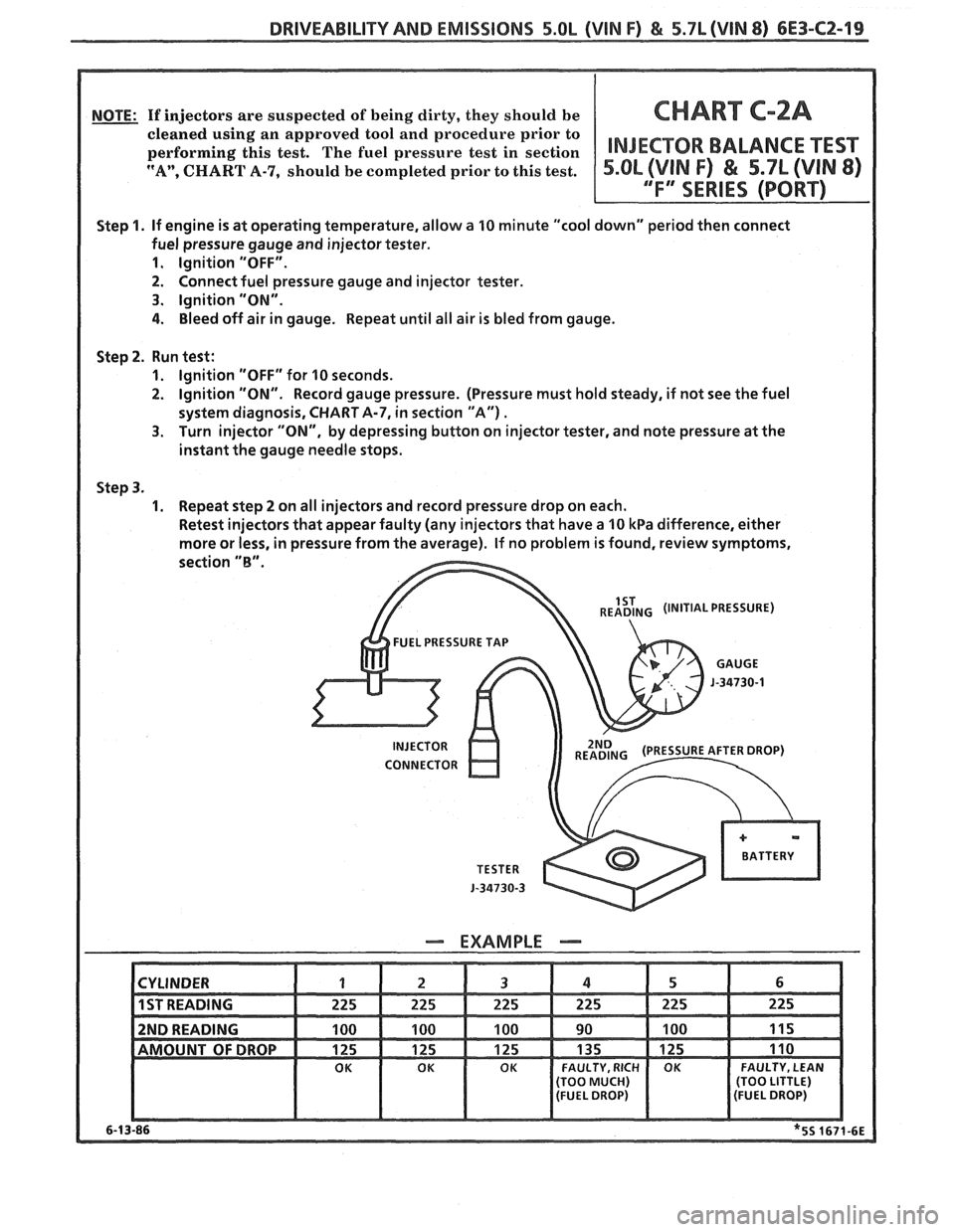

NOTE: If injectors are suspected of being dirty, they should be CHART Cm2A

INJEGWOR BALANCE TEST

Step 1. If engine is at operating temperature, allow a 10 minute "cool down" period then connect

fuel pressure gauge and injector tester.

1. Ignition "OFF".

2. Connect fuel pressure gauge and injector tester.

3. Ignition "ON".

4. Bleed off air in gauge. Repeat until all air is bled from gauge.

1. Ignition "OFF" for 10 seconds.

2. Ignition "ON". Record gauge pressure. (Pressure must hold steady, if not see the fuel

system diagnosis, CHART A-7, in section

"A") .

3. Turn injector "ON", by depressing button on injector tester, and note pressure at the

instant the gauge needle stops.

1. Repeat step 2 on all injectors and record pressure drop on each.

Retest injectors that appear faulty (any injectors that have a 10

kPa difference, either

Page 907 of 1825

6E3-C2-20 5.0L (VIN F) & 5.7L (WIN 8) DRIVEABILITY AND EMISSIONS

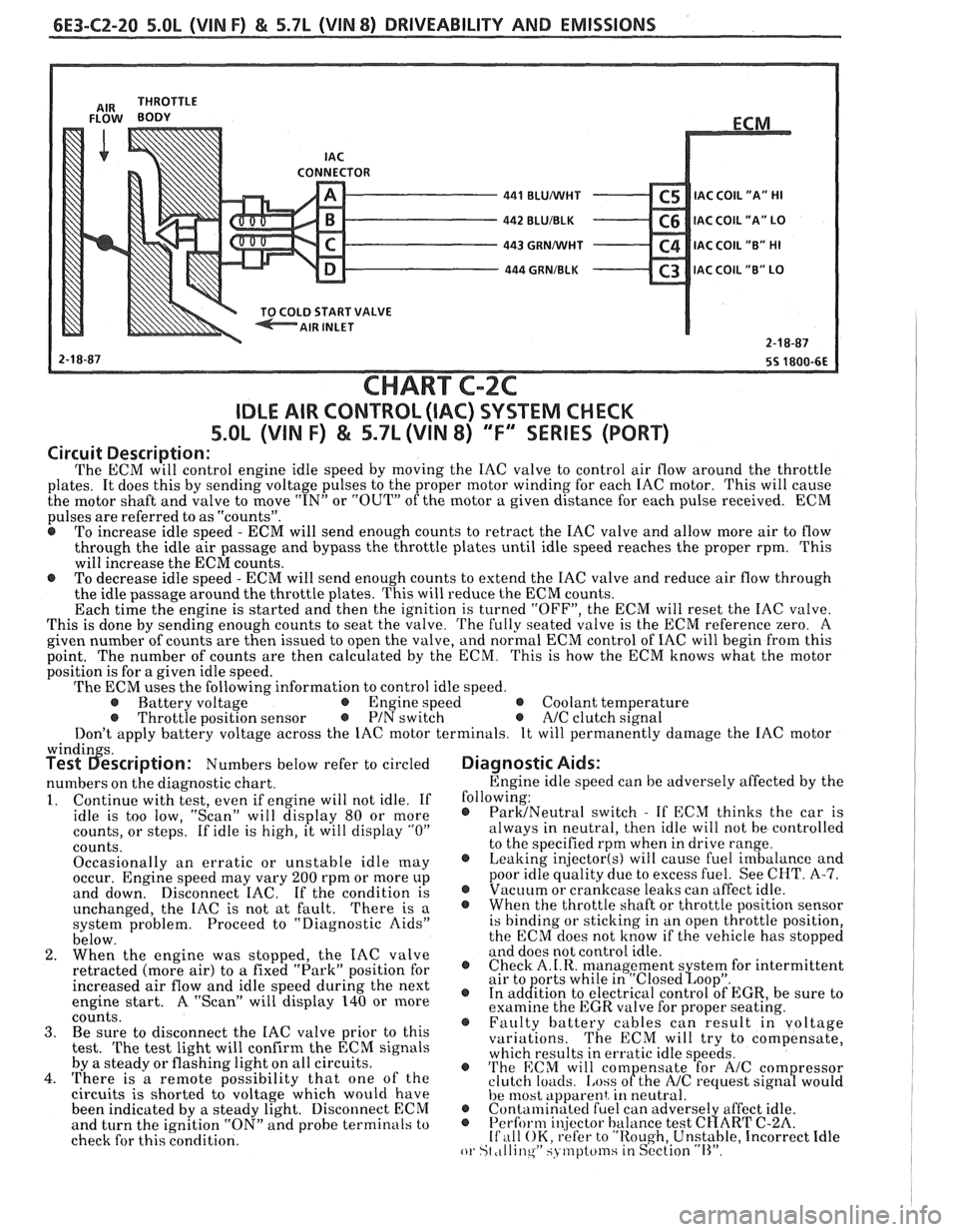

CONNECTOR - 441 BLUMlHT C5 IAC C0lL1'A" HI - 442 BLUIBLK C6 IAC COIL "A" LO - 443 GRNMlHT C4 IAC COIL "B" HI - 444 GRNIBLK C3 lAC COIL "B" LO v

START VALVE

CHART C-2C

IDLE AIR CONTROL (IAC) SYSTEM CHECK

S.OL (VIN F) & 5.7L (VIN 8) "F'" SERIES (PORT)

Circuit Description:

The ECM will control engine idle speed by moving the IAC valve to control air flow around the throttle

plates. It does this by sending voltage pulses to the proper motor winding for each IAC motor. This will cause

the motor shaft and valve to move

"IN" or "OUT" of the motor a given distance for each pulse received. ECM

pulses are referred to as "counts".

@ To increase idle speed - ECM will send enough counts to retract the IAC valve and allow more air to flow

through the idle air passage and bypass the throttle plates until idle speed reaches the proper rpm. This

will increase the ECM counts.

e To decrease idle speed - ECM will send enough counts to extend the IAC valve and reduce air flow through

the idle passage around the throttle plates. This will reduce the ECM counts.

Each time the engine is started and then the ignition is turned "OFF", the ECM will reset the IAC valve.

This is done by sending enough counts to seat the valve.

The fully seated valve is the ECM reference zero. A

given number of counts are then issued to open the valve, and normal ECM control of IAC will begin from this

point. The

number of counts are then calculated by the ECM. This is how the ECM knows what the motor

position is for a given idle speed.

The ECM uses the following information to control idle speed.

@ Battery voltage @ Engine speed @ Coolant temperature @ Throttle position sensor @ PIN switch e A/C clutch signal

Don't apply battery voltage across the IAC motor terminals. It will permanently damage the IAC motor

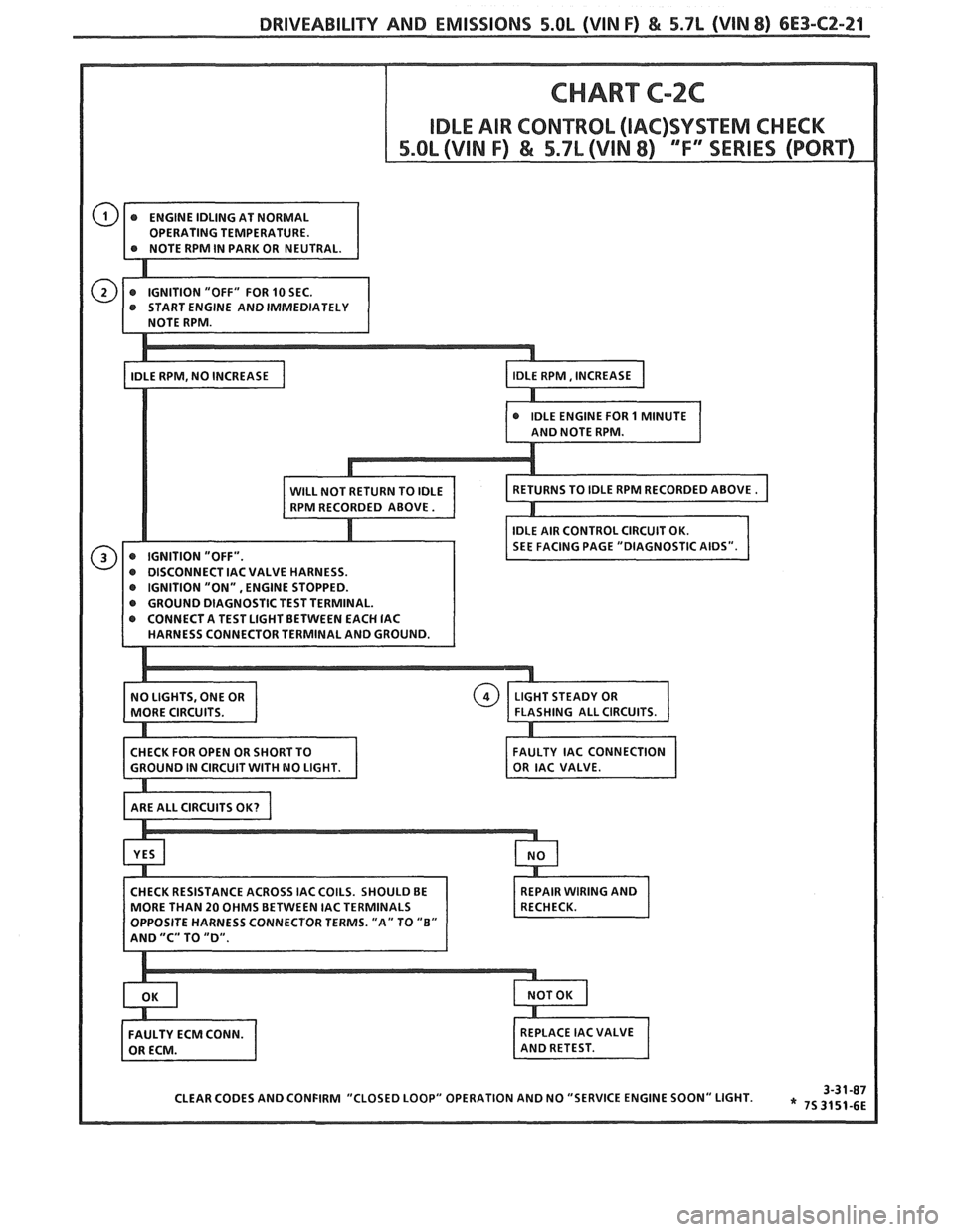

windin s. Test 6escription: Numbers below refer to circled

numbers on the diagnostic chart.

1. Continue with test, even if engine will not idle. If

idle is too low, "Scan" will display 80 or more

counts, or steps. If idle is high, it will display

"0"

counts.

Occasionally an erratic or unstable idle

[nay occur. Engine speed may vary 200 rpm or more up

and down. Disconnect IAC. If the condition is

unchanged, the IAC is not at fault.

There is a

system problem. Proceed to "Diagnostic Aids"

below.

2. When the engine was stopped, the IAC valve

retracted (more air) to

a fixed "Park" position for

increased air flow and idle speed during the next

engine start. A "Scan" will display 140 or more

coiints. 3. Be sure to disconnect the IAC valve prior to this

test.

The test light will confirm the ECM signals

by a steady or flashing light on all circuits.

4. There is a remote possibility that one of the

circuits is shorted to voltage which would have

been indicated by a steady light. Disconnect ECM

and turn the ignition "ON" and probe terminals to

check for this condition.

Diagnostic Aids:

Engine idle speed can be adversely affected by the

following:

@ ParMNeutral switch - If ECM thinks the car is

always in neutral, then idle will not be controlled

to the specified rpm when in drive range.

@ Leaking injector(s) will cause fuel imbalance and

poor idle quality due to excess fuel. See CHT.

A-7. @ Vacuum or crankcase leaks can affect idle. @ Whenthethrottleshaftorthrottlepositionsensor

is binding or sticking in an open throttle position,

the ECM does not know if the vehicle has stopped

and does not control idle.

@ Check A.I.R. management s stem for intermittent

air to orts while in "~losed~oo~". @ In ad&tion to electrical control of EGR, be sure to

examine the EGR valve for proper seating.

@ Faulty battery cables can result in voltage

variations. The ECM will try to compensate,

which results in erratic idle speeds.

@ 'I'he ECM will com ensate for A/C com ressor

clutch loacls. [.ass ofthe NC request sign8 would

he 11lost apparent, in neutral. @ Contalninatecl fuel can adverse1 affect idle. @ Perform i~!jector balance test C~ART C-2A. If ,111 OK, refer to "Rough, Unstable, Incorrect Idle or St ,tllinqW SJ tnptcfinsiin S~'ction "11''.

Page 908 of 1825

DRIVEABILITY AND EMISSIONS 5.OL (VIN F) & 5.7L (VIN 8) 6E3-C2-21

COILS. SHOULD BE

Page 909 of 1825

6E3-C2-22 5.BL (VIN F) & 5.7L (VIN 8) DRIVEABILITY AND EMISSIONS

BLANK

Page 910 of 1825

DRIVEABILITYAND EMISSIONS 5.OL (VIN F) & 5.7L (V1N 8) 6E3-C3-9

SECTION C3

EVAPORATIVE EMlSSlON CONTROL SYSTEM (EECS)

CONTENTS

...................... ............... GENERAL DESCRIPTION C3-1 DIAGNOSIS .. C3-2

.......... PURPOSE ........................ C3-1 VISUAL CHECK OF CANISTER C3-2

VAPOR CANISTER .............. C3-1 FUNCTIONAL TEST

EVAPORATIVE EMISSION SYSTEM

...... C3-1 Vapor Canister Purge Valve ........ C3-2

..... FUEL TANK PRESSURE CONTROLVALVE . . C3-2 Tank Pressure Control Valve 63-2

IN-TANK PRESSURE CONTROL VALVE . . C3-2 ON-CAR SERVICE ................. C3-3

RESULTS OF INCORRECT OPERATION .... C3-2 FUEL VAPOR CANISTER ............ C3-3

CANISTERHOSES. ................... C3-3

................ PARTS INFORMATION C3-3

GENERAL DESGRIP"T0N

PURPOSE

The canister is equipped with a normally closed

solenoid to control canister purge.

The ECM operates

the solenoid which controls vacuum to the purge valve

in the charcoal canister. Under cold engine or idle

conditions, the solenoid is turned

"OFF" by the ECM,

which closes the solenoid and blocks vacuum to the

canister purge valve.

The

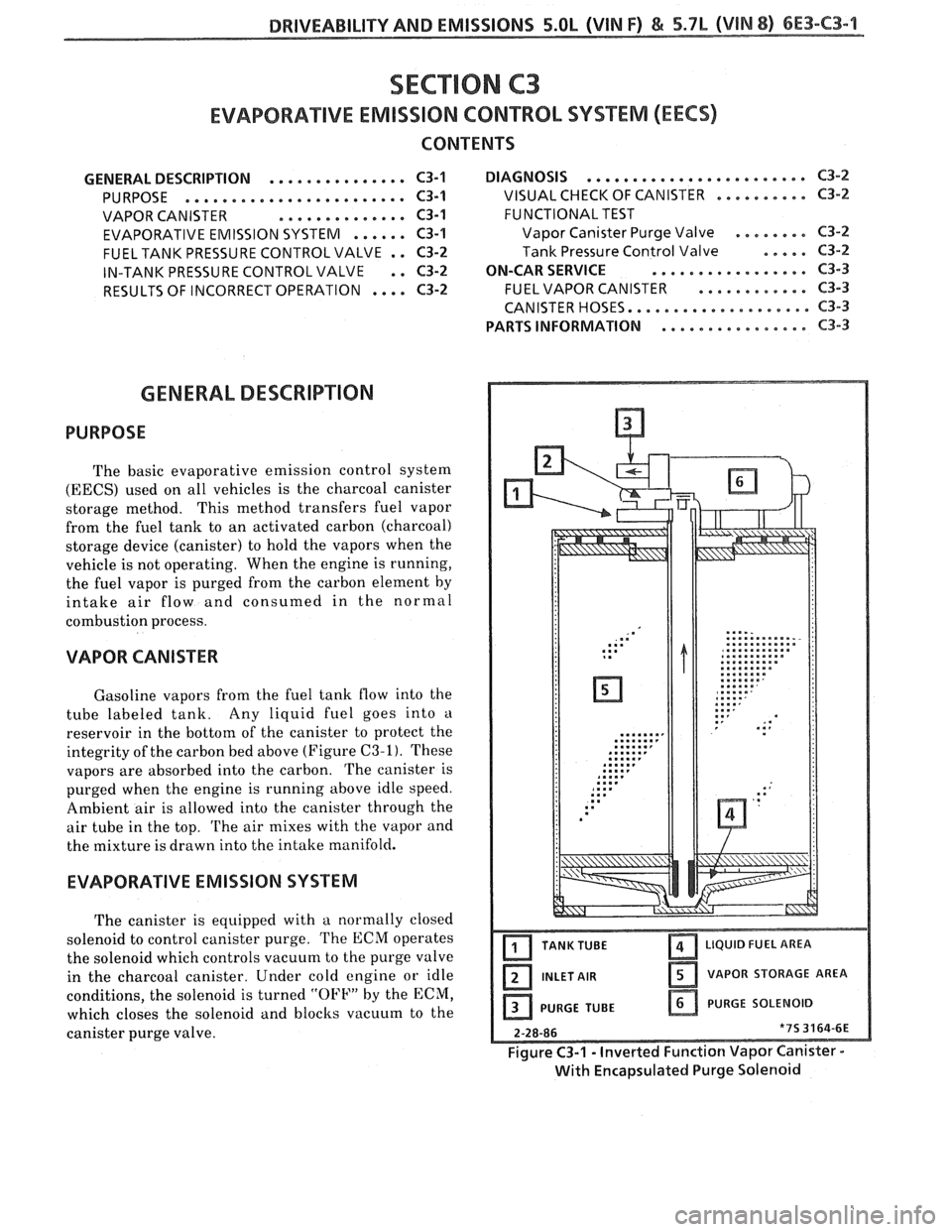

basic evaporative emission control system

(EECS) used on all vehicles is the charcoal canister

storage method. This method transfers fuel vapor

from the fuel tank to an activated carbon (charcoal)

storage device (canister) to hold the vapors when the

vehicle is not operating. When the engine is running,

the fuel vapor is purged from the carbon element by

intake air flow and consumed in the normal

combustion process.

VAPOR CANISTER

Gasoline vapors from the fuel tank flow into the

tube labeled tank. Any

liquid fuel goes into

a

reservoir in the bottom of the canister to protect the

integrity of the carbon bed above (Figure

C3-1). These

vapors are absorbed into the carbon. The canister is

purged when the engine is running above idle speed.

Ambient air is allowed into the canister through the

air tube in the top.

The air mixes with the vapor and

the mixture is drawn into the intake manifold.

EVAPORATIVE EMISSION SYSTEM

TANK TUBE

INLET AIR

I PURGE TUBE

fl LIQUID FUEL AREA

a VAPOR STORAGE AREA

a PURGE SOLENOID

Fiqure C3-1 - Inverted Function Vapor Canister - - With Encapsulated Purge Solenoid