PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 921 of 1825

6E3-C4-6 5.OL (WIN F) & 5.7% (WIN 8) DRIVEABILITY AND EMISSIONS

BLANK

Page 922 of 1825

DRIVEABILITY AND EMISSIONS 5.OL (VIN F) & 5.7L (VIN 8) 6E3-C5-1

SECTION C5

ELECTRONIC SPARK CONTROL (ESC) SYSTEM

CONTENTS

GENERAL DESCRIPTION ................ C5-1 ON-CAR SERVICE ..................... C5-1

PURPOSE ......................... C5-1 ESCSENSOR e............e......... C5-1

GENERAL DESCRIPTION .............. C5-1 ESC MODULE AND BRACKET .......... C5-2

DIAGNOSIS

......................... C5-1 PARTS INFORMATION ................. C5-2

GENERAL DESCRIPTION DIAGNOSIS

PURPOSE

Varying octane levels in today's gasoline can

cause detonation in high performance engines.

Detonation is sometimes called spark knock.

To control spark knock, an electronic spark control

(ESC) system has been added. This system is designed

to retard spark timing up to

20°, if necessary, to reduce

spark knock in the engine. This allows the engine to

use maximum spark advance to improve driveability

and fuel economy. Code

43 indicates that the ECM terminal

"B7" is

receiving less than

6 volts for a 4 second period with

the engine running. This is CKT 485, which normally

provides

u 8 to 10 volt signal from the ESC module to

the ECM. See Code 43 CHART for diagnosis if the

code is present.

When no Code 43 is present but the ESC system is

a potential cause of excessive spark knock, see

CI-IART C-5 which follows.

ON-CAR SERVICE

GENERAL DESCRIPTION ESC SENSOR

The ESC system has two major components:

@ ESC module

@ ESC knock sensor

The ESC knock sensor detects abnormal vibration

(spark knocking) in the engine. The

sensor is

mounted in the engine block near the cylinders. The

ESC module receives the knock sensor information

and sends a signal to the ECM. The ECM then adjusts

the electronic spark timing (EST) to reduce spark

knocking.

The ESC module sends a voltage signal

(8 to 10

volts) to the ECM when NO spark knock is detected by

the knock sensor, and the ECM provides normal spark

advance. When the knock sensor detects spark knock, the

module turns

"OFF" CKT 485 to the ECM. The ECM

then retards EST to reduce spark knock.

Loss of the ESC knock sensor signal or loss of

ground at ESC module terminal

"1)" would cause the

signal on CKT 485 to the ECM to remain high.

This

condition would cause the ECM to control EST as if no

spark knock was occuring. No retard would occur,

and

spark knock could become severe under heavy engine

load conditions. This condition should, however, cause

a Code

43 to set.

Loss of the ESC signal to the ECM would cause the

ECM to constantly retard EST. This will result in

sluggish performance and set a Code

43.

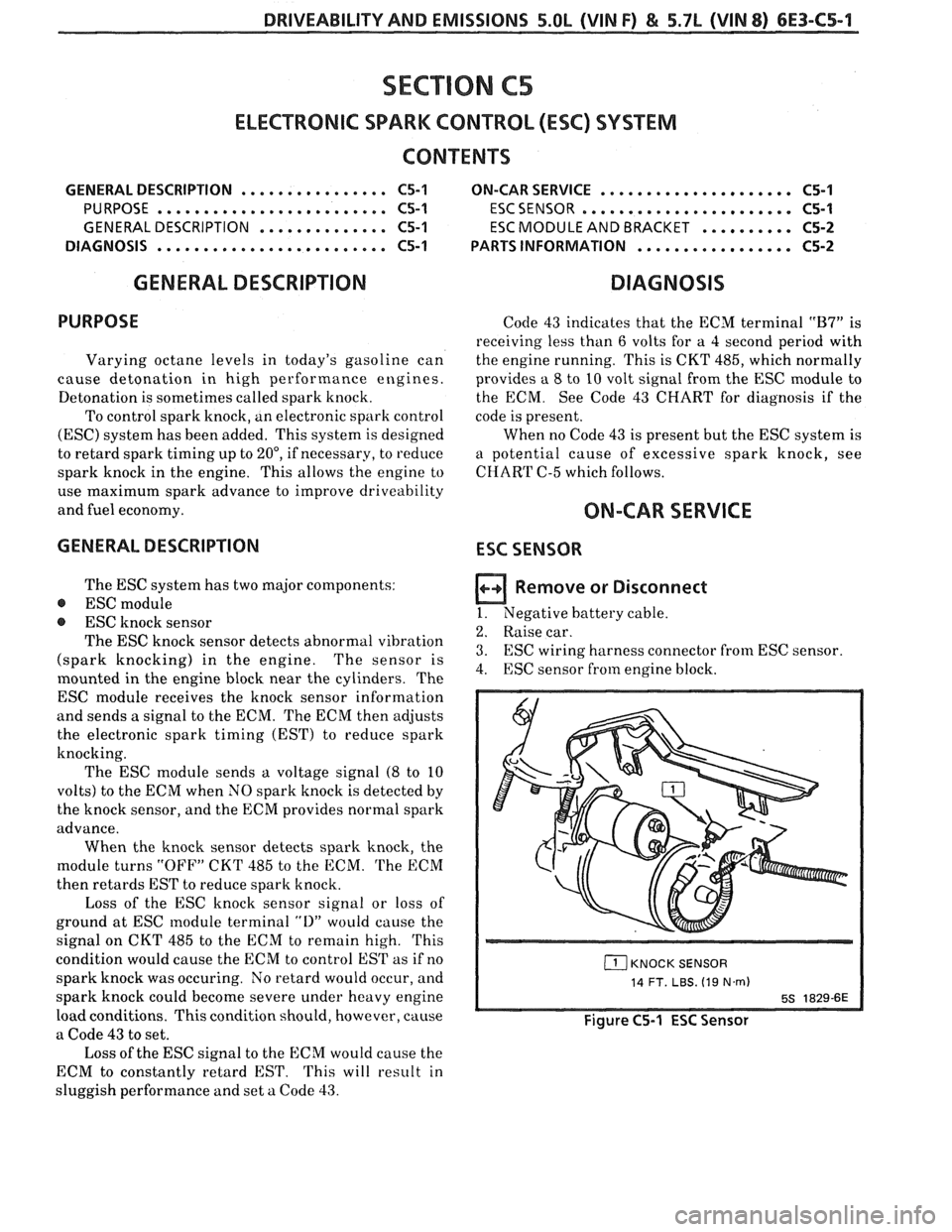

Remove or Disconnect

I. Negative battery cable.

2. Raise car.

3. ESC wiring harness connector from ESC sensor.

4. ESC sensor

from engine block.

(1 KNOCK SENSOR

14 FT. LBS. (19 N.m)

5s 1829-6E

Figure C5-1 ESC Sensor

Page 923 of 1825

Install or Connect

1. ESC sensor into engine block.

e Tighten to 14 ft. lbs. (19 Nsm).

2. ESC

wiring harness connector to the ESC sensor.

3. Lower car.

4. Negative battery cable.

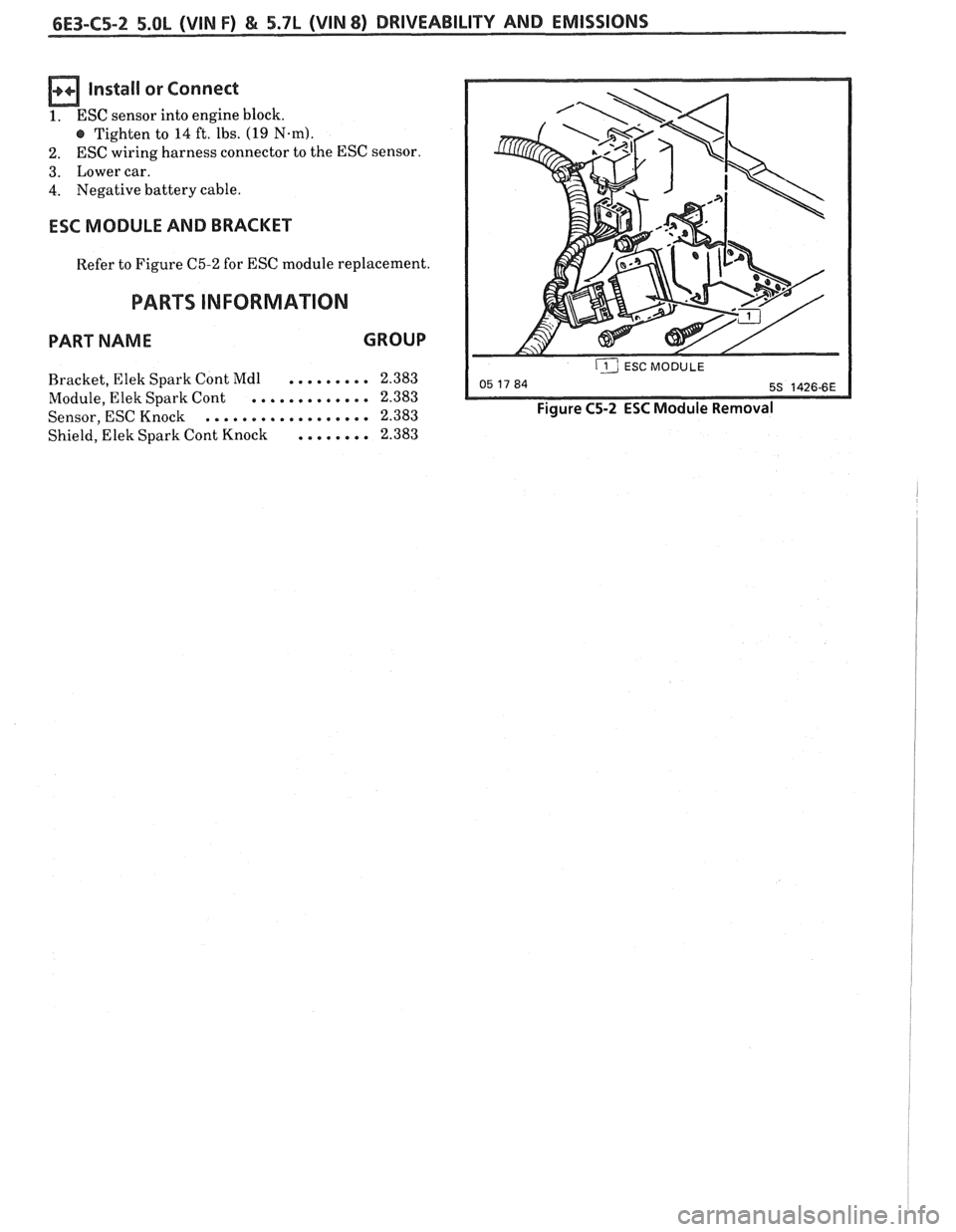

ESC MODULE AND BRACKET

Refer to Figure C5-2 for ESC module replacement.

PARTS INFORMATION

PART NAME GROUP

......... Bracket, Elek Spark Cont Mdl 2.383

............. Module,

Elek Spark Cont 2.383

.................. Sensor, ESC Knock 2.383

Shield, Elek Spark Cont Knock

........ 2.383

ij ESC MODULE --

Figure C5-2 ESC Module Removal

Page 924 of 1825

DRIVEABILITY AND EMISSIONS 5.OL (VIN F) & 5.7b (VIN 8) 6E3-C5-3

BLANK

Page 925 of 1825

6E3-C5-4 5.OL (VIN F) & 5.7L (VIN 8) DRIVEABILITY AND EMISSIONS

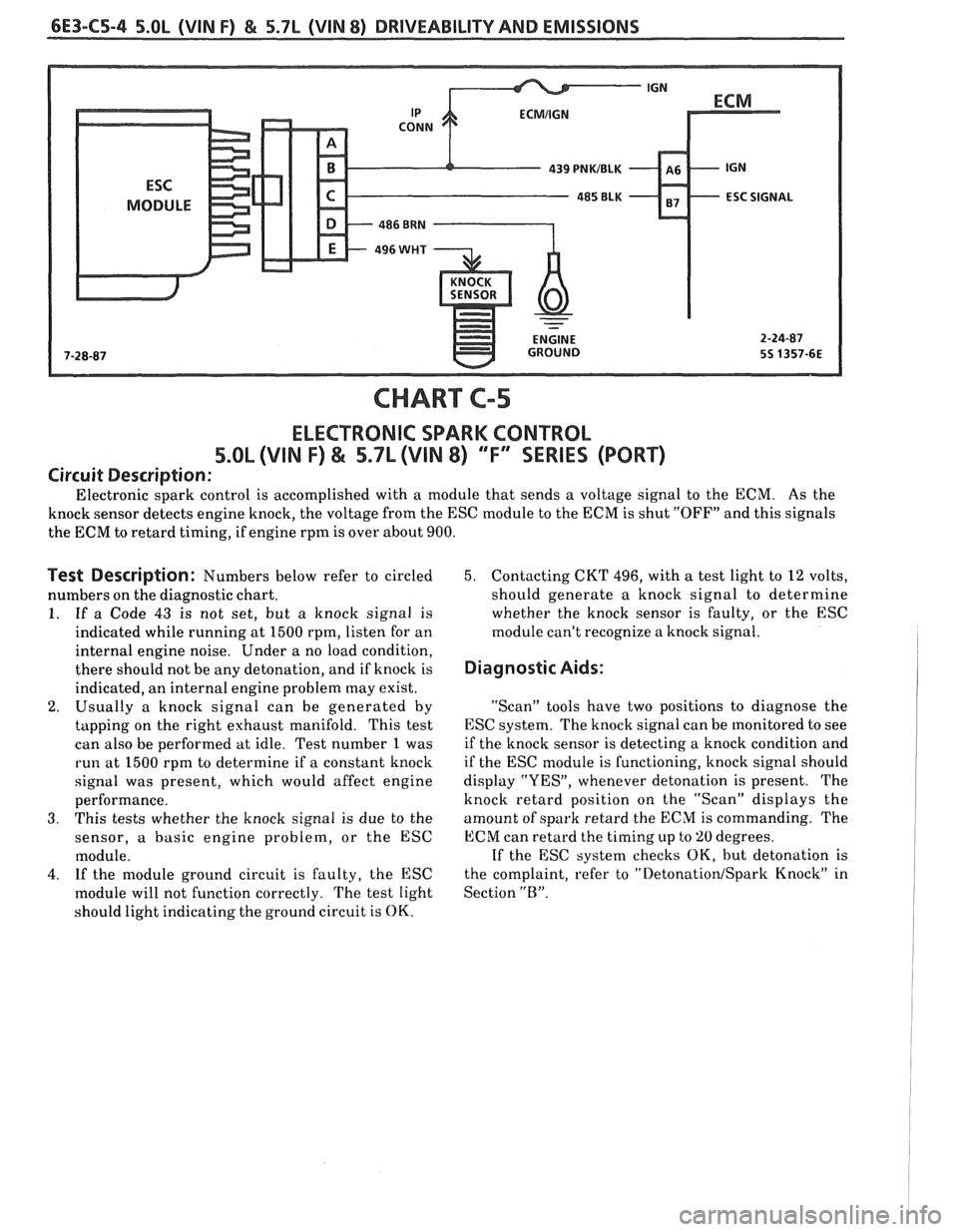

CHART C-5

ELECTRONIC SPARK CONTROL

5.OL (VIN F) & 5.7L (VIN 8) ""F-ERIES (PORT)

Circuit Description:

Electronic spark control is accomplished with a module that sends a voltage signal to the ECM. As the

knock sensor detects engine knock, the voltage from the

ESC module to the ECM is shut "OFF" and this signals

the ECM to retard timing, if engine rpm is over about 900.

Test Description: Numbers below refer to circled

numbers on the diagnostic chart.

1.

If a Code 43 is not set, but a knock signal is

indicated while running at 1500 rpm, listen for an

internal engine noise. Under a no load condition,

there should not be any detonation, and if knock is

indicated, an internal engine problem may exist.

2. Usually a knock signal can be generated by

tapping on the right exhaust manifold. This test

can also be performed at idle. Test number

1 was

run at 1500 rpm to determine if a constant knock

signal was present, which would affect engine

performance.

3. This tests whether the knock signal is due to the

sensor,

a basic engine problem, or the ESC

module.

4. If the module ground circuit is faulty, the ESC

module will not function correctly. The test light

should light indicating the ground circuit is

OK.

5. Contacting CKT 496, with a test light to 12 volts,

should generate a knock signal to determine

whether the knock sensor is faulty, or the ESC

module can't recognize a knock signal.

Diagnostic Aids:

"Scan" tools have two positions to diagnose the

ESC system. The knock signal can be tnonitored to see

if the knock sensor is detecting a knock condition and

if the ESC module is functioning, knock signal should

display "YES", whenever detonation is present. The

knock retard position on the "Scan" displays the

amount of spark retard the ECM is commanding. The

ECM can retard the timing up to 'LO degrees.

If the ESC system checks

OK, but detonation is

the complaint, refer to

"Detonation/Spark Knock" in

Section

"B".

Page 926 of 1825

DRIVEABILITY AND EMISSIONS 5.0L (VIN F) & 5.7b (VIN 8) 6E3-C5-5

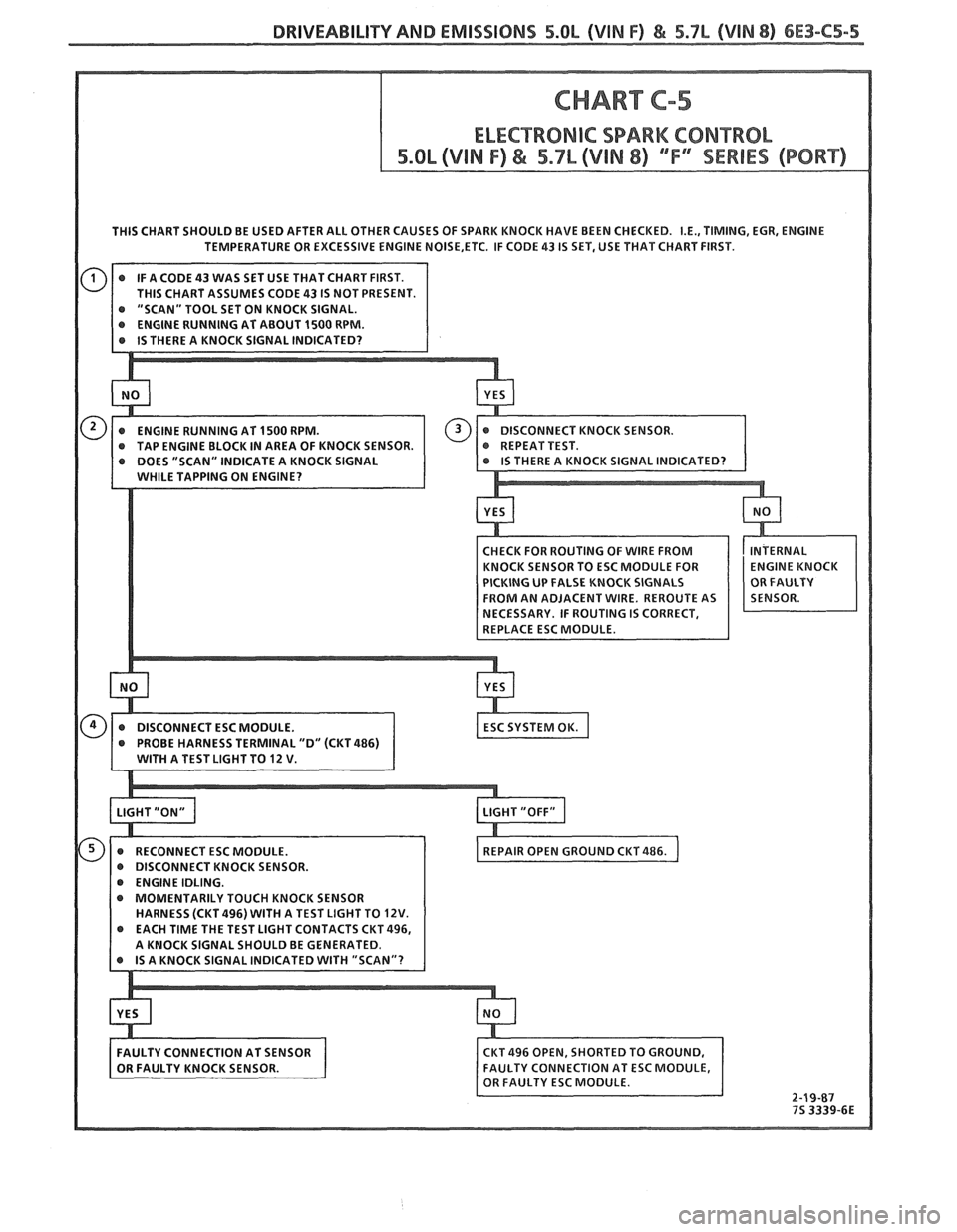

THIS CHART SHOULD BE USED AFTER ALL OTHER CAUSES OF SPARK KNOCK HAVE BEEN CHECKED. I.E., TIMING, EGR, ENGINE

TEMPERATURE OR EXCESSIVE ENGINE

NOISE,ETC. IF CODE 43 IS SET, USE THAT CHART FIRST.

@ "SCAN" TOOL SET ON KNOCK SIGNAL.

@ RECONNECT ESC MODULE.

DISCONNECT KNOCK SENSOR.

@ ENGINE IDLING.

MOMENTARILY TOUCH KNOCK SENSOR

HARNESS (CKT

496) WITH A TEST LIGHT TO 12V.

Page 927 of 1825

6E3-C5-6 5.OL (VIM F) & 5.7L (VIN 8) DRIVEABILITY AND EMISSIONS

BLANK

Page 928 of 1825

DRIVEABILITY AND EMISSIONS 5.OL (VIN F) & 5.7L (VIN 8) 6E3-C6-1

SECTION C6

AIR INJECTION REACTION (A.I.R.) SYSEEM

CONTENTS

GENERAL DESCRIPTION ............... C6-1

PURPOSE ....................... C6-1

OPERATION. ..................... C6-1

AIR CONTROL PEDES VALVE ......... C6-1

.... RESULTS OF INCORRECT OPERATION C6-2

DIAGNOSIS

........................ C6-2

OPERATIONAL CHECKS ............. C6-2

Air Pump ...................... C6-2

Hoses and Pipes ................. C6-3

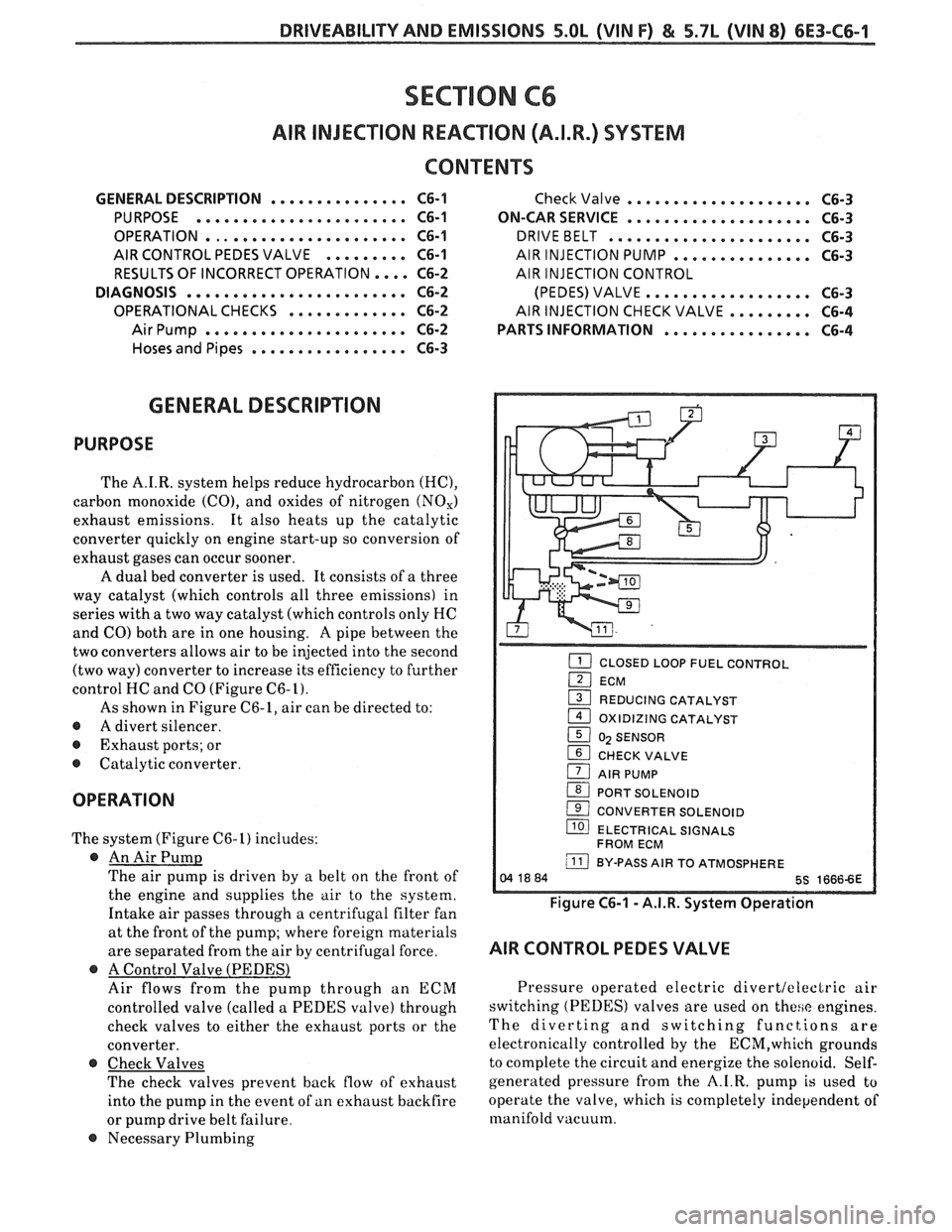

GENERAL DESCRIPTION

PURPOSE

The A.I.R. system helps reduce hydrocarbon (HC),

carbon monoxide (CO), and oxides of nitrogen (NO,)

exhaust emissions. It also heats up the catalytic

converter quickly on engine start-up so conversion of

exhaust gases can occur sooner.

A dual bed converter is used. It consists of a three

way catalyst (which controls all three emissions) in

series with

a two way catalyst (which controls only HC

and

CO) both are in one housing. A pipe between the

two converters allows air to be injected into the second

(two way) converter to increase its efficiency to further

control HC and CO (Figure

C6-L).

As shown in Figure C6-1, air can be directed to:

@ A divert silencer.

@ Exhaust ports; or

@ Catalytic converter.

OPERATION

The system (Figure C6-1) includes:

@ An Air Pump

The air pump is driven by a belt on the front of

the engine and supplies the air to the system.

Intake air passes through a centrifugal filter fan

at the front of the pump; where foreign materials

are separated from the air by centrifugal force.

@ A Control Valve (PEDESl

Air flows from the pump through an ECM

controlled valve (called a PEDES valve) through

check valves to either the exhaust ports or the

converter.

@ Check Valves

The check valves prevent back flow of exhaust

into the pump in the event of

an exhaust backfire

or pump drive belt failure.

@ Necessary Plumbing

Check Valve .................... C6-3

ON-CAR SERVICE

.................... C6-3

DRIVEBELT ...................... C6-3

AIR INJECTION PUMP ............... C6-3

AIR INJECTION CONTROL

(PEDES) VALVE..

................ C6-3

AIRINJECTIONCHECKVALVE.. ....... C6-4

PARTS INFORMATION

................ C6-4

CLOSED LOOP FUEL CONTROL I

(2I ECM

1 REDUCING CATALYST

1 OXIDIZING CATALYST

1 0) SENSOR

1 CHECK VALVE

1 AIR PUMP

(BI PORT SOLENOID

( CONVERTER SOLENOID

llO) ELECTRICAL SIGNALS

FROM ECM

j BY-PASS AIR TO ATMOSPHERE

Figure C6-1 - A.I.R. System Operation

AIR CONTROL PEDES VALVE

Pressure operated electric divertleleclric air

switching (PEDES) valves are used on

these engines.

The diverting and switching functions are

electronically controlled by the

ECM,which grounds

to complete the circuit and energize the solenoid. Self-

generated pressure from the A.I.R. pump

is used to

operate the valve, which is completely independent of

manifold vacuum.

Page 929 of 1825

6E3-C6-2 5.OL (VIN F) & 5.7L (VIN 8) DRIVEABILITY AND EMISSIONS

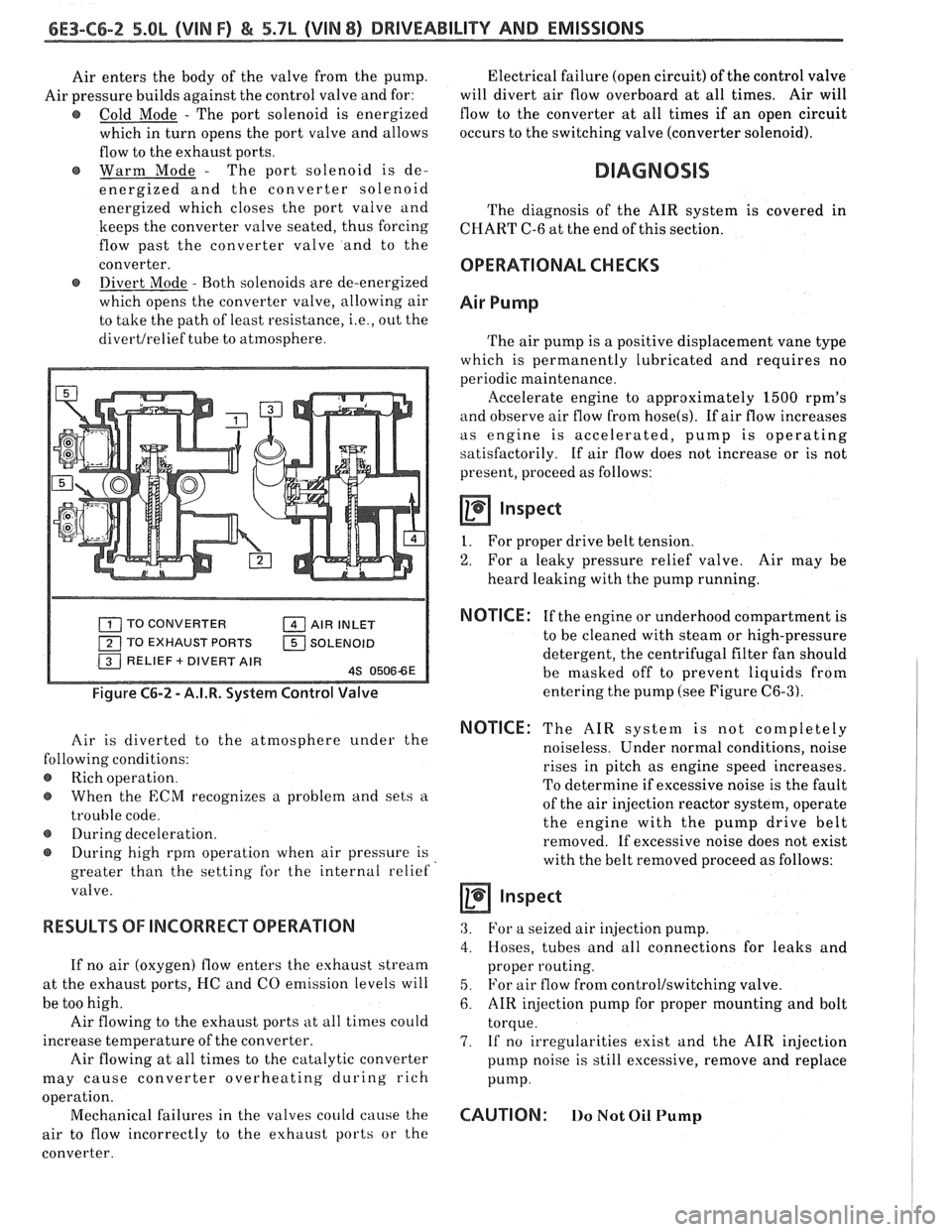

Air enters the body of the valve from the pump.

Air pressure builds against the control valve and for:

@ Cold Mode - The port solenoid is energized

which in turn opens the port valve and allows

flow to the exhaust ports.

Warm Mode

- The port solenoid is de-

energized and the converter solenoid

energized which closes the port valve and

keeps the converter valve seated, thus forcing

flow past the converter valve and to the

converter.

@ Divert Mode - Both solenoids are de-energized

which opens the converter valve, allowing air

to take the path of least resistance,

i.e., out the

divertlrelief tube to atmosphere. Electrical

failure (open circuit) of the control valve

will divert air flow overboard at all times. Air will

flow to the converter at all times if an open circuit

occurs to the switching valve (converter solenoid).

DIAGNOSIS

The diagnosis of the AIR system is covered in

CHART C-6 at the end of this section.

OPERATIONAL CHECKS

Air Pump

The air pump is a positive displacement vane type

which is permanently lubricated and requires no

periodic maintenance.

llccelerate engine to approximately 1500 rpm's

and observe air flow from hose(s). If air flow increases

as engine is accelerated, pump is operating

satisfactorily. If air flow does not increase or is not

present, proceed as follows:

Inspect

I. For proper drive belt tension.

2. For a leaky pressure relief valve. Air may be

heard leaking with the pump running.

TO CONVERTER AIR INLET

TO EXHAUST PORTS

1 SOLENOID

Figure C6-2 - A.I.R. System Control Valve

Air is diverted to the atmosphere under the

lowing conditions:

Rich operation.

When the

ECM recognizes a problem and sets a

trouble code.

@ During deceleration.

During high rprn operation when air pressure is

greater than the setting

for the internal relief

valve.

RESULTS OF INCORRECT OPERATION

If no air (oxygen) flow enters the exhaust stream

at the exhaust ports, I-IC and CO emission levels will

be too high.

Air flowing to the exhaust ports at all times could

increase temperature of the converter.

Air flowing at all times to the catalytic converter

may cause converter overheating during rich

a ion.

oper

t'

Mechanical failures in the valves could cause the

air to flow incorrectly to the exhaust ports or the

converter.

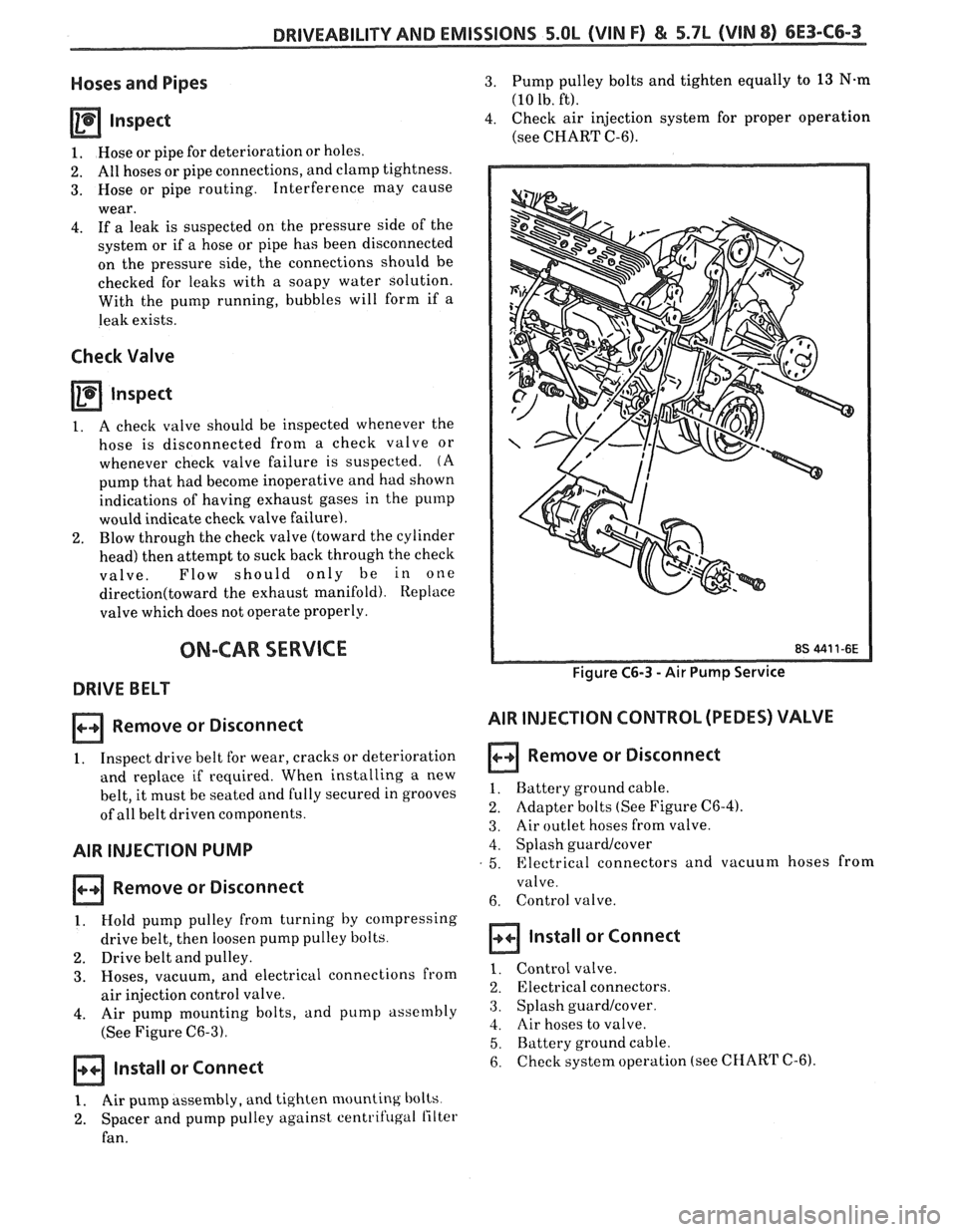

NOTICE : If the engine or underhood compartment is

to be cleaned with steam or high-pressure

detergent, the centrifugal filter fan should

be masked off to prevent liquids from

entering the pump (see Figure

C6-3).

NOTICE: The AIR system is not completely

noiseless. Under normal conditions, noise

rises in pitch as engine speed increases.

To determine if excessive noise is the fault

of the air injection reactor system, operate

the engine with the pump drive belt

removed. If excessive noise does not exist

with the belt removed proceed as follows:

a inspect

3. For a seized air injection pump.

4. Hoses, tubes and all connections for leaks and

proper routing.

5. For air flow from control/switching valve.

6. AIR injection pump for proper mounting and bolt

torque.

7. If no irregularities exist and the AIR injection

pump noise is still excessive, remove and replace

Pump.

CAUTION: 110 Not Oil Pump

Page 930 of 1825

DRlVEABlLlfVAND EMISSIONS 5.OL (VIN F) & 5.7L (VIN 8) 6E3-C6-3

Hoses and Pipes

1. Hose or pipe for deterioration or holes.

2. All hoses or pipe connections, and clamp tightness.

3. Hose or pipe routing. Interference may cause

wear.

4. If

a leak is suspected on the pressure side of the

system or if a hose or pipe has been disconnected

on the pressure side, the connections should be

checked for leaks with a soapy water solution.

With the pump running, bubbles will form if a

leak exists.

Check Valve

Inspect

1. A check valve should be inspected whenever the

hose is disconnected from a check valve or

whenever check valve failure is suspected.

(A

pump that had become inoperative and had shown

indications of having exhaust gases in the pump

would indicate check valve failure).

2. Blow through the check valve (toward the cylinder

head) then attempt to suck back through the check

valve. Flow should only be in one

direction(toward the exhaust manifold). Replace

valve which does not operate properly.

ON-CAR SERVICE

DRIVE BELT

Remove or Disconnect

1. Inspect drive belt for wear, cracks or deterioration

and replace if required. When installing a new

belt, it must be seated and fully secured in grooves

of all belt driven components.

AIR INJECTION PUMP

Remove or Disconnect

1. Hold pump pulley from turning by cotnpressing

drive belt, then loosen pump pulley bolts.

2. Drive belt and pulley.

3. Hoses, vacuum, and electrical connections from

air injection control valve.

4. Air pump mounting bolts, and pump assembly

(See Figure

C6-3).

Install or Connect

3. Pump pulley bolts and tighten equally to 13 N.m

(10 lb. ft).

4. Check air injection system for proper operation

(see CHART C-6).

Figure C6-3 - Air Pump Service

AIR INJECTION CONTROL (PEDES) VALVE

Remove or Disconnect

1. Battery ground cable.

2. Adapter bolts (See Figure C6-4).

3. Air outlet hoses from valve.

4. Splash guardlcover

5. Electrical connectors and vacuum hoses from

valve.

6. Control valve.

Install or Connect

1. Control valve.

2. Electrical connectors.

3. Splash guard/cover.

4. Air hoses to valve.

5. Battery ground cable.

6. checksystem operation (see CHART C-6).

1. Air pump assembly, and tighten mounting bolts

2. Spacer and pump pulley against centrifugal lilter

fan.